Dynamic Mechanical Properties and Damage Parameters of Marine Pipelines Based on Johnson–Cook Model

Abstract

:1. Introduction

2. Constitutive Model and Damage Model

2.1. Johnson–Cook Constitutive Model

2.2. Johnson–Cook Damage Model

3. Mechanical Properties Tests of the Material

3.1. Tested Material

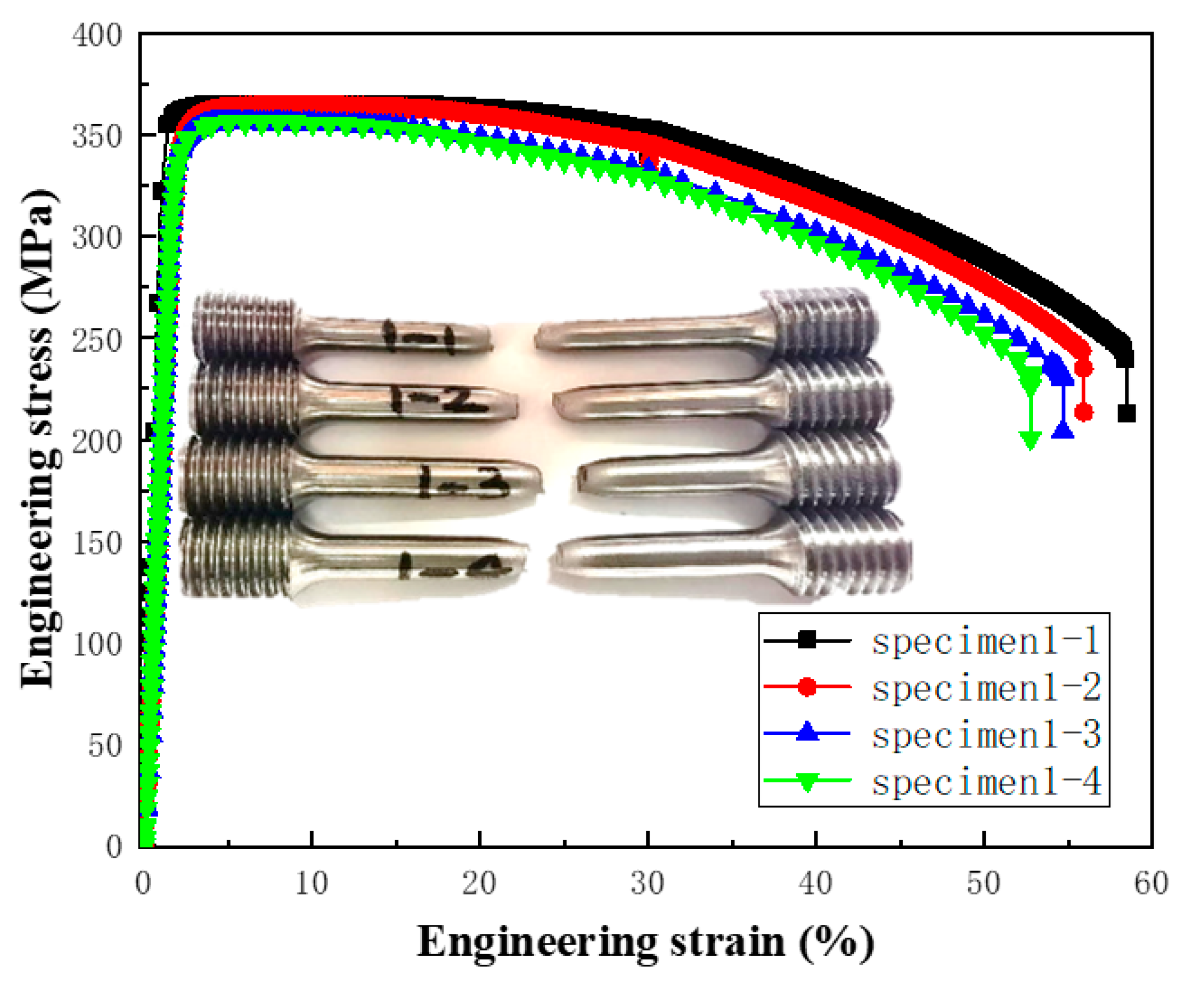

3.2. Quasi-Static Tensile Tests of Smooth Specimens

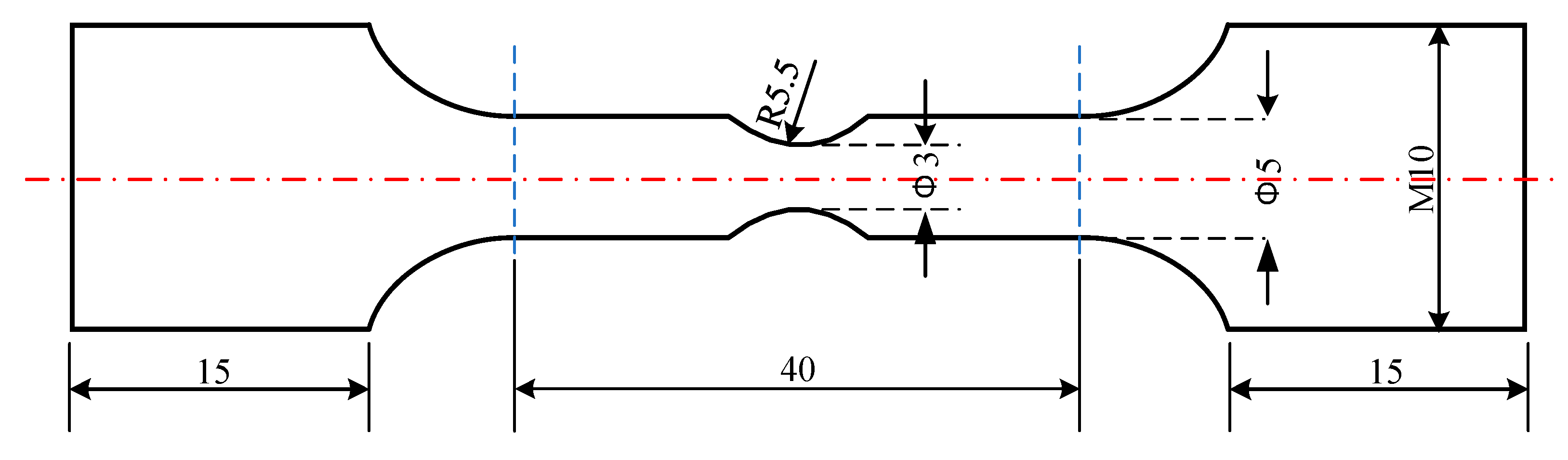

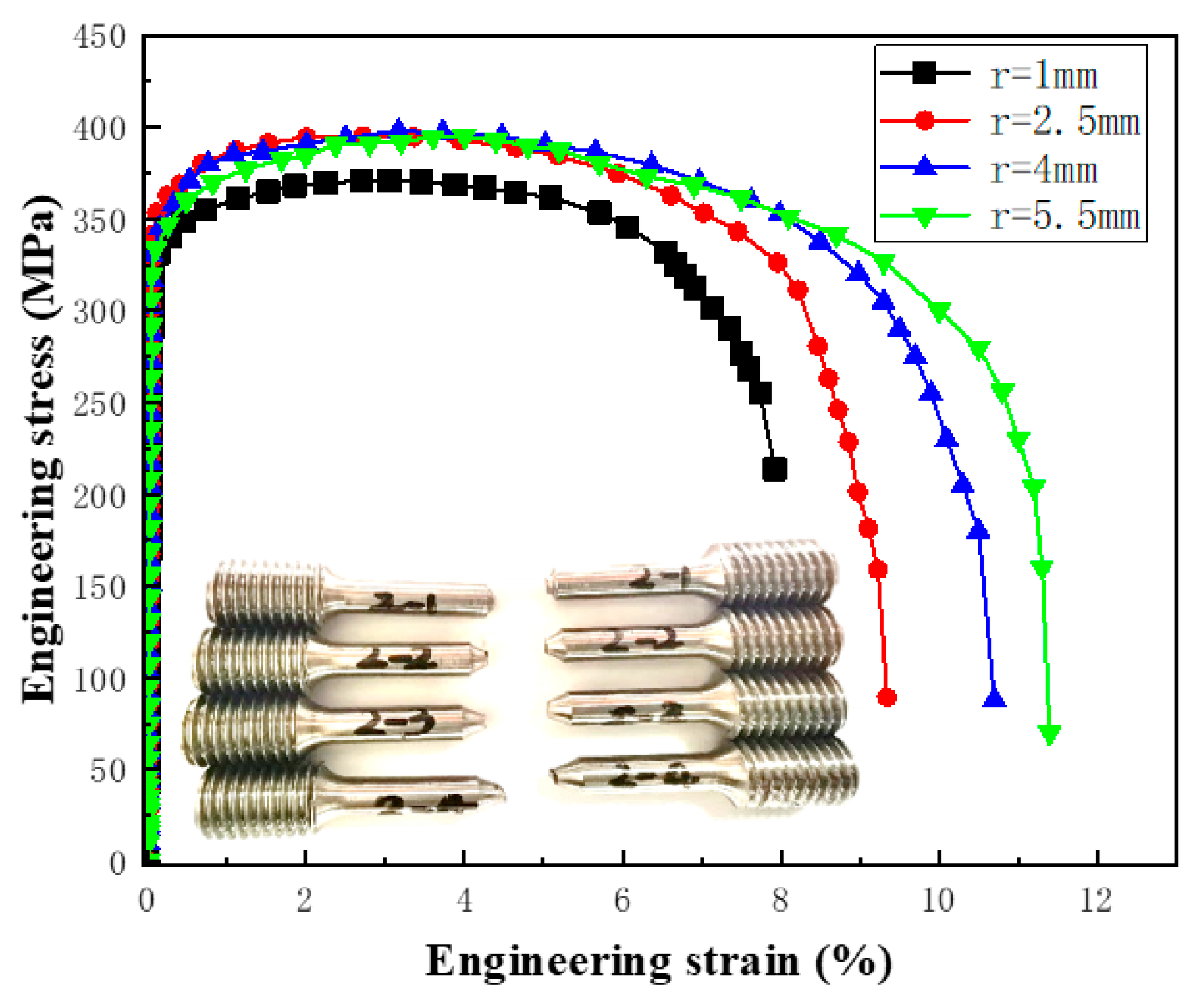

3.3. Tensile Tests of Notched Specimens

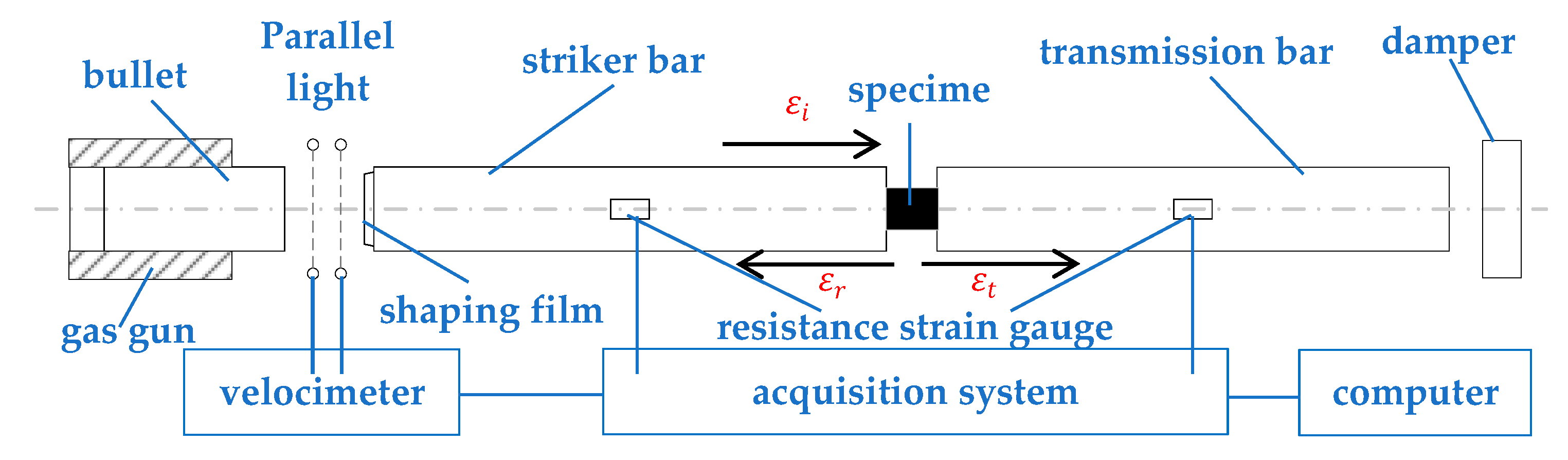

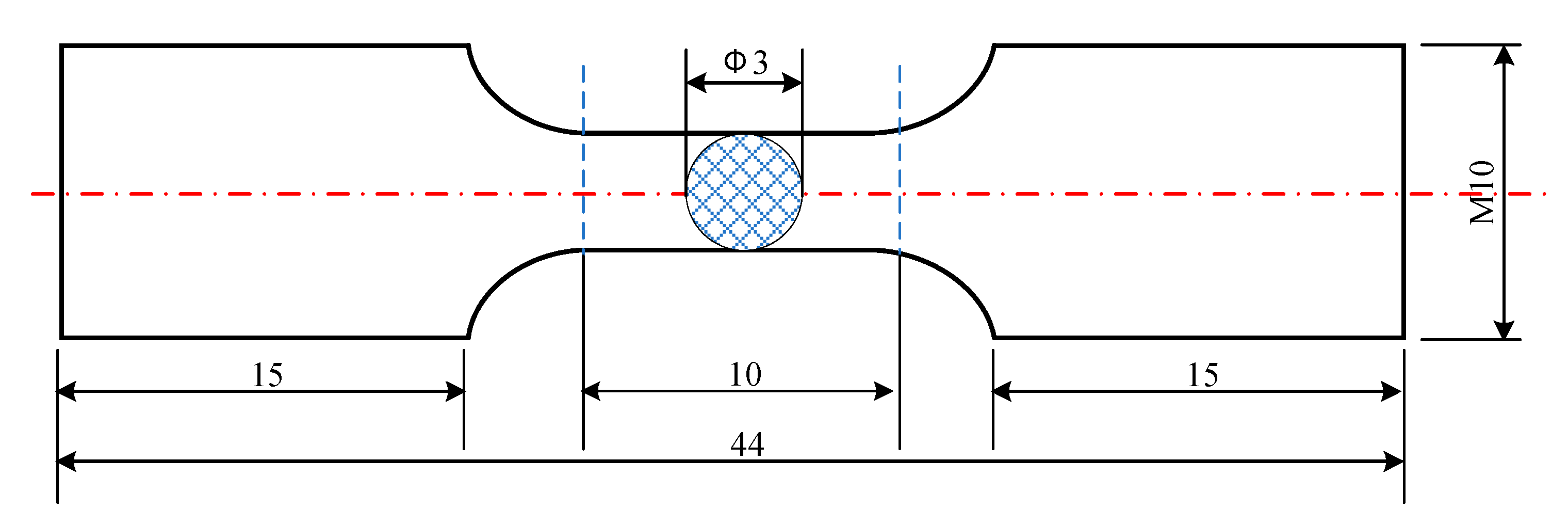

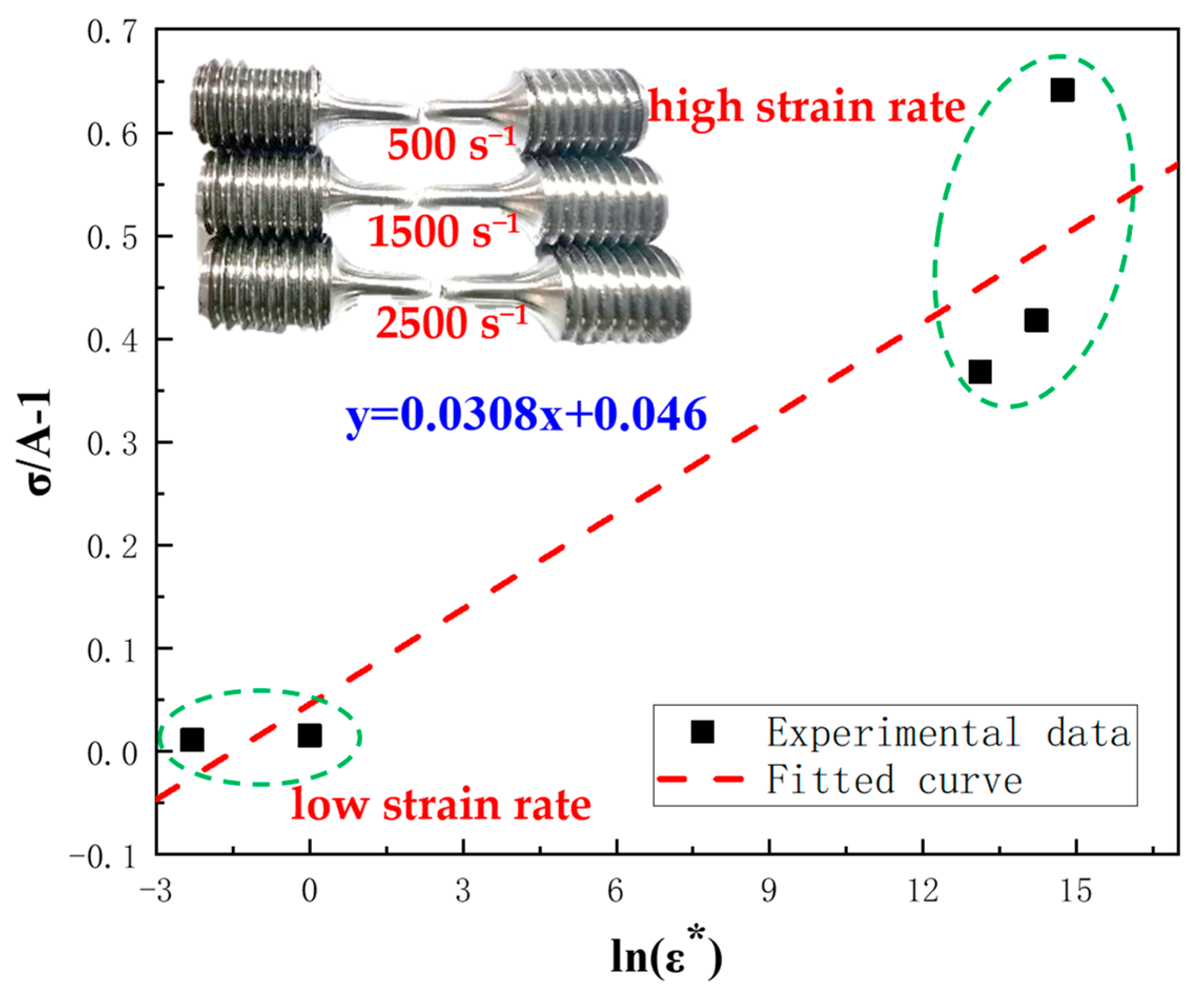

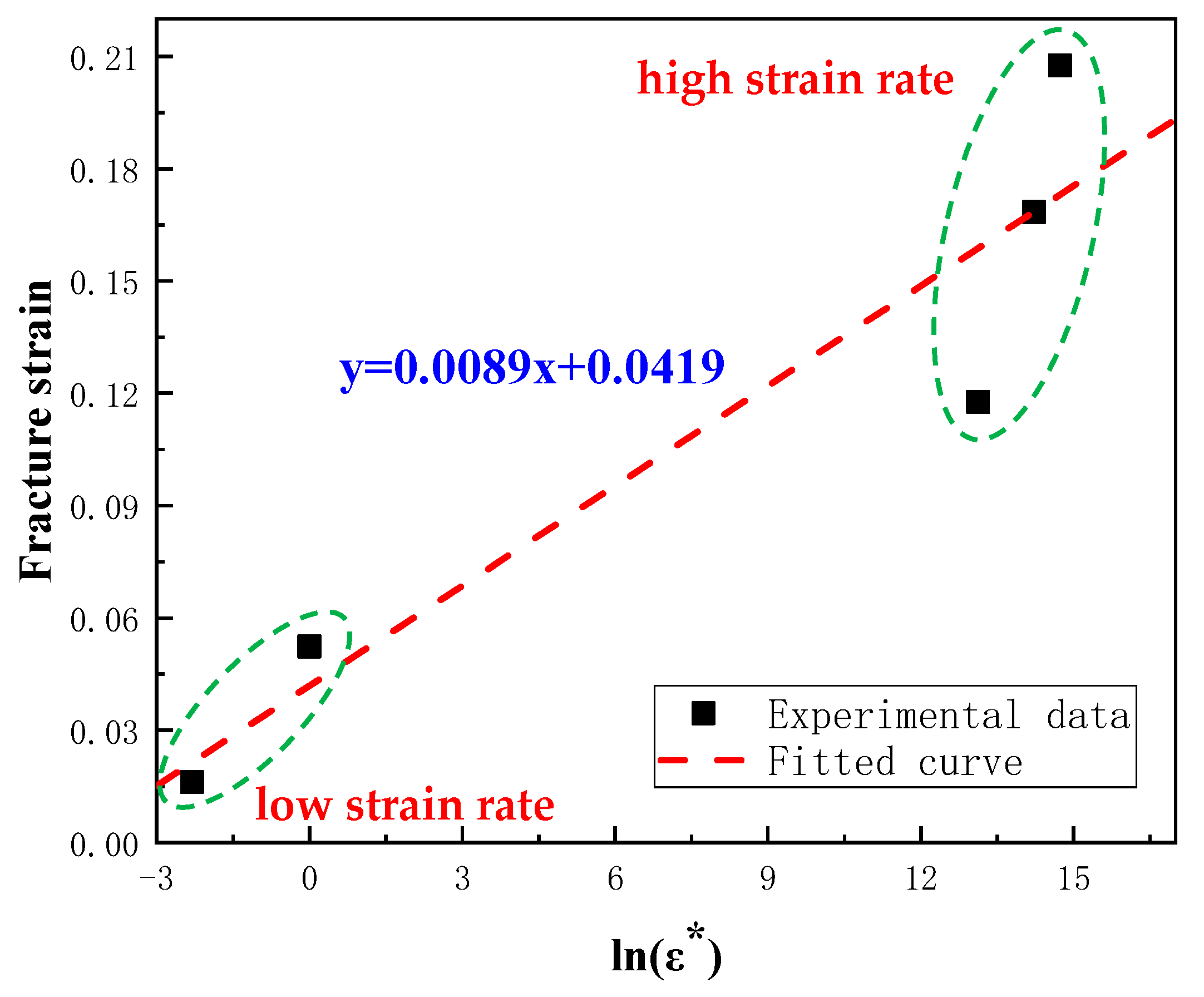

3.4. Hopkinson Tensile Test at Different Strain Rates

4. Validation of the Johnson–Cook Constitutive Model and Failure Parameters through Numerical Simulations

4.1. The Finite Element Models

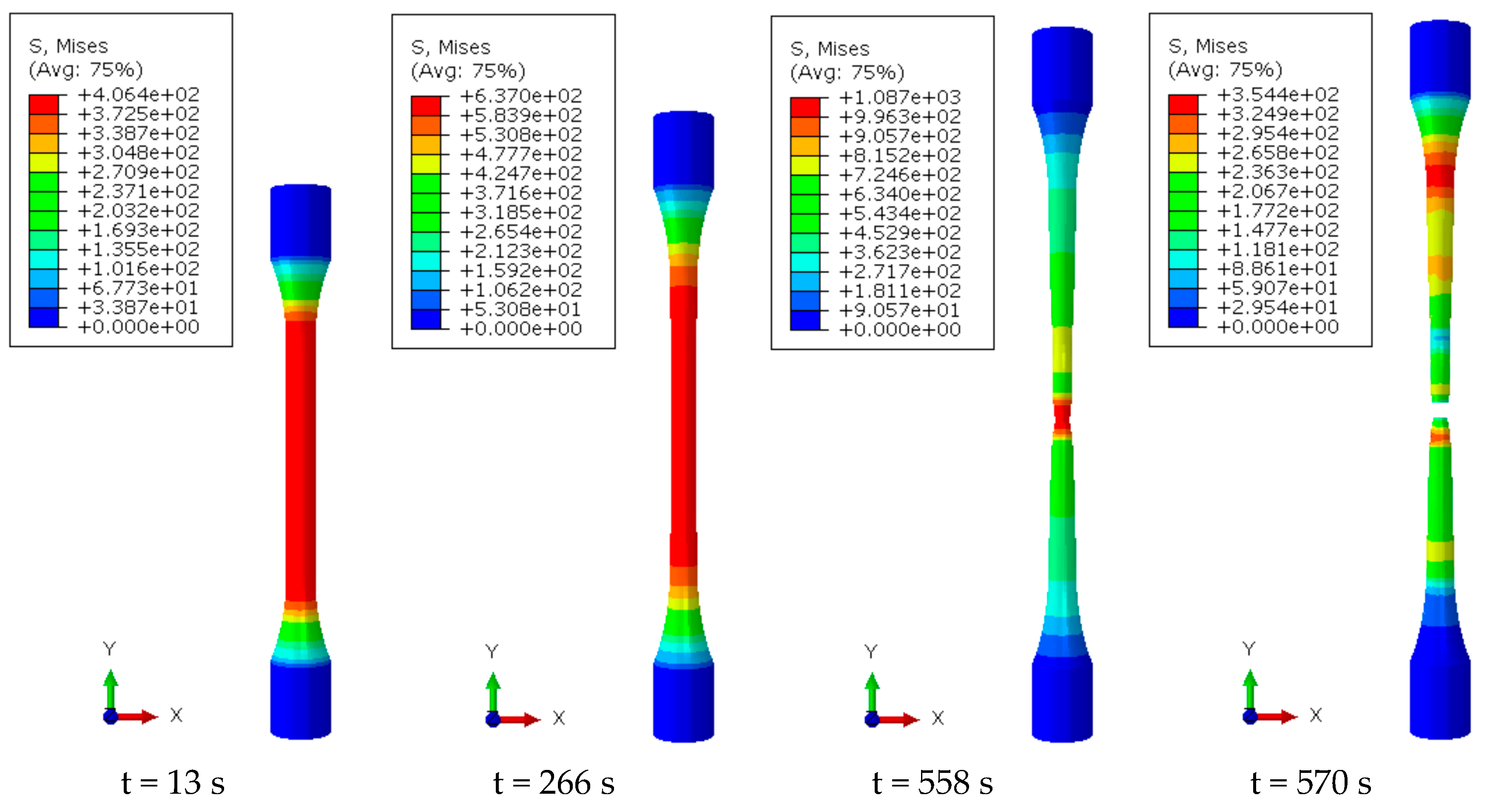

4.2. Finite Element Analysis

4.3. Discussions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gao, Q.; Duan, M.; Liu, X.; Wang, Y.; Jia, X.; An, C.; Zhang, T. Damage assessment for submarine photoelectric composite cable under anchor impact. Appl. Ocean. Res. 2018, 73, 42–58. [Google Scholar] [CrossRef]

- Longva, V.; Sævik, S.; Levold, E.; Ilstad, H. Dynamic simulation of subsea pipeline and trawl board pull-over interaction. Mar. Struct. 2013, 34, 156–184. [Google Scholar] [CrossRef]

- Ren, J.; Wang, C.; Zahng, X.; Suo, T.; Li, Y.; Tang, Z. Johnson-Cook constitutive model and failure parameters determination of B280VK high-strength steel. J. Plast. Eng. 2023, 30, 116–125. [Google Scholar]

- Vannucchi de Camargo, F. Survey on Experimental and Numerical Approaches to Model Underwater Explosions. J. Mar. Sci. Eng. 2019, 7, 15. [Google Scholar] [CrossRef]

- Ellinas, C.P. Ultimate strength of damaged tubular bracing members. J. Struct. Eng. 1984, 110, 245–259. [Google Scholar] [CrossRef]

- Wierzbicki, T.; Suh, M.S. Indentation of tubes under combined loading. Int. J. Mech. Sci. 1988, 30, 229–248. [Google Scholar] [CrossRef]

- Bai, Y.; Pedersen, P.T. Elastic-plastic behaviour of offshore steel structures under impact loads. Int. J. Impact Eng. 1993, 13, 99–115. [Google Scholar] [CrossRef]

- Wang, H.M. Action of Ship Anchoring on Submarine Pipeline in Bohai Bay. Navig. China 2015, 38, 56–59+68. [Google Scholar]

- DNVGL-ST-F101; Submarine Pipeline Systems. DNV: Bærum, Norway, 2021.

- DNVGL-RP-F107; Risk Assessment of Pipeline Protection. DNV: Bærum, Norway, 2017.

- Chen, K.; Shen, W.Q. Further experimental study on the failure of fully clamped steel pipes. Int. J. Impact Eng. 1998, 21, 177–202. [Google Scholar] [CrossRef]

- Palmer, A.; Neilson, A.; Sivadasan, S. Impact resistance of pipelines and the loss-of-containment limit state. In Proceedings of the International Pipeline Pigging Integrity Assessment and Repair Conference, Calgary, AB, Canada, 4–8 October 2004. [Google Scholar]

- Palmer, A.; Touhey, M.; Holder, S.; Anderson, M.; Booth, S. Full-scale impact tests on pipelines. Int. J. Impact Eng. 2006, 32, 1267–1283. [Google Scholar] [CrossRef]

- Zhang, R. Dynamic Response and Failure Mechanism of Structural Tubular Steel Members Subjected to Transverse Impact. Ph.D. Thesis, Harbin Institute of Technology, Shenzhen, China, 2018. [Google Scholar]

- Zeinoddini, M.; Harding, J.E.; Parke, G.A.R. Effect of impact damage on the capacity of tubular steel members of offshore structures. Mar. Struct. 1998, 11, 141–157. [Google Scholar] [CrossRef]

- Yan, S.W.; Tian, Y.H. Analysis of pipeline damage to impact load by dropped objects. Trans. Tianjin Univ. 2006, 12, 138–141. [Google Scholar]

- Huang, Q.F.; Guo, H.Y.; Li, W. Numerical simulation and experimental study on the damage of submarine pipeline impacted by dropped objects. Ocean. Eng. 2018, 36, 84–88. [Google Scholar]

- Zhang, D.N. A modified Johnson-Cook model of dynamic tensile behaviors for 7075-T6 aluminum alloy. J. Alloys Compd. 2015, 619, 186–194. [Google Scholar] [CrossRef]

- Banerjee, A.; Dhar, S.; Acharyya, S.; Datta, D.; Nayak, N. Determination of Johnson cook material and failure model constants and numerical modelling of Charpy impact test of armour steel. Mater. Sci. Eng. A 2015, 640, 200–209. [Google Scholar] [CrossRef]

- Cao, Y.; Zhen, Y.; Song, M.; Yi, H.; Li, F.; Li, X. Determination of Johnson–Cook parameters and evaluation of Charpy impact test performance for X80 pipeline steel. Int. J. Mech. Sci. 2020, 179, 105627. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, Z.; Liu, K.; Chen, G. Application of a material model based on the Johnson-Cook and Gurson-Tvergaard-Needleman model in ship collision and grounding simulations. Ocean. Eng. 2020, 205, 106768. [Google Scholar] [CrossRef]

- Wang, X.M.; Shi, J. Validation of Johnson-Cook plasticity and damage model using impact experiment. Int. J. Impact Eng. 2023, 60, 67–75. [Google Scholar] [CrossRef]

- Aktürk, M.; Boy, M.; Gupta, M.K.; Waqar, S.; Krolczyk, G.M.; Korkmaz, M.E. Numerical and experimental investigations of built orientation dependent Johnson-Cook model for selective laser melting manufactured AlSi10Mg. J. Mater. Res. Technol. 2021, 15, 6244–6259. [Google Scholar] [CrossRef]

- Deshpande, V.M.; Chakraborty, P.; Chakraborty, T.; Tiwari, V. Application of copper as a pulse shaper in SHPB tests on brittle materials-experimental study, constitutive parameters identification, and numerical simulations. Mech. Mater. 2022, 171, 104336. [Google Scholar] [CrossRef]

- Daoud, M.; Chatelain, J.F.; Bouzid, A. Effect of rake angle-based Johnson-Cook material constants on the prediction of residual stresses and temperatures induced in Al2024-T3 machining. Int. J. Mech. Sci. 2017, 122, 392–404. [Google Scholar] [CrossRef]

- Chao, Z.L.; Jiang, L.T.; Chen, G.Q.; Zhang, Q.; Zhang, N.B.; Zhao, Q.Q.; Pang, B.J.; Wu, G.H. A modified Johnson-Cook model with damage degradation for B4Cp/Al composites. Compos. Struct. 2022, 282, 115029. [Google Scholar] [CrossRef]

- Liu, Y.; Li, M.; Ren, X.W.; Xiao, Z.B.; Zhang, X.Y.; Huang, Y.C. Flow stress prediction of Hastelloy C-276 alloy using modified Zerilli-Armstrong, Johnson-Cook and Arrhenius-type constitutive models. Trans. Nonferrous Met. Soc. China 2020, 30, 3031–3042. [Google Scholar] [CrossRef]

- Xie, G.; Yu, X.; Gao, Z.; Xue, W.; Zheng, L. The modified Johnson-Cook strain-stress constitutive model according to the deformation behaviors of a Ni-W-Co-C alloy. J. Mater. Res. Technol. 2022, 20, 1020–1027. [Google Scholar] [CrossRef]

- Wei, G.; Zhang, W.; Deng, Y.F. Identification and validation of constitutive parameters of 45 Steel based on J-C model. J. Vib. Shock. 2019, 38, 173–178. [Google Scholar]

- Zhu, Y. Research on Dynamic Constitutive Relationship of Q355B Steel Based on Johnson-Cook Model. Ph.D. Thesis, Harbin University of Science and Technology, Harbin, China, 2019. [Google Scholar]

- Chen, J.L.; Shu, W.Y.; Li, J.W. Experimental study on dynamic mechanical property of Q235 steel at different strain rates. J. Tongji Univ. 2016, 44, 1071–1075. [Google Scholar]

- Chen, X.W.; Wei, L.M.; Li, J.C. Experimental research on the long rod penetration of tungsten-fiber/Zr-based metallic glass matrix composite into Q235 steel target. Int. J. Impact Eng. 2015, 79, 102–116. [Google Scholar] [CrossRef]

- Guo, Z.T.; Gao, B.; Guo, Z.; Zhang, W. Dynamic constitutive relation based on J-C model of Q235 steel. Explos. Shock. Waves 2018, 38, 804–810. [Google Scholar]

- Shokry, A.; Gowid, S.; Mulki, H.; Kharmanda, G. On the Prediction of the Flow Behavior of Metals and Alloys at a Wide Range of Temperatures and Strain Rates Using Johnson–Cook and Modified Johnson–Cook-Based Models: A Review. Materials 2023, 16, 1574. [Google Scholar] [CrossRef]

- Sirigiri VK, R.; Gudiga, V.Y.; Gattu, U.S.; Suneesh, G.; Buddaraju, K.M. A review on Johnson Cook material model. Mater. Today Proc. 2022, 62, 3450–3456. [Google Scholar] [CrossRef]

- Carra, F.; Charrondiere, C.; Guinchard, M.; Sacristan de Frutos, O. Design and construction of an instrumentation system to capture the response of advanced materials impacted by intense proton pulses. Shock. Vib. 2021, 2021, 8855582. [Google Scholar] [CrossRef]

| Parameters | Description |

|---|---|

| The equivalent stress | |

| The engineering stress | |

| The average stress | |

| , , | The principal stresses |

| the stress triaxiality | |

| The equivalent strain | |

| The engineering strain | |

| The strain rate | |

| The reference strain rate | |

| Dimensionless strain rate | |

| The effective fracture strain | |

| The yield stress of the material | |

| , | The strain hardening constants |

| The strain-rate strengthening coefficient | |

| , , , | Material damage parameters |

| C/% | Si/% | Mn/% | P/% | S/% |

|---|---|---|---|---|

| 0.16 | 0.12 | 0.38 | 0.023 | 0.040 |

| The Notch Radius /mm | Initial Specimen Diameter /mm | Specimen Diameter after Fracture /mm | The Initial Stress Triaxiality | The Stress Triaxiality after Fracture | Reduction of Area /% |

|---|---|---|---|---|---|

| 1 | 3 | 2.55125 | −0.8929 | −0.8267 | 13.83 |

| 2.5 | 3 | 2.40375 | −0.5957 | −0.5487 | 17.89 |

| 4 | 3 | 2.2975 | −0.5052 | −0.4675 | 20.66 |

| 5.5 | 3 | 2.16875 | −0.4612 | −0.4274 | 23.85 |

| 361.2 MPa | 526 MPa | 0.0308 | 0.58 | 0.2918 | 4.6156 | 6.1566 | 0.0089 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, X.; Pei, J.; Rong, J. Dynamic Mechanical Properties and Damage Parameters of Marine Pipelines Based on Johnson–Cook Model. J. Mar. Sci. Eng. 2023, 11, 1666. https://doi.org/10.3390/jmse11091666

Tian X, Pei J, Rong J. Dynamic Mechanical Properties and Damage Parameters of Marine Pipelines Based on Johnson–Cook Model. Journal of Marine Science and Engineering. 2023; 11(9):1666. https://doi.org/10.3390/jmse11091666

Chicago/Turabian StyleTian, Xiao, Jingjing Pei, and Jingjing Rong. 2023. "Dynamic Mechanical Properties and Damage Parameters of Marine Pipelines Based on Johnson–Cook Model" Journal of Marine Science and Engineering 11, no. 9: 1666. https://doi.org/10.3390/jmse11091666

APA StyleTian, X., Pei, J., & Rong, J. (2023). Dynamic Mechanical Properties and Damage Parameters of Marine Pipelines Based on Johnson–Cook Model. Journal of Marine Science and Engineering, 11(9), 1666. https://doi.org/10.3390/jmse11091666