Recent Progress on Built-in Wave Energy Converters: A Review

Abstract

1. Introduction

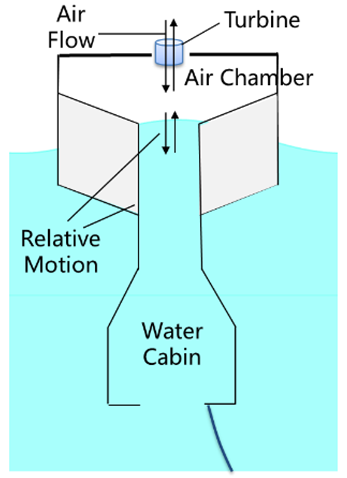

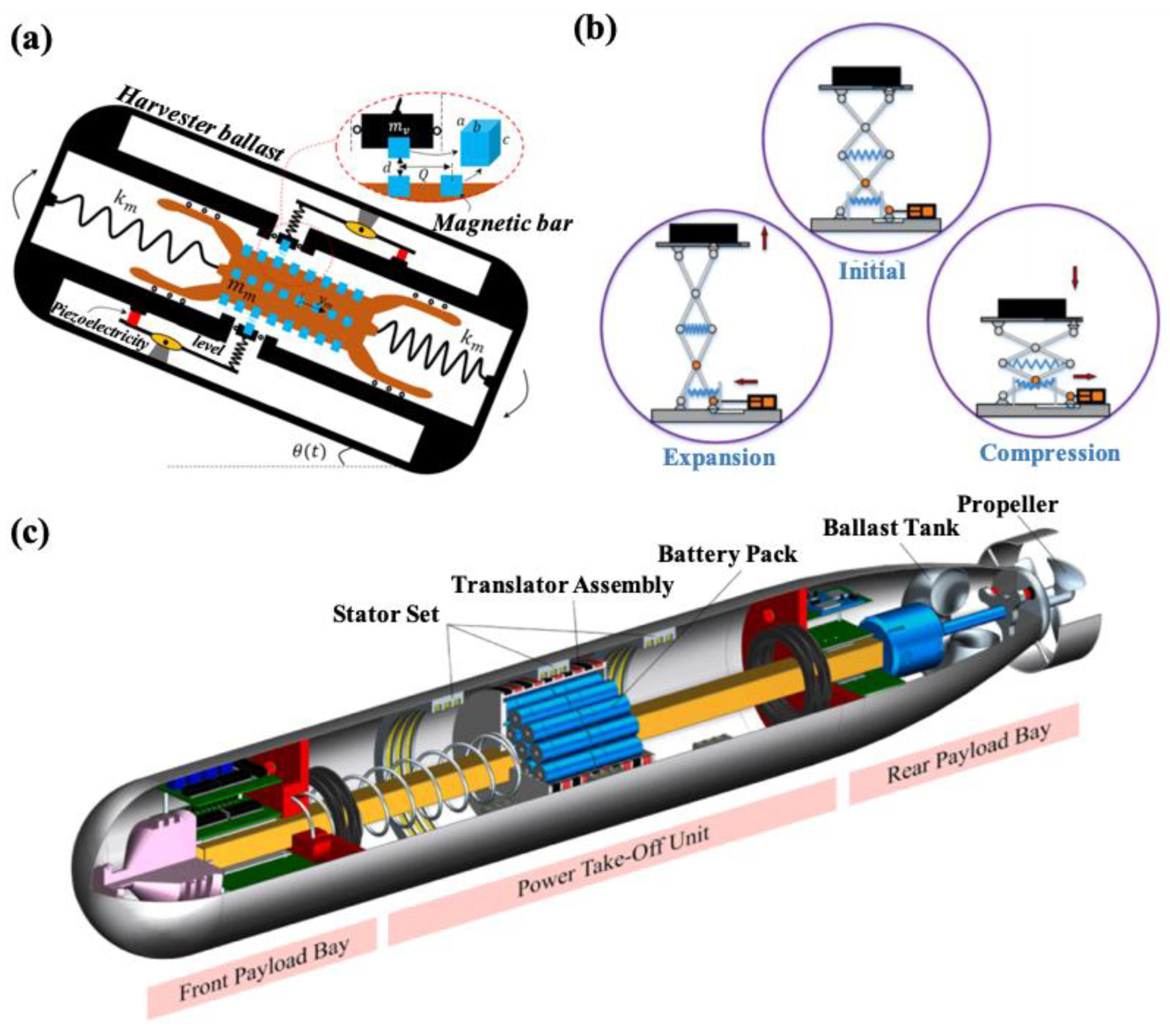

2. Wave Energy Capture

| Oscillating Water Column Type [29] | Oscillating Body Type (Two Bodies/Multiple Bodies) [30] | Oscillating Body Type (Single Body, Pull-Out Mooring Required) [31] | Oscillating Body Type (Single Body, Fully Encapsulated) [32] |

|---|---|---|---|

|  |  |  |

| 1. It is necessary to connect the air chamber, water compartment, and seawater successively; 2. Openings are required both above the waterline and below the waterline. | 1. Two or more floating bodies are required; 2. Transmission/connecting structures partially contact seawater directly. | 1. It is required to connect to an anchoring (fixed) point; 2. Transmission/connecting structures partially contact seawater directly. | 1. Completely integrated into its carrier as an internal module; 2. Transmission/connecting structure does not contact seawater directly. |

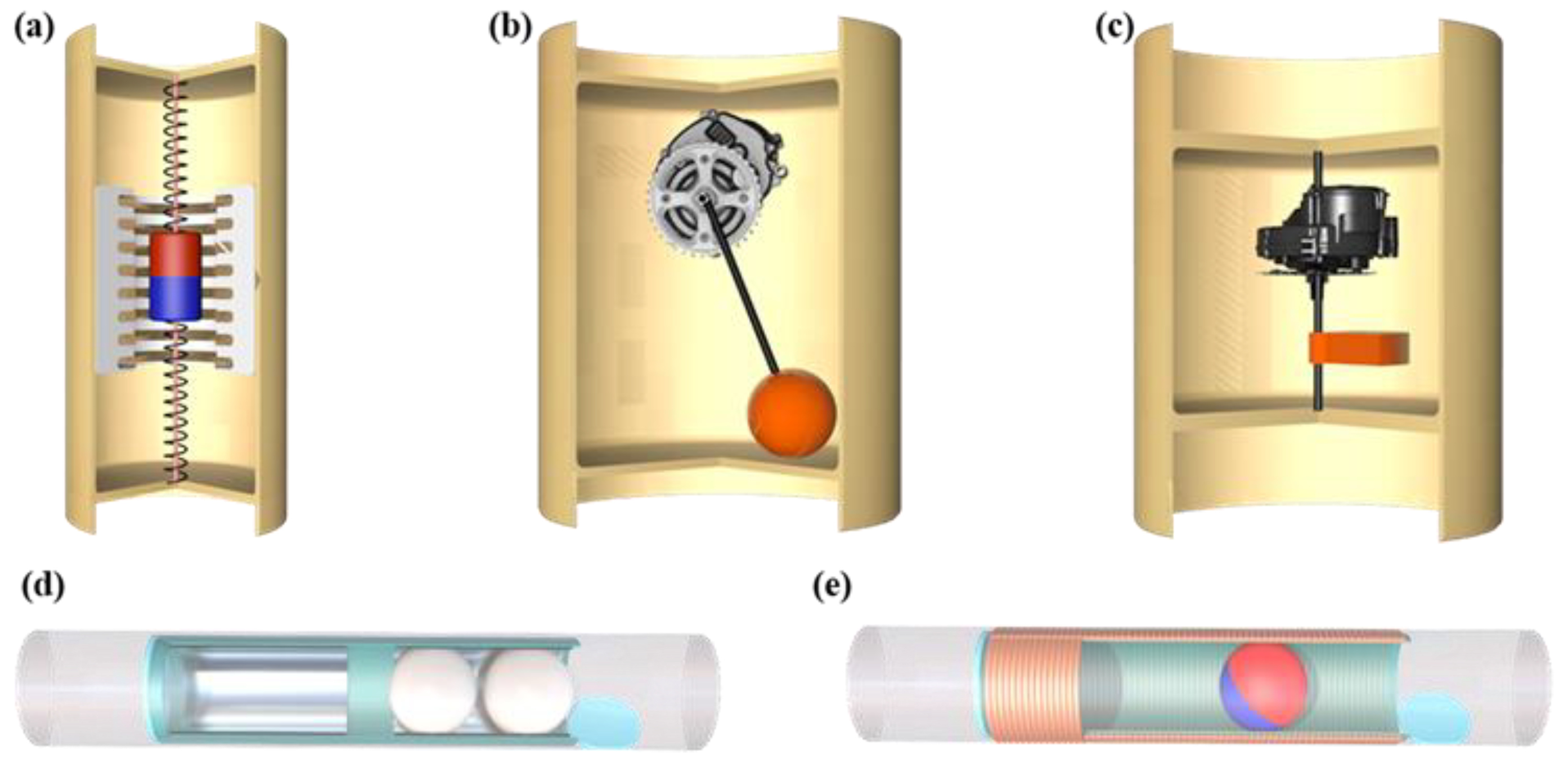

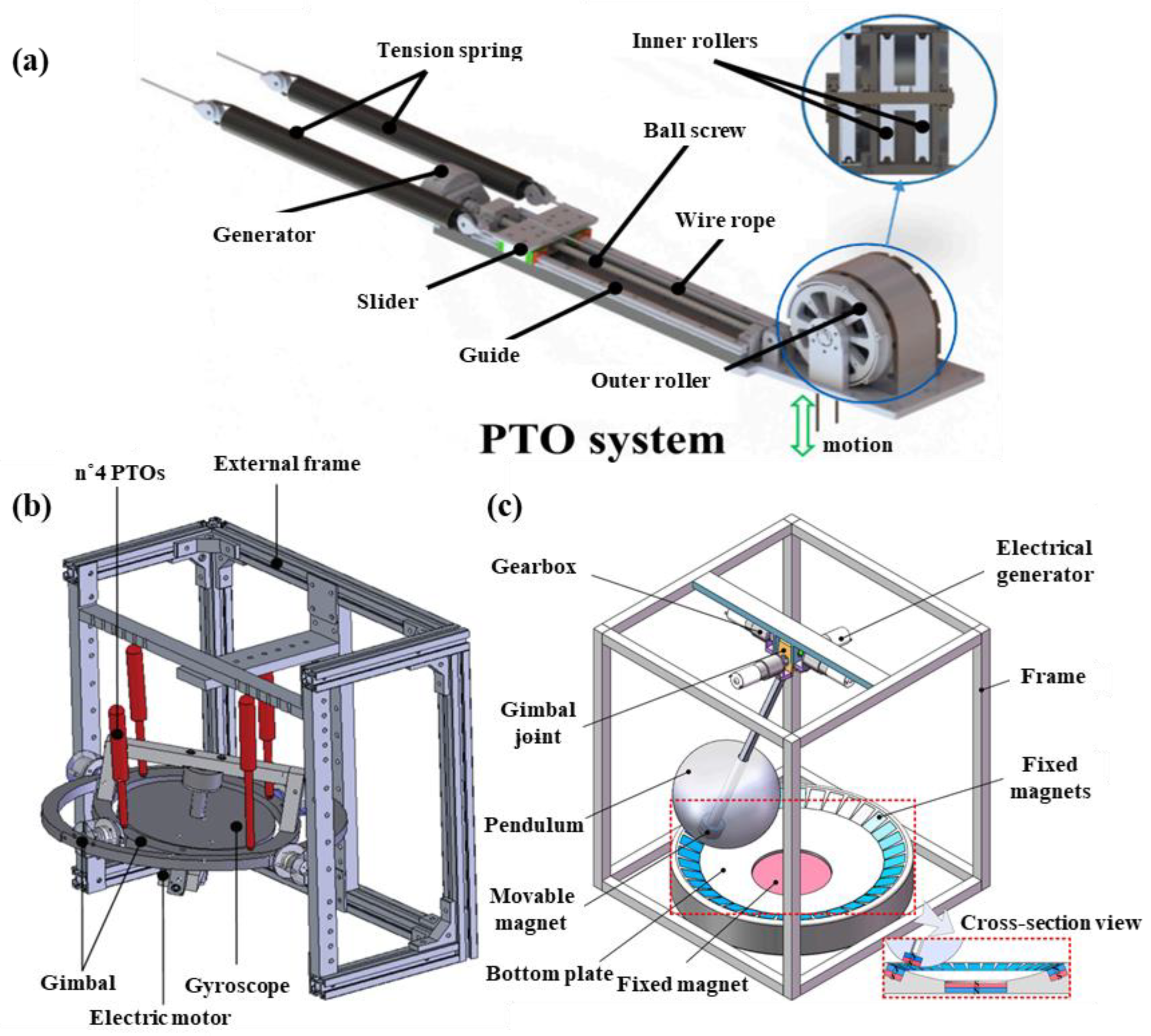

3. The Power Take-Off (PTO)

4. Controls

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, J.; Wang, Z.; Wang, Y.; Liu, S.; Li, Y. Current situation and trend of marine data buoy and monitoring network technology of China. Acta Oceanolog. Sin. 2016, 35, 1–10. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, Y.; Yu, X.; Yuan, C. Unmanned surface vehicles: An overview of developments and challenges. Annu. Rev. Control 2016, 41, 71–93. [Google Scholar] [CrossRef]

- Zhou, J.; Huang, H.; Huang, H.; Si, Y.; Shi, K.; Quan, X.Q.; Guo, C.; Chen, C.L.; Wang, Z.; Wang, Y. AUH, a New Technology for Ocean Exploration. Engineering 2023, 25, 21–27. [Google Scholar] [CrossRef]

- Krawczewicz, M.; Greene, E. Micro Ocean Renewable Energy; Eric Greene Associates, Inc.: Annapolis, MD, USA, 2012. [Google Scholar]

- Shaikh, K.; Zeadally, S. Energy harvesting in wireless sensor networks: A comprehensive review. Renew. Sustain. Energy Rev. 2016, 55, 1041–1054. [Google Scholar] [CrossRef]

- Mahdy, A.; Hasanien, M.; Aleem, A.; Al-Dhaifallah, M.; Zobaa, F.; Ali, M. State-of-the-Art of the most commonly adopted wave energy conversion systems. Ain Shams Eng. J. 2024, 15, 102322. [Google Scholar] [CrossRef]

- Mwasilu, F.; Jung, J. Potential for power generation from ocean wave renewable energy source: A comprehensive review on state-of-the-art technology and future prospects. IET Renew. Power Gener. 2019, 13, 363–375. [Google Scholar] [CrossRef]

- Zeng, F.; Wang, T. In-situ wave energy harvesting for unmanned marine devices: A review. Ocean Eng. 2023, 285, 115376. [Google Scholar] [CrossRef]

- Clemente, D.; Rosa-Santos, P.; Taveira-Pinto, F. On the potential synergies and applications of wave energy converters: A review. Renew. Sustain. Energy Rev. 2021, 135, 110162. [Google Scholar] [CrossRef]

- López, I.; Andreu, J.; Ceballos, S.; Martínez de Alegría, I.; Kortabarria, I. Review of wave energy technologies and the necessary power-equipment. Renew. Sustain. Energy Rev. 2013, 27, 413–434. [Google Scholar] [CrossRef]

- Barua, A.; Salauddin Rasel, M. Advances and challenges in ocean wave energy harvesting. Sustain. Energy Technol. Assess. 2024, 61, 103599. [Google Scholar] [CrossRef]

- Xu, R.; Wang, H.; Xi, Z.; Wang, W.; Xu, M. Recent Progress on Wave Energy Marine Buoys. J. Mar. Sci. Eng. 2022, 10, 566. [Google Scholar] [CrossRef]

- Ocean Power Technologies. OPT Unveils Autonomous Surface Surveillance Solution for Offshore Territorial Applications. 2020. Available online: https://oceanpowertechnologies.com/news/opt-unveils-autonomous-surface-surveillance-solution-for-offshore-territorial-applications/ (accessed on 5 May 2024).

- Shanghai Jiaotong University. Jiaolong Wave-Powered Gilder Sea Trialed Successfully. Available online: http://ime.sjtu.edu.cn/info/1050/2299.htm, (accessed on 15 May 2024).

- Chen, K.; Sheng, S.; Jiaqiang, J.; Wang, K.; Ye, Y.; Zhang, Y. Research on energy conversion system of kilowatt small hydraulic wave energy device. Acta Energ. Sol. Sin. 2022, 43, 471–476. (In Chinese) [Google Scholar]

- Hasan Maheen, M.; Yang, Y. Wave energy converters with rigid hull encapsulation: A review. Sustain. Energy Technol. Assess. 2023, 57, 103273. [Google Scholar] [CrossRef]

- Pei, Z.; Jing, H.; Tang, Z.; Fu, Y. Experimental Validation of a Gyroscope Wave Energy Converter for Autonomous Underwater Vehicles. Appl. Sci. 2021, 11, 11115. [Google Scholar] [CrossRef]

- Coe, R.G.; Neary, V.S.; Lawon, M.J.; Yu, Y.; Weber, J. Extreme Conditions Modeling Workshop Report; National Renewable Energy Lab (NREL): Golden, CO, USA, 2014.

- Khedkar, K.; Nangia, N.; Thirumalaisamy, R.; Bhalla, S. The inertial sea wave energy converter (ISWEC) technology: Device-physics, multiphase modeling and simulations. Ocean Eng. 2021, 229, 108879. [Google Scholar] [CrossRef]

- Penguin Wave Energy Device Starts Producing Power Offshore Basque Country. 2021. Available online: http://www.offshore-energy.biz/penguin-wave-energy-device-starts-producing-power-offshore-basque-country (accessed on 3 April 2024).

- Toyoshima, A.; Hosaka, H. Spin acceleration mechanism for wave energy converter using gyroscopic effect and geared feedback. Sens. Actuators A 2021, 332, 113186. [Google Scholar] [CrossRef]

- Bracco, G.; Giorcelli, E.; Mattiazzo, G. ISWEC: A gyroscopic mechanism for wave power exploitation. Mech. Mach. Theory 2011, 46, 1411–1424. [Google Scholar] [CrossRef]

- Falcão, O. Wave energy utilization: A review of the technologies. Renew. Sustain. Energy Rev. 2010, 14, 899–918. [Google Scholar] [CrossRef]

- Qiu, S.; Liu, K.; Wang, D.; Ye, J.; Liang, F. A comprehensive review of ocean wave energy research and development in China. Renew. Sustain. Energy Rev. 2019, 113, 109271. [Google Scholar] [CrossRef]

- Shalby, M.; Dorrell, G.; Walker, P. Multi–chamber oscillating water column wave energy converters and air turbines: A review. Int. J. Energy Res. 2019, 43, 681–696. [Google Scholar] [CrossRef]

- Zhou, Y.; Ning, D.; Liang, D.; Cai, S. Nonlinear hydrodynamic analysis of an offshore oscillating water column wave energy converter. Renew. Sustain. Energy Rev. 2021, 145, 111086. [Google Scholar] [CrossRef]

- Ning, D.; Liang, C.; Chen, L.; Zhang, C. Numerical investigation on the propagation and evolution of focused waves over a sloping bed. Ocean Eng. 2022, 250, 111035. [Google Scholar] [CrossRef]

- Liang, X.; Yang, G.; Wu, H. Research on the BD102G type wave energy generation device for navigational buoy. Renew. Energy Resour. 2014, 32, 1933–1938. (In Chinese) [Google Scholar]

- Correia da Fonseca, X.; Gomes, F.; Henriques, C.; Gato, C.; Falcão, O. Model testing of an oscillating water column spar-buoy wave energy converter isolated and in array: Motions and mooring forces. Energy 2016, 112, 1207–1218. [Google Scholar] [CrossRef]

- Ocean Power Technologies. 2022. Available online: https://oceanpowertechnologies.com/pb3-powerbuoy (accessed on 12 April 2024).

- Weaver, W.; Wilson, G.; Hagmuller, A.; Ginsburg, M.; Bacelli, G.; Robinett, D.; Coe, R.; Budi, G. Super Capacitor Energy Storage System Design for Wave Energy Converter Demonstration. In Proceedings of the 2020 International Symposium on Power Electronics, Electrical Drives, Automation and Motion (SPEEDAM), Sorrento, Italy, 24–26 June 2020. [Google Scholar]

- Li, B.; Zhang, R.; Zhang, B.; Cui, Y.; Yang, Q. A New Energy Recovery Device by Utilizing the Merchant Ship Rolling. IEEE Access 2020, 8, 162049–162065. [Google Scholar] [CrossRef]

- Chandrasekaran, S.; Khan, F.; Abbassi, R. Wave Energy Devices: Design, Development, and Experimental Studies; CRC Press: Boca Raton, FL, USA, 2022. [Google Scholar]

- Gallutia, D.; Fard, T.; Soto, G.; He, E. Recent advances in wave energy conversion systems: From wave theory to devices and control strategies. Ocean Eng. 2022, 252, 111105. [Google Scholar] [CrossRef]

- Hou, C.; Chen, T.; Li, Y.; Huang, M.; Shi, Q.; Liu, H.; Sun, L.; Lee, E. A rotational pendulum based electromagnetic/triboelectric hybrid-generator for ultra-low-frequency vibrations aiming at human motion and blue energy applications. Nano Energy 2019, 63, 103871. [Google Scholar] [CrossRef]

- Sirigu, S.A.; Bonfanti, M.; Passione, B.; Ermina, B.; Carlo, B.; Dafnakis, P.; Bracco, G.; Giorcelli, E.; Mattiazzo, G. Experimental investigation of the hydrodynamic performance of the ISWEC 1:20 scaled device. In Proceedings of the NAV International Conference on Ship and Shipping Research, Venice, Italy, 20 June 2018. [Google Scholar]

- Sirigu, S.A.; Bonfanti, M.; Begovic, E.; Bertorello, C.; Dafnakis, P.; Giorgi, G.; Bracco, G.; Mattiazzo, G. Experimental Investigation of the Mooring System of a Wave Energy Converter in Operating and Extreme Wave Conditions. J. Mar. Sci. Eng. 2020, 8, 180. [Google Scholar] [CrossRef]

- Zhang, Z.; Nielsen, R.; Basu, B. Dynamics and Control of the GyroPTO Wave Energy Point Absorber under Sea Waves. Procedia Eng. 2017, 199, 1828–1833. [Google Scholar] [CrossRef]

- Crowley, S.; Porter, R.; Taunton, D.; Wilson, P. Modelling of the WITT wave energy converter. Renew. Energy 2018, 115, 159–174. [Google Scholar] [CrossRef]

- Babarit, A.; Clement, A. Shape otimisation of the searev wave energy converter. In Proceedings of the World Renewable Energy Conference, Florence, Italy, 19–25 August 2006. [Google Scholar]

- McCabe, A.; Bradshaw, A.; Meadowcroft, J.; Aggidis, G. Developments in the design of the PS Frog Mk 5 wave energy converter. Renew. Energy 2006, 31, 141–151. [Google Scholar] [CrossRef]

- Chen, Z.; Zhou, B.; Zhang, L.; Sun, L.; Zhang, X. Performance evaluation of a dual resonance wave-energy convertor in irregular waves. Appl. Ocean Res. 2018, 77, 78–88. [Google Scholar] [CrossRef]

- Jin, C.; Kang, H.; Kim, M.; Bakti, F. Performance evaluation of surface riding wave energy converter with linear electric generator. Ocean Eng. 2020, 218, 108141. [Google Scholar] [CrossRef]

- Foteinis, R.; Reviews, E. Wave energy converters in low energy seas: Current state and opportunities. Renew. Sustain. Energy Rev. 2022, 162, 112448. [Google Scholar] [CrossRef]

- Zheng, X.; Jing, F.; He, B. Research on Built-in Power Supply Technology of Floating Equipment Based on Wave Energy. Digit. Ocean. Underw. Warf. 2021, 3, 236–241. (In Chinese) [Google Scholar]

- Lai, W.; Li, J.; Rong, S.; Yang, H.; Zheng, X. Experimental and numerical study on the integration of a built-in wave energy converter (BIWEC) and floating platform. Ocean Eng. 2024, 299, 117408. [Google Scholar] [CrossRef]

- Li, B.; Lv, J.; Deng, F.; Cui, Y.; Zhang, B. The Energy Recovery Effect of Wave Energy Utilization System under the Rolling Motion of Ships. J. Waterw. Port Coast. Ocean Eng. 2023, 149, 04022030. [Google Scholar] [CrossRef]

- Townsend, C.; Shenoi, A. Feasibility study of a new energy scavenging system for an autonomous underwater vehicle. Auton. Rob. 2016, 40, 973–985. [Google Scholar] [CrossRef]

- Clemente, D.; Rosa-Santos, P.; Taveira-Pinto, F.; Martins, P.; Paulo-Moreira, A. Proof-of-concept study on a wave energy converter based on the roll oscillations of multipurpose offshore floating platforms. Energy Convers. Manag. 2020, 224, 113363. [Google Scholar] [CrossRef]

- Clemente, D.; Rosa-Santos, P.; Taveira-Pinto, F.; Martins, P. Influence of platform design and power take-off characteristics on the performance of the E-Motions wave energy converter. Energy Convers. Manag. 2021, 244, 114481. [Google Scholar] [CrossRef]

- Rosa-Santos, P.; Taveira-Pinto, F.; Teixeira, L.; Ribeiro, J. CECO wave energy converter: Experimental proof of concept. J. Renew. Sustain. Energy 2015, 7, 061704. [Google Scholar] [CrossRef]

- Viet, V.; Wang, Q. Ocean wave energy pitching harvester with a frequency tuning capability. Energy 2018, 162, 603–617. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, X.; Al Shami, E.; Baker, J.; Ji, X. A study of a speed amplified linear generator for low-frequency wave energy conversion. Mech. Syst. Signal Process. 2021, 149, 107226. [Google Scholar] [CrossRef]

- Li, M.; Jing, X. A bistable X-structured electromagnetic wave energy converter with a novel mechanical-motion-rectifier: Design, analysis, and experimental tests. Energy Convers. Manag. 2021, 244, 114466. [Google Scholar] [CrossRef]

- Yang, Y.; Martinez, E. Feasibility analysis of a wave powered autonomous underwater vehicle. Energy Convers. Manag. X 2023, 18, 100352. [Google Scholar] [CrossRef]

- Afsharfard, A.; Shin, H.; Hosseini, S.; Kim, S.; Lee, I.; Kim, C. Design of vibro-impact electromagnetic ocean-wave energy harvesting system; an experimental study. Ocean Eng. 2022, 263, 112168. [Google Scholar] [CrossRef]

- Yoshimizu, K.; Sato, T.; Asai, T.; Watanabe, U.; Tsukamoto, S.; Nemoto, Y.; Taniyama, Y. An inerter-integrated wave energy converter for vibration mitigation of offshore floating buoys and its experimental validation. Ocean Eng. 2024, 303, 117789. [Google Scholar] [CrossRef]

- Niosi, F.; Begovic, E.; Bertorello, C.; Rinauro, B.; Sannino, G.; Bonfanti, M.; Sirigu, S.A. Experimental validation of Orcaflex-based numerical models for the PEWEC device. Ocean. Eng. 2023, 281, 114963. [Google Scholar] [CrossRef]

- Agati, G.; Alikhani, A.; Borello, D.; Bracco, G.; Mattiazzo, G.; Pozzi, N.; Sannino, G.; Rispoli, F.; Vissio, G. Assessment Of Loads And Performance Of A Wave Energy Converter For The Mediterranean Sea. In Proceedings of the OSES Conference, Bethesda, MD, USA, 13-15 July 2016. [Google Scholar]

- Pozzi, N.; Bracco, G.; Passione, B.; Sirigu, A.; Mattiazzo, G. PeWEC: Experimental validation of wave to PTO numerical model. Ocean Eng. 2018, 167, 114–129. [Google Scholar] [CrossRef]

- Afsharfard, A.; Lee, I.; Kim, C. Study application of an unmoored ocean wave energy harvester with harmonic and random excitation. Energy Convers. Manag. 2023, 293, 117535. [Google Scholar] [CrossRef]

- Pan, X.; Ling, P.; Bao, H.; He, W.; Li, Q.; Yan, B. Tumbler-inspired electromagnetic generator for low-frequency ocean wave energy harvesting. Energy Convers. Manag. 2023, 294, 117569. [Google Scholar] [CrossRef]

- Liu, W.; Li, Y.; Tang, H.; Zhang, Z.; Wu, X.; Zhao, J.; Zeng, L.; Tang, M.; Hao, D. The nexus of sustainable fisheries: A hybrid self-powered and self-sensing wave energy harvester. Ocean Eng. 2024, 295, 116996. [Google Scholar] [CrossRef]

- Graves, J.; Kuang, Y.; Zhu, M. Scalable pendulum energy harvester for unmanned surface vehicles. Sens. Actuators A 2020, 315, 112356. [Google Scholar] [CrossRef]

- Graves, J.; Kuang, Y.; Zhu, M. Counterweight-pendulum energy harvester with reduced resonance frequency for unmanned surface vehicles. Sens. Actuators A 2021, 321, 112577. [Google Scholar] [CrossRef]

- Wang, T.; Lou, H.; Zhu, S. Bandwidth enhancement of a gimbaled-pendulum vibration energy harvester using spatial multi-stable mechanism. Appl. Energy 2022, 326, 120047. [Google Scholar] [CrossRef]

- Li, Y.; Ma, X.; Tang, T.; Zha, F.; Chen, Z.; Liu, H.; Sun, L. High-efficient built-in wave energy harvesting technology: From laboratory to open ocean test. Appl. Energy 2022, 322, 119498. [Google Scholar] [CrossRef]

- Zhang, Y.; Wen, Y.; Han, X.; Zhang, W.; Gao, F.; Chen, W. Gyroscopic wave energy converter with a self-accelerating rotor in WEC-glider. Ocean Eng. 2023, 273, 113819. [Google Scholar] [CrossRef]

- Dai, C.; Zhou, X.; Zhang, Z.; Wu, X.; Li, H.; Xu, P.; Jin, Z.; Li, D. A wave energy harvesting system based on the double-wing flywheel for unmanned surface vessels. Energy Convers. Manag. 2022, 269, 116120. [Google Scholar] [CrossRef]

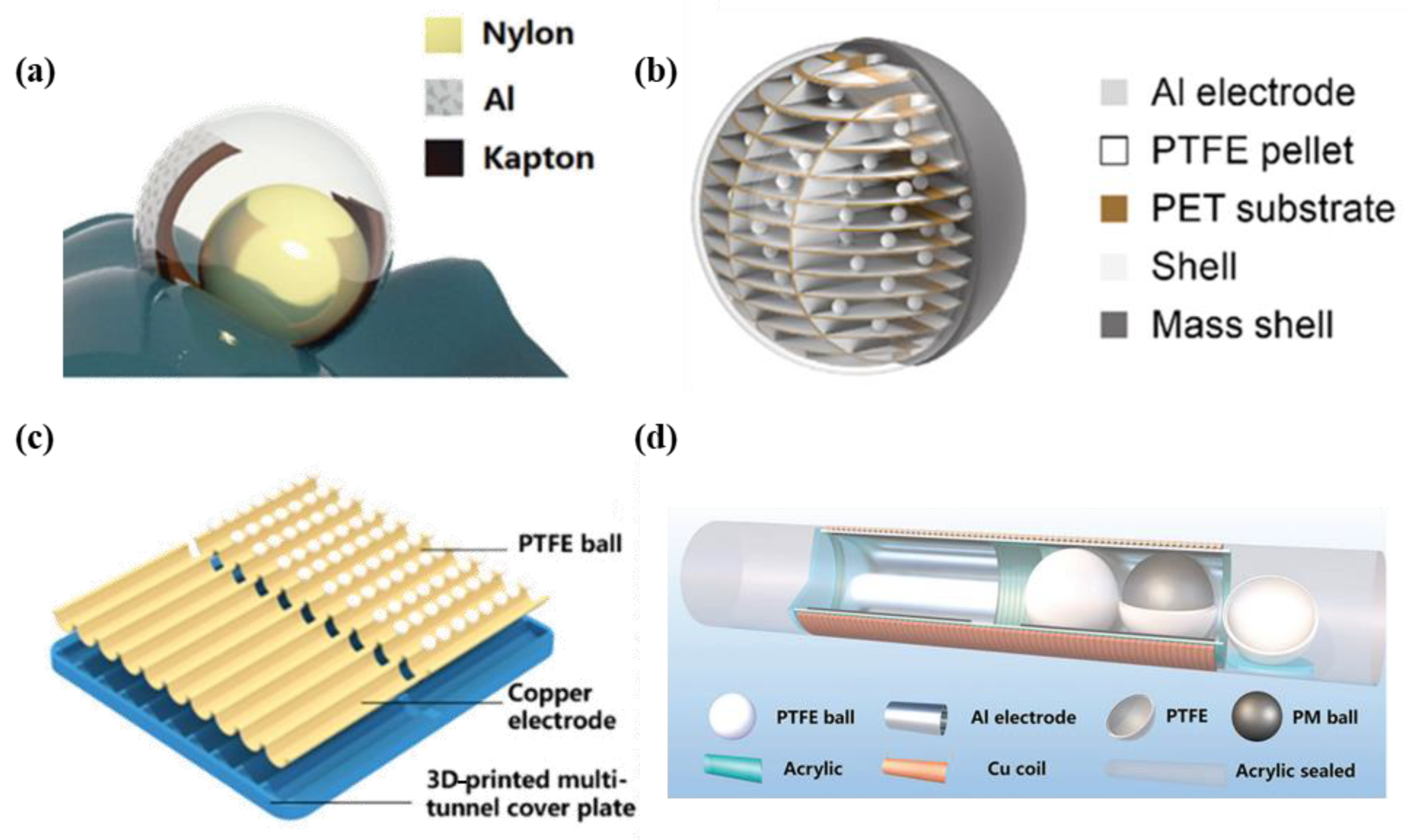

- Wang, X.; Niu, S.; Yin, Y.; Yi, F.; You, Z.; Wang, Z. Triboelectric Nanogenerator Based on Fully Enclosed Rolling Spherical Structure for Harvesting Low-Frequency Water Wave Energy. Adv. Energy Mater. 2015, 5, 1501467. [Google Scholar] [CrossRef]

- Lee, K.; Lee, J.; Kim, K.; Yoo, D.; Kim, D.; Hwang, W.; Song, I.; Sim, J. A Spherical Hybrid Triboelectric Nanogenerator for Enhanced Water Wave Energy Harvesting. Micromachines 2018, 9, 598. [Google Scholar] [CrossRef]

- Li, X.; Xu, L.; Lin, P.; Yang, X.; Wang, H.; Qin, H.; Wang, L. Three-dimensional chiral networks of triboelectric nanogenerators inspired by metamaterial’s structure. Energy Environ. Sci. 2023, 16, 3040–3052. [Google Scholar] [CrossRef]

- Liu, W.; Xu, L.; Bu, T.; Yang, H.; Liu, G.; Li, W.; Pang, Y.; Hu, C.; Zhang, C.; Cheng, T. Torus structured triboelectric nanogenerator array for water wave energy harvesting. Nano Energy 2019, 58, 499–507. [Google Scholar] [CrossRef]

- Wang, H.; Fan, Z.; Zhao, T.; Dong, J.; Wang, S.; Wang, Y.; Xiao, X.; Liu, C.; Pan, X.; Zhao, Y. Sandwich-like triboelectric nanogenerators integrated self-powered buoy for navigation safety. Nano Energy 2021, 84, 105920. [Google Scholar] [CrossRef]

- Wang, H.; Zhu, C.; Wang, W.; Xu, R.; Chen, P.; Du, T.; Xue, T.; Wang, Z.; Xu, M. A Stackable Triboelectric Nanogenerator for Wave-Driven Marine Buoys. Nanomaterials 2022, 12, 594. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, A.; Saadatnia, Z.; Hassan, I.; Zi, Y.; Xi, Y.; He, X.; Zu, J.; Wang, Z. Self-Powered Wireless Sensor Node Enabled by a Duck-Shaped Triboelectric Nanogenerator for Harvesting Water Wave Energy. Adv. Energy Mater. 2016, 7, 1601705. [Google Scholar] [CrossRef]

- Zhang, Z.; Hu, Z.; Wang, Y.; Wang, Y.; Zhang, Q.; Liu, D.; Wang, H.; Xu, M. Multi-Tunnel Triboelectric Nanogenerator for Scavenging Mechanical Energy in Marine Floating Bodies. J. Mar. Sci. Eng. 2022, 10, 455. [Google Scholar] [CrossRef]

- Duan, Y.; Xu, H.; Liu, S.; Chen, P.; Wang, X.; Xu, L.; Jiang, T.; Wang, Z. Scalable rolling-structured triboelectric nanogenerator with high power density for water wave energy harvesting toward marine environmental monitoring. Nano Res. 2023, 16, 11646–11652. [Google Scholar] [CrossRef]

- Zhu, C.; Wu, M.; Liu, C.; Xiang, C.; Xu, R.; Yang, H.; Wang, Z.; Wang, Z.; Xu, P.; Xing, F. Highly Integrated Triboelectric-Electromagnetic Wave Energy Harvester toward Self-Powered Marine Buoy. Adv. Energy Mater. 2023, 13, 2301665. [Google Scholar] [CrossRef]

- He, L.; Liu, R.; Liu, X.; Zheng, X.; Zhang, L.; Lin, J. A piezoelectric-electromagnetic hybrid energy harvester for low-frequency wave motion and self-sensing wave environment monitoring. Energy Convers. Manag. 2024, 300, 117920. [Google Scholar] [CrossRef]

- Wang, C.; Guo, L.; Chen, P.; Fu, Q.; Cui, L. Annular Electromagnetic Generator for Harvesting Ocean Wave Energy. J. Mar. Sci. Eng. 2023, 11, 2266. [Google Scholar] [CrossRef]

- Ringwood, J.; Zhan, S.; Faedo, N. Empowering wave energy with control technology: Possibilities and pitfalls. Annu. Rev. Control 2023, 55, 18–44. [Google Scholar] [CrossRef]

- Korde, U.; Ringwood, J. Hydrodynamic control of Wave Energy Devices; Cambridge University Press: Cambridge, UK, 2016. [Google Scholar]

- Liang, H.; Qiao, D.; Wang, X.; Zhi, G.; Yan, J.; Ning, D.; Ou, J. Energy capture optimization of heave oscillating buoy wave energy converter based on model predictive control. Ocean Eng. 2023, 268, 113402. [Google Scholar] [CrossRef]

- Ringwood, J.; Tom, N.; Ferri, F.; Yu, Y.; Coe, R.; Ruehl, K.; Bacelli, G.; Shi, S.; Patton, R.; Tona, P.; et al. The wave energy converter control competition (WECCCOMP): Wave energy control algorithms compared in both simulation and tank testing. Appl. Ocean Res. 2023, 138, 103653. [Google Scholar] [CrossRef]

- Cai, Y.; Zhao, S.; Liu, J. Built-in Double-Pendulum Active Resonant Wave Energy Converters. Eng. J. Wuhan Univ. 2021, 54, 916–926. (In Chinese) [Google Scholar]

- Ding, B.; Cazzolato, S.; Arjomandi, M. Sea-state based maximum power point tracking damping control of a fully submerged oscillating buoy. Ocean Eng. 2016, 126, 299–312. [Google Scholar] [CrossRef]

- Zheng, M.; Yang, J.; Lin, K. The maximum power tracking control based on the double degrees of freedom wave power system. Renew. Energy Resour. 2017, 35, 778–783. (In Chinese) [Google Scholar]

- Bracco, G.; Canale, M.; Cerone, V. Optimizing energy production of an inertial sea wave energy converter via model predictive control. Control Eng. Pract. 2020, 96, 104299. [Google Scholar] [CrossRef]

- Raffero, M.; Martini, M.; Passione, B. Stochastic control of inertial sea wave energy converter. Sci. World J. 2015, 2015, 980613. [Google Scholar] [CrossRef]

- Sergiienko, Y.; Cocho, M.; Cazzolato, S. Effect of a model predictive control on the design of a power take-off system for wave energy converters. Appl. Ocean Res. 2021, 115, 102836. [Google Scholar] [CrossRef]

- Wu, J.; Qian, C.; Zheng, S. Investigation on the wave energy converter that reacts against an internal inverted pendulum. Energy 2022, 247, 123493. [Google Scholar] [CrossRef]

- Bonfanti, M.; Carapellese, F.; Sirigu, A. Excitation forces estimation for non-linear wave energy converters: A neural network approach. IFAC-PapersOnLine 2020, 53, 12334–12339. [Google Scholar] [CrossRef]

- Bonfanti, M.; Hillis, A.; Sirigu, S.A. Real-time wave excitation forces estimation: An application on the ISWEC device. J. Mar. Sci. Eng. 2020, 8, 825. [Google Scholar] [CrossRef]

- Nguyen, N.; Tona, P. Wave excitation force estimation for wave energy converters of the point-absorber type. IEEE Trans. Control. Syst. Technol. 2017, 26, 2173–2181. [Google Scholar] [CrossRef]

- Abdelkhalik, O.; Zou, S. Control of small two-body heaving wave energy converters for ocean measurement applications. Renew. Energ. 2019, 132, 587–595. [Google Scholar] [CrossRef]

- Pereira, A.; de Oliveira, M.; Beirão, N. ISWEC devices on a wave farm handled by a multi-agent system. Appl. Ocean Res. 2021, 111, 102659. [Google Scholar] [CrossRef]

- Sirigu, A.; Foglietta, L.; Giorgi, G. Techno-Economic optimisation for a wave energy converter via genetic algorithm. J. Mar. Sci. Eng. 2020, 8, 482. [Google Scholar] [CrossRef]

- Clémot, H.; Babarit, A.; Dupriez-Robin, F. Development of a wave-to-wire model to calculate flicker caused by wave energy converters and study power quality. In Proceedings of the 2017 IEEE Manchester PowerTech, Manchester, UK, 18–22 June 2017. [Google Scholar]

- Tian, H.; Zhou, B.; Zhang, Z. Numerical Study of a Weight-Adjustable Buoy for Efficient Wave Energy Conversion. In Proceedings of the ASME/BATH 2021 Symposium on Fluid Power and Motion Control, Virtual, 19–21 October 2021. [Google Scholar]

- Haraguchi, R.; Asai, T. Enhanced power absorption of a point absorber wave energy converter using a tuned inertial mass. Energy 2020, 202, 117740. [Google Scholar] [CrossRef]

- Chen, H.; DelBalzo, D. Linear sliding wave energy converter. In Proceedings of the OCEANS 2015-Genova, Genova, Italy, 18–21 May 2015. [Google Scholar]

- Chen, H.; DelBalzo, D. Dynamic buoy effects on a sliding wave energy converter with eSpring control. In Proceedings of the OCEANS 2016-Shanghai, Shanghai, China, 10–13 April 2016. [Google Scholar]

- Chen, H.; DelBalzo, D. Heave-Enhanced Linear-Sliding Wave Energy Converter. In Proceedings of the OCEANS 2016 MTS/IEEE Monterey, Monterey, CA, USA, 19–23 September 2016. [Google Scholar]

- Chen, Z.; Zhou, B.; Zhang, L. Experimental and numerical study on a novel dual-resonance wave energy converter with a built-in power take-off system. Energy 2018, 165, 1008–1020. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, L.; Yeung, R. Analysis and optimization of a Dual Mass-Spring-Damper (DMSD) wave-energy convertor with variable resonance capability. Renew. Energ. 2019, 131, 1060–1072. [Google Scholar] [CrossRef]

- Sirigu, A.; Bracco, G.; Bonfanti, M. On-board sea state estimation method validation based on measured floater motion. IFAC-PapersOnLine 2018, 51, 68–73. [Google Scholar] [CrossRef]

- Bracco, G.; Cagninei, A.; Giorcelli, E. Experimental validation of the ISWEC wave to PTO model. Ocean Eng. 2016, 120, 40–51. [Google Scholar] [CrossRef]

- Clemot, H.; Dupriez-Robin, F.; Babarit, A. A wave-to-wire chain modeling and command for a direct drive wave energy converter. In Proceedings of the 2017 Twelfth International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte Carlo, Monaco, 11–13 April 2017. [Google Scholar]

- Cordonnier, J.; Gorintin, F.; De Cagny, A. SEAREV: Case study of the development of a wave energy converter. Renew. Energ. 2015, 80, 40–52. [Google Scholar] [CrossRef]

- Sheng, W.; Aggidis, G. Optimizations for Improving Energy Absorption of TALOS WEC. In Proceedings of the The 34th International Ocean and Polar Engineering Conference, Rhodes, Greece, 16–21 June 2024. [Google Scholar]

- Hall, M.; Sheng, W.; Yavuz, H. PTO Control Design for a Multi-Axis WEC Device. In Proceedings of the The 34th International Ocean and Polar Engineering Conference, Rhodes, Greece, 16–21 June 2024. [Google Scholar]

| Name/ Developer | Geometry | Shape Design Philosophy | Capture Mode | Stage | References |

|---|---|---|---|---|---|

| ISWEC | Boat-shaped | By WEC | Pitch | Full-Scale Sea Trial | [19] |

| Penguin | Boat-shaped | By WEC | Roll and Pitch | Full-scale Sea Trial | [20] |

| Soochow University | Observation Buoy | By Carrier | Roll and Pitch | Small-Scale Sea Trial | [35] |

| Zhejiang University | Unmanned Surface Vehicle | By Carrier | Roll and Pitch | Small-Scale Sea Trial | [28] |

| GyroPTO | Spherical | By WEC | Roll and Pitch | Wave Basin Test | [38] |

| WITT | Spherical | By WEC | Pitch | Wave Basin Test | [39] |

| SEAREV | Mushroom-Like Buoy | By WEC | Pitch | Wave Basin Test | [40] |

| Harbin Engineering University | Observation Buoy | By Carrier | Heave | Land Test | [46] |

| PS Frog Mk 5 | Large Paddle with a Ballast Handle | By WEC | Pitch | Design and Simulation | [41] |

| SR-WEC | Horizontal Cylinder | By WEC | Pitch | Design and Simulation | [43] |

| E-Motions | Horizontal Semi-Cylinder | By WEC | Pitch | Design and Simulation | [49] |

| Qingdao University of Science and Technology | Merchant Vessel | By Carrier | Mainly Roll | Design and Simulation | [47] |

| University of Southampton | AUV | By Carrier | Pitch | Design and Simulation | [48] |

| GWEC | AUV | By Carrier | Pitch | Design and Simulation | [17] |

| Name/Developer | PTO Mode | Generator Type | Output | Reference |

|---|---|---|---|---|

| Khalifa University of Science and Technology | Translational sliding | Electromagnetic and Piezoelectric Linear Motor | 900 W | [52] |

| Hong Kong Polytechnic University | Translational sliding | Electromagnetic Linear Motor | 1 W | [54] |

| University of Texas Rio Grande Valley | Translational sliding | Electromagnetic Linear and Rotary Motor | 730 W | [55] |

| Ferdowsi University of Mashhad | Translational sliding | Electromagnetic Linear Motor | 111.94 W | [56] |

| PeWEC | Vertical rotation | Electromagnetic Rotary Motor | 41 W | [59] |

| IPWEC | Vertical rotation | Electromagnetic Rotary Motor | 128 W | [61] |

| T-EMG | Vertical rotation | Electromagnetic Linear Motor | 120 mW | [62] |

| University of Exeter | Vertical rotation | Electromagnetic Rotary Motor | 0.72 W | [64] |

| University of Exeter | Vertical rotation | Electromagnetic Rotary Motor | 0.997 W | [65] |

| ISWEC | Horizontal rotation | Electromagnetic Rotary Motor | 5.96 W | [22] |

| Zhejiang University | Horizontal rotation | Electromagnetic Rotary Motor | 1.3 W | [66] |

| P-WEC | Horizontal rotation | Electromagnetic Rotary Motor | 520 mW | [67] |

| Shanghai Jiao Tong University | Horizontal rotation | Electromagnetic Rotary Motor | 54 W | [68] |

| RF-TENG | Horizontal rotation | Triboelectric Linear Motor | 10 mW | [70] |

| Beijing Institute of Nanoenergy and Nanosystems | Horizontally rolling | Triboelectric Linear Motor | 3.14 mW | [72] |

| MT-TENG | Horizontally rolling | Triboelectric Linear Motor | 2.7 mW | [77] |

| SR-TENG | Horizontally rolling | Triboelectric Linear Motor | 73.4 mW | [78] |

| PEHEH | Horizontally rolling | Electromagnetic and PiezoelectricLinear Motor | 32.58 mW | [80] |

| A-EMG | Horizontally rolling | Electromagnetic Linear Motor | 80.87 mW | [81] |

| WEC Type | Control Strategy | Remarks | Reference |

|---|---|---|---|

| CETO | MPPT damping control MPC | Up to an additional 0.1 GW h per unit is extracted annually. | [87] |

| A longer prediction horizon results in a more aggressive MPC design. | [91] | ||

| South China University of Technology | MPPT | The optimal load for achieving maximum output power is found. | [88] |

| ISWEC | MPC | The result is greater electricity generation under almost all conditions. | [89] |

| Multi-agent systems | The optimal control parameters are found. | [97] | |

| Reactive power control | There is strict control of the gyroscope’s rotation speed. | [19] | |

| IPWEC | Complex conjugate | The required average reactive power under capacitive control is 75% less than that under NPWEC. | [92] |

| Genetic algorithms | The optimal control parameters are found. | [92] | |

| Michigan Technological University | Multi-resonant control | One of its advantages is that it eliminates the need for wave prediction. | [96] |

| DR-WEC | Optimization algorithms (GPS) | The optimal control parameters are found. | [40] |

| PeWEC | Genetic algorithms | The optimal control parameters are found. | [98] |

| SEAREV | Torque and reactive power | The average power loss in grid connections is reduced. | [99] |

| LOD control | The approach for using the LOD control has been proven to be the current best solution. | [110] | |

| LS-WEC | Adjusting mass or spring stiffness | Tuning is carried out to improve wave energy conversion efficiency. | [100,101,102,103,104,105,106] |

| DMSD and others | Adjusting mass and spring stiffness | Better optimization results are achieved. | [50] |

| GyroWEC | PID | The is the active control of the rotor’s angular velocity. | [68] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Sun, J.; Xi, Z.; Dai, S.; Xing, F.; Xu, M. Recent Progress on Built-in Wave Energy Converters: A Review. J. Mar. Sci. Eng. 2024, 12, 1176. https://doi.org/10.3390/jmse12071176

Wang H, Sun J, Xi Z, Dai S, Xing F, Xu M. Recent Progress on Built-in Wave Energy Converters: A Review. Journal of Marine Science and Engineering. 2024; 12(7):1176. https://doi.org/10.3390/jmse12071176

Chicago/Turabian StyleWang, Hao, Jiajing Sun, Ziyue Xi, Shu Dai, Fuzhen Xing, and Minyi Xu. 2024. "Recent Progress on Built-in Wave Energy Converters: A Review" Journal of Marine Science and Engineering 12, no. 7: 1176. https://doi.org/10.3390/jmse12071176

APA StyleWang, H., Sun, J., Xi, Z., Dai, S., Xing, F., & Xu, M. (2024). Recent Progress on Built-in Wave Energy Converters: A Review. Journal of Marine Science and Engineering, 12(7), 1176. https://doi.org/10.3390/jmse12071176