1. Introduction

Under real sea conditions, the Unmanned Surface Vehicle (USV) may overturn when executing tasks. If the USV does not have the self-righting ability after overturning, it will lose maneuverability and can only wait for rescuing, which will cause problems when the USV sails out. Therefore, a USV with the self-righting ability is favored and researchers have conducted broad research on it.

At first, researchers mainly analyzed the self-righting performance via experiments; it is intuitive to improve the performance according to experimental results. Hudson et al. evaluated the design requirements of the hull form, the machinery installation and the construction materials [

1]. The results show that composite materials which were carefully designed could reduce high hydrodynamic influence. Shepard et al. introduced a high-speed and heavy-weather motor lifeboat, which was designed to have the self-righting ability and operate in a wave which is up to 20 feet in height [

2]. Renilson et al. conducted an experiment on a 1/12.5 scale model and developed two different experimental procedures which were for a single breaking wave and steep irregular waves, and then they tested four working conditions to explore the limit of stability [

3]. Kim et al. researched materials to prevent the overturn of a rigid inflatable boat [

4]. The results show that Thermoplastic Polyurethane tubes were better than single Hypalon tubes and that high buoyant materials arranged in empty spaces could increase the spare buoyancy of the ship. Fu researched the configuration of a self-righting lifeboat named Huaying 396 [

5]. Grenestedt et al. introduced a high-performance USV with applications for surveillance and monitoring tasks, and then they demonstrated an effective trajectory following a riverine environment at peak speeds of 30 mph [

6]. Akyildiz et al. used a watertight superstructure to provide enough buoyancy to realize the self-righting function [

7]. The results show the advantage of this structure by comparing it with airbags and self-operating ballast water replacement systems. Relying on experiments, researchers mainly tested self-righting performance under uncomplicated working conditions.

However, the model must be manufactured via complicated steps and the experiment can only research a few working conditions, which costs a lot and is not convenient, especially when it comes to large-scale ships. Furthermore, it is hard to measure some data such as restoring arms, which are important for self-righting analysis in the experiment. With the development of numerical methods and lots of commercial software, researchers began to use these new tools to analyze the self-righting performance.

Normally, the simulation of self-righting ability analyzes the static stability based on the theory of ship hydrostatics and stability. In this analysis method, the static stability curve should be computed first, and researchers should observe whether the restoring arm is always positive when the roll angle is between 0° and 180°. In static stability theory, the restoring arm is considered to be the criterium to analyze the self-righting performance. In order to guarantee enough static stability during the self-righting process, the restoring arm should be positive at all roll angles. Yim et al. proposed a stability analysis method under severe sea conditions and built roll-heave models with a high-degree polynomial approximation of restoring forces and moments [

8]. Bellec et al. applied artificial neural network technology to the parametric rolling prediction on head seas [

9]. Storey et al. developed a MATLAB simulator to model the vessel’s tilting motion on the surface of the sea [

10]. Jing et al. researched the self-righting performance of a 10 m rescue boat with different trims, gravity centers and water displacements through NAPA [

11]. Yao et al. established a nonlinear roll equation of a rotary-molded boat based on nonlinear feature analysis of restoring torques and damping torques [

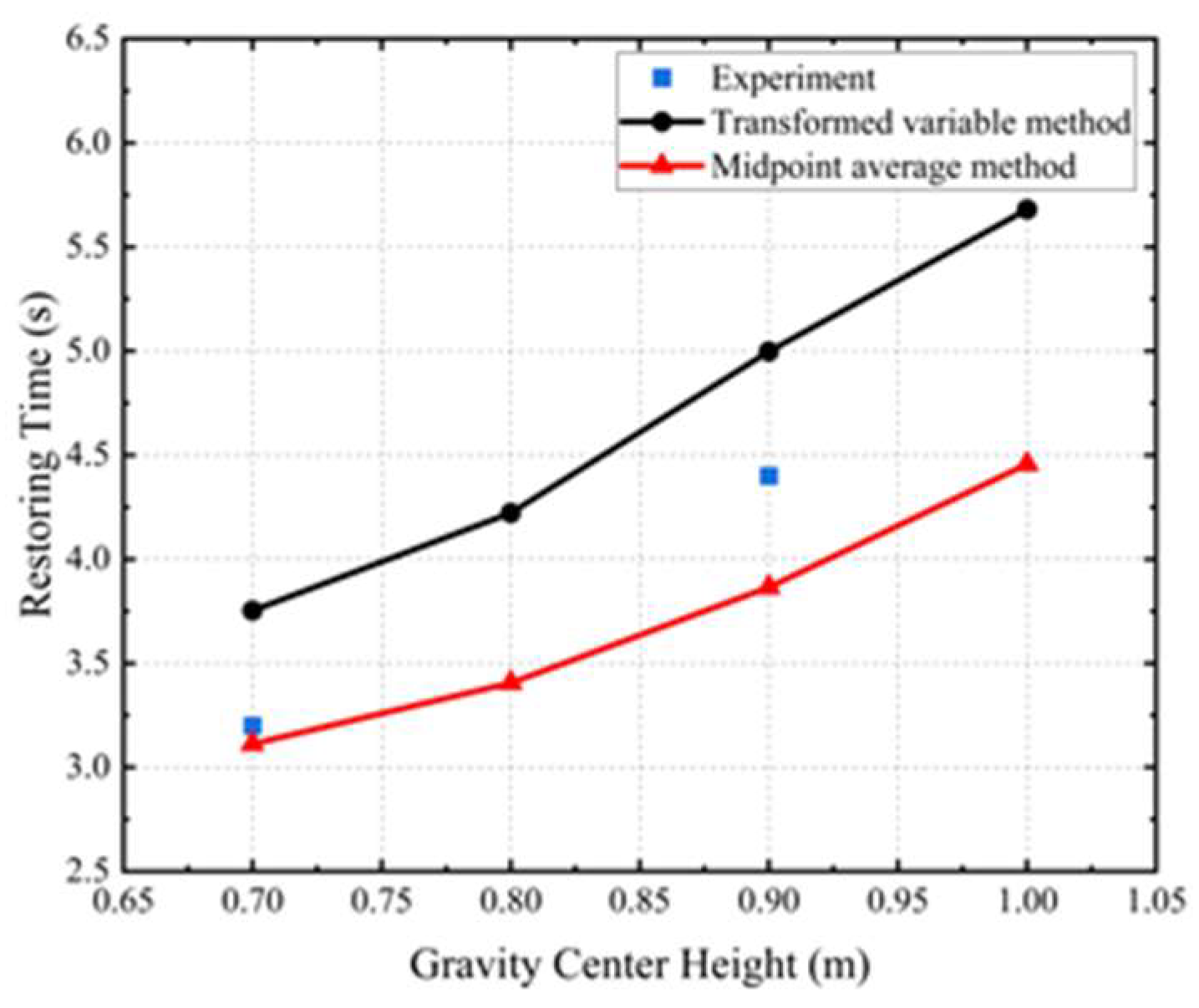

12]. Then, they dissected its dynamic characteristic of rolling motion via the simulation. Bai et al. computed the restoring time and rolling cycles by solving the motion equations based on the transformed variable method [

13]. The comparisons of computation results and the model experiment results of a float boat showed the reliability of this method. Tavakoli et al. determined the roll restoring moment by implementing an asymmetric parameter in previous lift equations and proposed an empirical method for computing restoring arms [

14]. Zaman et al. analyzed the effect of gravity point on the engine room longitudinally, vertically and transversely on the simulation’s ability to self-right [

15]. Lin et al. proposed a new self-righting design method based on the parametric design of decks for an unmanned speedboat [

16]. Deng et al. simulated the hydrofoil rotation around the center of a wave-powered boat and the passive rotation around the center of the hydrofoil [

17]. Guan et al. proposed a design method of self-righting decks, and they analyzed stability based on the combination of the particle swarm optimization and the sequential quadratic programming [

18]. Trimulyono et al. examined the design of an anti-capsize ship by improving the self-righting moment with different heights of deck house and designed a ship whose restoring arm is positive when the roll angle is between 0° and 180° [

19]. With the improvement of algorithms and software, the efficiency of self-righting designs has greatly increased compared with traditional experiments.

As the development of self-righting designs progresses, the period of restoring time has been restricted. Restoring time has been added to the criteria of self-righting performance analysis by more and more researchers [

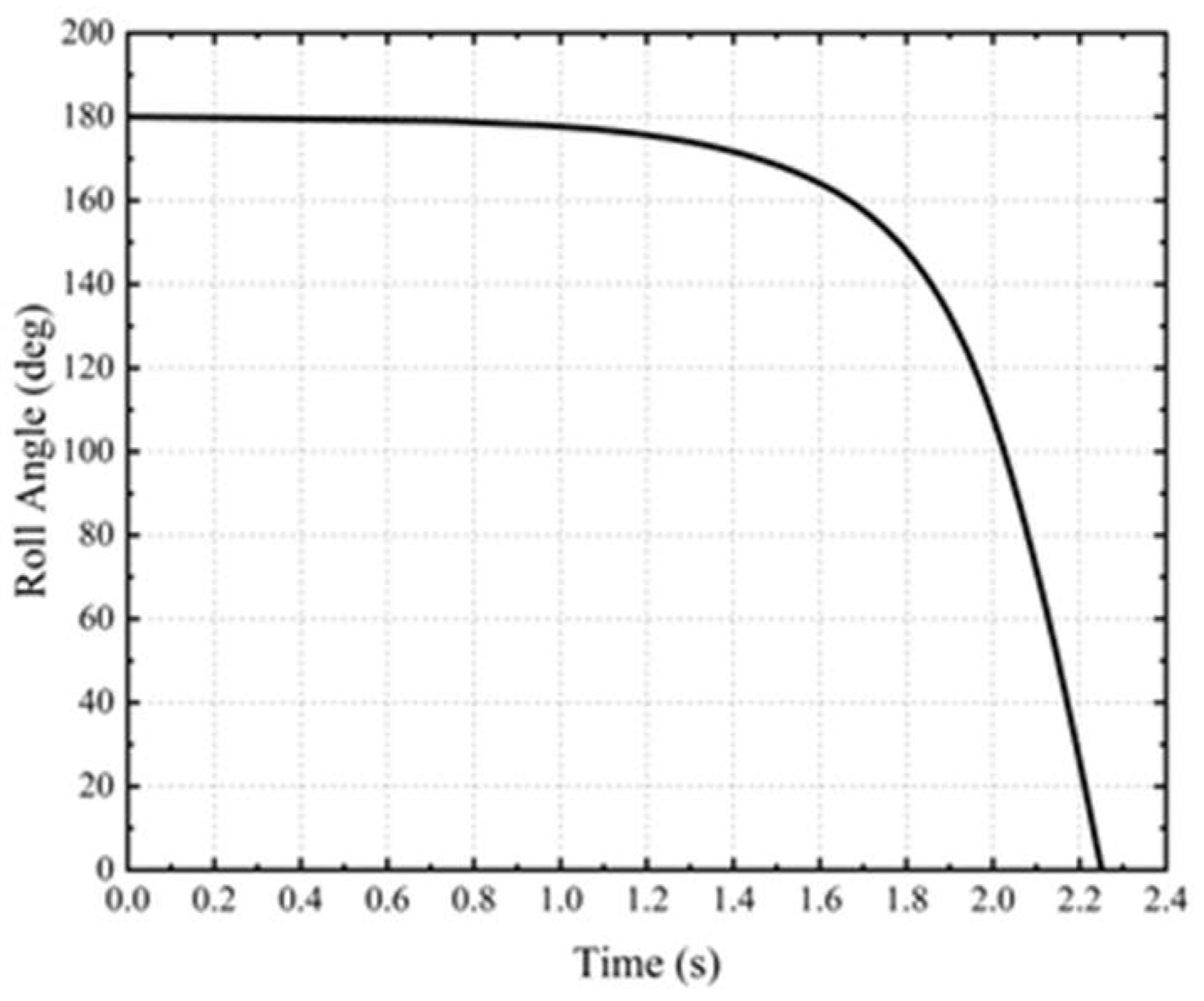

13]. According to the design requirement, restoring time refers to the time from the moment when the USV begins the self-righting motion to the moment when the USV returns to the upright position for the first time.

Xu simulated the whole self-righting process of an electric propulsion unmanned ship and computed restoring time [

20]. Nevertheless, the acquisition of restoring time is mainly based on static stability theory, in which the damping factor and the wave factor are not considered or are simplified via estimation. The above static stability method, which only exists according to restoring arm curves, cannot meet present design requirements which contain restoring time.

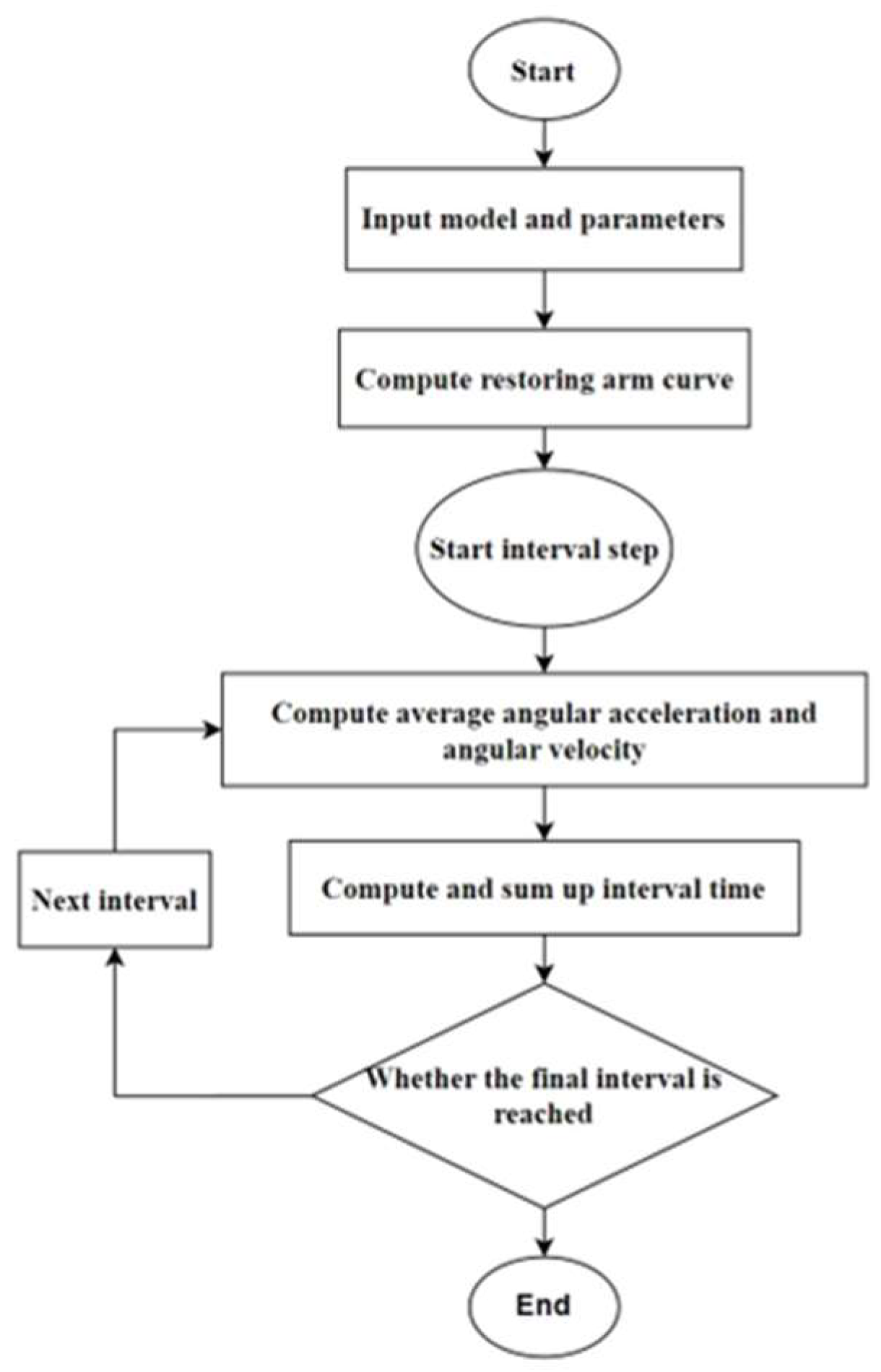

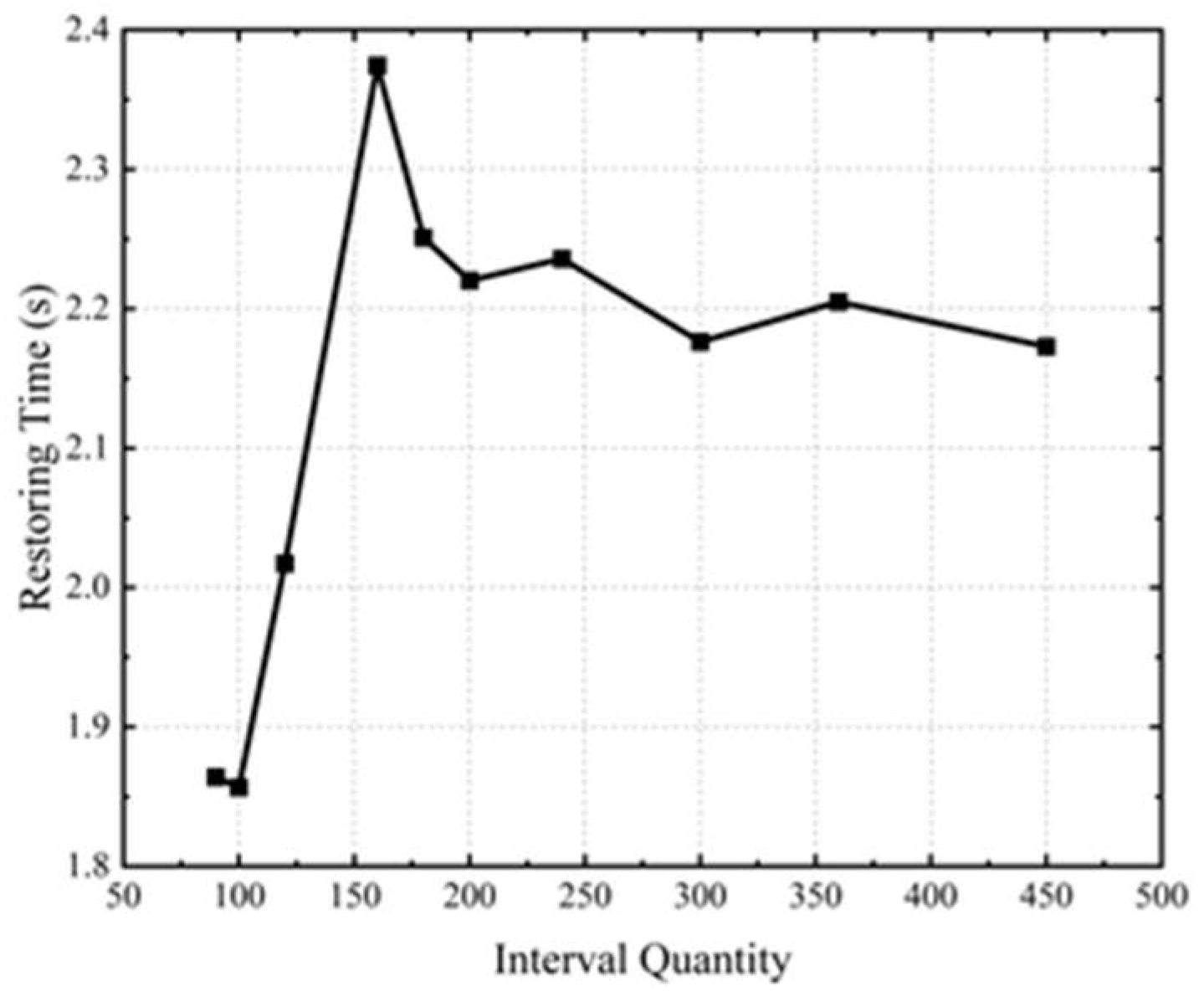

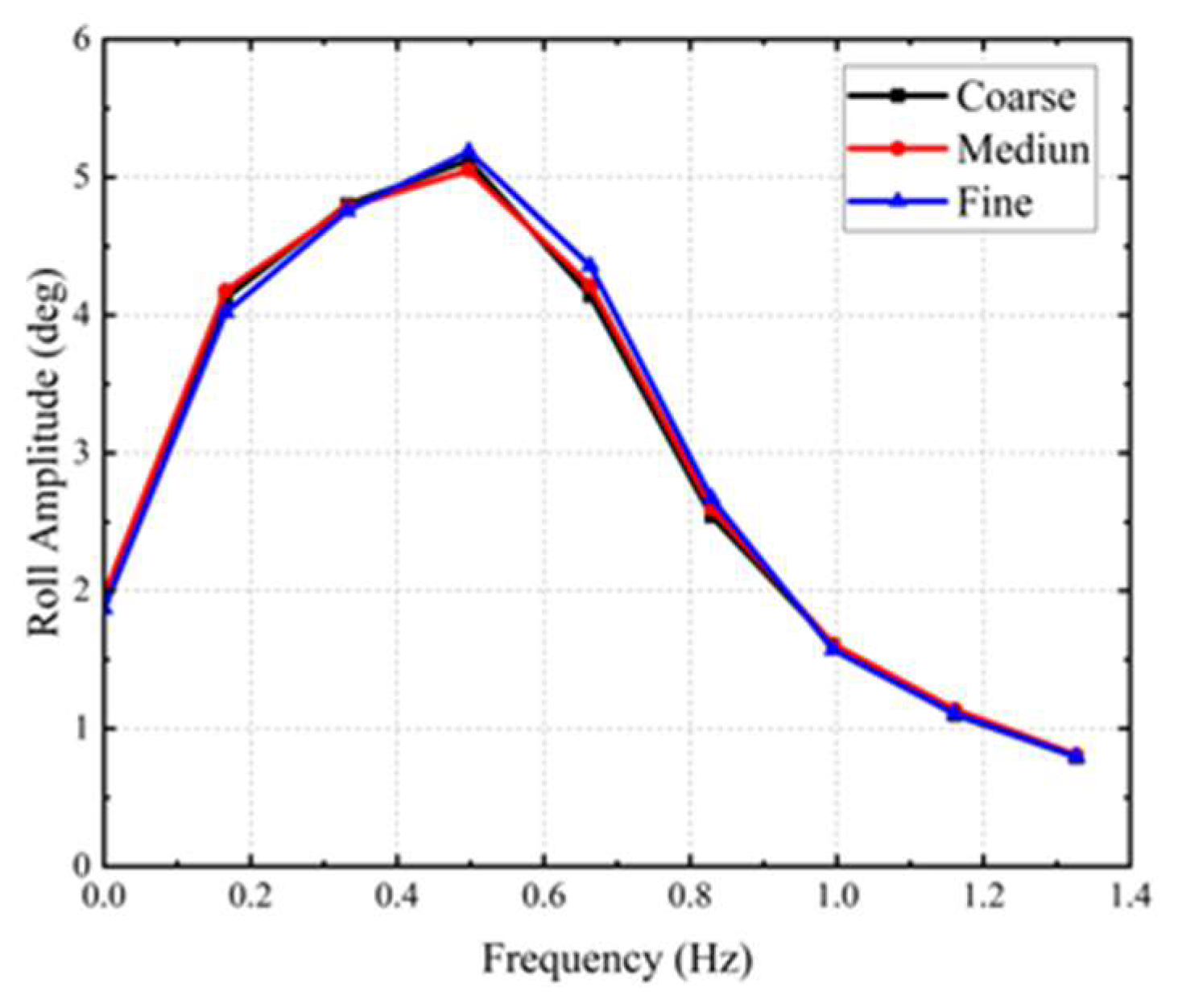

Based on the above studies, it is of great importance to improve the traditional static stability method and adopt a new numerical simulation method to predict the self-righting process of the USV. Before the simulation, a midpoint average method based on the static stability theory was used to compute the static restoring time. Even though the midpoint average method is not accurate enough under real sea conditions, its computational process is convenient because it only needs the restoring arm curve, the width of the USV and the gravity center height of the USV. Rigorous verification studies, including the Grid Convergence Index (GCI) analysis and the comparison with the experiment, were carried out to validate the simulation. A USV under four working conditions was used in CFD prediction. Comparisons between the self-righting process on four working conditions were performed to analyze the self-righting performance.

The remainder of this paper is divided into four parts. In

Section 2, the disadvantage of the traditional transformed variable method is analyzed, and a new midpoint average method is introduced and validated. In

Section 3, the detailed procedure of the simulation is introduced, and validation studies are conducted on the simulation. Then, the results of the simulation are compared with those of the midpoint average method and those of the experiment. In

Section 4, the simulation results of a USV under four working conditions are introduced and the restoring time results are analyzed. In

Section 5, there is the summary and the reflection for this paper.

4. Prediction of Self-Righting Performance

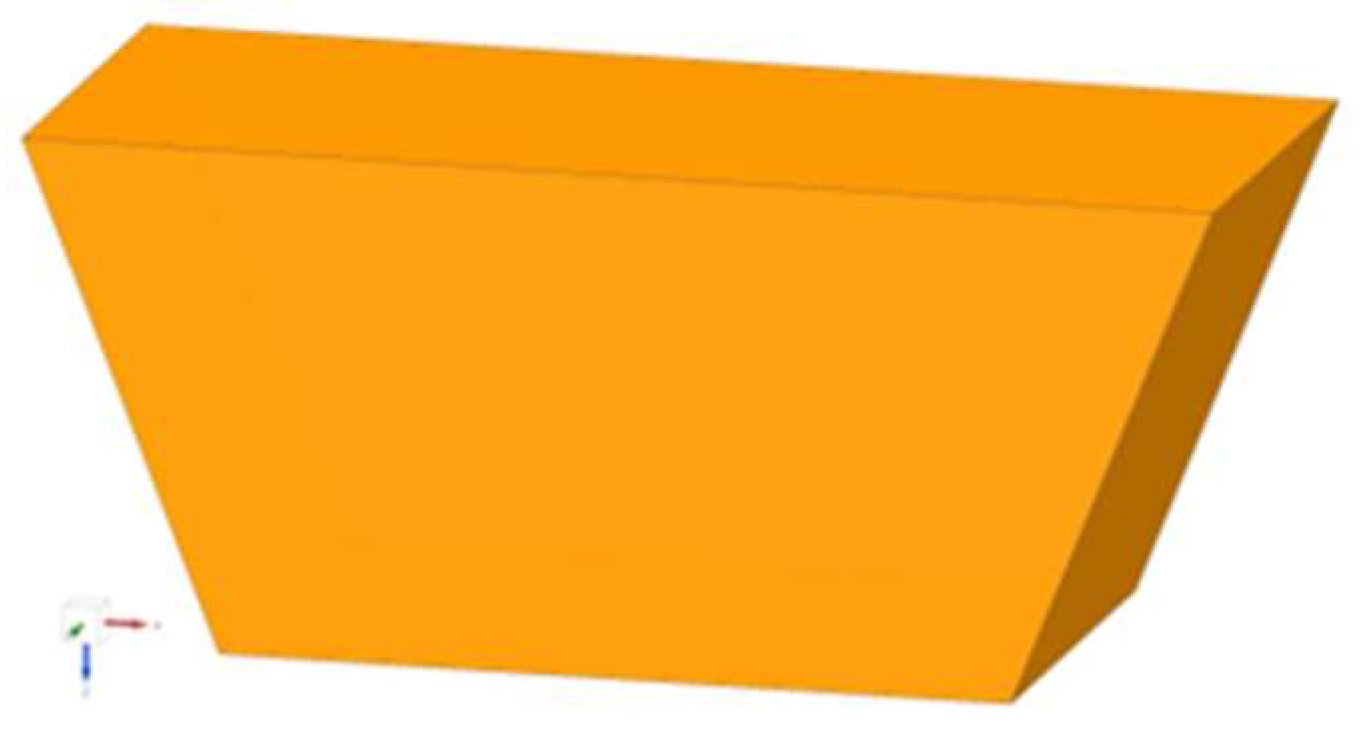

This USV was designed to execute rescue tasks and should have safe navigation ability under severe sea conditions. Parameters of the USV are listed in

Table 8, and a simplified model is shown in

Figure 15. There are four working conditions when the USV executes tasks: they are leaving port with the design load (condition 1), reaching port with the design load (condition 2), leaving port with maximum load (condition 3) and reaching port with maximum load (condition 4). The differences in the four working conditions can be simplified as differences in displacement and in gravity center position. The reference point is set at the backend of the bottom of the USV. The parameters of the four working conditions are listed in

Table 9. The numerical simulation method above was used to predict the self-righting performance of the USV under four working conditions.

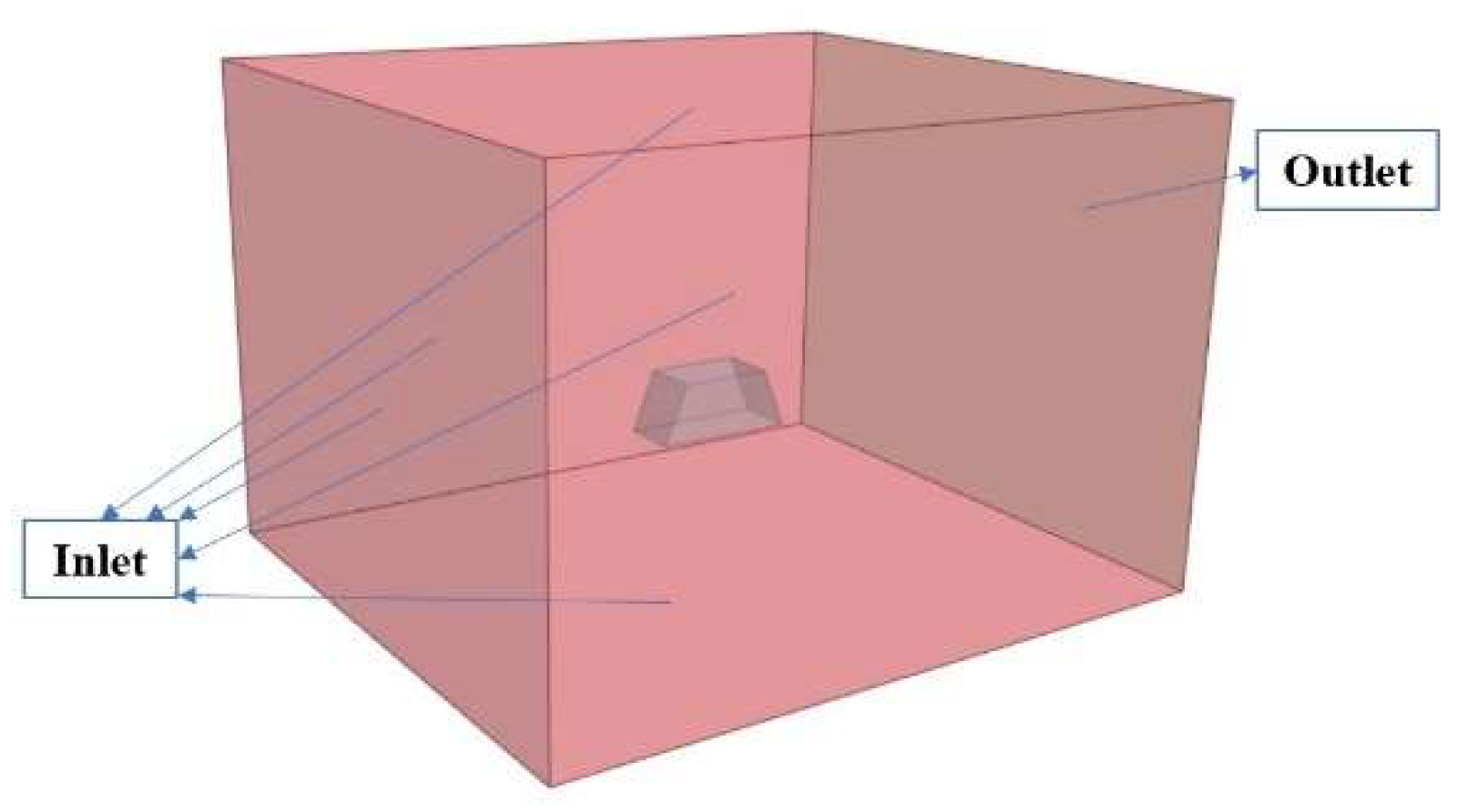

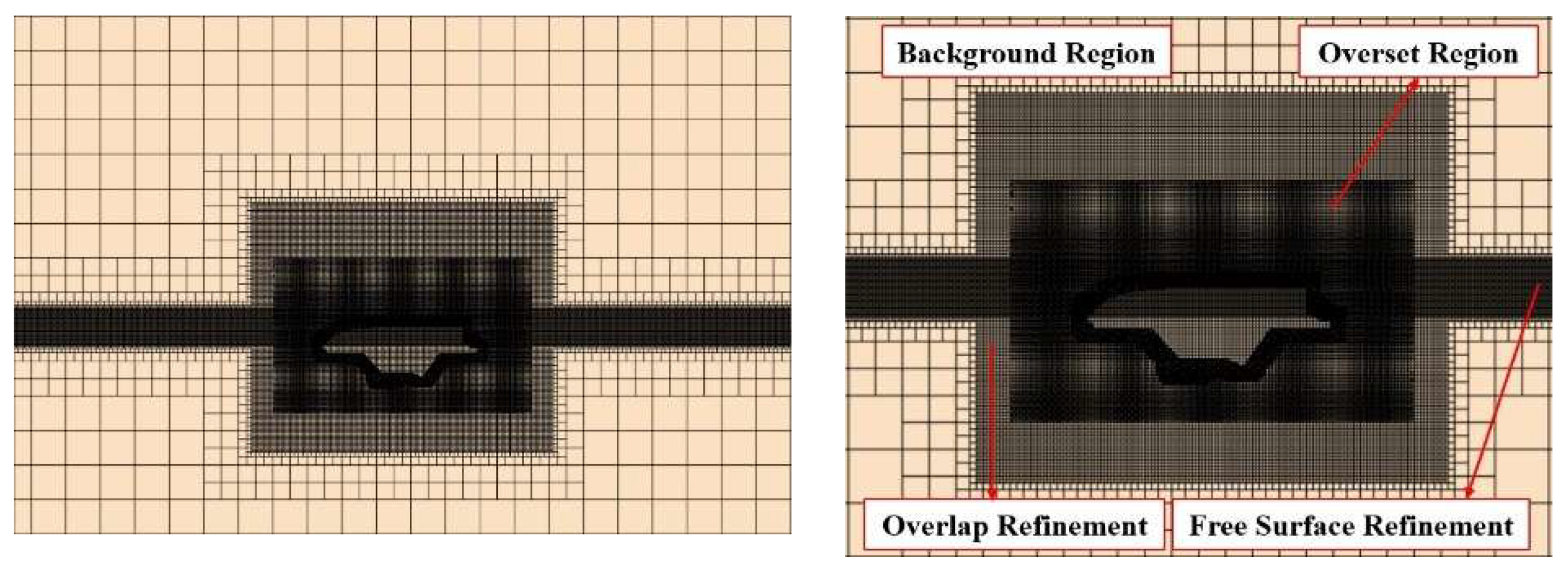

The setting of the computational domain is the same as the introduction in

Section 3. The length of it is 45 m, the width of it is 21.2 m and the height of it is 30 m, which is shown in

Figure 16. The size of the box for the overlap refinement is −4 m < x < 11 m, −4 m < y < 4 m, −5 m < z < 4 m, which is shown in

Figure 17. Similar to the simulation procedure in

Section 3, the total cell number of the computational domain is 4,268,280 cells and the time step is 0.005 s.

Head wave simulations were carried out to represent a severe sea condition in a wave with wave amplitude

and wavelength

, which follows INSEAN captive tests [

31].

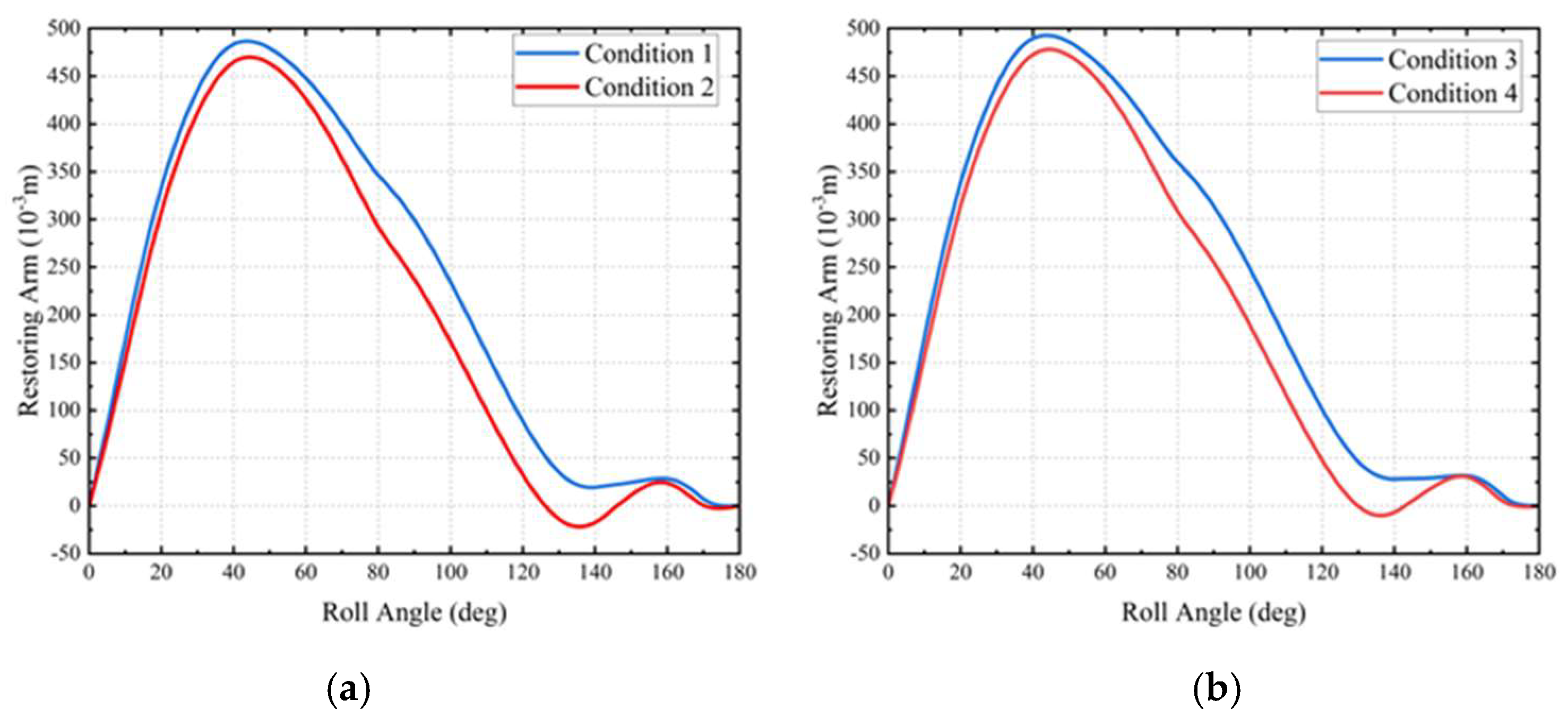

The displacement in condition 1 was smaller than that of condition 3, and the gravity center height of condition 1 was higher than that of condition 3. The displacement in condition 2 was smaller than that of condition 4, and the gravity center height of condition 2 was higher than that of condition 4. There were two factors which were different at the same time, and the influences of the two factors on self-righting performance were opposite. According to the restoring arm curves in

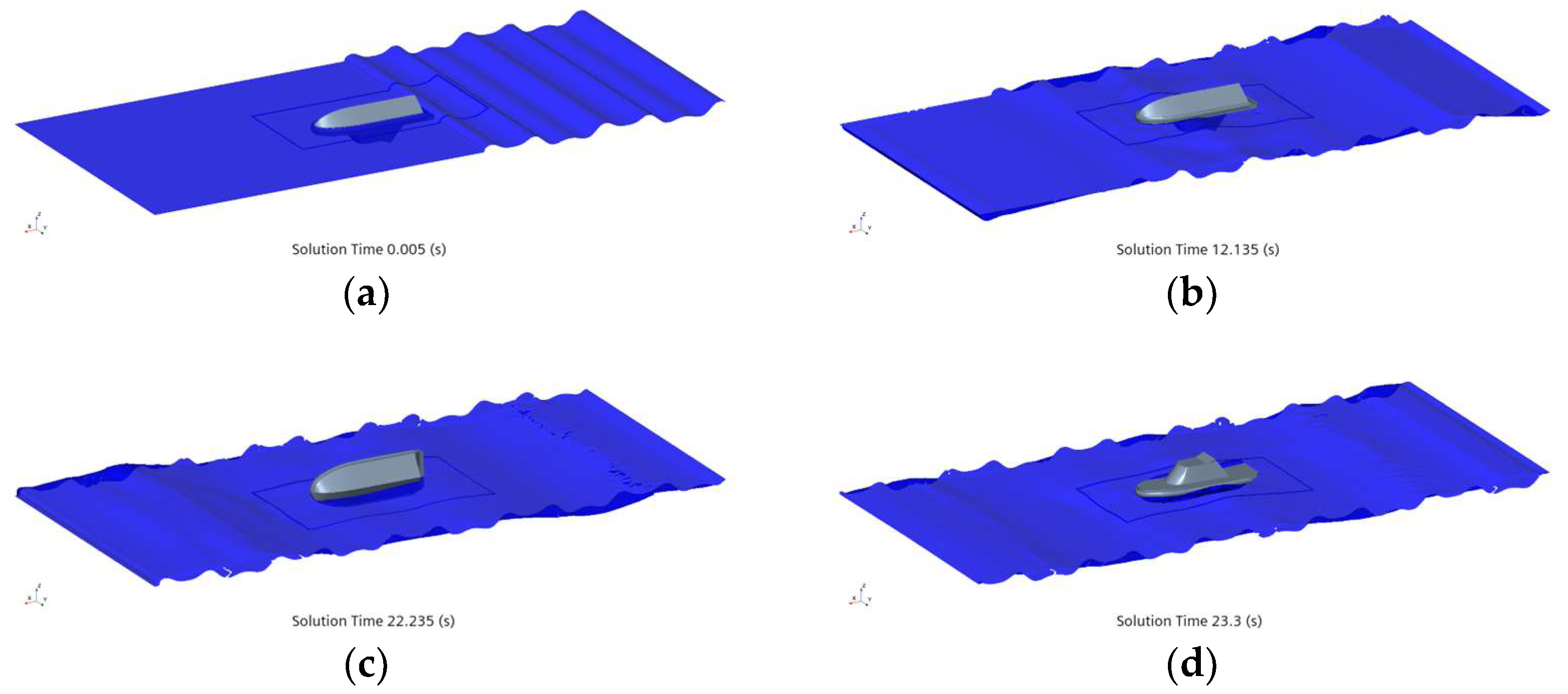

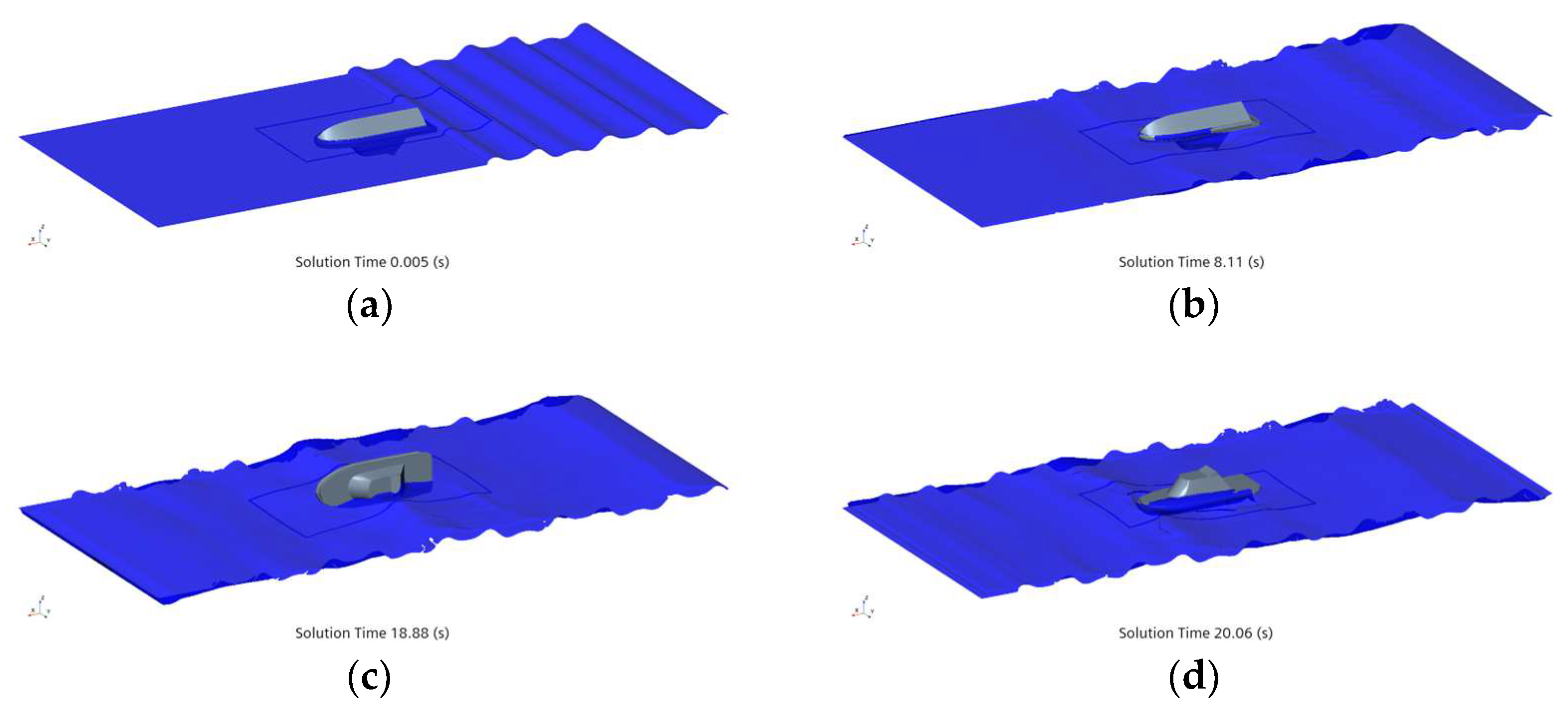

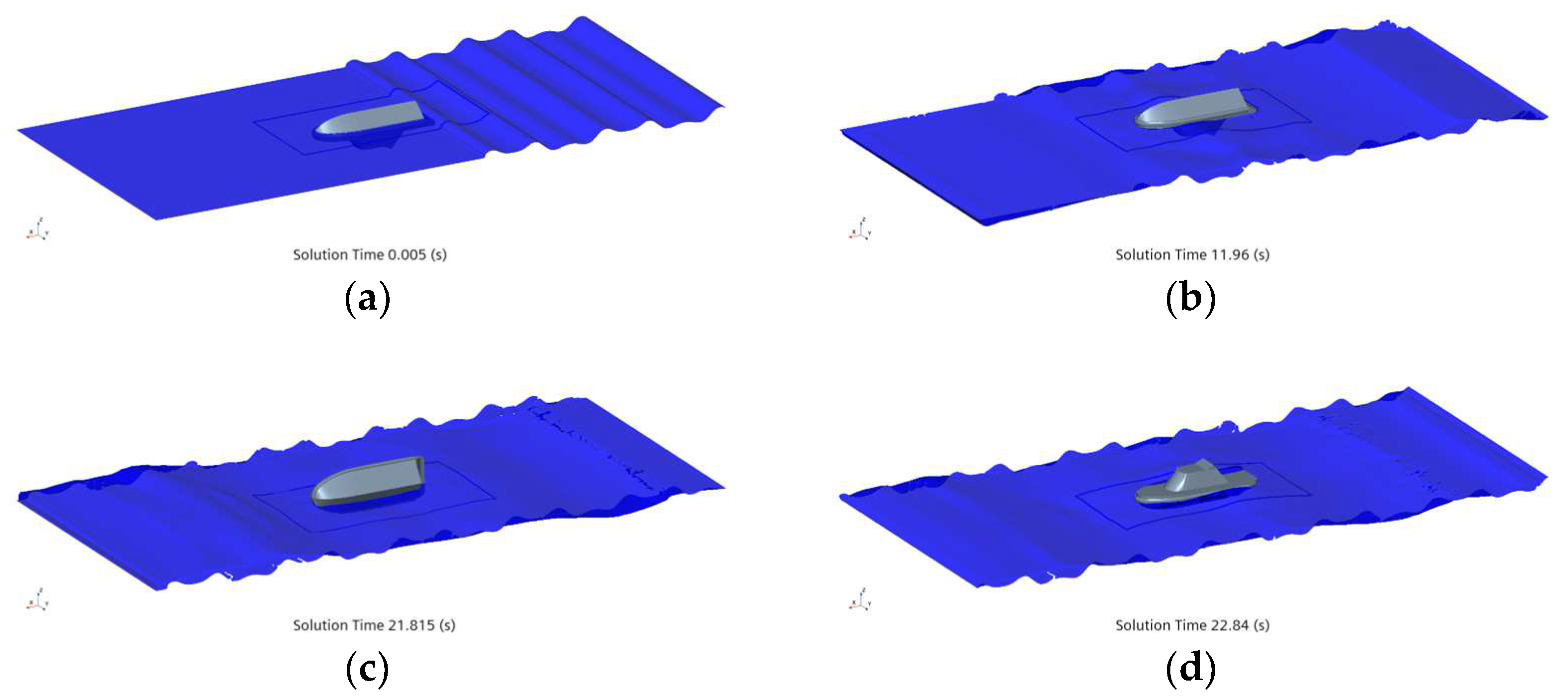

Figure 18, the restoring arm is less than zero between 126.4° and 146° for condition 2, and the restoring arm is less than zero between 130° and 142.8° for condition 2. The restoring arm curves mean that, based on the static stability theory, the USV should not have the self-righting ability under condition 2 and condition 4. However, the simulation results shown in

Figure 19,

Figure 20,

Figure 21 and

Figure 22 prove the self-righting ability under four working conditions. The change of water surface shape makes the restoring arm in the simulation different from that of the static stability method, which will influence the restoring time. In terms of the restoring time shown in

Table 10, the self-righting performance sorted from best to worse is as follows: condition 4, condition 3, condition 1 and condition 2.

5. Conclusions

In our study, the self-righting process and the restoring time of a physical model were computed by using the midpoint average method, the numerical simulation and the experimental method. Then, the reliability of the simulation was fully verified by comparing the CFD results with the results of the improved static method and the experimental method. Eventually, the self-righting performance of a USV under four working conditions was evaluated and analyzed via the simulation method. It was demonstrated that:

(1) The new midpoint average method has computational stability in the integration and is able to estimate the restoring time more conveniently.

(2) Compared with the experiment, the numerical simulation is accurate enough in the self-righting process. This numerical simulation method can be used to compute the restoring time precisely and to predict the self-righting process.

(3) The simulation results of a USV under four working conditions show that under condition 3 (leaving port with maximum load) and under condition 4 (reaching port with maximum load), the USV can return to upright position in 11 s. Under condition 1 (leaving port with the design load) and under condition 2 (reaching port with the design load), the USV returns to the upright position after more than 11 s. The self-righting performance with maximum load is better than that with the design load.

The new midpoint average method and the numerical simulation will serve as tools for the prediction of self-righting performance under different working conditions. However, there are also external forces such as winds and rain under real sea conditions which may greatly influence the self-righting performance of the USV. Future studies will add external forces to the CFD prediction.