Optimizing Fuel Efficiency and Emissions of Marine Diesel Engines When Using Biodiesel Mixtures Under Diverse Load/Temperature Conditions: Predictive Model and Comprehensive Life Cycle Analysis

Abstract

1. Introduction

- Developing multivariate regression models to predict emissions (NOx, CO, CO2) based on biodiesel ratio, load condition, and operating temperature

- Identifying the optimal balance point between engine performance and harmful gas emissions

- Conducting life cycle assessment (LCA) of biodiesel use on ships across the entire fuel lifecycle

- Proposing an adaptive optimization algorithm for marine engine operation in real conditions

- Providing practical implementation guidelines for maritime operators seeking to reduce emissions through biodiesel utilization

2. Research Methodology

2.1. Research Subjects and Testing Equipment

2.1.1. Marine Diesel Engines Specifications

- YANMAR 6HAL2-DTN engine (Yanmar Diesel Co., Ltd., Osaka, Japan): 6 cylinders, 4-stroke, 200 kW@1200 rpm, typical of smaller vessels and auxiliary power units

- Niigatta Engineering 6L34HX engine (Niigatta Engineering Co., Ltd., Tokyo, Japan): 6 cylinders, 4-stroke, 2471 kW@600 rpm, representative of medium-sized commercial and Fishing vessel main propulsion

2.1.2. Fuel Characteristics and Preparation

2.1.3. Emission Measurement Equipment

- Analyzer: ECO PHYSICS CLD 700 EL ht (chemiluminescence detection method)

- Measurement range: 0–10,000 ppm

- Accuracy: ±0.5% of full scale

- Response time: <5 s

- Calibration: Daily calibration with certified NO/NO2 calibration gases

- Analyzer: HORIBA MEXA-9100DEGR (non-dispersive infrared method)

- CO measurement range: 0–10% vol, accuracy: ±1% of full scale

- CO2 measurement range: 0–20% vol, accuracy: ±1% of full scale

- Resolution: 0.01% for CO2, 0.001% for CO

- Calibration: Pre-test calibration with certified calibration gases

- Equipment: Micro Motion CMF025 Coriolis mass flow meter

- Accuracy: ±0.1% of rate

- Repeatability: ±0.05%

- Temperature compensation: Automatic

- Exhaust gas temperature: K-type thermocouples (accuracy ±1.5 °C)

- Engine parameters: Speed, torque, power output, cooling water temperature

- Ambient conditions: Temperature, pressure, and humidity sensors

2.1.4. Test Bench Configuration

- Sampling rate: 1 Hz with a 10-point moving average

- Data logging: Continuous recording with 1-s intervals during stable operation periods

- Signal conditioning: Digital filtering to minimize transient fluctuations

- Data validation: Real-time monitoring with automated outlier detection

- Ambient temperature: 15–30 °C

- Fuel temperature: 35–55 °C

- Relative humidity: 45–60%

- Atmospheric pressure: 1010–1020 hPa

- YANMAR engine: Constant speed at 1200 rpm

- Niigatta engine: Constant speed at 600 rpm

- Load conditions: 10%, 25%, 50%, 75%, 100% of maximum continuous rating

- Stabilization period: 10 min at each test condition before data collection

- Data collection period: 3 min of stable operation per test point

- Each test condition was repeated three times on different days

- Complete fuel system purging when changing between biodiesel ratios

- Randomized test sequence to minimize systematic errors

- Equipment calibration verification before each test session

2.2. Experimental Design

- Engine warm-up to normal operating temperature

- Setting of load condition according to test matrix

- A stabilization period of 10 min at a constant load

- Data collection during the last 3 min when the engine had stabilized

- Transition to the next test condition with intermediate stabilization

- Ambient temperature: 15–30 °C

- Fuel temperature: 35–55 °C

- Relative humidity: 45–60%

- Atmospheric pressure: 1010–1020 hPa

- Engine speed information: YANMAR at 1200 rpm and Niigatta at 600 rpm

2.3. Development of Multivariate Prediction Model

- x1: Biodiesel ratio (%, range: 0–100)

- x2: Engine load (%, range: 10–100)

- x3: Ambient temperature (°C, range: 20–25)

- x4: Fuel temperature (°C, range: 35–45)

- E: Emission amount (NOx in g/kWh, CO in g/kWh, CO2 in kg/kWh)

- βi: Regression coefficients determined by least squares method

- ε: Random error (assumed normally distributed)

- Coefficient of determination (R2)

- Root mean square error (RMSE)

- Analysis of variance (ANOVA)

- Residual analysis for normality and homoscedasticity

2.4. Life Cycle Analysis (LCA)

- Biodiesel raw material production

- Processing and transportation

- Use on ship

- Post-use processing

2.5. Design of Adaptive Optimization Algorithm

- NOx emission objective function

- emission objective function

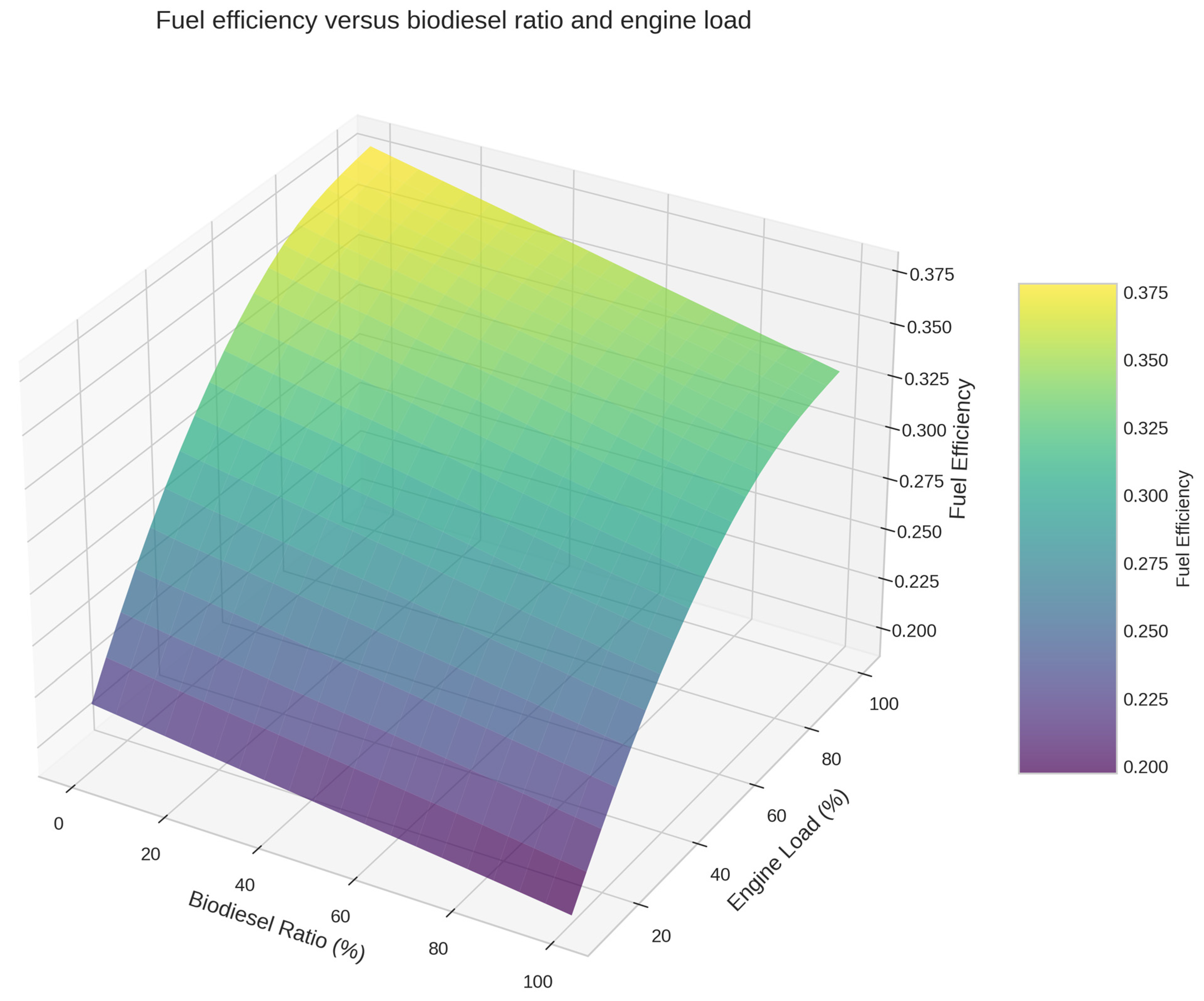

- Fuel efficiency objective function

- w1 (NOx) = 0.6, w2 (CO/CO2) = 0.3, w3 (Fuel efficiency) = 0.1

- Prioritizes NOx reduction for air quality compliance

- w1 (NOx) = 0.2, w2 (CO/CO2) = 0.5, w3 (Fuel efficiency) = 0.3

- Balances emission reduction with fuel economy

- w1 (NOx) = 0.1, w2 (CO/CO2) = 0.2, w3 (Fuel efficiency) = 0.7

- Emphasizes fuel consumption minimization

- Input Processing: Real-time acquisition of engine load, ambient temperature, and operational zone

- Scenario Selection: Automatic weight assignment based on GPS location and operational mode

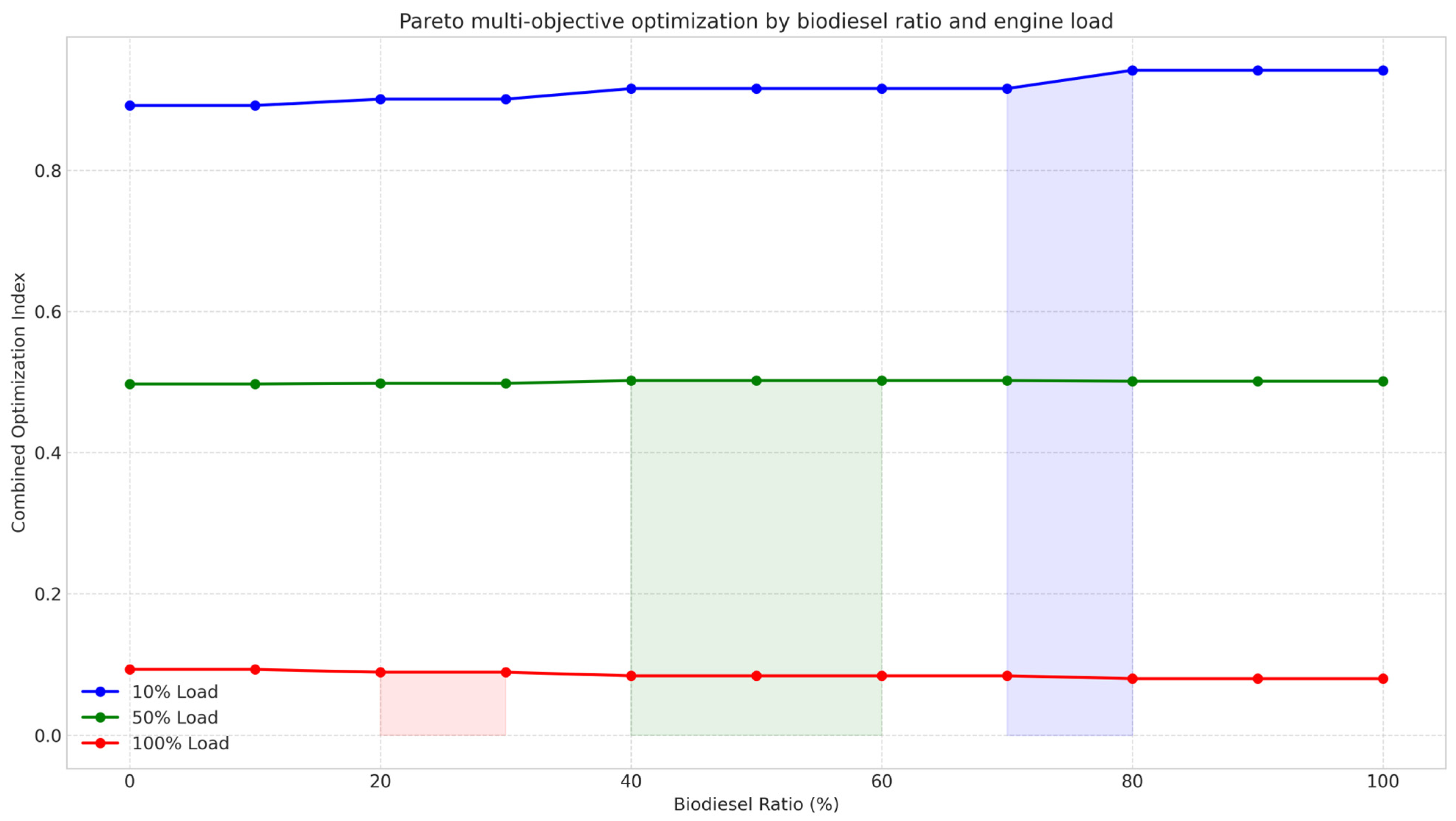

- Optimization Calculation: Pareto frontier determination using a genetic algorithm with 1000 iterations

- Output Generation: Optimal biodiesel ratio recommendation with a 95% confidence interval

- Validation Check: Comparison with constraint boundaries (engine limits, fuel availability).”

3. Results

3.1. Emission Characteristics by Biodiesel Ratio and Engine Load

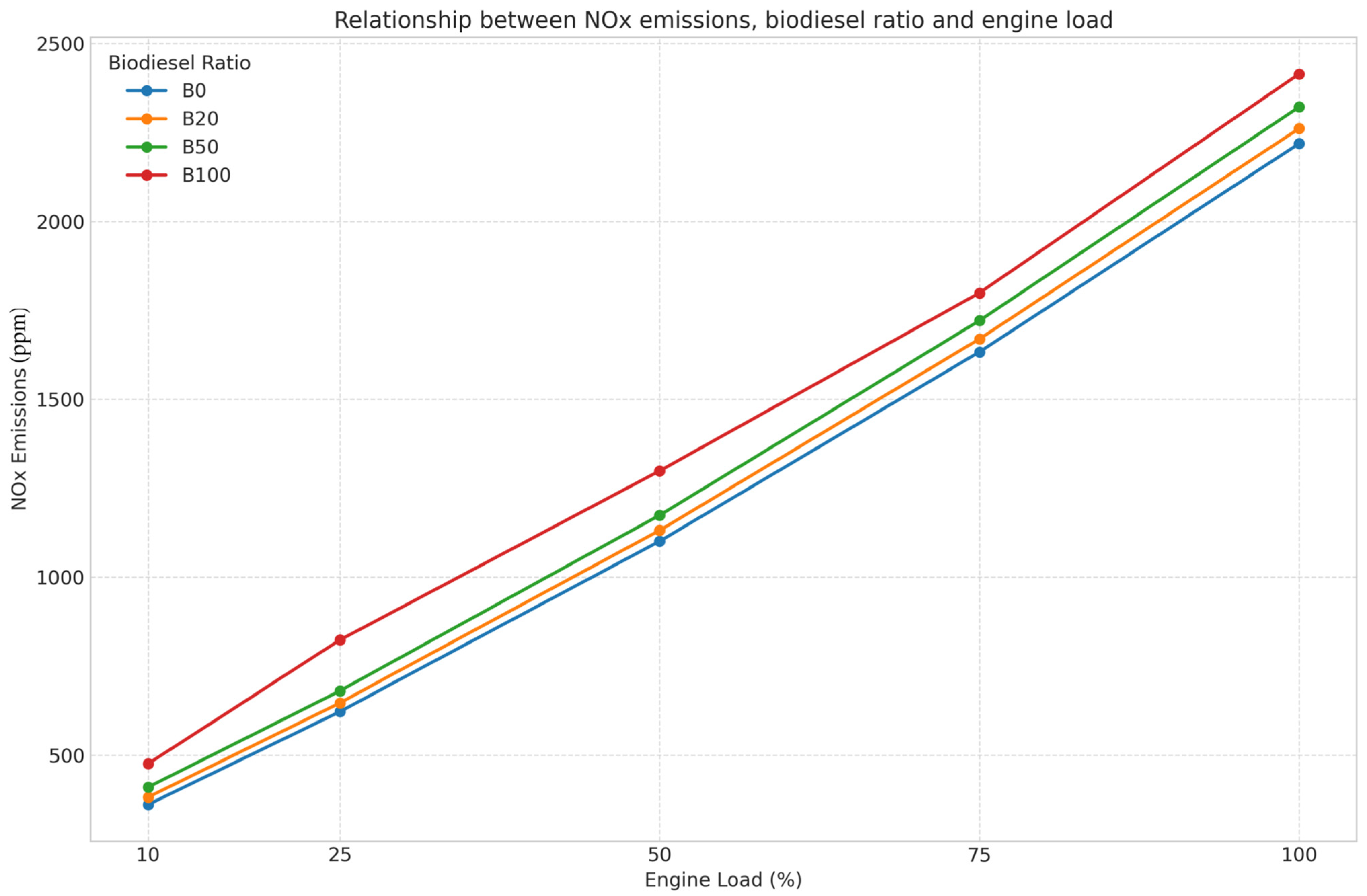

3.1.1. NOx Emissions

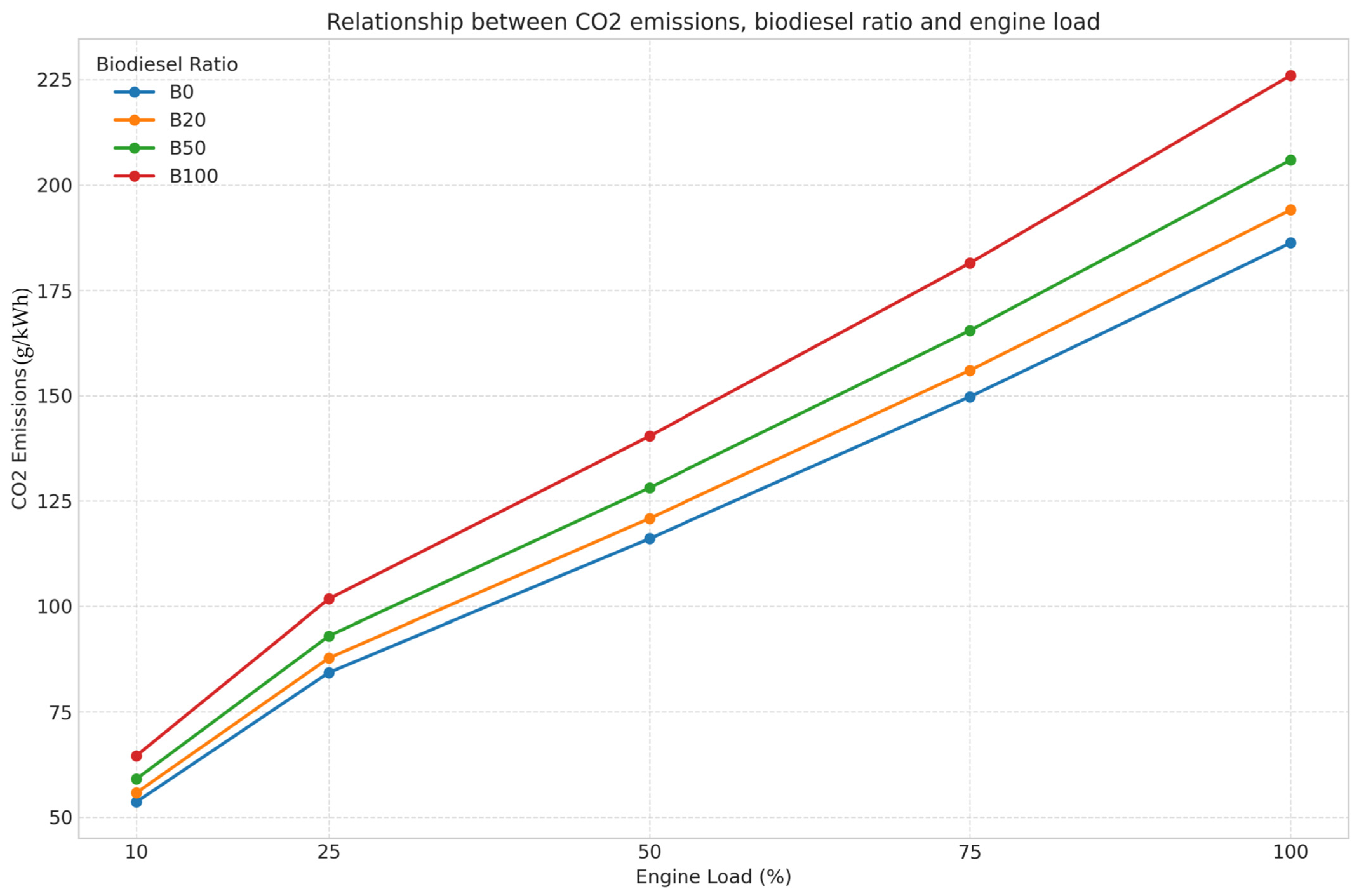

3.1.2. CO2 Emissions

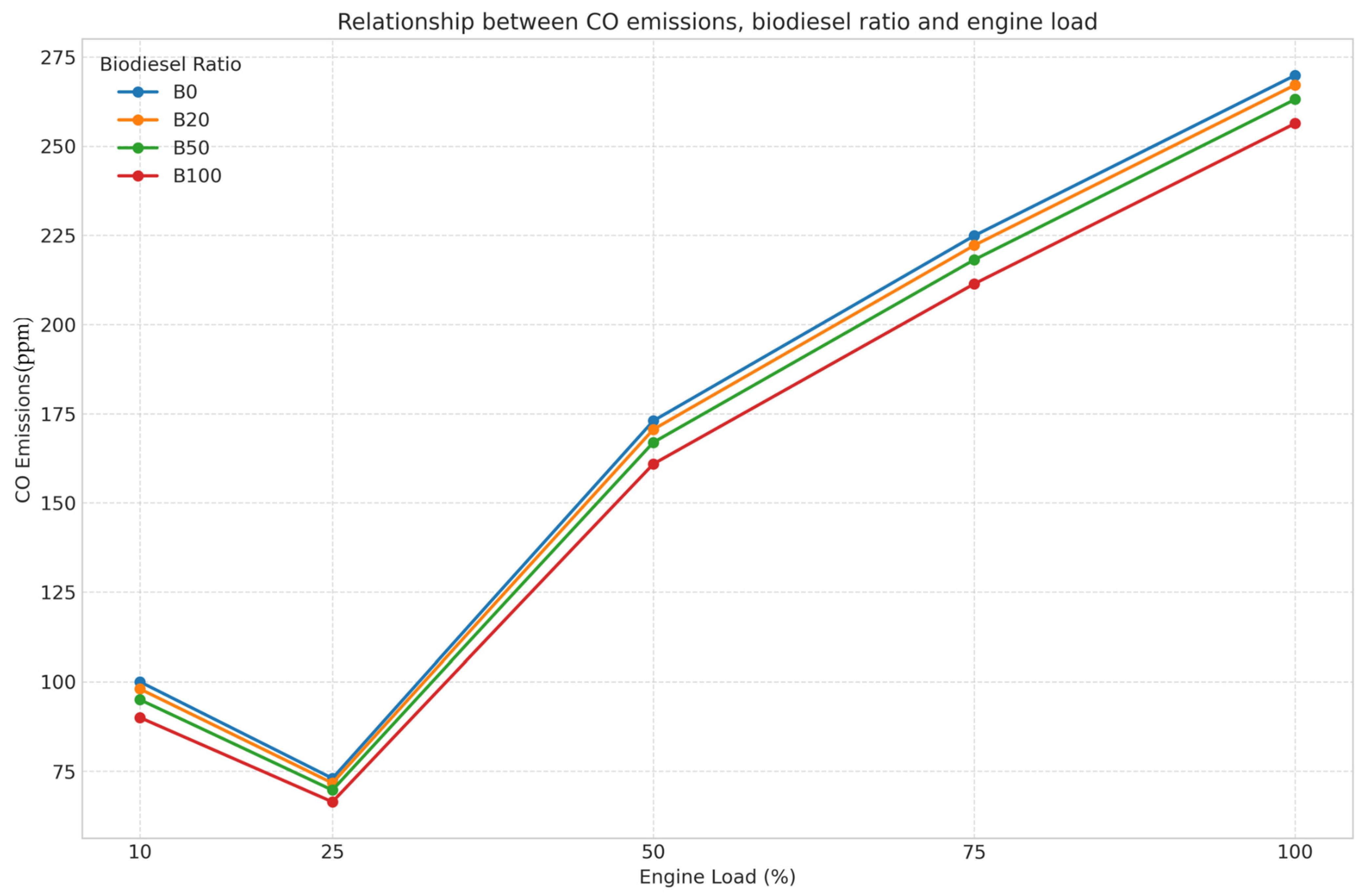

3.1.3. CO Emissions

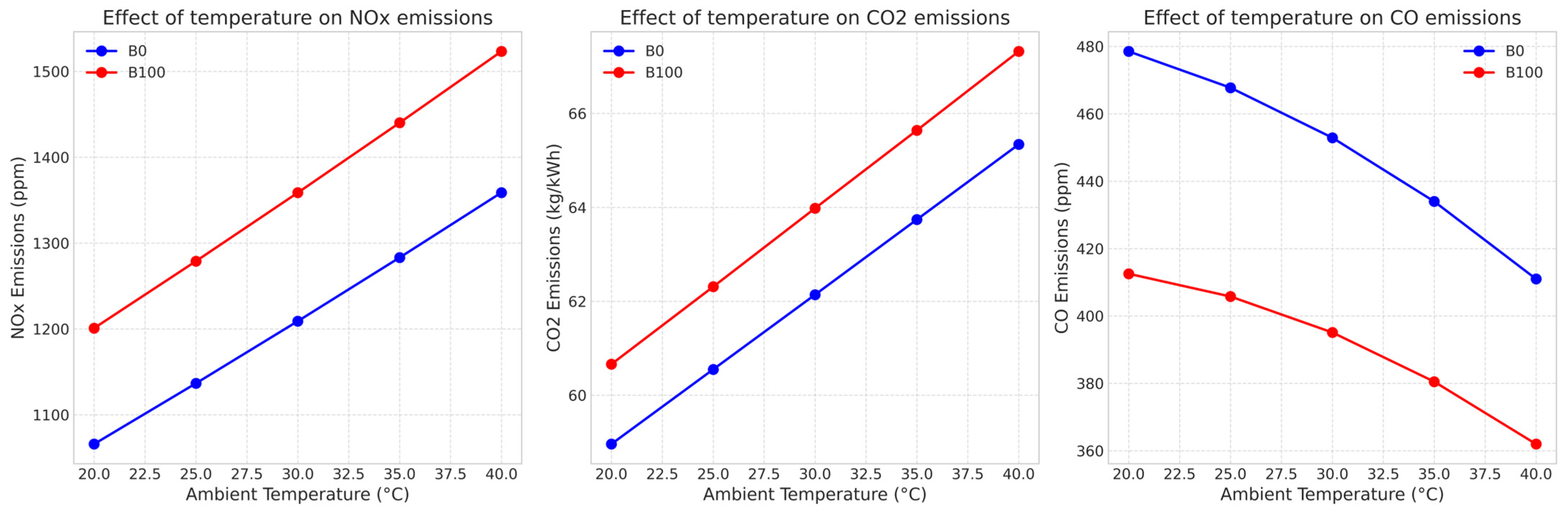

3.2. Multivariate Prediction Model

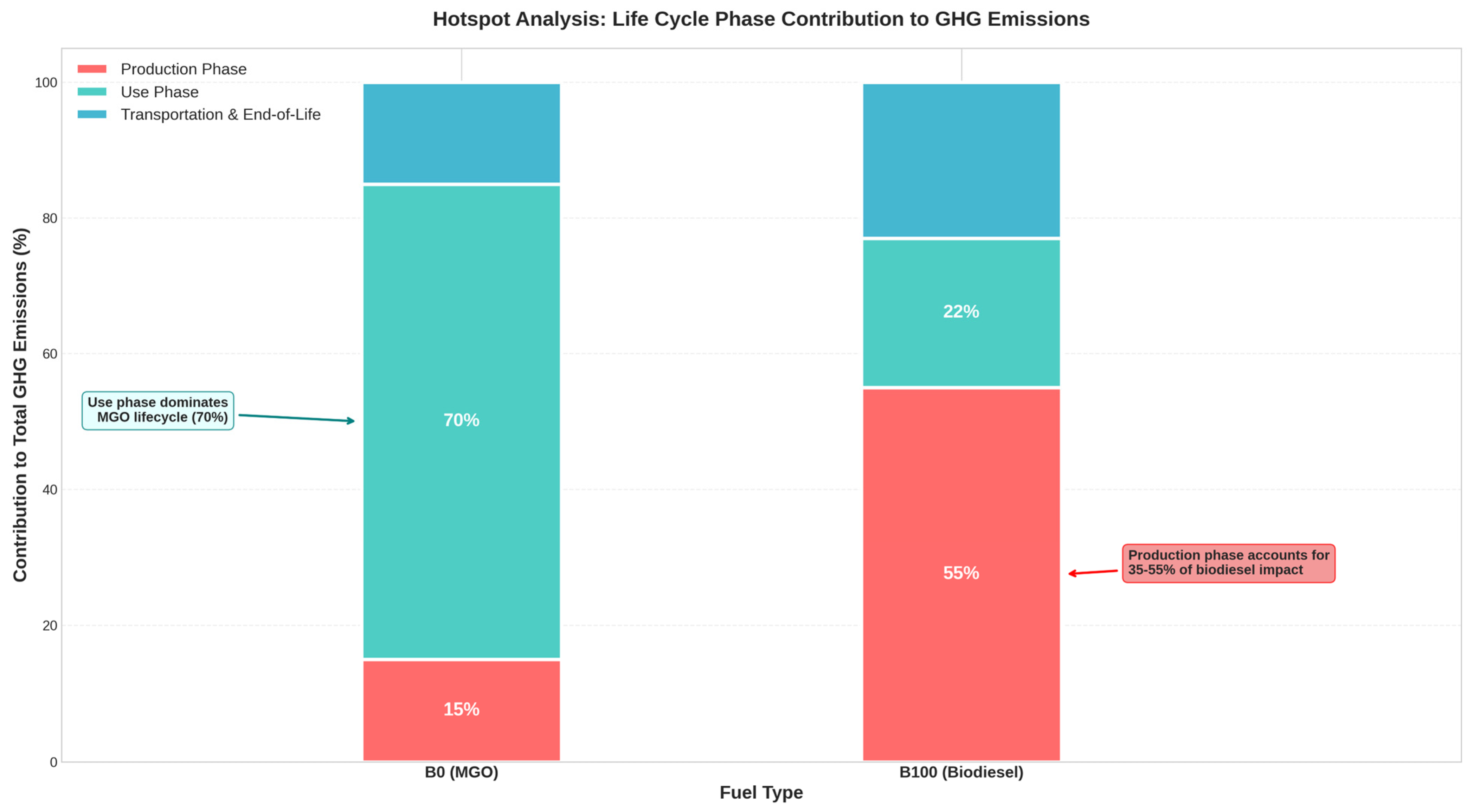

3.3. Life Cycle Analysis (LCA) Results

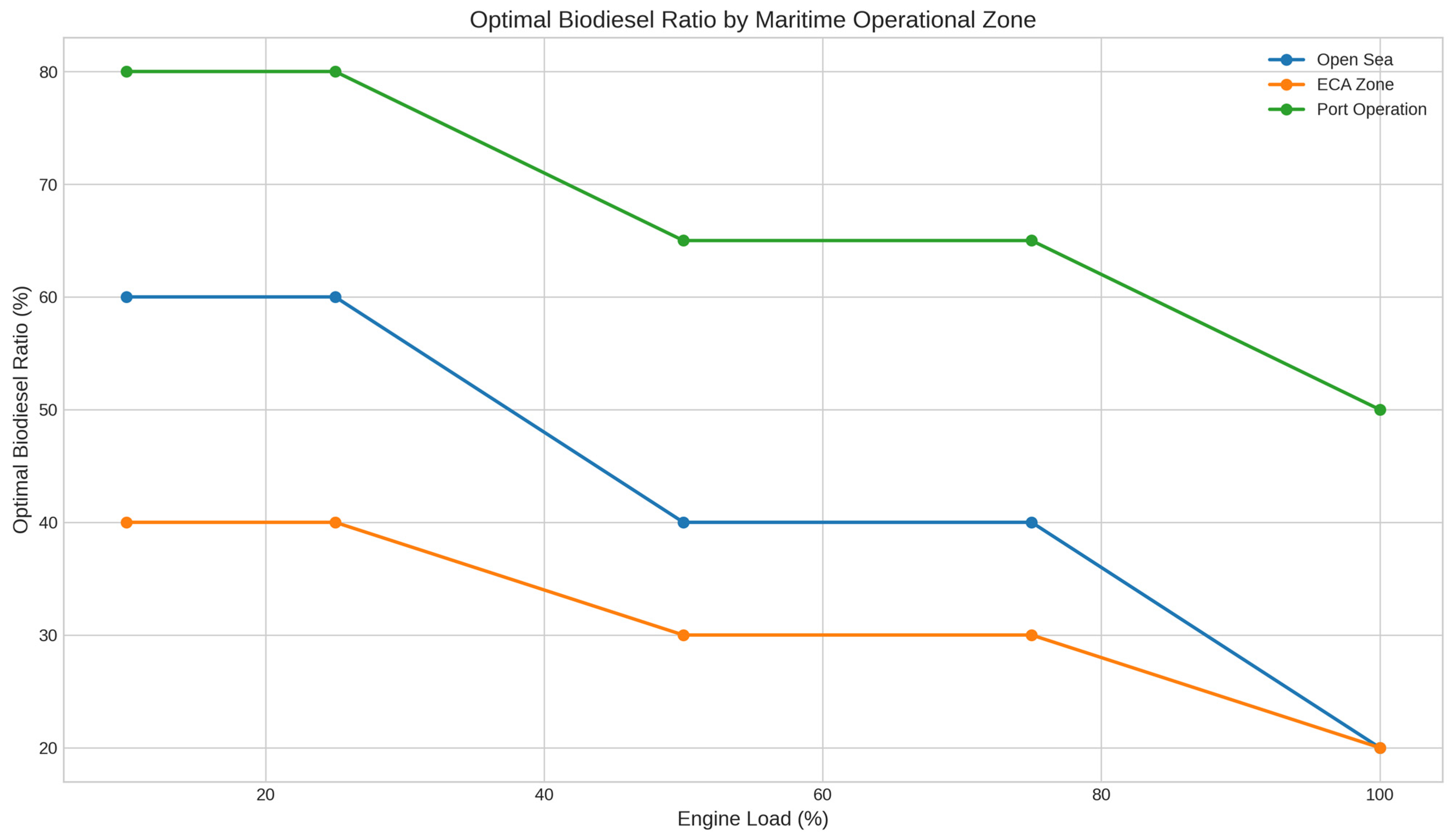

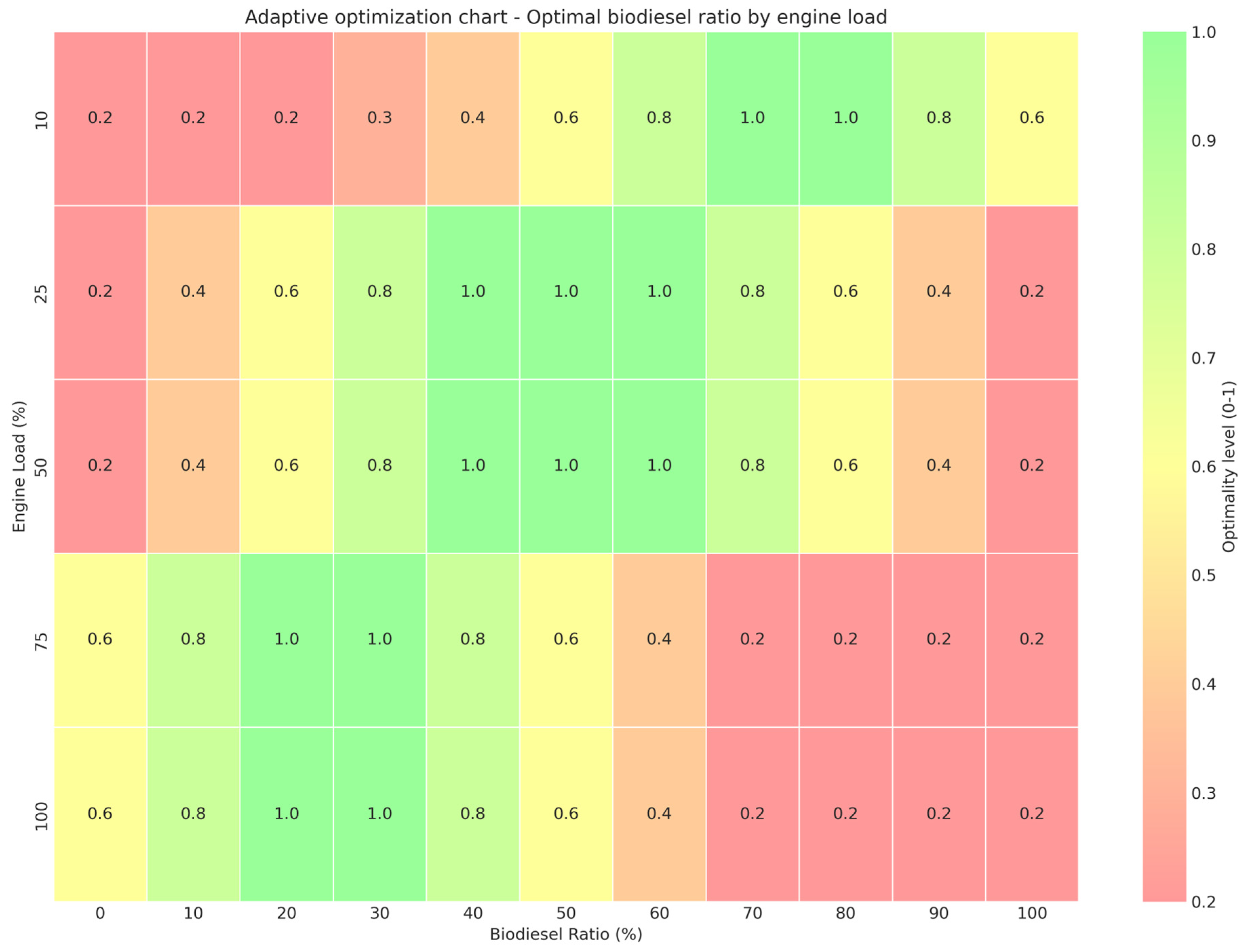

3.4. Adaptive Optimization Algorithm

3.4.1. Analysis of Optimization Results

- Zone A (Low Load): High biodiesel ratios achievable with minimal performance impact

- Zone B (Medium Load): Balanced optimization with moderate biodiesel ratios

- Zone C (High Load): Conservative biodiesel ratios to maintain power output

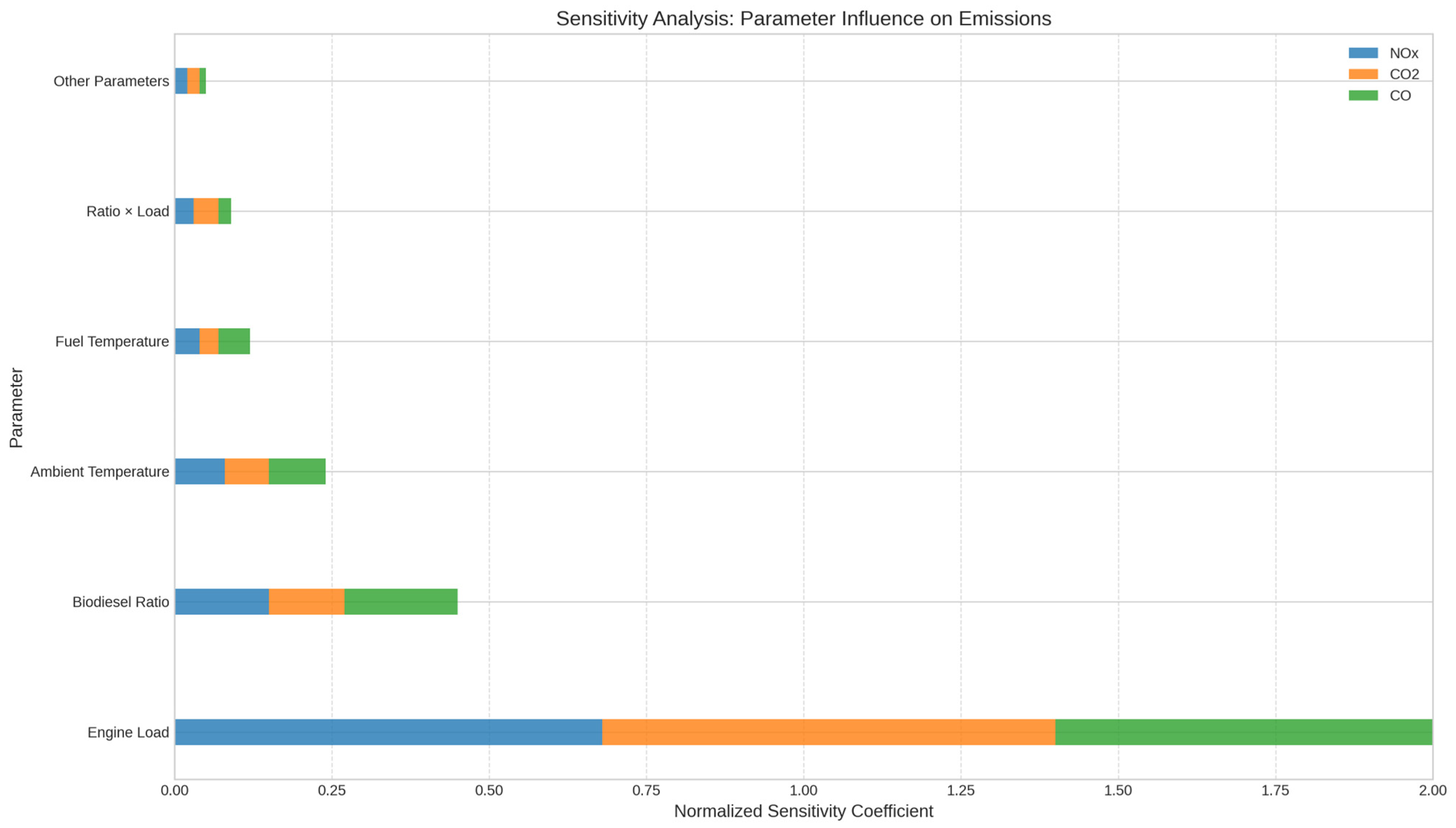

3.4.2. Sensitivity Analysis Results

4. Discussion and Practical Implications

- -

- Engine load emerges as the dominant factor affecting emissions, with 46–137% variation compared to 5–13% variation from biodiesel ratio changes. This finding emphasizes the critical importance of operational optimization in emission reduction strategies. Biodiesel demonstrates mixed emission impacts: a 5–13% increase in NOx and a 3–4% increase in CO2 per 20% blend ratio increase, offset by a 7–10% reduction in CO emissions. These trade-offs require careful consideration in regulatory compliance strategies. The identification of optimal combustion conditions at 25% engine load for all biodiesel ratios provides a foundation for developing load-optimized operational procedures.

- -

- The B50 biodiesel blend achieves optimal environmental performance with a 15% reduction in global warming potential compared to conventional marine gas oil while maintaining acceptable levels of other environmental impacts. Lifecycle assessment reveals that the biodiesel production phase contributes 35–55% of the environmental impact for biodiesel versus 20–30% for conventional fuel, highlighting opportunities for supply chain optimization. The complete elimination of sulfur content in biodiesel supports compliance with IMO 2020 sulfur regulations without requiring additional exhaust after-treatment systems.

- -

- The adaptive optimization algorithm enables dynamic biodiesel ratio adjustment: 40–60% blend ratios for medium loads (25–50%), 20–30% for high loads (75–100%), and 70–80% for low loads (10%). Predictive models with R2 values of 0.89–0.94 provide reliable emission forecasting capabilities for voyage planning and regulatory compliance verification. Implementation strategies should prioritize B50 as the optimal balance point between environmental benefits and operational practicality.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fourth, I.M.O. Greenhouse Gas Study; International Maritime Organization: London, UK, 2020. [Google Scholar]

- Choi, J.-H.; Cho, S.-G. Effect on Characteristics of Combustion by changing in Biofuel Temperature and Ratio of Bio injection Diesel Fuel. J. Power Syst. Eng. 2020, 24, 43–50. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change. Climate Change 2014: Synthesis Report; IPCC: Geneva, Switzerland, 2015. [Google Scholar]

- IMO. Initial IMO Strategy on Reduction of GHG Emissions from Ships. Resolut. MEPC 2018, 4, 304. [Google Scholar]

- Hansson, S. The impact of the IMO 2020 sulphur regulations on the shipping industry. Marit. Bus. Rev. 2020, 5, 150–168. [Google Scholar]

- Park, Y.H.; Chung, S.Y.; Son, Y.; Lee, W.K. Investigation on Enhancing Efficiency in International Cooperation for Climate Change Adaptation of Republic of Korea. J. Clim. Change Res. 2010, 1, 179–188. [Google Scholar]

- Yang, S.C.; Moon, C.J.; Chang, Y.H.; Soh, S.Y.; Chung, J.H.; Kim, E.S. Internet Monitoring of Wind-photovoltaic Hybrid Generation System. J. Korean Inst. Illum. Electr. Install. Eng. 2006, 20, 43–48. [Google Scholar]

- Goldsworthy, M. Spatial and temporal allocation of ship exhaust emissions in Australian coastal waters using AIS data: Analysis and treatment of data gaps. Atmos. Environ. 2017, 163, 77–86. [Google Scholar] [CrossRef]

- Smith, T.W.; Jalkanen, J.P.; Anderson, B.A.; Corbett, J.J.; Faber, J.; Hanayama, S.; O’Keeffe, E.; Parker, S.; Johansson, L.; Aldous, L.; et al. Third IMO GHG Study 2014; International Maritime Organization: London, UK, 2014. [Google Scholar]

- Park, J.W.; Shin, U.; Kim, D.G.; Yoon, J.H. A Study on Generation Characteristic of Building Integrated Photovoltaic System. J. Korean Sol. Energy Soc. 2013, 33, 75–81. [Google Scholar] [CrossRef]

- Park, K.H.; Kim, J.Y.; Kim, C.J.; Ko, J.H.; Park, H.I. The Effect of Bio-Diesel Fuel on Industrial Diesel Engine. J. Korean Soc. Mar. Eng. 2012, 36, 72–77. [Google Scholar] [CrossRef][Green Version]

- Abed, K.A.; El Morsi, A.K.; Sayed, M.M.; El Shaib, A.A.; Gad, M.S. Effect of waste cooking-oil biodiesel on performance and exhaust emissions of a diesel engine. Egypt. J. Pet. 2018, 27, 985–989. [Google Scholar] [CrossRef]

- Kim, J.K.; Ainll, G.; Song, K.K.; Jung, J.Y.; Kim, H.G. An Experimental Study on Spray Characteristics of Diesel and Bio-diesel Fuel. J. Korean Soc. Mar. Eng. 2011, 35, 53–59. [Google Scholar]

- Lapuerta, M.; Armas, O.; Rodríguez-Fernández, J. Effect of biodiesel fuels on diesel engine emissions. Prog. Energy Combust. Sci. 2008, 34, 198–223. [Google Scholar] [CrossRef]

- Kim, D.Y.; Cho, I.E.; Lee, S.W.; Oh, S.I. A Study on Spray and Combustion Characteristics Affected by Temperature of Bio-diesel Fuel. J. Korea Soc. Automot. Eng. 2007, 07-S0082, 533–538. [Google Scholar]

- Choi, J.H.; Cho, S.G. A Study on the Characteristics of Exhaust Gas Emission by Changing in Biofuel Ratio and Bifuel Temperature in Diesel Engine. J. Power Syst. Eng. 2020, 24, 94–102. [Google Scholar] [CrossRef]

- Cho, S.G. An Experimental Study on Combustion Characteristics of Biodiesel Fuel in Marine Diesel Engine. J. Korean Soc. Power Syst. Eng. 2015, 19, 29–35. [Google Scholar] [CrossRef]

- Johnson, M.; Samad, N.; D’Souza, B. Emissions characteristics of alternative marine fuels: A comparative analysis. J. Mar. Eng. Technol. 2019, 18, 342–353. [Google Scholar]

- Zhang, L.; Peterson, C. Biodiesel effects on engine combustion processes and emission characteristics. Bioresour. Technol. 2018, 197, 320–330. [Google Scholar]

- Jang, S.H. Combustion Characteristics of Biodiesel Fuel as an Alternative Fuel for a D.I. Diesel Engine. J. Korean Soc. Power Syst. Eng. 2009, 2, 54–59. [Google Scholar]

- Wilson, T.; Tyedmers, P. Life cycle assessment of biodiesel from marine sources in comparative context. Renew. Sustain. Energy Rev. 2017, 65, 196–203. [Google Scholar]

- Kumar, A.; Singh, R.K.; Patel, M.N. Advanced biodiesel blend optimization for marine applications: Performance and emission characteristics of second-generation biofuels. Mar. Pollut. Bull. 2023, 187, 114523. [Google Scholar]

- Chen, L.; Wang, H. Neural network-based prediction models for biodiesel performance in marine diesel engines: A machine learning approach. Appl. Energy 2023, 342, 121156. [Google Scholar]

- Gonzalez, M.A.; Rodriguez, P.J.; Silva, C.R. Long-term durability assessment of marine diesel engines operating with biodiesel blends: Component wear analysis and maintenance implications. Fuel 2023, 338, 127289. [Google Scholar]

- Andersen, K.T.; Eriksson, L.M. Economic viability of biodiesel implementation in maritime transportation: Cost-benefit analysis under emerging carbon pricing scenarios. Transp. Res. Part D Transp. Environ. 2023, 115, 103589. [Google Scholar]

- Thompson, S.D.; Williams, J.A.; Brown, K.L. Regulatory compliance strategies for IMO 2030 emissions targets: Analysis of alternative fuel pathways and implementation timelines. Mar. Policy 2023, 147, 105364. [Google Scholar]

- Thomson, H.; Corbett, J.J.; Winebrake, J.J. Natural gas as a marine fuel. Energy Policy 2015, 87, 153–167. [Google Scholar] [CrossRef]

- Robinson, A.; Williams, K. Comparative analysis of marine diesel performance with alternative fuels. Int. J. Mar. Eng. 2020, 28, 141–152. [Google Scholar]

- Achten, W.M.J.; Verchot, L.; Franken, Y.J.; Mathijs, E.; Singh, V.P.; Aerts, R.; Muys, B. Jatropha bio-diesel production and use. Biomass Bioenergy 2008, 32, 1063–1084. [Google Scholar] [CrossRef]

- Mohammadi, R.; Verbeek, M.A.; Heeres, H.J.; Pathak, P.D. Waste cooking oil: A feedstock for biodiesel and life cycle assessment. Waste Manag. 2019, 95, 240–251. [Google Scholar]

- Heo, J.W.; Choi, Y.H.; Kim, S.H.; Lee, S.H.; Choi, H.Y.; Yu, D.I.; Lee, Y.W. Predicting heat transfer performance in a complex heat exchanger for LNG FGSS development. J. Adv. Mar. Eng. Technol. 2023, 47, 52–58. [Google Scholar] [CrossRef]

- Lim, S.; Lee, H.; Yoon, J.; Kim, H. Performance evaluation of Ocean Thermal Energy Conversion (OTEC) stabilization based on risk analysis. J. Adv. Mar. Eng. Technol. 2023, 47, 1–11. [Google Scholar] [CrossRef]

- Chybowski, L.; Szczepanek, M.; Kuczyński, W.; Michalska-Pożoga, I.; Pusty, T.; Brożek, P.; Pełech, R. Content of Selected Compounds in the Exhaust Gas of a Naturally Aspirated CI Engine Fueled with Diesel–Tire Pyrolysis Oil Blend. Energies 2025, 18, 2621. [Google Scholar] [CrossRef]

- Jo, K.-S.; Han, S.-H.; Kim, M.-J. Analysis of Exhaust Gas Characteristics According to Load of 2.4 MW Class 4-stroke Main Engine (Centered on the Fishing Training Ship Saebada). J. Power Syst. Eng. 2021, 25, 69–78. [Google Scholar] [CrossRef]

- Jo, K.-S.; Choi, Y.-J.; Han, S.-H. Analysis of Exhaust Gas Characteristics by Load of Marine Diesel Engine Using Bio Diesel. J. Power Syst. Eng. 2022, 26, 14–22. [Google Scholar] [CrossRef]

| Attribute/Parameter | T/S SAEBADA–Niigata 6L34HX | Yanmar 6HAL2-DTN (Test Engine) |

|---|---|---|

| Manufacturer | Niigatta Engineering Co., Ltd. | Yanmar Diesel Co., Ltd. |

| Model | 6L34HX | 6HAL2-DTN |

| Year of build | 2000 | February 2001 |

| Engine type | 4-stroke, turbo-charged, water-cooled air cooler | Vertical, single-acting, 4-stroke diesel |

| Cylinder arrangement | 6-cylinder, in-line, vertical | 6-cylinder, in-line, vertical |

| Cylinder bore × stroke (mm) | 340 × 450 | 130 × 165 |

| Total displacement | 40.86 dm3 | 13.14 dm3 |

| Combustion-chamber type | Open combustion chamber with piston bowl | Direct injection with a piston bowl |

| Compression ratio | 13.3:1 | 17.5:1 |

| Rated power | 2471 kW@600 rpm | 199 kW@1200 rpm |

| Mean piston speed | 9.0 m/s | 6.60 m/s |

| Mean effective pressure | 1.51 MPa | 1.52 MPa |

| Dry mass (approx.) | 8500 kg | 1420 kg |

| Valve port size × number | Exhaust 115 mm × 2, Inlet 120 mm × 2 | Exhaust 50 mm × 2, Inlet 45 mm × 2 |

| Inlet-valve closing (° CA) | 35° CA after BDC | 40° CA after BDC |

| Fuel-injection timing (° CA BTDC) | 8–18° CA BTDC (single injection) | 12° CA BTDC (single injection) |

| Injector opening pressure | 34.5 ± 1.0 MPa | 30.0 ± 2.0 MPa |

| Fuel oil | Marine gas oil (MGO) | Marine diesel oil |

| Firing order | 1-5-3-6-2-4 | 1-4-2-6-3-5-1 |

| NOx Tier Classification | Pre-Tier I | Tier I |

| Parameter | MGO (B0) | Biodiesel (B100) | Test Method |

|---|---|---|---|

| Calorific value (MJ/kg) | 42.8 ± 0.3 | 37.2 ± 0.2 | ASTM D240 |

| Density @15 °C (kg/m3) | 828 ± 3 | 920 ± 2 | ASTM D1298 |

| Kinematic viscosity @40 °C (mm2/s) | 3.2 ± 0.1 | 4.8 ± 0.2 | ASTM D445 |

| Flash point (°C) | 68 ± 2 | 165 ± 3 | ASTM D93 |

| Sulfur content (mg/kg) | 8.5 ± 1.2 | <1.0 | ASTM D5453 |

| Cetane number | 42.3 ± 1.1 | 51.2 ± 0.8 | ASTM D613 |

| Oxidation stability (h) | >30 | 8.2 ± 0.5 | EN 14112 |

| Cold filter plugging point (°C) | −15 ± 2 | +2 ± 1 | ASTM D6371 |

| Acid value (mg KOH/g) | 0.15 ± 0.02 | 0.48 ± 0.03 | ASTM D664 |

| Water content (mg/kg) | 45 ± 5 | 180 ± 15 | ASTM D6304 |

| Parameter | NOx Model | CO2 Model | CO Model |

|---|---|---|---|

| β0 (Constant) | 147.35 | 2.312 | 98.67 |

| β1 (Biodiesel ratio) | 0.93 | 0.012 | −0.57 |

| β2 (Engine load) | 14.86 | 0.094 | −7.83 |

| β3 (Ambient temperature) | 1.23 | 0.005 | 2.13 |

| β4 (Fuel temperature) | 0.34 | 0.002 | 1.05 |

| β5 (Ratio × Load) | 0.012 | 0.0001 | −0.003 |

| β6 (Ratio × Temperature) | 0.001 | 0.00005 | −0.002 |

| β7 (Load × Temperature) | 0.035 | 0.0003 | 0.045 |

| β8 (Ratio2) | −0.002 | −0.00001 | 0.001 |

| β9 (Load2) | 0.043 | 0.0006 | 0.183 |

| 0.94 | 0.91 | 0.89 | |

| RMSE | 32.5 | 0.28 | 18.7 |

| Impact | B0 | B20 | B50 | B100 |

|---|---|---|---|---|

| Global warming potential (gCO2eq/MJ) | 91.2 | 88.3 | 77.4 | 81.7 |

| Acidification potential (gSO2eq/MJ) | 1.33 | 1.28 | 1.25 | 1.31 |

| Eutrophication potential (gPO4eq/MJ) | 0.19 | 0.25 | 0.33 | 0.50 |

| Non-renewable energy consumption | 2.83 | 2.39 | 1.75 | 0.69 |

| Water consumption (L/MJ) | 0.22 | 0.39 | 0.64 | 1.08 |

| Land use (m2a/MJ) | 0.003 | 0.003 | 0.003 | 0.003 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jo, K.-S.; Kong, K.-J.; Han, S.-H. Optimizing Fuel Efficiency and Emissions of Marine Diesel Engines When Using Biodiesel Mixtures Under Diverse Load/Temperature Conditions: Predictive Model and Comprehensive Life Cycle Analysis. J. Mar. Sci. Eng. 2025, 13, 1192. https://doi.org/10.3390/jmse13061192

Jo K-S, Kong K-J, Han S-H. Optimizing Fuel Efficiency and Emissions of Marine Diesel Engines When Using Biodiesel Mixtures Under Diverse Load/Temperature Conditions: Predictive Model and Comprehensive Life Cycle Analysis. Journal of Marine Science and Engineering. 2025; 13(6):1192. https://doi.org/10.3390/jmse13061192

Chicago/Turabian StyleJo, Kwang-Sik, Kyeong-Ju Kong, and Seung-Hun Han. 2025. "Optimizing Fuel Efficiency and Emissions of Marine Diesel Engines When Using Biodiesel Mixtures Under Diverse Load/Temperature Conditions: Predictive Model and Comprehensive Life Cycle Analysis" Journal of Marine Science and Engineering 13, no. 6: 1192. https://doi.org/10.3390/jmse13061192

APA StyleJo, K.-S., Kong, K.-J., & Han, S.-H. (2025). Optimizing Fuel Efficiency and Emissions of Marine Diesel Engines When Using Biodiesel Mixtures Under Diverse Load/Temperature Conditions: Predictive Model and Comprehensive Life Cycle Analysis. Journal of Marine Science and Engineering, 13(6), 1192. https://doi.org/10.3390/jmse13061192