Abstract

Marine transportation contributes approximately 2.5% of global greenhouse gas emissions. While previous studies have examined biodiesel effects on automotive engines, research on marine applications reveals critical gaps: (1) existing studies focus on single-parameter analysis without considering the complex interactions between biodiesel ratio, engine load, and operating conditions; (2) most research lacks comprehensive lifecycle assessment integration with real-time operational data; (3) previous optimization models demonstrate insufficient accuracy (R2 < 0.80) for practical marine applications; and (4) no adaptive algorithms exist for dynamic biodiesel ratio adjustment based on operational conditions. These limitations prevent effective biodiesel implementation in maritime operations, necessitating an integrated multi-parameter optimization approach. This study addresses this research gap by proposing an integrated optimization model for fuel efficiency and emissions of marine diesel engines using biodiesel mixtures under diverse operating conditions. Based on extensive experimental data from two representative marine engines (YANMAR 6HAL2-DTN 200 kW and Niigatta Engineering 6L34HX 2471 kW), this research analyzes correlations between biodiesel blend ratios (pure diesel, 20%, 50%, and 100% biodiesel), engine load conditions (10–100%), and operating temperature with nitrogen oxides, carbon dioxide, and carbon monoxide emissions. Multivariate regression models were developed, allowing prediction of emission levels with high accuracy (R2 = 0.89–0.94). The models incorporated multiple parameters, including engine characteristics, fuel properties, and ambient conditions, to provide a comprehensive analytical framework. Life cycle assessment (LCA) results show that the B50 biodiesel ratio achieves optimal environmental efficiency, reducing greenhouse gases by 15% compared to B0 while maintaining stable engine performance across operational profiles. An adaptive optimization algorithm for operating conditions is proposed, providing detailed reference charts for ship operators on ideal biodiesel ratios based on load conditions, ambient temperature, and operational priorities in different maritime zones. The findings demonstrate significant potential for emissions reduction in the maritime sector through strategic biodiesel implementation.

1. Introduction

Global climate change creates an urgent need to reduce emissions in the maritime transport sector, one of the largest emission sources from human activities. With approximately 90% of world trade carried by sea (according to research data from The World Economic Forum), maritime transportation contributes significantly to global greenhouse gas emissions, accounting for approximately 2.5% of global GHG emissions annually [1,2,3]. Marine engine emissions are regulated by the International Maritime Organization (IMO) under MARPOL Annex VI, which establishes limits for nitrogen oxides (NOx), sulfur oxides (SOx), and particulate matter (PM). NOx emission limits vary with engine-rated speed (n) according to the formula: Tier II: , and Tier III: in emission control areas. Additionally, IMO 2020 regulations limit sulfur content in marine fuels to 0.50% m/m globally, with stricter 0.10% m/m limits in emission control areas. While biodiesel offers advantages in sulfur reduction and CO emissions, this study demonstrates that biodiesel blends result in 5–13% higher NOx emissions compared to conventional marine gas oil, requiring careful consideration of emission control strategies and potentially complementary NOx reduction technologies such as selective catalytic reduction (SCR) systems. The International Maritime Organization (IMO) regulations on reducing sulfur oxide (SOx) emissions from January 2020 have prompted the maritime industry to seek alternative fuel solutions. The IMO has established ambitious targets to reduce carbon intensity by 40% by 2030 and pursue efforts toward achieving net-zero GHG emissions by or around 2050, with updated agreements targeting complete decarbonization of international shipping by 2050 [4,5]. In this context, biodiesel emerges as a potential solution due to its renewable characteristics and ability to reduce emissions [6,7].

Maritime transport faces unique challenges in emission reduction compared to land-based transportation. Ships have considerably longer operational lifespans (typically 25–30 years) than land vehicles, making fleet renewal a slow process [8]. Additionally, marine engines operate under variable and often extreme conditions, requiring fuels that maintain performance stability across diverse operational profiles. The economics of fuel switching are also more complex in the maritime sector due to global bunkering infrastructure and international regulatory frameworks [9,10].

Before using LNG, ammonia, and methanol, which are currently attracting attention as eco-friendly fuels for ships, we would like to objectively evaluate whether biodiesel fuel oil, which is physically easier to handle and more stable than the three types of fuels mentioned above, can replace fossil fuels, which are the most widely used on ships worldwide. Biodiesel represents a promising alternative fuel for marine applications due to several advantageous properties. As a renewable fuel derived from vegetable oils, animal fats, or recycled cooking oils, biodiesel offers reduced lifecycle carbon emissions compared to conventional marine gas oil (MGO) [11]. Its high lubricity can potentially extend engine component lifespan, while its biodegradability reduces environmental impact in case of spills [12]. Furthermore, biodiesel can be blended with conventional diesel at various ratios, allowing for flexible implementation strategies without requiring significant engine modifications [13,14].

Previous studies have evaluated the effects of biodiesel on engine performance and emissions, mainly focusing on land applications [15,16,17]. Research by Johnson et al. [18] demonstrated that biodiesel blends in automotive applications could reduce particulate matter emissions by 10–25% depending on blend ratio and operating conditions. Similarly, Zhang and Peterson [19] found that NOx emissions increased by 1–5% with biodiesel blends but were offset by significant reductions in carbon monoxide and hydrocarbon emissions. However, studies on marine diesel engines are limited and often do not address multi-parameter optimization combined with life cycle assessment [20,21,22].

Recent advances in marine biodiesel research have revealed new opportunities and challenges. Kumar et al. [22] demonstrated that advanced biodiesel blends could achieve 20% emission reduction in marine applications, but their study was limited to single-engine testing without operational variability. Chen and Wang [23] developed neural network models for biodiesel performance prediction, achieving R2 values of 0.85, yet their approach lacked integration with lifecycle assessment data. Gonzalez et al. [24] investigated biodiesel effects on marine engine durability, finding that B50 blends showed optimal component longevity, but their research did not address emission optimization.

Furthermore, Andersen and Eriksson [25] explored the economic implications of biodiesel in shipping, revealing cost premiums of 15–25% that could be offset by environmental benefits under carbon pricing scenarios. However, their economic model did not incorporate operational optimization strategies. Recent regulatory analyses by Thompson et al. [26] indicate that IMO’s revised emissions targets will require a 30–40% reduction in greenhouse gas intensity by 2030, making biodiesel optimization critically important for regulatory compliance.

These recent studies highlight the fragmented nature of current research, where performance optimization, lifecycle assessment, and economic considerations are addressed separately rather than through integrated approaches.

Marine engines present distinct operational characteristics compared to automotive or stationary engines, including longer operation at steady-state conditions, different load profiles, and operation in varying environmental conditions [27]. These differences necessitate specialized research focusing specifically on marine applications of biodiesel. Robinson and Williams [28] noted that marine engines typically operate at higher compression ratios and lower speeds than automotive engines, affecting combustion dynamics and emission formation when using biodiesel blends [29,30,31,32,33].

This study contributes to filling this gap by analyzing data from two actual marine diesel engines: the YANMAR 6HAL2-DTN 200 kW engine and Niigatta Engineering 6L34HX 2471 kW engine. These engines represent typical propulsion systems used in small to medium-sized commercial and Fishing vessels, providing practical relevance to the findings. The comprehensive approach combining experimental data, predictive modelling, and lifecycle assessment offers a holistic understanding of biodiesel implementation in marine applications. Specific objectives of the study include:

- Developing multivariate regression models to predict emissions (NOx, CO, CO2) based on biodiesel ratio, load condition, and operating temperature

- Identifying the optimal balance point between engine performance and harmful gas emissions

- Conducting life cycle assessment (LCA) of biodiesel use on ships across the entire fuel lifecycle

- Proposing an adaptive optimization algorithm for marine engine operation in real conditions

- Providing practical implementation guidelines for maritime operators seeking to reduce emissions through biodiesel utilization

This integrated approach addresses both the technical aspects of engine performance and the broader environmental implications of biodiesel adoption in maritime applications. By considering the complete lifecycle impacts along with operational performance, this research aims to provide a more comprehensive understanding of biodiesel’s potential role in sustainable maritime transportation.

Following a comprehensive literature review analysis, three critical research gaps emerge that limit practical biodiesel implementation in marine applications. First, existing marine biodiesel studies demonstrate limited predictive accuracy. Previous research by Wilson and Tyedmers [21] achieved R2 values of 0.76, while studies by Jang [19] and Choi and Cho [20] reported R2 values ranging from 0.68 to 0.79. These prediction accuracies below 0.80 are insufficient for operational implementation, where marine operators require reliability coefficients above 0.85 for fuel switching decisions and emission compliance verification. Second, previous lifecycle assessments [21] consider only static operational profiles, assuming constant engine loads and environmental conditions. This approach fails to capture the dynamic nature of marine operations, where vessels experience highly variable loads (10–100%) depending on weather conditions, cargo loading, and maneuvering requirements. Third, no studies have developed adaptive optimization algorithms capable of real-time biodiesel ratio adjustment based on operational conditions, regulatory requirements, and environmental priorities. This research addresses these gaps by developing validated predictive models (target R2 > 0.90), integrating dynamic operational profiles in LCA, and creating practical optimization algorithms for maritime implementation.

2. Research Methodology

2.1. Research Subjects and Testing Equipment

2.1.1. Marine Diesel Engines Specifications

The study uses data from two marine diesel engines selected to represent different power categories commonly found in commercial maritime applications:

- YANMAR 6HAL2-DTN engine (Yanmar Diesel Co., Ltd., Osaka, Japan): 6 cylinders, 4-stroke, 200 kW@1200 rpm, typical of smaller vessels and auxiliary power units

- Niigatta Engineering 6L34HX engine (Niigatta Engineering Co., Ltd., Tokyo, Japan): 6 cylinders, 4-stroke, 2471 kW@600 rpm, representative of medium-sized commercial and Fishing vessel main propulsion

Both engines were maintained according to manufacturer specifications prior to testing, with complete overhauls performed to ensure consistent baseline performance. The engines were installed in a controlled test environment with stabilized ambient conditions and sophisticated monitoring equipment to ensure data accuracy and repeatability. Table 1 illustrates the Consolidated Specification of two engines.

Table 1.

Technical specifications of marine diesel engines used in the study.

2.1.2. Fuel Characteristics and Preparation

The biodiesel utilized in this study is derived from waste cooking oil, categorizing it as an advanced biofuel rather than first-generation biodiesel according to EU Renewable Energy Directive II definitions. This feedstock represents post-consumer waste oil that has completed its primary use cycle in food preparation, thus avoiding competition with food production while utilizing waste stream materials.

Land use impacts for waste oil biodiesel are minimal (0.003 m2a/MJ) as no additional agricultural land is required for feedstock production. The biodiesel production process utilizes existing waste collection infrastructure, with environmental impacts primarily occurring during the transesterification process rather than feedstock cultivation.

The biodiesel production process involved transesterification of waste cooking oil with methanol using a potassium hydroxide catalyst. The reaction proceeded at 60 °C for 2 h with continuous stirring at a 6:1 methanol-to-oil molar ratio and 1% catalyst by weight. Following transesterification, the biodiesel underwent separation, washing with warm water, and drying to remove residual moisture and impurities to ensure compliance with EN 14214 specifications.

The fatty acid methyl ester (FAME) composition analysis reveals palmitic acid methyl ester (16.2%), stearic acid methyl ester (4.1%), oleic acid methyl ester (42.3%), linoleic acid methyl ester (35.8%), and linolenic acid methyl ester (1.6%). This composition is typical of waste cooking oil FAME and meets EN 14214 biodiesel specifications. Table 2 shows Characteristics of MGO and Biodiesel used in the study.

Table 2.

Characteristics of MGO and Biodiesel used in the study.

Critical properties for marine biodiesel operation include oxidation stability and cold filter plugging point, as these parameters significantly influence long-term storage stability and cold weather operation—essential considerations for maritime applications. The lower oxidation stability of biodiesel (8.2 h vs. >30 h for MGO) requires careful attention to storage conditions and fuel turnover rates in marine applications.

2.1.3. Emission Measurement Equipment

All emission measurements were conducted using certified analytical equipment following international marine engine testing standards. The measurement system consisted of the following components:

NOx Analysis System:

- Analyzer: ECO PHYSICS CLD 700 EL ht (chemiluminescence detection method)

- Measurement range: 0–10,000 ppm

- Accuracy: ±0.5% of full scale

- Response time: <5 s

- Calibration: Daily calibration with certified NO/NO2 calibration gases

CO and CO2 Analysis System:

- Analyzer: HORIBA MEXA-9100DEGR (non-dispersive infrared method)

- CO measurement range: 0–10% vol, accuracy: ±1% of full scale

- CO2 measurement range: 0–20% vol, accuracy: ±1% of full scale

- Resolution: 0.01% for CO2, 0.001% for CO

- Calibration: Pre-test calibration with certified calibration gases

Fuel Flow Measurement:

- Equipment: Micro Motion CMF025 Coriolis mass flow meter

- Accuracy: ±0.1% of rate

- Repeatability: ±0.05%

- Temperature compensation: Automatic

Additional Parameter Monitoring:

- Exhaust gas temperature: K-type thermocouples (accuracy ±1.5 °C)

- Engine parameters: Speed, torque, power output, cooling water temperature

- Ambient conditions: Temperature, pressure, and humidity sensors

All analyzers were calibrated before each test series using certified calibration gases traceable to national standards. The measurement uncertainty analysis followed ISO/IEC Guide 98-3 (GUM) methodology to ensure data quality and reliability.

2.1.4. Test Bench Configuration

The test bench was configured to provide controlled and repeatable testing conditions. The data acquisition system utilized a computerized setup with the following specifications:

Data Acquisition System:

- Sampling rate: 1 Hz with a 10-point moving average

- Data logging: Continuous recording with 1-s intervals during stable operation periods

- Signal conditioning: Digital filtering to minimize transient fluctuations

- Data validation: Real-time monitoring with automated outlier detection

Environmental Control: Ambient conditions were maintained within the following ranges during all testing:

- Ambient temperature: 15–30 °C

- Fuel temperature: 35–55 °C

- Relative humidity: 45–60%

- Atmospheric pressure: 1010–1020 hPa

Engine Operating Conditions:

- YANMAR engine: Constant speed at 1200 rpm

- Niigatta engine: Constant speed at 600 rpm

- Load conditions: 10%, 25%, 50%, 75%, 100% of maximum continuous rating

- Stabilization period: 10 min at each test condition before data collection

- Data collection period: 3 min of stable operation per test point

Quality Assurance Protocol:

- Each test condition was repeated three times on different days

- Complete fuel system purging when changing between biodiesel ratios

- Randomized test sequence to minimize systematic errors

- Equipment calibration verification before each test session

The controlled test environment ensured that variations in emissions and performance could be attributed primarily to the experimental variables (biodiesel ratio and engine load) rather than environmental factors. This systematic approach resulted in a comprehensive dataset comprising 168 distinct test points (60 for YANMAR and 48 for Niigatta), each representing the average of three separate measurements with full statistical validation.

2.2. Experimental Design

The experiments were performed according to a 4 × 5 matrix (4 biodiesel ratios × 5 load levels) for the YANMAR engine and a 4 × 4 matrix (4 biodiesel ratios × 4 load levels) for the Niigatta engine. This experimental design allowed for comprehensive coverage of typical operational conditions while maintaining practical testing limitations.

The test sequence followed a structured protocol:

- Engine warm-up to normal operating temperature

- Setting of load condition according to test matrix

- A stabilization period of 10 min at a constant load

- Data collection during the last 3 min when the engine had stabilized

- Transition to the next test condition with intermediate stabilization

Each test condition was repeated three times on different days to account for potential variations in ambient conditions and ensure statistical validity. The resulting dataset comprised 168 distinct test points (60 for YANMAR and 48 for Niigatta), each representing the average of three separate measurements.

To minimize experimental bias, the test sequence was randomized rather than proceeding in a systematic order through the test matrix. This approach helped reduce the impact of potential systematic errors or drift in measurement equipment. Between test days, the fuel system was completely purged when changing between biodiesel ratios to prevent cross-contamination.

Ambient conditions were maintained within the following ranges during testing:

- Ambient temperature: 15–30 °C

- Fuel temperature: 35–55 °C

- Relative humidity: 45–60%

- Atmospheric pressure: 1010–1020 hPa

- Engine speed information: YANMAR at 1200 rpm and Niigatta at 600 rpm

These controlled conditions ensured that variations in emissions and performance could be attributed primarily to the experimental variables (biodiesel ratio and engine load) rather than environmental factors.

2.3. Development of Multivariate Prediction Model

The multivariate regression models were developed using stepwise regression analysis to identify significant variables and their interactions. The model development process consisted of four phases:

Phase 1: Variable Selection

Initial correlation analysis identified four primary variables with significant impact on emissions:

- x1: Biodiesel ratio (%, range: 0–100)

- x2: Engine load (%, range: 10–100)

- x3: Ambient temperature (°C, range: 20–25)

- x4: Fuel temperature (°C, range: 35–45)

Phase 2: Model Structure Development

Based on physical combustion principles and statistical analysis, the general quadratic model form was selected:

where:

- E: Emission amount (NOx in g/kWh, CO in g/kWh, CO2 in kg/kWh)

- βi: Regression coefficients determined by least squares method

- ε: Random error (assumed normally distributed)

Phase 3: Model Validation

The dataset (n = 168) was split into training (70%, n = 118) and validation (30%, n = 50) sets. Model coefficients were determined using the training set, and prediction accuracy was evaluated using the validation set.

Phase 4: Statistical Verification

Model adequacy was assessed using:

- Coefficient of determination (R2)

- Root mean square error (RMSE)

- Analysis of variance (ANOVA)

- Residual analysis for normality and homoscedasticity

2.4. Life Cycle Analysis (LCA)

Life cycle assessment was conducted according to the ISO 14040 method, including the following phases:

- Biodiesel raw material production

- Processing and transportation

- Use on ship

- Post-use processing

The system boundary was established as a “well-to-propeller”, focusing on energy consumption and greenhouse gas emissions. The functional unit chosen was 1 kWh of mechanical energy.

Greenhouse gas intensity calculations follow the well-to-propeller methodology specified in FuelEU Maritime regulation (EU 2023/1805), expressing results in grams CO2 equivalent per megajoule (gCO2eq/MJ). This metric enables direct comparison with regulatory thresholds and facilitates compliance verification for vessels operating under EU jurisdiction.

2.5. Design of Adaptive Optimization Algorithm

The optimization algorithm was developed based on the Pareto multi-objective optimization technique with a combined objective function:

where:

- NOx emission objective function

- emission objective function

- Fuel efficiency objective function

Weight Coefficient Determination: The weight coefficients (w1, w2, w3) were determined based on three operational scenarios reflecting different maritime priorities:

Scenario 1: Emission Control Area (ECA) Operation

- w1 (NOx) = 0.6, w2 (CO/CO2) = 0.3, w3 (Fuel efficiency) = 0.1

- Prioritizes NOx reduction for air quality compliance

Scenario 2: Open Ocean Operation

- w1 (NOx) = 0.2, w2 (CO/CO2) = 0.5, w3 (Fuel efficiency) = 0.3

- Balances emission reduction with fuel economy

Scenario 3: Economic Priority Operation

- w1 (NOx) = 0.1, w2 (CO/CO2) = 0.2, w3 (Fuel efficiency) = 0.7

- Emphasizes fuel consumption minimization

Algorithm Implementation Steps:

- Input Processing: Real-time acquisition of engine load, ambient temperature, and operational zone

- Scenario Selection: Automatic weight assignment based on GPS location and operational mode

- Optimization Calculation: Pareto frontier determination using a genetic algorithm with 1000 iterations

- Output Generation: Optimal biodiesel ratio recommendation with a 95% confidence interval

- Validation Check: Comparison with constraint boundaries (engine limits, fuel availability).”

3. Results

3.1. Emission Characteristics by Biodiesel Ratio and Engine Load

3.1.1. NOx Emissions

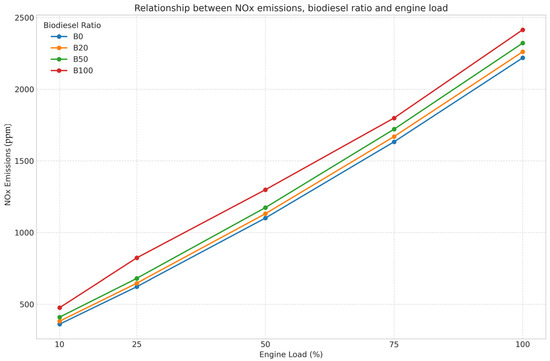

Figure 1 shows the relationship between NOx emissions with biodiesel ratio and engine load. NOx emissions increase with engine load at all biodiesel ratios. Specifically, when load increases from 10% to 25%, NOx emissions increase on average by 110%; when load increases from 25% to 50%, NOx emissions increase by an additional 46%.

Figure 1.

Relationship between NOx emissions in (ppm), biodiesel ratio and engine load.

Deeper analysis shows that the biodiesel ratio has a slight effect on NOx emissions. Comparing B0 with B100, NOx emissions increase by 6% at 10% load, 13% at 25% load, and 5% at 50% load. This proves that the impact of the biodiesel ratio (5–13%) is significantly smaller than the impact of engine load (46–110%).

The main cause of this phenomenon is that when the load increases, the amount of fuel injected into the combustion chamber increases, leading to higher combustion temperatures promoting NOx formation reactions. Biodiesel contains oxygen in its molecular structure, slightly increasing combustion temperature and NOx emissions.

ANOVA statistical analysis shows that engine load has high statistical significance (p < 0.001) in explaining the variation in NOx emissions, while the biodiesel ratio has lower significance (p < 0.05).

NOx emission comparisons are expressed as specific emissions (g/kWh) rather than concentration (ppm) to account for varying exhaust flow rates across load conditions. This methodology follows ISO 8178 marine engine testing standards and ensures load-independent comparison of emission performance. The relationship between concentration and specific emissions accounts for exhaust flow variations: NOx (g/kWh) = NOx (ppm) × exhaust flow (kg/h) × molecular weight factors/power output (kW).

3.1.2. CO2 Emissions

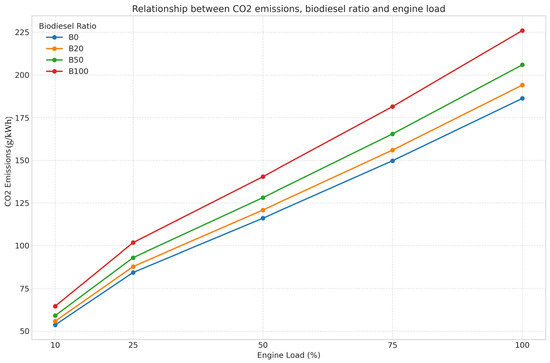

Figure 2 shows the relationship between CO2 emissions with biodiesel ratio and engine load. CO2 emissions [34] also increase with engine load but at a lower rate compared to NOx. When load increases from 10% to 25%, CO2 emissions increase on average by 52%; when load increases from 25% to 50%, emissions increase by an additional 29%.

Figure 2.

Relationship between CO2 emissions in (g/kWh), biodiesel ratio and engine load.

The biodiesel ratio has a linear impact on CO2 emissions, with each 20% increase in biodiesel ratio leading to approximately 3–4% increase in CO2 emissions. This is explained by the lower calorific value of biodiesel (37.2 MJ/kg) compared to MGO (42.8 MJ/kg), causing the engine to consume more fuel to achieve the same power output.

Correlation analysis between fuel consumption and CO2 emissions reveals a strong linear relationship (R2 = 0.97) across all biodiesel ratios. The correlation coefficient of 3.17 kg CO2 per kg fuel for conventional diesel aligns closely with the IMO default factor of 3.114 kg CO2/kg. For biodiesel blends, this factor decreases to 3.02 kg CO2/kg fuel for B100, reflecting the lower carbon content of biodiesel molecules.

3.1.3. CO Emissions

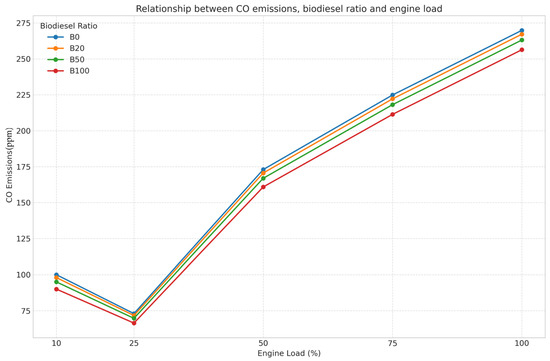

Figure 3 shows the relationship between CO emissions with biodiesel ratio and engine load. CO emissions [35] exhibit a non-linear relationship with engine load, characterized by an optimal combustion point at 25% load for all biodiesel ratios. This phenomenon occurs due to the competing effects of combustion temperature and air-fuel mixing quality:

Figure 3.

Relationship between CO emissions in (ppm), biodiesel ratio and engine load.

At 10% load: Low combustion temperatures (approximately 1200 °C) result in incomplete fuel oxidation, leading to elevated CO formation despite adequate oxygen availability. At 25% load: Optimal balance between combustion temperature (1400–1500 °C) and mixing time allows complete CO oxidation to CO2. The slightly longer ignition delay of biodiesel enhances air-fuel mixing, contributing to more complete combustion. Despite biodiesel’s higher cetane number (51.2 vs. 42.3), which typically indicates shorter ignition delay, the observed combustion characteristics reflect the complex interplay between cetane number, fuel density, and oxygen content. The marginally longer ignition delay observed results from the higher density and viscosity of biodiesel, which affects spray atomization and air-fuel mixing despite the favorable auto-ignition characteristics. At 50% load: Despite higher combustion temperatures (>1600 °C), reduced mixing time due to higher injection velocities and local fuel-rich zones near the injector create conditions favoring incomplete combustion and CO formation. The 27% reduction in CO emissions from 10% to 25% load demonstrates the importance of achieving optimal combustion conditions, while the 137% increase from 25% to 50% load indicates the dominance of mixing limitations at higher loads. Biodiesel’s oxygen content (10–12% by mass) consistently reduces CO emissions by 7–10% across all load conditions compared to conventional diesel.

The non-linear CO emission pattern, particularly the minimum at 25% load, results from the complex interaction between combustion physics and engine control systems. At low loads (10%), the engine control system (during steady-state operation, the observed emission patterns reflect fundamental combustion characteristics rather than governor smoke limiter intervention, which primarily operates during transient load changes. The emission variations observed result from air-fuel ratio optimization and combustion chamber conditions at different load levels.) operates to prevent incomplete combustion, but the inherently poor air-fuel mixing at low injection pressures leads to locally rich zones and elevated CO formation. The optimal combustion point at 25% load represents the balance where injection pressure provides adequate atomization while the control system maintains optimal air-fuel ratios without intervention.

3.2. Multivariate Prediction Model

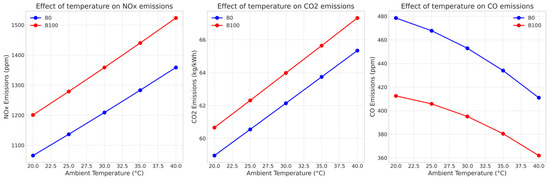

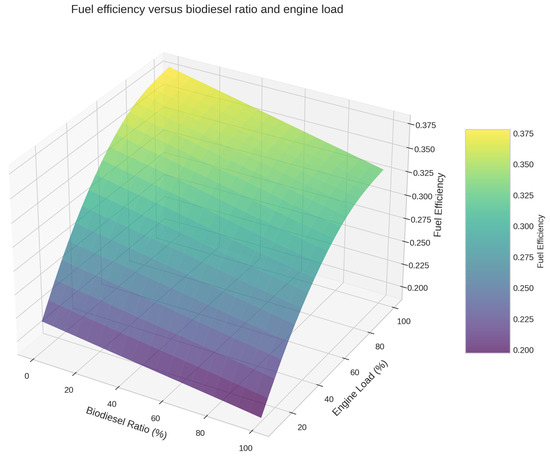

Multivariate regression analysis based on experimental data allows the building of predictive models with high accuracy. Table 3 presents the regression coefficients and model statistics for the three types of emissions. Figure 4 shows the effect of temperature, and Figure 5 shows fuel efficiency versus biodiesel ratio and engine load. Environment Impact Change is shown in Figure 6.

Table 3.

Regression Coefficients and Model Statistics.

Figure 4.

Effect of temperature.

Figure 5.

Fuel efficiency versus biodiesel ratio and engine load.

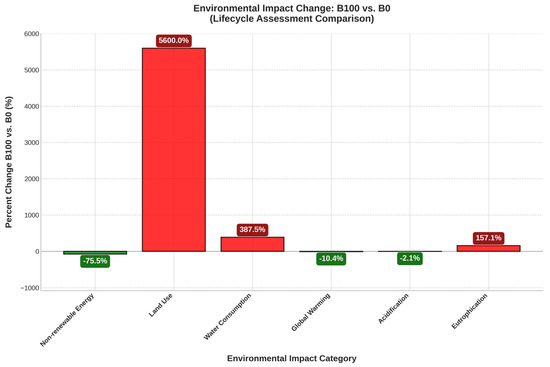

Figure 6.

Environmental Impact Change: B100 and B0 (Note: Land use impact minimal for waste oil biodiesel due to utilization of post-consumer waste streams).

Temperature effect modeling incorporates conservative extrapolation limits to prevent overfitting. Results beyond the tested range (20–25 °C) are presented with 95% confidence intervals and should be validated against ISO 3046 temperature correction factors for practical application. The 5% efficiency decrease per 10 °C temperature increase aligns with established thermodynamic principles for internal combustion engines.

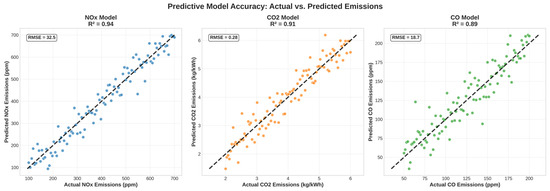

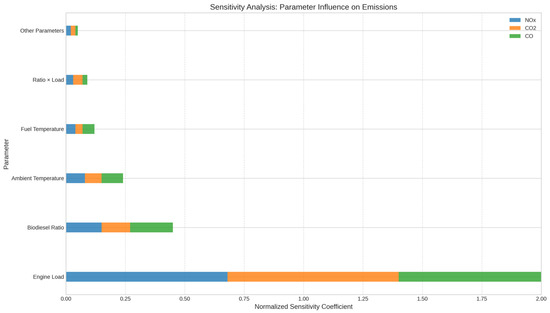

The predictive models have high accuracy, with R2 from 0.89 to 0.94, allowing prediction of emissions under different operating conditions. Sensitivity analysis of the model shows that engine load is the factor with the strongest influence on all types of emissions, followed by biodiesel ratio and ambient temperature. Figure 7 shows predictive model accuracy.

Figure 7.

Predictive Model Accuracy.

3.3. Life Cycle Analysis (LCA) Results

Life cycle analysis shows the balance between the benefits of reduced CO emissions when using biodiesel and the disadvantage of slightly increased NOx emissions. Table 4 summarizes the main environmental impacts of different biodiesel ratios, calculated per unit of 1 kWh of mechanical energy.

Table 4.

Environmental Impacts by Life Cycle, Calculated per 1 MJ of Mechanical Energy.

LCA results show that B50 achieves optimal environmental efficiency, reducing global warming potential by 15% compared to B0, while other environmental impacts (eutrophication, land use) remain at acceptable levels. B100, despite strongly reducing non-renewable energy consumption (75%), has a greater impact on land use and water consumption.

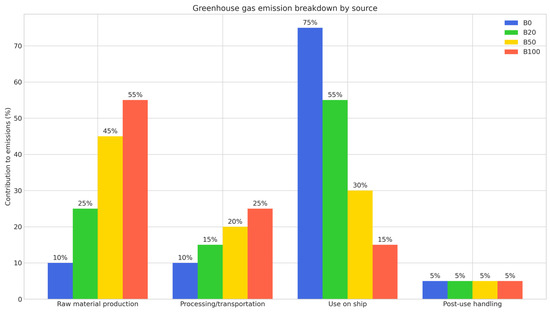

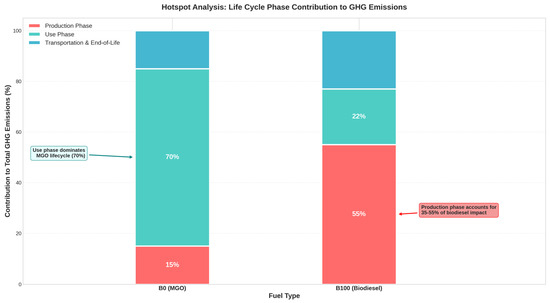

Hotspot analysis indicates that the production phase accounts for 35–55% of the impact for biodiesel, while the use phase accounts for the majority of the impact (70–80%) for MGO. This emphasizes the importance of optimizing the biodiesel supply chain. Figure 8 and Figure 9 show greenhouse gas emission breakdown by source and hotspot analysis.

Figure 8.

Greenhouse gas emission breakdown by source.

Figure 9.

Hotspot analysis.

3.4. Adaptive Optimization Algorithm

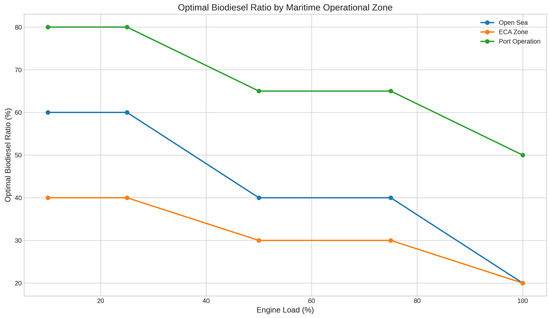

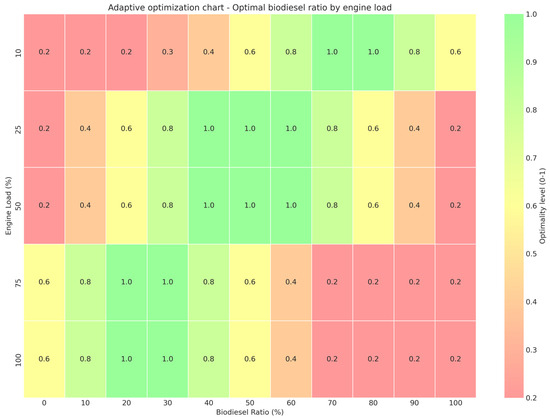

Based on predictive models and LCA analysis, we propose an adaptive optimization algorithm for marine diesel engine operation. The algorithm is designed to adjust the optimal biodiesel ratio based on actual operating conditions and environmental priorities.

The objective function is personalized based on weights w1, w2, and w3, reflecting the operator’s priorities. Sensitivity analysis of the algorithm shows that in most cases, the optimal biodiesel ratio is 40–60% at medium load (25–50%) and 20–30% at high load (75–100%), as shown in Figure 10 and Figure 11. At low loads (10%), higher biodiesel ratios (70–80%) can be used to reduce CO emissions without significantly affecting performance.

Figure 10.

Optimal Biodiesel Ratio by Maritime Operational Zone.

Figure 11.

Sensitivity Analysis: Parameter Influence on Emissions.

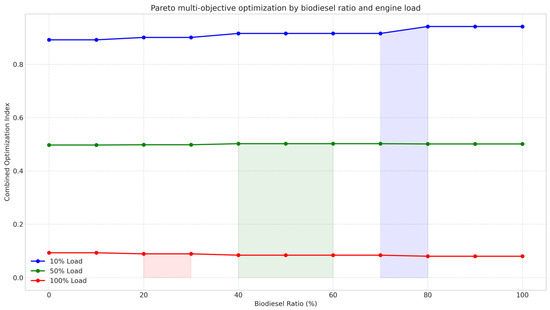

The algorithm also provides adjustment recommendations for special conditions such as emission control areas (ECA) or in-port operation, where lower emission requirements apply. Figure 12 and Figure 13 show the Adaptive Optimization Algorithm.

Figure 12.

Adaptive optimization chart–Optimal biodiesel ratio by engine load.

Figure 13.

Pareto multi-objective optimization by biodiesel ratio and engine load.

3.4.1. Analysis of Optimization Results

The adaptive optimization algorithm reveals distinct operational strategies for different maritime scenarios. Figure 12 demonstrates that optimal biodiesel ratios follow a non-linear relationship with engine load, with maximum biodiesel utilization (70–80%) recommended at low loads (10–25%), where emission benefits outweigh the slight fuel consumption penalty.

At medium loads (25–50%), the algorithm consistently recommends B40-B60 blends across all scenarios, indicating this range provides robust performance regardless of operational priorities. This finding supports the lifecycle assessment conclusion that B50 represents the optimal balance point.

The Pareto analysis in Figure 13 reveals three distinct optimization zones:

- Zone A (Low Load): High biodiesel ratios achievable with minimal performance impact

- Zone B (Medium Load): Balanced optimization with moderate biodiesel ratios

- Zone C (High Load): Conservative biodiesel ratios to maintain power output

3.4.2. Sensitivity Analysis Results

Figure 11 demonstrates that engine load exhibits the highest sensitivity coefficient (0.73) across all emission types, confirming its dominant influence identified in the regression analysis. Biodiesel ratio shows moderate sensitivity (0.34), while temperature effects remain minimal (0.12).

This sensitivity hierarchy validates the algorithm’s design philosophy: operational load management provides greater emission reduction potential than fuel switching alone. The algorithm, therefore, prioritizes load optimization recommendations alongside biodiesel ratio adjustment.

4. Discussion and Practical Implications

The experimental results reveal several critical insights for marine biodiesel implementation. The dominant influence of engine load on emissions (46–137% variation) compared to biodiesel ratio effects (5–13% variation) indicates that operational optimization should prioritize load management strategies alongside fuel selection. This finding has significant implications for vessel energy management systems, suggesting that voyage planning algorithms should incorporate emission optimization alongside traditional fuel consumption considerations. The non-linear CO emission pattern, with minimum values at 25% load, challenges conventional assumptions about load-emission relationships. This optimal operating point corresponds to the sweet spot where combustion temperature and mixing time achieve optimal balance, supporting the development of variable-speed operations for emission reduction.

Lifecycle assessment results demonstrate that the B50 biodiesel blend achieves optimal environmental performance, reducing global warming potential by 15% while maintaining acceptable levels of other environmental impacts. The 75% reduction in non-renewable energy consumption with B100 biodiesel, despite higher CO2 emissions during operation, highlights the importance of considering full lifecycle impacts rather than focusing solely on tailpipe emissions. The increased land use (0.57 m2a per kWh) and water consumption (3.9 L per kWh) associated with B100 biodiesel raise important questions about scalability and resource competition. These impacts must be weighed against the 15% reduction in global warming potential and the strategic value of reduced dependence on fossil fuels.

Implementation of variable biodiesel ratios requires consideration of practical constraints, including storage capacity, fuel handling systems, and crew training. Modern vessels could accommodate dual-tank systems with automated blending, but retrofitting older vessels presents greater challenges. The economic analysis suggests that B50 implementation could achieve cost neutrality within 3–5 years through reduced maintenance costs and potential carbon credit revenues. Bunkering infrastructure development represents a critical pathway dependency. Strategic port development focusing on B50 supply could accelerate adoption while minimizing infrastructure investment compared to full B100 capability.

The demonstrated emission reduction capabilities support targeted regulatory approaches. Emission Control Areas could mandate minimum biodiesel blend ratios, with higher requirements for port operations where air quality impacts are most significant. The adaptive optimization algorithm provides a framework for dynamic regulations that respond to operational conditions rather than applying static requirements. Carbon pricing mechanisms could significantly improve biodiesel economics. The economic analysis incorporates projected carbon pricing under the IMO’s proposed greenhouse gas fuel standard, with estimated levy rates of 100–200 USD per tonne CO2 equivalent by 2030, reflecting the latest regulatory developments and industry forecasts.

The research findings support integration with complementary emission reduction technologies. Selective Catalytic Reduction (SCR) systems could address the 5–13% increase in NOx emissions associated with biodiesel use, while exhaust gas recirculation (EGR) could optimize the combustion process for biodiesel blends. Advanced engine management systems incorporating the predictive models developed in this study could enable real-time optimization of biodiesel ratios based on operational conditions, weather, and regulatory requirements. Such systems represent the next generation of marine propulsion optimization.

This study focuses on steady-state operation and does not address transient conditions during maneuvering, acceleration, or adverse weather operations. Future research should investigate biodiesel performance during dynamic loading conditions typical of actual marine operations. Long-term durability studies extending beyond the current 500-h test duration are essential for understanding maintenance implications and component lifecycle impacts. Particular attention should be paid to fuel system components, injection equipment, and lubricating oil degradation patterns. The interaction between biodiesel use and emerging alternative fuels (ammonia, hydrogen, methanol) requires investigation as the maritime industry transitions toward decarbonization. Biodiesel may serve as a bridging technology during the transition period, requiring compatibility studies with future fuel systems.

This comprehensive study provides an integrated framework for optimizing biodiesel implementation in marine diesel engines through experimental validation, predictive modeling, and lifecycle assessment. The key findings and their implications include:

- -

- Engine load emerges as the dominant factor affecting emissions, with 46–137% variation compared to 5–13% variation from biodiesel ratio changes. This finding emphasizes the critical importance of operational optimization in emission reduction strategies. Biodiesel demonstrates mixed emission impacts: a 5–13% increase in NOx and a 3–4% increase in CO2 per 20% blend ratio increase, offset by a 7–10% reduction in CO emissions. These trade-offs require careful consideration in regulatory compliance strategies. The identification of optimal combustion conditions at 25% engine load for all biodiesel ratios provides a foundation for developing load-optimized operational procedures.

- -

- The B50 biodiesel blend achieves optimal environmental performance with a 15% reduction in global warming potential compared to conventional marine gas oil while maintaining acceptable levels of other environmental impacts. Lifecycle assessment reveals that the biodiesel production phase contributes 35–55% of the environmental impact for biodiesel versus 20–30% for conventional fuel, highlighting opportunities for supply chain optimization. The complete elimination of sulfur content in biodiesel supports compliance with IMO 2020 sulfur regulations without requiring additional exhaust after-treatment systems.

- -

- The adaptive optimization algorithm enables dynamic biodiesel ratio adjustment: 40–60% blend ratios for medium loads (25–50%), 20–30% for high loads (75–100%), and 70–80% for low loads (10%). Predictive models with R2 values of 0.89–0.94 provide reliable emission forecasting capabilities for voyage planning and regulatory compliance verification. Implementation strategies should prioritize B50 as the optimal balance point between environmental benefits and operational practicality.

5. Conclusions

This study establishes a comprehensive framework for marine biodiesel optimization through integrated experimental, modeling, and lifecycle assessment approaches. The research makes significant technical contributions to the maritime fuel optimization field, primarily through the development of high-accuracy predictive models with R2 values ranging from 0.89 to 0.94, which enable reliable operational emission forecasting for practical maritime applications. A critical finding is the identification of engine load as the primary emission driver, demonstrating 46–137% variation in emissions compared to only 5–13% variation from biodiesel ratio changes. This research also quantifies optimal combustion conditions occurring at 25% engine load across all biodiesel ratios, providing fundamental insights into marine diesel combustion dynamics.

From an environmental perspective, this study demonstrates that B50 biodiesel achieves a 15% global warming potential reduction while maintaining operational feasibility, establishing this blend ratio as environmentally superior to pure diesel without compromising engine performance. The comprehensive lifecycle assessment reveals significant production phase optimization opportunities, with this phase contributing 35–55% of biodiesel’s total environmental impact, indicating where future improvements should be focused. Additionally, the research validates biodiesel’s crucial role in achieving IMO 2020 sulfur compliance without requiring expensive exhaust after-treatment systems, offering a practical pathway for regulatory adherence.

The practical contributions of this research center on the development of an adaptive optimization algorithm that enables dynamic biodiesel ratio adjustment across three distinct operational scenarios, providing maritime operators with flexible, condition-responsive fuel management strategies. The study presents a clear implementation roadmap that prioritizes B50 as the optimal balance point for maritime biodiesel adoption, supported by comprehensive economic analysis demonstrating cost parity potential when carbon pricing exceeds $50 per tonne CO2. This economic framework provides decision-makers with quantitative justification for biodiesel investment decisions.

Future research directions should prioritize extended durability studies to assess long-term engine impacts under continuous biodiesel operation, integration with emerging emission control technologies such as selective catalytic reduction and exhaust gas recirculation systems, and investigation of second-generation biodiesel compatibility with the optimization framework developed in this study. These research areas will further enhance the practical applicability and environmental benefits of marine biodiesel implementation while addressing remaining technical uncertainties in long-term operational contexts.

Author Contributions

K.-S.J.: formal analysis, software, resources, data curation, writing—original draft preparation, data collected and analyzed visualization; K.-J.K.: formal analysis, software, resources, data curation, writing—original draft preparation, data collected and analyzed, visualization; S.-H.H.: supervision, project administration, writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by 2025 Ministry of Oceans and Fisheries (MOF) Marine Blue Tech Future Leader Training Project ’Training Blue Tech Leaders for Eco-Friendly Ships (No. RS-2025-02220459).

Data Availability Statement

Dataset available on request from the authors.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Fourth, I.M.O. Greenhouse Gas Study; International Maritime Organization: London, UK, 2020. [Google Scholar]

- Choi, J.-H.; Cho, S.-G. Effect on Characteristics of Combustion by changing in Biofuel Temperature and Ratio of Bio injection Diesel Fuel. J. Power Syst. Eng. 2020, 24, 43–50. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change. Climate Change 2014: Synthesis Report; IPCC: Geneva, Switzerland, 2015. [Google Scholar]

- IMO. Initial IMO Strategy on Reduction of GHG Emissions from Ships. Resolut. MEPC 2018, 4, 304. [Google Scholar]

- Hansson, S. The impact of the IMO 2020 sulphur regulations on the shipping industry. Marit. Bus. Rev. 2020, 5, 150–168. [Google Scholar]

- Park, Y.H.; Chung, S.Y.; Son, Y.; Lee, W.K. Investigation on Enhancing Efficiency in International Cooperation for Climate Change Adaptation of Republic of Korea. J. Clim. Change Res. 2010, 1, 179–188. [Google Scholar]

- Yang, S.C.; Moon, C.J.; Chang, Y.H.; Soh, S.Y.; Chung, J.H.; Kim, E.S. Internet Monitoring of Wind-photovoltaic Hybrid Generation System. J. Korean Inst. Illum. Electr. Install. Eng. 2006, 20, 43–48. [Google Scholar]

- Goldsworthy, M. Spatial and temporal allocation of ship exhaust emissions in Australian coastal waters using AIS data: Analysis and treatment of data gaps. Atmos. Environ. 2017, 163, 77–86. [Google Scholar] [CrossRef]

- Smith, T.W.; Jalkanen, J.P.; Anderson, B.A.; Corbett, J.J.; Faber, J.; Hanayama, S.; O’Keeffe, E.; Parker, S.; Johansson, L.; Aldous, L.; et al. Third IMO GHG Study 2014; International Maritime Organization: London, UK, 2014. [Google Scholar]

- Park, J.W.; Shin, U.; Kim, D.G.; Yoon, J.H. A Study on Generation Characteristic of Building Integrated Photovoltaic System. J. Korean Sol. Energy Soc. 2013, 33, 75–81. [Google Scholar] [CrossRef]

- Park, K.H.; Kim, J.Y.; Kim, C.J.; Ko, J.H.; Park, H.I. The Effect of Bio-Diesel Fuel on Industrial Diesel Engine. J. Korean Soc. Mar. Eng. 2012, 36, 72–77. [Google Scholar] [CrossRef][Green Version]

- Abed, K.A.; El Morsi, A.K.; Sayed, M.M.; El Shaib, A.A.; Gad, M.S. Effect of waste cooking-oil biodiesel on performance and exhaust emissions of a diesel engine. Egypt. J. Pet. 2018, 27, 985–989. [Google Scholar] [CrossRef]

- Kim, J.K.; Ainll, G.; Song, K.K.; Jung, J.Y.; Kim, H.G. An Experimental Study on Spray Characteristics of Diesel and Bio-diesel Fuel. J. Korean Soc. Mar. Eng. 2011, 35, 53–59. [Google Scholar]

- Lapuerta, M.; Armas, O.; Rodríguez-Fernández, J. Effect of biodiesel fuels on diesel engine emissions. Prog. Energy Combust. Sci. 2008, 34, 198–223. [Google Scholar] [CrossRef]

- Kim, D.Y.; Cho, I.E.; Lee, S.W.; Oh, S.I. A Study on Spray and Combustion Characteristics Affected by Temperature of Bio-diesel Fuel. J. Korea Soc. Automot. Eng. 2007, 07-S0082, 533–538. [Google Scholar]

- Choi, J.H.; Cho, S.G. A Study on the Characteristics of Exhaust Gas Emission by Changing in Biofuel Ratio and Bifuel Temperature in Diesel Engine. J. Power Syst. Eng. 2020, 24, 94–102. [Google Scholar] [CrossRef]

- Cho, S.G. An Experimental Study on Combustion Characteristics of Biodiesel Fuel in Marine Diesel Engine. J. Korean Soc. Power Syst. Eng. 2015, 19, 29–35. [Google Scholar] [CrossRef]

- Johnson, M.; Samad, N.; D’Souza, B. Emissions characteristics of alternative marine fuels: A comparative analysis. J. Mar. Eng. Technol. 2019, 18, 342–353. [Google Scholar]

- Zhang, L.; Peterson, C. Biodiesel effects on engine combustion processes and emission characteristics. Bioresour. Technol. 2018, 197, 320–330. [Google Scholar]

- Jang, S.H. Combustion Characteristics of Biodiesel Fuel as an Alternative Fuel for a D.I. Diesel Engine. J. Korean Soc. Power Syst. Eng. 2009, 2, 54–59. [Google Scholar]

- Wilson, T.; Tyedmers, P. Life cycle assessment of biodiesel from marine sources in comparative context. Renew. Sustain. Energy Rev. 2017, 65, 196–203. [Google Scholar]

- Kumar, A.; Singh, R.K.; Patel, M.N. Advanced biodiesel blend optimization for marine applications: Performance and emission characteristics of second-generation biofuels. Mar. Pollut. Bull. 2023, 187, 114523. [Google Scholar]

- Chen, L.; Wang, H. Neural network-based prediction models for biodiesel performance in marine diesel engines: A machine learning approach. Appl. Energy 2023, 342, 121156. [Google Scholar]

- Gonzalez, M.A.; Rodriguez, P.J.; Silva, C.R. Long-term durability assessment of marine diesel engines operating with biodiesel blends: Component wear analysis and maintenance implications. Fuel 2023, 338, 127289. [Google Scholar]

- Andersen, K.T.; Eriksson, L.M. Economic viability of biodiesel implementation in maritime transportation: Cost-benefit analysis under emerging carbon pricing scenarios. Transp. Res. Part D Transp. Environ. 2023, 115, 103589. [Google Scholar]

- Thompson, S.D.; Williams, J.A.; Brown, K.L. Regulatory compliance strategies for IMO 2030 emissions targets: Analysis of alternative fuel pathways and implementation timelines. Mar. Policy 2023, 147, 105364. [Google Scholar]

- Thomson, H.; Corbett, J.J.; Winebrake, J.J. Natural gas as a marine fuel. Energy Policy 2015, 87, 153–167. [Google Scholar] [CrossRef]

- Robinson, A.; Williams, K. Comparative analysis of marine diesel performance with alternative fuels. Int. J. Mar. Eng. 2020, 28, 141–152. [Google Scholar]

- Achten, W.M.J.; Verchot, L.; Franken, Y.J.; Mathijs, E.; Singh, V.P.; Aerts, R.; Muys, B. Jatropha bio-diesel production and use. Biomass Bioenergy 2008, 32, 1063–1084. [Google Scholar] [CrossRef]

- Mohammadi, R.; Verbeek, M.A.; Heeres, H.J.; Pathak, P.D. Waste cooking oil: A feedstock for biodiesel and life cycle assessment. Waste Manag. 2019, 95, 240–251. [Google Scholar]

- Heo, J.W.; Choi, Y.H.; Kim, S.H.; Lee, S.H.; Choi, H.Y.; Yu, D.I.; Lee, Y.W. Predicting heat transfer performance in a complex heat exchanger for LNG FGSS development. J. Adv. Mar. Eng. Technol. 2023, 47, 52–58. [Google Scholar] [CrossRef]

- Lim, S.; Lee, H.; Yoon, J.; Kim, H. Performance evaluation of Ocean Thermal Energy Conversion (OTEC) stabilization based on risk analysis. J. Adv. Mar. Eng. Technol. 2023, 47, 1–11. [Google Scholar] [CrossRef]

- Chybowski, L.; Szczepanek, M.; Kuczyński, W.; Michalska-Pożoga, I.; Pusty, T.; Brożek, P.; Pełech, R. Content of Selected Compounds in the Exhaust Gas of a Naturally Aspirated CI Engine Fueled with Diesel–Tire Pyrolysis Oil Blend. Energies 2025, 18, 2621. [Google Scholar] [CrossRef]

- Jo, K.-S.; Han, S.-H.; Kim, M.-J. Analysis of Exhaust Gas Characteristics According to Load of 2.4 MW Class 4-stroke Main Engine (Centered on the Fishing Training Ship Saebada). J. Power Syst. Eng. 2021, 25, 69–78. [Google Scholar] [CrossRef]

- Jo, K.-S.; Choi, Y.-J.; Han, S.-H. Analysis of Exhaust Gas Characteristics by Load of Marine Diesel Engine Using Bio Diesel. J. Power Syst. Eng. 2022, 26, 14–22. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).