The Impact of Container Ship Trim on Fuel Consumption and Navigation Safety

Abstract

1. Introduction

- Stability: Improves the stability of the ship and reduces the risk of overturning or rolling due to sea conditions.

- Efficiency: It reduces the water resistance, which leads to less fuel consumption.

- Safety: Properly distributed cargo reduces the risk of shifting cargo during navigation, which can cause accidents.

- Maneuverability: It facilitates ship management, especially at lower speeds and in confined spaces such as ports.

2. Materials and Methods

- -

- Maximum accepted sea state on the Douglas scale up to condition 4;

- -

- Maximum accepted true wind on the Beaufort scale up to condition 5.

- -

- Metacentric height above 1 m;

- -

- Bending moments and shear forces less than 98;

- -

- Torsion moments less than 95%.

- -

- Propeller immersion over 110%;

- -

- Minimum UKC 70 m.

Calculation of Parameters Relevant to the Research

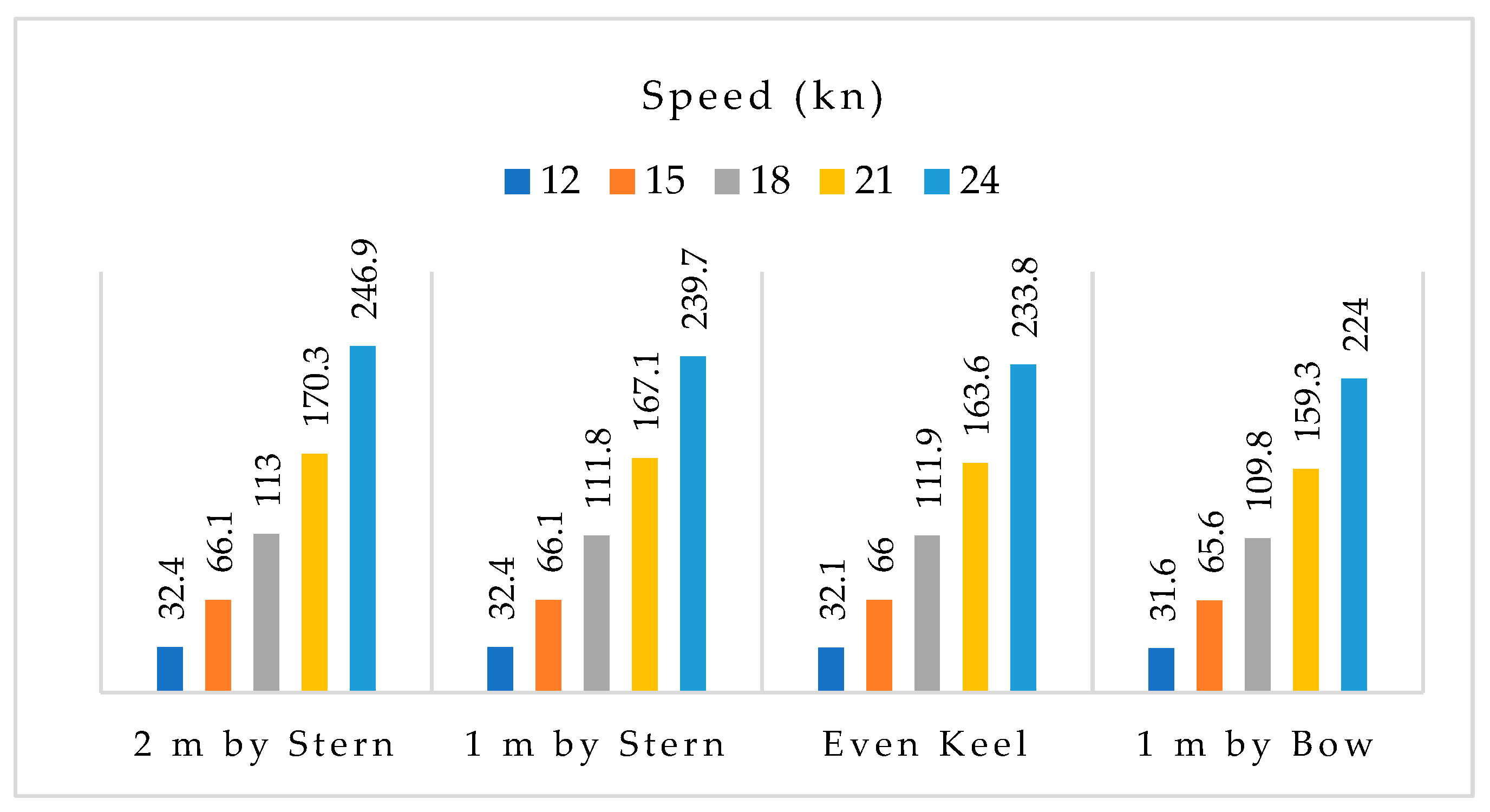

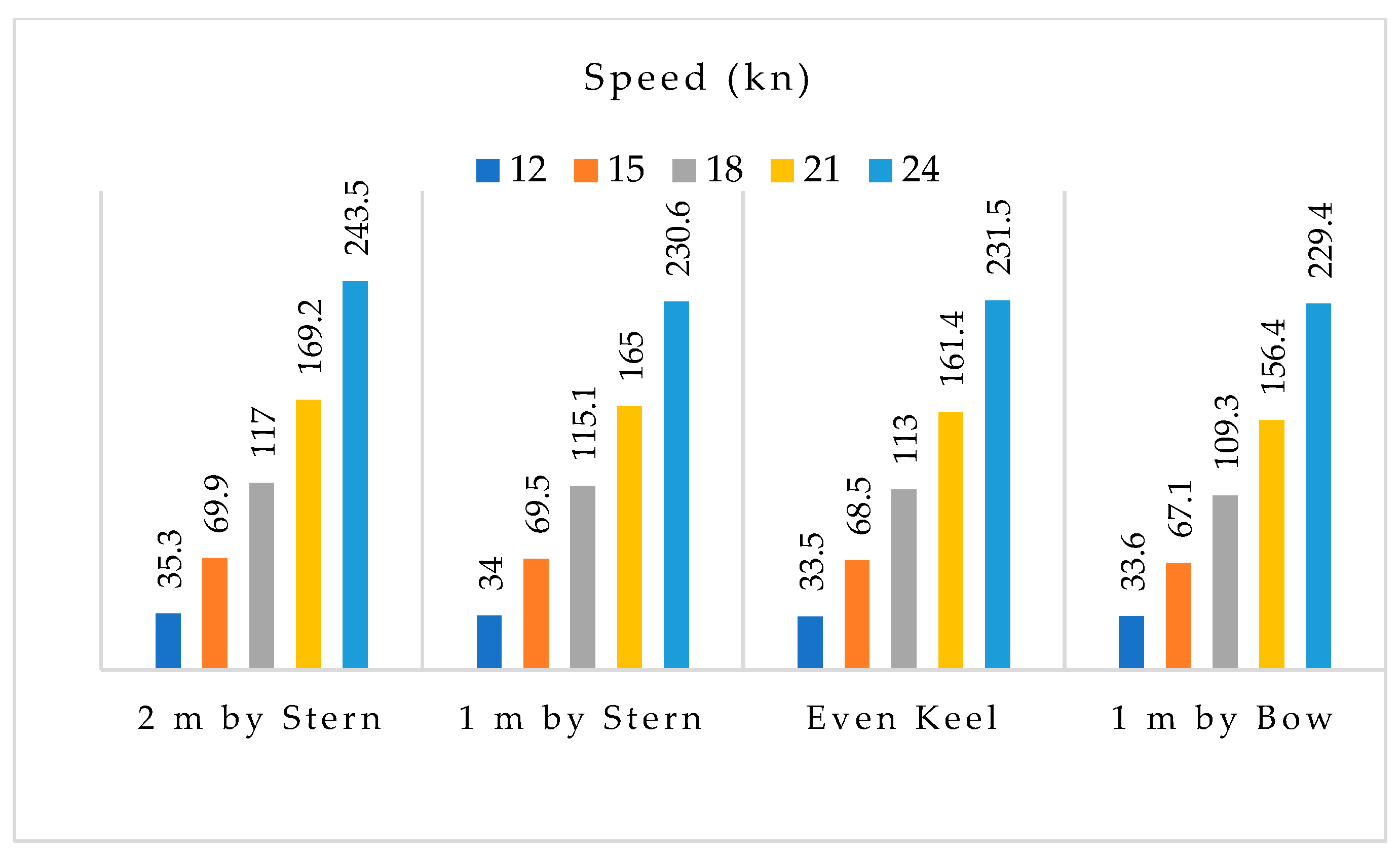

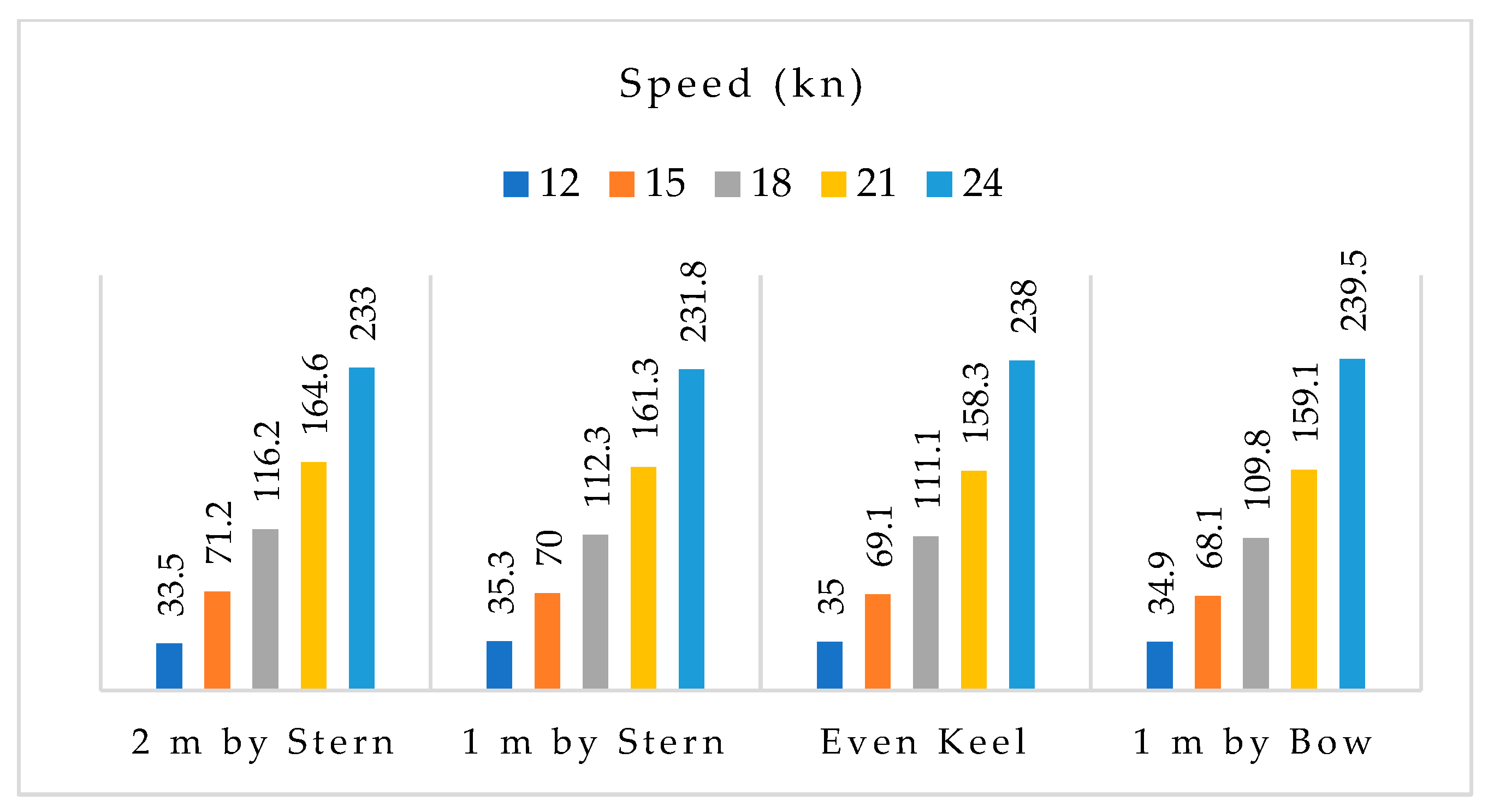

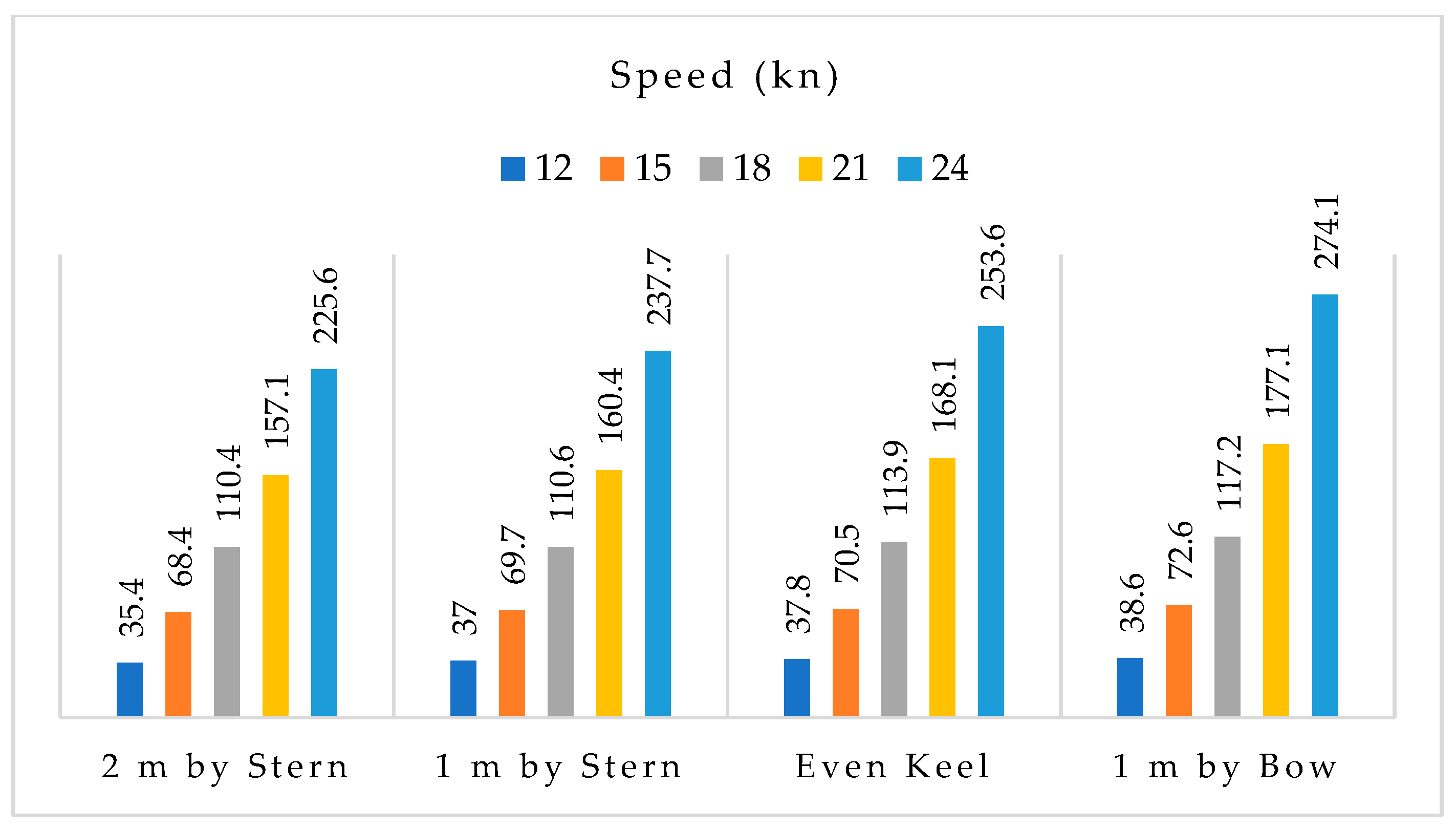

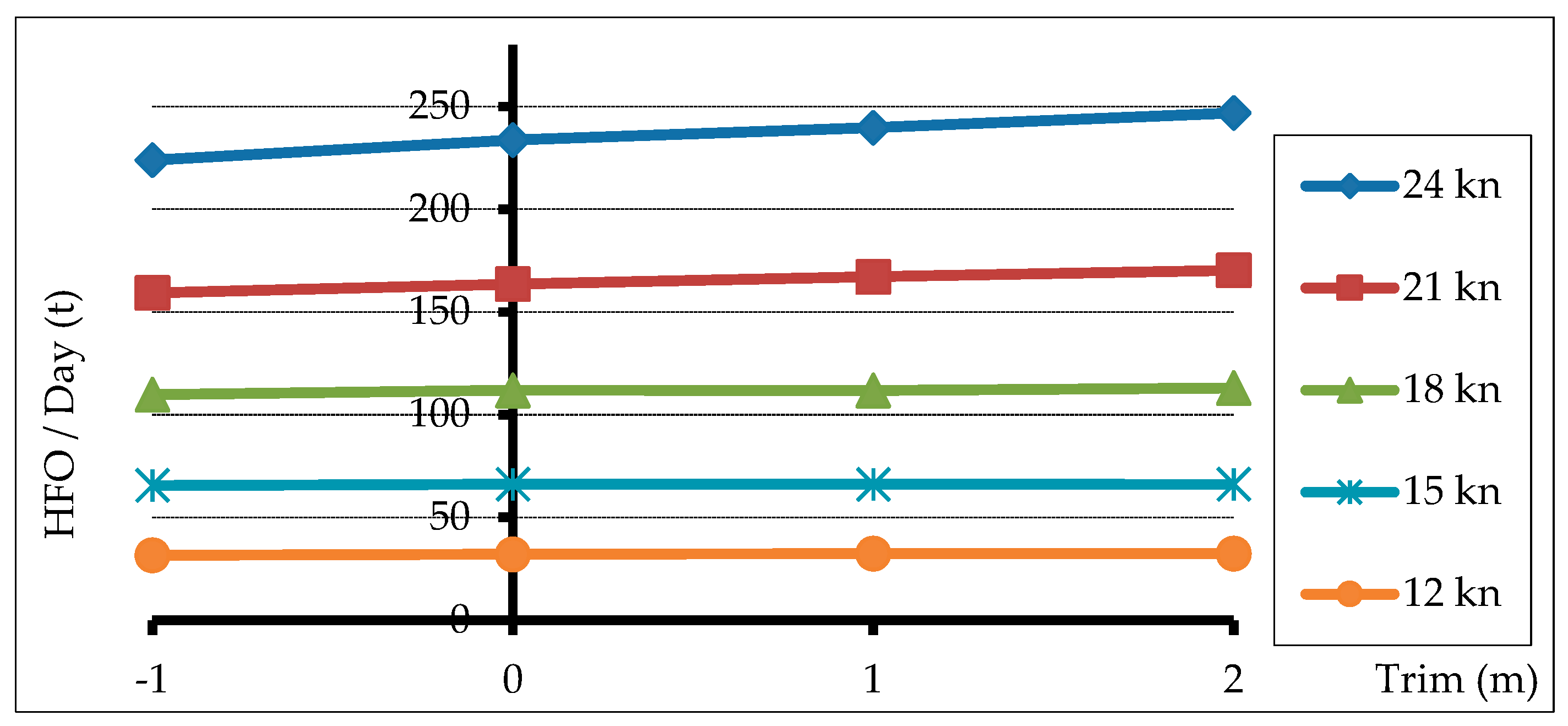

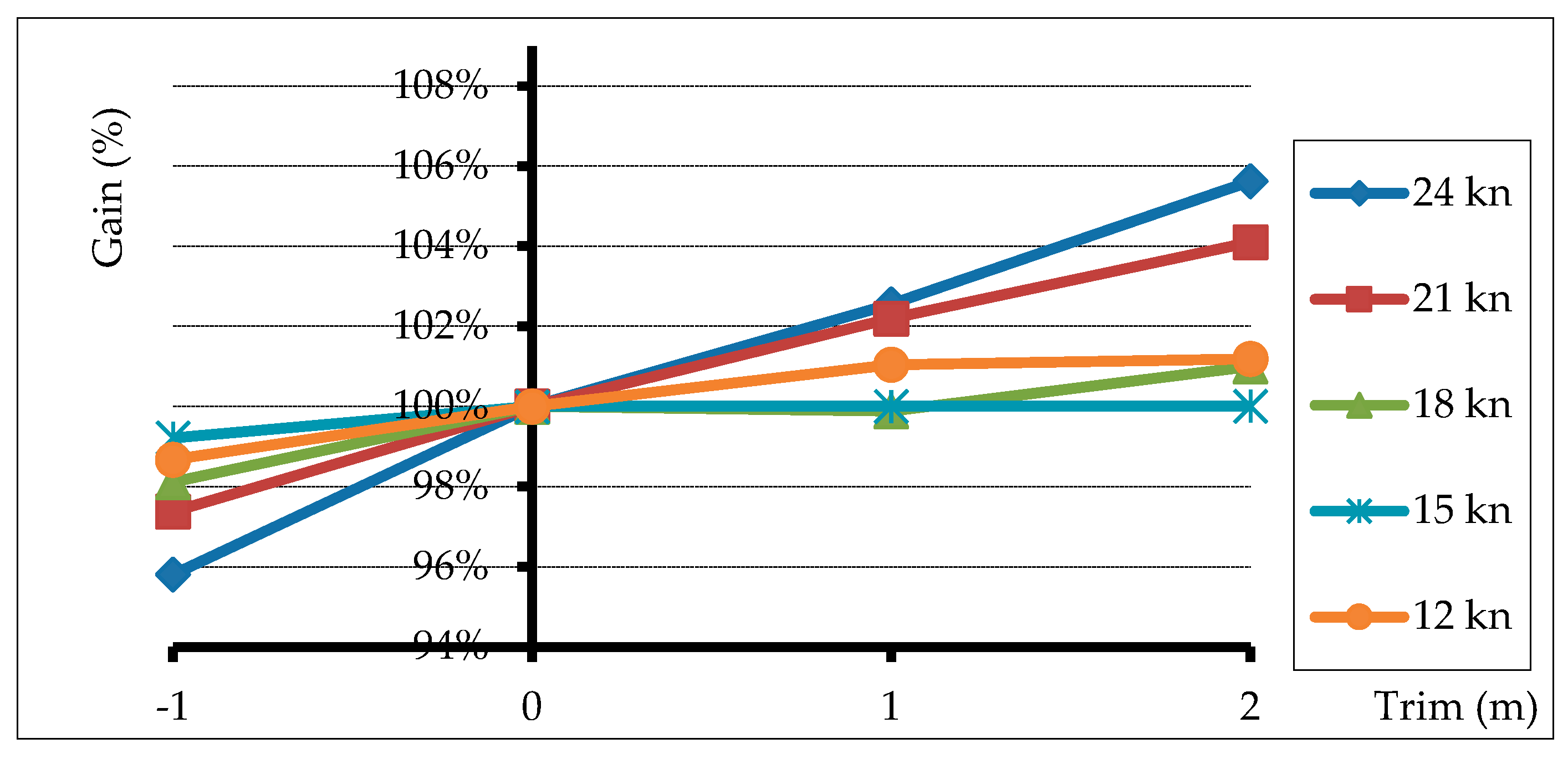

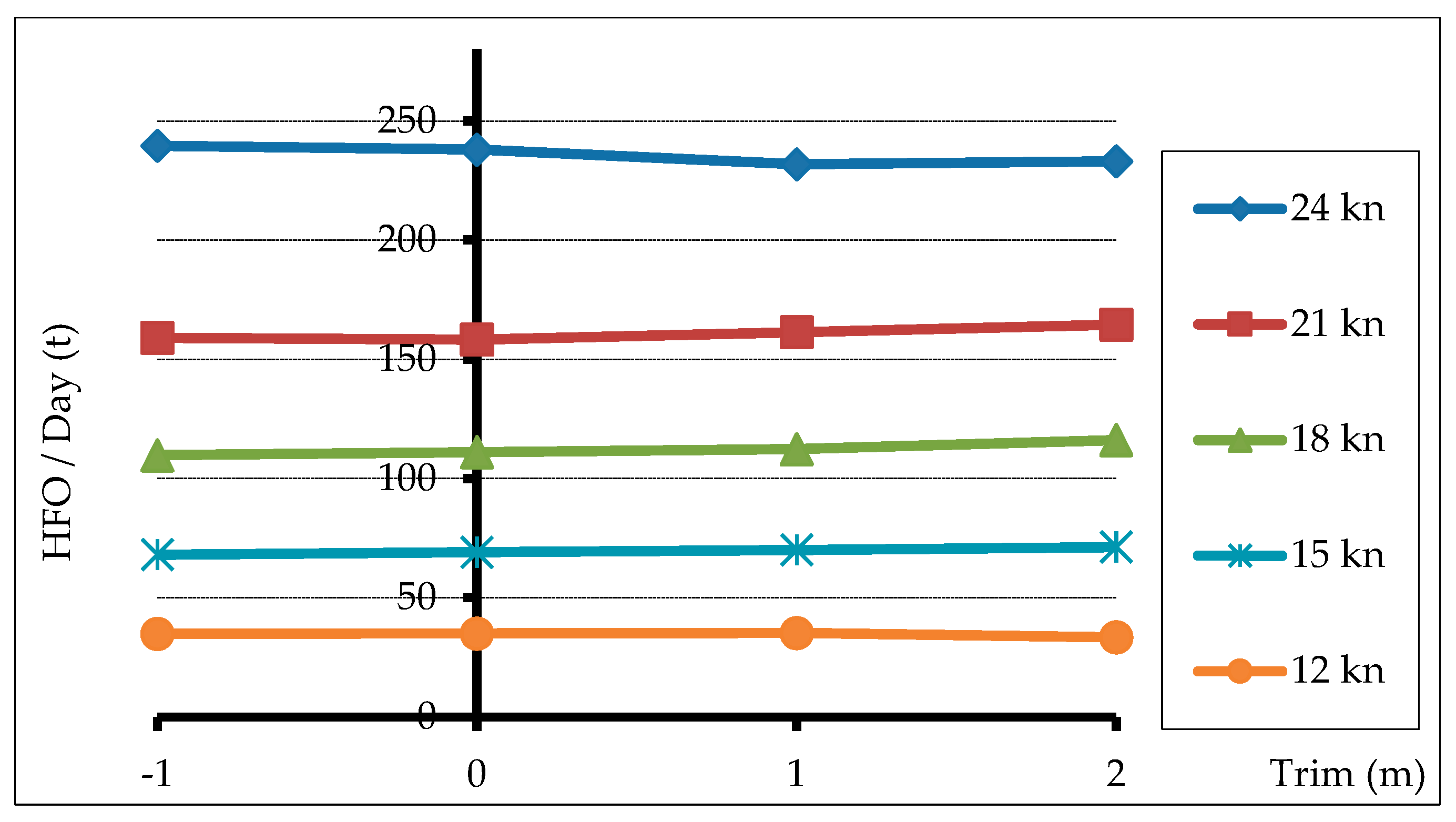

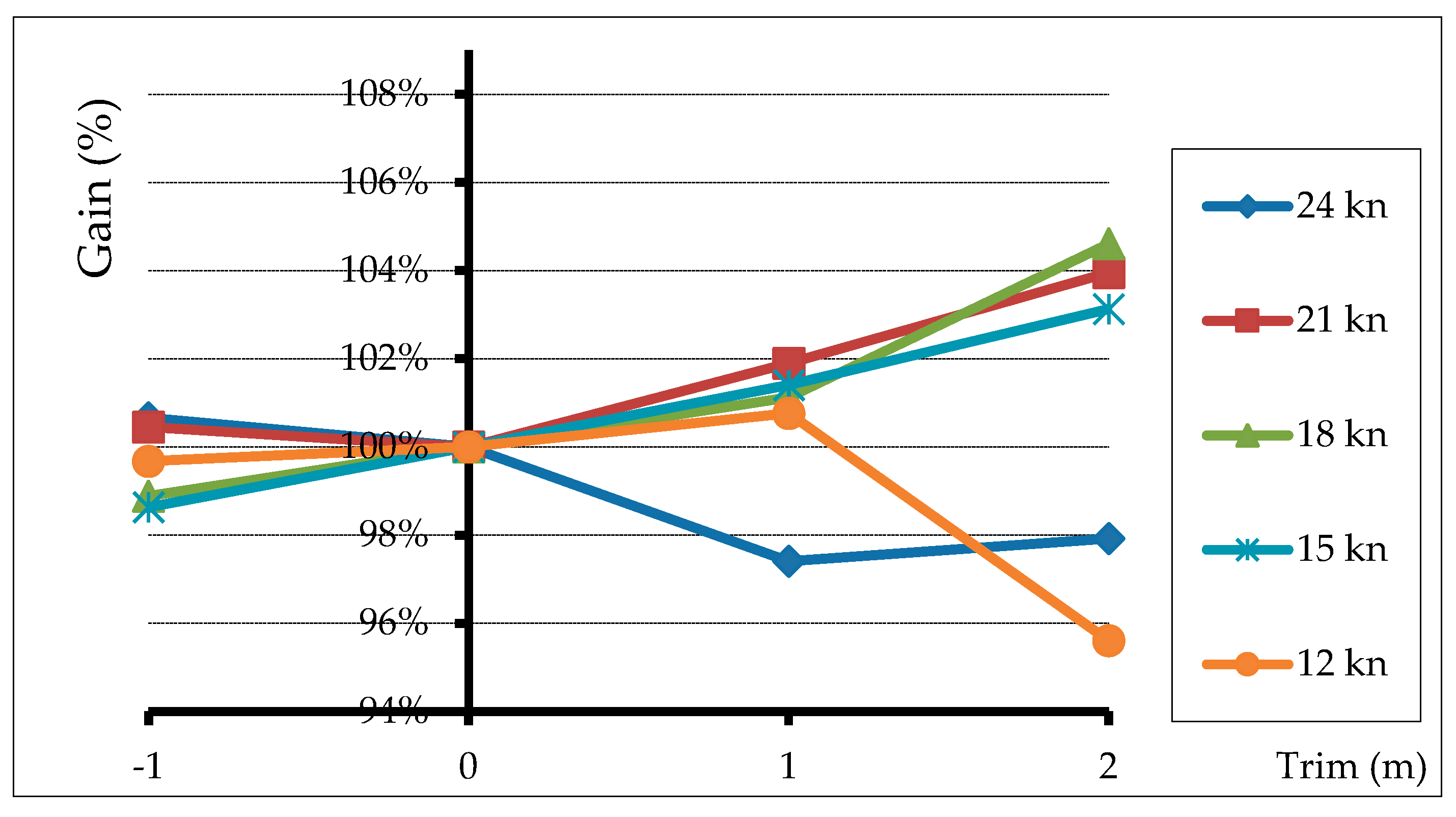

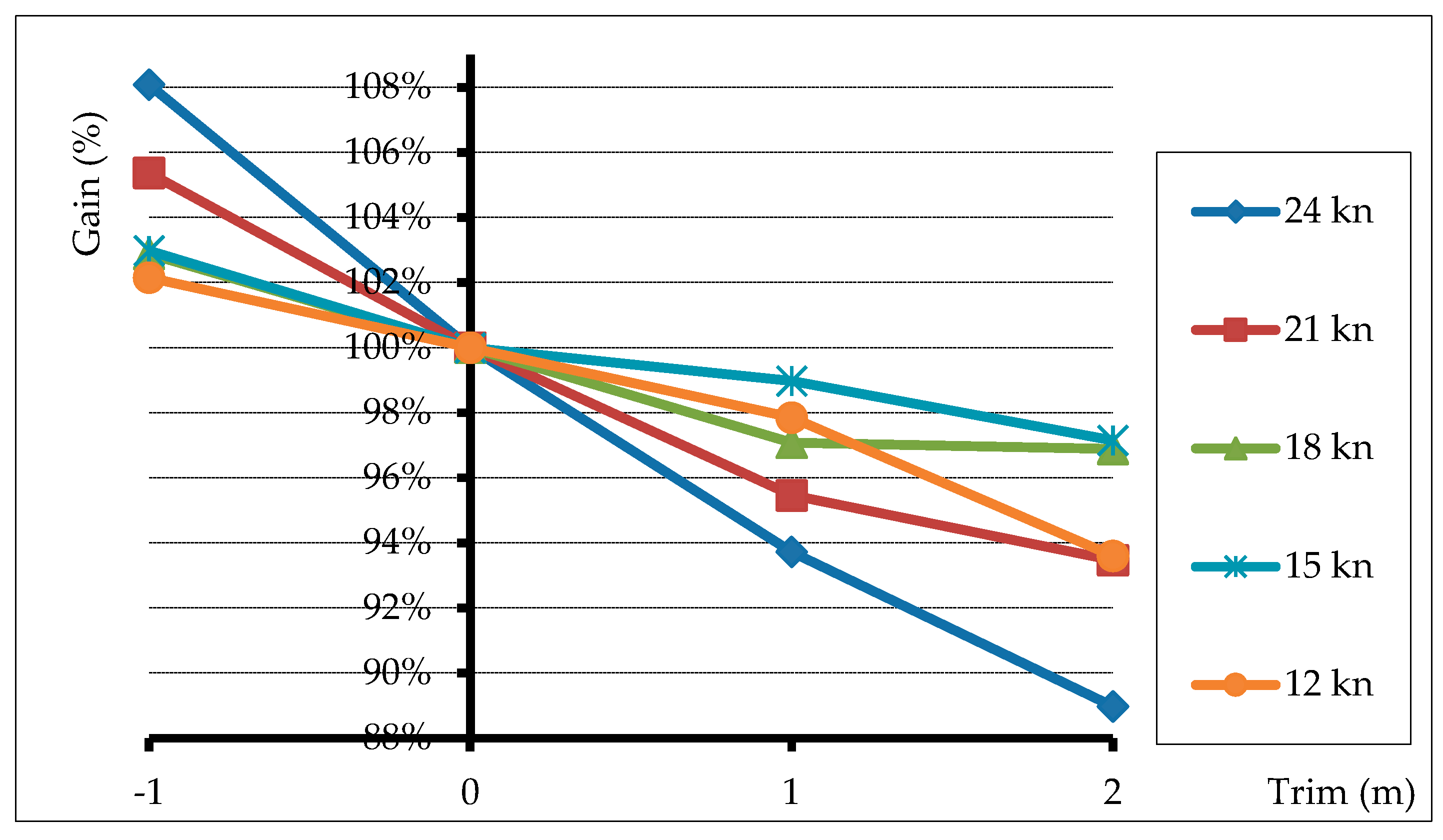

3. Results

4. Discussion

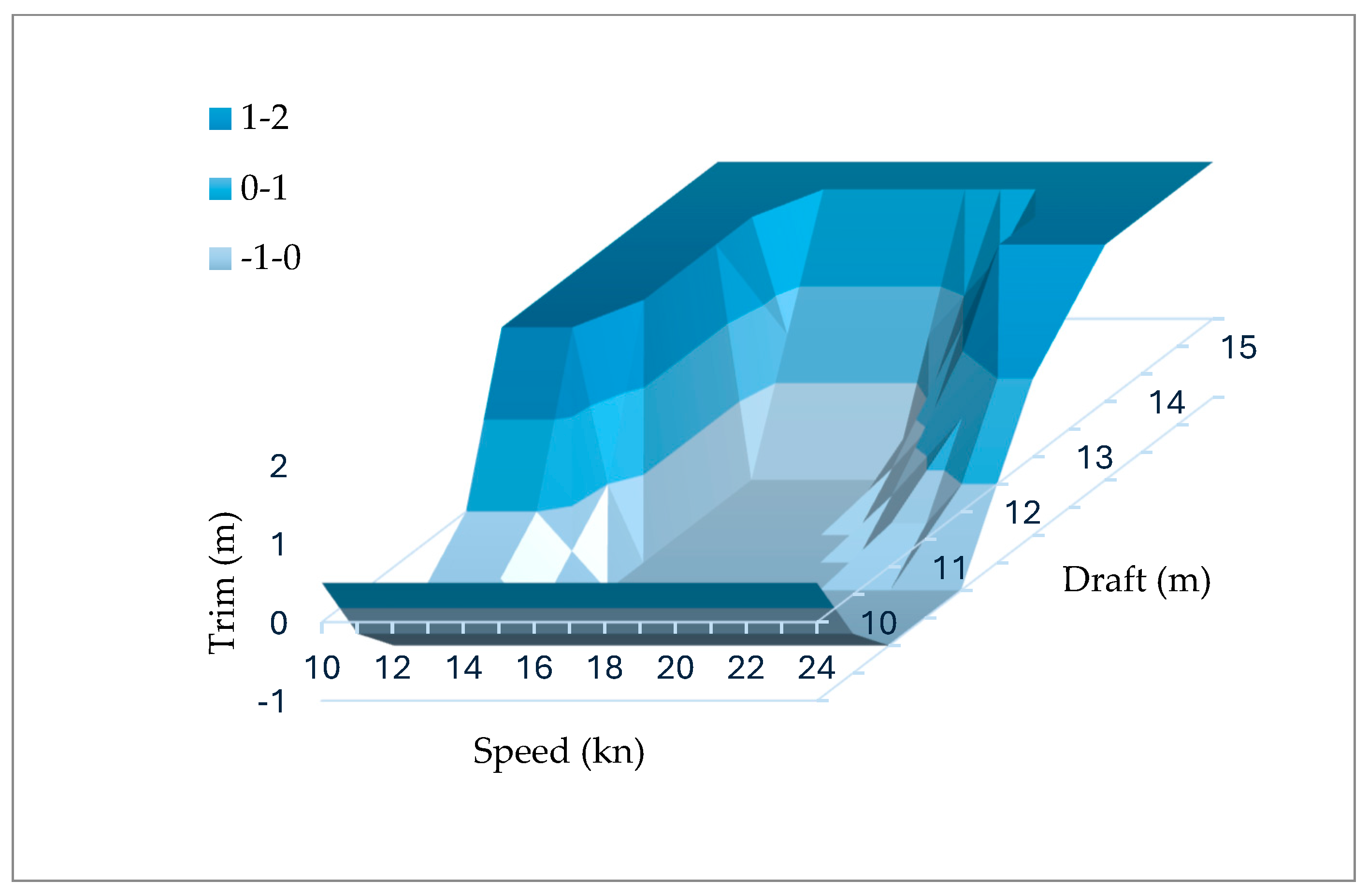

- -

- For any speed range at a draft of 11 m;

- -

- For a speed range of 14–24 kn at a draft of 12 m;

- -

- For a speed range 14–19 kn at drafts 13 and 14 m.

4.1. Case Study—Comparative Analysis of Fuel Consumption and Environmental Pollution Reduction on the Rotterdam—Singapore Route Concerning Ship Trim

Exhaust Gas Emission

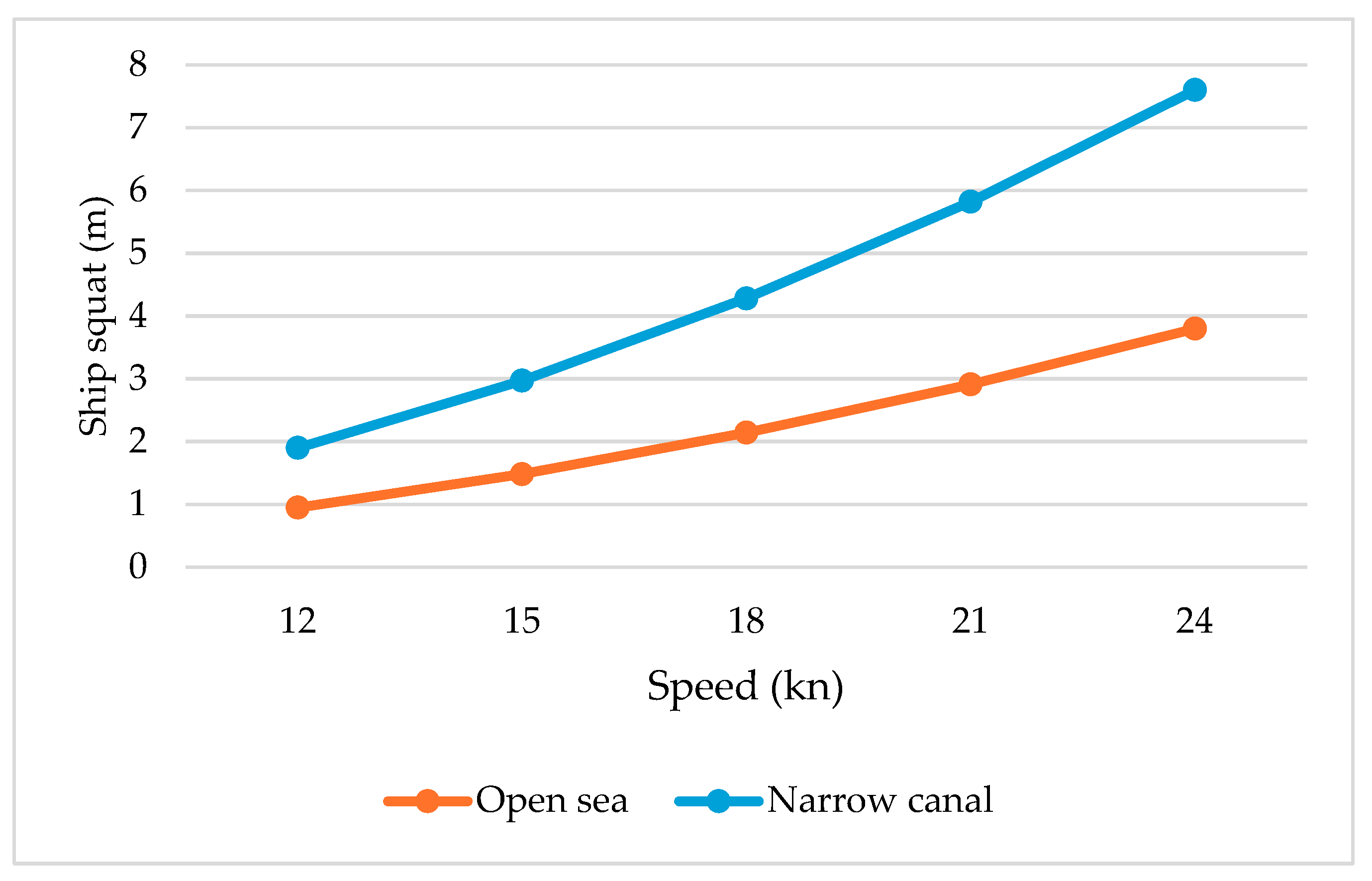

4.2. The Relationship between the Safety of Navigation and Trim of the Ship

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| TEU | Twenty-foot equivalent unit |

| EU | European Union |

| IMO | International Maritime Organization |

| GHG | Greenhouse gases |

| SEEMP | Ship energy efficiency management plan |

| ME | Main engine |

| kn | Knot |

| m | Meter |

| kW | Kilowatt |

| GT | Gross tonnage |

| LOA | Length overall |

| HFO | Heavy fuel oil |

| nm | Nautical mile |

| t | Ton |

| US | United States |

| t/day | Tons per day |

| CO2 | Carbon dioxide |

| CO | Carbon monoxide |

| NOX | Nitrogen oxides |

| SOX | Sulfur oxides |

| PM | Particulate matter (mg/m3 or μg/m3) |

References

- European Commission. Reducing Emissions from the Shipping Sector. Available online: https://climate.ec.europa.eu/eu-action/transport/reducing-emissions-shipping-sector_en (accessed on 11 June 2024).

- IMO. Third IMO Greenhouse Gas Study 2014. Available online: https://wwwcdn.imo.org/localresources/en/OurWork/Environment/Documents/Third%20Greenhouse%20Gas%20Study/GHG3%20Executive%20Summary%20and%20Report.pdf (accessed on 11 June 2024).

- IMO. Fourth IMO GHG Study 2020. Available online: https://wwwcdn.imo.org/localresources/en/OurWork/Environment/Documents/Fourth%20IMO%20GHG%20Study%202020%20-%20Full%20report%20and%20annexes.pdf (accessed on 11 June 2024).

- IMO. Guidelines for the Development of a Ship Energy Efficiency Management Plan (SEEMP) 2022. Available online: https://wwwcdn.imo.org/localresources/en/KnowledgeCentre/IndexofIMOResolutions/MEPCDocuments/MEPC.346(78).pdf (accessed on 13 June 2024).

- Xie, X.-W.; Sun, B.-Z.; Li, X.-H.; Zhao, Y.-H.; Chen, Y.-M. Joint optimization of ship speed and trim based on machine learning method under consideration of load. Ocean Eng. 2023, 287, 115917. [Google Scholar] [CrossRef]

- IMO. Available online: https://www.imo.org/ (accessed on 8 September 2024).

- What Is a Ship Trim? Available online: https://www.marineinsight.com/naval-architecture/ship-trim/ (accessed on 18 June 2024).

- Lokukaluge, P.-P.; Brage, M.; Leifur, A.-K. Identification of Optimal Trim Configurations to improve Energy Efficiency in Ships. IFAC-PapersOnLine 2015, 28, 267–272. [Google Scholar]

- Abouelfadl, A.H.; Abdelraouf, E.E.Y. The Impact of Optimizing Trim on Reducing Fuel Consumption. J. Shipp. Ocean Eng. 2016, 6, 3. [Google Scholar] [CrossRef][Green Version]

- Undap, R.; Fadillah, A. The Effect of Trim on Tanker, Container and Bulk Carrier Ship toward the Reduction of Ship’s Exhaust Gas Emission. Kapal J. Ilmu Pengetah. Teknol. Kelaut. 2021, 18, 58–68. [Google Scholar] [CrossRef]

- Gao, X.-J.; Shi, S.-Z.; Wang, M.-Z.; Zhang, J.-X. Study on trim optimization for an oil tanker. J. Phys. Conf. Ser. 2021, 1985, 012018. [Google Scholar] [CrossRef]

- Zwart, R.-H.; Bogaard, J.; Kana, A.-A. Grey-box model approach using noon report data for trim optimization. Int. Shipbuild. Prog. 2023, 70, 41–63. [Google Scholar] [CrossRef]

- Cepowski, T.; Drozd, A. Measurement-based relationships between container ship operating parameters and fuel consumption. Appl. Energy 2023, 347, 121315. [Google Scholar] [CrossRef]

- Yu, Y.; Zhang, H.; Mu, Z.; Li, Y.; Sun, Y.; Liu, J. Trim and Engine Power Joint Optimization of a Ship Based on Minimum Energy Consumption over a Whole Voyage. J. Mar. Sci. Eng. 2024, 12, 475. [Google Scholar] [CrossRef]

- Trim and Stability: Understanding the Nautical Term. Available online: https://merchantnavyinfo.com/trim-and-stability-what-does-it-mean-when-a-ship-is-trimming/ (accessed on 18 June 2024).

- Kim, K.-S.; Roh, M.-I. ISO 15016:2015-Based Method for Estimating the Fuel Oil Consumption of a Ship. J. Mar. Sci. Eng. 2020, 8, 791. [Google Scholar] [CrossRef]

- Barrass, B.; Derrett, D.R.B. Ship Stability for Masters and Mates, 6th ed.; Butterworth-Heinemann: Oxford, UK, 2006; pp. 490–491. [Google Scholar]

- Şerban, S.P.; Katona, C.; Panaitescu, V.N. The analysis of squat and underkeel clearance for different ship types in a trapezoidal cross-section channel. UPB Sci. Bull. Ser. D 2015, 77, 3. [Google Scholar]

- Shah, D.; Patel, M. Comparative Study of Design Berthing Energy on Fender as per Indian Standard IS4651 Part-3:1974 and British Standard BS6349 Part-4:1994. Int. J. Marit. Technol. 2016, 6, 51–58. [Google Scholar] [CrossRef][Green Version]

- Švetak, J. Ship Squat. Promet-Traffic Transp. 2001, 13, 247–251. Available online: https://traffic.fpz.hr/index.php/PROMTT/article/view/1082 (accessed on 20 June 2024).

- Zhang, C.; Ringsberg, J.W.; Thies, F. Development of a ship performance model for power estimation of inland waterway vessels. Ocean Eng. 2023, 287, 115731. [Google Scholar] [CrossRef]

- World Bunker Prices-Ship & Bunker. Available online: https://shipandbunker.com/prices (accessed on 20 August 2024).

- Distance and Transit Time Calculator. Available online: http://www.searates.com/distance-time/ (accessed on 15 September 2024).

- IMO. Strategy on Reduction of GHG Emissions from Ships. Available online: https://wwwcdn.imo.org/localresources/en/OurWork/Environment/Documents/annex/MEPC80/Annex15.pdf (accessed on 13 June 2024).

- IMO. Guidelines for Voyage Planning. 1999. Available online: https://wwwcdn.imo.org/localresources/en/KnowledgeCentre/IndexofIMOResolutions/AssemblyDocuments/A.893(21).pdf (accessed on 26 July 2024).

- SOLAS, Chapter V Safety of Navigation. Available online: https://assets.publishing.service.gov.uk/media/5a7f0081ed915d74e33f3c6e/solas_v_on_safety_of_navigation.pdf (accessed on 25 July 2024).

- ICS. Bridge Procedures Guide Fifth Edition. Available online: https://www.ics-shipping.org/resource/bridge-procedures-guide/ (accessed on 25 July 2024).

- IMO. Standards for Ship Maneuverability. Available online: https://wwwcdn.imo.org/localresources/en/KnowledgeCentre/IndexofIMOResolutions/MSCResolutions/MSC.137(76).pdf (accessed on 26 July 2024).

| Specifications | Value |

|---|---|

| Main engine type | Diesel engine—HYUNDAI B&W |

| Main engine power Auxiliary engines | 72,240 kW 4 × 4300 kW |

| Gross tonnage | 131,332 GT |

| Draught | 15.5 m |

| LOA (Length overall) | 363.61 m |

| Breadth | 45.66 m |

| Height | 69.7 m |

| Displacement | 171,371 t |

| TEU | 11,388 |

| Speed max. | −25 kn |

| Fuel type | HFO |

| Class | Bureau Veritas |

| Variables | Value | HFO Consumption |

|---|---|---|

| Distance | 9223 Nm | / |

| Time | 21.3 days | / |

| Speed | 15 kn | / |

| Draught | 13 m | / |

| Trim 1 m by bow (optimal) | 68.1 t/day | 1450.5 t |

| Trim even keel | 69.1 t/day | 1471.8 t |

| Trim 1 m by stern | 70 t/day | 1491 t |

| Trim 2 m by stern | 71.2 t/day | 1516.6 t |

| Pollutant | Emission Factor | Trim 1 m by Bow (Optimal) | Trim 2 m by Stern | % * |

|---|---|---|---|---|

| CO2 | 3114 | 4.58 × 106 | 4.72 × 106 | 3.05 |

| CO | 2545 | 3.69 × 106 | 3.85 × 106 | 4.33 |

| NOX | 77.26 | 1.12 × 105 | 1.17 × 105 | 4.46 |

| SOX | 47.73 | 69.23 × 103 | 72.38 × 103 | 4.55 |

| PM | 7.25 | 1.05 × 104 | 1.10 × 104 | 4.76 |

| Speed/Trim | 2 m | 1 m | 0 m | −1 m |

|---|---|---|---|---|

| 12 kn | 9% | 9% | 9% | 9% |

| 15 kn | 20% | 20% | 19% | 19% |

| 18 kn | 35% | 34% | 34% | 32% |

| 21 kn | 52% | 51% | 50% | 48% |

| 24 kn | 75% | 72% | 72% | 71% |

| 12 [kn] | 15 [kn] | 18 [kn] | 21 [kn] | 24 [kn] | |

|---|---|---|---|---|---|

| Open sea | 0.95 m | 1.48 m | 2.14 m | 2.91 m | 3.80 m |

| Narrow canal | 1.90 m | 2.97 m | 4.28 m | 5.82 m | 7.60 m |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Musulin, M.; Mihanović, L.; Balić, K.; Musulin, H.N. The Impact of Container Ship Trim on Fuel Consumption and Navigation Safety. J. Mar. Sci. Eng. 2024, 12, 1658. https://doi.org/10.3390/jmse12091658

Musulin M, Mihanović L, Balić K, Musulin HN. The Impact of Container Ship Trim on Fuel Consumption and Navigation Safety. Journal of Marine Science and Engineering. 2024; 12(9):1658. https://doi.org/10.3390/jmse12091658

Chicago/Turabian StyleMusulin, Mario, Luka Mihanović, Katarina Balić, and Hrvoje Nenad Musulin. 2024. "The Impact of Container Ship Trim on Fuel Consumption and Navigation Safety" Journal of Marine Science and Engineering 12, no. 9: 1658. https://doi.org/10.3390/jmse12091658

APA StyleMusulin, M., Mihanović, L., Balić, K., & Musulin, H. N. (2024). The Impact of Container Ship Trim on Fuel Consumption and Navigation Safety. Journal of Marine Science and Engineering, 12(9), 1658. https://doi.org/10.3390/jmse12091658