Abstract

Recently, more wind turbine systems have been installed in deep waters far from the coast. Several concepts of floating wind turbine systems (FWTS) have been developed, among which, the semi-submersible platform—due to its applicability in different water depths, good hydrodynamic performance, and facility in the installation process—constitutes the most explored technology compared to the others. However, a significant obstacle to the industrialization of this technology is the design of a cost-effective FWTS, which can be achieved by optimizing the geometry, size, and weight of the floating platform, together with the mooring system. This is only possible by selecting a method capable of accurately analyzing the FWTS-coupled hydro–aero–structural dynamics at each design stage. Accordingly, this paper provides a detailed overview of the most commonly coupled numerical and physical methods—including their basic assumptions, formulations, limitations, and costs used for analyzing the dynamics of FWTS, mainly those supported by a semi-submersible—to assist in the choice of the most suitable method at each design phase of the FWTS. Finally, this article discusses possible future research directions to address the challenges in modeling FWTS dynamics that persist to date.

1. Introduction

The offshore wind industry has experienced continuous growth over the last few years. Recently, more wind turbines have been installed in deeper waters, further away from the coast, comprising a considerable share of offshore wind resources with less turbulence [1]. However, over deep-sea sites, bottom-fixed concepts are no longer viable as these structures are not economical solutions for water depths of more than 50 m [2]. Therefore, several floating wind turbine system (FWTS) concepts have been developed for use in deeper waters [3,4]. Among these floating concepts, the semi-submersible platform, stabilized mainly by buoyancy, is a promising technology and is the most explored technology compared to the others. This is due to the applicability of these platforms in different water depths, their good hydrodynamic performance, and facility in the installation process [3,5,6].

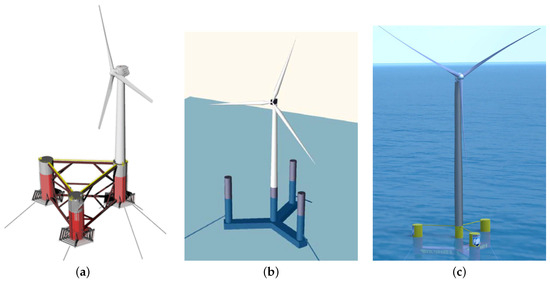

Several examples of commissioned semi-submersible FWTS include the 2 MW WindFloat semi-submersible in Portugal [7], 3 × 8.4 MW WindFloat Atlantic semi-submersibles in Portugal [8], the 2 MW Fukushima Mirai 4-column semi-submersible in Japan [9], the 7 MW Fukushima Shimpuu V-shape 3-column semi-submersible [9], and 5 × 9.5 MW plus 2 MW Kincardine semi-submersibles in Scotland [10]. Several FWTS are under construction, such as the 5 MW Eolink 4-column semi-submersible in France and the 10 MW concrete OO-Star Norway semi-submersible [8]. Several popular semi-submersible configurations include the WindFloat, the braceless platform, and VolturnUS-S, as shown in Figure 1 [11,12,13,14,15].

Figure 1.

Popular semi-submersible configurations. (a) the WindFloat platform (image courtesy of Principle Power) [16]; (b) the braceless platform [17]; (c) the VolturnUS-S platform [13].

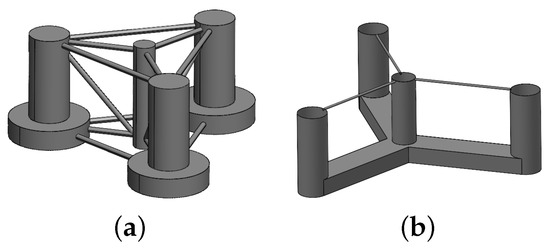

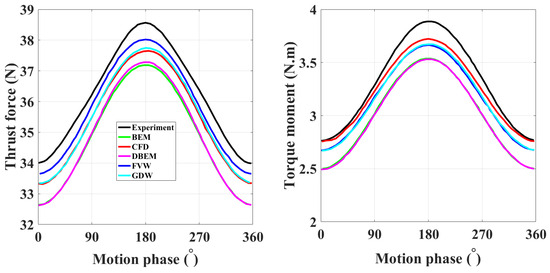

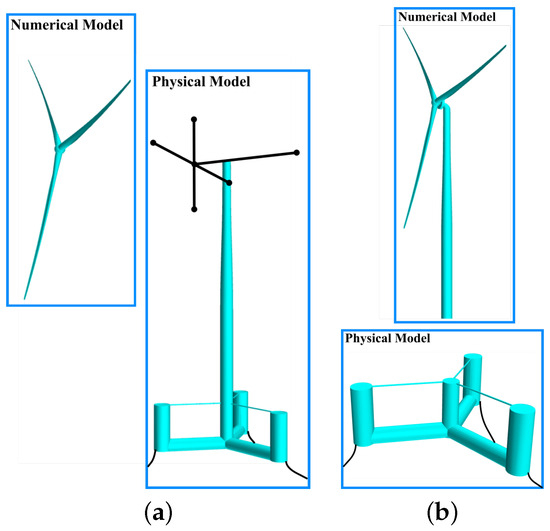

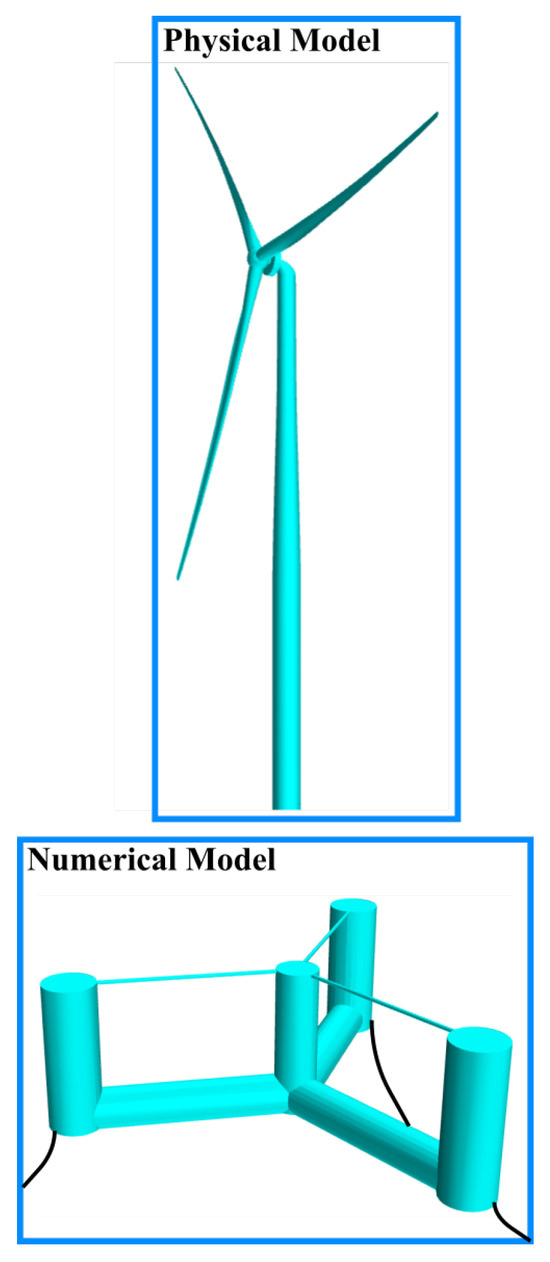

Figure 2 depicts the layout of two semi-submersible platforms. Figure 2a presents the DeepCwind semi-submersible platform [18], designed within phase II of the Offshore Code Comparison Collaboration Continuation (OC4) project to support the National Renewable Energy Laboratory (NREL) offshore 5-MW wind turbine [19]. Figure 2b shows the UMaine VolturnUS-S reference platform, which was developed to sustain the IEA 15-MW Offshore Reference Wind Turbine (also shown in Figure 1c) [13]. Semi-submersible platforms may possess different offset columns. As shown in [20], increasing these columns can reduce the platform motions. Although most of the semi-submersibles are made of steel, there is a tendency to use concrete for FWTS structures owing to lower construction costs, as well as the superior durability and fatigue resistance of concrete compared to steel [21,22,23,24].

Figure 2.

Two examples of semi-submersible platforms with three offset columns. (a) DeepCwind semi-submersible platform; (b) UMaine VolturnUS-S Reference Platform.

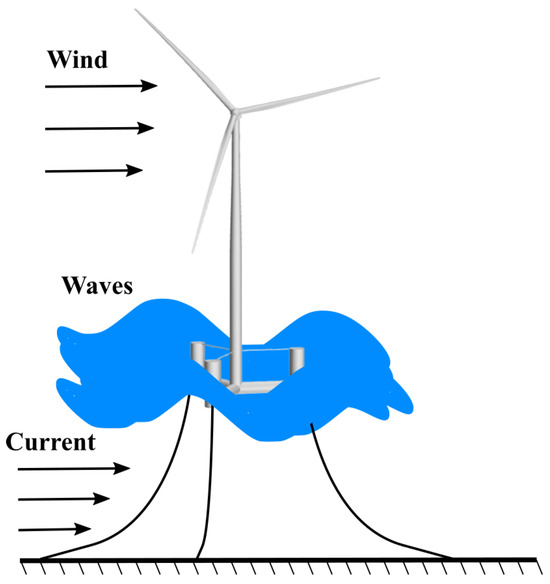

Nonetheless, FWTS are less mature than their bottom-fixed counterparts owing to their more complicated operating conditions and higher prices. The FWTS are subject to loads emanating from several sources, namely wave, current, wind, and, in certain locations, ice [25,26]. Although the similarities between FWTS and floating platforms in the oil and gas industry lead to a partial transfer of technology [27], there are numerous differences between the two industries, such as the presence of aerodynamic loads acting on wind turbines, which significantly affect the dynamics of FWTS and give rise to several new technical challenges [25,28]. For instance, the coupled current–wave–wind loads acting on the FWTS, as shown schematically in Figure 3, may cause large motions of the platform across the structure’s degrees of freedom, and combined with the aeroelastic deformations of the blades, results in highly dynamic inflow to the turbine rotor, affecting the structural integrity of the turbine [29,30]. Furthermore, to ensure safe turbine operations, platform motions induced by offshore environmental loads need to be restricted to an acceptable limit [31]. Generally, large motions are considered undesirable for floating wind turbines due to the possibility of excessive displacements at the top of the tower. Therefore, several strategies have been proposed in the literature to mitigate the motions of FWTS [32,33,34], where tuned mass dampers and tuned mass absorbers constitute the most popular methods for this purpose [35,36,37].

Figure 3.

A FWTS subject to loads emanating from several sources, such as waves, currents, and wind.

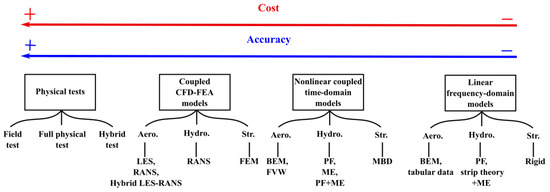

Accordingly, floating wind turbines are complex systems subject to coupled hydro-aerodynamic loads, and a better understanding of the behavior of these machines, which is substantial for their efficient design, requires the accurate evaluation of the nature and order of the coupled loading on the structure. The design of a cost-effective FWTS is a major obstacle to the industrialization of this technology [21]. Cost reduction can be achieved by optimizing the geometry, size, and weight of the floating platform, along with the mooring system, anchors, and installation and maintenance processes [5,21,38]. Further cost reduction, particularly the levelized cost of energy, can be achieved by improving the power production by minimizing the platform’s motion, a function of platform geometry, control system, and mooring system [39]. This is only possible by selecting a method that can accurately analyze the coupled hydro–aero–structural dynamics of FWTS at each design stage while incorporating control algorithms, such as power and pitch control [40,41]. Thus, a rather detailed overview of the basic assumptions, formulations, accuracies, and computational demands of the most common methods capable of evaluating the coupled behavior of FWTS in various design stages is required. This provides the necessary knowledge to identify the most suitable method at each design stage. For this purpose, based on the review carried out in this paper, a wide range of methods with different fidelities, as shown in Figure 4, can be used.

Figure 4.

Methods for evaluating the coupled hydro–aero–structural dynamic behavior of FWTS.

Generally, from right to left, the fidelity increases. The higher the method’s fidelity, the more closely it represents reality by producing more detailed information. However, this comes at the cost of more computational demand and less efficiency. Therefore, the choice of a method at each design stage is a compromise between the accuracy and computational cost.

The simplest methods, as shown on the extreme right of Figure 4, are the linear frequency-domain models with the lowest levels of fidelity, which, due to their ability to provide results in a short time period, are suitable in the early conceptual design phases for sizing and optimization purposes [42]. The hydrodynamics and aerodynamics of rigid FWTS structures are evaluated by the strip theory based on potential flow (PF) together with Morison’s Equation (ME) and a simplified blade element momentum (BEM) approach or tabular data, respectively. In this stage, in addition to structural sizing and static analysis, one must also optimize the response amplitude operators (RAOs) [43]. QuLAF [44] and SLOW [45] codes are examples of low-fidelity frequency-domain tools.

Fully coupled nonlinear time-domain models, used at the basic design stages, are categorized as mid-fidelity models (see Figure 4). These models are more accurate than the low-fidelity tools, which come at the cost of higher computational demand. The aerodynamic part is modeled using either the BEM, the generalized dynamic wake (GDW) model, or the free vortex wake (FVW) method. Note that, in the case of FWTS, the large blade deformations combined with the platform motions may lead to an interaction of the blades with their own shed vortices, which is a violation of basic assumptions of the BEM method [29,46]. In this regard, the FVW is more capable of modeling these complex physics than the BEM method while maintaining the computational cost to an acceptable level. The hydrodynamic loads are modeled based on PF, ME, or a combination of them. Further, the structural dynamics are modeled using multi-body dynamics (MBD), where flexibility is considered in selected components, such as turbine blades and towers. Due to the efficiency and accuracy offered by the MBD for slender bodies, it has become a common tool for wind turbine structural simulations [47].

The mid-fidelity simulation tools based on nonlinear time-domain methods are used for the analysis of dynamic responses of FWTS under a variety of operating and extreme conditions. These tools, through time-domain analysis, allow the adequate assessment of the impact of fatigue and extreme loads on FWTS in various operational and extreme conditions [48]. These tools are also excellent for the control design of the floating offshore wind plant. Note that the control design can be more complex for this technology, as the objective function is established in order to fulfill the following obligations: the optimization of energy production, as well as a reduction in structural loads and platform motions [49,50,51,52,53,54,55,56,57]. The OpenFAST software from NREL is an example of these tools, which can perform real-time coupled hydro-aero-servo-elastic simulations for FWTS [58,59].

Next, as presented in Figure 4, are the high-fidelity methods based on both finite element analysis (FEA) and computational fluid dynamics (CFD). These tools are employed in the final phases of the project where further investigations are required for extreme conditions, as well as intricate flow conditions, e.g., vortex detachment from heave plates [48]. These models involve less parameterization than the other categories, making them computationally more expensive. These models are also suitable for fine-tuning the design, as well as the calibration of the low- and mid-fidelity models [48,60,61,62,63,64]. CFD uses either large eddy simulation (LES), Reynolds-averaged Navier–Stokes (RANS) equations, or hybrid LES-RANS, to predict the aero-hydrodynamic loads acting on FWTS. Unlike BEM and FVW methods, which rely on external aerodynamic load inputs and semi-empirical corrections to account for 3D effects, dynamic stall, etc. CFD naturally takes all these effects into account. CFD can also better capture the turbulent wake behind a turbine, which leads to transient loads on the downstream machines in a wind farm.

Furthermore, the three-dimensional FEA with sufficient details can better capture complex blade deformations at a higher computational cost than MBD, in which the blades are modeled as one-dimensional beams. Structural failure often emanates from local stress raisers, which the MBD method cannot adequately capture. Despite this, the MBD method can provide reasonable boundary conditions for local finite element analyses.

High-fidelity tools are an attractive option for evaluating FWTS dynamics; however, the results of these tools depend on several factors, such as temporal and spatial resolutions, turbulence modeling, free surface modeling, etc. Accordingly, reliable measurements from physical testing, including hybrid testing, full physical testing, and field testing, as shown in Figure 4, are required to gain more confidence in these numerical tools.

Therefore, the low-, mid-, and high-fidelity models, as shown in Figure 4, are obtained by combining numerical models that can evaluate the structural dynamics, hydrodynamics, and aerodynamics of FWTS at different levels of accuracy. As one advances in the design stages, more accurate and detailed methods become essential.

The present paper aims to provide a detailed overview of the most common coupled methods, as depicted in Figure 4, including their basic assumptions, formulations, limitations, and costs used for FWTS, mainly those supported by a semi-submersible, to assist in the choice of the most suitable method at each design stage of the FWTS. Note that several review papers are available on the hydro–aero–structural dynamic evaluation of FWTS [5,8,25,30,48,65,66,67,68].

In this regard, experimental testing and numerical models employed to assess FWTS are reviewed in [8]. However, full physical testing, field testing, numerical methods such as FVW methods, structural dynamics, and nonlinear second-order wave loads are not covered. An overview of the numerical methods, as well as the physical and hybrid tests, are covered in [48]. However, the field tests, as well as the physical basis and formulations of the numerical models, are not presented. An overview of the coupled numerical models for optimizing an FWTS structure in conceptual, basic, and detailed design stages is presented in [5]. An overview of the coupled numerical tools and full physical tests for FWTS are presented in [25]. A review of the experimental and numerical methods is presented in [65], without any details about numerical methods. A general review of numerical and physical models is presented in [30]. The physical and hybrid model tests are reviewed in [66,67,68].

The present review can be considered one of the few works where the basic assumptions, formulations, limitations, and costs of the most popular methods, as well as their recent advances—for analyzing the coupled dynamics of floating wind turbines—are investigated in detail. Furthermore, based on this review, several necessary future research areas are identified and recommended for academic researchers. Therefore, the present review is built upon the previous review efforts by providing a more detailed and up-to-date overview of the state of the art of the most popular physical and numerical coupled modeling techniques for FWTS, as presented in Figure 4.

The paper is organized as follows: Section 2 presents the low-fidelity linear frequency-domain models. Afterward, the nonlinear coupled time-domain methods are described in Section 3. This is followed by the presentation of the high-fidelity modeling techniques of FWTS in Section 4. Moreover, some final notes about numerical models are presented in Section 5, and after that, Section 6 focuses on physical testing. Finally, a summary and conclusions are presented in Section 7.

2. Low-Fidelity Methods—Linear Frequency-Domain Models

These models are based on a linear frequency-domain mathematical model capable of providing steady-state responses for the FWTS [42,69,70]. The FWTS responses are computed using the following six DOF equations [70,71]:

Here, denotes the frequency of the incident wave, denotes the DOF dynamic response of the FWTS, denotes the excitation forces and moment vectors due to wind and waves, M denotes the FWTS mass and inertia matrices, A denotes added mass and inertia matrix, B denotes the damping matrix, and C denotes the restoring matrix. Note that matrices A and B contain contributions from aerodynamics and hydrodynamics, while the C matrix includes mooring loads, in addition to hydrostatic forces. Mooring loads are computed using either analytical equations based on a simple linear spring model or a quasi-static approach [30,44,69,70,72]. The hydrodynamic loads are estimated using a linearized PF theory or strip theory combined with a linearized ME [70,71,73]. The ME may be modified to account for the effect of heave plates [74]. Additionally, aerodynamic loads are considered as a point force at the hub, computed using either a steady-state BEM method or tabular pre-computed data [44,69,71,73]. Note that these models can typically capture only the rigid-body dynamics [30,45,75].

Examples of these models are the open-source frequency-domain code developed in [69], as well as the in-house codes developed in [71,73,76].

3. Mid-Fidelity Methods–Nonlinear Coupled Time-Domain Models

3.1. Hydrodynamics

Both PF and ME are employed for the assessment of the hydrodynamic behavior of an FWTS based on the characteristic length of the floating platform compared to the incident wavelength [77,78,79].

In this regard, when the characteristic length of the floating platform (D) is much larger than the incident wavelength (), the diffraction theory from the linear PF is used to assess the hydrodynamic loads.

The governing equation of the PF theory (obtained by assuming the flow) is incompressible, inviscid, and irrotational. Thus, there will be a velocity potential , whose gradient describes the velocity field as follows:

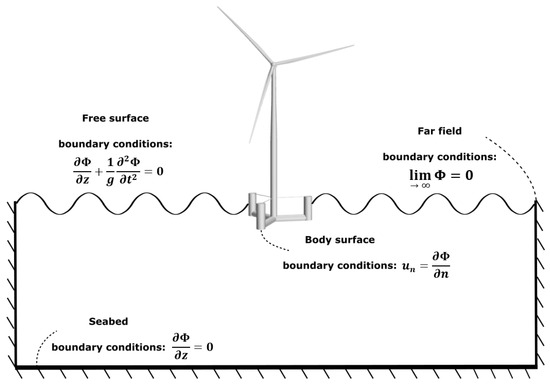

This Laplace equation is solved using proper linearized boundary conditions, as shown in Figure 5. In this Figure, n is the vector normal to the body surface. Thus, having calculated the velocity potential and, as a consequence, the velocity components, the pressure on the surface of the floating structure is computed using Bernoulli’s equation. Solving this equation with linearized boundary conditions leads to deriving the linear (Airy) wave theory for surface propagating waves. Although other wave theories, like stream functions and stokes, are used to compute wave kinematics based on wave steepness and water depth, the linear Airy wave theory is the most predominant wave theory employed in the offshore industry [30,77,78,80].

Figure 5.

Linearized boundary conditions typically used in the linear potential flow theory.

To compute the hydrodynamic loads, the incident, diffraction, and radiation wave linear potentials are obtained [79,81,82,83]. Note that as the linear assumption is employed, it is possible to consider that the potential function is a summation of these three potential functions, as follows:

where is the velocity potential related to the incident waves, is the velocity potential related to the diffraction of the incident waves, and is the velocity potential related to the radiation.

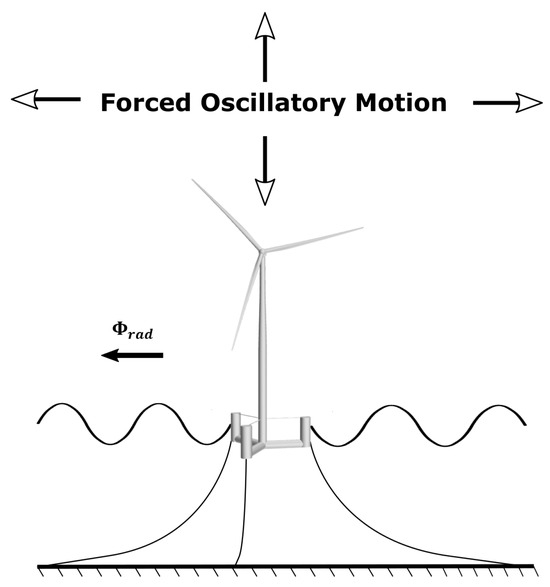

The radiation part is related to the case without the presence of any incident waves, and the floating platform is forced to oscillate along its DOF of motion, as shown schematically in Figure 6, which leads to the calculation of added mass and damping loads [81].

Figure 6.

The radiation problem related to an FWTS.

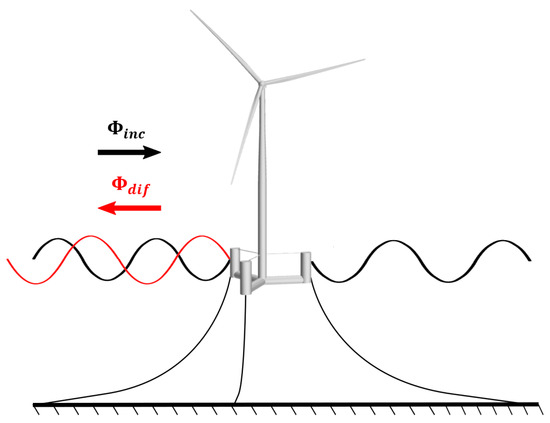

The diffraction part is related to the case where a floating platform is fixed, causing the scattering of the incident waves, as shown schematically in Figure 7. The diffraction loads come from the undisturbed pressure field (Froude–Krylov) and the disturbed pressure field due to wave scattering (diffraction) [79].

Figure 7.

Velocity potential related to the diffraction of the incident waves to an FWTS.

Note that numerical solutions are obtained using the panel methods where the floating platform is discretized into a limited number of panels [84,85,86,87]. A convergence study may be required to determine the minimum number of panels to obtain a precise solution [85,87].

On the other hand, for [81], the diffraction effects are negligible, and the semi-empirical ME capable of accounting for viscous effects can be used for the calculation of hydrodynamic loads [77,78,83]. The total hydrodynamic load acting on each structural element modeled as a line beam, considering the local velocity and acceleration of the floating system to account for the structure’s motion effects, is estimated as follows:

Here, is the drag coefficient, is the added-mass coefficient, u and are the water particles’ velocity and acceleration, and and are the velocity and acceleration of the floating structure.

To ensure the accuracy of the ME, a proper estimation of the inertial and drag coefficients is crucial [88]. A wide range of methods, from high-fidelity experiments and CFD to semi-empirical equations, can be used to determine these coefficients [89,90]. To include the loads due to the water current, one needs to modify the velocity of water particles to account for the presence of the current.

Note that the ME may be combined with the strip theory to calculate both the linear wave loads and nonlinear viscous loads for slender structural elements [91]. The strip theory in hydrodynamics, as in the BEM theory in aerodynamics, splits the slender structure into a finite number of strips, where two-dimensional hydrodynamic loads are utilized to calculate the overall hydrodynamic forces acting on the structure [81].

Most of the time—as the part of the FWTS in contact with water has members with characteristic lengths that are both much larger and smaller than the incident wavelength—a combination of ME and PF is employed to calculate the hydrodynamic loads due to the viscous drag, as well as the incident, radiation, and diffraction wave potentials [18,83,92].

Note that the predictions provided by linear potential flow theory are inadequate for several cases, such as severe sea states with platforms experiencing large motions, an accurate description of the horizontal motions of a moored platform, and a reliable determination of the excitations related to semi-submersible natural frequencies in the horizontal plane, which typically fall outside the wave-excitation frequency region [83,89,93,94,95]. To overcome these limitations, it is necessary to consider the nonlinear second-order or higher-order effects [83,92,93,96,97,98].

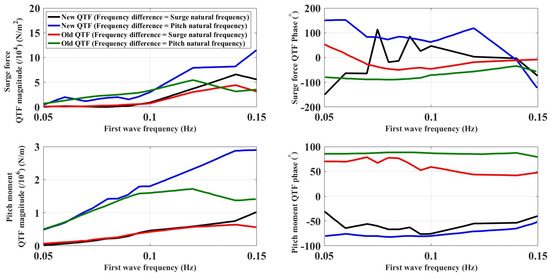

The second-order effects, which are functions of the square of wave height, are commonly considered by using quadratic transfer functions (QTFs) obtained from the second-order potential-flow problem, which requires detailed knowledge of the first-order potential quantities [81,93,94,99]. In this regard, second-order hydrodynamic loads are expressed in terms of the sum and difference of frequencies of sets of two incident waves with amplitudes and and frequencies and , typically using the following double Fourier transform [93,100]:

where and , which are the QTFs to be determined, represent the ith component of sum- and difference-frequency second-order loads, and the asterisk (*) is an indication of the complex conjugate. Note that, for (diagonal terms), the difference-frequency term results in mean hydrodynamic loads, also known as mean-drift loads, which are responsible for the average displacement of floating platforms from their undisturbed initial positions [101,102].

The full sum- and difference-frequency QTF matrices can be computed using available hydrodynamic codes such as the WAMIT, ANSYS-AQWA, and WADAM modules from the SESAM code [12,98,101,103,104,105,106]. Alternatively, as outlined in [93], one can make use of the symmetry properties of the QTFs by dividing the matrices into three different regions, , , and , to reduce the numerical difficulties and computational costs.

Thus, the frequencies in the second-order effects contain the sum and difference of the frequencies of the waves that make up the irregular sea state [107,108]. The high-frequency hydrodynamic loads emanating from the sum of frequencies may lead to higher ultimate and fatigue loads due to the excitation of structural natural frequencies, especially in the case of fixed-bottom and tension-leg offshore wind turbines [100,101,105,108,109]. The low-frequency hydrodynamic loads originating from the difference of frequencies are extremely important for an optimum mooring system design for floating structures [83,92,93,95,96]. This is because a moored floating platform, unlike an unrestricted platform, has natural frequencies in the horizontal plane, generally smaller than the frequency range of the incident waves. The natural frequencies in the horizontal plane are, in fact, excited by the low second-order frequencies emanating from the second-order potential problem. Thus, in the horizontal plane, low-frequency second-order hydrodynamic loads can cause large-amplitude motions (commonly called slow drift motions) in the FWTS, an effect that is not captured by a first-order PF theory [110,111]. This shortcoming of the first-order PF theory can lead to a significant underestimation of FWTS motion responses and, as a result, lead to an inaccurate estimate of the loads acting on the mooring system in the design process. Low-frequency second-order hydrodynamic loads are required to be considered in a coupled dynamic analysis of an FWTS, provided that the loads acting on the mooring lines are of interest. Consequently, increasing attention has been given to the evaluation of the second-order low-frequency hydrodynamic loads in the case of FWTS [98,112,113,114].

Due to its complexity, using the full QTF matrices is sometimes avoided in the offshore industry, and instead, Newman’s approximation has been the most common approach to account for second-order effects. This method estimates the slow-drift forces based on the symmetry of the matrix of the difference-frequency QTF and the mean drift forces [115]. However, the reliability of this method is questionable for intermediate and shallow waters [98,100,113,116].

Another option to compute the matrix of the difference-frequency QTF is the white-noise approach proposed in [116,117]. In this approach, by decoupling the degrees of freedom of motion, it is assumed that the slow-drift motion is excited mainly by a limited portion of frequencies around the platform’s natural frequency, and consequently, the spectrum of the second-order force can be considered constant within this band. The advantage of this method is that the QTF matrix is computed based only on the sets of two frequencies, whose difference gives the drift motion natural frequency.

To improve the predictions of second-order wave loads, one can use the results from wave basin tests or high-fidelity simulations to tune the QTFs obtained from PF solvers [63,118,119]. For instance, the second-order difference-frequency loads are evaluated in [120] using both CFD simulations and physical tests in five different bichromatic incident wave pairs [121]. The platform model is a simplified version of the OC5-DeepCwind floater [83], where only the three cylindrical lateral columns are considered. The bichromatic wave pairs are selected in such a way that they result in a different frequency near the platform surge and pitch natural frequencies. To obtain the quantities of interest, which are typically the amplitude of low-frequency hydrodynamic loads in the predetermined direction, fast Fourier transforms are applied to the time series of hydrodynamic wave loads. As recommended in this study, in the case of CFD simulation, the use of a relatively fine grid close to the free surface interface is necessary for accurate modeling of bichromatic incident waves and, consequently, accurate prediction of difference-frequency hydrodynamic loads.

Based on the QTFs obtained from CFD simulations and physical tests, the values of the QTFs calculated from PF solvers can be modified and then incorporated in the time-domain simulation tools for FWTS to have a more accurate prediction of hydrodynamic wave loads of low frequency [62].

The reason for considering bichromatic waves rather than fully irregular sea states is twofold [120]. First, due to the small repeat periods of the adopted bichromatic incident wave pairs, which are around 100 s at full scale, only runs with a few repeat periods are needed to capture the low-frequency effects based on CFD simulations. This significantly reduces the computational cost compared to a full irregular sea state simulation, in which typically up to 3 h of physical time is required. Secondly, using bichromatic waves, it is possible to make a direct comparison between the low-frequency hydrodynamic loadings obtained from the CFD or physical tests and PF-based QTFs. Consequently, this facilitates the calibration of QTFs.

To consider second-order effects, alternatively, the full second-order velocity potential can be obtained through perturbation analysis, and then the loads can be calculated through direct integration of the pressure acting on the instantaneous wetted surface of FWTS [94,95,99,122]. Second-order loads are computed more accurately using this approach, which is computationally more demanding.

Another important subject is the assessment of the dynamic responses of the FWTS subject to extreme sea states such as freak waves [123,124,125]. These extreme waves can be generated by dividing the wave spectrum into uniform N parts, which are then summed up after modifying the initial phases of some of these components.

Finally, to perform the time-domain simulations using the frequency-dependent loads presented so far, the Cummins equation, where a convolution integral formulation is used to capture the fluid memory effects, is employed [12,84,126,127]:

Here, M is the inertia matrix, is the added-mass matrix at infinite frequency, C is the restoring (hydrostatic stiffness) matrix, is the displacement vector of the floating platform, is the retardation function (fluid memory), and denotes the time-varying external forces.

3.2. Aerodynamics

3.2.1. BEM Method

The BEM theory is the most popular method to evaluate wind turbine aerodynamics. This method is a combination of two theories: blade element and momentum. The blade element theory considers that the blades comprise a finite number of elements with negligible interaction with the nearby elements. It is further considered that these elements operate as two-dimensional airfoils. The momentum theory is also used to calculate the induced axial and tangential velocities. Thus, combining these two theories gives origin to the BEM theory, an iterative process to evaluate turbine aerodynamics.

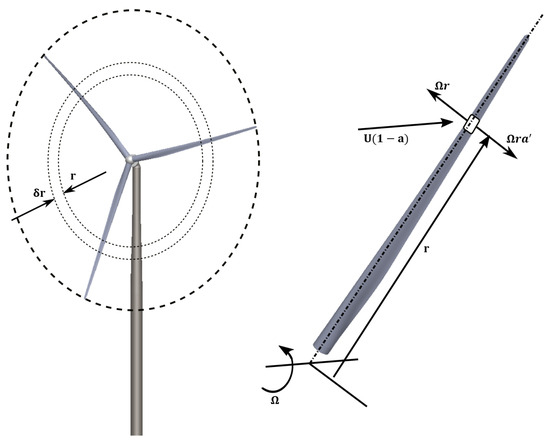

In this regard, the elements along the blade span located at the radial position of r, which extend to , as shown in Figure 8, affect the airflow momentum that travels across the circular ring area covered by these rotating elements due to their aerodynamic loads.

Figure 8.

Elements along the blade span located at the radial position of r, extending to , affect the airflow momentum that travels across the circular ring area covered by these rotating elements due to their aerodynamic loads.

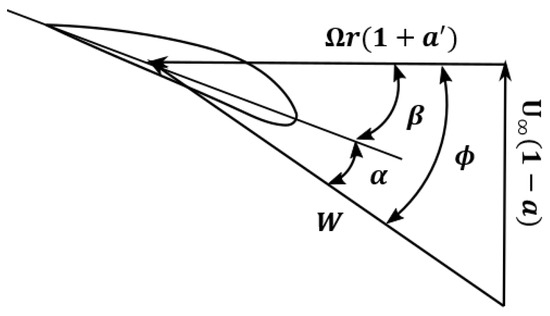

The element’s aerodynamic loads are calculated using the two-dimensional airfoil properties based on an angle of attack (), which is defined in terms of the total incident wind speed, W, written as follows, based on Figure 9:

where and a are the tangential and axial induction factors, U denotes the freestream wind speed, and denotes the angular rotor speed.

Figure 9.

angle of attack, pitch angle, angle enclosed by the rotor plane and the total incident wind speed W.

To improve the predictions given by the BEM method, several corrections are introduced to account for the effects such as blade-tip and -root losses, a finite number of blades, tower shadow, three-dimensional stall delay, dynamic stall, yawed condition, unsteady loading, and dynamic inflow [29,128,129,130,131,132].

However, both the large platform motions and blade aeroelastic deformations result in the rotor interaction with its own shed vortices, a condition where the BEM method may give unrealistic results [75,92,133,134]. FWTS are more frequently subject to yawed inflow conditions since they have little yaw stiffness. However, the BEM theory was originally developed for the inflow condition perpendicular to the rotor plane, and the commonly used corrections may give erroneous results [92,114,133,135].

To evaluate turbine aerodynamics, the GDW model can be used alternatively to intrinsically consider the three-dimensional effects and dynamic wake effects [136,137]. The GDW method is normally employed to model the tip losses at the blades and the performance of a turbine under yawed conditions more accurately. However, its limitations at small wind speeds lead to unstable computations [138]. Generally, the BEM method is more commonly used in the coupled analyses of FWTS. This can be deduced from the availability of this method in most of the codes used for the investigation of the coupled dynamics of FWTS, such as Bladed, OpenFAST, OrcaFlex, SIMA, SESAM, and HAWC2 [83,128,139,140,141,142,143].

3.2.2. FVW Method

The FVW method is capable of characterizing the wake evolution of a wind turbine over time, which may give more reliable predictions in the case of FWTS due to the possibility of movement of the rotor into its own wake [29,144,145].

The FVW belongs to vorticity-based methods, such as the vortex lattice method (VLM) [128,130,146], assuming that the flow is inviscid, incompressible, and irrotational [147], and it has long been used in the field of wind energy [148,149,150,151,152,153].

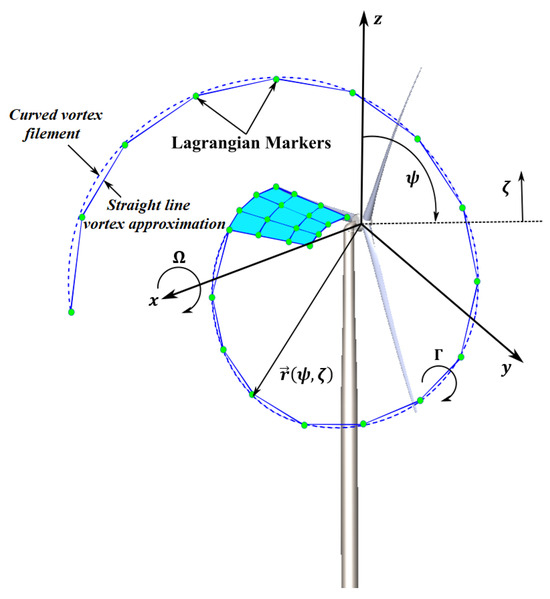

The FVW method is used to solve the turbine wake in a time-accurate manner, in which, contrary to the prescribed vortex methods, the convection, stretching, and diffusion of vortices are captured [29]. This is performed using a Lagrangian approach that can discretize the turbine wake into Lagrangian markers, defined as functions of the wake age and azimuthal blade location , as shown in Figure 10 [29,147]. A wide range of methods is available for the representation of the wake using Lagrangian markers [150], such as the hybrid lattice/filament, which is used within the OpenFAST code [145] (see Figure 10). Over the near-wake region, a lattice method is used, as shown schematically in Figure 10. A user-defined angle is used to specify the near-wake span [154], which is usually assumed to be degrees [154]. This angle may not be sufficient for challenging operating conditions, e.g., high thrust conditions [145]. The near-wake region is followed by instantaneous wake aggregation into tip vortices, which are considered the principal flow characteristics over the rest of the wake [155]. Straight-line vortex filaments with second-order accuracy are used to connect the Lagrangian markers together [155] (see Figure 10).

Figure 10.

FVW method explanation.

The vortex-filament motion is expressed as follows [153,156,157,158]:

Here, denotes the positions of the Lagrangian markers and denotes the velocity vector [153,159]. This vector is the summation of three components: the freestream, induced velocity, and velocity emanating from the platform movements due to environmental loading [147,153,159,160]. Each straight-line vortex filament creates an induced velocity at point k, where its calculation is based on the Biot–Savart law [155]:

where is the vortex filament circulation strength, l is the vector used to connect the endpoint locations of filaments, and is the normal distance from l to point k. The factor is used to consider the effect of viscosity on the vortex core [161,162,163]. is obtained regarding the lift force acting on the blade element airfoil using the Kutta–Joukowski theorem [30].

The blade can be represented using either a lifting line or lifting surface [157], or more attractive options such as the Weissinger-L blade model, which has been demonstrated to provide more reliable results than the lifting line model, with a computational cost lower than the lifting-surface model [145,157,158]. Based on a blade model, the circulation along the blade span is computed by discretizing the blade into a finite number of panels, and then the connection to the wake is performed by dependence on the induced velocities.

The FVW is available only in a few simulation tools for the coupled analysis of FWTS, such as QBlade and OpenFAST [58,164]. This method, despite being able to consider the turbine–wake interaction, has not been commonly used in the coupled analyses of FWTS [165].

3.3. Structural Dynamics

Coupled analyses of floating wind turbine systems are performed using a wide range of structural models, from modal analysis methods to more sophisticated finite element methods, such as Euler–Bernoulli and Timoshenko, all based on the following second-order differential equation:

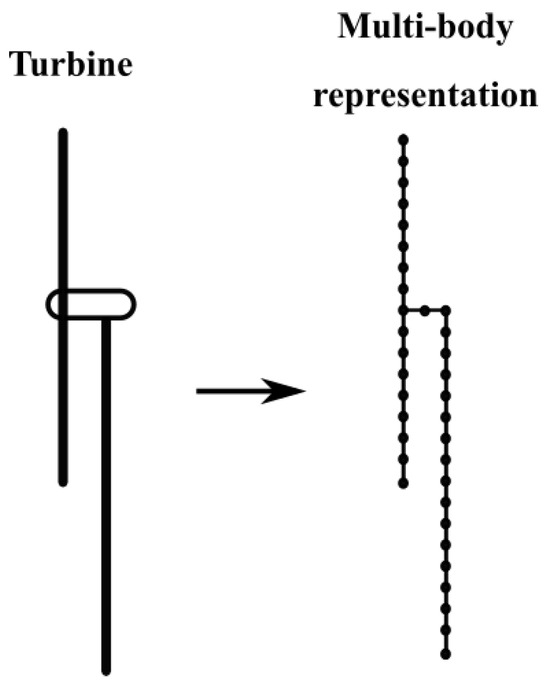

where M, B, and C denote the structural inertia, damping, and stiffness matrices, respectively. Additionally, x is the vector of structural displacements (deformations), and F is the vector of external forces. The structural dynamics are typically considered through the use of an MBD formulation, where the flexibility is considered in selected components, such as blades and towers, as shown schematically in Figure 11. The MBD formulation, the most common approach for the structural dynamic assessment of FWTS, is available in many low- and mid-fidelity simulation tools, such as HAWC2, OpenFAST, SIMA, Bladed, QBlade, Virtual.Lab Motion, and Multibody Bladed [58,166,167,168,169,170,171,172,173].

Figure 11.

Multi-body representation of a wind turbine.

In this technique, the geometry of the wind turbine is split into a limited number of interconnected rigid or flexible bodies, which may undergo translational and rotational motions [8]. The connection between the bodies occurs via force and joint elements that express their dynamic and kinematic restrictions. The description of the motion of the bodies is performed through a group of differential-algebraic equations, including the differential equations describing the motion of the bodies and a set of algebraic equations expressing the motion restrictions [41,174]. Among the turbine’s structural elements, the blades normally have the largest number of bodies due to being the most flexible components [41,174].

The long flexible blades and towers are commonly modeled as beam members based on either a linear modal analysis (MA) or more sophisticated beam theories, such as Euler–Bernoulli and Timoshenko [41].

The simplest form of representing the flexible turbine’s structural components is by using the linear MA [30], which is available in many coupled analysis tools for FWTS, such as OpenFAST, Bladed, and QBlade [58,167,168,169,170,175,176,177]. Briefly, in this method, a modal transformation is used to separate the structural responses into various eigenfrequencies, resulting in distinct vibration modes, whose linear superposition gives the total structural response [25,178,179]. Thus, due to its linearity assumption, its use is restricted to small deflections [25]. The flexibility properties of blades and towers, the spanwise mass and stiffness distributions, and their mode shapes based on equivalent polynomial coefficients are defined [179,180]. These mode shapes, where typically only the first few are considered in the modal representation, are commonly determined using a finite element method [180,181]. Therefore, the accuracy of a modal analysis depends highly on the correct determination of the mode shapes, which is a principal disadvantage of this method [30].

However, in the case of large blade deformations, using more advanced beam theories such as Euler–Bernoulli and Timoshenko is preferred over the modal approach [48,182]. For example, using nonlinear beam theories, the OpenFAST from NREL and HAWC2 from the Technical University of Denmark (DTU), can simulate flexible blades. More specifically, OpenFAST employs both theories of the Euler–Bernoulli beam and geometrically exact beam with Legendre-spectral finite elements. The latter can better model the geometric nonlinearities and large blade deformations compared to the former [183], while HAWC2 uses the Timoshenko finite-element modeling approach [184]. The results obtained from these codes are expected to be similar, as shown in [185].

Nonlinear beam theories, by taking geometric nonlinearities into account, mathematically describe how external loads are related to a slender body deflection (based on Equation (10)) through the discretization of the structure into several one-dimensional beam elements. Note that, unlike the Euler–Bernoulli method, the Timoshenko approach considers deformation arising from shear and is, consequently, more suitable for thicker beam elements [31]. On the other hand, in modal analysis, structural deformation is obtained by the linear superposition of a portion of the mode shapes of the structure. Therefore, the use of this method is restricted to small deformations, where the linearity assumption is valid. Furthermore, the predictions given by modal analysis are limited to the modes that are determined and included in the model, and typically, a small portion of geometric nonlinearities can be accounted for.

The floating structure is typically modeled as a rigid body, the same practice adopted in the oil and gas industry. However, accounting for floating platform flexibility can be crucial in the floating wind system design and optimization process, considering the increasing use of large platforms for offshore wind power and the growing tendency to reduce substructure costs.

3.4. Mooring System

A mooring system serves as a station-keeping system for a floating platform. Proper implementation of the mooring system is crucial for keeping the wind turbine nearly fixed in its position, in such a manner, to guarantee the safe operation of the machine.

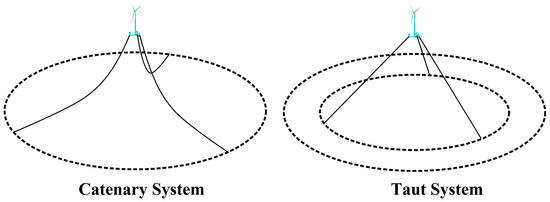

Generally, there are two types of mooring line systems: catenary and taut, as shown in Figure 12.

Figure 12.

Mooring line systems: catenary and taut.

In the case of the catenary system, the station-keeping is performed through the weight of the portion of the mooring lines in contact with the seafloor [21,186]. In the case of the taut system, this is performed by the high tension in the cables. In other words, while the mooring line weight provides the restoring force in the catenary mooring system, the elasticity of the mooring line provides this force in the taut mooring system.

Catenary mooring lines are typically made of steel chains and/or wires [187,188], while taut mooring lines are made of synthetic fibers, such as polyester, nylon, or wires [188,189,190,191,192,193]. Recent studies have shown that a taut system composed of nylon may significantly reduce the cost of the floating wind turbine system, especially for shallow water applications, compared to the same system with polyester [189,191].

It is also possible to use a combination of materials for catenary applications (the semi-taut mooring system) to reduce the weight and cost of the mooring system [194]. The chain is typically used to adjust the length and tension of the upper portion, where the mooring line is connected to the floater at the fairlead. Again, the chain is preferred due to its stiffness at the seabed, where the mooring line rests on the sea floor. Synthetic fibers, nylon, or wire can be used for cost and weight reduction. The Hywind project, for instance, uses a combination of steel chain and wire [194].

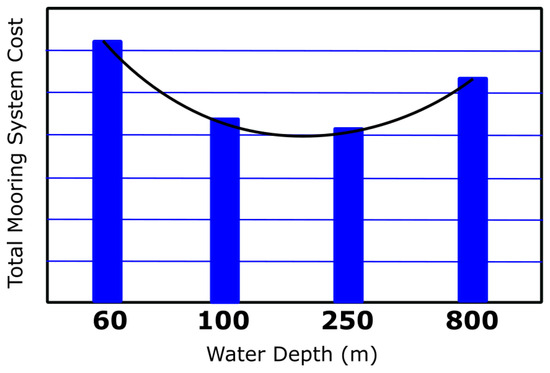

The catenary configuration is usually applied to the floating platforms at water depths between 100 m and 250 m, where it can be considered an optimum solution for the station-keeping of the system [195]. Based on Figure 13, which shows the cost evolution of a traditional steel chain catenary system regarding water depth, in the case of shallow waters with a depth smaller than 100, the highly dynamic condition in which the floater operates calls for a more expensive station-keeping system [196]. Additionally, the additional mooring line length increases the cost as the water depth exceeds values larger than 250 m.

Figure 13.

Cost evolution of a traditional steel chain catenary system regarding water depth (figure generated using data from [195]).

On the other hand, the taut configuration can be used in water depths smaller than 100 m or larger than 250 m [196]. An example of a taut system used at a water depth shallower than 100 m is the Ideol platform installed close to the French coastline at a water depth of nearly 30 m [197].

A floating platform equipped with a catenary system can have some horizontal movement. However, a floating platform with a taut system typically has limited horizontal movement. The disadvantages of the catenary system include its greater seabed disruption and larger footprint. On the other hand, as the anchor experiences relatively fewer loads, the catenary system has more economical anchors. Considering a taut system, the disadvantage is the higher cost of installation and anchoring due to the large horizontal and vertical loads acting on the anchor [27,198]. However, its lower seafloor disruption, smaller footprint, and suitability for shallow and deep waters are the main advantages of a taut system.

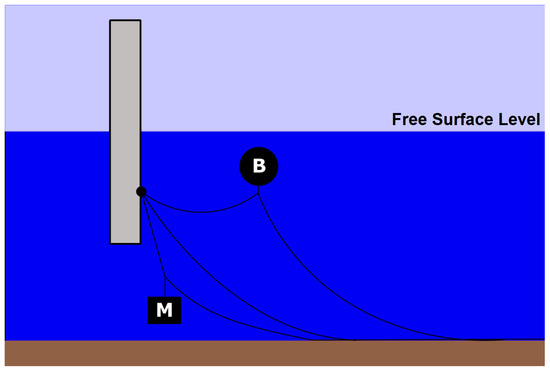

In the case of catenary systems, to increase the mooring line tension and, consequently, the restoring force acting on the floating platform, especially in the case of shallow waters, the clump weights can be used, as shown schematically in Figure 14. It is also possible to reduce the mooring line dynamics and weight effects on the platform in the case of deep waters using buoyancy modules, as shown in Figure 14 [199].

Figure 14.

A catenary mooring system with clump weights and buoyancy modules (M: clump weight, B: buoyancy module).

One main challenge related to floating wind turbines is the high cost of anchoring for a single floating platform. An alternative to reducing these costs is using shared mooring or shared anchoring systems [200,201,202].

However, the use of shared mooring lines is accompanied by several challenges, as follows [203,204]:

- The installation process is more complex.

- The difficulty in towing a single floating wind turbine to a nearby port when it is necessary for operation and maintenance.

- The complexity of a mooring line may increase to a point where it is exposed to failure risk.

- The natural period of several mooring lines may have coupled effects with their surrounding floating wind turbines.

- In the event of a mooring line or anchor failure, this scenario may affect several turbines.

The use of shared anchors is only beneficial under certain situations, calling for a site-specific investigation [204]. Savings from shared anchors can be lost due to the need to increase the length of mooring lines to respect the minimum spacing between turbines, a factor that depends highly on the energy yield calculations of the specific site. Shared anchors are more feasible for sites where it is possible to have smaller turbine spacing [203].

The coupled analysis of a floating wind turbine system is generally accompanied by a mooring line modeling, which is performed using either a quasi-static or dynamic method.

3.4.1. Quasi-Static Method

Quasi-static models can be seen as simple linear stiffness matrices to more complex catenary equations, where Newton’s force equation is solved for each node of connection [205]. These models consider that the mooring is in the balance between the anchor and the FWTS attachment point [30]. Additionally, the dynamic effects, such as inertia, hydrodynamic drag force, and vortex shedding, are not considered [79,94,206,207,208,209].

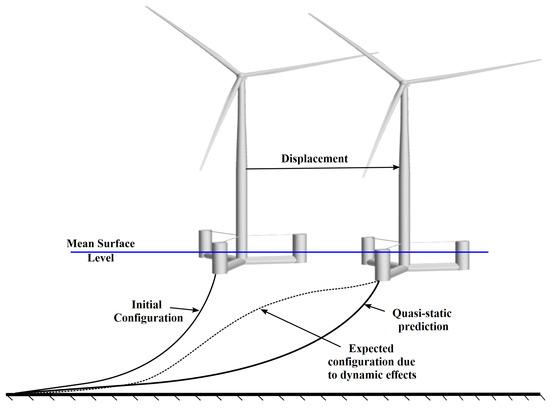

Figure 15 illustrates how the responses of a mooring line can be affected when dynamic effects are ignored. As can be seen, although the mooring line close to the fairlead tends to follow the floating platform motions, the lower portion of the mooring line may respond with a delay to this displacement. This can be regarded as a violation of the quasi-static assumption, which considers that the line is in static equilibrium at each time step [210].

Figure 15.

Possible response of a mooring line under quasi-static and dynamic assumptions.

The quasi-static models tend to underestimate the restoring load, particularly for extreme sea states [48,211,212], and as shown in [213], they are unable to reliably estimate the fairlead load amplitudes.

3.4.2. Dynamic Method

Considering or neglecting the dynamic effects of mooring lines for FWTS is a hot topic in the hydrodynamics of these structures. Due to the smallness of mass and motions, the dynamics may be neglected in the case of mooring systems used in shallow waters. However, it is crucial to consider the dynamic effects of deep water conditions. The oil and gas platform and vessel demonstrate the importance of considering line dynamics for water depths larger than 150 m [92]. Further, using dynamic models is essential for the reliable estimations of ultimate and fatigue loads in a mooring line and the correct modeling of the peak tension in extreme events [30,83].

Dynamic models are better able to simulate real-life conditions, providing the possibility to perform a fully hydro-aero-mooring dynamic analysis of an FWTS. Dynamic models discretize each mooring line into several elements to which separate dynamic equations are applied. These dynamic equations take into account internal forces, including tension, torsion, damping, and bending, which are expressed as functions of the properties of the elements, and external loads, such as gravitational loads and hydrodynamic loads (usually based on the Morison equation).

Therefore, while the quasi-static method assumes that the mooring lines create the restoring loads based on a static equilibrium condition between the anchor and fairlead, the dynamic models consider that the mooring lines are kinematic chains composed of several elements exposed to hydrodynamic loads, as well as interactions with surrounding boundaries. As a consequence, nonlinear effects emanating from dynamic excitation loads are considered in dynamic models.

The main discrepancy between dynamic and quasi-static models originates from the estimation of the magnitude of the tension load, which is usually underpredicted by the quasi-static models, as well as from how the mooring line–environment interaction occurs [30]. This leads to the use of higher safety factors and, consequently, more expensive designs when the quasi-static method is employed. Therefore, to correctly simulate the peak tension, especially in extreme environmental conditions, the use of dynamic models is essential.

One challenge related to the numerical implementation of dynamic models is numerical instability. The best way to control instability is through the use of suitable hydrodynamic and structural damping values, which can confine the transverse oscillation amplitudes [31]. Note that damping values must be chosen carefully in such a way that, while ensuring numerical stability, they do not encourage unrealistic behavior of the mooring lines.

The dynamic models are based on either the lumped mass approach (similar to MBD) [98,107,214,215,216], FEA [94,95,210,217], or the finite difference (FD) method [218]. The hydrodynamic drag and added mass are considered for all the elements resulting from line discretization.

The simplest model is the lumped mass method, where the mooring line model is a set of compact masses connected through massless spring-damper elements [107]. A sensitivity study may be required to determine the number of multibodies beyond which the results remain unchanged. The drawback of this method is that it neglects the mooring line’s torsional stiffness [213,219]. Due to its simplistic nature, the lumped mass method is available in many FWTS simulation tools, such as OpenFAST and OrcaFlex [92].

A higher fidelity solution can be achieved using either the FD or FE methods. However, the results obtained from the lumped mass, FD, and FE methods are expected to be very similar under sufficient resolution [30,213,220].

3.5. Recent Research

Studies carried out on FWTS using nonlinear time-domain models can be subdivided into aero–structural and fully coupled hydro–aero–structural analyses.

The aero–structural analysis is performed either on a fixed wind turbine such as [183], or on a wind turbine under prescribed (harmonic) motions [29,156,159,221,222,223].

In this regard, ref. [183] developed a coupled FVW-geometrically-exact beam theory model to evaluate the aeroelastic behavior of the NREL 5 MW wind turbine.

The aero–structural analysis of FWTS is typically performed under either harmonic platform motions or prescribed time-series motions over single and multiple DOFs estimated from a nonlinear time-domain model such as the OpenFAST code.

Aero–structural analysis of FWTS is typically performed under harmonic platform motions [156,159,221,222,223], or prescribed time series describing platform motions over single and multiple DOFs estimated from a nonlinear time-domain model, such as the OpenFAST code [29].

Accordingly, the aerodynamics of the NREL 5MW FWTS under prescribed motions over single and multiple DOFs is investigated in [29] using an FVW code. The platform motions are estimated using the OpenFAST software. The obtained results demonstrate the importance of using the FVW method to capture complex physics due to the interaction between the rotor and its own shed vortices.

Regarding the prescribed harmonic platform motions, an FVW-MBD coupled model is developed in [156,159] to assess the aeroelastic behavior of the NREL 5 MW wind turbine under harmonic platform motions. Further, an FVW solver is used in [222,223] to evaluate the aerodynamic performance of a rigid FWTS under harmonic surge motions with various amplitudes and frequencies. For tip speed ratios close to the optimum value, it is shown that the turbine power can surpass the Betz limit mainly because of the platform’s axial motions induced on the rotor. Likewise, the aeroelastic analysis of a 15 MW FWTS under the prescribed harmonic pitch and surge motions is performed in [224] using a coupled HAWC2-FVW code, and the results are compared against those obtained from a HAWC2-BEM code. The results highlight a large difference between these codes for high wind speeds.

Many works have been carried out to evaluate the fully coupled hydro–aero–structural behavior of FWTS using nonlinear time-domain models.

For instance, the performances of different codes, such as OpenFAST, Bladed, OrcaFlex, HAWC2, and SESAM, to simulate the dynamics of the semi-submersible floating NREL 5 MW wind turbine are assessed in [11,83] under different load cases. The structural part is modeled using a wide range of methods, from the MBD method to the FEA method. Aerodynamics is represented using mid-fidelity methods, such as the BEM and FVW methods. Hydrodynamic modeling is mainly based on the PF theory with or without the ME. It is shown that the codes based on the Morison approach need to consider the effect of the heave plates as an additional damping force [11,83].

Several works, such as [78,225], demonstrate the importance of considering second-order nonlinear effects when evaluating the coupled dynamics of FWTS. In this context, the 2D harmonic polynomial cell wave tank [226] is used in [78] to calculate linear and nonlinear wave kinematics based on potential flow theory to be used in a coupled analysis for the 5 MW OC4 semi-submersible FWTS [18] based on the HAWC2 code [168,184,227]. The results show the importance of considering a fully nonlinear wave theory for FWTS in shallow and intermediate water depths. Further, the SIMPACK tool based on the ME via a strip theory, the BEM method, and the MBD method is used in [225] to evaluate the dynamics of a 10 MW FWTS. The numerical results are compared against the measurements from a scaled OC4 semi-submersible platform supporting a 1:60 scaled DTU 10 MW wind turbine. A comparison of the calculations and measurements highlights the significance of accounting for the second-order wave effects in the coupled dynamic analysis of the FWTS. Moreover, ref. [100] conducted a coupled analysis of a conceptual 10 MW FWTS using the OpenFAST code. The second-order effects are considered through full QTFs and the Newman approximation. The BEM method is used to model the wind turbine aerodynamics. The results show that using the full QTFs is necessary to model second-order responses accurately. The same conclusion is reached in [228], where the coupled behavior of a 6-MW FWTS at a depth of 100 m is evaluated by using both experimental and numerical methods. The numerical model is developed using OpenFAST. Similarly, the responses of two FWTS (15-MW spar WindCrete [229] and 15-MW ActiveFloat semi-submersible [230], both made of concrete) under static and dynamic conditions are evaluated in [12] using the OpenFAST code. The results show that the second-order wave loads dominate the platforms’ responses more than the first-order wave forces. Likewise, ref. [140] analyzes the low-frequency second-order wave effects on the 5-MW OC4 FWTS using both SIMA (SIMO/RIFLEX/AeroDyn) and OpenFAST codes. In the same vein, the second-order wave effects based on the full QTFs on 10 MW and 5 MW FWTS are evaluated in [100,108] using the OpenFAST code. Another noteworthy study is carried out in [231], where the OpenFAST code is utilized to evaluate the impact of second-order wave hydrodynamic forces based on the full QTF method as well as Newman’s approximation on the time-domain analyses of three FWTS supporting the NREL 5 MW turbine.

Several other works evaluating the coupled dynamics of FWTS are summarized in the following paragraphs:

- The wave–body interaction for an FWTS is simulated in [84] through coupling a hydrodynamic model based on the PF theory and BEM aerodynamic code.

- The performance of two codes, SIMO–RIFLEX and HAWC2, in modeling the coupled dynamic behavior of an FWTS is evaluated in [232]. The structural dynamics and hydrodynamics are modeled in both codes using an MBD method and PF plus ME, respectively.

- A hydrodynamic model based on PF and ME that can account for second-order wave loading is coupled to an aero-servo-elastic model based on the BEM and MBD methods in [233] to predict the responses of the GustoMSC Tri-Floater FWTS.

- The authors of Ref. [234] assess the coupled behavior of a novel catamaran FWTS, where the OpenFAST software is used for the estimation of the aero-elastic part while ANSYS AQWA is utilized to predict the hydrodynamic loads.

- Ref. [235] performs the numerical investigation of the behavior of a 5 MW FWTS through a combination of the PF-based ANSYS-AQWA tool, capable of accounting for second-order loads based on the full QTFs and a BEM code. The flexible blades are modeled using a nonlinear deflection model.

- The dynamic behaviors of four different platforms supporting the NREL 5-MW turbine are compared in [236] against the onshore turbine performance using the OpenFAST code.

- The dynamics of the 5-MW WindFloat FWTS is investigated in [237] using a coupled PF-ME-BEM-MBD code under coupled wave-wind conditions.

- Coupled simulations of a V-shaped semi-submersible FWTS are carried out in [238,239,240] using the coupled PF-BEM-MBD SIMO/RIFLEX/AeroDyn code [241].

- Ref. [242] extends the OpenFAST code to analyze three coupled hydro–aero–structural dynamic behaviors of wind turbines mounted on the same semi-submersible platform.

- The dynamics of a 5-MW braceless steel semi-submersible FWTS is assessed in [243] through coupling a structural model based on beam elements, a first-order PF model, and a BEM method available in the coupled SIMO/RIFLEX/AeroDyn code [244].

- Refs. [83,245] use the OpenFAST software to model the hydro-aero-servo-elastic behavior of the OC5 DeepCwind semi-submersible FWTS, where the full QTFs are used to account for the second-order effects. The same code is also used in [246] to evaluate the coupled behavior of the OC4 DeepCwind semi-submersible FWTS.

- The coupled analysis of a 5-MW–13.2-MW FWTS is performed in [247,248] using a coupled BEM-PF-ME model. The second-order hydrodynamic loads are considered through the full QTFs. The structural responses are modeled using an MBD method with Euler–Bernoulli beams for flexible blades and towers.

- The OpenFAST code is also used in [249] to assess the behavior of a 5-MW V-shaped FWTS in moderate water depths.

- Motions and loads predicted by the open-source OpenFAST and commercial OrcaFlex codes for FWTS are compared together in [250] and it is shown that the predictions provided by these codes are generally in good agreement.

- A coupled numerical model based on BEM-PF-ME is developed in [251] to investigate the dynamic responses of FWTS.

One of the main advantages of nonlinear time-domain models is their ability to simulate mooring system behavior for the FWTS under a variety of operational and extreme conditions. In this regard, the dynamics of the OC4 semi-submersible supporting the NREL 5-MW turbine with a broken mooring line is simulated in [252] using the OpenFAST code. Ref. [253] tests different mooring configurations for a 5-MW FWTS using the OpenFAST code. The behavior of the OC4 DeepCwind semi-submersible FWTS with a mooring line failure is assessed in [217] by coupling the BEM aerodynamic model available in the OpenFAST software to ANSYS-AQWA, which is responsible for the computation of the hydrodynamic loads. The responses of the drive train are also considered through a multibody drive train model using SIMPACK [254]. The dynamics of the OC4 FWTS after one of its mooring lines is broken is assessed in [255] using both ANSYS-AQWA and OrcaFlex software. Ref. [256] analyzes the coupled behavior of a 5-MW FWTS, where the aero-servo-elastic part of the OpenFAST code is coupled to ANSYS-AQWA, and is capable of modeling nonlinear hydrodynamics and mooring line behavior.

As mentioned previously, time-domain simulations are predominantly performed by considering a rigid floating platform rather than a flexible one. Accordingly, the impact of platform hydroelastic deformations on the dynamic responses of a 20 MW FWTS is assessed in [257], using the nonlinear aero-hydro-servo-elastic code ‘SIMA’, which is a combination of RIFLEX and SIMO software. RIFLEX is responsible for structural analysis based on a nonlinear beam theory approach, which here models the platform, tower, and turbine blades. The hydro-aerodynamic loads are computed from a coupled BEM-PF-ME with the difference-frequency second-order loads. The results confirm the need to take hydroelastic deformations into account in coupled dynamic analysis for large floating wind turbines, especially in extreme conditions.

Another notable study is carried out in [258], where the OpenFAST code is used to evaluate the impact of the motions of two types of floating platforms, e.g., OC3-UMaine spar and OC4-DeepCwind semi-submersible, on the power generation of the NREL 5 MW turbine subjected to irregular waves and various wind conditions imported from the LES code SOWFA from NREL [259].

4. High-Fidelity Models

4.1. Hydrodynamic and Aerodynamic Modeling Based on Computational Fluid Dynamics

The fluid dynamics around FWTS can be most accurately captured by solving the NSE based on CFD [260]. The NSE, in the case of incompressible Newtonian fluids for Cartesian coordinates, is as follows:

Here, variables and P denote the instantaneous velocity components and pressure, which vary over time (t) and space . is the instantaneous strain rate tensor. Note that in the case of wind turbine simulations, several new terms may be added to the NSE to consider the effects of Coriolis and buoyancy forces [261,262].

To compute the pressure and velocity fields, the NSE is solved together with the continuity equation, as follows:

A reliable aerodynamic evaluation of the FWTS depends on the accurate turbulence modeling around these machines [263]. In this regard, in the case of turbulent flows, CFD solves the NSE using three different approaches: direct numerical simulation (DNS), LES, and (unsteady) RANS equations. An adequately formulated DNS captures all the relevant turbulence scales up to the Kolmogorov scale using an extremely refined grid [264], which is not viable due to being prohibitively expensive. Therefore, LES and RANS are used to partially or entirely model the turbulence effect on the flow [265].

The important energetic large eddies are captured by LES, while the influences of the smaller eddies, whose properties are more universal, are parameterized based on a subgrid-scale (SGS) model [265]. A spatial filtering operation is used by LES to divide the scales into large eddies constituting the resolved scales and small eddies representing the unresolved scales [260,266]. Applying this filtering operation transforms the NSE as follows:

Here, the variables and are the filtered velocity components and pressure. Additionally, is the tensor of strain rate, defined as a function of the resolved velocity components. The new term is the tensor of SGS Reynolds stress that emerges in the NSE due to spatial filtering. Through this term, the influence of the unresolved smaller eddies is parameterized. The most common approach to compute is the Smagorinsky model [267,268]:

where is the eddy viscosity, which is characterized in terms of the resolved velocity field [269]. However, this model is unable to account for the turbulence anisotropy and secondary flows due to the use of the Boussinesq hypothesis [264,270,271]. To overcome these limitations, several other SGS turbulence models are proposed, such as scale-dependent dynamic, anisotropic minimum dissipation, dynamic Smagorinsky, and mixed SGS [272,273,274,275].

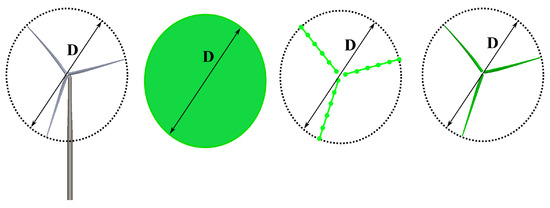

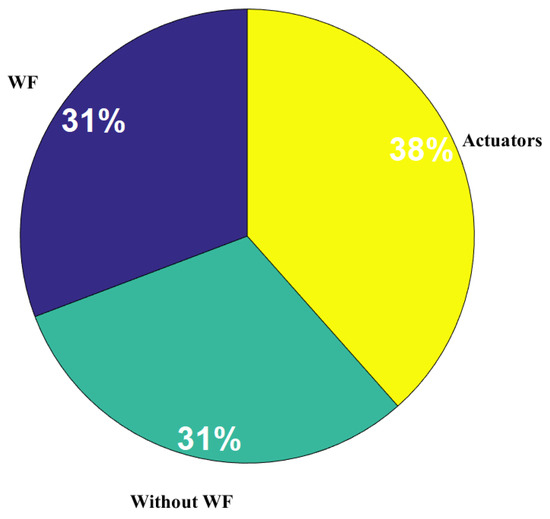

However, the LES requirement of grid refinement in three directions close to a solid wall to compute the turbulent boundary layer makes applying LES to the turbine blades infeasible. Thus, LES is generally used for simulating turbine wakes where the turbine rotor is parameterized using actuator methods, including the actuator disk, actuator line, and actuator surface, as shown schematically in Figure 16 [276,277,278,279,280]. Using actuator methods leads to a drastic drop in computational costs due to eliminating the need for resolving the boundary layer close to the blades. Another way to decrease the computational demand of LES is to utilize hybrid RANS-LES methods, in which RANS equations are used for modeling the boundary layer close to the body, while LES is employed over the separated unsteady region far from the body [174,281,282,283].

Figure 16.

From left to right: wind turbine geometry, actuator disk, actuator line, and actuator surface [280].

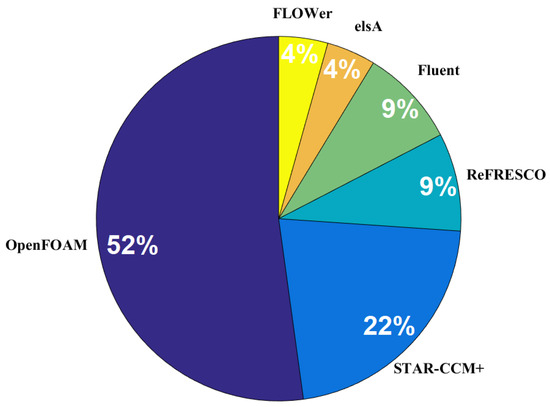

The simulations based on RANS equations constitute the most popular approaches for the aerodynamic evaluation of turbines based on CFD methods [284,285]. Similarly, hydrodynamic loads acting on FWTS are most commonly calculated using RANS equations with a turbulence model, which are solved numerically using the finite volume method [8,79,206,207,260,286,287].

The RANS equations, which are the result of ensemble averaging of the Navier–Stokes equations (NSE), are written as follows [206,207,288]:

Here, the variables and p denote the ensemble mean velocity components and pressure, which may vary over time, t, and space . Additionally, , , and are the fluid density, fluid kinematic viscosity, and mean strain rate tensor, respectively.

The term is called the Reynolds stress tensor representing the turbulence effect. This term is most commonly modeled using eddy viscosity (EV) models based on the Boussinesq hypothesis [289]:

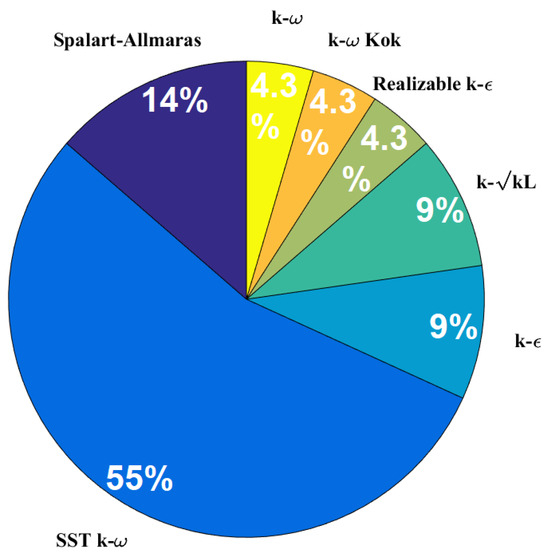

where k is the turbulence kinetic energy, is the Kronecker delta function, and is the EV. In the simplest way, the EV can be determined without solving any further transport equations, e.g., the mixing-length model of Prandtl [290,291]. Later, more sophisticated one-equation and two-equation turbulence models are developed to compute directly or indirectly the EV [79,88,207,208,286,292]. The most popular models for the hydrodynamic evaluation of FWTS are the two-equation models, such as k-ε, k-ω, and k-ω shear stress transport (SST) [63,79,287,292,293], in which by solving two transport equations the turbulence is modeled. This is again true for the aerodynamic evaluation of an FWTS, where the most popular models are the two-equation models, especially k-ω and k-ω SST [294,295,296,297,298,299,300,301]. Nevertheless, due to the use of the Boussinesq hypothesis, these models are incapable of considering the turbulence anisotropy [270,271,302,303,304]. Thus, more sophisticated models such as realizable models [305,306], Reynolds stress turbulence (RST) models, and nonlinear EV models are recommended, especially for the accurate prediction of aerodynamic loads [270,271,307,308,309,310]. The RST models, in which each Reynolds stress term is computed from a separate transport equation, provide the most accurate results at the cost of higher computational demand [270,271,309,311]. An alternative is the use of nonlinear quadratic and cubic EV models, which can account for the turbulence anisotropy at a much lower computational cost. It is worth mentioning that—to diminish the computational demand—the use of actuator methods to represent the turbine rotor is also common in the RANS context [312].

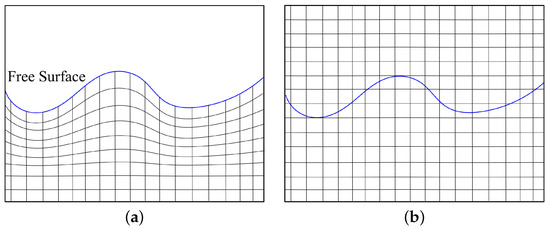

To model the free surface, CFD uses two main approaches: interface tracking and interface capturing [313,314] (see Figure 17).

Figure 17.

Free surface modeling in CFD. (a) Interface-tracking approach; (b) interface-capturing approach.

The interface-tracking method, as its name implies, tracks the free surface by implementing a Lagrangian grid fitted to the free surface interface (see Figure 17a). Nevertheless, tracking the free surface where this interface experiences large motions imposes certain difficulties, which can only be remedied by remeshing techniques. Using this technique—in addition to increasing the computational demand—can introduce errors in the numerical solutions.

Nonetheless, the interface-capturing method, which is also called the Eulerian grid method, as its name implies, captures the free surface interface by computing a volume inside a computational domain encompassing the free surface. Contrary to the interface-tracking method, the grid does not track the free surface evolution over time (see Figure 17b).

The free surface modeling in the case of FWTS is most commonly performed using the volume of fluid (VOF) and the level set, with both belonging to the interface-capturing methods [41,63,79,88,206,209,275,286,292,293,315,316,317].

To capture the free surface profile using the interface-capturing method an increased cell density is required to be close to the free surface. The common approach is to employ a certain number of cells perpendicular and normal to the free surface for spatial discretization [318]. The increased cell density on the free surface can also be achieved based on the kinetic wave energy [292,319].

Two methods exist to ensure that no wave reflection will occur on the boundaries of the numerical domain. The first method involves dampening the waves by coarsening the grid toward the boundaries [287,318]. Another method involves using a damping (relaxation) function over a damping (relaxation) zone close to the boundaries to force the wave field toward the undisturbed free surface or wave [206,209,286,292,320].

4.2. Structural Dynamics

The FEA method is usually applied to model the structural responses, but it is also used for fluid dynamics [321].

The FEA, similar to CFD, uses the blade’s exact geometry and is based on a methodology similar to other numerical methods, approximating continuous governing partial differential equations with a set of algebraic equations [322].

The governing equation is obtained by assuming that the amount of virtual work performed by external loads equals the amount of virtual work absorbed by dissipation, inertia, and internal forces [30]. The governing equation form is depicted as a set of second-order differential equations, as follows:

Here, M is the matrix of element mass, B is the matrix of element damping, x is the vector of structural displacement, is the vector of internal reaction loads, and is the vector of external forces. Note that in the case of materials with linear elasticity, is related linearly to x through a matrix of stiffness.

In the first step, the turbine geometry is discretized into a finite number of elements. These elements are typically triangles, quadrilaterals, tetrahedra, and hexahedra. The blades are typically discretized into 3D composite shell elements [25,323].

In each element, the displacement values at the element nodes are used to construct the distribution of this variable within the element [324]. Note that the stresses and strains, which are also of interest, are expressed in terms of nodal values of displacements based on Cauchy relations and Hook’s law [325]. Based on local distributions of the displacement, shape functions, usually based on polynomial forms, are used to interpolate the displacement values to any other point inside the element. The global system of algebraic equations is obtained by assembling all the element equations. This system of algebraic equations is solved using direct or iterative methods to obtain the nodal values of the displacements.

4.3. Recent Research

The coupled CFD-FEA method provides an intriguing option for investigating hydro–aero–structural dynamics of an FWTS under coupled loading due to its high accuracy and minimum level of parametrization. However, this method is rarely used to evaluate the hydro–aero–structural dynamics of these structures due to its high computational demand. Ref. [317] carries out an example of these types of studies to evaluate the fluid–structure interaction for the NREL 5 MW supported by the OC3-Hywind SPAR floater [169], where the free surface is modeled using the NSE with the level set method. Additionally, the FEA is used to discretize the fluid dynamic-governing equations, and the FWTS structural dynamics are modeled based on an isogeometric analysis. However, the developed coupled model is only applied to the parked configuration of the wind turbine. Thus, considering the prohibitively high computational cost of a coupled CFD-FEA method, the researchers have reduced the coupled analyses of FWTS to aerodynamic analysis under prescribed platform motions, aeroelastic and hydro-aerodynamic analyses.

4.3.1. Aerodynamic Analysis under Prescribed Platform Motions

In these analyses, to reduce the computational cost, the hydrodynamic part is simplified to focus on the aerodynamic part. Therefore, the harmonic motion will be prescribed on the platform in a predetermined degree of freedom (DOF) of motion to emulate the reaction of oscillating wave loads on FWTS.

Several studies have been performed in the literature to evaluate the aerodynamics of a wind turbine (predominantly the NREL 5-MW model [19]) under harmonic motion in surge and/or pitch and/or yaw direction(s) using a CFD code based on URANS equations [46,75,143,221,326,327,328,329]. The turbulence modeling is mainly carried out using the two-equation k-ω SST model, except for [221,326,329], where the k-ω Kok turbulence model, no turbulence model, and the realizable k-ε model, respectively, are employed. Furthermore, to model the turbine rotor, some studies, such as [326,329] choose to use an actuator line (AL) method rather than modeling it directly in the CFD simulation.

In the AL method, the aerodynamic loads acting on the turbine blades are calculated using the angle of attack of the flow incident on each two-dimensional airfoil element along the blades, plus the tabular aerodynamic data of the airfoils. Furthermore, a 3D Gaussian correction method is used to ensure that the aerodynamic loads acting on the blades have a smooth distribution over the mesh cells, without any singular behavior [326,329]. Additionally, among studies where rotor geometry is simulated directly, only Ref. [143] specifies the modeling approach for the turbulent boundary layer adjacent to the blade surface, using wall functions. In other studies of this type, no information is provided on how the turbulent flow near the turbine blades is captured [46,221,327]; although some studies mention the size of the thickness of the first prismatic layer adjacent to the blade surface [75,328].

To simulate the platform and rotor angular motions, several methods are used. In this regard, the unsteady motions of the platform are modeled using an overset grid in [46,221,326,327,328]. The platform motion is modeled using a different approach based on a dynamic mesh technique in Refs. [75,143]. As shown in [75], for large platform motions in which the grid is highly deformed, leading to a low-quality mesh, the utilization of a remeshing method is necessary to regenerate the mesh in locals with low quality, based on criteria capable of assessing the mesh quality, such as cell volume and skewness. The rotor rotational motion is simulated either using the moving reference frame approach [46,75,143] or a sliding mesh technique [143,328]. In the moving reference frame approach, the grid remains stationary, and no physical motion is modeled. Moreover, the authors in [327] apply an optimization technique to the overlapping area of the overset mesh between the background stationary grid and the moving part to increase the accuracy of interpolation between these two areas.

Generally, the results obtained from these studies demonstrate the significant impact of harmonic motions, especially in pitch and surge directions, of the platform on the turbine aerodynamics. This is mainly due to the interaction between the rotor and its shed vortices, which certainly affects the aerodynamics of the machine. Furthermore, comparing the CFD results with the results obtained from the OpenFAST code, as performed in [221], demonstrates the importance of CFD for the accurate prediction of complex unsteady aerodynamics in FWTS.

A few works have also evaluated the platform motions under prescribed aerodynamic loads. For instance, the hydrodynamics of an FWTS is evaluated in [287] for various wind–wave conditions using RANS equations with the k-ω SST model without the turbine presence. The corresponding aerodynamic loads for each wind speed are exerted at the center of rotation of the platform.

4.3.2. Aeroelastic Simulations