An Experimental Study on the Resistance of a High-Speed Air Cavity Craft

Abstract

1. Introduction

2. Nomenclature

3. Test Content and Methodology

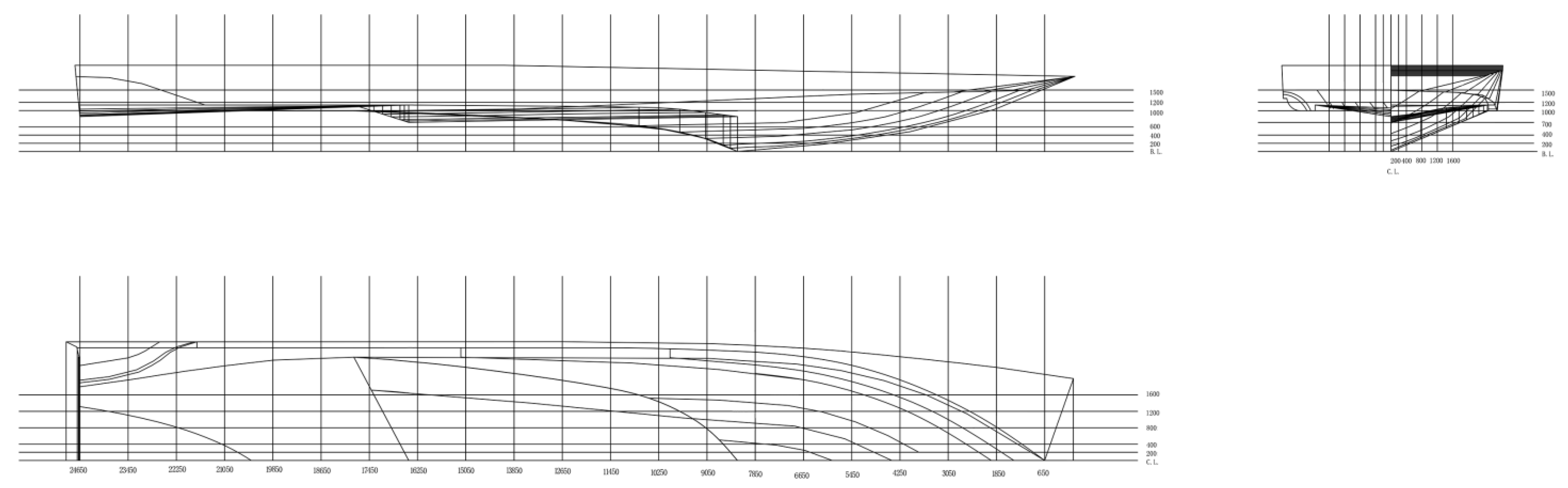

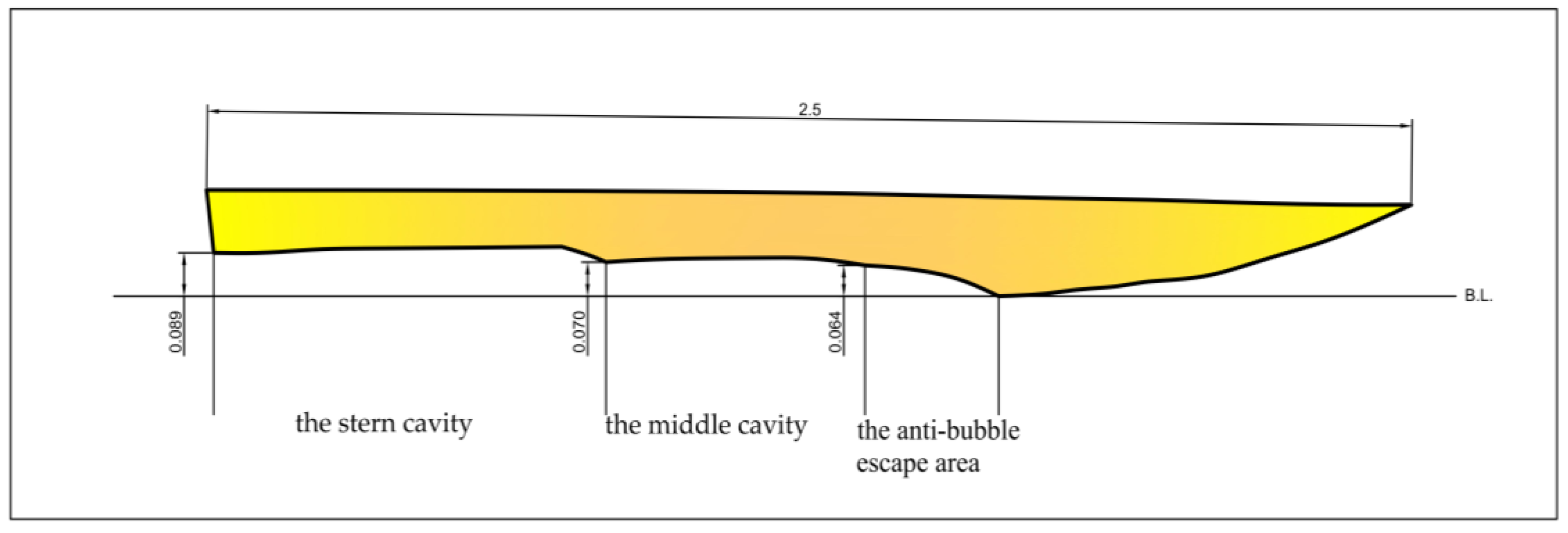

3.1. Hull Parameters

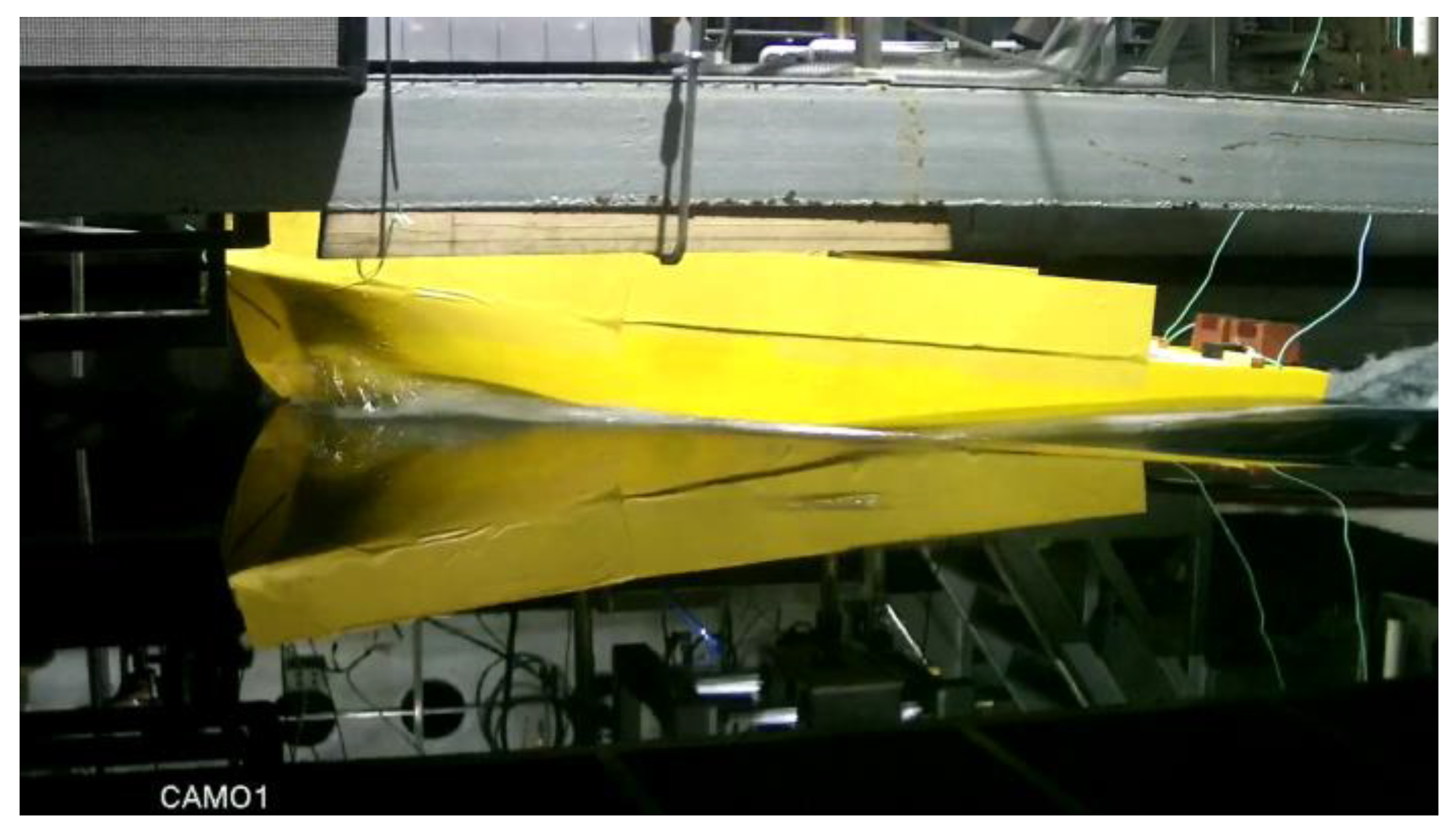

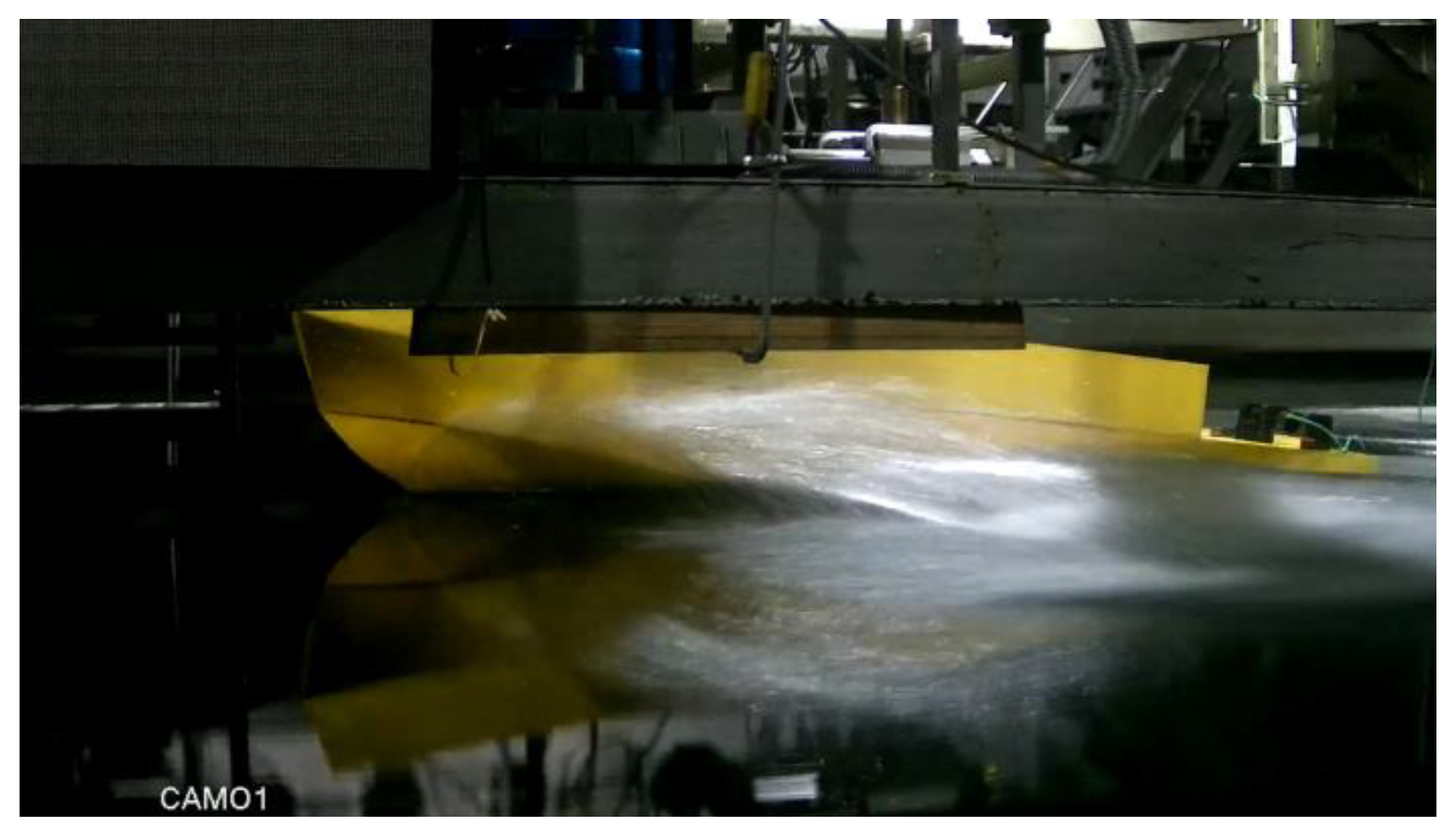

3.2. Test Setup and Model

3.3. Test Content

4. Results and Discussion

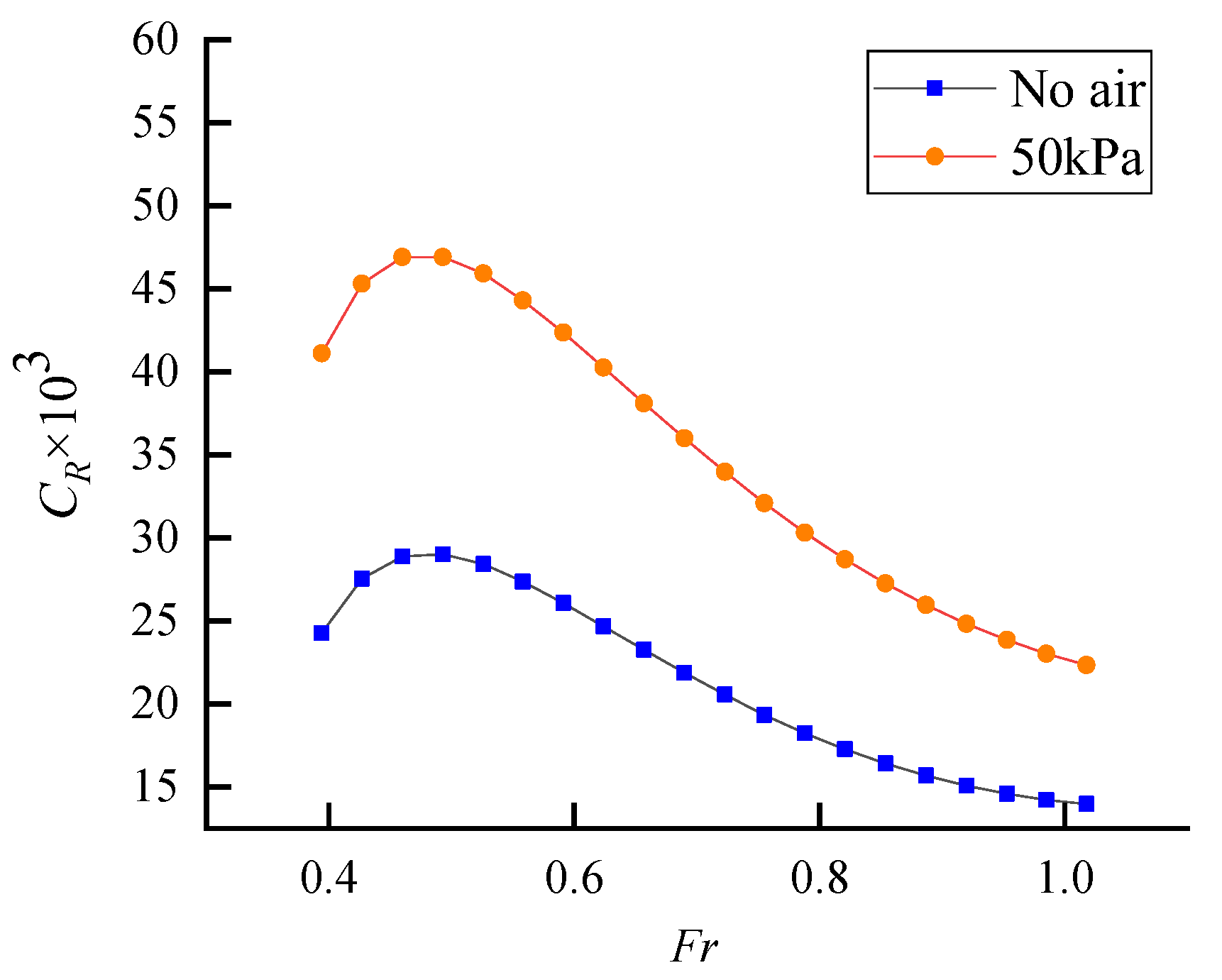

4.1. Text Results

4.2. Calculation Method

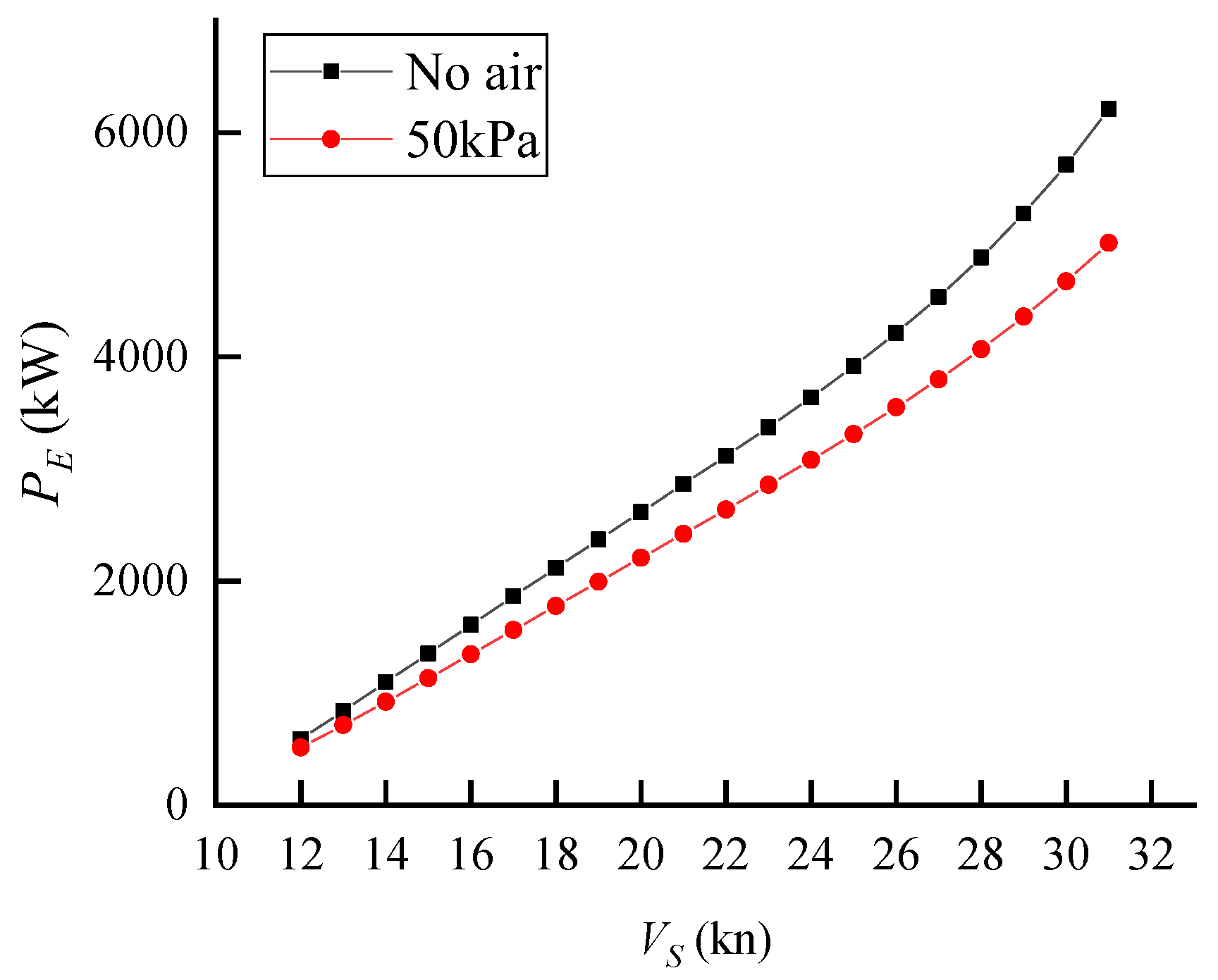

4.3. Effective Power

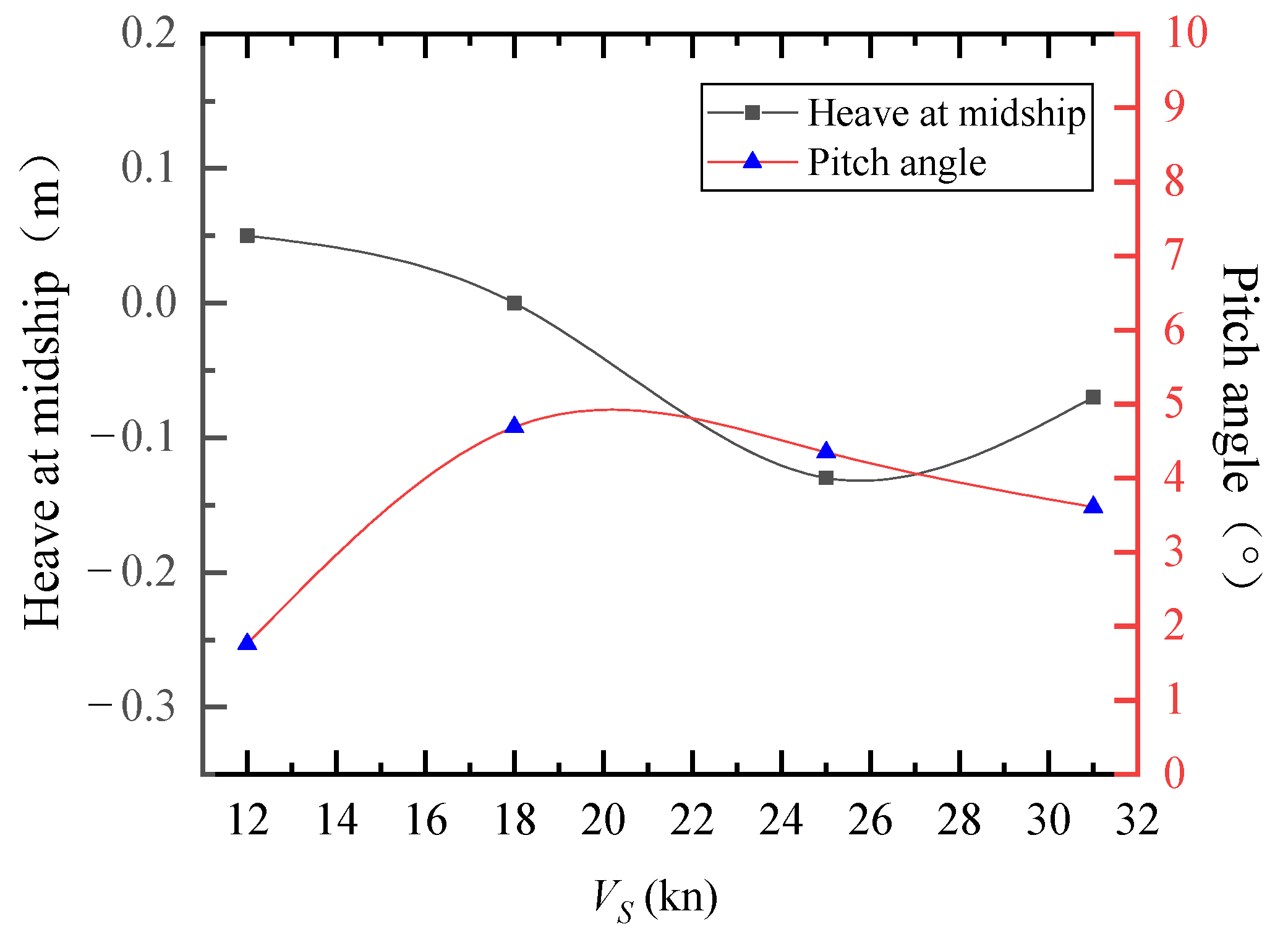

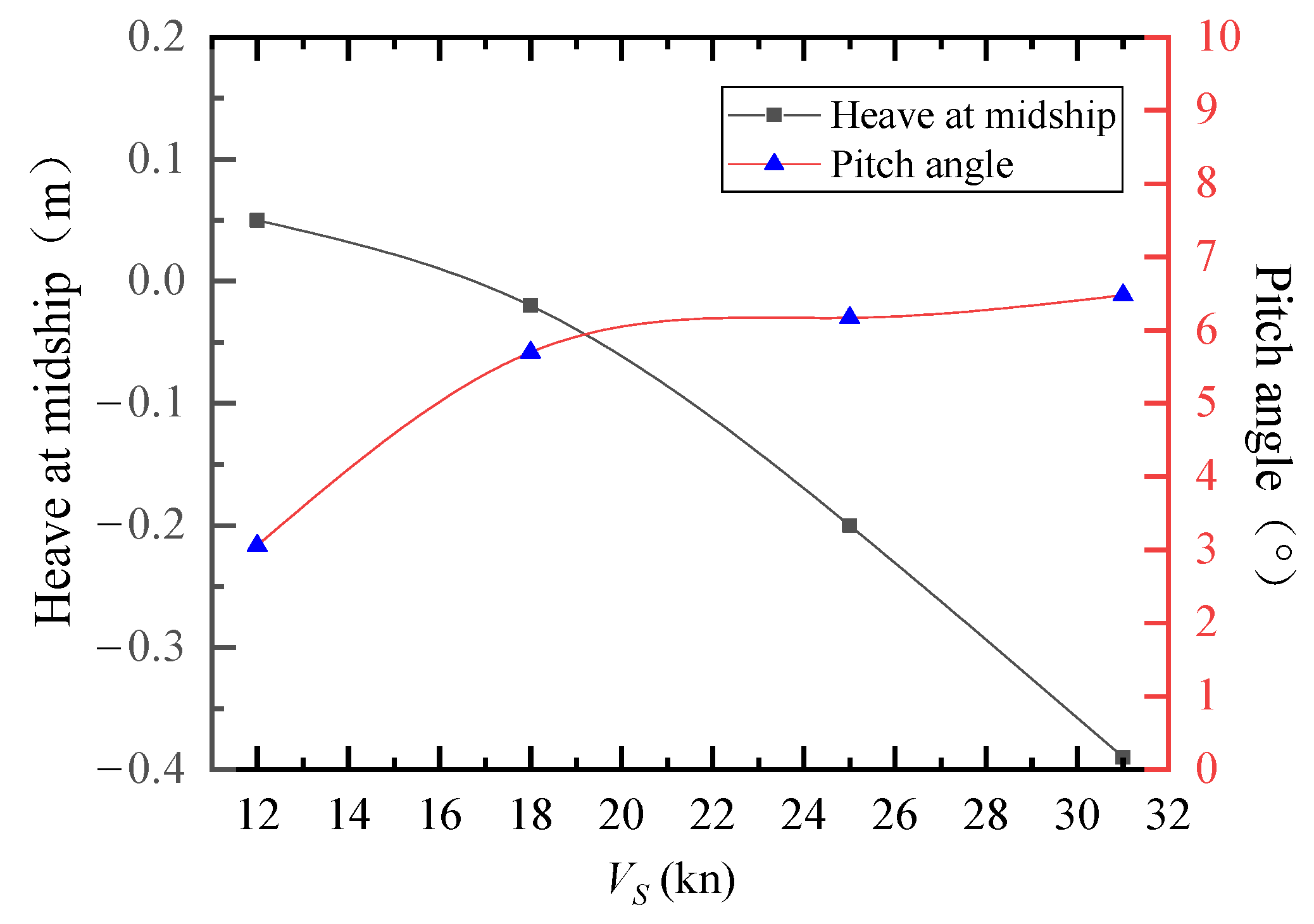

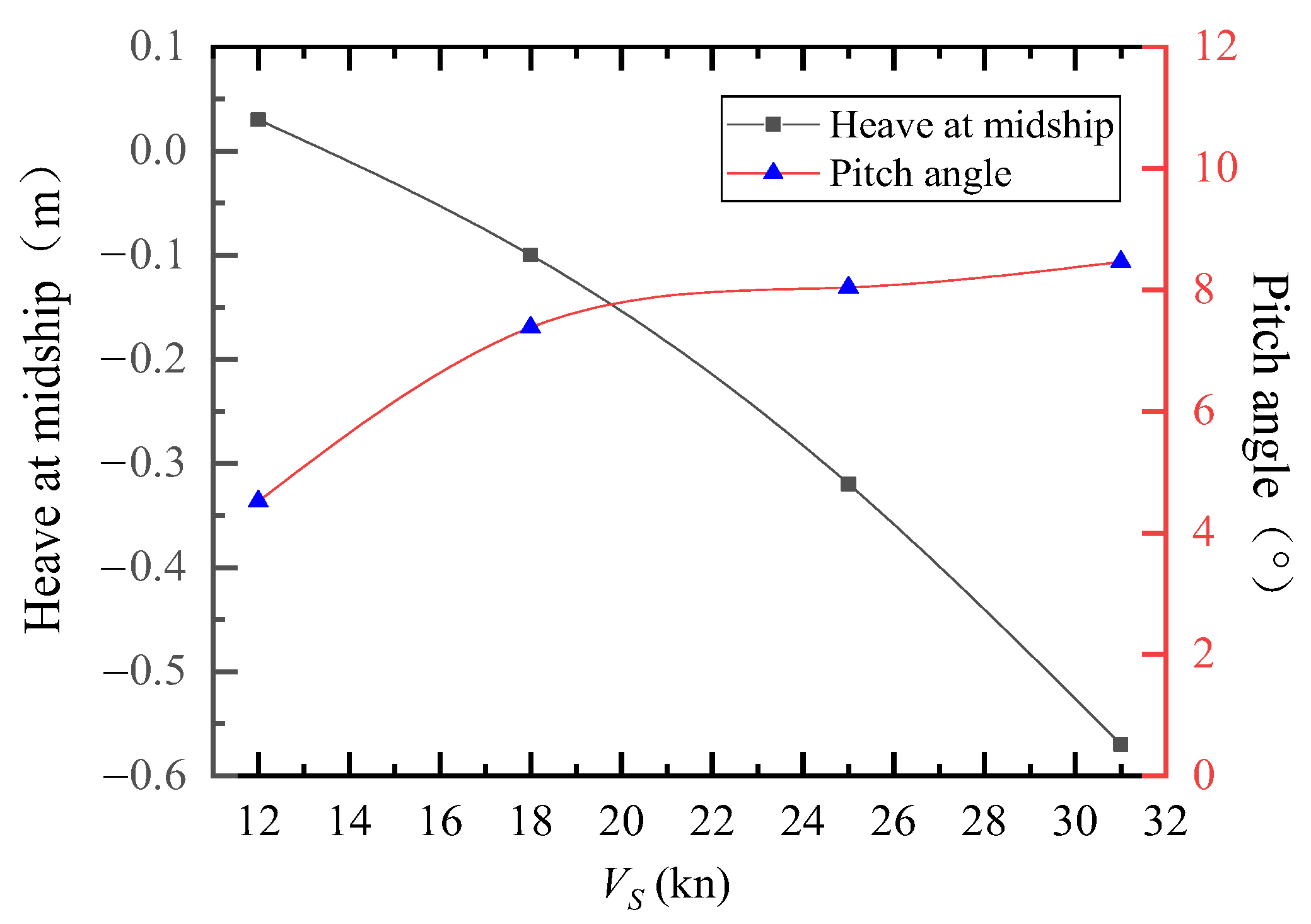

4.4. Heave and Pitch Angle during the Test

- When the longitudinal inclination is inadequate, the air does not exert a considerable lifting effect on the model. The high-speed air cavity craft does not attain the gliding state during operation and remains in the phase of ascending resistance peak, thus failing to achieve the optimal resistance reduction effect;

- Excessive longitudinal inclination leads to the lifting of the hull, gradual reduction of the wetted length, and a constant backward shift of the center of dynamic pressure at the bottom. Such an inclination results in poor stability of the ship at high speeds, and a significant change in sailing lift that causes higher splash and more severe waves within the amidships range of −0.4 to 0.05 m. This, in turn, leads to an increase in wave-making resistance and the growing contribution of splash resistance to the residual resistance, thus impairing the reduction of resistance.

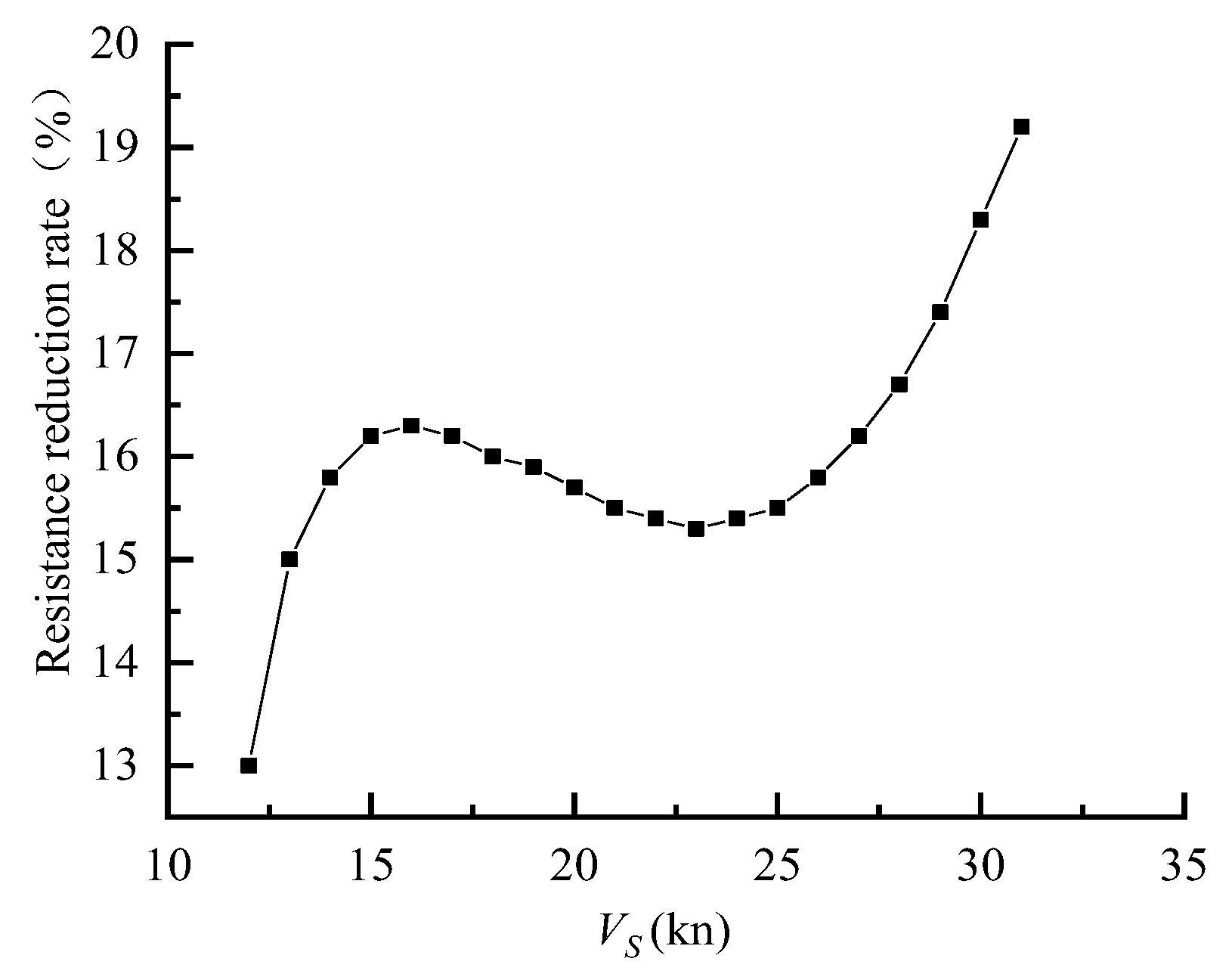

4.5. Resistance Reduction Effect Analysis

5. Summary

- (1)

- In order to achieve a more effective reduction in resistance, the high-speed air cavity craft should select an appropriate initial stern inclination angle, and if feasible, the angle should vary with speed;

- (2)

- The influence of air pressure on model resistance is significant. As the air pressure increases, the resistance value gradually decreases until it reaches the optimal air pressure, after which the resistance remains relatively stable;

- (3)

- At the displacement state of a real ship of 125 t and a chamber pressure of 50 kPa, the resistance of the initial stern inclination of 2.5° is observed to be at its minimum near the design speed of Vs = 30 kn. Comparatively, the reduction effect is estimated to be 18.3% when compared to the state without air injection;

- (4)

- Before the formal test, a preliminary test was conducted to evaluate the test conditions, check the scientific feasibility of the experimental design, and accurately control the relevant variables, laying a foundation for the formal test. The pretest is crucial in preventing the inefficient use of manpower, materials, and financial resources resulting from poorly designed or blindly conducted tests. By reducing costs and saving time, the pretest plays a positive role in enhancing the efficiency and effectiveness of the overall testing process.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Pavlov, G.A.; Yun, L.; Bliault, A.; He, S.-L. Air Cavity Ship Concept Evaluation. In Air Lubricated and Air Cavity Ships: Development, Design, and Application; Pavlov, G.A., Yun, L., Bliault, A., He, S.-L., Eds.; Springer: New York, NY, USA, 2020; pp. 179–229. [Google Scholar]

- Mäkiharju, S.A.; Perlin, M.; Ceccio, S.L. On the energy economics of air lubrication drag reduction. Int. J. Nav. Archit. Ocean Eng. 2012, 4, 412–422. [Google Scholar] [CrossRef]

- Yun, L.; Bliault, A. Theory and Design of Air Cushion Craft; Hodder Headline: London, UK; Elsevier: Amsterdam, The Netherlands, 2000. [Google Scholar]

- An, H.; Pan, H.; Yang, P. Research Progress of Air Lubrication Drag Reduction Technology for Ships. Fluids 2022, 7, 319. [Google Scholar] [CrossRef]

- Kim, H.; Park, S. Coupled Level-Set and Volume of Fluid (CLSVOF) Solver for Air Lubrication Method of a Flat Plate. J. Mar. Sci. Eng. 2021, 9, 231. [Google Scholar] [CrossRef]

- Dong, W.; Liu, Z.; Ou, Y.; Guo, R. Experimental study on the hull form of high-speed air cavity craft. In Proceedings of the 9th International Conference on Fast Sea Transportation, FAST 2007, Shanghai, China, 23–27 September 2007; pp. 265–270. [Google Scholar]

- Tanaka, T.; Oishi, Y.; Park, H.J.; Tasaka, Y.; Murai, Y.; Kawakita, C. Frictional drag reduction caused by bubble injection in a turbulent boundary layer beneath a 36-m-long flat-bottom model ship. Ocean Eng. 2022, 252, 111224. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, X.-S.; Wan, D.-C. Research progress on the hydrodynamic performance of water-air-bubble mixed flows around a ship. J. Hydrodyn. 2022, 34, 171–188. [Google Scholar] [CrossRef]

- Sayyaadi, H.; Nematollahi, M. Determination of optimum injection flow rate to achieve maximum micro bubble drag reduction in ships; an experimental approach. Sci. Iran. 2013, 20, 535–541. [Google Scholar] [CrossRef]

- Sun, T.; Zhang, X.; Zhang, J.; Wang, C. Experimental Study on the Unsteady Natural Cloud Cavities: Influence of Cavitation Number on Cavity Evolution and Pressure Pulsations. J. Mar. Sci. Eng. 2021, 9, 487. [Google Scholar] [CrossRef]

- Wu, H.; Wu, W.; Chen, K. Review of Research on Air Bubble Drag Reduction on Ships. Shipbuild. China 2019, 60, 212–227. [Google Scholar]

- Gokcay, S.; Insel, M.; Odabasi, A.Y. Revisiting artificial air cavity concept for high speed craft. Ocean Eng. 2004, 31, 253–267. [Google Scholar] [CrossRef]

- Matveev, K.I.; Burnett, T.J.; Ockfen, A.E. Study of air-ventilated cavity under model hull on water surface. Ocean Eng. 2009, 36, 930–940. [Google Scholar] [CrossRef]

- Matveev, K.I.; Miller, M.J. Air cavity with variable length under a model hull. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2011, 225, 161–169. [Google Scholar] [CrossRef]

- Matveev, K.I. Transom effect on the properties of an air cavity under a flat-bottom hull. Ships Offshore Struct. 2012, 7, 143–149. [Google Scholar] [CrossRef]

- Matveev, K.I. Hydrodynamic modeling of semi-planing hulls with air cavities. Int. J. Nav. Archit. Ocean Eng. 2015, 7, 500–508. [Google Scholar] [CrossRef]

- Matveev, K.I. Simplified model for unsteady air cavities under ship hulls. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2019, 234, 100–107. [Google Scholar] [CrossRef]

- Collins, J.M.; Matveev, K.I. Investigation of influence of compact actuators on air cavity in water flow under recessed hull. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2020, 235, 421–431. [Google Scholar] [CrossRef]

- Matveev, K.I. Numerical simulation of air cavity under a simplified model-scale hull form. J. Ocean. Eng. Sci. 2020, 5, 68–72. [Google Scholar] [CrossRef]

- Cucinotta, F.; Guglielmino, E.; Sfravara, F. An experimental comparison between different artificial air cavity designs for a planing hull. Ocean Eng. 2017, 140, 233–243. [Google Scholar] [CrossRef]

- Cucinotta, F.; Nigrelli, V.; Sfravara, F. A preliminary method for the numerical prediction of the behavior of air bubbles in the design of air cavity ships. In Advances on Mechanics, Design Engineering and Manufacturing: Proceedings of the International Joint Conference on Mechanics, Design Engineering & Advanced Manufacturing (JCM 2016), Catania, Italy, 14–16 September 2016; Springer International Publishing: Cham, Switzerland, 2017; pp. 509–516. [Google Scholar] [CrossRef]

- Cucinotta, F.; Guglielmino, E.; Sfravara, F.; Strasser, C. Numerical and experimental investigation of a planing Air Cavity Ship and its air layer evolution. Ocean Eng. 2018, 152, 130–144. [Google Scholar] [CrossRef]

- Cucinotta, F.; Nigrelli, V.; Sfravara, F. Numerical prediction of ventilated planing flat plates for the design of Air Cavity Ships. Int. J. Interact. Des. Manuf. (IJIDeM) 2018, 12, 537–548. [Google Scholar] [CrossRef]

- Cucinotta, F.; Mancini, D.; Sfravara, F.; Tamburrino, F. The Effect of Longitudinal Rails on an Air Cavity Stepped Planing Hull. J. Mar. Sci. Eng. 2021, 9, 470. [Google Scholar] [CrossRef]

- Butterworth, J.; Atlar, M.; Shi, W. Experimental analysis of an air cavity concept applied on a ship hull to improve the hull resistance. Ocean Eng. 2015, 110, 2–10. [Google Scholar] [CrossRef]

- Wu, H.; Ou, Y.-P. Experimental Study of Air Layer Drag Reduction with Bottom Cavity for A Bulk Carrier Ship Model. China Ocean Eng. 2019, 33, 554–562. [Google Scholar] [CrossRef]

- Wang, L.; Huang, B.; Qin, S.; Cao, L.; Fang, H.; Wu, D.; Li, C. Experimental investigation on ventilated cavity flow of a model ship. Ocean Eng. 2020, 214, 107546. [Google Scholar] [CrossRef]

- Song, K.-W.; Guo, C.-Y.; Wang, C.; Sun, C.; Li, P.; Zhong, R.-F. Experimental and numerical study on the scale effect of stern flap on ship resistance and flow field. Ships Offshore Struct. 2020, 15, 981–997. [Google Scholar] [CrossRef]

- Molland, A.F.; Turnock, S.R.; Hudson, D.A. Ship Resistance and Propulsion; Cambridge University Press: Cambridge, UK, 2017. [Google Scholar]

| Symbol | Definition | Unit |

|---|---|---|

| AM | midship section area under the design waterline | m2 |

| B | breadth | m |

| CB | block coefficient | |

| CM | midship section coefficient | |

| LPP | length between perpendiculars | m |

| LWL | waterline length | m |

| S | wetted surface area | m2 |

| T | draft | m |

| TF | fore draft | m |

| TA | aft draft | m |

| ∇ | molded volume | m3 |

| ρ | water density | kg/m3 |

| CFM | frictional resistance coefficient of ship model | |

| CFS | frictional resistance coefficient of full-scale ship | |

| CTM | total resistance coefficient of ship model | |

| CTS | total resistance coefficient of a real ship | |

| CR | residual resistance coefficient | |

| Fr | Froude number | |

| PE | effective power | kW |

| RT | total resistance of ship | |

| RM | total resistance of ship model | N |

| Re | Reynolds number | |

| RS | total resistance of full-scale ship | N |

| LM | length of model | m |

| LS | length of ship | m |

| VM | velocity of model | m2/s |

| VS | velocity of ship | kn |

| CF | frictional resistance coefficient | |

| ΔCF | roughness allowance coefficient | |

| υ | kinematic viscosity coefficient of water | m2/s |

| Symbol | Ship | Model | Unit |

|---|---|---|---|

| LWL | 25.0 | 2.5 | m |

| LPP | 25.0 | 2.5 | m |

| B | 5.8 | 0.58 | m |

| TF | 1.25 | 0.125 | m |

| TA | 2.38 | 0.238 | m |

| T | 1.851 | 0.185 | m |

| ∇ | 125.0 | 0.125 | m3 |

| AM | 7.17 | 0.0717 | m2 |

| S | 181.0 | 1.810 | m2 |

| CB | 0.465 | ||

| CM | 0.668 | ||

| LPP/B | 4.31 | ||

| B/T | 3.20 | ||

| Resistance (N) | ||||||

|---|---|---|---|---|---|---|

| VS (knots) | VM (m/s) | Fr | No Air 2.5° | 50 kPa 1.5° | 50 kPa 2.5° | 50 kPa 3.5° |

| 12 | 1.952 | 0.394 | 95.005 | 77.401 | 81.965 | 85.970 |

| 13 | 2.115 | 0.427 | 124.516 | 100.001 | 105.156 | 114.157 |

| 14 | 2.277 | 0.460 | 150.490 | 119.654 | 125.898 | 139.395 |

| 15 | 2.440 | 0.493 | 173.273 | 136.724 | 144.405 | 161.890 |

| 16 | 2.603 | 0.526 | 193.211 | 151.577 | 160.888 | 181.848 |

| 17 | 2.765 | 0.558 | 210.650 | 164.578 | 175.560 | 199.473 |

| 18 | 2.928 | 0.591 | 225.934 | 176.092 | 188.634 | 214.974 |

| 19 | 3.091 | 0.624 | 239.409 | 186.485 | 200.321 | 228.554 |

| 20 | 3.253 | 0.657 | 251.421 | 196.122 | 210.834 | 240.420 |

| 21 | 3.416 | 0.690 | 262.314 | 205.369 | 220.386 | 250.778 |

| 22 | 3.579 | 0.723 | 272.435 | 214.590 | 229.188 | 259.834 |

| 23 | 3.741 | 0.755 | 282.128 | 224.151 | 237.453 | 267.792 |

| 24 | 3.904 | 0.788 | 291.739 | 234.417 | 245.393 | 274.860 |

| 25 | 4.067 | 0.821 | 301.614 | 245.753 | 253.221 | 280.915 |

| 26 | 4.229 | 0.854 | 312.097 | 258.526 | 261.149 | 286.117 |

| 27 | 4.392 | 0.887 | 323.534 | 273.099 | 269.389 | 291.221 |

| 28 | 4.555 | 0.920 | 336.272 | 289.839 | 278.153 | 296.555 |

| 29 | 4.717 | 0.953 | 350.654 | 309.111 | 287.655 | 302.445 |

| 30 | 4.880 | 0.985 | 367.026 | 331.279 | 298.105 | 309.220 |

| 31 | 5.043 | 1.018 | 385.735 | 356.710 | 309.718 | 317.207 |

| Speed | Stern Inclination Angle (°) | ||

|---|---|---|---|

| (kn) | 1.5 | 2.5 | 3.5 |

| 28 | 289.59 | 278.17 | 296.53 |

| 29 | 309.08 | 287.58 | 302.51 |

| 30 (design) | 331.32 | 298.11 | 309.27 |

| 31 | 356.73 | 309.76 | 317.19 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, L.; Yu, J.; Yu, Y.; Wang, Z.; Wu, S.; Gao, R. An Experimental Study on the Resistance of a High-Speed Air Cavity Craft. J. Mar. Sci. Eng. 2023, 11, 1256. https://doi.org/10.3390/jmse11071256

Song L, Yu J, Yu Y, Wang Z, Wu S, Gao R. An Experimental Study on the Resistance of a High-Speed Air Cavity Craft. Journal of Marine Science and Engineering. 2023; 11(7):1256. https://doi.org/10.3390/jmse11071256

Chicago/Turabian StyleSong, Lin, Jianxing Yu, Yang Yu, Zhaoyu Wang, Shibo Wu, and Ruilong Gao. 2023. "An Experimental Study on the Resistance of a High-Speed Air Cavity Craft" Journal of Marine Science and Engineering 11, no. 7: 1256. https://doi.org/10.3390/jmse11071256

APA StyleSong, L., Yu, J., Yu, Y., Wang, Z., Wu, S., & Gao, R. (2023). An Experimental Study on the Resistance of a High-Speed Air Cavity Craft. Journal of Marine Science and Engineering, 11(7), 1256. https://doi.org/10.3390/jmse11071256