Abstract

Plastic pollution has been recognized as an emerging risk for the aquatic environment. Shifting from the prevailing linear “take-make-dispose” model to a “circular” economy framework is essential for mitigating the environmental impact of plastics. Microplastics (MPs) in the natural environment are formed when synthetic polymers are fragmented and micronized to a size ≤ 5 mm. MPs are a global environmental problem, particularly within aquatic ecosystems, due to their persistence, accumulation, and uncertain long-term effects. This review examines the degradation pathways of polymers that result in MP formulation, their rate and distribution across ecosystems, and their potential entry into food systems. Key challenges include a lack of standardized detection methods, specifically for nanoparticles; limited evidence of long-term toxicity; and the inefficiency of current waste management frameworks. Emphasis is placed on the cradle-to-grave lifecycle of plastic materials, highlighting how poor design, excessive packaging, and inadequate post-consumer treatment contribute to MP release. The transition from Directive 94/62/EC to the new Regulation (EU) 2025/40 marks a significant policy shift towards stronger preventive measures. In line with the waste hierarchy and reduction in unnecessary packaging and plastic use, effective recycling must be supported by appropriate collection systems, improved separation processes, and citizen education to prevent waste and improve recycling rates to minimize the accumulation of MPs in the environment and reduce health impacts. This review identifies critical gaps in current knowledge and suggests crucial approaches in order to mitigate MP pollution and protect marine biodiversity and public health.

1. Introduction

Currently, plastics are used in various sectors, with an annual demand of 54 Mt [1]. Packaging makes up 39% of this use and is dominated by food packaging that accounts for around 90% [2]. In this sector, the end-of-life treatment of plastics is underperforming, especially when compared with more homogenous materials, such as metals or glass, traditionally used in food packaging [3].

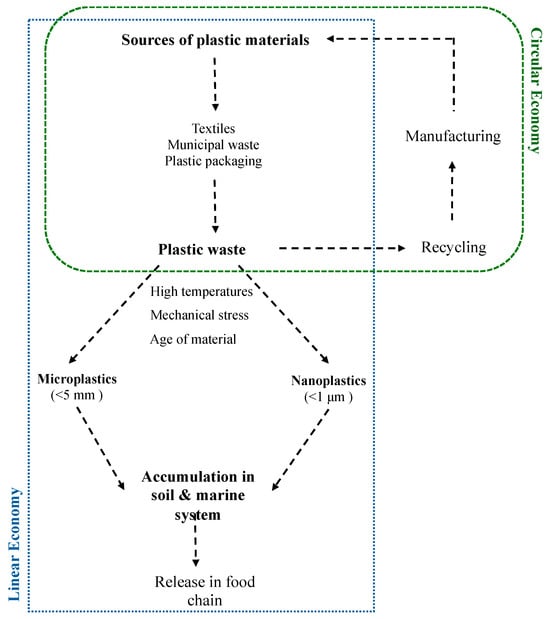

Plastic pollution has been recognized as an emerging risk for the aquatic environment (Figure 1). MPs and nanoplastics (NPs) that contaminate the natural environment are formed when synthetic polymers are fragmented and micronized to a size < 5 mm or <1 μm, respectively, and they are known to pose significant hazards to animals in marine and other ecosystems as they may induce impaired growth, oxidative stress, neurotoxicity, or other physiological harm [4]. However, despite increasing evidence, the full extent of their ecological impact, especially under environmentally relevant concentrations, remains uncertain, with some studies reporting no controversial results at trophic levels [5,6,7]. This uncertainty is further compounded by the presence of plastic additives, such as phthalates and bisphenols, which may leach from packaging materials and exert toxic effects independently of the polymer matrix [8,9]. The biggest source of MPs is textiles [10], accounting for approximately 35% of the total MPs present in the ocean, followed by tires/rubbers and municipal waste, including fossil-based polymers, e.g., polyethylene (PE), polypropylene (PP), and polystyrene (PS) [11]. MPs enter the oceans from a diversity of sources, including cosmetics, plastic packaging, discarded and lost fishing equipment, through wastewater, wind, and rain and they often accumulate in the air and terrestrial ecosystems. MP prevalence in groundwater has been correlated with intense anthropogenic activities (agricultural, industrial, and urban) [12].

Figure 1.

Schematic presentation of current and circular plastic concept (adapted from Balwada et al., 2021) [13].

Worldwide, 0.8–2.5 million tn of MPs are estimated to end up in the oceans annually [14]. Of the MPs that pass through wastewater treatment plants, approximately 95% are estimated to be retained as biosolids [15]. Annually, 63,000–430,000 tn of MPs enter into European agroecosystems through biosolids alone, while relevant calculations for North America range from 44,000 to 300,000 tn annually [11]. According to Plastics Europe, in 2023, 35.5 Mt of plastic waste was recycled in Europe. Nevertheless, there are many opportunities to reduce plastic waste and improve end-of-life treatment [16]. The recently adopted EC’s plastics strategy aims to decouple plastic production from virgin materials, reducing its leakage into the environment and improving the economics and uptake of recycling to support the transition from a linear to a circular economy model. Recent research aims to reinforce the strong bond that the bioplastics sector has with the packaging sector (which is by far the largest consumer of biodegradable and bio-based plastics) by providing alternative packaging materials for foodstuff and other goods [17,18,19]. The main benefits of using bioplastics vs. conventional plastics are linked to saving non-renewable resources and their low toxicity. However, bioplastics often present poor mechanical and barrier properties, and their fragility and brittleness may limit their potential for application and shorten the shelf life of sensitive food products. Recyclable and/or recycled packaging materials have the potential to effectively preserve food without limiting its shelf life [20,21].

This review aims to offer a novel and integrated perspective on the rational use of plastics in the food and beverage sector to restrict MP pollution. Although numerous studies address polymer degradation mechanisms or the environmental effects of MPs, a comprehensive analysis that connects plastic use in food systems with the formation, entry routes, and policy context of MPs remains lacking. This work addresses that gap by interconnecting the role of plastics throughout the food supply chain with the environmental mechanisms that lead to their degradation, the routes through which MPs enter the food chain, and the significant contribution of food and beverage packaging to MP pollution. Furthermore, it critically examines the European Union’s evolving legislative framework on plastic use, highlighting new legislation that aims to restrict the excessive use of plastic packaging materials. Therefore, the present review aims to enhance understanding of the current state of MP pollution in relation to food systems, a perspective currently lacking in the literature, while supporting the development of targeted, multidisciplinary strategies for pollution mitigation.

2. Polymer Degradation and Microplastic Pollution

The various types of polymer degradation play a critical role in the generation and accumulation of microplastics across ecosystems. This section outlines how microplastic pollution can be generally identified and assessed in the environment, while its entry into food systems and food chains is analyzed in the following section.

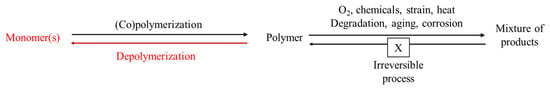

Polymer degradation is based on a chemical modification in the molecular structure of the polymer that alters its properties. A wide range of polymers, which are available for extensive use in different sectors, have different chemical structures and thus are more or less susceptible to different types of degradation process. Degradation is a complex process in which a polymeric material, when subjected to environmental factors and mechanical stress, gradually loses its initial characteristics. A central feature of this process is the breakdown of macromolecules. In many contexts, the term "polymer degradation" specifically refers to the fragmentation of these large molecules into smaller segments with varying structures and sizes. If this breakdown results in monomers, it is known as depolymerization as it reverses the polymerization reaction (Figure 2). Conversely, when the disintegration of macromolecules is not the main mechanism, the process is typically called polymer aging or corrosion [22].

Figure 2.

Schematic representation of the relationship between polymerization, depolymerization, and degradation [22].

Degradation is caused by microorganisms, specific enzymes, or the combined effects of natural environmental factors, which is referred to as biodegradation. Commonly used polymers, such as PE, PP, PS, and polyvinylchloride (PVC), possess a carbon backbone that is resistant to hydrolytic and enzymatic degradation. For this reason, microorganisms do not have the necessary enzymes to assimilate and mineralize conventional polymers, and this has led to their accumulation in the environment. For example, the lifetime of polyolefins on land is in the range of hundreds of years [23]. Polymer degradation in soil may be achieved by photo- and thermos-oxidative degradation and some degree of biodegradation after exposure to certain microorganisms and an extensive level of oxidation [11].

A polymer without active centers remains stable at temperatures higher than its ceiling temperature (Tc) because of the high-activation Gibbs energy required for center formation. The polymer is kinetically stable but thermodynamically unstable. Decomposition begins only after initiation, when active centers are formed within the polymer. The primary degradation-active species are free radicals, which may arise through various mechanisms such as thermal activation, exposure to light (photochemical processes), mechanical stress, or oxidative reactions [22]. Table 1 summarizes the four main types of polymer degradation.

Table 1.

Types of polymer degradation.

In order to assess the risk of MPs in ecosystems, methodologies are needed to assess, extract, quantify, and characterize MP contamination in water and sediment samples [24]. Although extensive research has identified the detrimental effects to the biosphere of large plastic debris, the effect of MPs and NPs remains less clear. In lab-based studies, high doses are often used to assess the effect of a specific pollutant in experimental studies so one can determine dose–response curves and elicit toxicological endpoints. Considering studies on pesticides and other endocrine-disrupting chemicals, nonlinear or non-sigmoidal dose–response relationships are often observed (e.g., U-shaped responses). Specifically, while evaluating the biological effect of NPs, the particle surface area or concentration seem to have a more prominent effect than mass-based doses [25].

Choosing an appropriate subject is critical for the reliability of results. For example, if the test organisms are already exposed to high background levels of a pollutant, a lack of response compared with the tested treatment may merely be an artifact of the organism’s prior exposure. Certain organisms have also been proven to be more sensitive compared with others, such as juvenile organisms at early developmental stages, and these should be prioritized in initial screenings [11]. In a recent study, the effect of PS NP exposure (50, 500, and 1000 nm and concentrations ranging from 0.001 to 10 μg/mL) on fibroblast cell lines from zebrafish as well as human male newborns and female adults. The PS NPs negatively affected fibroblast migration in a time-, size- and concentration-dependent manner, with larger PS NPs at higher concentrations causing a more significant inhibition of cell migration and human fibroblasts having a higher sensitivity to NPs. This means that by controlling the concentration and time of exposure to MPs it may be possible to limit their impact on the environment and public health [26].

3. Entry Points of MPs into Food Systems and the Food Chain

There are multiple pathways that allow the entry of MPs into the food chain. There are organisms that ingest the MPs or there is the possibility of direct contamination during the food processing steps. MPs enter the food chain primarily through aquatic organisms such as plankton, fish, and aquatic species of crustaceans and mollusks, although terrestrial mollusks and crustaceans may also play a role in MPs’ transfer within terrestrial ecosystems. Moreover, indirect contamination may occur during food processing due to the use of plastic materials or machinery at stages such as manufacturing, storage, and transport, which are crucial for MP release [27].

Beer et al. (2018) investigated the amount of MPs in wild fish of the Baltic Sea and found 1–3 plastic items in the digestive tract of 63 herring and 97 sprat samples of 814 examined fish (i.e., approximately 20%). Among the plastic items, 95% were characterized as MPs and 93% as fibers. The authors did not report significant differences between species, locations, and the time of day the fish were caught. However, they pointed out that samples collected during the summer were more contaminated with MPs compared with those caught during the spring period, which was attributed to the increasing food uptake with size and seasonal differences during the feeding period. Seasonal variations influence microplastic ingestion, with a higher number of particles observed in the digestive tracts of fish during the summer period compared with spring [28].

Seafood such as shellfish and crustaceans are also reported to be highly contaminated food systems [29]. Abbasi et al. (2018) analyzed the commercially important species of pelagic fish and crustaceans (tiger prawn) for the presence of MPs. They found that MPs in fish exist mainly in the gut, skin, gills, muscle, and liver while the MPs in prawns were found in the exoskeleton and muscle. Tiger prawns, Penaeus semisulcatus, were the most contaminated test species. The average MP quantities were between 0.16 g−1 on a mass basis for the mesopelagic fish Cynoglossus abbreviatus and 1.5 g−1 on a mass basis for Penaeus semisulcatus across all tissues from each species. However, the researchers could not explain the pathways of entry of MPs into the non-digested marine species’ tissues [30].

Honey is also studied for the presence of MPs, and their presence may be attributed to the environment through flowers, transport by bees to the hive, or plastic bags used for carrying sugars [31].

4. The Role of Plastic Packaging of Foods and Beverages in Microplastic Production

Plastic packaging materials for food and beverages mainly consist of thermoplastic resins, i.e., high-density polyethylene (HDPE), low-density polyethylene (LDPE), PP, polyethylene terephthalate (PET), PVC, and PS, depending on the features of the material and the proposed application [32]. Food storage and consumption are mainly based on plastic containers (pouches, wraps, trays, cups, and bottles) or plastic coatings in the inner part of metal cans or paper wraps. Cox et al. (2019) recently estimated that the range of exposure to microplastics through air and highly consumed foods for humans is approximately 203–332 particles per person per day [33]. Extensive research is being carried out to investigate direct human exposure to MPs, particularly from ocean food and water and indirectly via the food chain [34,35]. However, the release of MPs from plastic packaging products and exposure to humans via this route remain poorly studied.

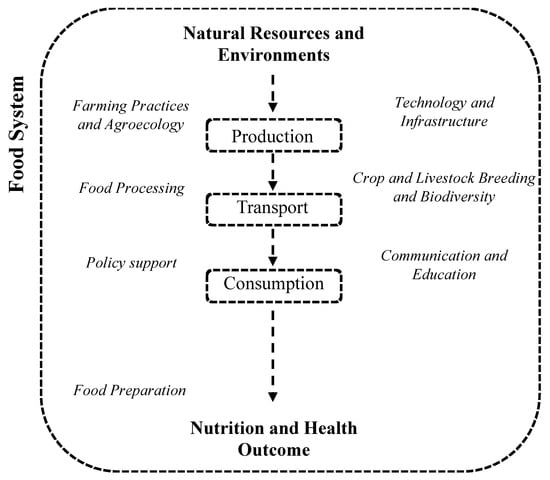

The chemical composition and the physical characteristics of MPs influence the potential release of MPs from packaging material. Most MPs are transparent or white and can be detected in food systems (Figure 3) with analytical methods such as Micro-Raman Spectroscopy, Scanning Electron Microscopy (SEM) analysis, or Fourier Transform Infrared Spectroscopy (FTIR). The shape of the MPs is variable and may be cubical, spherical, rod-like, or irregular and can influence the consequences of exposure [32]. In the literature, exposure to such irregular MPs is frequently discriminated by the terms “microplastic fragments” or “fibers”. The size of MPs detected in food systems is influenced by the type of food packaging. For example, plastic food containers have microplastics between 100 and 500 μm [36] and plastic food trays with sealing films can generate sub-millimeter fragments [37]. The MPs from paper cups with an inner plastic layer range from 150 nm to 764.8 μm [38], while most of the MPs in single-use plastic bottles are lower than 1.5 μm [39]. Reusable PET bottles produce MPs mainly between 1.5 and 5 μm [40].

Figure 3.

The food system aspect (adapted from Tansey and Worsley, 2014) [41].

The release rate of MPs from packaging material into a food system increases when the size of the MPs and the polymer dynamic viscosity decrease. Smaller MPs have a higher surface-area-to-volume ratio, increasing their mobility, the possibility of their release, and their ability to absorb environmental contaminants. Additionally, plastic materials with lower polymer dynamic viscosity have a tendency to show weaker intermolecular forces and so are more prone to wear abrasion and migration under stress conditions like high temperatures [42,43].

The potential release of MPs from packaging materials into packaged food is currently under investigation for different types of food commodities [32,37]. Although numerous studies have investigated the presence of microplastics in food, only a limited number have specifically attributed their occurrence to migration from food packaging materials. Table 2 provides a summary of the occurrence of MPs in food and beverages attributed to their packaging. Temperatures higher than 40 °C increase the risk of MP migration into packaged food, for example, in the case of plastic teabags or cups for hot beverages where temperatures may reach 70 °C or even higher [44]. In the case of in-pack heating of food, the thermal resistance and stability of polymers are key selection parameters to ensure an appropriate material is used [45]. The mechanical stress of bottles was, in a work from Winkler et al. (2019), proposed to be a potential reason for MP release into water. According to this study, the squeezing of PET bottles did not affect the morphological characteristics of the inner wall of the bottles, implying that bottles are not a consistent source of MPs due to mechanical stress [39]. According to Du et al. (2020), the major cause of the migration of MPs in plastic containers to food is a consequence of mechanical forces, loose structures, and rough surfaces. A higher risk of MP ingestion by humans has been correlated with the reuse of single-use plastic bottles, although the MPs primarily originate from the bottleneck–cap system [36]. The age of the bottle and the number of times it is reused are directly correlated with the amount of MPs released into the packed material and ranges from a 3-fold to 8-fold higher MP particle release into water compared with single-use bottles [40,46].

Table 2.

Literature review of MPs in food and beverages due to their packaging.

To investigate the sources of MPs in bottled water (as a standardized product stored long-term in plastic containers) and evaluate the MPs released from packaging material, a recent study was carried out in Germany by Weisser et al. (2021). The first step of mineral water bottling is pumping from a groundwater source, which is generally safe and free of contaminants such as ferric (iron) ions, specifically Fe(II) and Fe(III), which are naturally occurring in groundwater, and MPs [55]. Water quality, including MP prevalence, is not uniform in all groundwaters and can be affected by the soil type and anthropogenic activities on the top-ground layer [56]. After the aeration and precipitation of ferric ions, water is filtered to remove germs and other physical, chemical, and biological contaminants and transferred into appropriate bottles under sterile conditions. According to the results reported by Weisser et al. (2021), 81% of MPs resembled the PE-based cap sealing material, leading to the conclusion that abrasion from the sealings may be the main entry path for MPs into bottled mineral water, which is in line with the results of Winkler et al. (2019) [39,55]. However, systematic studies are needed to evaluate the potential prevalence of MPs in groundwater as a function of geographic distribution, climate, and human activities.

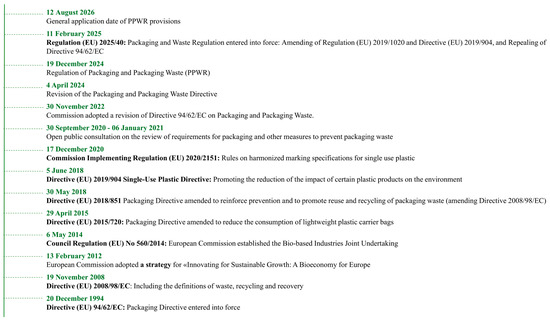

5. European Union’s Targets for Plastic Reduction

The regulatory framework of the European Union concerning packaging and packaging waste has evolved significantly over the past decades. It began with the entry into force of Directive 94/62/EC on 20 December 1994 [57], establishing the foundation for EU-wide rules on packaging and waste management. Over time, this directive was complemented and amended by several other legal instruments. On 19 November 2008, Directive 2008/98/EC [58] introduced essential definitions for waste, recycling, and recovery, enhancing legal clarity (Figure 4).

Figure 4.

Historical timeline of regulations towards plastic reduction.

In a world of finite resources, the transition to a knowledge-based post-petroleum economy is imperative. To support this evolution towards a low-carbon Europe, reducing its heavy dependency on fossil resources, the EC presented in 2012 a roadmap targeting the establishment of sustainable and competitive bio-based industries and value chains [59]. The Bioeconomy Strategy and its Action Plan pave the way towards a more innovative, resource-efficient, and competitive EU society, and were revised in 2017 [60] and subsequently updated in 2018 [61]. The aim of the transition is to accelerate the change towards a more sustainable EU bioeconomy and the contribution to the UN 2030 Agenda and associated Sustainable Development Goals (SDGs) as well as the Paris Agreement, the new EU policy priorities (in particular, the renewed Industrial Policy Strategy), the Circular Economy Action Plan, and Communication on Accelerating Clean Energy Innovation. As part of this strategy, the European Commission published Directive (EU) 2019/904 on the reduction of the impact of certain plastic products on the environment, also known as the Directive on single-use plastics [62]. These rules aim to prevent and reduce the impact of certain plastic products on the environment—in particular, the marine environment—and on human health.

On 19 December 2024, the Regulation on Packaging and Packaging Waste (PPWR) was introduced to replace the Packaging and Packaging Waste Directive with a more directly applicable legal framework. Regulation (EU) 2025/40 entered into force on 11 February 2025 [63], officially repealing Directive 94/62/EC and amending both Regulation (EU) 2019/1020 and Directive (EU) 2019/904.

Currently, the total greenhouse gas emissions caused by the plastics value chain are estimated to be 208 million tons of CO2-eq. The 2025 model estimates that the total plastics value chain emissions will be 182 Mt of CO2-eq, corresponding with a reduction potential of approximately 26 Mt of CO2-eq or 13%. The 2025 model is based on the set targets and expected trends. The greater reduction in the future model is derived from increased recycling and replacing polymers produced from fossil fuels. However, a specific global target for GHG emission reductions is not globally established in the plastic industry. The absence of a standardized basis makes it demanding to definitively determine if a 13% reduction is in accordance with the initial expectations. The EU aims at a 15% reduction in annual overall GHG emissions, resulting in a positive scenario of an 8.7% further decrease. The negative scenario corresponds with a 7% less decrease when contrasted with the on-target 2025 model [64].

6. Discussion

The degradation of plastic materials into MPs and NPs in marine and terrestrial environments is influenced by multiple factors. These include the physicochemical properties of the polymer, such as its composition, and the presence of structural additives, which affect its susceptibility to degradation. Furthermore, biological processes, including microbial or enzymatic activity, can also contribute to the degradation of plastics. Temperature, UV radiation, and oxygen availability are the main environmental conditions that play a significant role in the process. The location of the particles in a marine environment further determines the degradation rate. For example, particles that are in the upper water layer are more exposed to sunlight and wave-induced abrasion, while those buried in sediments degrade more slowly due to reduced oxygen and light penetration. The combination of mechanical stress, chemical transformation, and biological activity accelerates the degradation. This understanding is crucial for evaluating the long-term persistence of MPs [65].

MPs are widespread across marine ecosystems, accumulating in surface waters, sediments, and biota. Their detection relies on physical separation techniques and spectroscopic tools such as FTIR and Raman microscopy. However, challenges remain due to polymer selectivity, interference from organic matter, and the absence of standardized protocols. These limitations restrict accurate quantification and cross-study comparisons. Despite this, ongoing improvements in detection methods have enhanced our understanding of microplastic distribution and ecological impacts. Crucially, many marine organisms—ranging from plankton to commercially important fish—are known to ingest microplastics, raising serious concerns about trophic transfer and human exposure through water and food consumption [66].

Considering that the risk is a function of hazard and exposure, one needs to quantitatively determine both. Significant effort has been devoted to the quantification and characterization of MPs in media such as water and sediments [67]. However, it has become evident that quantifying plastic particles smaller than 100 μm in environmental matrices is analytically challenging [68]. Alak et al. (2021) determined the presence, shape, size, and polymer type of MPs in rainbow trout (Oncorhynchus mykiss) fillets packed using different packaging types and stored at two temperatures (+4 and −20 °C). The results showed that fillets packed using polystyrene plate and wrapped film had the highest presence of MPs, while fillets packed using chitosan film and polystyrene plate and wrapped film had the lowest amount of MPs. In terms of temperature conditions, the presence of MPs was determined at a high level at −20 °C while, in terms of chemical parameters, samples at this temperature had better results. TBARS were found to be high in the samples with high MP contents [69].

Overall, MP contamination is a huge problem for food and food security, leading to nutrition deficiencies and causing concern not only for the environment but also for public health. Risk assessments, risk management, and preventive measures are necessary to determine the exact pathway and the amount of MPs in food and, finally, in humans. Shifting from the current dominant linear “take-make-dispose” to the “circular” economy model is currently considered to be imperative for reducing the impact of plastics on the environment and the food chain [70]. Recent research findings and upcoming legislation indicate the rational use of plastics as a prerequisite, with commitments over the entire lifecycle. In line with the waste hierarchy [58] and reductions in unnecessary packaging and plastic use, effective recycling must be supported by appropriate collection systems, improved separation processes, and citizen education to prevent waste and improve recycling rates to minimize exposure to MPs and reduce environmental and health impacts. The regulations and policies target the circular plastic economy by producing plastic materials based on renewable energy and bioplastic consumption.

Despite the numerous studies on microplastics, several knowledge gaps remain regarding their long-term behavior in marine environments. The degradation kinetics of polymers in real aquatic conditions are still not fully understandable. The absence of standard protocols for the detection and characterization of MPs and NPs in food systems limits the impact of them on human and animal health. Interdisciplinary collaboration will help to understand the complexity of MP pollution and develop effective mitigation strategies [71]. An important but often underexplored aspect of microplastic research concerns the limited availability of detailed information on the additives used in plastic materials. These substances, which serve various functional roles such as improving flexibility, durability, or color, may be released into the environment as plastics degrade, potentially contributing to the complexity of microplastic impacts. Although the chemical composition of plastics is well understood within the industry for production and performance purposes, access to such data by regulators, researchers, and consumers remains limited. This lack of transparency can pose challenges for comprehensive risk assessments and the development of effective regulatory frameworks. Enhancing communication and data sharing in this area, while respecting intellectual property and commercial sensitivities, could support more informed policy decisions, foster public trust, and contribute to improved understanding of the environmental and health dimensions of microplastics. Encouraging dialogue and collaboration among stakeholders may serve as a constructive path forward.

7. Conclusions

Currently, considerable uncertainty exists regarding the impact of MPs on most trophic levels in ecosystems due to the limited research reported in the literature, demonstrating evidence of either effects or no-effects under relevant conditions. Systematic ecotoxicity tests should be implemented to evaluate the direct and indirect consequences of MPs on food safety. Holistic approaches, which include sustainable agriculture, and effective policies that reduce the risk of the actual loading of MPs in food systems should be followed in accordance with European and international guidelines. Reference particles must be also used in order to identify the specific effects of MPs in experimental procedures. The ultimate goal is the prediction of the risk of MP pollution for natural populations within the context of any relevant environmental factors. Moreover, improving transparency regarding the composition of plastic materials, particularly in relation to additives, would support more accurate risk assessments and inform future regulatory and research efforts aimed at mitigating microplastic pollution.

Author Contributions

Conceptualization, T.T.; validation, E.A., D.M.P., E.F. and T.T.; formal analysis, E.A., D.M.P., E.F. and T.T.; investigation, E.A., D.M.P., E.F. and T.T.; resources, D.M.P., E.F. and T.T.; data curation, E.A. and T.T.; writing—original draft preparation, E.A.; writing—review and editing, E.A., D.M.P., E.F. and T.T.; visualization, E.A.; supervision, D.M.P., E.F. and T.T. All authors have read and agreed to the published version of the manuscript.

Funding

This study was supported by the European Union’s Horizon 2020 research and innovation program under the Marie Sklodowska-Curie Grant agreement 872217 (project acronym: ICHTHYS).

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Statista Researcher Department. Global Plastics Industry—Statistics & Facts; Statista: Hamburg, Germany, 2025. [Google Scholar]

- Ncube, L.K.; Ude, A.U.; Ogunmuyiwa, E.N.; Zulkifli, R.; Beas, I.N. Environmental Impact of Food Packaging Materials: A Review of Contemporary Development from Conventional Plastics to Polylactic Acid Based Materials. Materials 2020, 13, 4994. [Google Scholar] [CrossRef]

- European Bioplastics. Bioplastics Market Development Update 2023; European Bioplastics e.V.: Berlin, Germany, 2023. [Google Scholar]

- Ali, S.S.; Elsamahy, T.; Al-Tohamy, R.; Sun, J. A Critical Review of Microplastics in Aquatic Ecosystems: Degradation Mechanisms and Removing Strategies. Environ. Sci. Ecotechnol. 2024, 21, 100427. [Google Scholar] [CrossRef] [PubMed]

- Castro-Castellon, A.T.; Horton, A.A.; Hughes, J.M.R.; Rampley, C.; Jeffers, E.S.; Bussi, G.; Whitehead, P. Ecotoxicity of Microplastics to Freshwater Biota: Considering Exposure and Hazard across Trophic Levels. Sci. Total Environ. 2022, 816, 151638. [Google Scholar] [CrossRef]

- Banyoi, S.-M.; Porseryd, T.; Larsson, J.; Grahn, M.; Dinnétz, P. The Effects of Exposure to Environmentally Relevant PFAS Concentrations for Aquatic Organisms at Different Consumer Trophic Levels: Systematic Review and Meta-Analyses. Environ. Pollut. 2022, 315, 120422. [Google Scholar] [CrossRef] [PubMed]

- Walkinshaw, C.; Lindeque, P.K.; Thompson, R.; Tolhurst, T.; Cole, M. Microplastics and Seafood: Lower Trophic Organisms at Highest Risk of Contamination. Ecotoxicol. Environ. Saf. 2020, 190, 110066. [Google Scholar] [CrossRef]

- Campanale, C.; Massarelli, C.; Savino, I.; Locaputo, V.; Uricchio, V.F. A Detailed Review Study on Potential Effects of Microplastics and Additives of Concern on Human Health. Int. J. Environ. Res. Public Health 2020, 17, 1212. [Google Scholar] [CrossRef] [PubMed]

- Hahladakis, J.N.; Velis, C.A.; Weber, R.; Iacovidou, E.; Purnell, P. An Overview of Chemical Additives Present in Plastics: Migration, Release, Fate and Environmental Impact during Their Use, Disposal and Recycling. J. Hazard. Mater. 2018, 344, 179–199. [Google Scholar] [CrossRef]

- Yang, T.; Xu, Y.; Liu, G.; Nowack, B. Oligomers Are a Major Fraction of the Submicrometre Particles Released during Washing of Polyester Textiles. Nat. Water 2024, 2, 151–160. [Google Scholar] [CrossRef]

- Ng, E.-L.; Huerta Lwanga, E.; Eldridge, S.M.; Johnston, P.; Hu, H.-W.; Geissen, V.; Chen, D. An Overview of Microplastic and Nanoplastic Pollution in Agroecosystems. Sci. Total Environ. 2018, 627, 1377–1388. [Google Scholar] [CrossRef]

- Perraki, M.; Skliros, V.; Mecaj, P.; Vasileiou, E.; Salmas, C.; Papanikolaou, I.; Stamatis, G. Identification of Microplastics Using Μ-Raman Spectroscopy in Surface and Groundwater Bodies of SE Attica, Greece. Water 2024, 16, 843. [Google Scholar] [CrossRef]

- Balwada, J.; Samaiya, S.; Mishra, R.P. Packaging Plastic Waste Management for a Circular Economy and Identifying a Better Waste Collection System Using Analytical Hierarchy Process (AHP). Procedia CIRP 2021, 98, 270–275. [Google Scholar] [CrossRef]

- International Union for Conservation of Nature and Natural Resources; Boucher, J.; Friot, D. Primary Microplastics in the Oceans: A Global Evaluation of Sources; IUCN: Gland, Switzerland, 2017; ISBN 978-2-8317-1827-9. [Google Scholar]

- Ziajahromi, S.; Neale, P.A.; Leusch, F.D.L. Wastewater Treatment Plant Effluent as a Source of Microplastics: Review of the Fate, Chemical Interactions and Potential Risks to Aquatic Organisms. Water Sci. Technol. 2016, 74, 2253–2269. [Google Scholar] [CrossRef] [PubMed]

- Plastics Europe. Plastics—The Fast Facts 2023; Plastics Europe: Brussels, Belgium, 2023. [Google Scholar]

- Athanasopoulou, E.; Michailidi, A.; Ladakis, D.; Kalliampakou, K.I.; Flemetakis, E.; Koutinas, A.; Tsironi, T. Extraction of Fish Protein Concentrates from Discards and Combined Application with Gelatin for the Development of Biodegradable Food Packaging. Sustainability 2023, 15, 12062. [Google Scholar] [CrossRef]

- Athanasopoulou, E.; Bigi, F.; Maurizzi, E.; Karellou, E.I.E.; Pappas, C.S.; Quartieri, A.; Tsironi, T. Synthesis and Characterization of Polysaccharide- and Protein-Based Edible Films and Application as Packaging Materials for Fresh Fish Fillets. Sci. Rep. 2024, 14, 517. [Google Scholar] [CrossRef]

- Dumitru, A.C.; Espinosa, F.M.; Garcia, R.; Foschi, G.; Tortorella, S.; Valle, F.; Dallavalle, M.; Zerbetto, F.; Biscarini, F. In Situ Nanomechanical Characterization of the Early Stages of Swelling and Degradation of a Biodegradable Polymer. Nanoscale 2015, 7, 5403–5410. [Google Scholar] [CrossRef]

- Tsironi, T.N.; Chatzidakis, S.M.; Stoforos, N.G. The Future of Polyethylene Terephthalate Bottles: Challenges and Sustainability. Packag. Technol. Sci. 2022, 35, 317–325. [Google Scholar] [CrossRef]

- Basdeki, E.; Mpenetou, E.; Papazoglou, P.; Ladakis, D.; Flemetakis, E.; Koutinas, A.; Tsironi, T. Evaluation of a Calcium Carbonate-Based Container for Transportation and Storage of Fresh Fish as a Sustainable Alternative to Polystyrene Boxes. Sustainability 2023, 16, 130. [Google Scholar] [CrossRef]

- Vohlídal, J. Polymer Degradation: A Short Review. Chem. Teach. Int. 2021, 3, 213–220. [Google Scholar] [CrossRef]

- Kyrikou, I.; Briassoulis, D. Biodegradation of Agricultural Plastic Films: A Critical Review. J Polym Env. 2007, 15, 125–150. [Google Scholar] [CrossRef]

- EFSA Panel on Contaminants in the Food Chain (CONTAM). Presence of Microplastics and Nanoplastics in Food, with Particular Focus on Seafood. Efsa J. 2016, 14, e04501. [Google Scholar] [CrossRef]

- Petersen, E.J.; Diamond, S.A.; Kennedy, A.J.; Goss, G.G.; Ho, K.; Lead, J.; Hanna, S.K.; Hartmann, N.B.; Hund-Rinke, K.; Mader, B.; et al. Adapting OECD Aquatic Toxicity Tests for Use with Manufactured Nanomaterials: Key Issues and Consensus Recommendations. Environ. Sci. Technol. 2015, 49, 9532–9547. [Google Scholar] [CrossRef]

- Peng, M.; Félix, R.C.; Canário, A.V.M.; Power, D.M. The Physiological Effect of Polystyrene Nanoplastic Particles on Fish and Human Fibroblasts. Sci. Total Environ. 2024, 914, 169979. [Google Scholar] [CrossRef] [PubMed]

- Sharma, P. Microplastic Contamination in Food Processing: Role of Packaging Materials. Food Sci. Eng. 2024, 5, 271–287. [Google Scholar] [CrossRef]

- Beer, S.; Garm, A.; Huwer, B.; Dierking, J.; Nielsen, T.G. No Increase in Marine Microplastic Concentration over the Last Three Decades—A Case Study from the Baltic Sea. Sci. Total Environ. 2018, 621, 1272–1279. [Google Scholar] [CrossRef]

- Mamun, A.A.; Prasetya, T.A.E.; Dewi, I.R.; Ahmad, M. Microplastics in Human Food Chains: Food Becoming a Threat to Health Safety. Sci. Total Environ. 2023, 858, 159834. [Google Scholar] [CrossRef] [PubMed]

- Abbasi, S.; Soltani, N.; Keshavarzi, B.; Moore, F.; Turner, A.; Hassanaghaei, M. Microplastics in Different Tissues of Fish and Prawn from the Musa Estuary, Persian Gulf. Chemosphere 2018, 205, 80–87. [Google Scholar] [CrossRef]

- Toussaint, B.; Raffael, B.; Angers-Loustau, A.; Gilliland, D.; Kestens, V.; Petrillo, M.; Rio-Echevarria, I.M.; Van Den Eede, G. Review of Micro- and Nanoplastic Contamination in the Food Chain. Food Addit. Contam. Part A 2019, 36, 639–673. [Google Scholar] [CrossRef]

- Jadhav, E.B.; Sankhla, M.S.; Bhat, R.A.; Bhagat, D.S. Microplastics from Food Packaging: An Overview of Human Consumption, Health Threats, and Alternative Solutions. Environ. Nanotechnol. Monit. Manag. 2021, 16, 100608. [Google Scholar] [CrossRef]

- Cox, K.D.; Covernton, G.A.; Davies, H.L.; Dower, J.F.; Juanes, F.; Dudas, S.E. Human Consumption of Microplastics. Environ. Sci. Technol. 2019, 53, 7068–7074. [Google Scholar] [CrossRef]

- Carbery, M.; O’Connor, W.; Palanisami, T. Trophic Transfer of Microplastics and Mixed Contaminants in the Marine Food Web and Implications for Human Health. Environ. Int. 2018, 115, 400–409. [Google Scholar] [CrossRef]

- Mercogliano, R.; Avio, C.G.; Regoli, F.; Anastasio, A.; Colavita, G.; Santonicola, S. Occurrence of Microplastics in Commercial Seafood under the Perspective of the Human Food Chain. A Review. J. Agric. Food Chem. 2020, 68, 5296–5301. [Google Scholar] [CrossRef] [PubMed]

- Du, F.; Cai, H.; Zhang, Q.; Chen, Q.; Shi, H. Microplastics in Take-out Food Containers. J. Hazard. Mater. 2020, 399, 122969. [Google Scholar] [CrossRef] [PubMed]

- Kedzierski, M.; Lechat, B.; Sire, O.; Le Maguer, G.; Le Tilly, V.; Bruzaud, S. Microplastic Contamination of Packaged Meat: Occurrence and Associated Risks. Food Packag. Shelf Life 2020, 24, 100489. [Google Scholar] [CrossRef]

- Ranjan, V.P.; Joseph, A.; Goel, S. Microplastics and Other Harmful Substances Released from Disposable Paper Cups into Hot Water. J. Hazard. Mater. 2021, 404, 124118. [Google Scholar] [CrossRef]

- Winkler, A.; Santo, N.; Ortenzi, M.A.; Bolzoni, E.; Bacchetta, R.; Tremolada, P. Does Mechanical Stress Cause Microplastic Release from Plastic Water Bottles? Water Res. 2019, 166, 115082. [Google Scholar] [CrossRef]

- Oßmann, B.E.; Sarau, G.; Holtmannspötter, H.; Pischetsrieder, M.; Christiansen, S.H.; Dicke, W. Small-Sized Microplastics and Pigmented Particles in Bottled Mineral Water. Water Res. 2018, 141, 307–316. [Google Scholar] [CrossRef]

- Tansey, G.; Worsley, A. The Food System; Routledge: London, UK, 2014; ISBN 978-1-135-04795-5. [Google Scholar]

- Kaseke, T.; Lujic, T.; Cirkovic Velickovic, T. Nano- and Microplastics Migration from Plastic Food Packaging into Dairy Products: Impact on Nutrient Digestion, Absorption, and Metabolism. Foods 2023, 12, 3043. [Google Scholar] [CrossRef]

- Negrete-Bolagay, D.; Guerrero, V.H. Opportunities and Challenges in the Application of Bioplastics: Perspectives from Formulation, Processing, and Performance. Polymers 2024, 16, 2561. [Google Scholar] [CrossRef]

- Bach, C.; Dauchy, X.; Severin, I.; Munoz, J.-F.; Etienne, S.; Chagnon, M.-C. Effect of Temperature on the Release of Intentionally and Non-Intentionally Added Substances from Polyethylene Terephthalate (PET) Bottles into Water: Chemical Analysis and Potential Toxicity. Food Chem. 2013, 139, 672–680. [Google Scholar] [CrossRef]

- Coles, R.; Kirwan, M. (Eds.) Food and Beverage Packaging Technology, 1st ed.; Wiley: Hoboken, NJ, USA, 2011; ISBN 978-1-4051-8910-1. [Google Scholar]

- Schymanski, D.; Goldbeck, C.; Humpf, H.-U.; Fürst, P. Analysis of Microplastics in Water by Micro-Raman Spectroscopy: Release of Plastic Particles from Different Packaging into Mineral Water. Water Res. 2018, 129, 154–162. [Google Scholar] [CrossRef]

- Iñiguez, M.E.; Conesa, J.A.; Fullana, A. Microplastics in Spanish Table Salt. Sci. Rep. 2017, 7, 8620. [Google Scholar] [CrossRef] [PubMed]

- Chaïb, I.; Doyen, P.; Merveillie, P.; Dehaut, A.; Duflos, G. Microplastic contaminations in a set of beverages sold in France. J. Food Compos. Anal. 2025, 144, 10719. [Google Scholar] [CrossRef]

- Shruti, V.C.; Pérez-Guevara, F.; Elizalde-Martínez, I.; Kutralam-Muniasamy, G. First Study of Its Kind on the Microplastic Contamination of Soft Drinks, Cold Tea and Energy Drinks—Future Research and Environmental Considerations. Sci. Total Environ. 2020, 726, 138580. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Feng, Z.; Zhang, T.; Ma, C.; Shi, H. Microplastics in the Commercial Seaweed Nori. J. Hazard. Mater. 2020, 388, 122060. [Google Scholar] [CrossRef] [PubMed]

- Hernandez, L.M.; Xu, E.G.; Larsson, H.C.E.; Tahara, R.; Maisuria, V.B.; Tufenkji, N. Plastic Teabags Release Billions of Microparticles and Nanoparticles into Tea. Environ. Sci. Technol. 2019, 53, 12300–12310. [Google Scholar] [CrossRef]

- Oliveri Conti, G.; Ferrante, M.; Banni, M.; Favara, C.; Nicolosi, I.; Cristaldi, A.; Fiore, M.; Zuccarello, P. Micro- and Nano-Plastics in Edible Fruit and Vegetables. The First Diet Risks Assessment for the General Population. Environ. Res. 2020, 187, 109677. [Google Scholar] [CrossRef]

- Liu, Q.; Chen, Z.; Chen, Y.; Yang, F.; Yao, W.; Xie, Y. Microplastics Contamination in Eggs: Detection, Occurrence and Status. Food Chem. 2022, 397, 133771. [Google Scholar] [CrossRef]

- Shruti, V.C.; Kutralam-Muniasamy, G.; Pérez-Guevara, F.; Roy, P.D.; Elizalde-Martínez, I. First Evidence of Microplastic Contamination in Ready-to-Use Packaged Food Ice Cubes. Environ. Pollut. 2023, 318, 120905. [Google Scholar] [CrossRef]

- Weisser, J.; Beer, I.; Hufnagl, B.; Hofmann, T.; Lohninger, H.; Ivleva, N.P.; Glas, K. From the Well to the Bottle: Identifying Sources of Microplastics in Mineral Water. Water 2021, 13, 841. [Google Scholar] [CrossRef]

- Sangkham, S.; Islam, M.A.; Adhikari, S.; Kumar, R.; Sharma, P.; Sakunkoo, P.; Bhattacharya, P.; Tiwari, A. Evidence of Microplastics in Groundwater: A Growing Risk for Human Health. Groundw. Sustain. Dev. 2023, 23, 100981. [Google Scholar] [CrossRef]

- European Parliament and Council. Directive 94/62/EC on 20 December 1994; European Parliament and Council: Brussels, Belgium, 1994; p. 14. [Google Scholar]

- European Parliament and Council. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives; European Parliament and Council: Brussels, Belgium, 2008; p. 28. [Google Scholar]

- European Commission, Directorate General for Research and Innovation. Innovating for Sustainable Growth: A Bioeconomy for Europe; Publications Office: Luxembourg, 2012. [Google Scholar]

- European Commission, Directorate General for Research and Innovation. Review of the 2012 European Bioeconomy Strategy; Publications Office: Luxembourg, 2018. [Google Scholar]

- European Commission, Directorate-General for Research and Innovation. Updated Bioeconomy Strategy 2018; Publications Office: Luxembourg, 2018. [Google Scholar]

- European Union. Directive (EU) 2019/904 of the European Parliament and of the Council of 5 June 2019 on the Reduction of the Impact of Certain Plastic Products on the Environment; European Union: Brussels, Belgium, 2019; pp. 1–19. [Google Scholar]

- European Parliament and Council. Regulation (EU) 2025/40 of the European Parliament and of the Council of 19 December 2024 on Packaging and Packaging Waste, Amending Regulation (EU) 2019/1020 and Directive (EU) 2019/904, and Repealing Directive 94/62/EC; European Parliament and Council: Brussels, Belgium, 2024. [Google Scholar]

- Tenhunen-Lunkka, A.; Rommens, T.; Vanderreydt, I.; Mortensen, L. Greenhouse Gas Emission Reduction Potential of European Union’s Circularity Related Targets for Plastics. Circ. Econ. Sust. 2023, 3, 475–510. [Google Scholar] [CrossRef] [PubMed]

- Corcoran, P.L. Degradation of Microplastics in the Environment. In Handbook of Microplastics in the Environment; Rocha-Santos, T., Costa, M.F., Mouneyrac, C., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 531–542. ISBN 978-3-030-39040-2. [Google Scholar]

- Pandey, B.; Pathak, J.; Singh, P.; Kumar, R.; Kumar, A.; Kaushik, S.; Thakur, T.K. Microplastics in the Ecosystem: An Overview on Detection, Removal, Toxicity Assessment, and Control Release. Water 2022, 15, 51. [Google Scholar] [CrossRef]

- Rocha-Santos, T.A.P. Editorial Overview: Micro and Nano-Plastics. Curr. Opin. Environ. Sci. Health 2018, 1, 52–54. [Google Scholar] [CrossRef]

- Ogonowski, M.; Gerdes, Z.; Gorokhova, E. What We Know and What We Think We Know about Microplastic Effects—A Critical Perspective. Curr. Opin. Environ. Sci. Health 2018, 1, 41–46. [Google Scholar] [CrossRef]

- Alak, G.; Köktürk, M.; Atamanalp, M. Evaluation of Different Packaging Methods and Storage Temperature on MPs Abundance and Fillet Quality of Rainbow Trout. J. Hazard. Mater. 2021, 420, 126573. [Google Scholar] [CrossRef]

- Ward, C.P.; Reddy, C.M.; Edwards, B.; Perri, S.T. To Curb Plastic Pollution, Industry and Academia Must Unite. Nature 2024, 625, 658–662. [Google Scholar] [CrossRef]

- Wang, W.-X. Marine Micro(Nano)Plastics Toxicology: Knowledge Gaps and Perspectives. J. Hazard. Mater. 2025, 492, 138086. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).