Numerical Study on Optimization of Combustion Cycle Parameters and Exhaust Gas Emissions in Marine Dual-Fuel Engines by Adjusting Ammonia Injection Phases

Abstract

1. Introduction

2. Materials and Methods

2.1. Research Object and Strategy

2.2. Mathematical Model and Verification

3. Results

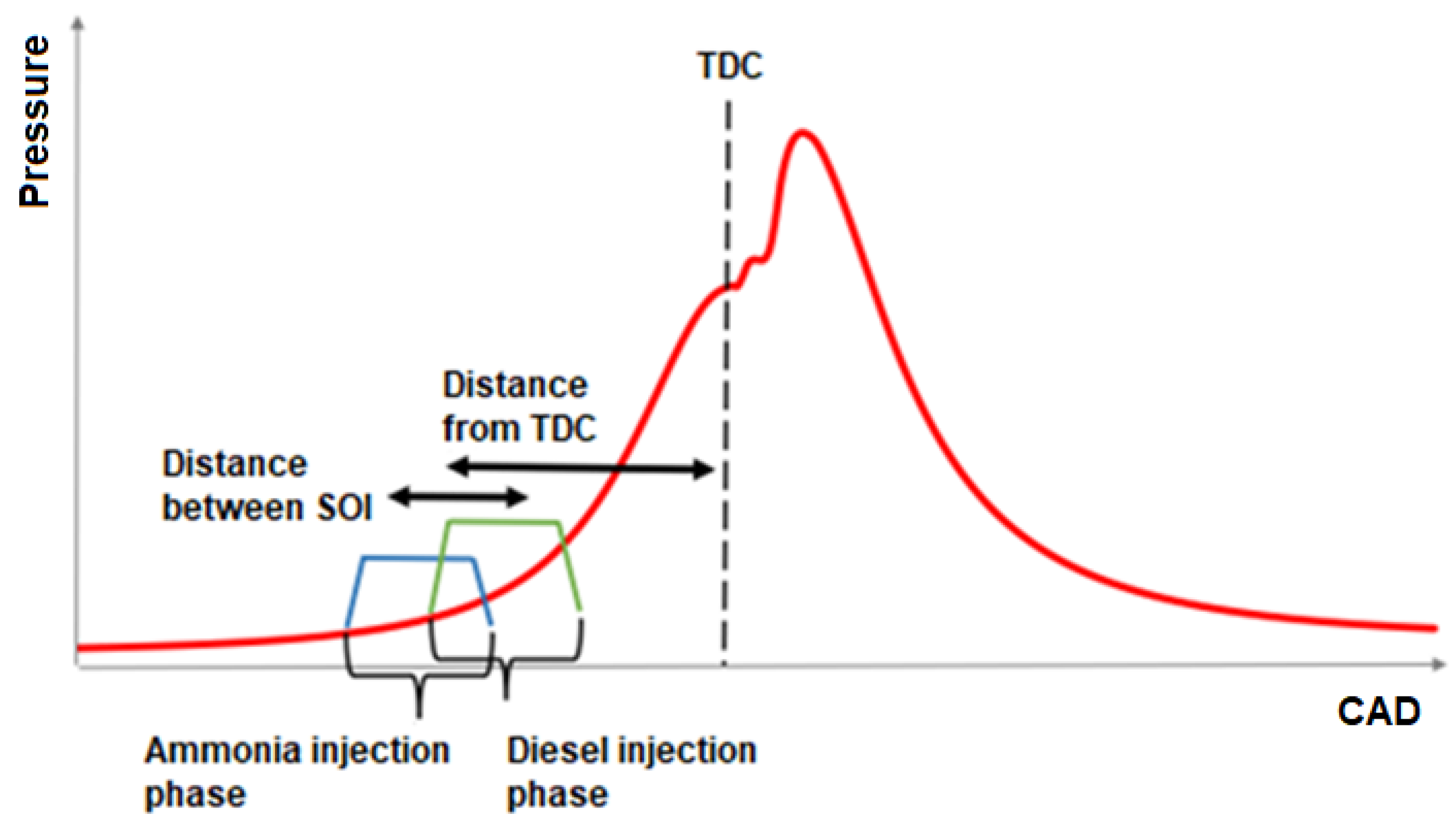

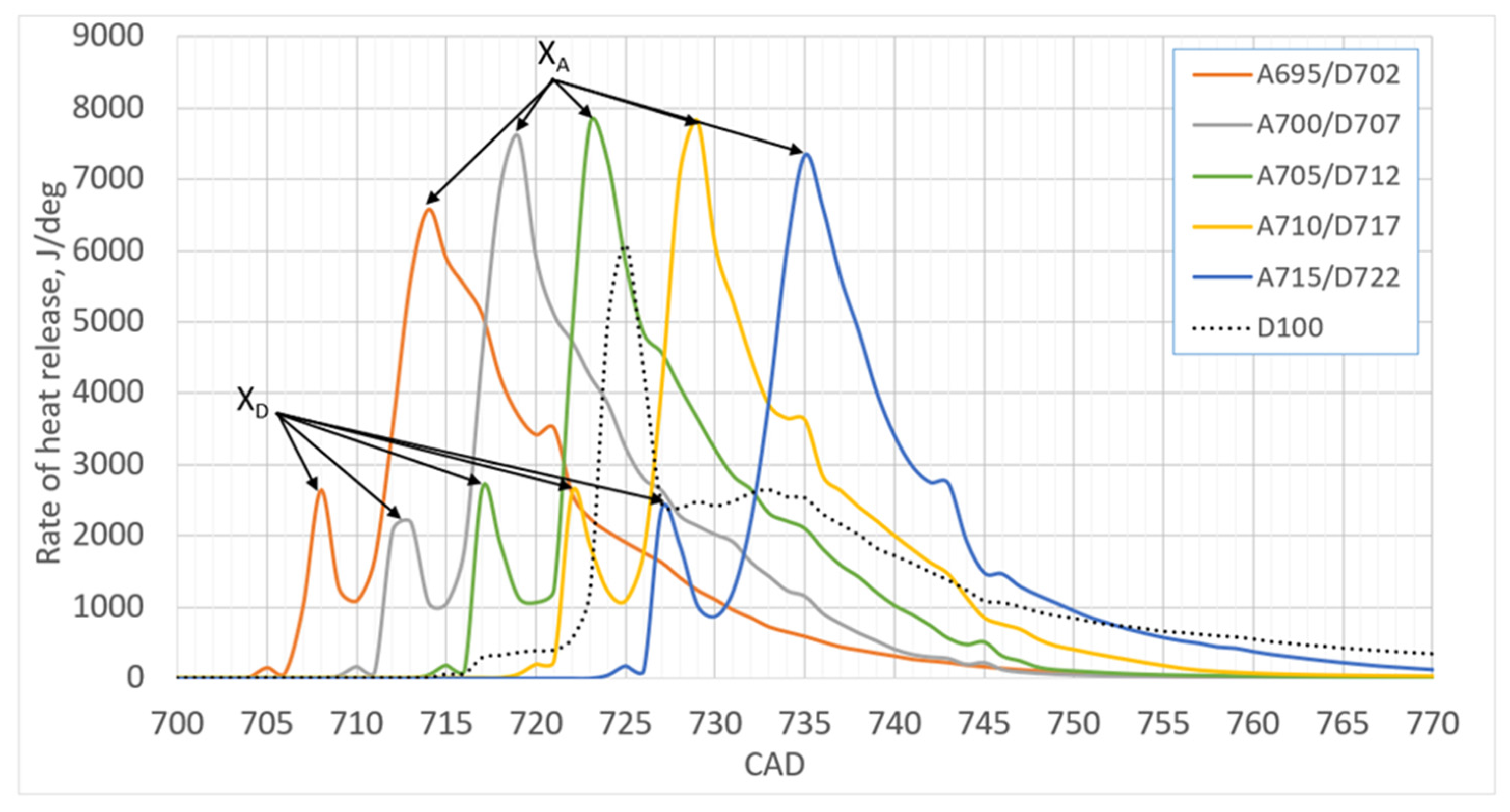

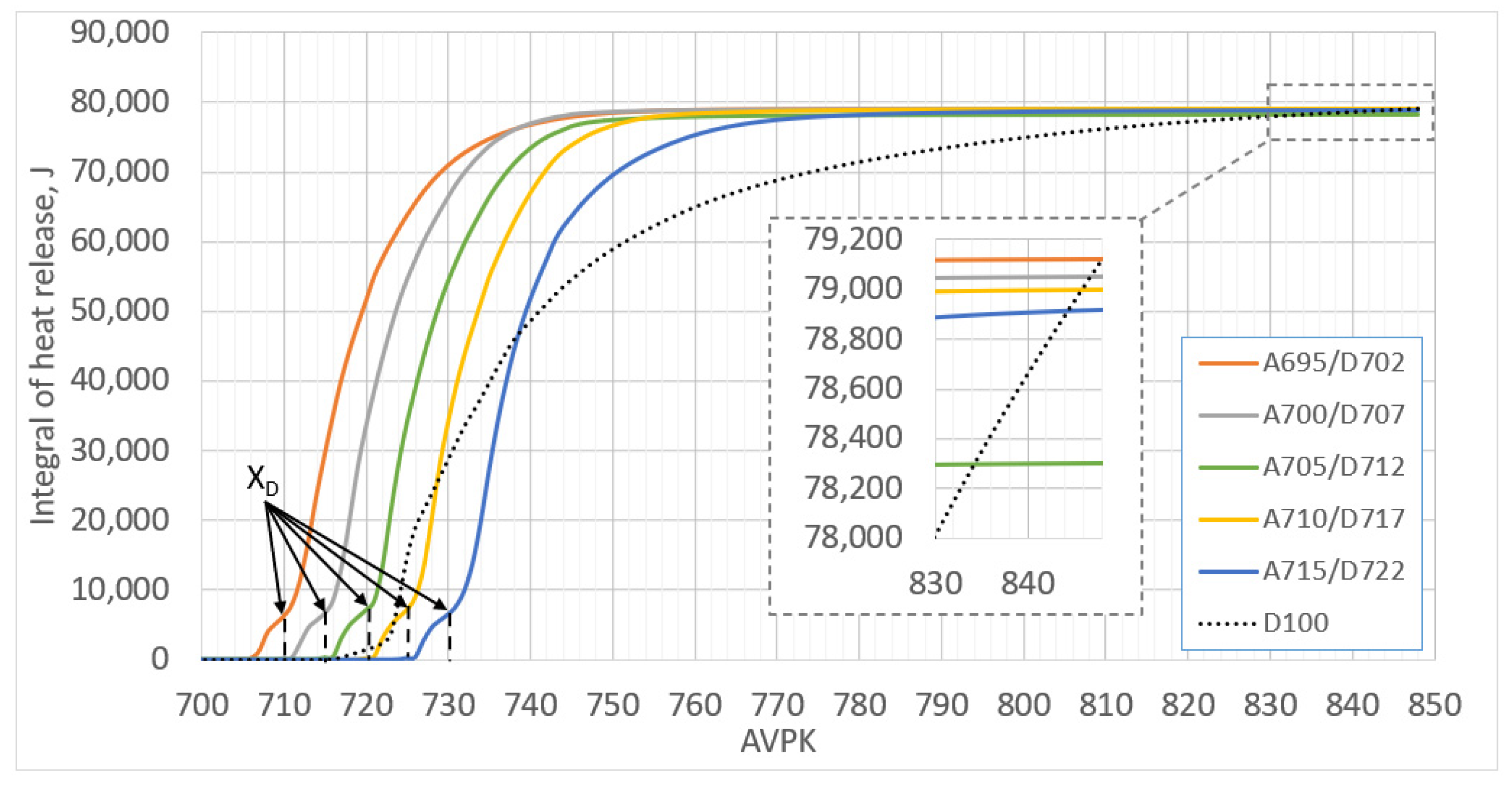

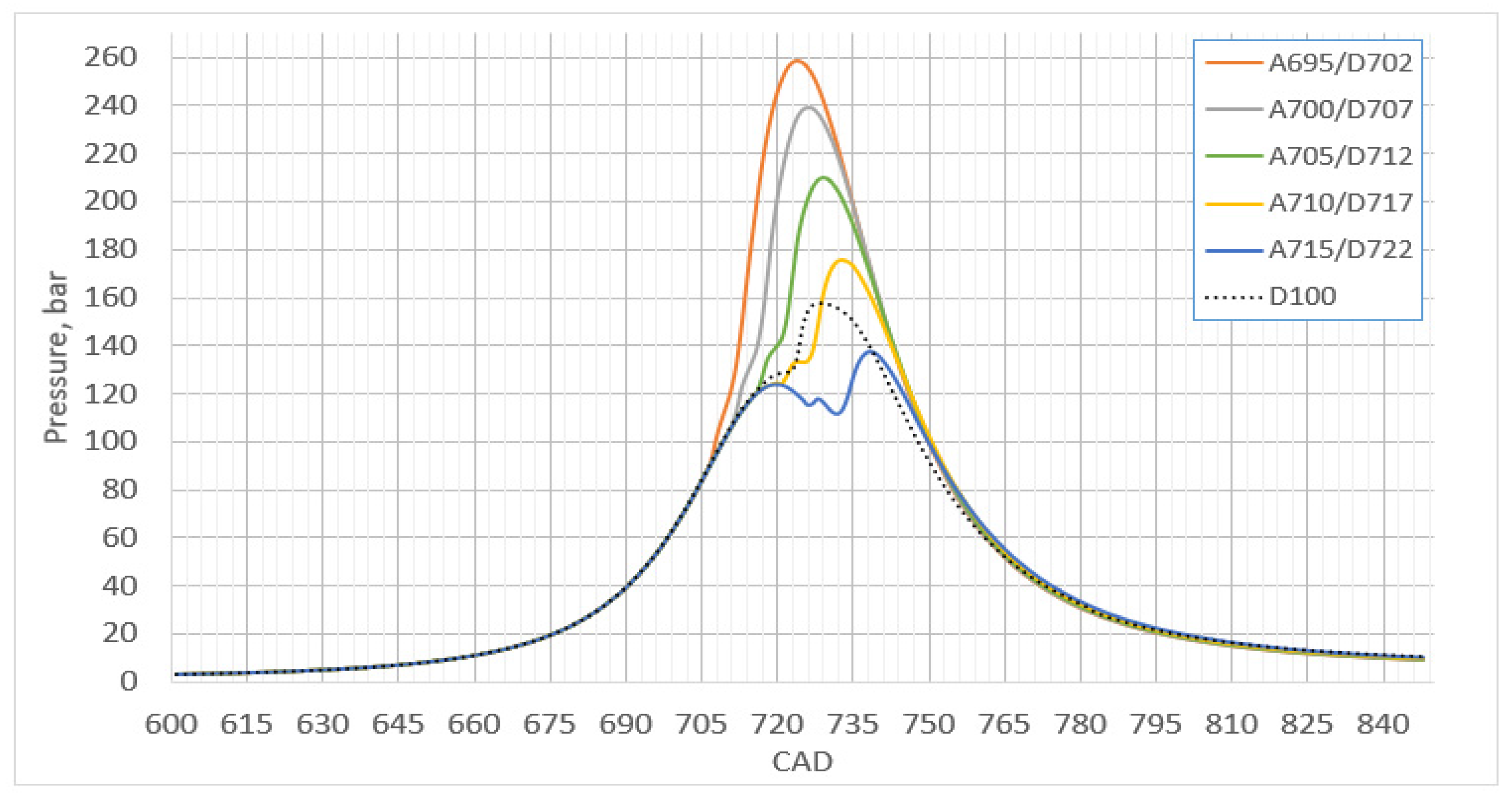

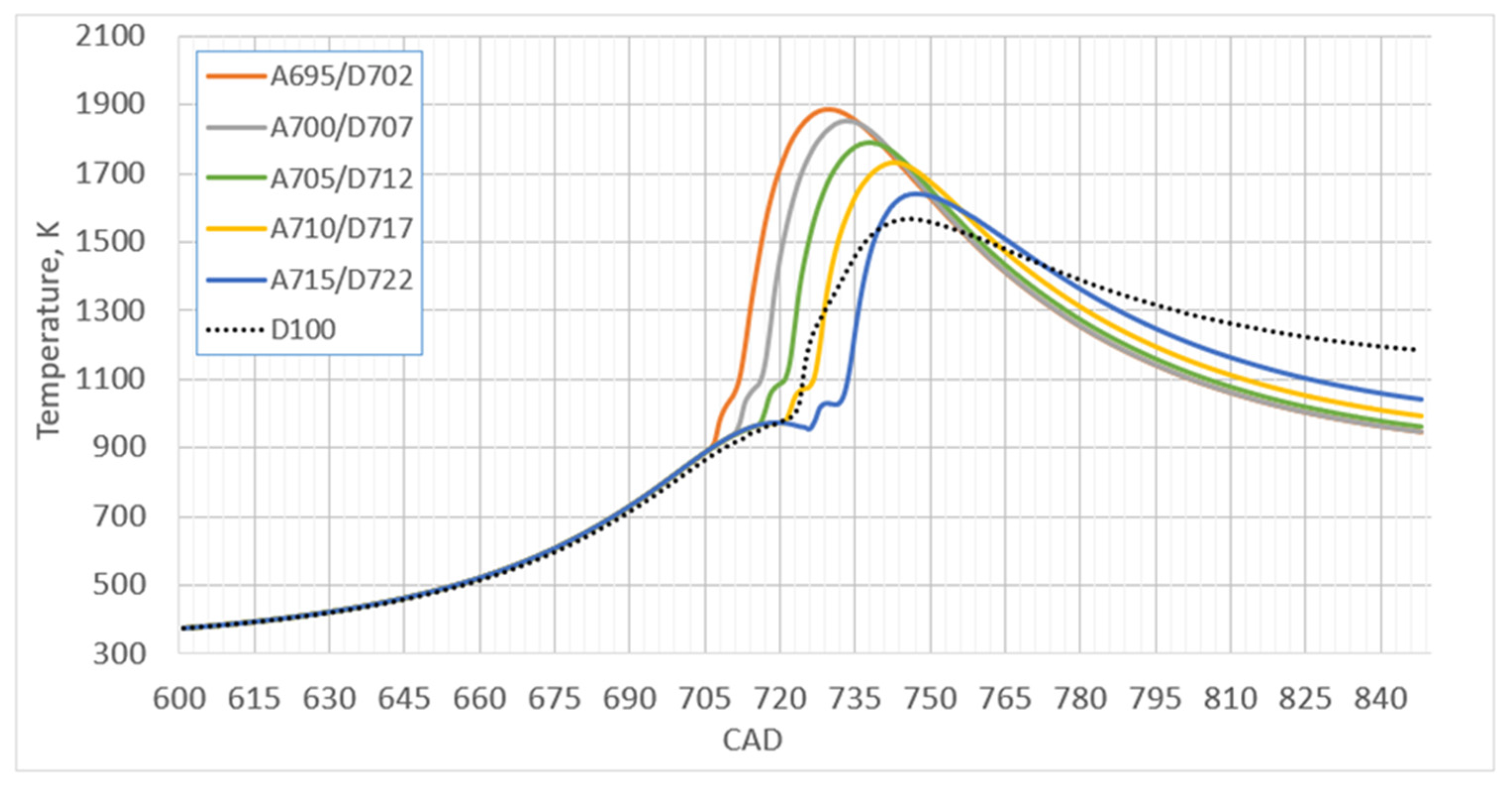

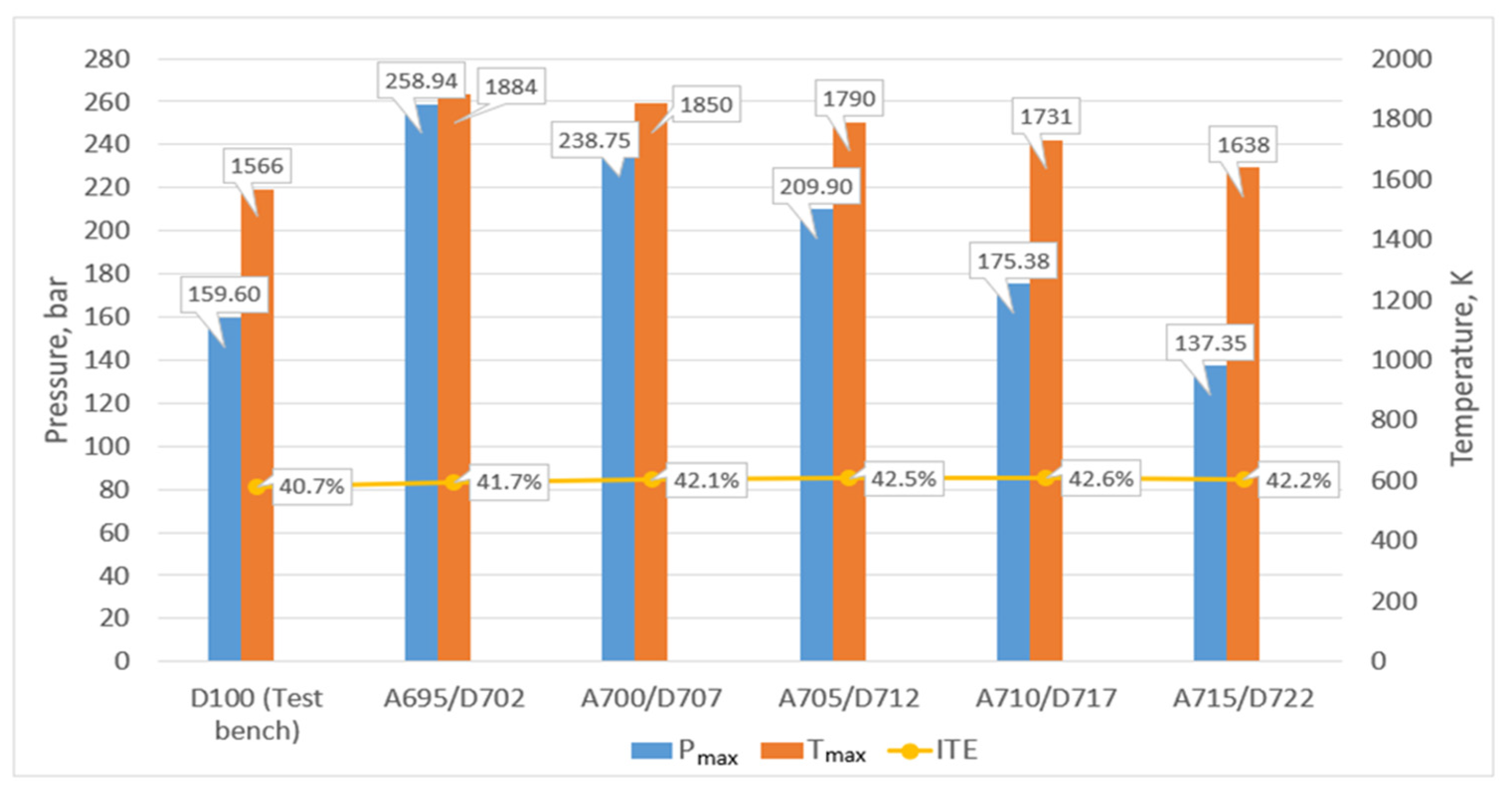

3.1. The Influence of the Distance between Injection Phases on Combustion Cycle Characteristics

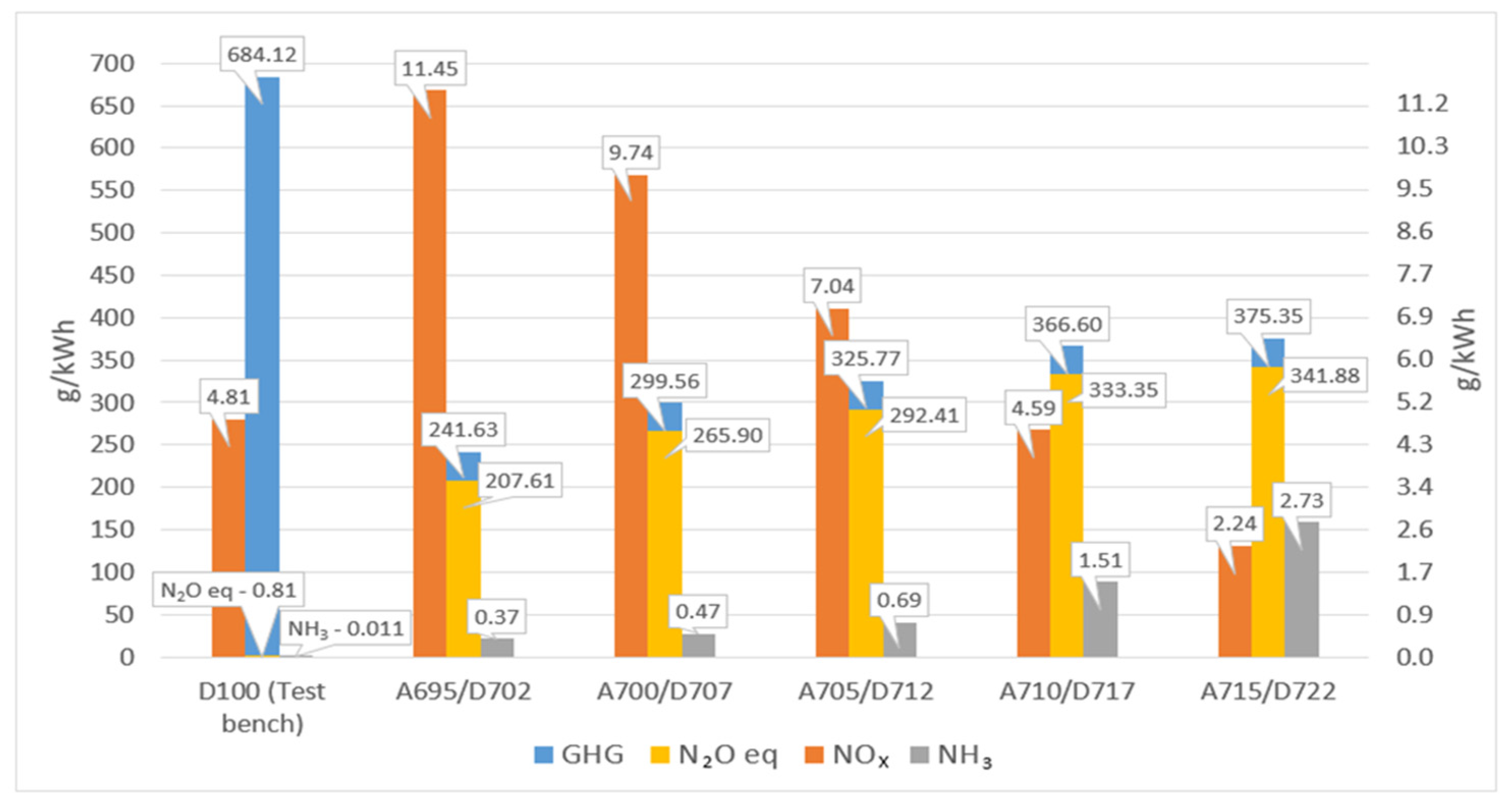

3.2. The Influence of the Distance between Injection Phases on Exhaust Gas Emissions

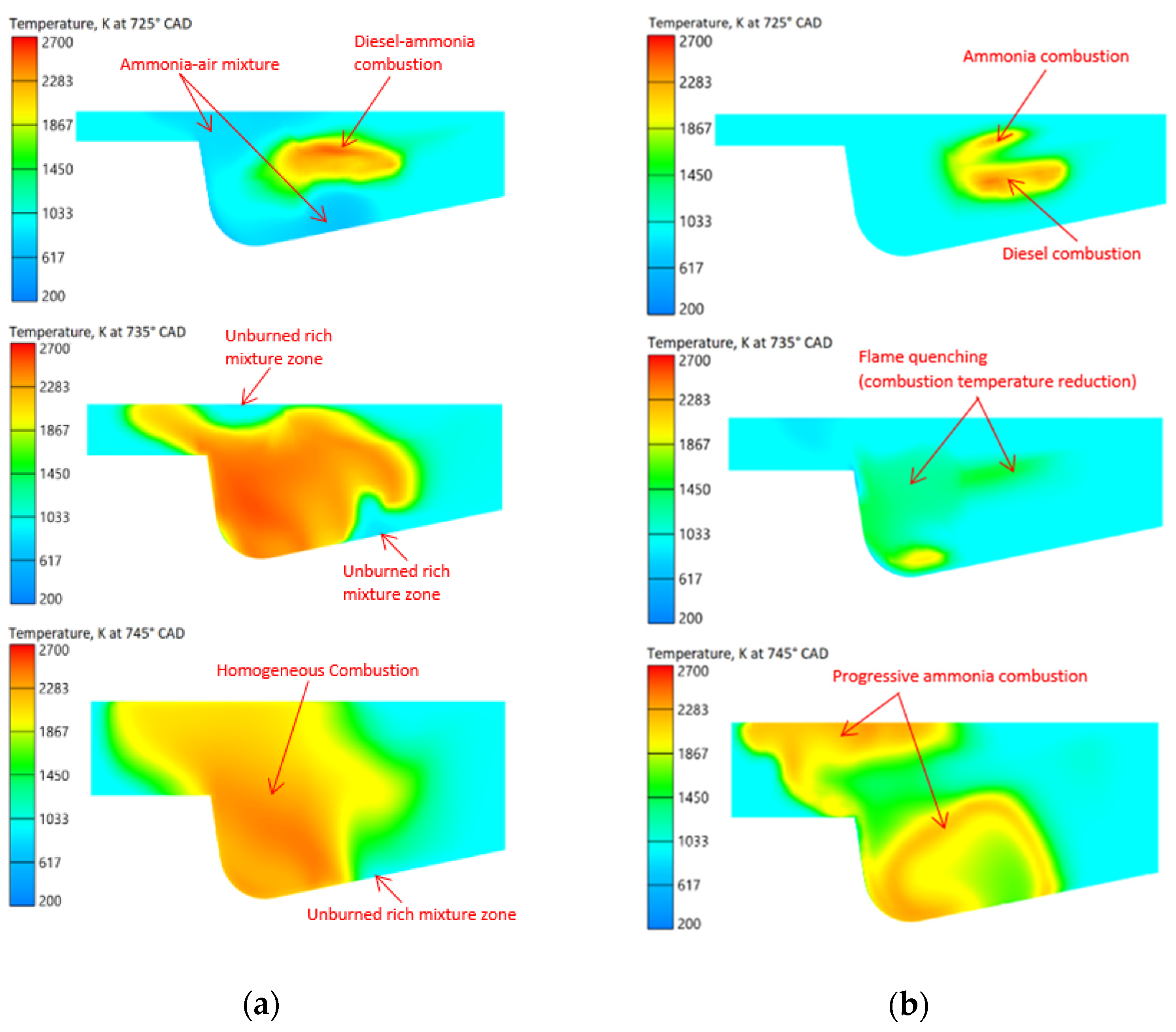

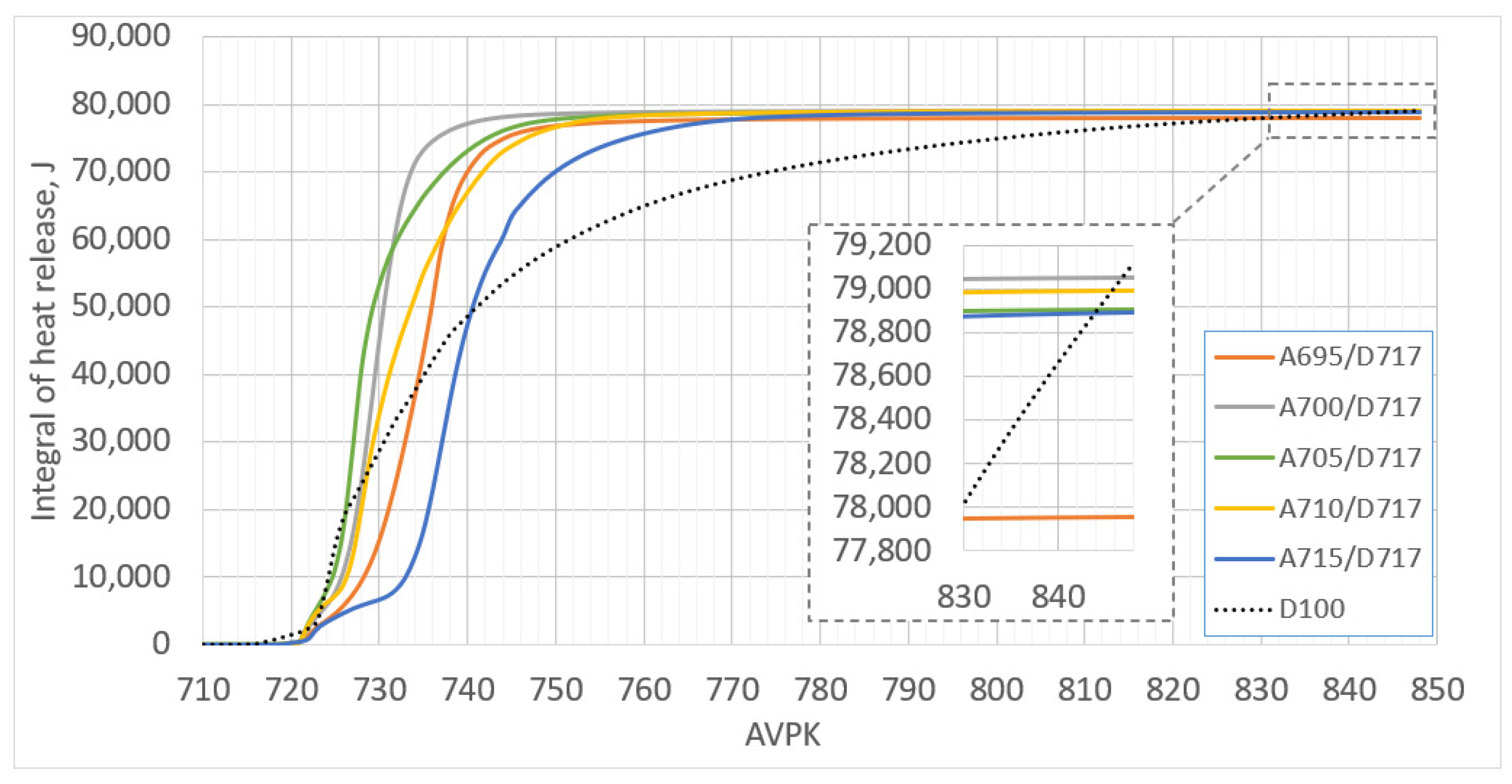

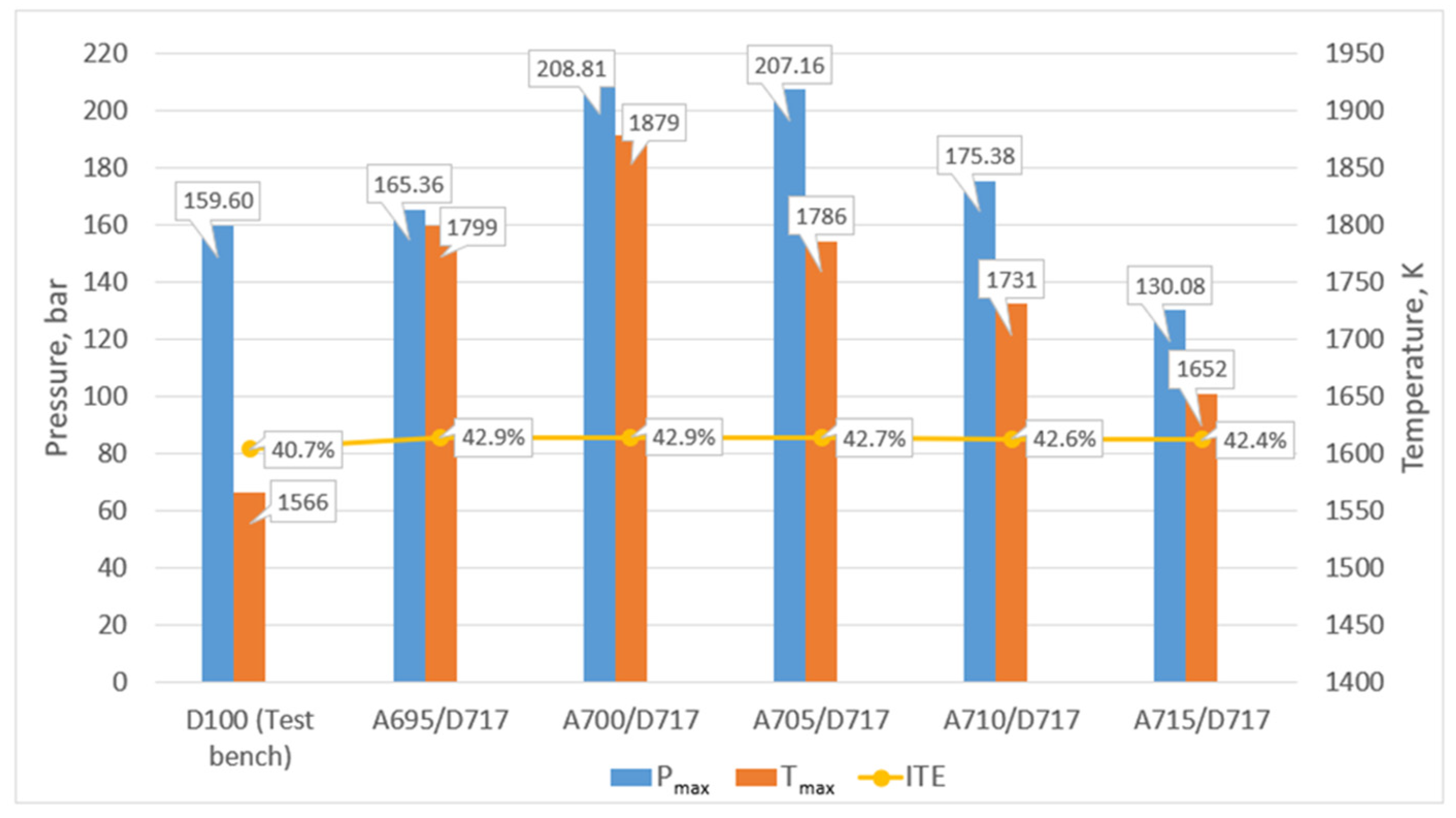

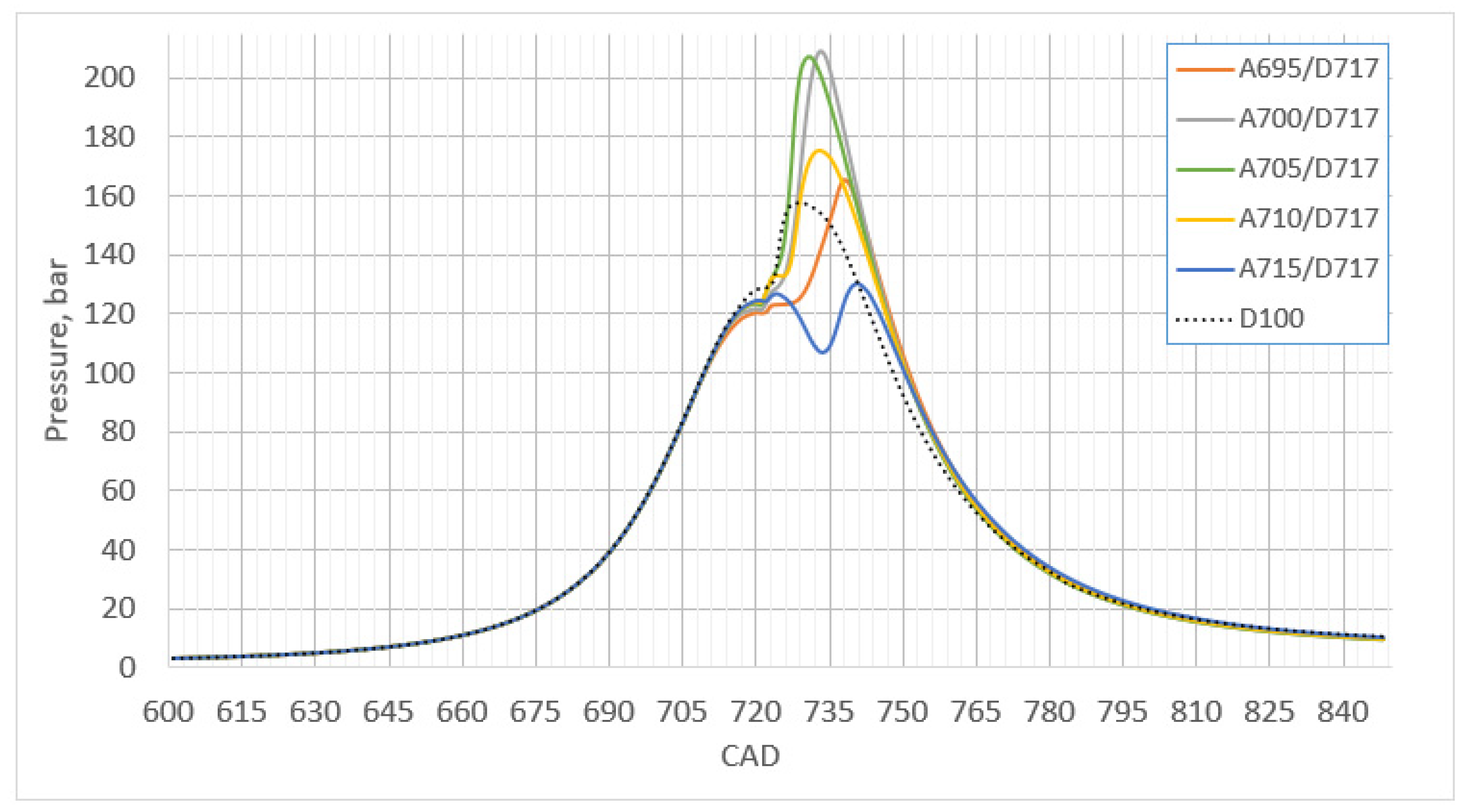

3.3. The Influence of Injection Phase Distance from TDC on Combustion Cycle Characteristics

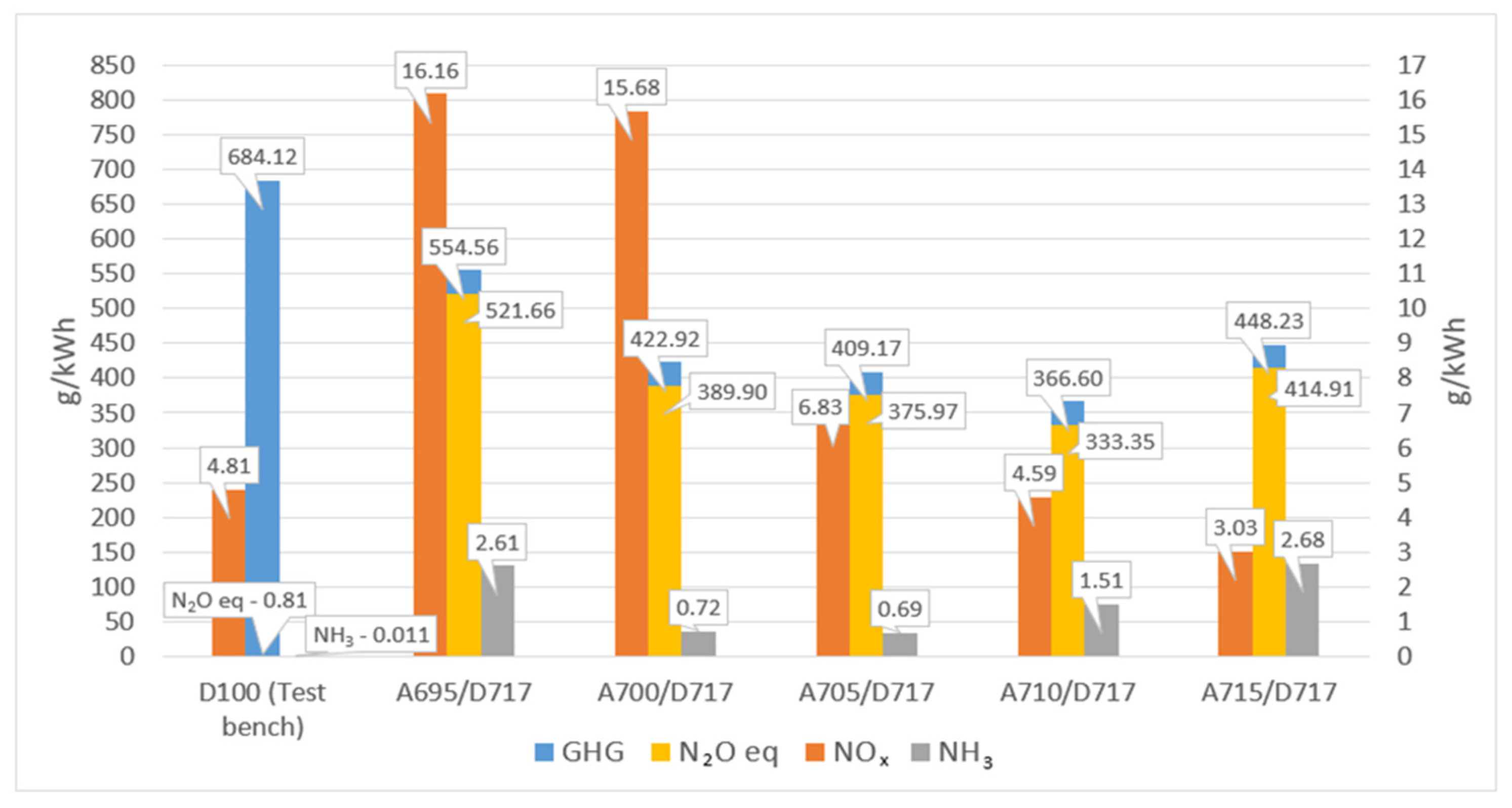

3.4. The Influence of Injection Phase Distance from TDC on Exhaust Gas Emissions

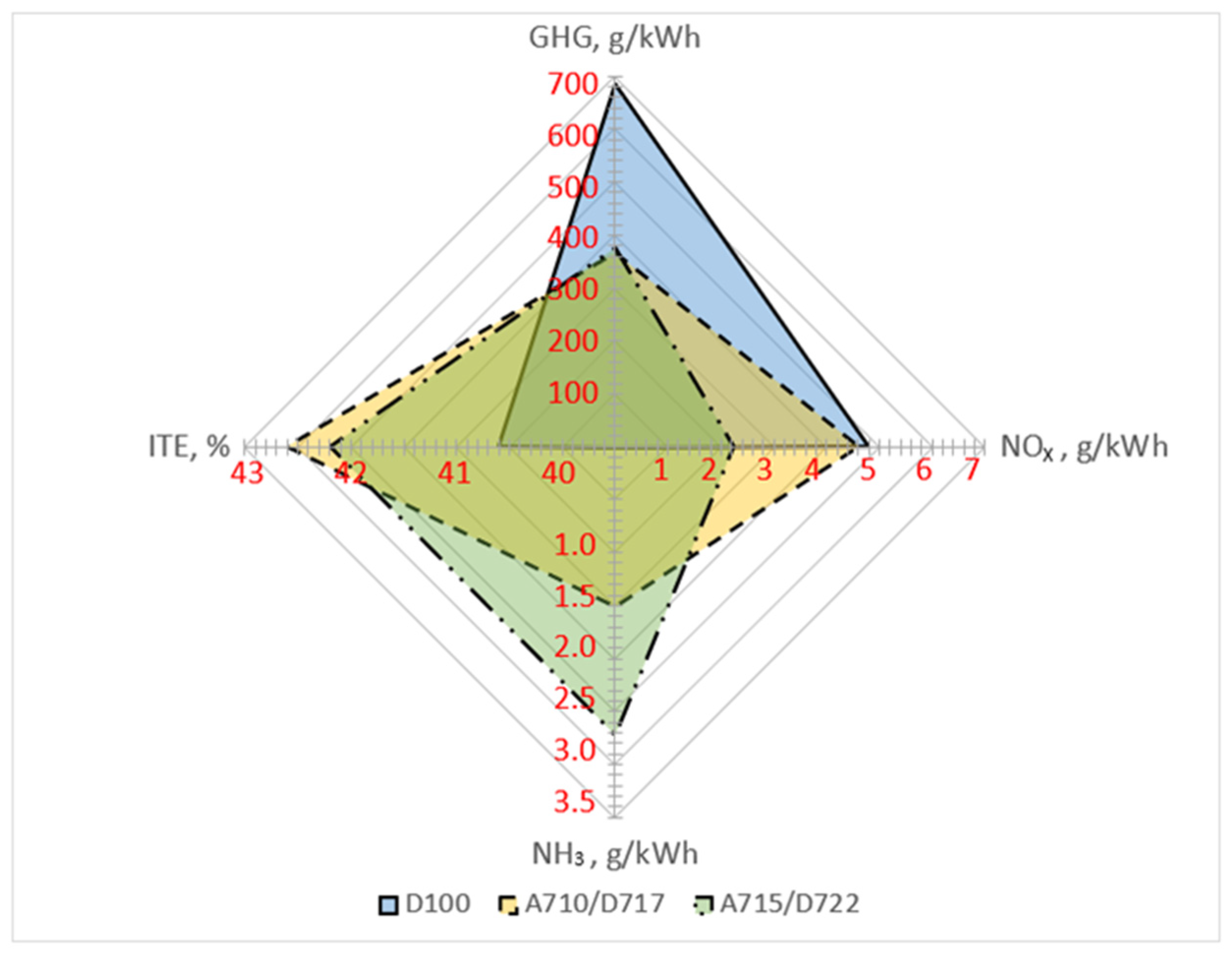

3.5. Summary of Results

3.6. Effect of Engine Loads on Air Pollution Compliance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| B/S | cylinder bore, stroke; |

| BSFC | brake specific fuel consumption; |

| CAD | crank angle degrees; |

| CH4 | methane; |

| CO2 | carbon dioxide; |

| D100 | 100% diesel fuel; |

| D5/A95 | mixture of 5% diesel and 95% ammonia fuel; |

| EU | European Union; |

| GHG | greenhouse gases; |

| HPDF | high-pressure dual-fuel strategy; |

| HRC | heat release characteristic; |

| IMEP | indicated mean indicative pressure; |

| IMO | International Maritime Organization; |

| ITE | indicative thermal efficiency; |

| LNG | liquified natural gas; |

| LPDF | low-pressure dual-fuel strategy; |

| MM | mathematical model; |

| N2O | dinitrogen oxide; |

| NH3 | ammonia; |

| NOx | nitrous oxides; |

| PM | particulate matter; |

| TDC | top dead center; |

| Symbols | |

| Pi | indicated power (kW); |

| Pinj | ammonia injection pressure (bar); |

| Pk | cylinder pressure reading (bar); |

| Pmax | maximum cycle pressure (bar); |

| Tmax | maximum cycle temperature (K). |

References

- United Nations Conference on Trade and Development. Review of Maritime Transport 2023. UNCTAD 2023. Available online: https://unctad.org/publication/review-maritime-transport-2023 (accessed on 17 May 2024).

- International Maritime Organization. Annex 15, Resolution MEPC.377(80). 2023 Strategy on Reduction of GHG Emissions from Ships. Available online: https://wwwcdn.imo.org/localresources/en/OurWork/Environment/Documents/annex/MEPC%2080/Annex%2015.pdf (accessed on 17 May 2024).

- SEC (2021) 562 Final. Regulation of the European Parliament and of the Council on the Use of Renewable and Low-Carbon Fuels in Maritime Transport and Amending Directive 2009/16/EC. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=COM:2021:562:FIN (accessed on 18 May 2024).

- DNV Report. Maritime Forecast to 2050. Available online: https://www.dnv.com/maritime/publications/maritime-forecast-2023/index.html (accessed on 18 May 2024).

- Maersk. Maersk to Deploy First Large Methanol-Enabled Vessel on Asia—Europe Trade Lane. 7 December 2023. Available online: https://www.maersk.com/news/articles/2023/12/07/maersk-to-deploy-first-large-methanol-enabled-vessel-on-asia-europe-trade-lane (accessed on 21 May 2024).

- Wartsila. Methanol as Marine Fuel—Is It the Solution You Are Looking For? 20 February 2023. Available online: https://www.wartsila.com/insights/article/methanol-fuel-for-thought-in-our-deep-dive-q-a (accessed on 20 May 2024).

- Reiter, A.J.; Kong, S.C. Combustion and emissions characteristics of compression-ignition engine using dual ammonia-diesel fuel. Fuel 2011, 90, 87–97. [Google Scholar] [CrossRef]

- French, J.M.B.; Northrop, W.J.; Ricketts, D.S. Ammonia as a transportation fuel: Challenges and opportunities. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2006, 220, 785–800. [Google Scholar]

- Huang, Y.; Zhou, Y.; Xu, M.; Liu, X.; Zhang, Y.; Wang, J.; Li, Y.; Chen, H.; Guo, Q.; Zhang, Y.; et al. Formation and environmental impact of secondary aerosols from ammonia slip in diesel engine exhaust. Environ. Sci. Technol. 2020, 54, 2345–2353. [Google Scholar]

- Zhang, Y.; Li, J.; Huang, Y.; Chen, H.; Xu, M.; Zhang, Y.; Liu, X.; Zhou, Y.; Wang, J.; Guo, Q.; et al. Health effects of fine particulate matter and secondary aerosols formed from ammonia slip. Atmos. Environ. 2022, 265, 118736. [Google Scholar]

- Glibert, P.M.; Burkholder, J.M.; Anderson, D.M.; Coyne, K.J.; Dennison, W.C.; Glasgow, H.B.; Golisz, S.; Heil, C.A.; Hoagland, P.; Hutchins, D.A.; et al. Eutrophication and harmful algal blooms: A review of the past, present, and future. Harmful Algae 2015, 4, 12–33. [Google Scholar]

- Bricker, S.B.; Long, S.; Ward, S.; Weisman, W.; Tanguay, S.; McGinty, M.; McClain, M.; Batiuk, R.A.; Smith, D.E.; Johnson, K.M.; et al. Effects of nutrient enrichment on the water quality and eutrophication of coastal systems. Mar. Pollut. Bull. 2008, 56, 1844–1860. [Google Scholar]

- Jørgensen, B.B.; Kuhl, M.; Tiano, L.; Herndl, G.J.; Meyer-Reil, L.A.; Berg, P.; Canfield, D.E.; Des Marais, D.J.; Fennel, K.; Gundersen, J.K.; et al. The role of ammonia in marine ecosystems. Mar. Ecol. Prog. Ser. 2013, 475, 93–110. [Google Scholar]

- Smith, R.; Kim, J.; Lewis, D. Application of exhaust gas recirculation in CI engines. J. Mech. Eng. 2020, 42, 112–125. [Google Scholar]

- Johnson, A.; Lee, H. Effectiveness of wet scrubbers in reducing ammonia emissions. Environ. Eng. Sci. 2019, 36, 673–684. [Google Scholar]

- Wang, L.; Zhao, Y.; Zhang, Q. Ammonia oxidation catalysts for emission control. Catal. Rev. 2021, 63, 785–800. [Google Scholar]

- Brown, T.; Green, R.; Wilson, J. Selective catalytic reduction for NOx control in diesel engines. J. Emiss. Control. 2018, 12, 145–158. [Google Scholar]

- DNV Report 2024. New DNV Fuel Ready and Gas Fuelled Ammonia Class Notations Provide Maximum Flexibility to Tackle Shipping’s Carbon Curve. Available online: https://www.dnv.com/news/new-dnv-fuel-ready-and-gas-fuelled-ammonia-class-notations-provide-maximum-flexibility-to-tackle-shipping-s-carbon-curve-203646 (accessed on 24 May 2024).

- Ryu, K.; Zacharakis-Jutz, G.E.; Kong, S.C. Performance characteristics of compression-ignition engine using high concentration of ammonia mixed with dimethyl ether. Appl. Energy 2014, 113, 488–499. [Google Scholar] [CrossRef]

- Dimitriou, P.; Javaid, R. A review of ammonia as a compression ignition engine fuel. Int. J. Hydrogen Energy 2020, 45, 7098–7118. [Google Scholar] [CrossRef]

- Nadimi, E.; Przybyła, G.; Lewandowski, M.T.; Adamczyk, W. Effects of ammonia on combustion, emissions, and performance of the ammonia/diesel dual-fuel compression ignition engine. J. Energy Inst. 2023, 107, 101158. [Google Scholar] [CrossRef]

- Yousefi, A.; Guo, H.; Dev, S.; Liko, B.; Lafrance, S. Effects of ammonia energy fraction and diesel injection timing on combustion and emissions of an ammonia/diesel dual-fuel engine. Fuel 2022, 314, 122723. [Google Scholar] [CrossRef]

- Li, T.; Zhou, X.; Wang, N.; Wang, X.; Chen, R.; Li, S. A comparison between low and high-pressure injection dual-fuel modes of diesel-pilot-ignition ammonia combustion engines. J. Energy Inst. 2022, 102, 362–373. [Google Scholar] [CrossRef]

- Scharl, V.; Sattelmayer, T. Ignition and combustion characteristics of diesel piloted ammonia injections. Fuel Commun. 2022, 11, 100068. [Google Scholar] [CrossRef]

- Shin, J.; Park, S. Numerical analysis and optimization of combustion and emissions in an ammonia-diesel dual-fuel engine using an ammonia direct injection strategy. Energy 2024, 289, 130014. [Google Scholar] [CrossRef]

- Zhang, Z.; Long, W.; Dong, P.; Tian, H.; Tian, J.; Li, B.; Wang, Y. Performance characteristics of a two-stroke low speed engine applying ammonia/diesel dual direct injection strategy. Fuel 2023, 332, 126086. [Google Scholar] [CrossRef]

- Li, T.; Zhou, X.; Wang, N.; Wang, X.; Chen, R.; Li, S. Pilot diesel-ignited ammonia dual fuel low-speed marine engines: A comparative analysis of ammonia premixed and high-pressure spray combustion modes with CFD simulation. Renew. Sustain. Energy Rev. 2023, 173, 113108. [Google Scholar]

- Kruggel, O. Progress in the combustion technology of high performance diesel engines toward reduction of exhaust emissions without reduction of operation economy. In Proceedings of the Baden–Wurttemberg Technology Conference, Westborough, MA, USA, 12–14 June 1989; p. 14. [Google Scholar]

- Kakaee, A.H.; Rahnama, P.; Paykani, A. Influence of fuel composition on combustion and emissions characteristics of natural gas/diesel RCCI engine. J. Nat. Gas Sci. Eng. 2015, 25, 58–65. [Google Scholar] [CrossRef]

- Yang, B.; Xi, C.; Wei, X.; Zeng, K.; Lai, M.C. Parametric investigation of natural gas port injection and diesel pilot injection on the combustion and emissions of a turbocharged common rail dual-fuel engine at low load. Appl. Energy 2015, 143, 130–137. [Google Scholar] [CrossRef]

- Gatts, T.; Liu, S.; Liew, C.; Ralston, B.; Bell, C.; Li, H. An experimental investigation of incomplete combustion of gaseous fuels of a heavy-duty diesel engine supplemented with hydrogen and natural gas. Int. J. Hydrogen Energy 2012, 37, 7848–7859. [Google Scholar] [CrossRef]

- Wang, C.; Yang, Y.; Yang, J. Numerical simulation of ammonia combustion in a marine diesel engine using a multi-zone combustion model. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2021, 235, 282–293. [Google Scholar]

- Togashi, M.; Nishimura, S.; Ishikawa, K.; Yamada, Y. Multi-zone modeling of ammonia combustion in a marine diesel engine. J. Mar. Sci. Technol. 2021, 26, 275–287. [Google Scholar]

- Sato, K.; Suzuki, Y.; Takagi, Y.; Hasegawa, H. Development of a multi-zone combustion model for ammonia combustion in diesel engines. Energy 2020, 208, 118387. [Google Scholar]

- AVL BOOST Simulation Software. Available online: https://www.avl.com/en/simulation-solutions (accessed on 2 June 2024).

- Mollenhauer, K.; Tschöke, H. Handbook of Diesel Engines; Springer: Berlin/Heidelberg, Germany, 2010; 636p. [Google Scholar]

- Heywood, J.B. Internal Combustion Engine Fundamentals; McGraw-Hill Education: New York, NY, USA, 1988; 930p. [Google Scholar]

- Drazdauskas, M.; Lebedevas, S. Optimization of combustion cycle energy efficiency and exhaust gas emissions of marine dual-fuel engine by intensifying ammonia injection. J. Mar. Sci. Eng. 2024, 12, 309. [Google Scholar] [CrossRef]

- Woodyard, D. Medium speed engines—Introduction. In Marine Diesel Engines; Elsevier: Amsterdam, The Netherlands, 2004; pp. 498–516. [Google Scholar]

- Glarborg, P.; Miller, J.A.; Ruscic, B.; Klippenstein, S.J. Modeling nitrogen chemistry in combustion. Prog. Energy Combust. Sci. 2018, 67, 31–68. [Google Scholar] [CrossRef]

- Dukowicz, J.K. A Particle-fluid numerical model for liquid sprays. J. Comput. Phys. 1980, 35, 229–253. [Google Scholar] [CrossRef]

- Schiller, L.; Naumann, A. A Drag Coefficient Correlation. VDI Ztg. 1933, 77, 318–320. [Google Scholar]

- Abramzon, B.; Sirignano, W.A. Droplet vaporization model for spray combustion calculations. In Proceedings of the AIAA 26th Aerospace Sciences Meeting, Reno, NV, USA, 11–14 January 1988. [Google Scholar]

- ISO 8178-1:2017; Internal Combustion Engines—Exhaust Emission Measurement—Part 1: Test Cycle for Diesel Engines. Available online: https://www.iso.org/standard/64710.html (accessed on 10 June 2024).

- Schulte, H.; Duernholz, M.; Wuebbeke, K. The Contribution of the fuel injection system to meeting future demands on truck diesel engines. SAE Trans. 1990, 99, 157–162. [Google Scholar]

- MTU, Deutsche Aerospace. Series 396 Engines; VTS 05076 (520 E); MTU, Deutsche Aerospace: Munich, Germany, 1990; 22p. [Google Scholar]

- Shundoh, S.; Kakegawa, T.; Tsujimura, K.; Kobayashi, S. The effect of injection parameters and swirl on diesel combustion with high pressure fuel injection. SAE Trans. 1991, 100, 793–805. [Google Scholar]

- Stas, M.; Wajand, J.; Bestimmung, D.V. Parameters for the two-phase combustion process in direct injection diesel engines. MTZ Mot. 1988, 49, 289–293. [Google Scholar]

- Lyon, R.K. The chemistry of the thermal DeNOx process: A review of the thechnology’s possible application to control of NOx from diesel engines. In Proceedings of the 7th Diesel Engine Emissions Reduction (DEER) Workshop 2001, Portsmouth, VA, USA, 5–9 August 2001. [Google Scholar]

| Parameter | Diesel (D100) | Ammonia + Diesel (D5/A95) |

|---|---|---|

| Case D100 start of injection, CAD | 710° | - |

| Case A695/D702 start of injection, CAD | - | 695° NH3; 702° Pilot |

| Case A700/D707 start of injection, CAD | - | 700° NH3; 707° Pilot |

| Case A705/D712 start of injection, CAD | - | 705° NH3; 712° Pilot |

| Case A710/D717 start of injection, CAD | - | 710° NH3; 717° Pilot |

| Case A715/D722 start of injection, CAD | - | 715° NH3; 722° Pilot |

| Case A695/D717 start of injection, CAD | - | 695° NH3; 717° Pilot |

| Case A700/D717 start of injection, CAD | - | 700° NH3; 717° Pilot |

| Case A705/D717 start of injection, CAD | - | 705° NH3; 717° Pilot |

| Case A715/D717 start of injection, CAD | - | 715° NH3; 717° Pilot |

| Diesel injection duration, CAD | 26° | 3° |

| Ammonia injection duration, CAD | - | 26° |

| Injected mass (Diesel), g | 1.87 | 0.1037 |

| Injected mass (Ammonia), g | - | 4.016 |

| Injection pressure (Diesel), bar | 500 | 500 |

| Injection pressure (Ammonia), bar | - | 1000 |

| Diesel calorific value, MJ/kg | 42.5 | |

| Ammonia calorific value, MJ/kg | 18.8 |

| Case 1 | Case 2 | |||

|---|---|---|---|---|

| Parameter | Pinj 500 bar | Li, T. et al. [23] | Pinj 1000 bar | Li, T. et al. [27] |

| Engine type | 4-stroke | 4-stroke | 4-stroke | 2-stroke |

| Bore, mm | 460 | 95 | 460 | 340 |

| Stroke, mm | 580 | 102 | 580 | 1600 |

| Engine speed, RPM | 500 | 1000 | 500 | 157 |

| Dual-fuel ratio | D5/A95 | D3/A97 | D5/A95 | D3/A97 |

| Diesel injector nozzle hole number | 10 | 8 | 10 | 4 |

| Ammonia injector nozzle hole number | 10 | 8 | 10 | 4 |

| Diesel and ammonia injector nozzle hole angle | 0° | 0° | 0° | 0° |

| Diesel injection pressure, bar | 500 | 600 | 500 | 200 |

| Ammonia injection pressure, bar | 500 | 600 | 1000 | 1000 |

| Start of diesel injection, CAD | −3° TDC | −8° TDC | −3° TDC | −4° TDC |

| Start of ammonia injection, CAD | −10° TDC | −5° TDC | −10° TDC | −2° TDC |

| Ammonia ignition delay after diesel ignition, CAD | 7° | 4° | 4° | 1° |

| * Pmax, % | >17 | >8 | <9 | <10 |

| * Tmax, % | >2 | >7 | <10 | 0 |

| * T at 60° CAD ATDC, % | >5 | >7 | >7 | >20 |

| * ITE, % | <2.2 | 0 | <4.6 | >1.1 |

| * CO2, % | >94 | >96 | >94 | >96 |

| * NOx, % | >72 | >50 | >5 | >46 |

| N2O, g/kWh | from 0.003 to 1.67 | from 0 to 25 ppm | from 0.003 to 1.22 | from 0.0007 to 0.0016 |

| Unburned NH3, g/kWh | from 0.011 to 8.94 | from 0 to 130 ppm | from 0.011 to 1.51 | N/A |

| Parameter | Engine Parameters under the E2 Cycle, IMO MARPOL VI Annex VI | |||

|---|---|---|---|---|

| Engine load, % | 100 | 75 | 50 | |

| Impact coefficient | 0.2 | 0.5 | 0.3 | |

| Emissions with D100 fuel, including impact coefficient | Sum of E2 cycle emissions, g/kWh | |||

| NOx, g/kWh | 1.09 | 2.40 | 2.17 | 5.7 |

| CO2, g/kWh | 106.37 | 281.98 | 191.64 | 580.0 |

| GHG, g/kWh | 110.10 | 342.06 | 273.40 | 725.6 |

| Emissions with D5/A95 fuel, including impact coefficient | ||||

| NOx, g/kWh | 1.28 | 2.35 | 0.32 | 4.0 |

| CO2, g/kWh | 6.72 | 17.04 | 12.81 | 36.6 |

| GHG, g/kWh | 46.71 | 187.95 | 60.26 | 294.9 |

| Emissions regulation targets | ||||

| NOx limit per IMO Reg. 13, g/kWh | Tier I—13.0 | Tier II—10.5 | Tier III—2.6 | |

| Year 2030 | Year 2040 | Year 2050 | ||

| IMO EEXI (CO2) | 40% | - | - | |

| IMO GHG | 20–30% | 70–80% | 100% | |

| EU GHG | 55% | - | 90% | |

| Calculated limit for D100 fuel, used as the basis for the D5/A95 limit, g/kWh | ||||

| IMO EEXI (CO2) | 348.0 | - | - | |

| IMO GHG | 580.4–507.9 | 217.7–145.1 | 0 | |

| EU GHG | 326.5 | - | 72.6 | |

| Actual result for D5/A95 fuel, g/kWh | ||||

| IMO EEXI (CO2) | 36.6 | |||

| IMO GHG | 294.9 | |||

| EU GHG | 294.9 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Drazdauskas, M.; Lebedevas, S. Numerical Study on Optimization of Combustion Cycle Parameters and Exhaust Gas Emissions in Marine Dual-Fuel Engines by Adjusting Ammonia Injection Phases. J. Mar. Sci. Eng. 2024, 12, 1340. https://doi.org/10.3390/jmse12081340

Drazdauskas M, Lebedevas S. Numerical Study on Optimization of Combustion Cycle Parameters and Exhaust Gas Emissions in Marine Dual-Fuel Engines by Adjusting Ammonia Injection Phases. Journal of Marine Science and Engineering. 2024; 12(8):1340. https://doi.org/10.3390/jmse12081340

Chicago/Turabian StyleDrazdauskas, Martynas, and Sergejus Lebedevas. 2024. "Numerical Study on Optimization of Combustion Cycle Parameters and Exhaust Gas Emissions in Marine Dual-Fuel Engines by Adjusting Ammonia Injection Phases" Journal of Marine Science and Engineering 12, no. 8: 1340. https://doi.org/10.3390/jmse12081340

APA StyleDrazdauskas, M., & Lebedevas, S. (2024). Numerical Study on Optimization of Combustion Cycle Parameters and Exhaust Gas Emissions in Marine Dual-Fuel Engines by Adjusting Ammonia Injection Phases. Journal of Marine Science and Engineering, 12(8), 1340. https://doi.org/10.3390/jmse12081340