Abstract

The goal of increasing fuel efficiency and decreasing greenhouse gas (GHG) emissions has increased interest in the application of renewable energy sources and the usage of new technologies in the maritime industry. In order to implement the most suitable source, factors such as voyage duration, storage availability, and the condition of existing vessels as well as those that are still under construction should be taken into account. Propeller optimization is proposed as a long-term solution. This paper investigates the environmental aspects of propeller optimization, focusing on its potential to reduce ship vibrations fuel consumption, and, therefore, the ship’s carbon footprint. The case study presents propeller optimization on a Ro-Ro passenger ship. The data collected during sea trials before and after propeller optimization will be compared. Expected fuel oil consumption will be correlated to the CO2 emission reduction. Besides propeller optimization, the paper performs a SWOT (strengths, weaknesses, opportunities, threats) analysis comparing it with solar and wind power applications on ships.

1. Introduction

1.1. Problem Background

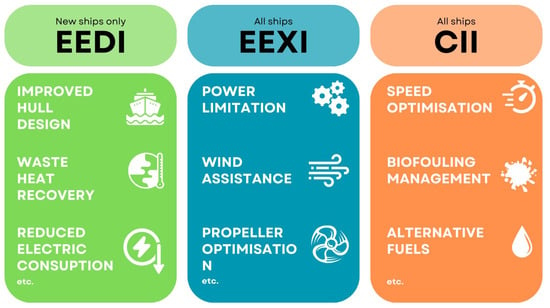

In general, maritime transport is strongly related to global trade. Any rise in global trade is expected to increase demand for maritime transport. The global fleet has nearly doubled in size by deadweight tonnage since 2007 and, at the end of 2022, accounted for roughly 61,000 vessels. Growth has been linear, increasing by 3% in the most recent year [1]. As a result, emissions from ships are projected to rise. The International Maritime Organization (IMO) strives to contribute to the global fight against climate change, calling for immediate action by adopting a strategy for the reduction of greenhouse gas (GHG) emissions from international shipping. The 2023 IMO GHG Strategy calls for a reduction in the carbon intensity of international shipping through increased energy efficiency in new ships as well as the adoption of zero or near-zero GHG emission technologies, fuels, and/or energy sources [2]. Technical and operational approaches to increase ship energy efficiency are consolidated through the Energy Efficiency Design Index (EEDI), the Energy Efficiency Existing Ship Index (EEXI), and the Ship Energy Efficiency Management Plan (SEEMP) [3,4]. Examples of solutions for compliance with these measures are visible in Figure 1.

Figure 1.

Energy Efficiency Design Index (EEDI), Energy Efficiency Existing Ship Index (EEXI), and Carbon Intensity Indicator (CII) are examples of solutions for compliance.

The EEDI is a technical measure encouraging the adoption of more energy-efficient equipment and engines in the construction of new ships to reduce pollution, while the SEEMP is a cost-effective operational mechanism. All existing ships of 400 GT and above are obliged, with specified exceptions, to compute their reached Energy Efficiency Existing Ship Index (EEXI), which indicates the ship’s “technical” or “design” efficiency. The Carbon Intensity Indicator (CII) rating represents a ship’s operational energy efficiency (in terms of how efficiently a ship transports goods or passengers, expressed in grams of CO2 emitted per transport work and nautical miles), using fuel oil consumption data from the IMO DCS and the SEEMP as a management tool.

1.2. Energy Efficiency and GHG Reduction in Shipping

Energy efficiency improvements can be achieved through propulsion system optimization and alternative fuel usage [5,6,7,8,9,10,11], improved hull designs [12,13], and operational measures such as lower speed [14], voyage optimization [15], etc., that can achieve significant reductions in fuel consumption and resulting CO2 emissions. The connection between ship propeller design, vibrations, and fuel consumption is an essential aspect of ship performance. Ship propeller optimization is crucial for improving marine vessel efficiency, maneuverability, and overall performance. The typical approach involves creating an initial design plan and refining it by achieving the best compromise between goals and limitations. This process naturally evolves into an optimization task [16]. This study shows that propellers have a significant impact on a vessel’s performance, leading to an increase in the trim angle and a decrease in resistance. These effects result from a notable decrease in pressure near the propellers [17]. Engineers can achieve optimal power transfer, reduce fuel consumption, and limit the environmental effect by fine-tuning the design and features of ship propellers. The results of the method for improving the performance of marine propellers, particularly the wide chord tip (WCT) propeller, which maximizes propeller performance by altering enlarged regions of the propeller blade, can improve efficiency by more than 2% [18]. Hydrodynamic optimization of propellers using gradient and non-gradient-based algorithms revealed a nearly 13% increase in the efficiency and a nearly 15% drop in the torque coefficient for the first propeller, as well as a nearly 10% increase in the efficiency for the later propeller are attainable [19]. Research results indicate that it is possible to create a medium-sized flexible composite propeller that will reduce fuel consumption while withstanding the imposed loads. The design and optimization of a flexible composite material marine propeller results in a 1.25% reduction in fuel consumption for the combined scenario, equating to a 4.7% drop in cruising speed [20]. A comprehensive test system for ship-model testing in real wind, wave, and current flow settings was created to determine the 25-m-long ship performance in actual sea conditions. This platform was used to test the effects of an energy-saving technology and the results proved the reliability of the proposed approach [21]. The measurements and analyses performed, when compared to the ship’s output performances before and after propeller optimization, demonstrate a successful procedure for optimizing a fixed-pitch propeller and the justification for using Prop Scan technology [22]. Berg Propulsion, a Swedish company specializing in propellers, claims significant success by redesigning propulsion systems on existing ships, managing to achieve remarkable fuel savings of up to 22% in a recent case through their redesign efforts [23]. The optimization method of trimaran hull form for resistance reduction and propeller intake flow improvement focuses on two main goals: reducing the total resistance and improving the propeller intake flow, making it a multi-objective optimization challenge. The optimization outcomes reveal a 13.3% decrease in resistance and a 7.58% enhancement in the wake coefficient for the obtained hull form [24]. Shifting the propeller toward the rear and expanding its area revealed significant potential for reducing power requirements. This adjustment enables a larger propeller diameter without the risk of transmitting pressure pulses to the hull. This enhancement in efficiency can consequently diminish environmental effects and costs [25]. A thorough analysis aimed to enhance the energy efficiency of large shipping vessels by optimizing the propeller boss cap with fins (PBCFs) in a cost-effective manner. After achieving an optimal PBCF design, it was integrated into a model-scale modern propeller/rudder system that initially lacked PBCFs. Operating under the designed conditions, this implementation provided an efficiency improvement of 0.728 percentage points, equivalent to a 1.043% increase over the original propeller/rudder system [26]. Designing propellers to enhance efficiency and minimize cavitation issues demands significant computational resources, especially during the initial planning stage. While the boundary element method (BEM) is commonly used at this stage due to its lower computational demands, it often brings about higher uncertainties [27]. Adjusting the propeller’s shape for better efficiency also alters its behavior in terms of cavitation, vibrations, and internal noise. Consequently, the only viable approach is to discover a balanced design specific to each ship and its particular requirements. The purpose of optimization is to find the proper propeller geometry that decreases the power required to obtain a given thrust. The use of a cross-section airfoil angle of attack as a function of blade span as a design variable strengthens the optimization process by preserving the airfoil properties from calculation at supercritical angles of attack and reducing the amount of calculations performed throughout the optimization. The development algorithm was confirmed both experimentally and numerically using the CFD approach. The study demonstrates that the improved propeller geometry outperforms commercial alternatives on the market [28]. Recently, there has been significant work on automated optimization methods for blade design support [29]. Despite promising outcomes, applying this approach in industrial settings has proven challenging due to difficulties in setting up the optimization algorithm to reach a converged solution. Given these challenges, the traditional manual design process appears more reliable and efficient than grappling with a fully automated optimization approach. A summary of the literature findings, together with authors and year published, is published in Table 1.

Table 1.

Chronological presentation of the literature findings regarding ship efficiency.

2. Materials and Methods

This paper aims to evaluate the impact of optimized propellers on ship vibrations and fuel consumption and explores how they can reduce the environmental impact of maritime transportation.

Concerning the previously mentioned research problem of ship propeller optimization, the following hypotheses are defined:

- −

- Optimized propeller design reduces vibrations;

- −

- Vibration reduction enhances propeller efficiency and decreases fuel consumption;

- −

- Propeller optimization reduces greenhouse gas (GHG) emissions from shipping.

To confirm these hypotheses, fuel consumption and vibrations on the Ro-Ro passenger ship during sea trials will be measured before and after ship propeller optimization on the same route. This data will be compared and expected fuel savings will be correlated to the CO2 emission reduction.

Furthermore, a SWOT analysis will compare propeller optimization efficiency to other technologies (solar and wind power applications). The process is shown in Figure 2.

Figure 2.

SWOT analysis block diagram.

3. Propeller Optimization—Case Study

The specific geometry of the propeller enhances the power transformation. The power produced is the product of the propeller thrust (Tp) and the advanced velocity (ua). The thrust power produced by the propeller is defined as [30]:

The shaft power is the product of the shaft torque and the shaft’s angular velocity. In this paper, the shaft torque is referred to as the propeller torque (Qp) and the shaft angular velocity is referred to as the propeller angular velocity (ω). Therefore:

Efficiency is defined as the ratio of useful and produced power used throughout the process:

Therefore, propeller efficiency can be defined as:

Propeller optimization can significantly improve efficiency by maximizing thrust while minimizing energy consumption. Vibrations in a ship’s propulsion system can cause a variety of problems, including decreased efficiency, component failure, and discomfort for passengers and crew. Typically, propeller-induced vibrations are influenced by the: angular speed of the propeller (represented as revolutions per minute—rpm), propeller blade design, and hull and shaft alignment.

To reduce vibrations and fuel consumption, the propeller design must be optimized, taking into account the ship’s operational conditions, size, and intended use. Proper propulsion system maintenance and alignment, as well as frequent cavitation checks, are critical for decreasing vibrations and improving fuel economy. Finally, the relationship between the ship propeller design, vibrations, and fuel usage is complicated and dependent on a variety of factors. These parameters can be optimized to save money, increase performance, and reduce environmental impact.

The ship’s propeller design is one of the most critical aspects affecting fuel consumption and vibrations. A well-designed propeller can significantly impact the ship’s performance. Tolerances for the fabrication of propellers in all geometric dimensions are provided by the international standard ISO 484-2:2015 [31]. This standard takes into account all propeller criteria such as pitch, diameter, chord length, rake, thickness, and blade separation. The size of various radii must be varied depending on the type of propeller manufactured according to the regulation. The ISO-484 standard has 4 classes of tolerance for propeller classes, where class III has wide tolerances, class II stands for medium accuracy, class I stands for high accuracy, and class S has very high accuracy. Pitch tolerances are shown in Table 2.

Table 2.

International Standard Organization ISO-484-2 tolerances on pitch.

3.1. Prop Scan System

Prop Scan is a sophisticated technology used in the marine industry to optimize ship propeller efficiency [32]. It is a computerized system that examines and refines propellers to improve efficiency, minimize vibrations, and improve overall ship handling. The Prop Scan system for inspecting and diagnosing propellers consists of a workstation with a propeller base and a measuring sensor, all connected to the computer. This method makes use of a specific process that analyzes propeller surfaces. A high-precision 3D scanner i = was employed to capture propeller geometry, along with the corresponding software, to define the propeller shape. Measurements were taken on the radius , along the curve PQ, at any angle α, to determine the radius and the height difference (Δh) in addition to the reference plan. This measurement provided the section pitch. This value was compared to the intended value and classified into tolerance classes. The pitch per radius and per blade was calculated for each radius by multiplying the difference in height among the furthest distant measuring sites at each radius [33]:

Measurement was made on the pressure face of the blade, which involved selecting around 5 evenly distributed places between the leading and tailing edges for the initial measurement. The propeller was measured at different radii, with each radius measured as a fraction of the full radius (R = 0.2 × R, 0.3 × R, 0.4 × R, 0.5 × R, 0.6 × R, 0.7 × R, 0.8 × R, 0.9 × R, 0.95 × R, 0.975 × R, 0.985 × R). Furthermore, the average values can be compared and a tolerance class defined [22,33].

These data were then entered into software that analyzes, simulates, and determines the most efficient design changes.

Computational fluid dynamics (CFD) methods were used to simulate and calculate fluid behavior. The numerical approach was based on Reynolds averaged Navier–Stokes equations [33].

The Prop Scan system software processed the data and displayed the propeller blade shape in a linear and bar graph. Prop Scan detects flaws or abnormalities in the propeller surfaces. Minor damages or abnormalities can have a substantial impact on a propeller’s performance, generating vibrations, lower fuel economy, and inefficient vessel handling. Prop Scan technology enables rigorous scanning and inspection, allowing professionals to identify and rectify these flaws with great precision. Following the diagnostics, some changes to the propeller, or rather a pitch correction, had to be made in accordance with the base set of the propeller blade’s new design (linear diagram). Technicians altered the propeller blades using specialized machinery based on the software’s recommendations. To obtain the appropriate standards, they manually reshaped and refined the blades. After the repairs were completed, the propeller was scanned again to ensure that the changes were made correctly. This approach ensures that the propeller satisfies the requirements and functions properly.

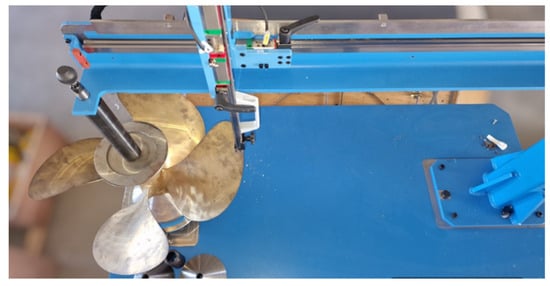

Figure 3 shows the Prop Scan workstation and propeller.

Figure 3.

Prop Scan workstation.

3.2. Measurements and Data Collection

Propeller optimization was performed on a Ro-Ro passenger ship. Specifications such as the year when the ship was built, the length of the hull, the ship’s breadth, depth, gross tonnage, and propulsion characteristics were provided from the yacht Certificate of Registry and presented in Table 3.

Table 3.

Ro-Ro passenger ship specifications.

During sea trials, fuel consumption and vibrations on the engine were measured. Propeller optimization was conducted by the Adriatic Propeleri company [34]. On the day of the sea trial, all working parameters were measured in two different directions in order to avoid the effect of the wind and sea current. At the beginning of the trip, the ship’s speed and fuel consumption were recorded using the ship’s instruments at the nominal number of revolutions. This was followed by a ten-minute drive against the sea current and ten minutes in the direction of the sea current in the area of the Zadar channel in order to make a comparison after the optimization process. The results before propeller optimization are presented in Table 4 and Table 5.

Table 4.

Ship speed and fuel consumption before propeller optimization.

Table 5.

Ship vibrations before propeller optimization.

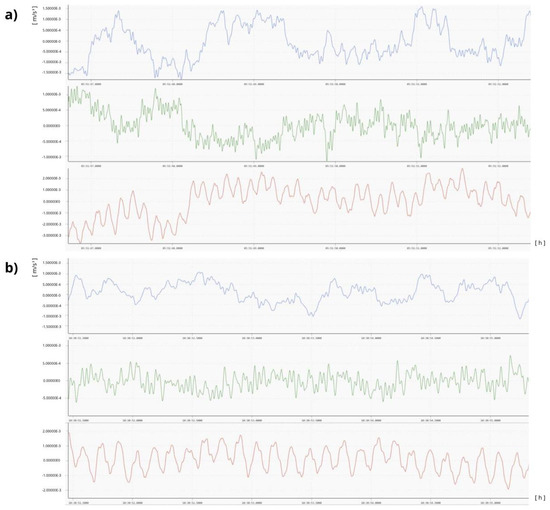

4. Results after Optimization of the Ship Propeller

After propeller optimization, fuel consumption and vibrations were measured. The measurements were conducted according to the same principles as before the propeller optimization, allowing for comparison of the results. The results after propeller optimization are presented in Table 6 and Table 7. Vibrations before and after optimization (X, Y, Z-direction separately) are shown in Figure 4.

Table 6.

Ship speed and fuel consumption after propeller optimization.

Table 7.

Ship vibrations after propeller optimization.

Figure 4.

Vibrations before (a) and after (b) optimization (X, Y, Z-direction separately).

Comparing the results before and after propeller optimization, there was approximately a 1.41% drop in fuel consumption. Achieving a 1.41% reduction in fuel consumption through propeller optimization not only leads to cost savings but also has effects on emissions and the environment. Reduced greenhouse gas emissions are one of the most direct and immediate benefits of reduced fuel consumption. When fossil fuels are burned for propulsion, carbon dioxide (CO2) is created, which is a key contributor to climate change. The Ro-Ro passenger ship consumes approximately 2,540,456 L of marine diesel oil (MDO) annually according to the Coastal liner shipping agency, which is the main regulatory body of the Republic of Croatia for issues of liner passenger traffic on the Adriatic. Propeller optimization results in substantial fuel savings, amounting to around 35,852.45 L per year [35]. Considering the average CO2 emissions factor of 3.151 tons CO2 per fuel ton for marine diesel oil (MDO) and converting the fuel savings from liters to metric tons, and taking into account the density of marine diesel oil, the Ro-Ro passenger ship’s annual fuel savings contribute to a reduction of approximately 96,098.26 tons of CO2 emissions [36].

Aside from CO2 reduction, propeller optimization can aid in the reduction of particulate matter and nitrogen oxide emissions. Many countries have rigorous regulations in place to limit transportation emissions. A 1.41% reduction in fuel consumption achieved by propeller optimization can assist firms in meeting and exceeding these legal criteria, avoiding penalties and exhibiting environmental responsibility.

The cost of propeller optimization varies depending on different parameters such as the size and type of vessel, the existing status of the propeller, and the level of customization necessary. Overall, the cost of propeller optimization can fluctuate based on individual requirements and constraints of the optimization project. Fuel savings, improved performance, and environmental benefits are all advantages of optimization. Vessels with optimized propeller systems may obtain a competitive advantage in the market by offering lower operating costs, superior performance, and enhanced environmental credentials. Propeller optimization is a long-term investment that can yield benefits throughout the vessel’s lifecycle. Assessing the long-term economic feasibility of optimization techniques requires considering factors such as future fuel price predictions, technological advancements, and increasing regulatory requirements.

The propeller optimization result of a 1.41% decrease in fuel consumption falls within a comparable range to the other discussed techniques. For instance, the optimization of the flexible composite marine propeller resulted in a 1.25% reduction in fuel consumption, while the optimization of the propeller boss cap led to a 0.728 percentage point increase in efficiency. Similarly, optimizing marine propellers using algorithms can yield significant efficiency gains of approximately 13% in certain conditions, contributing distinctly to improving propeller performance and fuel efficiency in the marine industry, with vessel type and operational conditions determining its effectiveness.

Furthermore, such optimization efforts help to achieve the industry’s sustainability goals by lowering greenhouse gas emissions and minimizing its environmental impact. Propeller optimization not only saves fuel but also enhances vessel performance, reliability, and market competitiveness. It enables maritime businesses to operate more efficiently and maintain competitiveness in a global market where fuel prices and environmental concerns hold high importance for the industry.

To compare results among ships of different sizes and demonstrate the efficiency of Prop Scan technology propeller optimization, a study on propeller optimization on an 18.34 m long fishing ship was reviewed. After optimizing the propeller from class II to class S, the fishing ship consumed 15.66% more fuel for the same number of diesel engine revolutions. Additionally, preoptimization vibrations were significantly reduced. This fishing ship has reached the same speed with fewer diesel engine revolutions.

Potential limits of propeller optimization include challenges in obtaining approvals for ship retrofitting, as upgrading existing vessels may need regulatory approval. Obtaining these permits can be a lengthy process involving compliance with environmental, safety, and classification society requirements. The effectiveness of propeller optimization depends on the vessel type, size, and speed and the propeller condition. While propeller optimization can lead to significant fuel savings and performance advantages for some vessels, others may not experience such substantial results. Additionally, inaccurate or inadequate data might undermine the effectiveness of optimization attempts, resulting in unsatisfactory outcomes. While propeller optimization contributes to fuel saving and emission reduction, its environmental impact may be lower compared to renewable energy sources such as wind, solar, or hydrogen propulsion.

5. Comparing Photovoltaic Panels Application, Wind Application, and Propeller Optimization

The aim of propeller optimization is to increase efficiency, consequently reducing fuel consumption. A 1.41% reduction in fuel consumption is noteworthy and directly translates into lower CO2 emissions. This is consistent with worldwide efforts to reduce greenhouse gas emissions and to combat climate change. Furthermore, the effects of optimization extend beyond CO2 reduction; it can also aid in diminishing particulate matter and nitrogen oxide emissions, thus enhancing environmental sustainability. Propeller optimization has various strengths, including the potential for increased ship efficiency and environmental benefits from lower emissions. The capacity to customize designs for specific ships is another benefit. However, weaknesses such as optimization costs, process complexity, and potential integration issues may prevent wider implementation. Opportunities arise from the increasing demand for environmentally friendly transportation solutions and potential legislative incentives promoting the integration of solar applications with maritime fleets Threats include the need to handle technical uncertainty and reluctance to change within the maritime industry.

Solar power installation, on the other hand, provides a renewable energy source that does not rely on fossil fuels. Utilizing solar energy on ships is widely recognized as a viable approach to reducing greenhouse gas emissions and advancing marine sustainability. Comparing the CO2 reduction achieved through the optimization of ship propellers with the CO2 reduction achieved through the implementation of solar applications, the solar application results in a substantially higher reduction compared to the optimization of fuel consumption alone. For instance, propeller optimization on Ro-Ro passenger ships results in an annual fuel saving equivalent to approximately 96,098.26 kg of CO2 emissions, whereas the implementation of solar applications on the same ships leads to a reduction of 513,530 kg of CO2 emissions per year [37]. Both propeller optimization and solar power usage on ships contribute to environmental aims. Solar power minimizes reliance on traditional fuel sources, resulting in cleaner mobility. Both technologies enable customization. Solar applications can be tailored to a ship’s energy requirements and available space. The growing market demand for sustainable and energy-efficient maritime technologies presents a common opportunity for both solar energy application and propeller optimization. Propeller optimization aims to improve the efficiency of traditional propulsion systems, whereas solar power applications use photovoltaic panels to directly harness energy from the sun. Both technologies face integration issues but they are fundamentally different. Propeller optimization may include changes to current propulsion systems but solar power applications must take into account space restriction. Solar power applications are weather dependent since energy generation depends on sunlight availability. Propeller optimization, on the other hand, requires less reliance on external weather conditions once accomplished.

Wind-powered ships use innovative sail technologies, providing a greener alternative by considerably reducing dependency on traditional fossil fuels. By harnessing the force of the wind, they aim to reduce carbon emissions. Although the unpredictability of the wind poses challenges, ongoing advancements in sail designs and navigation systems are steadily enhancing their efficiency, thus establishing more effective marine transportation. The study investigating the carbon footprint (CF) of Croatia’s Ro-Ro passenger fleet in the Adriatic Sea revealed that 27 Ro-Ro ships emit approximately 29,000 tons of CO2 per year [38]. The investigation separates two lines that contribute much more to overall emissions. Through the utilization of a wind density map on the specific routes and the installation of appropriate wind turbines on Ro-Ro ships, tailpipe emissions could be reduced by approximately 24.3 kg CO2/h, or 213 tons, annually, resulting in a CF reduction of around 17%. However, on the other route, where the mean annual wind power density is substantially lower, the reduction in CF is less than 3.2%, making it unsuitable for this route. Wind energy usage on ships, like solar power, includes using a renewable source for ship propulsion. Wind-assisted technology can considerably improve fuel efficiency by using wind power to supplement existing propulsion systems. Wind energy usage, like solar energy usage and propeller optimization, allows for modification to accommodate a variety of ship types and sizes. However, barriers to wider use include high initial investment costs, required changes to ship design for effective wind collection, and limited wind conditions. Table 8 illustrates the SWOT analysis of propeller optimization, wind power application, and solar power application.

Table 8.

SWOT analysis for propeller–wind–solar propulsion.

6. Conclusions

Propeller optimization aims to improve the efficiency of existing systems on ships, resulting in lower fuel consumption and emissions. This paper presents a case study on the propeller optimization of Ro-Ro passenger ships. This research examined data from sea trials conducted both before and after propeller optimization to provide insights into ship vibrations and fuel consumption. The propeller optimization, resulting in a transition from Class 2 to Class S in ISO 484-2:2015 standard, led to a 1.41% reduction in fuel consumption, achieving the dual goal of enhancing fuel efficiency and reducing the vessel’s environmental impact. Furthermore, the results of this case study align with regulatory and policy frameworks governing maritime operations, underscoring its significance in meeting environmental standards. The demonstrated efficacy of propeller modification in decreasing CO2 emissions is consistent with the primary goals of international agreements such as the International Maritime Organization’s (IMO) greenhouse gas emission regulations for ships.

Propeller optimization is one of several methods that show promise for developing sustainable practices in the maritime industry. Combining solar power application, wind power application, and propeller optimization holds the potential to yield even more significant outcomes. Previous research on the implementation of photovoltaic (PV) systems on Ro-Ro ships and a high-speed vessel revealed that renewable energy sources could reduce CO2 emissions from 513.53 to 1324.85 t/year and NOX emissions by 9.15 to 23.6 t/year. The carbon footprint can be reduced between 3.2% and 17% by installing suitable wind turbines on ro-ro ships depending on the route.

Future research will explore the effects of various parameters contributing to optimal energy resources management, aiming to reduce the emission of harmful gases and enhance energy efficiency. The primary scientific contribution will involve determining the optimal number of vessels retrofitted with renewable energy sources to enhance energy efficiency. Furthermore, we will identify parameters that affect energy efficiency and emissions of harmful gases in the surrounding area and develop an optimization algorithm that determines the acceptable number of renewable resources, minimizing gas emissions and fostering optimal energy efficiency management.

Author Contributions

Conceptualization, B.B.B., M.K. and Z.J.; methodology, B.B.B. and M.K.; validation, B.B.B., M.K. and Z.J.; formal analysis, B.B.B. and M.K.; investigation, B.B.B.; writing—original draft preparation, B.B.B. and M.K.; visualization, B.B.B., M.K. and Z.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

We thank the company Adriatic Propeleri d.o.o. for their help and assistance throughout writing the manuscript.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Shipping Fleet Statistics: 2022|Hellenic Shipping News Worldwide. Available online: https://www.hellenicshippingnews.com/shipping-fleet-statistics-2022/ (accessed on 5 September 2023).

- 2023 IMO Strategy on Reduction of GHG Emissions from Ships. Available online: https://www.imo.org/en/OurWork/Environment/Pages/2023-IMO-Strategy-on-Reduction-of-GHG-Emissions-from-Ships.aspx (accessed on 5 September 2023).

- EEDI—Rational, Safe and Effective. Available online: https://www.imo.org/fr/MediaCentre/HotTopics/Pages/EEDI.aspx (accessed on 5 September 2023).

- Improving the Energy Efficiency of Ships. Available online: https://www.imo.org/en/OurWork/Environment/Pages/Improving%20the%20energy%20efficiency%20of%20ships.aspx (accessed on 5 September 2023).

- Litwin, W.; Lesniewski, W.; Piatek, D.; Niklas, K. Experimental Research on the Energy Efficiency of a Parallel Hybrid Drive for an Inland Ship. Energies 2019, 12, 1675. [Google Scholar] [CrossRef]

- Elkafas, A.G.; Shouman, M.R. A Study of the Performance of Ship Diesel-Electric Propulsion Systems From an Environmental, Energy Efficiency, and Economic Perspective. Mar. Technol. Soc. J. 2022, 56, 52–58. [Google Scholar] [CrossRef]

- He, Y.; Fan, A.; Wang, Z.; Liu, Y.; Mao, W. Two-phase energy efficiency optimisation for ships using parallel hybrid electric propulsion system. Ocean Eng. 2022, 238, 109733. [Google Scholar] [CrossRef]

- Faitar, C.; Novac, I. A new approach on the upgrade of energetic system based on green energy. A complex comparative analysis of the EEDI and EEOI. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2016. [Google Scholar] [CrossRef]

- Ančić, I.; Vladimir, N.; Luttenberger, L.R. Energy efficiency of ro-ro passenger ships with integrated power systems. Ocean Eng. 2018, 166, 350–357. [Google Scholar] [CrossRef]

- Ammar, N.R.; Seddiek, I.S. Evaluation of the environmental and economic impacts of electric propulsion systems onboard ships: Case study passenger vessel. Environ. Sci. Pollut. Res. 2021, 28, 37851–37866. [Google Scholar] [CrossRef]

- El Geneidy, R.; Otto, K.; Ahtila, P.; Kujala, P.; Sillanpää, K.; Mäki-Jouppila, T. Increasing energy efficiency in passenger ships by novel energy conservation measures. J. Mar. Eng. Technol. 2018, 17, 85–98. [Google Scholar] [CrossRef]

- Lützen, M.; Kristensen, H. A Model for Prediction of Propulsion Power and Emissions: Tankers and Bulk Carriers. In Proceedings of the World Maritime Technology Conference, St-Petersburg, Russia, 29 May–1 June 2012. [Google Scholar]

- Kristensen, H.; Lützen, M. Existing Design Trends for Tankers and Bulk Carriers: Design Changes for Improvement of the EEDI in the Future. In Proceedings of the IMDC2012, Galsgow, UK, 11–14 June 2012. [Google Scholar]

- Radonja, R.; Pelić, V.; Pavić, D.; Glujić, D. Methodological approach on optimizing the speed of navigation to reduce fuel consumption and increase energy efficiency of the cruising ship. Sci. J. Marit. Res. 2019, 33, 222–231. [Google Scholar] [CrossRef]

- Zaccone, R.; Ottaviani, E.; Figari, M.; Altosole, M. Ship voyage optimization for safe and energy-efficient navigation: A dynamic programming approach. Ocean Eng. 2018, 153, 215–224. [Google Scholar] [CrossRef]

- Vesting, F.; Johansson, R.; Bensow, R.E. Parameter Influence Analysis in Propeller Optimisation. In Proceedings of the Third International Symposium on Marine Propulsors, Launceston, Australia, 5–8 May 2013. [Google Scholar]

- Roshan, F.; Dashtimanesh, A.; Tavakoli, S.; Niazmand, R.; Abyn, H. Hull–propeller interaction for planing boats: A numerical study. Ships Offshore Struct. 2020, 16, 955–967. [Google Scholar] [CrossRef]

- Lee, C.S.; Choi, Y.D.; Ahn, B.K.; Jang, H.G.; Shin, M.S. Performance optimization of marine propellers. Int. J. Nav. Archit. Ocean Eng. 2010, 2, 211–216. [Google Scholar] [CrossRef]

- Taheri, R.; Mazaheri, K. Hydrodynamic Optimization of Marine Propeller Using Gradient and Non-Gradient-based Algorithms. Acta Polytech. Hung. 2013, 10, 221–237. [Google Scholar] [CrossRef]

- Blasques, J.P.; Berggreen, C.; Andersen, P. Hydro-elastic analysis and optimization of a composite marine propeller. Mar. Struct. 2010, 23, 22–38. [Google Scholar] [CrossRef]

- Lin, J.F.; Zhao, D.G.; Guo, C.Y.; Su, Y.M.; Zhong, X.H. Comprehensive test system for ship-model resistance and propulsion performance in actual seas. Ocean Eng. 2020, 197, 106915. [Google Scholar] [CrossRef]

- Vetma, V.; Kulenović, Z.; Antonić, R.; Tomas, V. Optimiziranje brodskog vijka s konstantnim usponom 1 optimization of marine propellers with constant pitch 2 sažetak. Pomorstvo. Sci. J. Marit. Res. 2012, 26, 375–396. [Google Scholar]

- Redesigned Propeller Blades Increase Fuel Efficiency up to 22%. Available online: https://maritime-executive.com/article/redesigned-propeller-blades-increase-fuel-efficiency-up-to-22 (accessed on 20 November 2023).

- Hamed, A. Multi-objective optimization method of trimaran hull form for resistance reduction and propeller intake flow improvement. Ocean Eng. 2022, 244, 110352. [Google Scholar] [CrossRef]

- Knutsson, D.; Larsson, L. Large Area Propellers. Ph.D. Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2011. [Google Scholar]

- Yin, C.; Rosenvinge, C.K.; Sandland, M.P.; Ehlers, A.; Shin, K.W. Improve Ship Propeller Efficiency via Optimum Design of Propeller Boss Cap Fins. Energies 2023, 16, 1247. [Google Scholar] [CrossRef]

- Doijode, P.S.; Hickel, S.; van Terwisga, T.; Visser, K. A machine learning approach for propeller design and optimization: Part I. Appl. Ocean Res. 2022, 124, 103178. [Google Scholar] [CrossRef]

- Sedelnikov, A.; Kurkin, E.; Quijada-Pioquinto, J.G.; Lukyanov, O.; Nazarov, D.; Chertykovtseva, V.; Kurkina, E.; Hoang, V.H. Algorithm for Propeller Optimization Based on Differential Evolution. Computation 2024, 12, 52. [Google Scholar] [CrossRef]

- Gypa, I.; Jansson, M.; Wolff, K.; Bensow, R. Propeller optimization by interactive genetic algorithms and machine learning. Ship Technol. Res. 2023, 70, 56–71. [Google Scholar] [CrossRef]

- Triantafyllou, M.; Hover, S. Maneuvering and Control of Marine Vehicles; Department of Ocean Engineering, Massachusetts Institute of Technology: Cambridge, MA, USA, 2003. [Google Scholar]

- ISO 484-2:2015; Shipbuilding—Ship screw propellers—Manufacturing tolerances—Part 2: Propellers of diameter between 0.80 and 2.50 m inclusive. ISO: Geneva, Switzerland, 2015. Available online: https://www.iso.org/standard/68084.html (accessed on 5 September 2023).

- Prop Scan—General Propeller. Available online: https://www.generalpropeller.com/prop-scan (accessed on 19 April 2024).

- Vobner, J. Vpliv Tolerančnih Razredov na Zmogljivost Ladijskega Vijaka: Diplomsko Delo. 2021. Available online: https://dk.um.si/IzpisGradiva.php?id=79810 (accessed on 9 May 2024).

- Adriatic Propeleri|Popravak, Modifikacija i Optimizacija Svih Vrsta Propelera. Available online: https://adriaprop.hr/ (accessed on 8 December 2023).

- Agencija. Available online: https://agencija-zolpp.hr/agencija/ (accessed on 19 April 2024).

- International Maritime Organization. Guidelines on the Method of Calculation of the Attained Energy Efficiency Design Index (EEDI) for New Ships. Available online: https://wwwcdn.imo.org/localresources/en/KnowledgeCentre/IndexofIMOResolutions/MEPCDocuments/MEPC.364%2879%29.pdf (accessed on 19 April 2024).

- Bašić, B.B.; Krčum, M.; Gudelj, A. Adaptation of Existing Vessels in Accordance with Decarbonization Requirements—Case Study—Mediterranean Port. J. Mar. Sci. Eng. 2023, 11, 1633. [Google Scholar] [CrossRef]

- Ančić, I.; Perčić, M.; Vladimir, N. Alternative power options to reduce carbon footprint of ro-ro passenger fleet: A case study of Croatia. J. Clean. Prod. 2020, 271, 122638. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).