Delamination-Driven Nonlinear Buckling of Metal–Composite Cylindrical Shells with Different Interfacial Strengths

Abstract

1. Introduction

2. Materials and Methods

2.1. Surface Quality and Bond Strength Testing

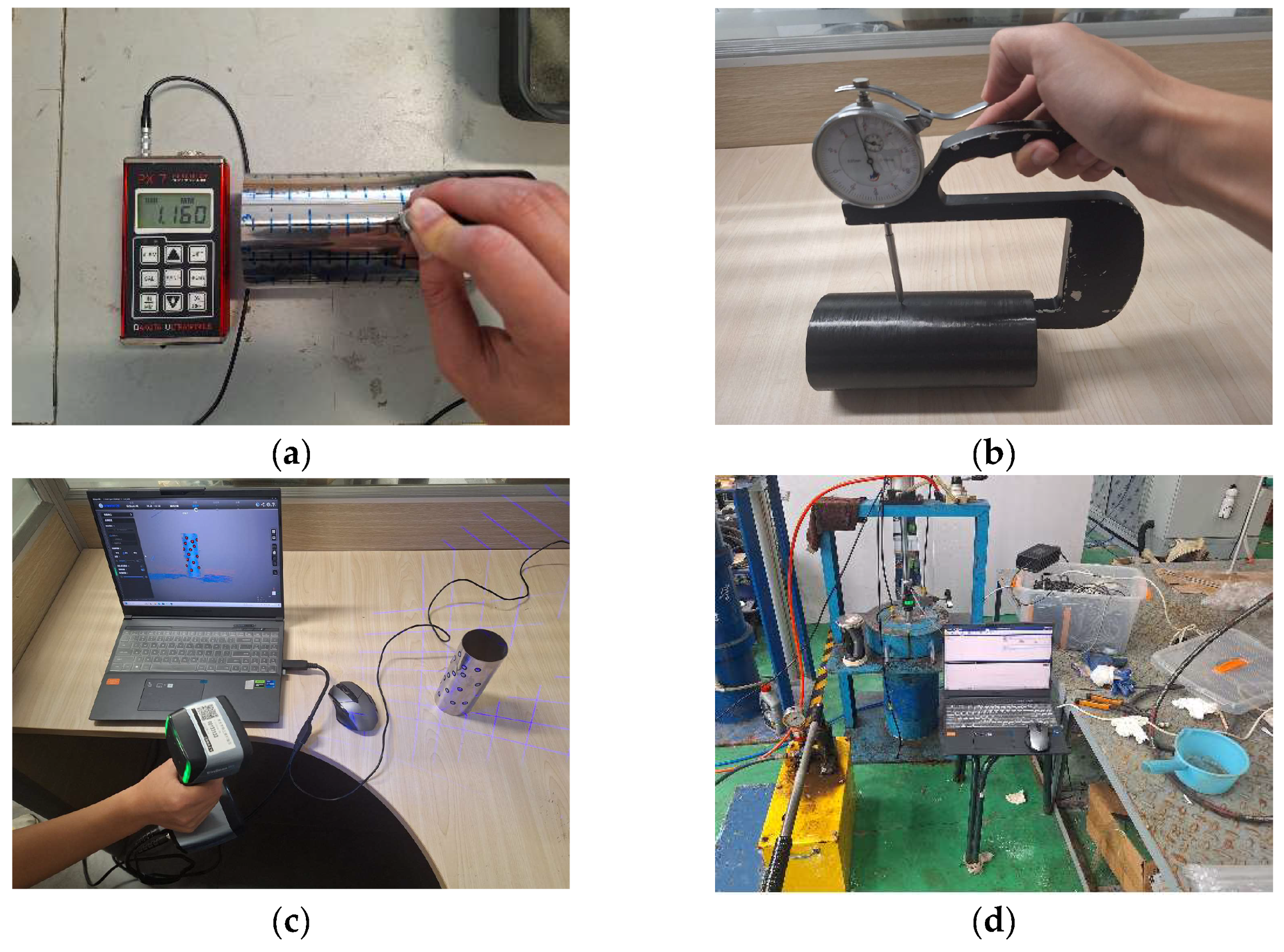

2.2. Fabrication of Single-Lap Shear Specimens

2.3. Fabrication of Cylindrical Shells

2.4. Fabrication Accuracy and Hydrostatic Testing

3. Results and Discussion

3.1. Experimental Investigations

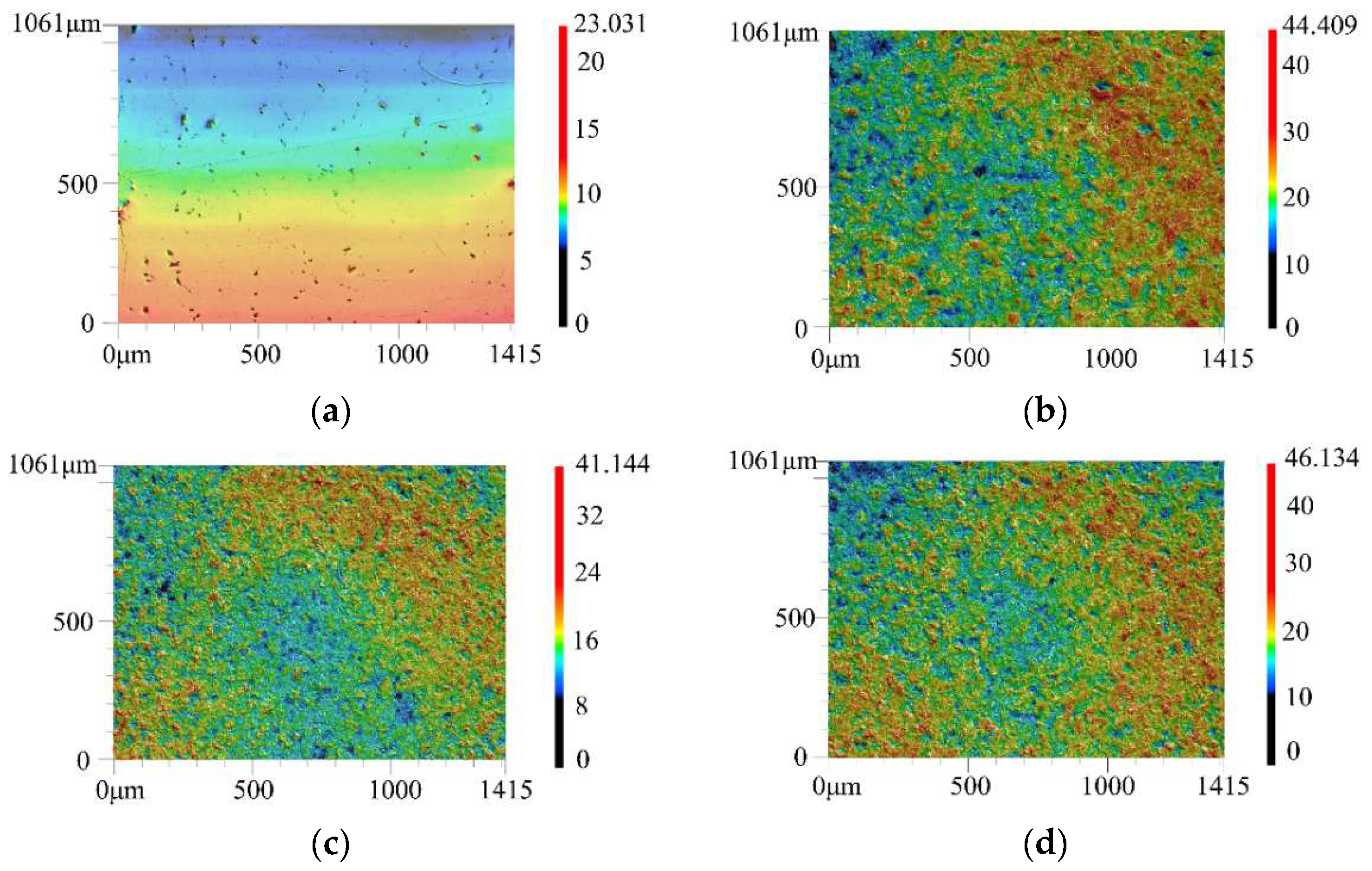

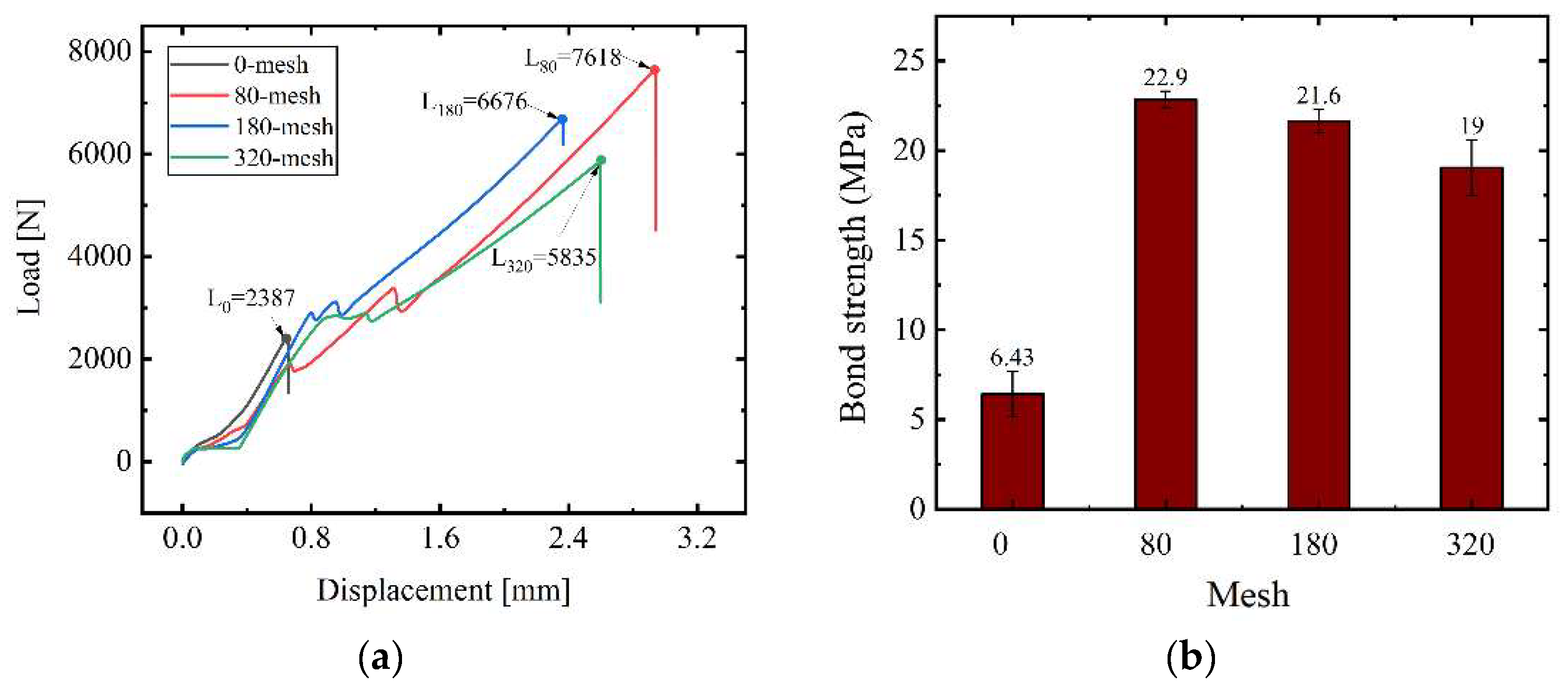

3.1.1. Micro-Structural Properties of Bonding Interfaces Between the Steel and Composite

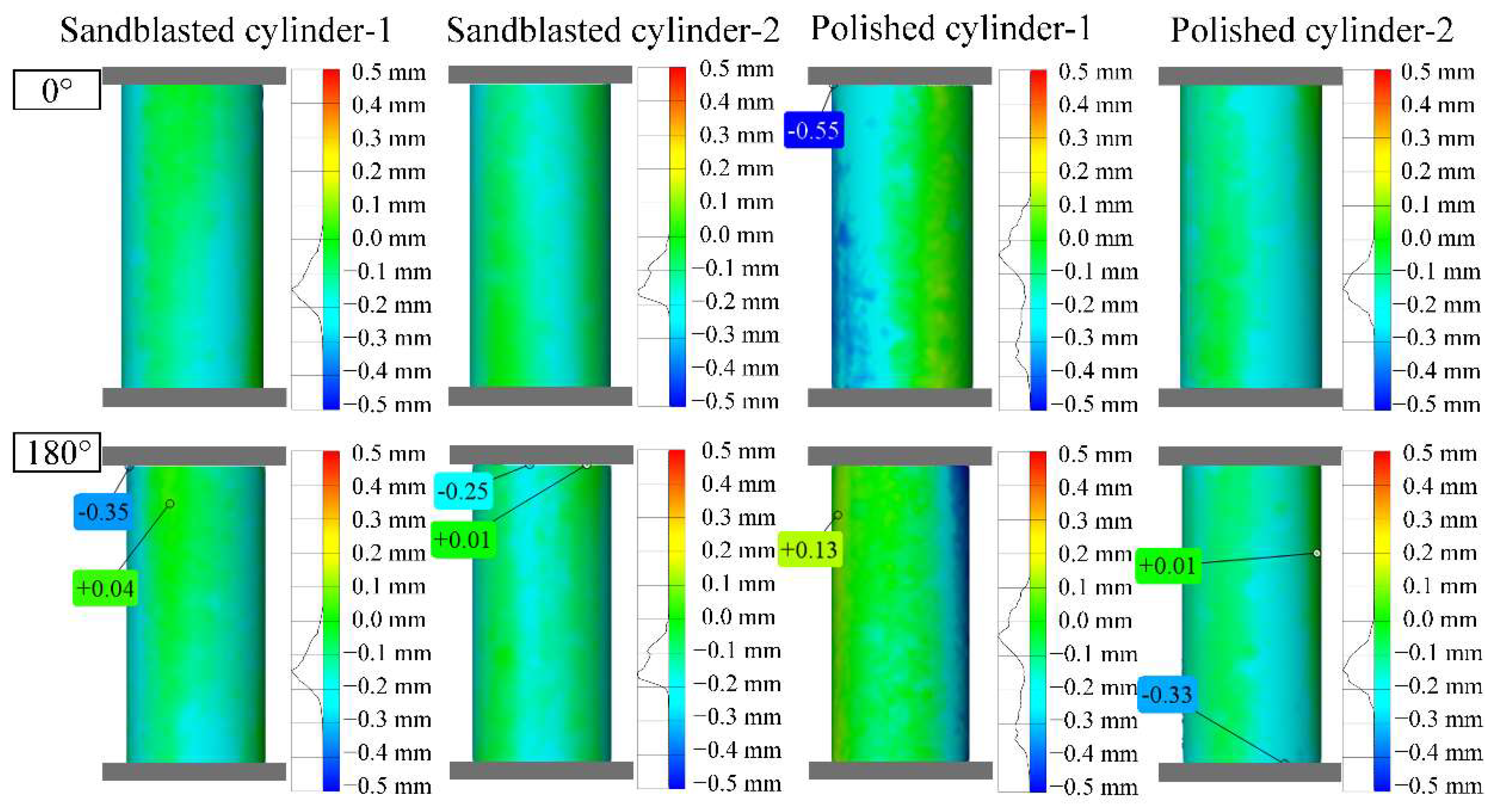

3.1.2. Measured Geometric Properties of the Fabricated Metal–Composite Cylinders

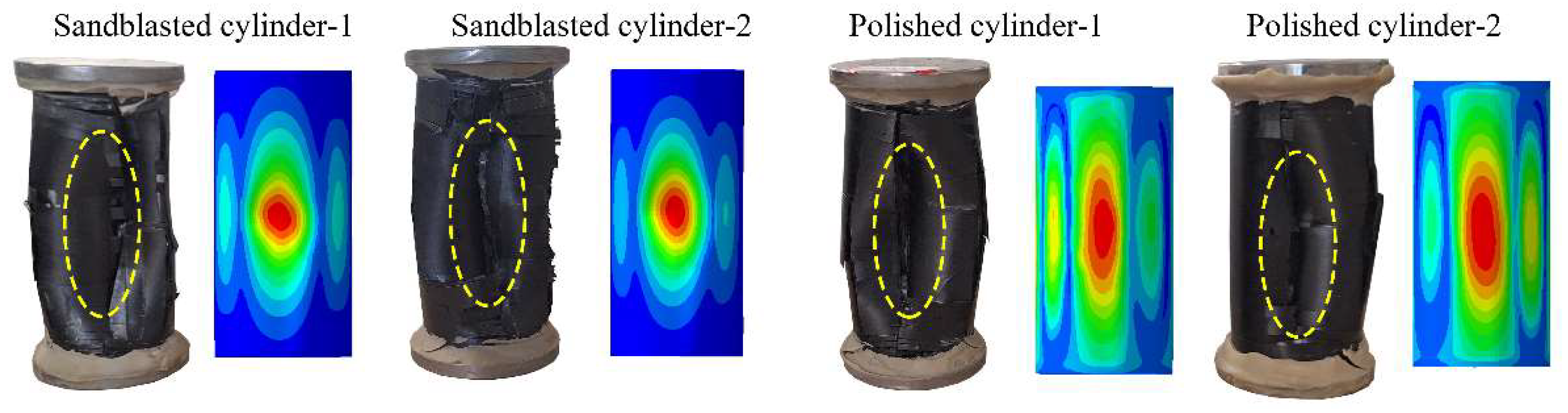

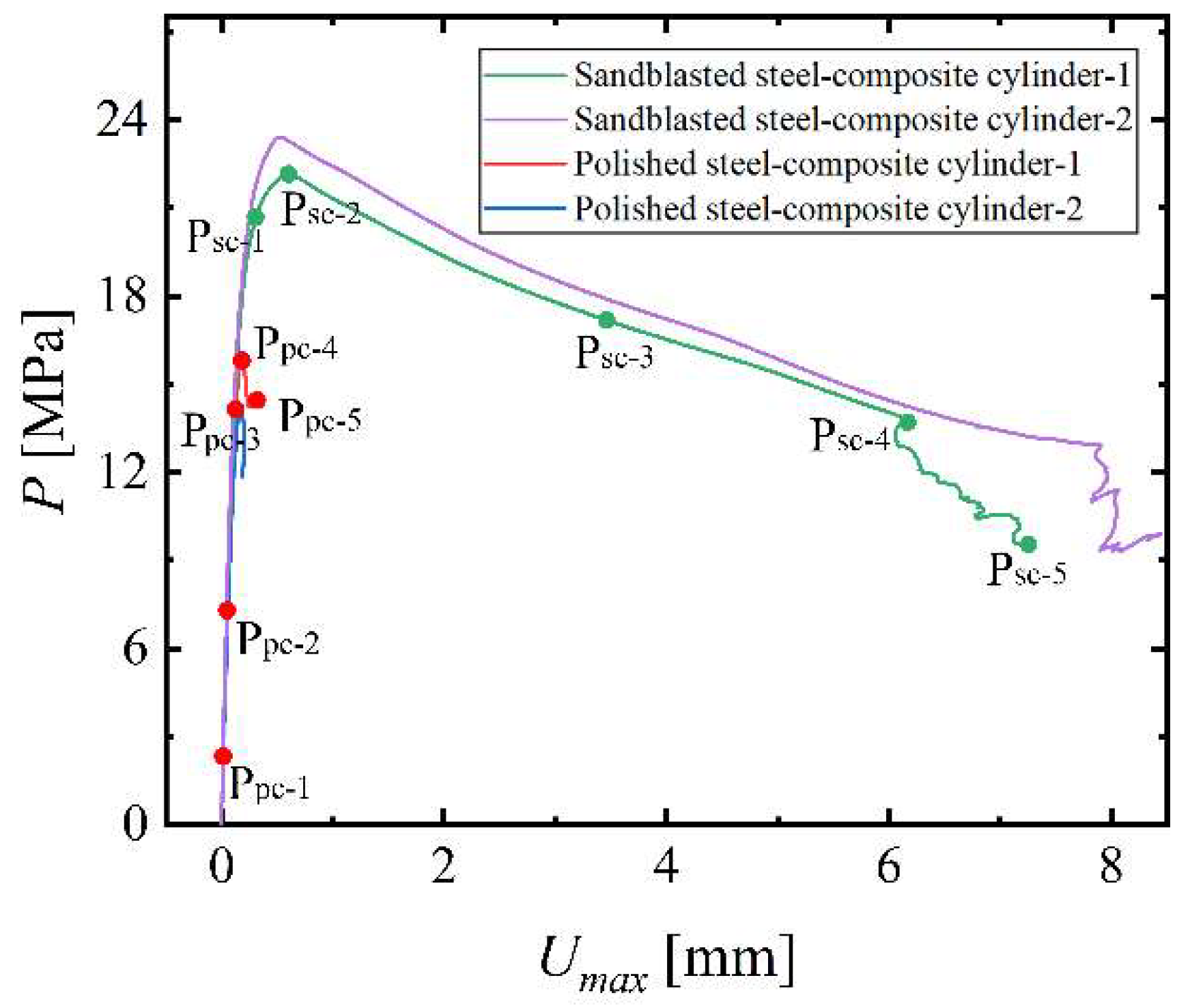

3.1.3. Mechanical Properties of the Fabricated Metal–Composite Cylinders

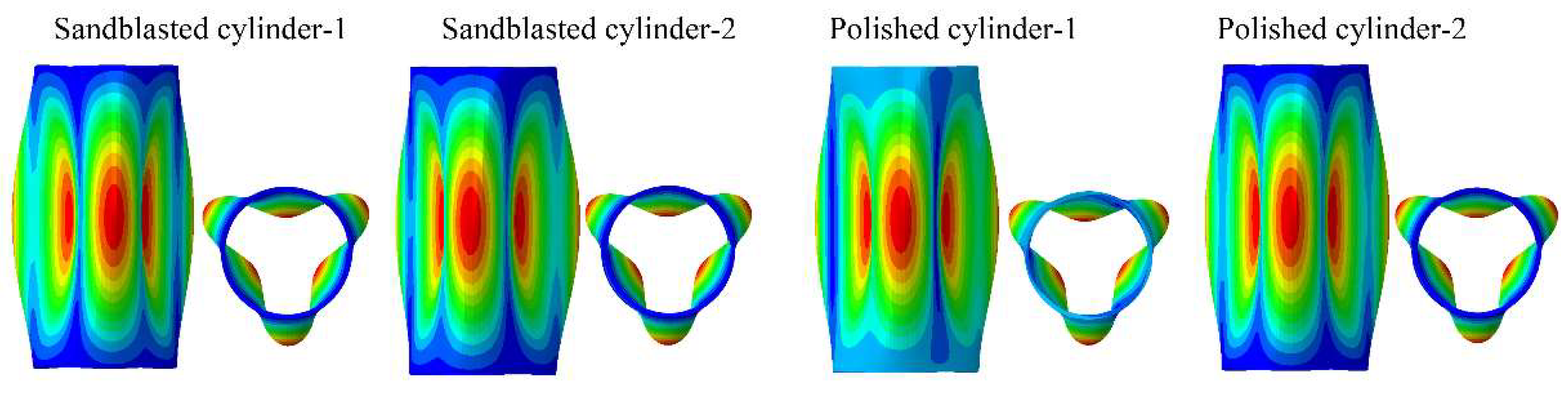

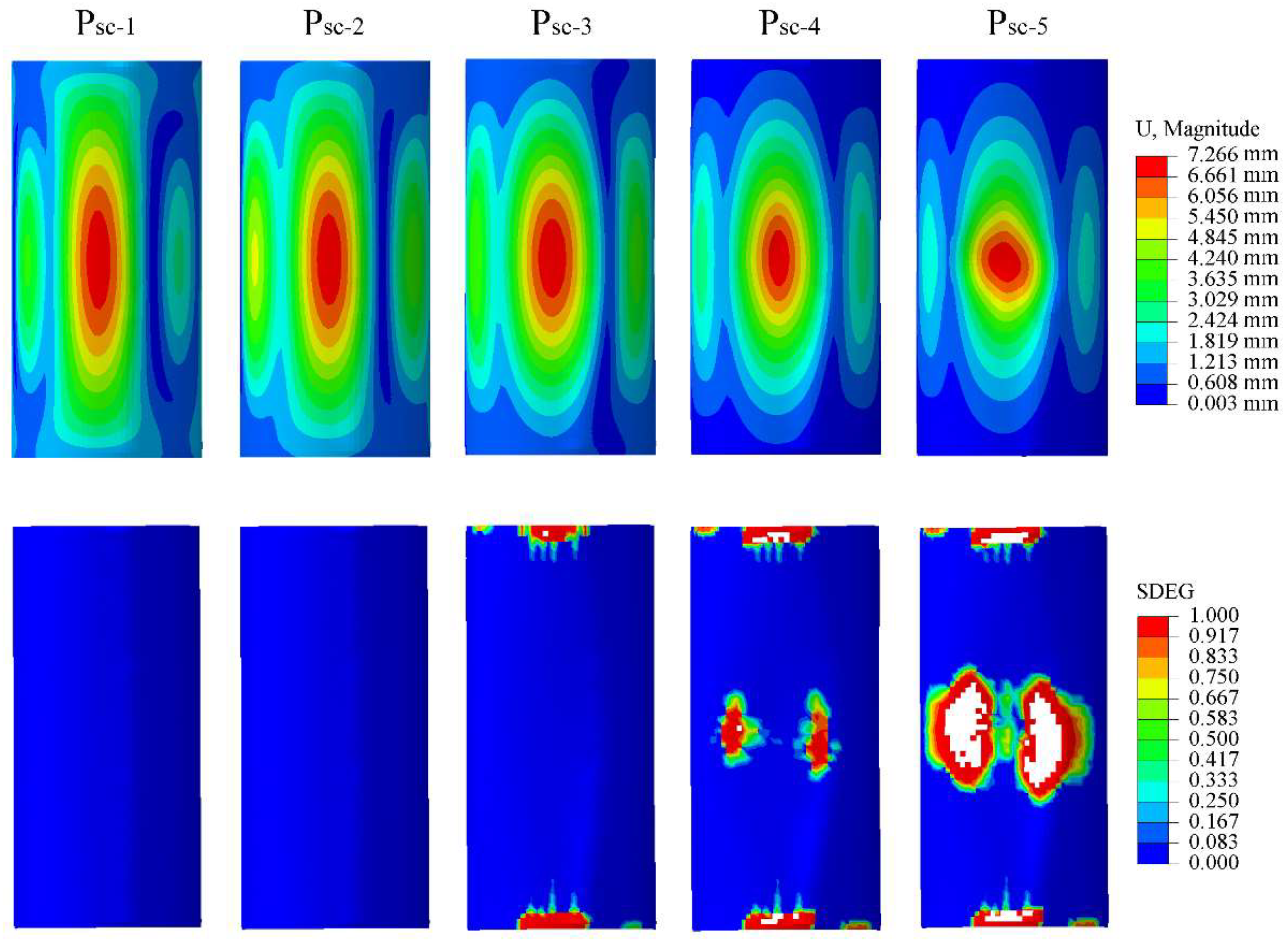

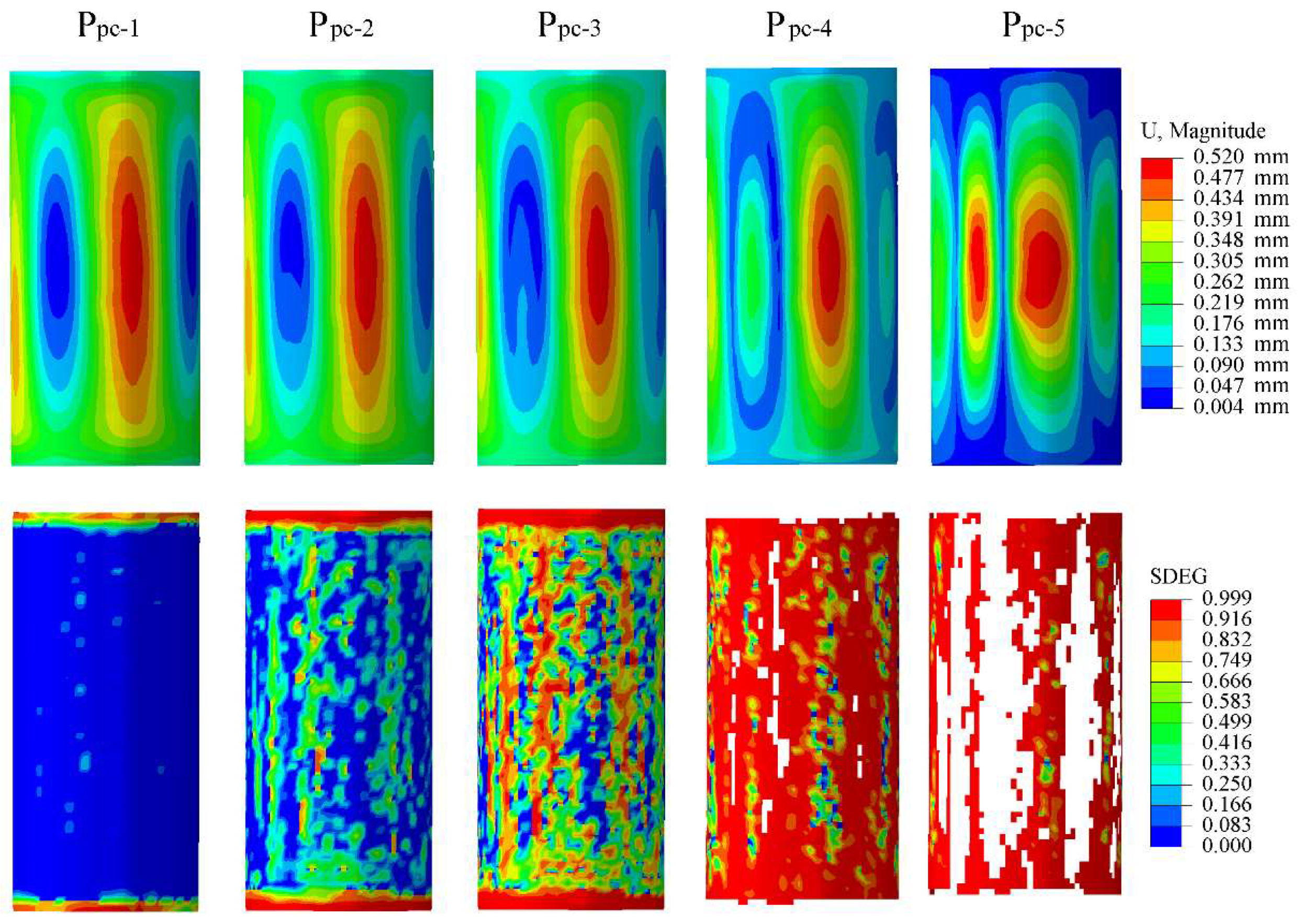

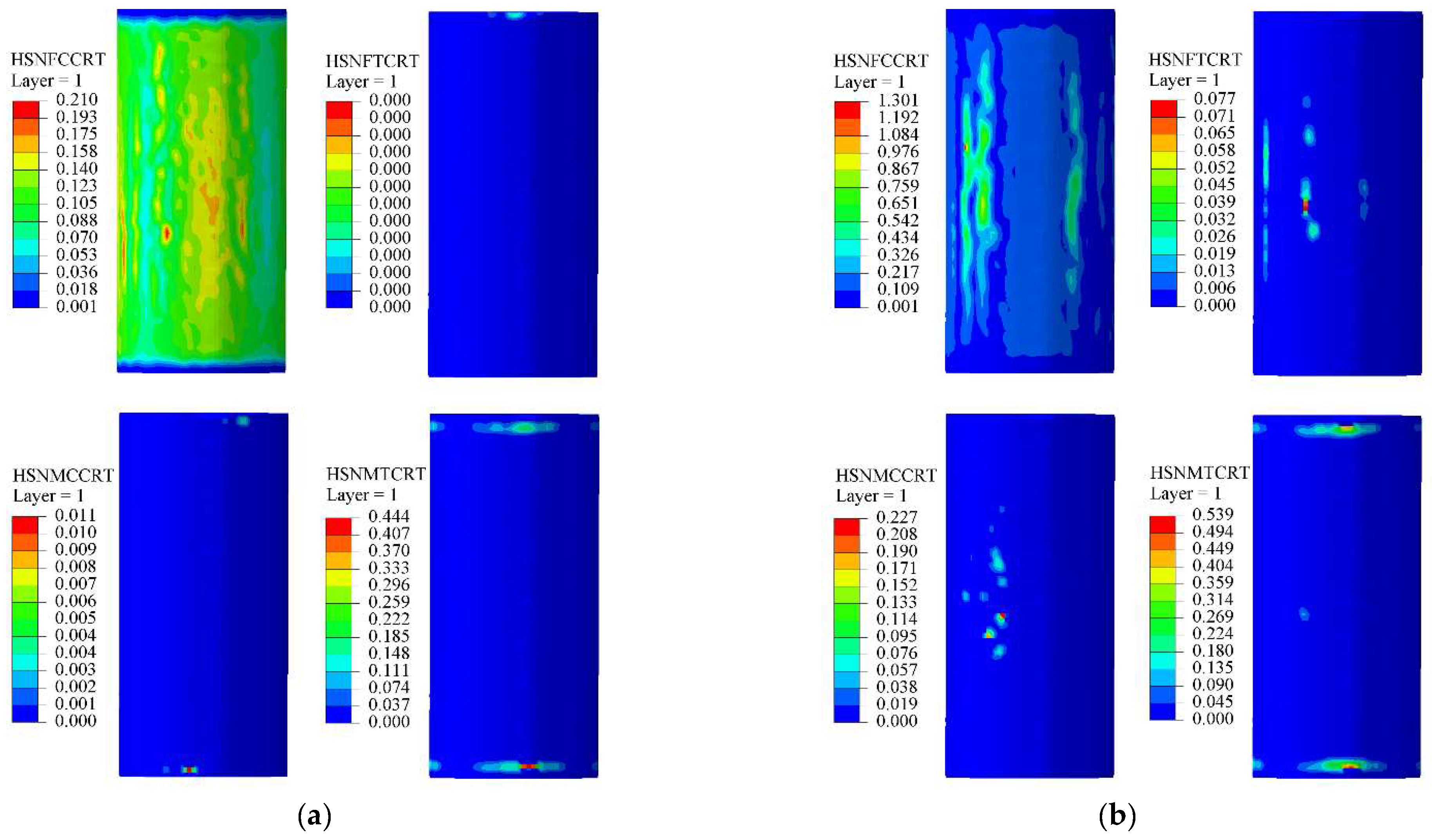

3.2. Numerical Investigations

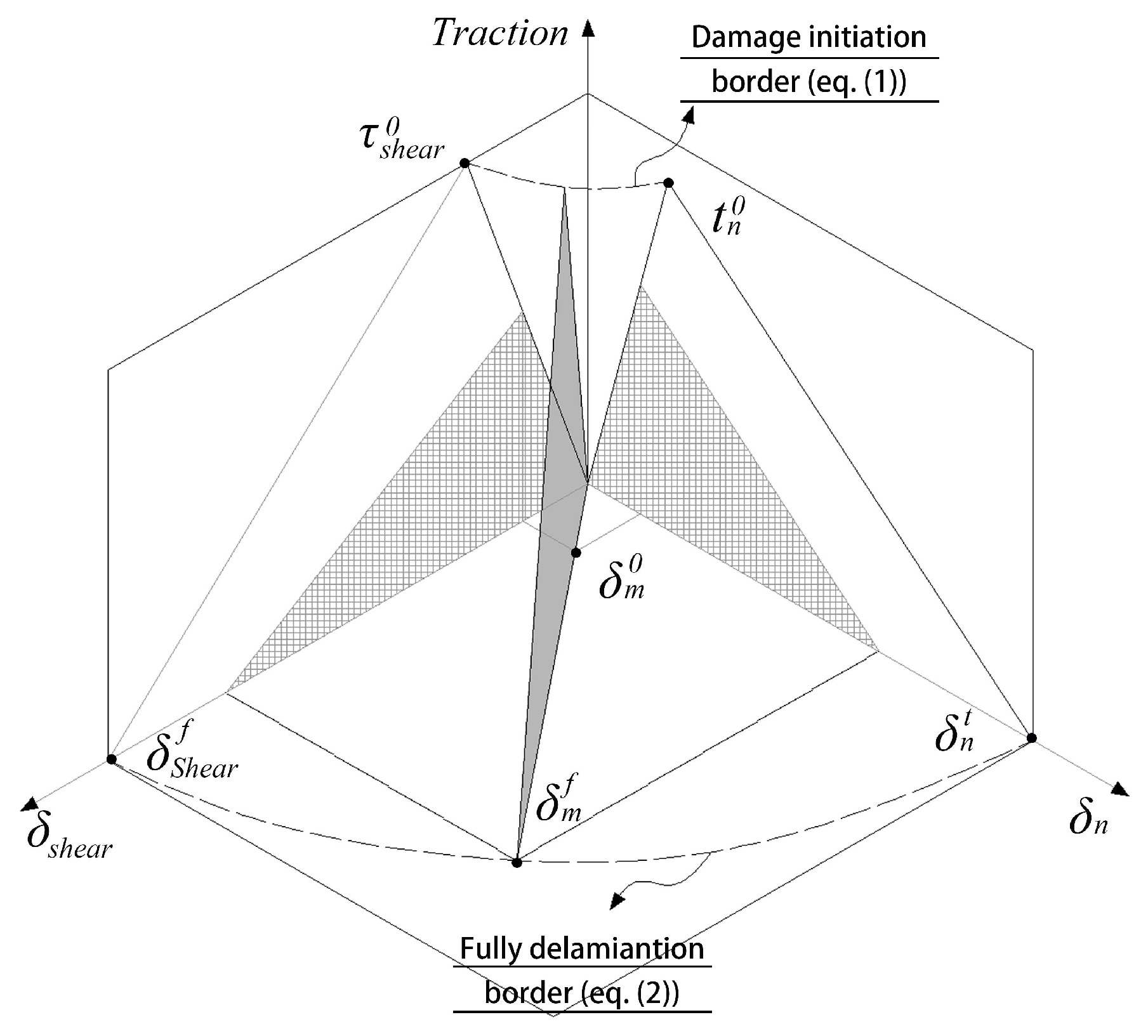

3.2.1. Cohesive Zone Model

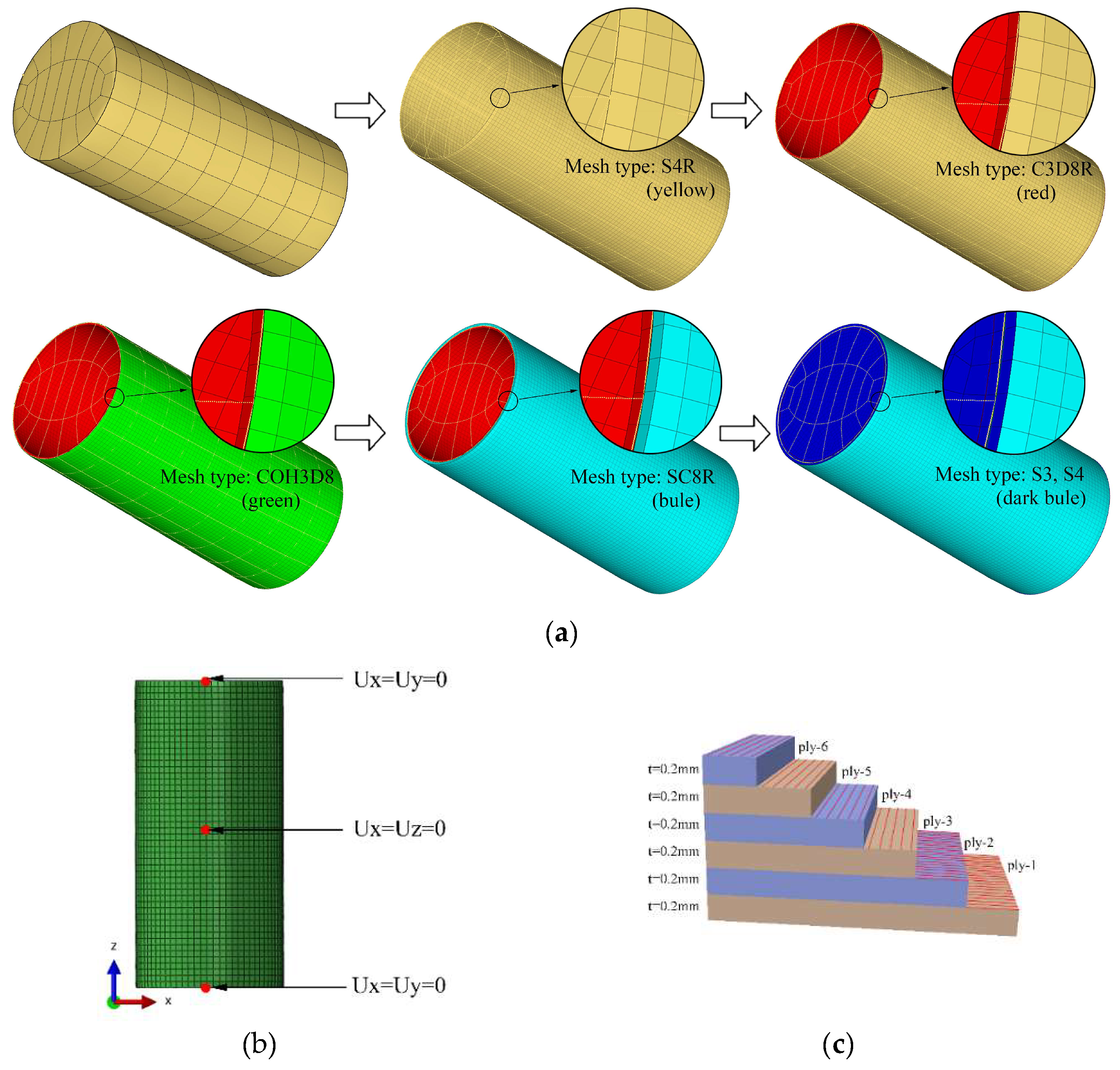

3.2.2. Finite Element Modeling

3.2.3. Numerical Results and Discussion

3.3. Effects of Cohesive Zone Parameters and Geometric Imperfection on the Buckling Load

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cui, W.; Lian, L.; Pan, G. Frontiers in deep-sea equipment and technology. J. Mar. Sci. Eng. 2023, 11, 715. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, X.; Tang, W.; Wang, F.; Zhu, Y. Non-linear collapse behavior of externally pressurized resin toroidal and cylindrical shells: Numerical and experimental studies. Ships Offshore Struct. 2021, 16, 529–545. [Google Scholar] [CrossRef]

- Sheta, A.; Ma, X.; Zhuge, Y.; ElGawady, M.; Mills, J.E.; Abd-Elaal, E. Axial compressive behaviour of thin-walled composite columns comprise high-strength cold-formed steel and PE-ECC. Thin-Walled Struct. 2023, 184, 110471. [Google Scholar] [CrossRef]

- Hosseini, S.M.; Shariati, M. Experimental analysis of energy absorption capability of thin-walled composite cylindrical shells by quasi-static axial crushing test. Thin-Walled Struct. 2018, 125, 259–268. [Google Scholar] [CrossRef]

- Xie, L.; Qi, Y.; Bai, Y.; Qiu, C.; Wang, H.; Fang, H.; Zhao, X. Sandwich assemblies of composites square hollow sections and thin-walled panels in compression. Thin-Walled Struct. 2019, 145, 106412. [Google Scholar]

- Hu, Y.; Wei, Y.; Han, G.; Zhang, J.; Sun, G.; Hu, X.; Cheng, F. Comparison of impact resistance of carbon fibre composites with multiple ultra-thin CNT, aramid pulp, PBO and graphene interlayers. Compos. Part A Appl. Sci. Manuf. 2022, 155, 106815. [Google Scholar] [CrossRef]

- Zuo, X.; Zhang, J.; Tang, W.; Li, Y.; Li, H. Buckling behavior of steel and steel–composite cylinders under external pressure. Thin-Walled Struct. 2022, 181, 110011. [Google Scholar] [CrossRef]

- Zuo, X.; Zhang, J.; Tang, W.; Li, Y.; Zhan, M. Collapse of externally pressurized elliptical steel cylinders stiffened with helical composite stripes. Ocean Eng. 2022, 263, 112376. [Google Scholar] [CrossRef]

- Zuo, X.; Tang, W.; Zhang, J.; Li, Y.; Zhan, M. Collapse of externally pressurized steel–composite hybrid cylinders: Analytical solution and experimental verification. Metals 2022, 12, 1591. [Google Scholar] [CrossRef]

- Hilburger, M.W.; Starnes, J.H. Effects of imperfections of the buckling response of composite shells. Thin-Walled Struct. 2004, 42, 369–397. [Google Scholar] [CrossRef]

- Fazlalipour, N.; Showkati, H. Geometric properties and imperfections influence on buckling behavior of Variable-Thickness steel cylindrical shells subjected to combined Loading: Experimental and numerical study. Structures 2023, 55, 834–852. [Google Scholar] [CrossRef]

- Tsouvalis, N.G.; Zafeiratou, A.A.; Papazoglou, V.J. The effect of geometric imperfections on the buckling behaviour of composite laminated cylinders under external hydrostatic pressure. Compos. B Eng. 2003, 34, 217–226. [Google Scholar] [CrossRef]

- Hartwich, T.S.; Panek, S.; Wilckens, D.; Wille, T.; Krause, D. The influence of R/t-ratio on the imperfection sensitivity of the buckling load of thin-walled CFRP cylindrical shells. Compos. Struct. 2024, 341, 118216. [Google Scholar] [CrossRef]

- Wang, W.; Zhu, Y.; Zhou, L.; Zhang, J. Buckling characteristics of carbon fiber composite/aluminium alloy combined cylindrical shells under external hydrostatic pressure. Int. J. Press. Vessel. Pip. 2024, 208, 105125. [Google Scholar] [CrossRef]

- Cai, B.; Liu, Y.; Liu, Z.; Tian, X.; Ji, R.; Li, H. Reliability-based load and resistance factor design of composite pressure vessel under external hydrostatic pressure. Compos. Struct. 2011, 93, 2844–2852. [Google Scholar] [CrossRef]

- Li, B.; Pang, Y.; Cheng, Y.; Zhu, X. Collaborative optimization for ring-stiffened composite pressure hull of underwater vehicle based on lamination parameters. Int. J. Nav. Archit. Ocean Eng. 2017, 9, 373–381. [Google Scholar] [CrossRef]

- Sumana, B.G.; Vidya Sagar, H.N.; Sharma, K.V.; Krishna, M. Numerical analysis of the effect of fiber orientation on hydrostatic buckling behavior of fiber metal composite cylinder. J. Reinf. Plast. Compos. 2015, 34, 1422–1432. [Google Scholar] [CrossRef]

- Rezaiee-Pajand, M.; Arabi, E.; Masoodi, A.R. Nonlinear analysis of FG-sandwich plates and shells. Aerosp. Sci. Technol. 2019, 87, 178–189. [Google Scholar] [CrossRef]

- Ghandehari, M.A.; Masoodi, A.R.; Hosseininia, E.S. Temperature-dependency and boundary condition impacts on the multiscale vibrational behavior of laminated nested dual conical shell structure semi-AUV applications. Appl. Ocean Res. 2025, 154, 104425. [Google Scholar] [CrossRef]

- Zhang, L.; Zhao, L.; Pan, L.; Gao, J. Research progress of composite cylindrical shells. Polym. Compos. 2023, 44, 7298–7316. [Google Scholar] [CrossRef]

- Kachanov, L.M. Layering in glass-fiber pipes subject to external pressure. Polym. Mech. 1976, 11, 947–949. [Google Scholar] [CrossRef]

- Kachanov, L.M. Separation failure of composite materials. Polym. Mech. 1976, 12, 812–815. [Google Scholar] [CrossRef]

- Rasheed, H.A.; Tassoulas, J.L. Delamination growth in long composite tubes under external pressure. Int. J. Fract. 2001, 108, 1–23. [Google Scholar] [CrossRef]

- Fu, Y.; Yang, J. Delamination growth for composite laminated cylindrical shells under external pressure. Appl. Math. Mech. 2007, 28, 1131–1144. [Google Scholar] [CrossRef]

- Wei, R.; Shen, K.; Pan, G. A numerical study on the effect of delamination on composite cylindrical shells subjected to hydrostatic pressure. Ocean Eng. 2022, 262, 112294. [Google Scholar] [CrossRef]

- Qu, Y.; Chen, N.; Yuan, L. Cohesive zone model based reliability analysis for a sandwich pipe. Ocean Eng. 2023, 270, 113550. [Google Scholar] [CrossRef]

- Wan, F.; Guan, F.; Zhou, C.; Liu, S.; Yang, T. Pressure capacity of sandwich pipe with cement-based core configuration under deep-water external pressure. J. Sandw. Struct. Mater. 2020, 22, 1292–1326. [Google Scholar] [CrossRef]

- Yang, Y.; Wan, F.; Guan, F.; Tian, H.; Chen, W. Buckling behavior of sandwich pipe under external pressure and lateral load. Int. J. Press. Vessel. Pip. 2024, 207, 105114. [Google Scholar] [CrossRef]

- Xie, P.; Lin, G.; Teng, J.G.; Jiang, T. Modelling of concrete-filled filament-wound FRP confining tubes considering nonlinear biaxial tube behavior. Eng. Struct. 2020, 218, 110762. [Google Scholar] [CrossRef]

- Teng, J.; Fernando, D.; Yu, T.; Zhao, X. Debonding failures in CFRP-strengthened steel structures. In Proceedings of the 3rd Asia-Pacific Conference on FRP in Structures, Sapporo, Japan, 2–4 February 2012. [Google Scholar]

- Teng, J.G.; Fernando, D.; Yu, T. Finite element modelling of debonding failures in steel beams flexurally strengthened with CFRP laminates. Eng. Struct. 2015, 86, 213–224. [Google Scholar] [CrossRef]

- Fernando, D.; Teng, J.; Yu, T.; Zhao, X. Preparation and characterization of steel surfaces for adhesive bonding. J. Compos. Constr. 2013, 17, 04013012. [Google Scholar] [CrossRef]

- Budhe, S.; Ghumatkar, A.; Birajdar, N.; Banea, M.D. Effect of surface roughness using different adherend materials on the adhesive bond strength. Appl. Adhes. Sci. 2015, 3, 20. [Google Scholar] [CrossRef]

- Zielecki, W.; Pawlus, P.; Perłowski, R.; Dzierwa, A. Surface topography effect on strength of lap adhesive joints after mechanical pre-treatment. Arch. Civ. Mech. Eng. 2013, 13, 175–185. [Google Scholar] [CrossRef]

- Kadlečková, M.; Minařík, A.; Smolka, P.; Mráček, A.; Wrzecionko, E.; Novák, L.; Musilová, L.; Gajdošík, R. Preparation of textured surfaces on aluminum-alloy substrates. Materials 2018, 12, 109. [Google Scholar] [CrossRef] [PubMed]

- Ye, J.; Wang, H.; Dong, J.; Liu, C.; Gao, Y.; Gong, B.; Su, B.; Peng, H. Metal surface nanopatterning for enhanced interfacial adhesion in fiber metal laminates. Compos. Sci. Technol. 2021, 205, 108651. [Google Scholar] [CrossRef]

- Maressa, P.; Anodio, L.; Bernasconi, A.; Demir, A.G.; Previtali, B. Effect of surface texture on the adhesion performance of laser treated Ti6Al4V alloy. J. Adhes. 2015, 91, 518–537. [Google Scholar] [CrossRef]

- Schweizer, M.; Meinhard, D.; Ruck, S.; Riegel, H.; Knoblauch, V. Adhesive bonding of CFRP: A comparison of different surface pre-treatment strategies and their effect on the bonding shear strength. J. Adhes. Sci. Technol. 2017, 31, 2581–2591. [Google Scholar] [CrossRef]

- Saleema, N.; Gallant, D. Atmospheric pressure plasma oxidation of AA6061-T6 aluminum alloy surface for strong and durable adhesive bonding applications. Appl. Surf. Sci. 2013, 282, 98–104. [Google Scholar] [CrossRef]

- Wang, B.; Bai, Y.; Hu, X.; Lu, P. Enhanced epoxy adhesion between steel plates by surface treatmentand CNT/short-fibre reinforcement. Compos. Sci. Technol. 2016, 127, 149–157. [Google Scholar] [CrossRef]

- Hu, Y.; Zhang, J.; Wang, L.; Jiang, H.; Cheng, F.; Hu, X. A simple and effective resin pre-coating treatment on grinded, acid pickled and anodised substrates for stronger adhesive bonding between Ti-6Al-4V titanium alloy and CFRP. Surf. Coat. Technol. 2022, 432, 128072. [Google Scholar] [CrossRef]

- Hu, Y.; Yuan, B.; Cheng, F.; Hu, X. NaOH etching and resin pre-coating treatments for stronger adhesive bonding between CFRP and aluminium alloy. Compos. B Eng. 2019, 178, 107478. [Google Scholar] [CrossRef]

- Choqueuse, D.; Bigourdan, B.; Deuff, A.; Douchin, B.; Quetel, L. Hydrostatic compression behaviour of steel composite hybrid tubes. In Proceedings of the ICCM17, Edinburgh, UK, 27–31 July 2009. [Google Scholar]

- Di, C.; Zhang, J.; Hu, Y.; Kang, C. Buckling of steel-composite cylindrical pressure hulls with initial delamination. Thin-Walled Struct. 2024, 202, 112042. [Google Scholar] [CrossRef]

- ISO 25178-2:2021; Geometrical Product Specifications (GPS)—Surface Texture: Areal—Part 2: Terms, Definitions and Surface Texture Parameters. IOS: Geneva, Switzerland, 2021.

- ASTM D5868; Standard Test Method for Lap Shear Adhesion for Fiber Reinforced Plastic (FRP) Bonding. ASTM: West Conshohocken, PA, USA, 2014.

- Mao, Y.; Dong, G.; Fu, Y.; Li, Y.; Huang, P.; Fu, S. High performance shape-adjustable structural lithium-ion battery based on hybrid fiber reinforced epoxy composite. Compos. Struct. 2023, 325, 117598. [Google Scholar] [CrossRef]

- Esmaeili, Y.R.; Cosco, B.; Najjaran, H. Vacuum bag leak detection for resin infusion: An electric current–based analogy. Int. J. Adv. Manuf. Technol. 2023, 124, 1775–1786. [Google Scholar] [CrossRef]

- Hu, C.; Xu, Z.; Huang, M.; Cai, C.; Wang, R.; He, X. An insight into the mechanical behavior and failure mechanisms of T-stiffened composite structures with through-interface debonding defects. Ocean Eng. 2024, 300, 117342. [Google Scholar] [CrossRef]

- ISO 16809:2017; International Organisation for Standardisation, Non-Destructive Testing—Ultrasonic Thickness Measurement. IOS: Geneva, Switzerland, 2017.

- Wang, J.; Ai, C.; Yun, X.; Chen, Z.; He, B. Effects of 3D roughness parameters of sandblasted surface on bond strength of HVOF sprayed WC-12Co coatings. Coatings 2022, 12, 1451. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, Y.; Chen, L. Crater array generated on Al alloy surface by nanosecond laser: Surface characteristics and bonding strength. Opt. Laser Technol. 2024, 169, 110079. [Google Scholar] [CrossRef]

- Ourahmoune, R.; Salvia, M.; Mathia, T.G.; Mesrati, N. Surface morphology and wettability of sandblasted PEEK and its composites: Surface morphology and wettability. Scanning 2014, 36, 64–75. [Google Scholar] [CrossRef]

- Wenzel, R.N. Resistance of solid surfaces to wetting by water. Ind. Eng. Chem. 1936, 28, 988–994. [Google Scholar] [CrossRef]

- Ebnesajjad, S.; Landrock, A.H. Adhesives Technology Handbook, 3rd ed.; William Andrew Publishing: New York, NY, USA, 2014. [Google Scholar]

- Levy, A.; Hubert, P. Vacuum-bagged composite laminate forming processes: Predicting thickness deviation in complex shapes. Compos. Part A Appl. Sci. Manuf. 2019, 126, 105568. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, B.; Ding, W.; Pu, C.; Peng, S.; Ma, F. A short review on machining deformation control of aero-engine thin-walled casings. Int. J. Adv. Manuf. Technol. 2022, 121, 2971–2985. [Google Scholar] [CrossRef]

- Zhang, J.; Teng, Y.; Di, C.; Zuo, X.; Wang, F. Collapse of composite-repaired cylinders with internal metal loss subjected to external hydrostatic pressure. Mar. Struct. 2023, 88, 103347. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, C.; Tang, W.; Wang, F.; Zhao, X.; Zhang, J.; Tang, L. Collapse of barreled frustums under external hydrostatic pressure. Mar. Struct. 2022, 84, 103218. [Google Scholar] [CrossRef]

- Zhang, J.; Cheng, P.; Wang, F.; Tang, W.; Zhao, X. Hydroforming and buckling of an egg-shaped shell based on a petal-shaped preform. Ocean Eng. 2022, 250, 111057. [Google Scholar] [CrossRef]

- Zhang, J.; Dai, M.; Wang, F.; Tang, W.; Zhao, X.; Zhu, Y. Theoretical and experimental study of the free hydroforming of egg-shaped shell. Ships Offshore Struct. 2022, 17, 257–267. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, F.; Wang, F.; Zhao, X.; Tang, W.; Chen, F. Buckling properties of bulged barrels under external pressure. Thin-Walled Struct. 2021, 168, 108226. [Google Scholar] [CrossRef]

- Ameri, B.; Moradi, M.; Mohammadi, B.; Salimi-Majd, D. Investigation of nonlinear post-buckling delamination in curved laminated composite panels via cohesive zone model. Thin-Walled Struct. 2020, 154, 106797. [Google Scholar] [CrossRef]

- Mohammadi, B.; Salimi-Majd, D. Investigation of delamination and damage due to free edge effects in composite laminates using cohesive interface elements. Eng. Solid Mech. 2014, 2, 101–118. [Google Scholar] [CrossRef]

- Heidari, M.; Salimi-Majd, D.; Mohammadi, B. Failure analysis of composite wing adhesive joints using 3D cohesive interface element. J. Compos. Sci. Technol. 2015, 2, 31–40. [Google Scholar]

- Zhang, Y.; Liu, Z.; Xin, J.; Wang, Y.; Zhang, C.; Zhang, Y. The attenuation mechanism of CFRP repaired corroded marine pipelines based on experiments and FEM. Thin-Walled Struct. 2021, 169, 108469. [Google Scholar] [CrossRef]

- China Classification Society. Rules For Classification of Diving Systems and Submersibles; China Classification Society: Beijing, China, 2018. [Google Scholar]

- Zhang, J.; Zhang, S.; Cui, W.; Zhao, X.; Tang, W.; Wang, F. Buckling of circumferentially corrugated cylindrical shells under uniform external pressure. Ships Offshore Struct. 2019, 14, 879–889. [Google Scholar] [CrossRef]

- Zhang, J.; Zhu, Z.; Wang, F.; Zhao, X.; Zhu, Y. Buckling behaviour of double-layer and single-layer stainless steel cylinders under external pressure. Thin-Walled Struct. 2021, 161, 107485. [Google Scholar] [CrossRef]

- Liu, P.; Gu, Z.; Hu, Z. Revisiting the numerical convergence of cohesive-zone models in simulating the delamination of composite adhesive joints by using the finite-element analysis. Mech. Compos. Mater. 2016, 52, 651–664. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, X.; Tang, W.; Wang, F.; Yin, B. Experimental and numerical buckling analysis of toroidal shell segments under uniform external pressure. Thin-Walled Struct. 2020, 150, 106689. [Google Scholar] [CrossRef]

- Jiang, S.; Zhang, A.; Zhan, X.; Jiang, H. Surface microtexturing design, laser-etching and adhesive failure of aluminum alloy single-lap-joint: Experiment and simulation. Thin-Walled Struct. 2023, 193, 111237. [Google Scholar] [CrossRef]

- Orifici, A.C.; de Zarate Alberdi, I.O.; Thomson, R.S.; Bayandor, J. Compression and post-buckling damage growth and collapse analysis of flat composite stiffened panels. Compos. Sci. Technol. 2008, 68, 3150–3160. [Google Scholar] [CrossRef]

- Dogan, C.; Kaman, M.O.; Erdem, S.; Albayrak, M. Comparison of Hashin and Puck criterions for failure behavior of pin loaded composite plates. Materwiss. Werksttech. 2024, 55, 314–329. [Google Scholar] [CrossRef]

- Rahman, M.M.; Ismail, A.E.; Ramli, M.F.; Abdul Rashid, A.H. A review of experimentation numerical simulation of low-velocity impact performances and damages of fiber-reinforced composites. J. Adv. Res. Appl. Mech. 2024, 123, 147–184. [Google Scholar] [CrossRef]

- Al-Azzawi, A.S.M.; Featherston, C.A.; Lupton, C.; Jiang, C.; Barouni, A.; Koklu, U.; Giasin, K. Impact characteristics of S2-glass fibre/FM94-epoxy composites under high and cryogenic temperatures: Experimental and numerical investigation. Compos. B Eng. 2024, 287, 111786. [Google Scholar] [CrossRef]

- Huang, Y.; Zhang, Y.; Kong, B.; Gu, J.; Wang, Z.; Chen, P. Experimental and numerical studies on buckling and post-buckling behavior of T-stiffened variable stiffness panels. Chin. J. Aeronaut. 2024, 37, 459–470. [Google Scholar] [CrossRef]

- Lu, X.; Ridha, M.; Chen, B.Y.; Tan, V.B.C.; Tay, T.E. On cohesive element parameters and delamination modelling. Eng. Fract. Mech. 2019, 206, 278–296. [Google Scholar] [CrossRef]

| Mesh | Ra | Rq | Rt | Rp | Rv |

|---|---|---|---|---|---|

| μm | |||||

| 0 | 0.147 | 0.283 | 4.631 | 3.562 | 1.069 |

| 80 | 2.448 | 3.084 | 19.183 | 9.704 | 9.467 |

| 180 | 1.815 | 2.363 | 16.999 | 8.388 | 8.610 |

| 320 | 1.941 | 2.489 | 17.112 | 8.644 | 8.425 |

| Mesh | Sample-1 | Sample-2 | Sample-3 | Sample-4 | Sample-5 | Sample-6 | Mean |

|---|---|---|---|---|---|---|---|

| MPa | |||||||

| 0 | 6.52 | 4.52 | 6.98 | 7.40 | 5.32 | 7.83 | 6.43 |

| 80 | 22.25 | 22.63 | 22.79 | 22.80 | 23.05 | 23.61 | 22.86 |

| 180 | 20.70 | 20.95 | 21.69 | 22.08 | 22.12 | 22.30 | 21.64 |

| 320 | 17.90 | 18.06 | 18.09 | 18.27 | 20.34 | 21.63 | 19.05 |

| Sample | L | R | ts-nom | tc-nom | D | a | b | c | h | H |

|---|---|---|---|---|---|---|---|---|---|---|

| mm | ||||||||||

| cylinder | 162 | 70 | 1.2 | 1.2 | 90 | 4.25 | 2 | 3 | 8 | 6 |

| Sample | ts-av | ts-max | ts-min | tSt. dev. |

|---|---|---|---|---|

| mm | ||||

| Sandblasted cylinder-1 | 1.137 | 1.230 | 1.074 | 0.027 |

| Sandblasted cylinder-2 | 1.140 | 1.176 | 1.114 | 0.015 |

| Polished cylinder-1 | 1.149 | 1.434 | 1.122 | 0.051 |

| Polished cylinder-2 | 1.137 | 1.206 | 1.098 | 0.029 |

| Sample | ts-av | ts-max | ts-min | tSt. dev. | Ptest | Mean |

|---|---|---|---|---|---|---|

| mm | MPa | |||||

| Sandblasted cylinder-1 | 2.378 | 2.467 | 2.340 | 0.043 | 21.929 | 22.093 |

| Sandblasted cylinder-2 | 2.390 | 2.492 | 2.300 | 0.059 | 22.257 | |

| Polished cylinder-1 | 2.391 | 2.462 | 2.360 | 0.035 | 15.444 | 14.258 |

| Polished cylinder-2 | 2.415 | 2.605 | 2.340 | 0.089 | 13.072 | |

| Sample | S4R | S3 | COH3D8 | C3D8R | SC8R | Plinear [MPa] | Pnon [MPa] | Pnon/Ptest |

|---|---|---|---|---|---|---|---|---|

| Sandblasted cylinder-1 | 2887 | 14 | 8175 | 8175 | 8175 | 24.1 | 22.2 | 1.012 |

| Sandblasted cylinder-2 | 3225 | 34 | 8175 | 8175 | 8175 | 26.0 | 23.4 | 1.051 |

| Polished cylinder-1 | 2632 | 92 | 8175 | 8175 | 8175 | 26.6 | 15.8 | 1.023 |

| Polished cylinder-2 | 3038 | 106 | 8175 | 8175 | 8175 | 24.7 | 14.3 | 1.094 |

| Parameter | Value | Parameter | Value (Sandblast) | Value (Polish) | ||

|---|---|---|---|---|---|---|

| Elastic modulus (GPa) | E1 | 138 | Critical strain energy release rate (N/mm) | GIC | 0.0876 | 0.0876 |

| E2 | 10.16 | GIIC | 0.3152 | 0.3152 | ||

| E3 | 10.16 | GIIIC | 0.3152 | 0.3152 | ||

| Poisson’s ratio | v12 | 0.28 | Interlaminar tensile strength (MPa) | 44.54 | 0.6 | |

| v13 | 0.28 | 106.9 | 1.4 | |||

| v23 | 0.3 | 106.9 | 1.4 | |||

| Shear modulus (GPa) | G12 | 5.86 | Penalty stiffness (N/mm3) | 106 | 106 | |

| G12 | 5.86 | 106 | 106 | |||

| G23 | 4.79 | 106 | 106 | |||

| Viscosity | η | 1.75 | 1.75 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Di, C.; Hu, Y.; Jiao, H.; Kaewunruen, S.; Zhang, J. Delamination-Driven Nonlinear Buckling of Metal–Composite Cylindrical Shells with Different Interfacial Strengths. J. Mar. Sci. Eng. 2025, 13, 1279. https://doi.org/10.3390/jmse13071279

Di C, Hu Y, Jiao H, Kaewunruen S, Zhang J. Delamination-Driven Nonlinear Buckling of Metal–Composite Cylindrical Shells with Different Interfacial Strengths. Journal of Marine Science and Engineering. 2025; 13(7):1279. https://doi.org/10.3390/jmse13071279

Chicago/Turabian StyleDi, Chenyang, Yunsen Hu, Huifeng Jiao, Sakdirat Kaewunruen, and Jian Zhang. 2025. "Delamination-Driven Nonlinear Buckling of Metal–Composite Cylindrical Shells with Different Interfacial Strengths" Journal of Marine Science and Engineering 13, no. 7: 1279. https://doi.org/10.3390/jmse13071279

APA StyleDi, C., Hu, Y., Jiao, H., Kaewunruen, S., & Zhang, J. (2025). Delamination-Driven Nonlinear Buckling of Metal–Composite Cylindrical Shells with Different Interfacial Strengths. Journal of Marine Science and Engineering, 13(7), 1279. https://doi.org/10.3390/jmse13071279