A Quick Method for Appraising Pore Connectivity and Ultimate Imbibed Porosity in Shale Reservoirs

Abstract

1. Introduction

2. Sample Background, Experimental Methods, and Theory Preparation

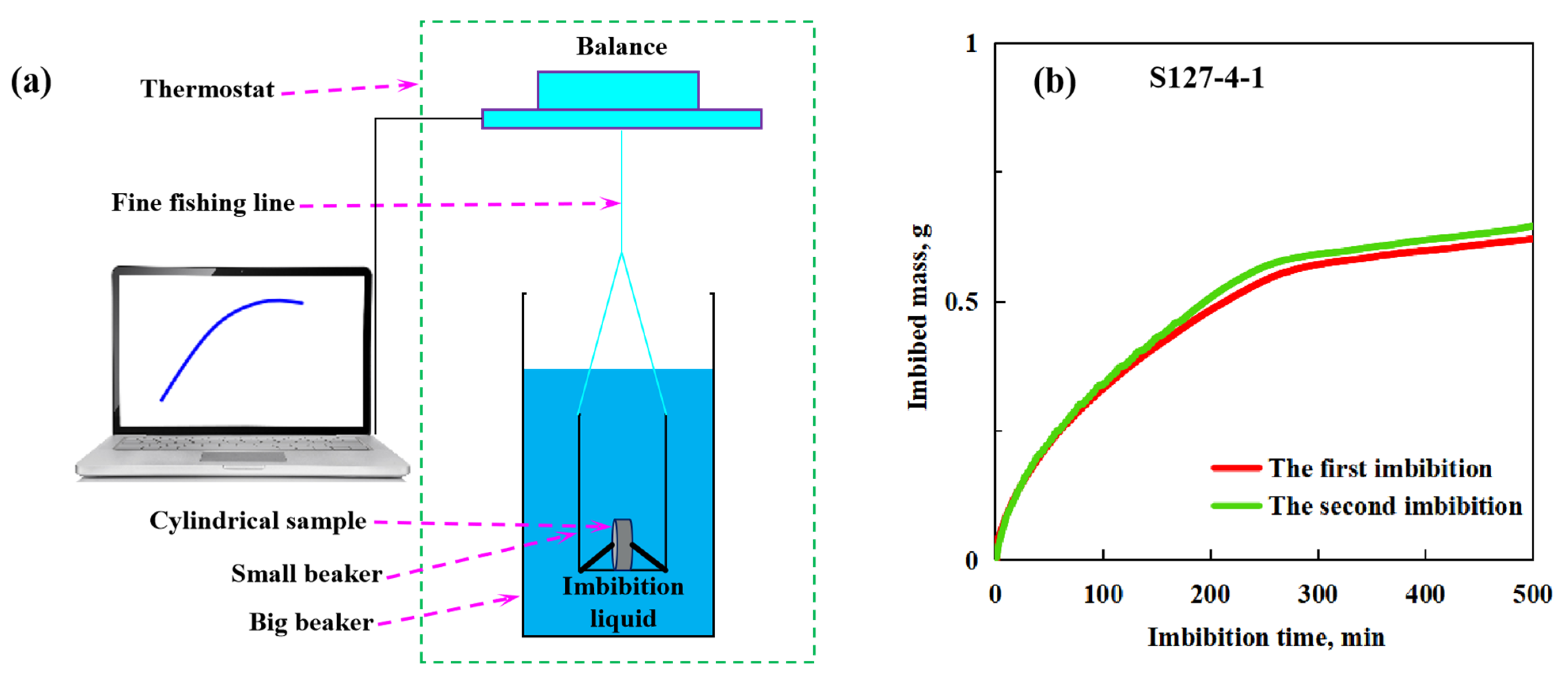

2.1. Sample Background and Experimental Methods

2.2. Theory Preparation

3. Results and Discussion

3.1. Basic Properties and Material Components

3.2. SEM Analysis

3.3. Changes in the Imbibition Curves with Sample Thickness

3.4. The Imbibition Curves of the Offshore Shale Samples

3.5. The Distribution of the Three Parameters

4. Conclusions

- (1)

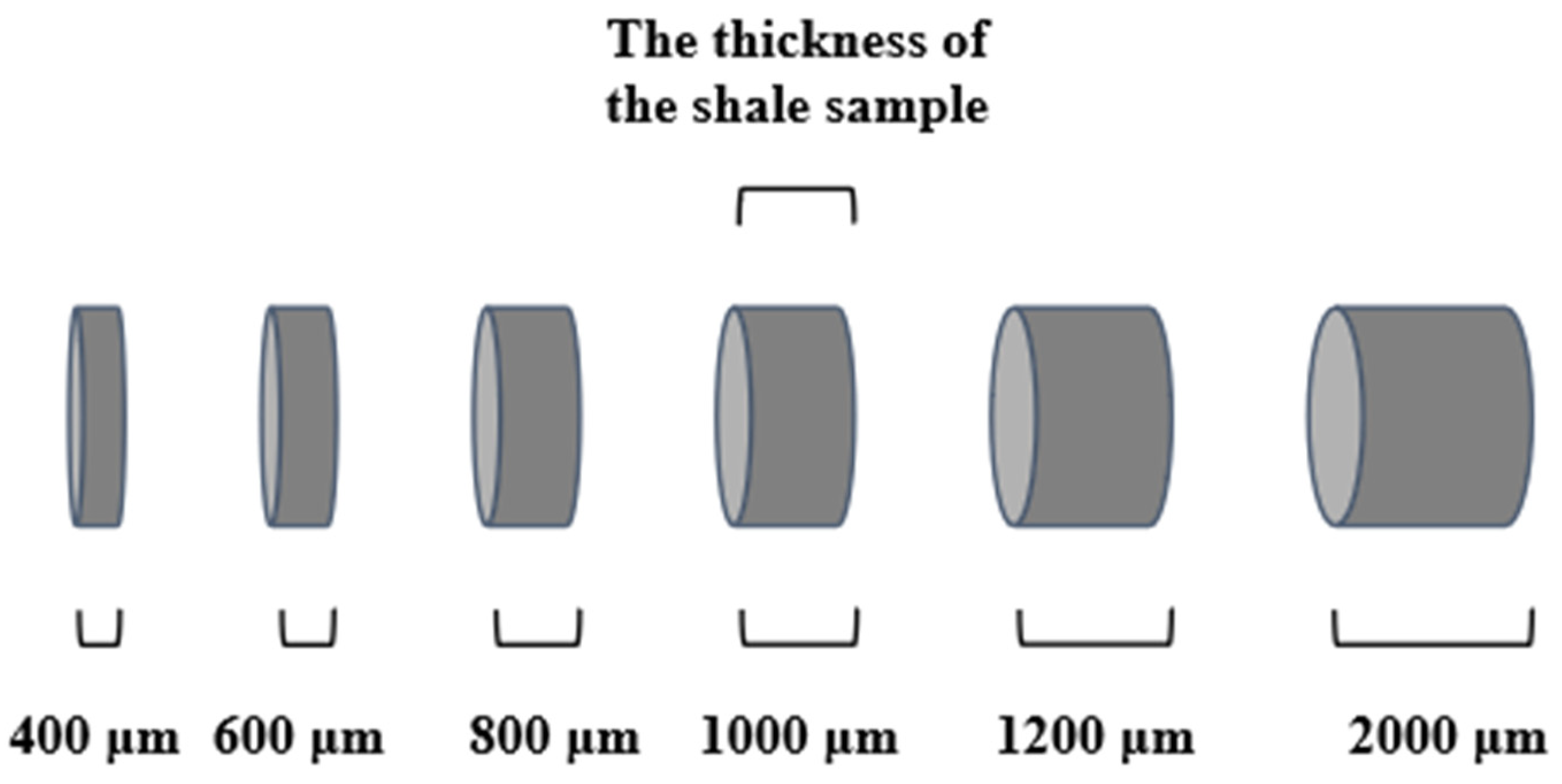

- A quick method was established to measure the pore connectivity and ultimate imbibed porosity of shale by using spontaneous imbibition with thin samples. Within the time of a day, the imbibition results of 400 μm samples can be acquired.

- (2)

- The three parameters change with sample thicknesses. For sample D86-5, the average pore connectivity is 0.265 and the penetration depth is large, so water enters all connected pores, resulting in a stable ultimate imbibed porosity of around 3.7%. And the stable time increases with the addition of thicknesses. For sample Y172, when the thickness increases, the average pore connectivity is 0.026 and the penetration depth is much smaller with inaccessible pores, so the ultimate imbibed porosity declines with increasing thickness from 3.1% to 0.8%. The stable time of Y172 increases with the thickness from 460 μm to 680 μm before fluctuating around 1211 min, so the penetration depth of Y172 is between 230 μm and 340 μm.

- (3)

- Comparing the samples around 400 μm, the sample from the Qingshankou Fm has the smallest stable time and the largest pore connectivity, but the ultimate imbibed porosity is only 3.7%. The sample from the Shahejie Fm has a longer stable time and the smallest ultimate imbibed porosity and pore connectivity. The samples from the Liushagang Fm have the longest stable time and ultimate imbibed porosity and an average pore connectivity of 0.097.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Marchionna, M. Fossil energy: From conventional oil and gas to the shale revolution. EPJ Web Conf. 2018, 189, 00004. [Google Scholar] [CrossRef][Green Version]

- National Energy Administration. China’s Oil and Gas Industry Analysis and Outlook Series Blue Book. 2024. Available online: http://www.nea.gov.cn/2024-04/26/c_1310772762.htm (accessed on 26 April 2024).

- Loucks, R.; Reed, R.; Ruppel, S.; Hammes, U. Spectrum of pore types and networks in mudrocks and a descriptive classification for matrix related pores. AAPG Bull. 2012, 96, 1071–1098. [Google Scholar] [CrossRef]

- Chen, Y.; Jiang, C.; Leung, J.Y.; Wojtanowicz, A.K.; Zhang, D. Multiscale characterization of shale pore-fracture system: Geological controls on gas transport and pore size classification in shale reservoirs. J. Pet. Sci. Eng. 2021, 202, 108442. [Google Scholar] [CrossRef]

- Zhang, P.F.; Lu, S.F.; Li, J.Q.; Chang, X.C.; Zhang, J.J.; Pang, Y.M.; Lin, Z.Z.; Chen, G.; Yin, Y.J.; Liu, Y.Q. Quantitative characterization of shale pore connectivity and controlling factors using spontaneous imbibition combined with nuclear magnetic resonance T2 and T1-T2. Pet. Sci. 2023, 20, 1947–1960. [Google Scholar] [CrossRef]

- Ji, W.; Hao, F.; Gong, F.; Zhang, J.; Bai, Y.; Liang, C.; Tian, J. Petroleum migration and accumulation in a shale oil system of the Upper Cretaceous Qingshankou Formation in the Songliao Basin, northeastern China. AAPG Bull. 2024, 108, 1611–1648. [Google Scholar] [CrossRef]

- Jia, C.; Xiao, B.; Lijun, Y.; Yang, Z.; Yili, K. Experimental study of water imbibition characteristics of the lacustrine shale in Sichuan Basin. Petroleum 2023, 9, 572–578. [Google Scholar] [CrossRef]

- Wei, J.; Zhang, A.; Jiangtao, L.; Demiao, S.; Xiaofeng, Z. Study on microscale pore structure and bedding fracture characteristics of shale oil reservoir. Energy 2023, 278, 127829. [Google Scholar] [CrossRef]

- Yuan, Y.; Rezaee, R.; Mei-Fu, Z.; Stefan, I. A comprehensive review on shale studies with emphasis on nuclear magnetic resonance (NMR) technique. Gas Sci. Eng. 2023, 120, 205163. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Z.; Zhengchen, Z.; Shanshan, Y.; Hong, Z.; Guoqing, Z.; Feifei, L.; Lele, F.; Kouqi, L.; Liangliang, J. Recent techniques on analyses and characterizations of shale gas and oil reservoir. Energy Rev. 2024, 3, 100067. [Google Scholar] [CrossRef]

- Zhang, J.; Xiao, X.; Jianguo, W.; Wei, L.; Denglin, H.; Chenchen, W.; Yu, L.; Yan, X.; Xiaochan, Z. Pore structure and fractal characteristics of coal-bearing Cretaceous Nenjiang shales from Songliao Basin, Northeast China. J. Nat. Gas. Geosci. 2024, 9, 197–208. [Google Scholar] [CrossRef]

- Yasin, Q.; Liu, B.; Mengdi, S.; Ghulam Mohyuddin, S.; Atif, I.; Mariusz, M.; Naser, G.; Yan, M.; Xiaofei, F. Automatic pore structure analysis in organic-rich shale using FIB-SEM and attention U-Net. Fuel 2024, 358, 130161. [Google Scholar] [CrossRef]

- Norman, R.M.; Geoffrey, M. Recovery of oil by spontaneous imbibition. Curr. Opin. Colloid. Interface Sci. 2001, 6, 321–337. [Google Scholar] [CrossRef]

- Ding, Y.; Liu, X.; Liang, L.; Xiong, J.; Hou, L. Experimental and model analysis on shale spontaneous imbibition and its influence factors. J. Nat. Gas Sci. Eng. 2022, 99, 104462. [Google Scholar] [CrossRef]

- Meng, M.; Ge, H.; Yinghao, S.; Qinhong, H.; Longlong, L.; Zhiye, G.; Tonghui, T.; Jing, C. The effect of clay-swelling induced cracks on imbibition behavior of marine shale reservoirs. J. Nat. Gas. Sci. Eng. 2020, 83, 103525. [Google Scholar] [CrossRef]

- Meng, M.; Ge, H.; Yinghao, S.; Fei, R.; Wenming, J. A novel method for monitoring the imbibition behavior of clay-rich shale. Energy Rep. 2020, 6, 1811–1818. [Google Scholar] [CrossRef]

- Hu, J.; Zhao, H.; Du, X.; Zhang, Y. An analytical model for shut-in time optimization after hydraulic fracturing in shale oil reservoirs with imbibition experiments. J. Pet. Sci. Eng. 2022, 210, 110055. [Google Scholar] [CrossRef]

- Lan, Q.; Xu, M.; Binazadeh, M.; Dehghanpour, H.; Wood, J.M. A comparative investigation of shale wettability: The significance of pore connectivity. J. Nat. Gas Sci. Eng. 2015, 27, 1174–1188. [Google Scholar] [CrossRef]

- Vasheghani Farahani, M.; Mousavi Nezhad, M. On the effect of flow regime and pore structure on the flow signatures in porous media. Phys. Fluids 2022, 34, 115139. [Google Scholar] [CrossRef]

- Cheng, Z.; Tong, S.; Shang, X.; Yu, J.; Li, X.; Dou, L. Lattice Boltzmann simulation of counter-current imbibition of oil and water in porous media at the equivalent capillarity. AIP Adv. 2024, 14, 085314. [Google Scholar] [CrossRef]

- Alvarado, V.; Manrique, E. Chapter 2—Enhanced Oil Recovery Concepts. In Enhanced Oil Recovery; Alvarado, V., Manrique, E., Eds.; Gulf Professional Publishing: Boston, MA, USA, 2010; pp. 7–16. [Google Scholar]

- Yuan, S.; Han, H.; Wang, H.; Luo, J.; Wang, Q.; Lei, Z.; Xi, C.; Li, J. Research progress and potential of new enhanced oil recovery methods in oilfield development. Pet. Explor. Dev. 2024, 51, 963–980. [Google Scholar] [CrossRef]

- Valluri, S.; Claremboux, V.; Kawatra, S. Opportunities and challenges in CO2 utilization. J. Environ. Sci. 2022, 113, 322–344. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Z.; Ning, Z.; Yu, X.; Wang, Q.; Zhang, W. New insights into spontaneous imbibition in tight oil sandstones with NMR. J. Pet. Sci. Eng. 2019, 179, 455–464. [Google Scholar] [CrossRef]

- Hamid, S.; Syed Mohammad, M.; Reza, R.; Ali, S. Conventional methods for wettability determination of shales: A comprehensive review of challenges, lessons learned, and way forward. Mar. Pet. Geol. 2021, 133, 105288. [Google Scholar] [CrossRef]

- Lin, Z.; Hu, Q.; Na, Y.; Shengyu, Y.; Huimin, L.; Jing, C. Nanopores-to-microfractures flow mechanism and remaining distribution of shale oil during dynamic water spontaneous imbibition studied by NMR. Geoenergy Sci. Eng. 2024, 241, 213202. [Google Scholar] [CrossRef]

- Wang, X.; Wang, M.; Li, Y.; Zhang, J.; Li, M.; Li, Z.; Guo, Z.; Li, J. Shale pore connectivity and influencing factors based on spontaneous imbibition combined with a nuclear magnetic resonance experiment. Mar. Pet. Geol. 2021, 132, 105239. [Google Scholar] [CrossRef]

- Liu, Z.; Bai, B.; Wang, Y.; Qu, H.; Xiao, Q.; Zeng, S. Spontaneous imbibition characteristics of slickwater and its components in Longmaxi shale. J. Pet. Sci. Eng. 2021, 202, 108599. [Google Scholar] [CrossRef]

- Liu, J.; Sheng, J.J. Experimental investigation of surfactant enhanced spontaneous imbibition in Chinese shale oil reservoirs using NMR tests. J. Ind. Eng. Chem. 2019, 72, 414–422. [Google Scholar] [CrossRef]

- Sun, M.; Yu, B.; Qinhong, H.; Rui, Y.; Yifan, Z.; Bo, L. Pore connectivity and tracer migration of typical shales in south China. Fuel 2017, 203, 32–46. [Google Scholar] [CrossRef]

- Lin, M.; Xi, K.; Cao, Y.; Liu, Q.; Zhang, Z.; Li, K. Petrographic features and diagenetic alteration in the shale strata of the Permian Lucaogou Formation, Jimusar sag, Junggar Basin. J. Pet. Sci. Eng. 2021, 203, 108684. [Google Scholar] [CrossRef]

- Wang, W.; Xie, Q.; Li, J.; Sheng, G.; Lun, Z. Fracturing fluid imbibition impact on gas-water two phase flow in shale fracture-matrix system. Nat. Gas Ind. B 2023, 10, 323–332. [Google Scholar] [CrossRef]

- Yang, R.; Hu, Q.; Yi, J.; Zhang, B.; He, S.; Guo, X.; Hou, Y.; Dong, T. The effects of mineral composition, TOC content and pore structure on spontaneous imbibition in Lower Jurassic Dongyuemiao shale reservoirs. Mar. Pet. Geol. 2019, 109, 268–278. [Google Scholar] [CrossRef]

- Yang, R.; Hu, Q.; Sheng, H.; Fang, H.; Xusheng, G.; Jizheng, Y.; Xipeng, H. Pore structure, wettability and tracer migration in four leading shale formations in the Middle Yangtze Platform, China. Mar. Pet. Geol. 2018, 89, 415–427. [Google Scholar] [CrossRef]

- Davudov, D.; Moghanloo, R.G.; Zhang, Y. Interplay between pore connectivity and permeability in shale sample. Int. J. Coal Geol. 2020, 220, 103427. [Google Scholar] [CrossRef]

- Yang, J.; Yang, B.; Liang, W.; Junliang, P.; Yunhui, F.; Yun, T. Invasion depths of fracturing fluid imbibition displacement in matrix pores of Da’an Zhai shale oil reservoirs in central Sichuan Basin. Pet. Geol. Recovery Effic. 2023, 30, 84–91. [Google Scholar]

- Ye, Y.; Tang, S.; Zhaodong, X.; Dexin, J.; Yang, D. Quartz types in the Wufeng-Longmaxi Formations in southern China: Implications for porosity evolution and shale brittleness. Mar. Pet. Geol. 2022, 137, 105479. [Google Scholar] [CrossRef]

- Tuzingila, R.M.; Kong, L.; Kasongo, R.K. A review on experimental techniques and their applications in the effects of mineral content on geomechanical properties of reservoir shale rock. Rock Mech. Bull. 2024, 3, 100110. [Google Scholar] [CrossRef]

- Xiao, D.; Zheng, L.; Jilin, X.; Min, W.; Rui, W.; Xiaodie, G.; Xueyi, G. Coupling control of organic and inorganic rock components on porosity and pore structure of lacustrine shale with medium maturity: A case study of the Qingshankou Formation in the southern Songliao Basin. Mar. Pet. Geol. 2024, 164, 106844. [Google Scholar] [CrossRef]

- Liu, B.; Mastalerz, M.; Schieber, J. SEM petrography of dispersed organic matter in black shales: A review. Earth-Sci. Rev. 2022, 224, 103874. [Google Scholar] [CrossRef]

- Wang, Q.; Li, Y.; Utley, J.E.P.; Gardner, J.; Liu, B.; Hu, J.; Shao, L.; Wang, X.; Gao, F.; Liu, D.; et al. Terrestrial dominance of organic carbon in an Early Cretaceous syn-rift lake and its correlation with depositional sequences and paleoclimate. Sediment. Geol. 2023, 455, 106472. [Google Scholar] [CrossRef]

- Meng, M.; Ge, H.; Shen, Y.; Ji, W. Evaluation of the Pore Structure Variation During Hydraulic Fracturing in Marine Shale Reservoirs. J. Energy Resour. Technol. 2020, 143, 083002. [Google Scholar] [CrossRef]

- Washburn, E.W. The Dynamics of Capillary Flow. Phys. Rev. 1921, 17, 273–283. [Google Scholar] [CrossRef]

- Handy, L.L. Determination of Effective Capillary Pressures for Porous Media from Imbibition Data. Trans. AIME 1960, 219, 75–80. [Google Scholar] [CrossRef]

- Hu, Q.; Ewing, R.P.; Dultz, S. Low pore connectivity in natural rock. J. Contam. Hydrol. 2012, 133, 76–83. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Y.; Liao, Y.; Wang, J.; Xiong, Y.; Wang, Y.; Peng, P.a. Factors controlling the heterogeneity of shale pore structure and shale gas production of the Wufeng–Longmaxi shales in the Dingshan plunging anticline of the Sichuan Basin, China. Int. J. Coal Geol. 2024, 282, 104434. [Google Scholar] [CrossRef]

- Hao, L.; Qing, L.; Yue, D.; Wu, Y.; Gao, J.; Wu, S.; Wang, W.; Li, M.; An, K. Quantitative characterization and formation mechanism of the pore system heterogeneity: Examples from organic-rich laminated and organic-poor layered shales of the upper triassic chang 7 member in the southern Ordos Basin, China. Mar. Pet. Geol. 2023, 147, 105999. [Google Scholar] [CrossRef]

- Ge, H.-K.; Yang, L.; Shen, Y.-H.; Ren, K.; Meng, F.-B.; Ji, W.-M.; Wu, S. Experimental investigation of shale imbibition capacity and the factors influencing loss of hydraulic fracturing fluids. Pet. Sci. 2015, 12, 636–650. [Google Scholar] [CrossRef]

| Thickness, mm | Buoyant Sample Volume, cm3 | |

|---|---|---|

| D86-5 | 0.45 | 0.2022 |

| 0.64 | 0.2965 | |

| 0.75 | 0.3605 | |

| 1.1 | 0.5251 | |

| 1.27 | 0.6353 | |

| 1.94 | 0.9492 | |

| Y172 | 0.46 | 0.2067 |

| 0.68 | 0.313 | |

| 0.84 | 0.4171 | |

| 1.07 | 0.5226 | |

| 1.14 | 0.5436 | |

| BW1-1 | 0.44 | 0.0621 |

| BW1-2 | 0.40 | 0.0591 |

| BW1-3 | 0.41 | 0.042 |

| Samples | Quartz, % | Feldspar, % | Calcite, % | Ankerite, % | Siderite, % | Pyrite, % | Clay, % | TOC, % | Formation | Depth, m |

|---|---|---|---|---|---|---|---|---|---|---|

| D86-5 | 22.2 | 13.7 | 1.1 | / | 6.5 | 2.9 | 46.8 | 2.2 | Qingshankou | 1957.6 |

| Y172 | 21.5 | 1.9 | 27.4 | 20.6 | / | 3.9 | 24.7 | 3.0 | Shahejie | 3530.0 |

| BW1-1 | 18.3 | 1.3 | 32.6 | 10.4 | 3.4 | 5.6 | 28.4 | 2.7 | Liushagang | 3556.5 |

| BW1-2 | 37.1 | 1.7 | 6.8 | 5.1 | 0.8 | 9.7 | 38.8 | 5.8 | Liushagang | 3557.8 |

| BW1-3 | 32.5 | 0.9 | 0.2 | / | 3.1 | 6.8 | 56.5 | 3.9 | Liushagang | 3561.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hong, Z.; Meng, M.; Deng, K.; Bao, J.; Wang, Q.; Liu, X. A Quick Method for Appraising Pore Connectivity and Ultimate Imbibed Porosity in Shale Reservoirs. J. Mar. Sci. Eng. 2025, 13, 174. https://doi.org/10.3390/jmse13010174

Hong Z, Meng M, Deng K, Bao J, Wang Q, Liu X. A Quick Method for Appraising Pore Connectivity and Ultimate Imbibed Porosity in Shale Reservoirs. Journal of Marine Science and Engineering. 2025; 13(1):174. https://doi.org/10.3390/jmse13010174

Chicago/Turabian StyleHong, Ziqing, Mianmo Meng, Kong Deng, Jingwen Bao, Qianyou Wang, and Xingchen Liu. 2025. "A Quick Method for Appraising Pore Connectivity and Ultimate Imbibed Porosity in Shale Reservoirs" Journal of Marine Science and Engineering 13, no. 1: 174. https://doi.org/10.3390/jmse13010174

APA StyleHong, Z., Meng, M., Deng, K., Bao, J., Wang, Q., & Liu, X. (2025). A Quick Method for Appraising Pore Connectivity and Ultimate Imbibed Porosity in Shale Reservoirs. Journal of Marine Science and Engineering, 13(1), 174. https://doi.org/10.3390/jmse13010174