A Prediction Method of Ship Motion Based on LSTM Neural Network with Variable Step-Variable Sampling Frequency Characteristics

Abstract

1. Introduction

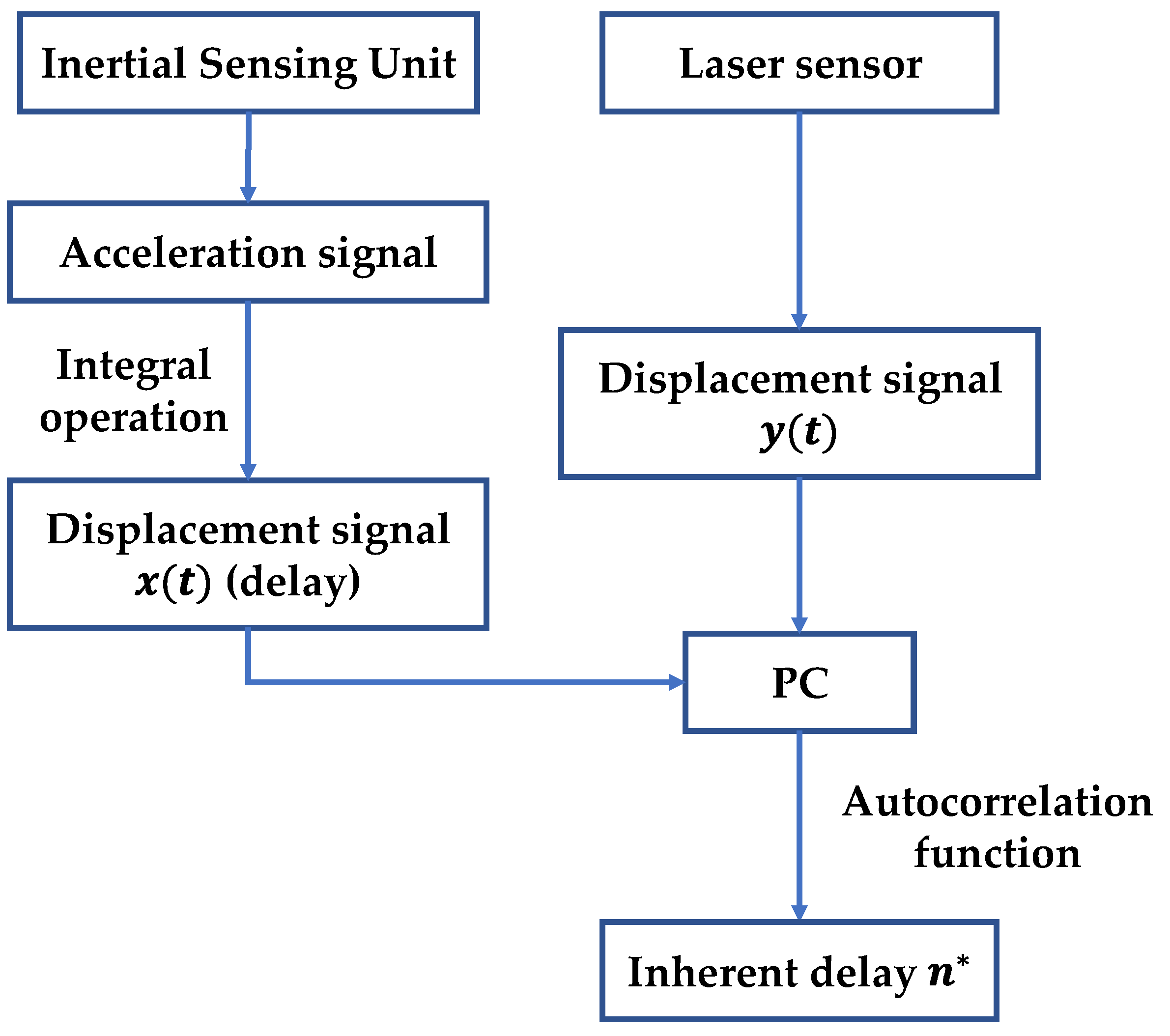

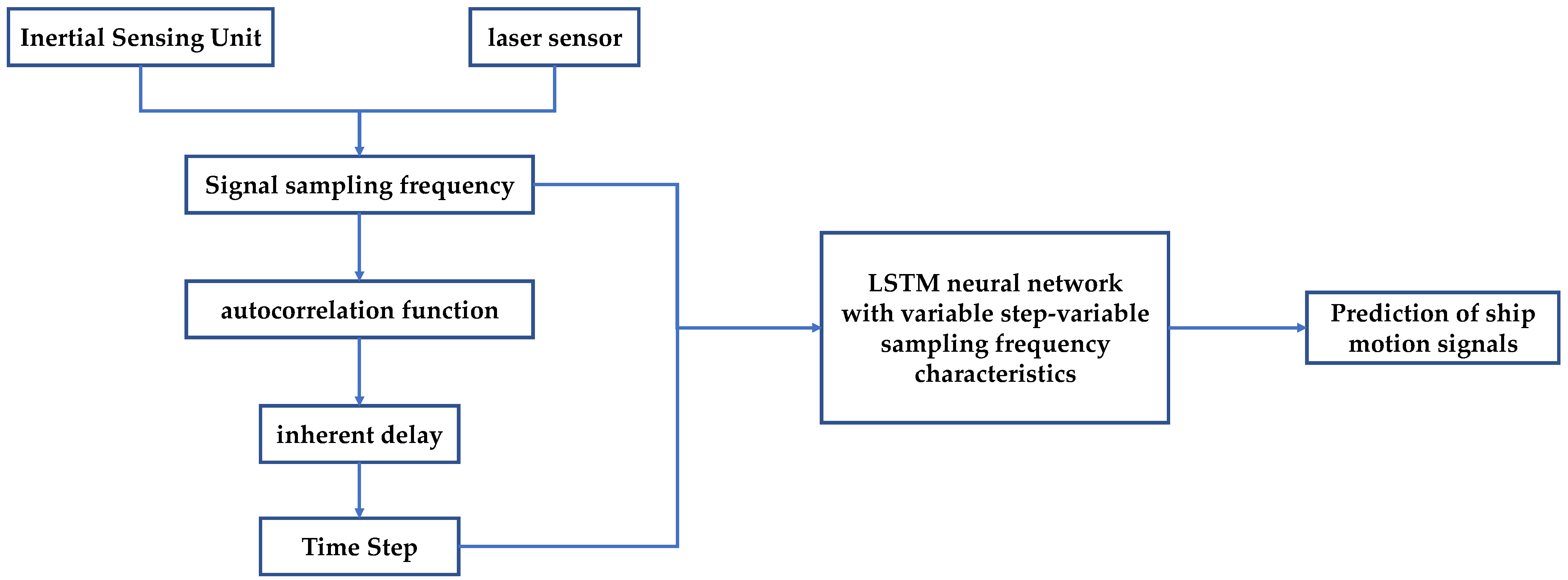

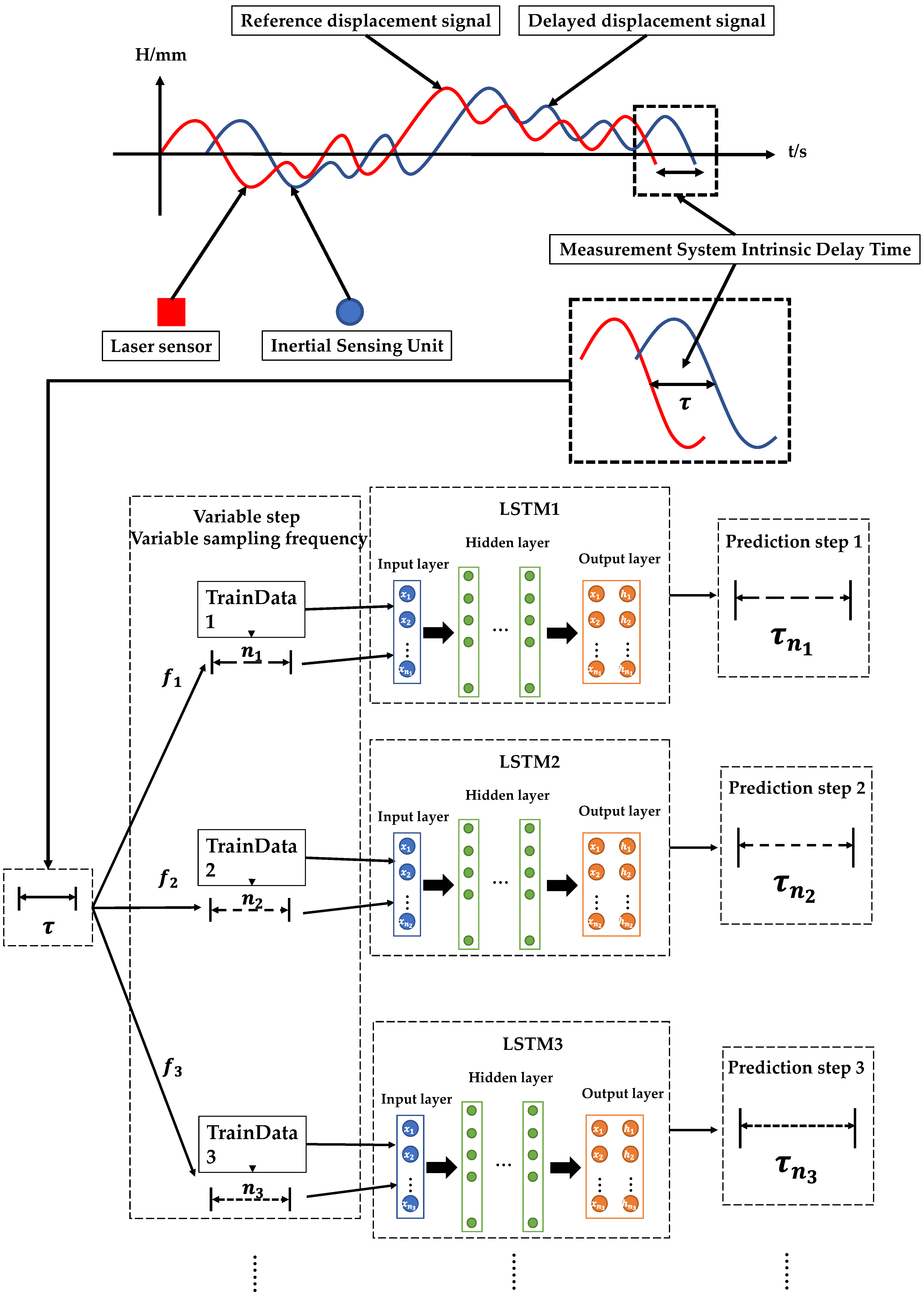

- An algorithm to eliminate the inherent time delay in the active heave compensation measurement system was proposed. Using the autocorrelation function, the inherent delay in the measurement system was solved by performing a cross-correlation analysis on the actual motion signal of the ship and the signal collected by the ship measurement system. According to the obtained inherent delay, the LSTM neural network with variable step-variable sampling frequency characteristics was built to predict the ship heave signal.

- According to the obtained inherent delay, a ship motion prediction method based on an LSTM neural network with variable step-variable sampling frequency characteristics was proposed to predict the ship heave signal. The formulation of the training set was improved according to the characteristics of the low-frequency motion of the ship. The training set not only included the short-term period characteristics of the low-frequency ship motion, but also included the long-term characteristics of the ship under the influence of the wave force. It made the predicted waveform signal more suitable for the prediction of ship movement.

2. Preliminary Work

2.1. Autocorrelation Function

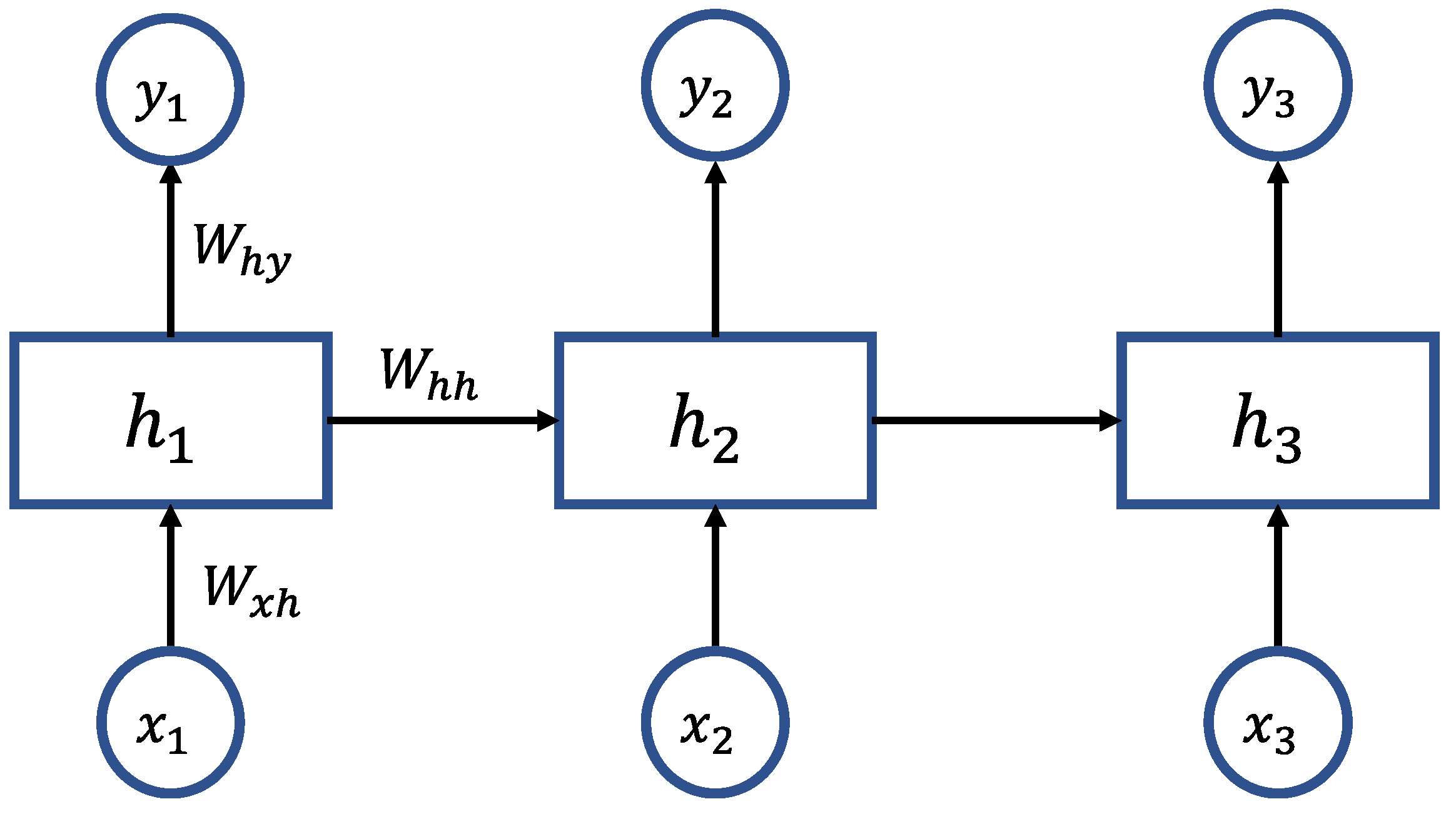

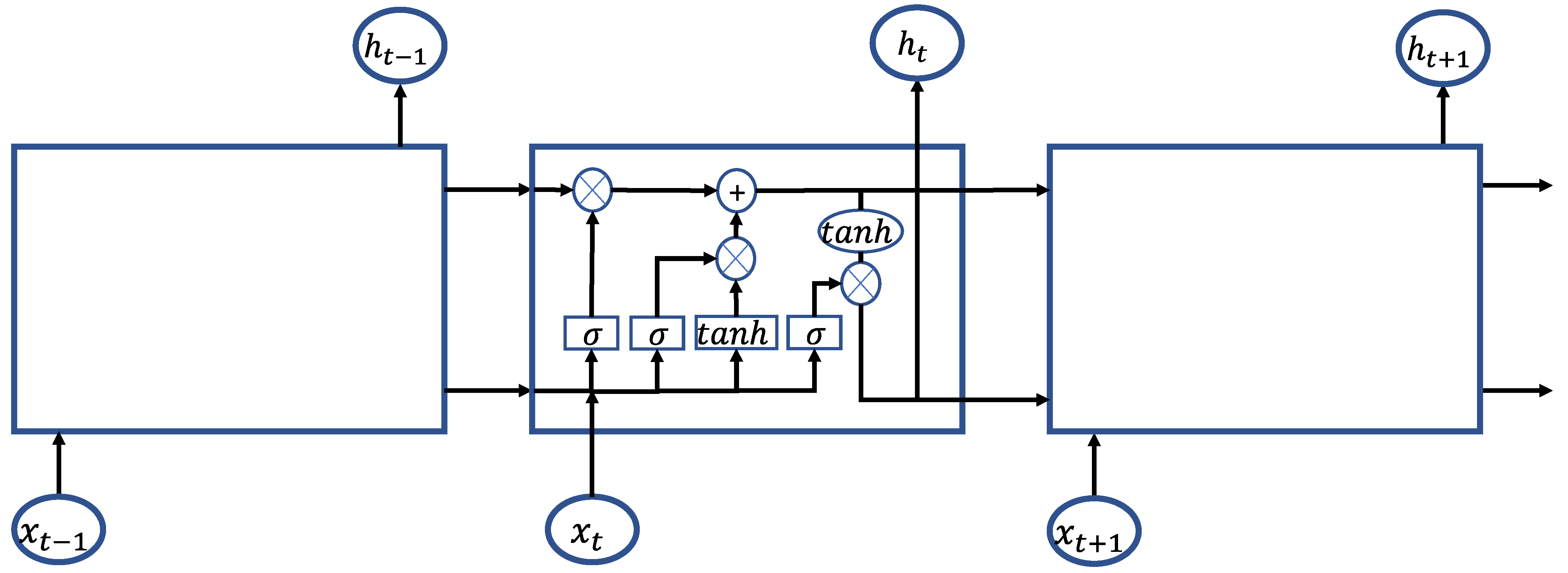

2.2. LSTM Neural Network

3. The Proposed Method

3.1. Solution of Inherent Delay in Ship Motion Measurement System

3.2. LSTM Neural Network with Variable Step-Variable Sampling Frequency Characteristics

4. Experimental Results and Analysis

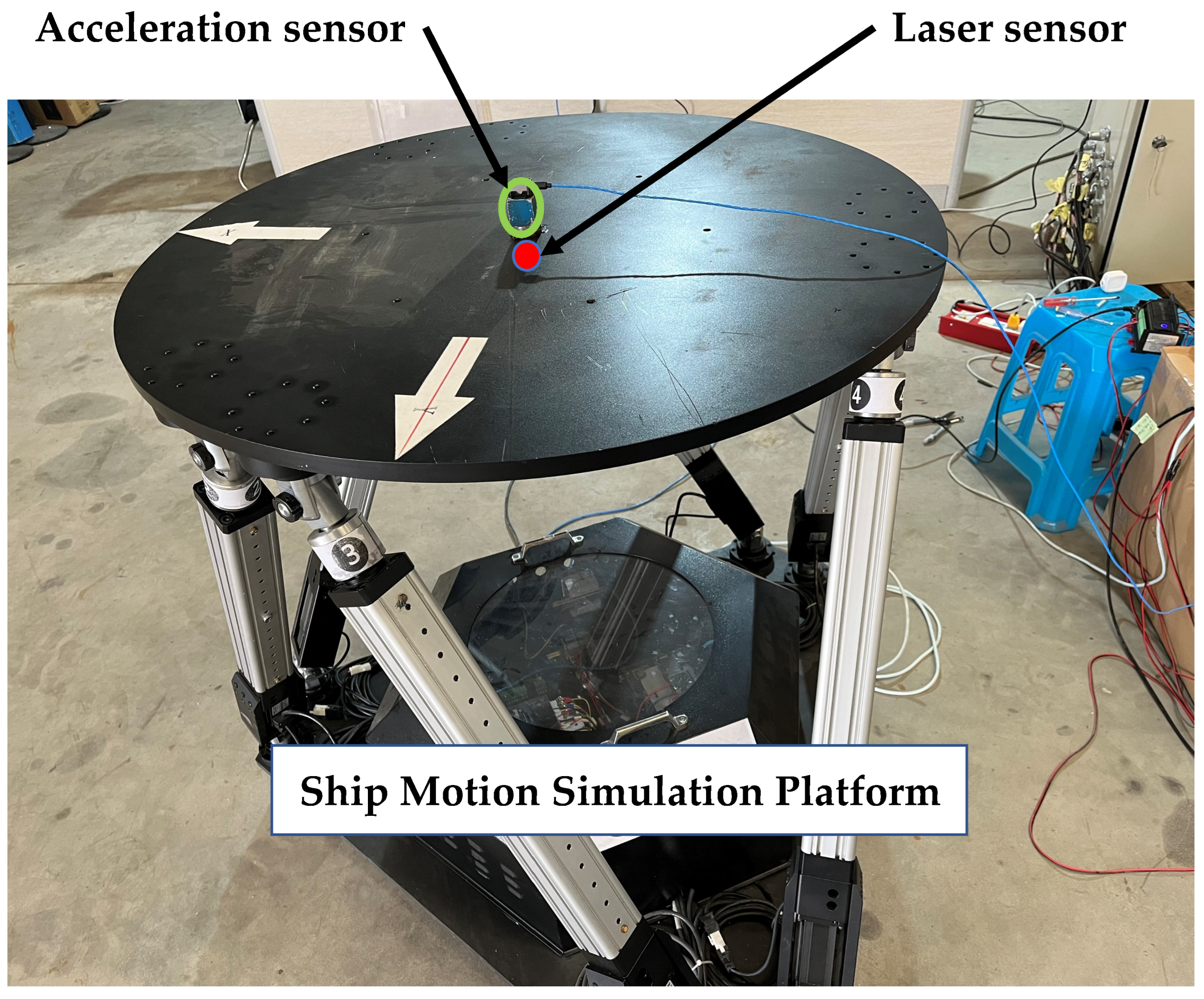

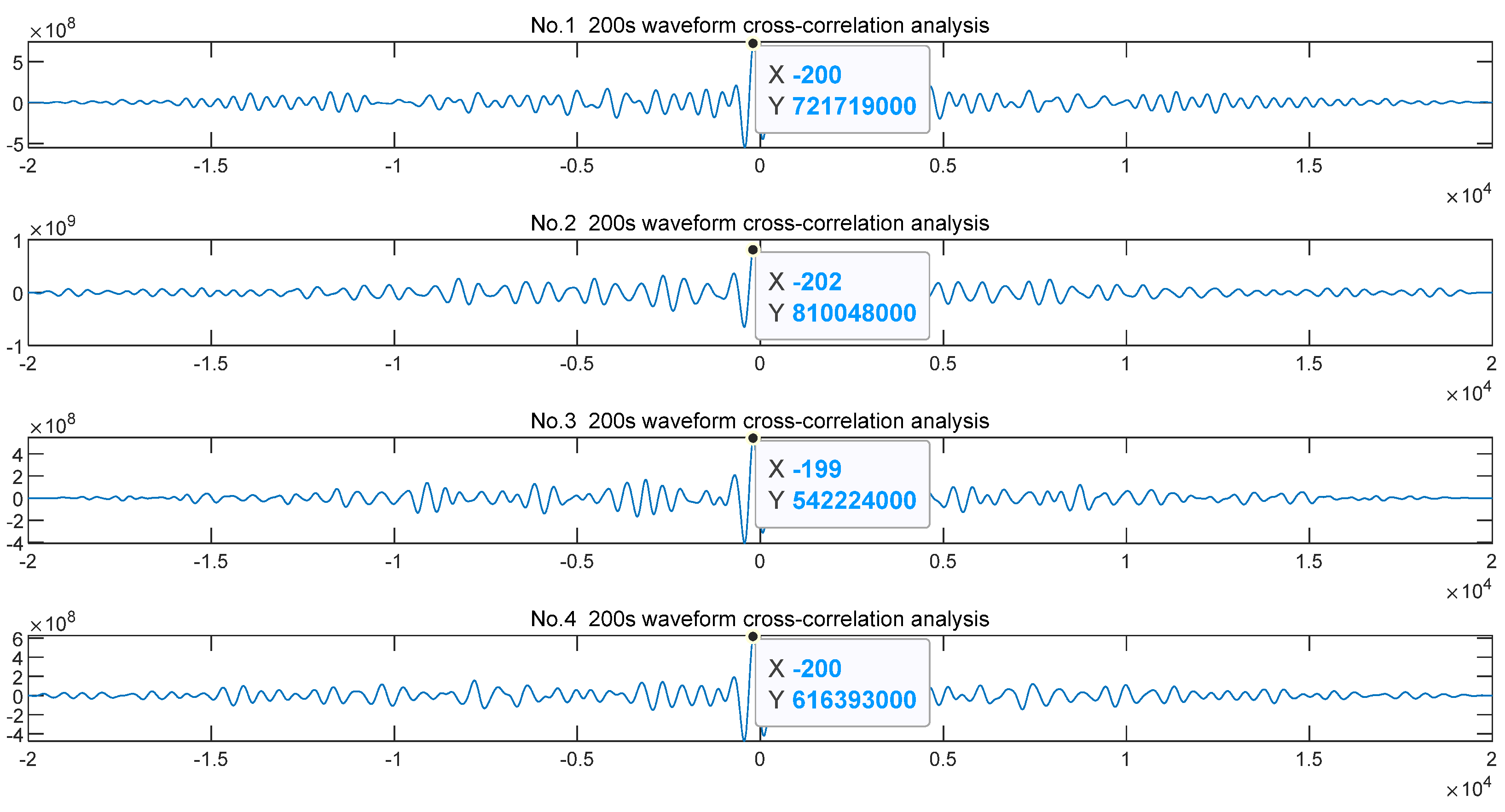

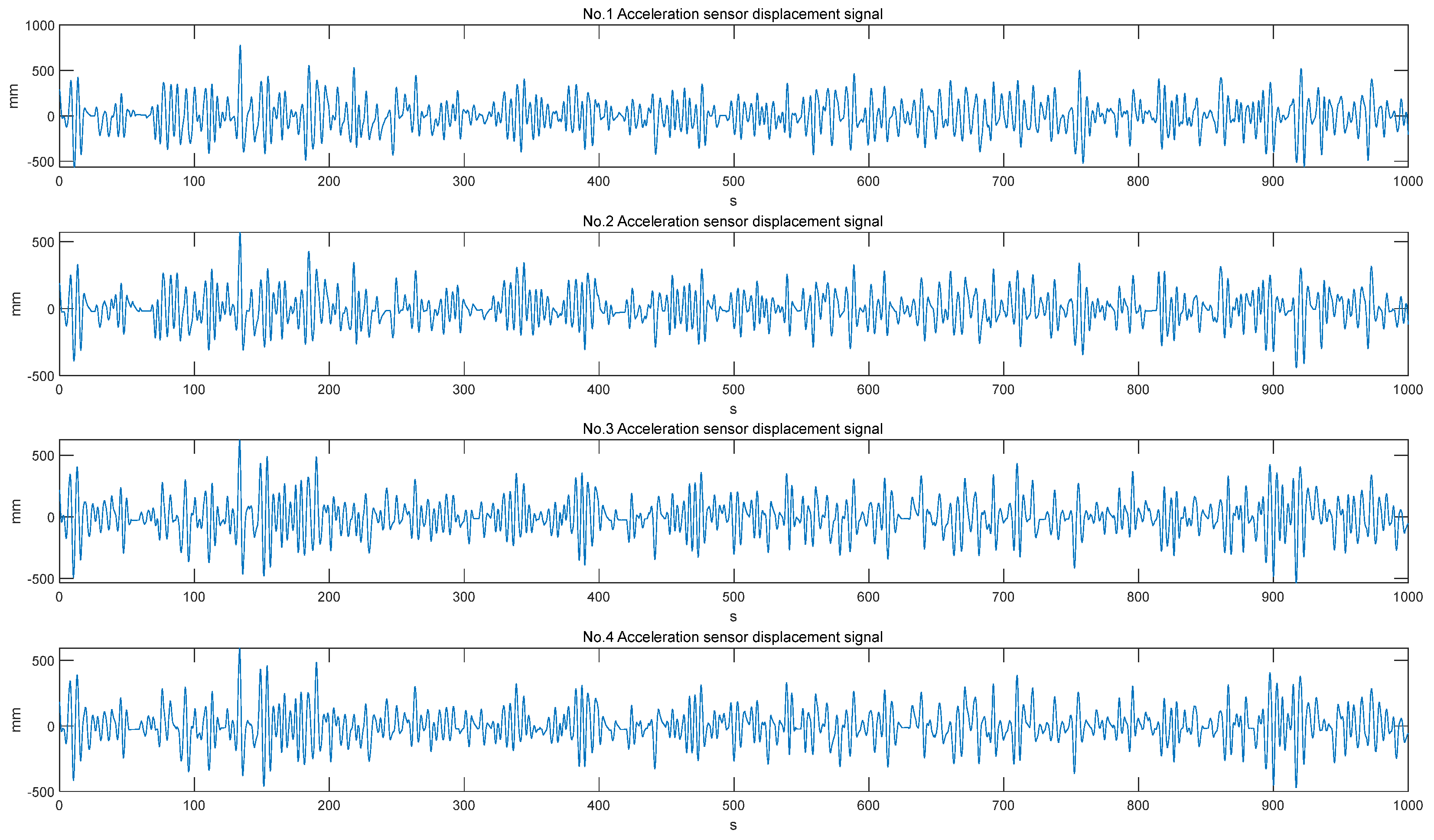

4.1. Calculation of Inherent Delay in Ship Motion Measurement System

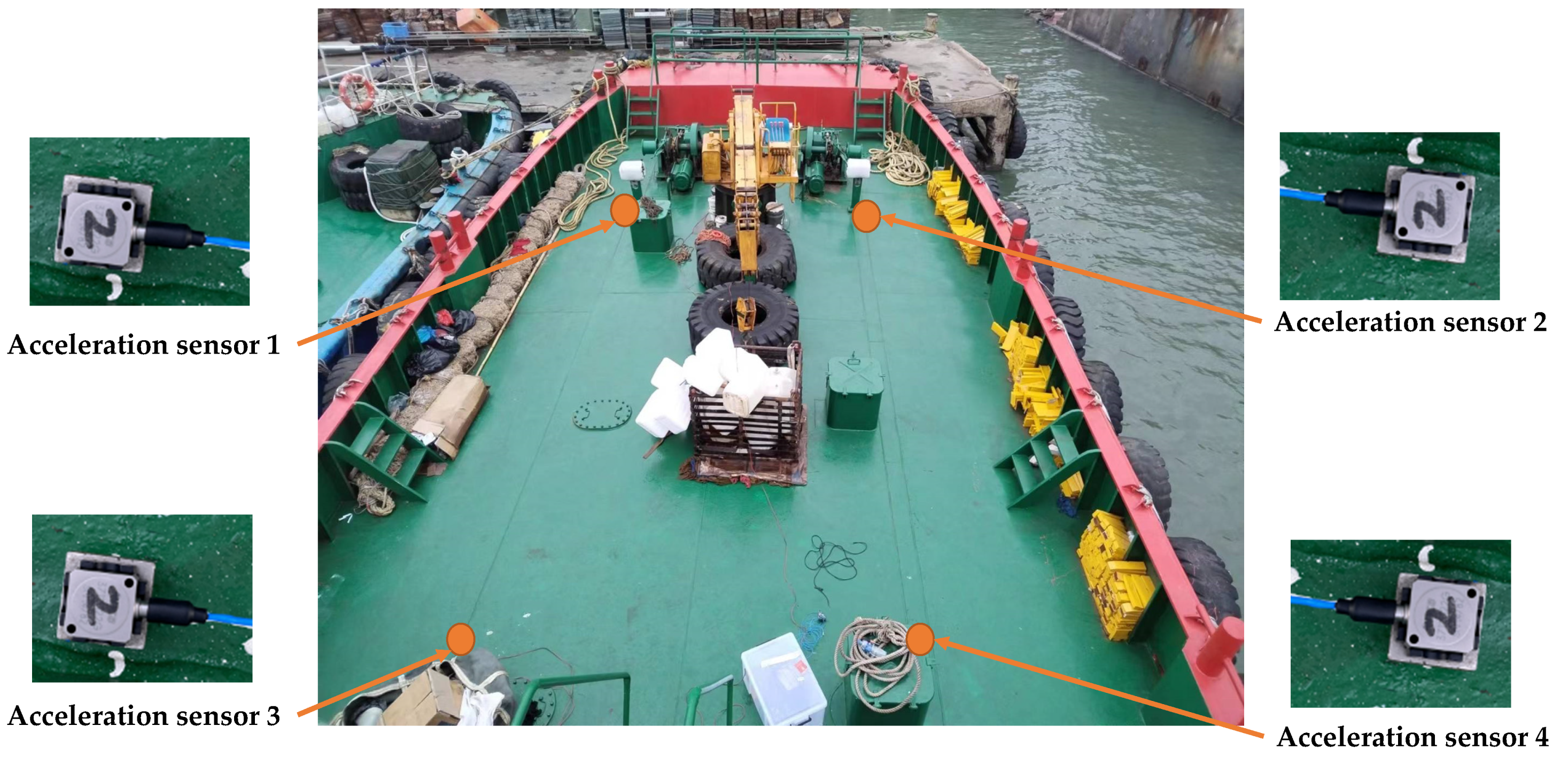

4.2. Calculation of Inherent Delay in Ship Motion Measurement System

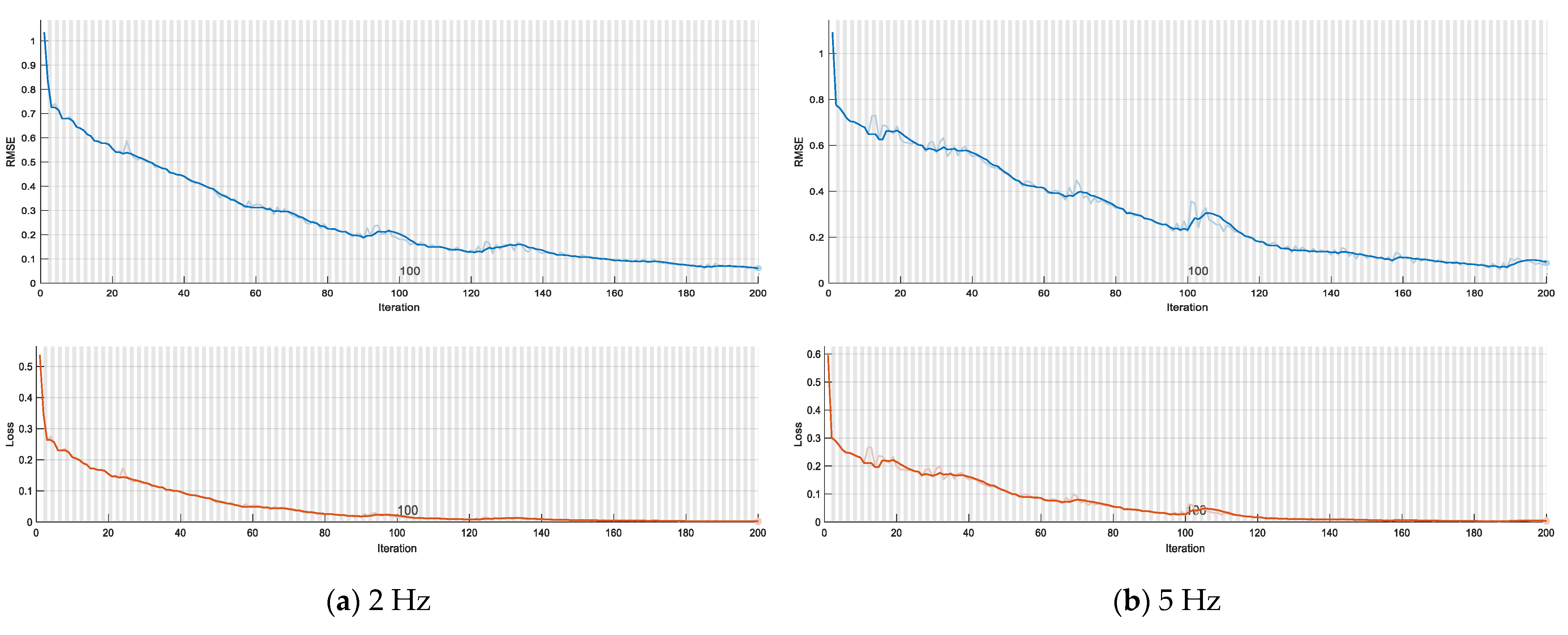

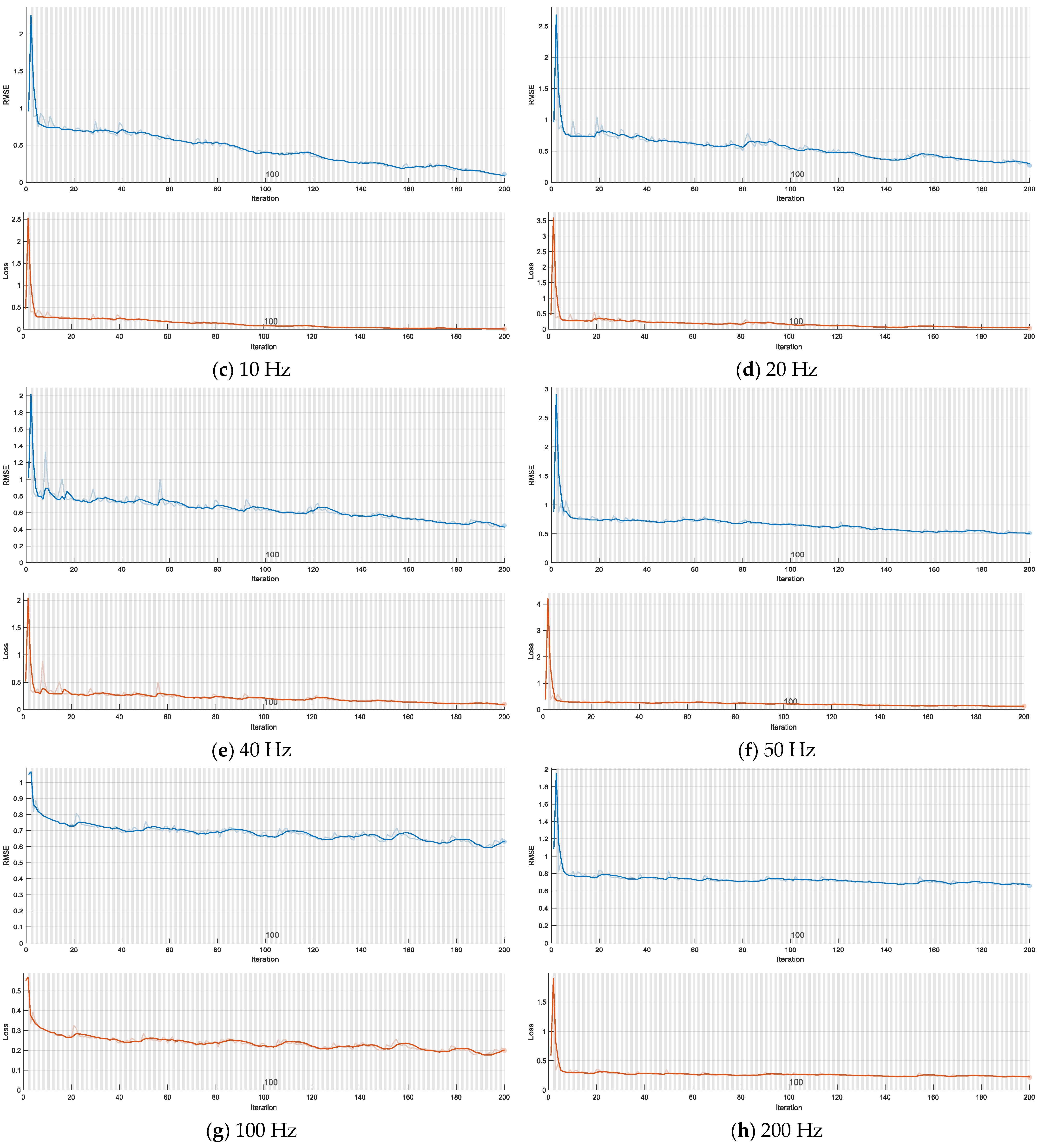

- Hz = 2, Step = 4, the average prediction error of the ship motion signal within 2 s of the inherent delay is 158.53 mm, and the average prediction error of the overall duration is 27.16 mm. The prediction accuracy of the model for the signal within the inherent delay is 72.66%;

- Hz = 5, Step = 10, the average prediction error of the ship motion signal within 2 s of the inherent delay is 102.41 mm, and the average prediction error of the overall duration is 25.58 mm. The prediction accuracy of the model for the signal within the inherent delay is 82.34%;

- Hz = 10, Step = 20, the average prediction error of the ship motion signal within 2 s of the inherent delay is 71.31 mm, and the average prediction error of the overall duration is 26.21 mm. The prediction accuracy of the model for the signal within the inherent delay is 87.71%;

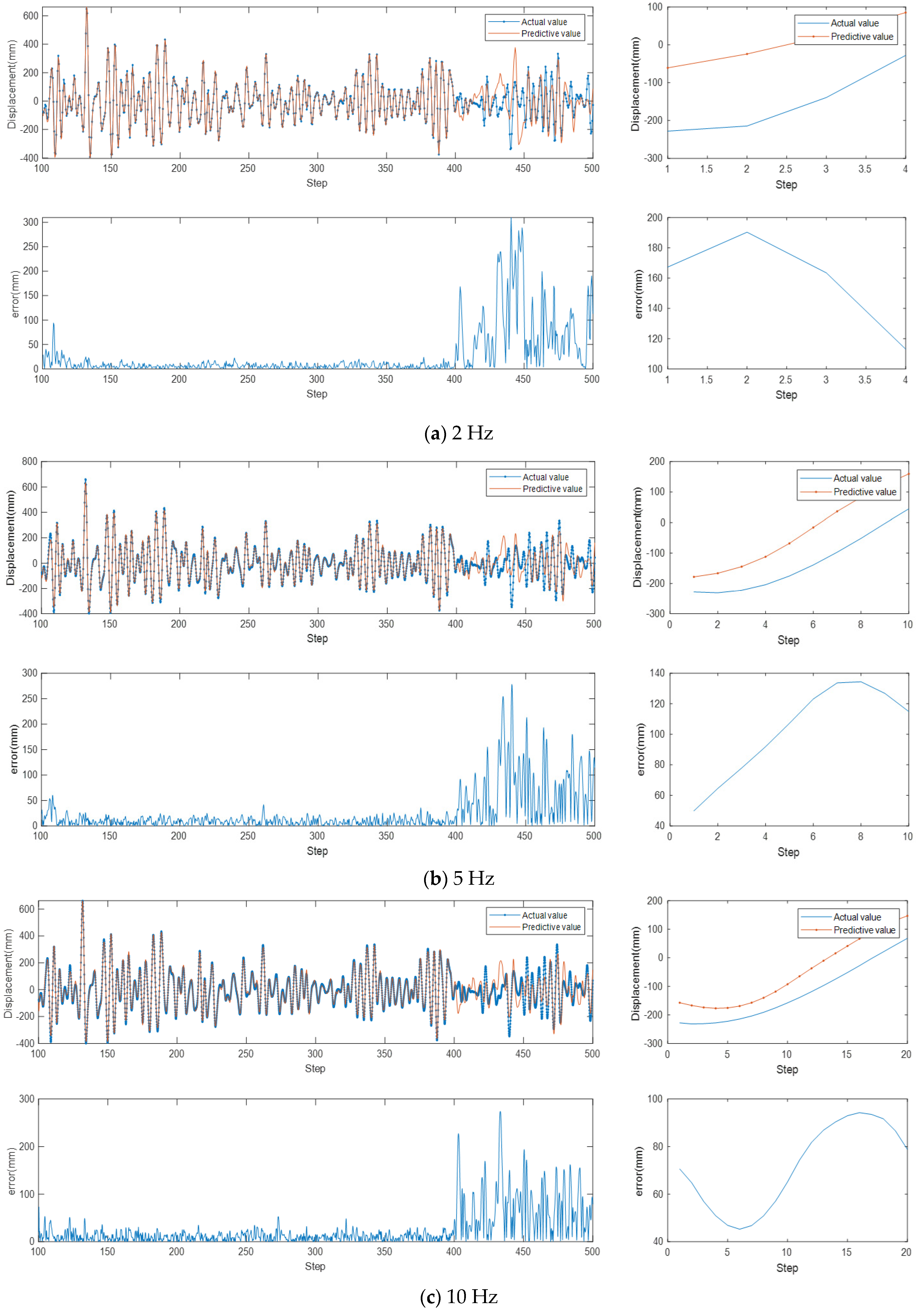

- Hz = 20, Step = 40, the average prediction error of the ship motion signal within 2 s of the inherent delay is 18.85 mm, and the average prediction error of the overall duration is 38.29 mm. The prediction accuracy of the model for the signal within the inherent delay is 96.75%;

- Hz = 40, Step = 80, the average prediction error of the ship motion signal within 2 s of the inherent delay is 22.38 mm, and the average prediction error of the overall duration is 51.78 mm. The prediction accuracy of the model for the signal within the inherent delay is 96.14%;

- Hz = 50, Step = 100, the average prediction error of the ship motion signal within 2 s of the inherent delay is 39.83 mm, and the average prediction error of the overall duration is 58.52 mm. The prediction accuracy of the model for the signal within the inherent delay is 93.13%;

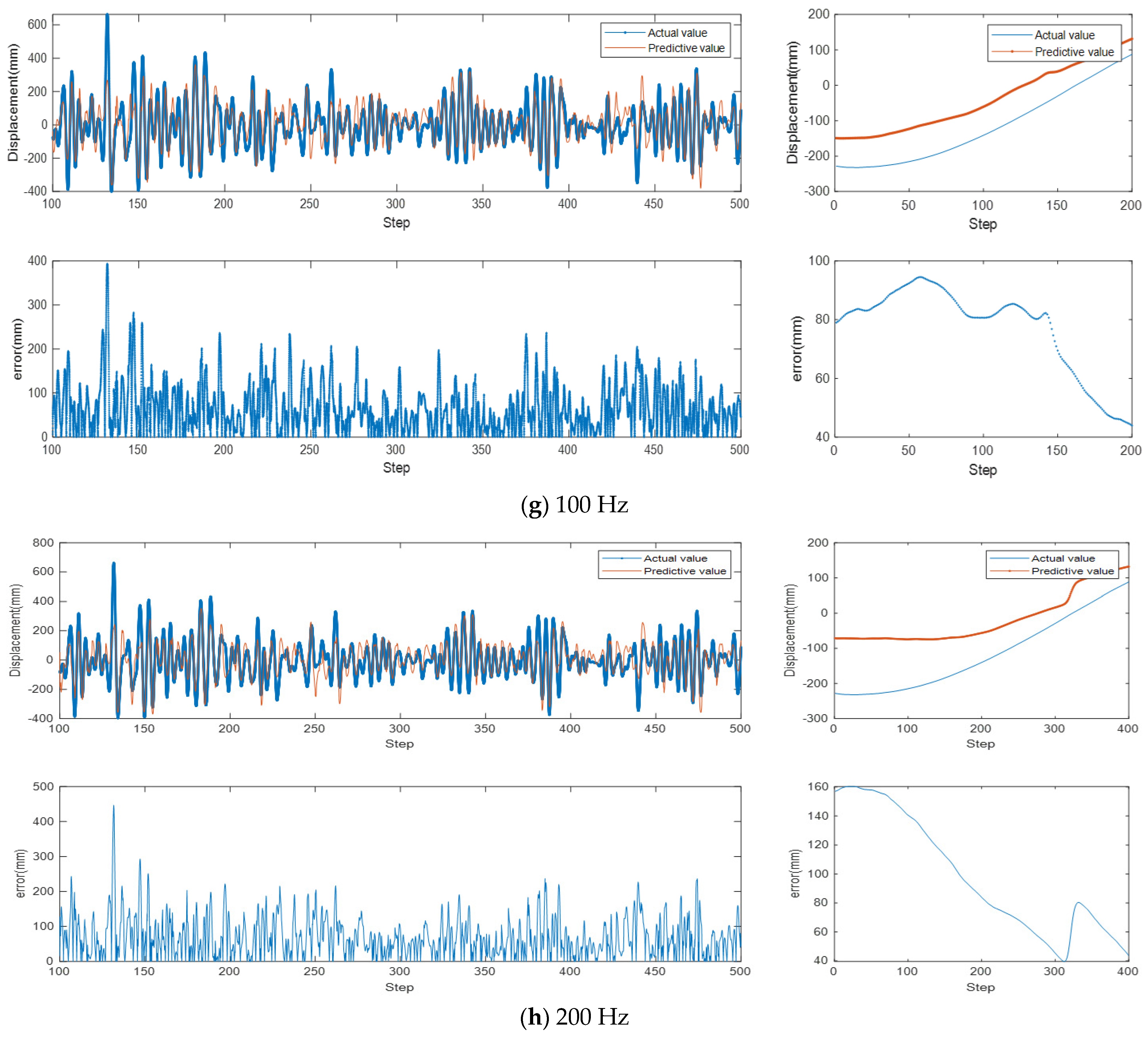

- Hz = 100, Step = 200, the average prediction error of the ship motion signal within 2 s of the inherent delay is 77.11 mm, and the average prediction error of the overall duration is 66.63 mm. The prediction accuracy of the model for the signal within the inherent delay is 86.71%;

- Hz = 200, Step = 400, the average prediction error of the ship motion signal within 2 s of the inherent delay is 98.32 mm, and the average prediction error of the overall duration is 69.98 mm. The prediction accuracy of the model for the signal within the inherent delay is 83.04%;

4.3. Experimental Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Woodacre, J.K.; Bauer, R.J.; Irani, R.A. A Review of Vertical Motion Heave Compensation Systems. Ocean Eng. 2015, 104, 140–154. [Google Scholar] [CrossRef]

- Hatleskog, J.T.; Dunnigan, M.W. Heave Compensation Simulation for Non-Contact Operations in Deep Water. In Proceedings of the OCEANS 2006, Boston, MA, USA, 18–21 September 2006; pp. 1–6. [Google Scholar]

- Do, K.D.; Pan, J. Nonlinear Control of an Active Heave Compensation System. Ocean Eng. 2008, 35, 558–571. [Google Scholar] [CrossRef]

- Küchler, S.; Sawodny, O. Nonlinear Control of an Active Heave Compensation System with Time-Delay. In Proceedings of the 2010 IEEE International Conference on Control Applications, Yokohama, Japan, 8–10 September 2010; pp. 1313–1318. [Google Scholar]

- Kyllingstad, A. Method and Apparatus for Active Heave Compensation. U.S. Patent 8,265,811, 11 September 2012. [Google Scholar]

- Küchler, S.; Mahl, T.; Neupert, J.; Schneider, K.; Sawodny, O. Active Control for an Offshore Crane Using Prediction of the Vessel’s Motion. IEEE/ASME Trans. Mechatron. 2010, 16, 297–309. [Google Scholar] [CrossRef]

- Liu, J.; Chen, X. Adaptive Control Based on Neural Network and Beetle Antennae Search Algorithm for an Active Heave Compensation System. Int. J. Control Autom. Syst. 2022, 20, 515–525. [Google Scholar] [CrossRef]

- Richter, M.; Arnold, E.; Schneider, K.; Eberharter, J.K.; Sawodny, O. Model Predictive Trajectory Planning with Fallback-Strategy for an Active Heave Compensation System. In Proceedings of the 2014 American Control Conference, Portland, OR, USA, 4–6 June 2014; pp. 1919–1924. [Google Scholar]

- Chu, Y.; Li, G.; Zhang, H. Incorporation of Ship Motion Prediction into Active Heave Compensation for Offshore Crane Operation. In Proceedings of the 2020 15th IEEE Conference on Industrial Electronics and Applications (ICIEA), Kristiansand, Norway, 9–13 November 2020; pp. 1444–1449. [Google Scholar]

- Hu, L.; Zhang, M.; Yuan, Z.M.; Zheng, H.; Lv, W. Predictive control of a heaving compensation system based on machine learning prediction algorithm. J. Mar. Sci. Eng. 2023, 11, 821. [Google Scholar] [CrossRef]

- Richter, M.; Schaut, S.; Walser, D.; Schneider, K.; Sawodny, O. Experimental Validation of an Active Heave Compensation System: Estimation, Prediction and Control. Control Eng. Pract. 2017, 66, 1–12. [Google Scholar] [CrossRef]

- Neupert, J.; Mahl, T.; Haessig, B.; Sawodny, O.; Schneider, K. A Heave Compensation Approach for Offshore Cranes. In Proceedings of the 2008 American Control Conference, Seattle, WA, USA, 11–13 June 2008; pp. 538–543. [Google Scholar]

- Woodacre, J.K.; Bauer, R.J.; Irani, R. Hydraulic Valve-Based Active-Heave Compensation Using a Model-Predictive Controller with Non-Linear Valve Compensations. Ocean Eng. 2018, 152, 47–56. [Google Scholar] [CrossRef]

- Shi, B.; Xian, L.; Wu, Q.; Zhang, Y. Active Heave Compensation Prediction Research for Deep Sea Homework Crane Based on KPSO-SVR. In Proceedings of the 33rd Chinese Control Conference, Nanjing, China, 28–30 July 2014; pp. 7637–7642. [Google Scholar]

- Li, G.; Kawan, B.; Wang, H.; Zhang, H. Neural-Network-Based Modelling and Analysis for Time Series Prediction of Ship Motion. Ship Technol. Res. 2017, 64, 30–39. [Google Scholar] [CrossRef]

- De Masi, G.; Gaggiotti, F.; Bruschi, R.; Venturi, M. Ship Motion Prediction by Radial Basis Neural Networks. In Proceedings of the 2011 IEEE Workshop on Hybrid Intelligent Models and Applications, Paris, France, 11–15 April 2011; pp. 28–32. [Google Scholar]

- Skulstad, R.; Li, G.; Fossen, T.I.; Vik, B.; Zhang, H. A Hybrid Approach to Motion Prediction for Ship Docking—Integration of a Neural Network Model into the Ship Dynamic Model. IEEE Trans. Instrum. Meas. 2020, 70, 1–11. [Google Scholar] [CrossRef]

- Khan, A.; Bil, C.; Marion, K.E. Theory and Application of Artificial Neural Networks for the Real Time Prediction of Ship Motion. In Proceedings of the Knowledge-Based Intelligent Information and Engineering Systems: 9th International Conference, KES 2005, Melbourne, Australia, 14–16 September 2005; Proceedings, Part I 9. Springer: Berlin/Heidelberg, Germany, 2005; pp. 1064–1069. [Google Scholar]

- Yao, Y.; Han, L.; Wang, J. Lstm-Pso: Long Short-Term Memory Ship Motion Prediction Based on Particle Swarm Optimization. In Proceedings of the 2018 IEEE CSAA Guidance, Navigation and Control Conference (CGNCC), Xiamen, China, 10–12 August 2018; pp. 1–5. [Google Scholar]

- Zhang, G.; Tan, F.; Wu, Y. Ship Motion Attitude Prediction Based on an Adaptive Dynamic Particle Swarm Optimization Algorithm and Bidirectional LSTM Neural Network. IEEE Access 2020, 8, 90087–90098. [Google Scholar] [CrossRef]

- Liu, Y.; Duan, W.; Huang, L.; Duan, S.; Ma, X. The Input Vector Space Optimization for LSTM Deep Learning Model in Real-Time Prediction of Ship Motions. Ocean Eng. 2020, 213, 107681. [Google Scholar] [CrossRef]

- Duan, S.; Ma, Q.; Huang, L.; Ma, X. A LSTM Deep Learning Model for Deterministic Ship Motions Estimation Using Wave-Excitation Inputs. In Proceedings of the 29th International Ocean and Polar Engineering Conference, Honolulu, HI, USA, 16–21 June 2019. [Google Scholar]

- Sun, Q.; Tang, Z.; Gao, J.; Zhang, G. Short-Term Ship Motion Attitude Prediction Based on LSTM and GPR. Appl. Ocean Res. 2022, 118, 102927. [Google Scholar] [CrossRef]

- Zhang, T.; Zheng, X.-Q.; Liu, M.-X. Multiscale Attention-Based LSTM for Ship Motion Prediction. Ocean Eng. 2021, 230, 109066. [Google Scholar] [CrossRef]

- Su, Y.; Lin, J.; Zhao, D.; Guo, C.; Wang, C.; Guo, H. Real-Time Prediction of Large-Scale Ship Model Vertical Acceleration Based on Recurrent Neural Network. J. Mar. Sci. Eng. 2020, 8, 777. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, H.; Zou, D.; Fu, H. Ship Roll Prediction Algorithm Based on Bi-LSTM-TPA Combined Model. J. Mar. Sci. Eng. 2021, 9, 387. [Google Scholar] [CrossRef]

- Huang, L.; Deng, X.; Bo, Y.; Zhang, Y.; Wang, P. Evolutionary Optimization Assisted Delayed Deep Cycle Reservoir Modeling Method with Its Application to Ship Heave Motion Prediction. ISA Trans. 2022, 126, 638–648. [Google Scholar] [CrossRef] [PubMed]

- Guo, W.; Piao, S.; Guo, J.; Lei, Y.; Iqbal, K. Passive Detection of Ship-Radiated Acoustic Signal Using Coherent Integration of Cross-Power Spectrum with Doppler and Time Delay Compensations. Sensors 2020, 20, 1767. [Google Scholar] [CrossRef] [PubMed]

- Gao, F.; Xu, T.; Wang, N.; He, Y.; Luo, X. A Shipborne Experiment Using a Dual-Antenna Reflectometry System for GPS/BDS Code Delay Measurements. J. Geod 2020, 94, 88. [Google Scholar] [CrossRef]

- Hu, T.; Xu, Q.; Huang, G.; Nie, Y. Adaptive Time Delay Compensation Realization for Remote Ship Main Engine Rotation Measurement. In Proceedings of the 2016 International Conference on Education, Management and Computer Science, Shenyang, China, 27–29 May 2016; Atlantis Press: Amsterdam, The Netherlands, 2016; pp. 34–38. [Google Scholar]

- Abebe, M.; Noh, Y.; Kang, Y.-J.; Seo, C.; Kim, D.; Seo, J. Ship Trajectory Planning for Collision Avoidance Using Hybrid ARIMA-LSTM Models. Ocean Eng. 2022, 256, 111527. [Google Scholar] [CrossRef]

- Zhang, Z.; Ni, G.; Xu, Y. Ship Trajectory Prediction Based on LSTM Neural Network. In Proceedings of the 2020 IEEE 5th Information Technology and Mechatronics Engineering Conference (ITOEC), Chongqing, China, 12–14 June 2020; pp. 1356–1364. [Google Scholar]

- Kaklis, D.; Eirinakis, P.; Giannakopoulos, G.; Spyropoulos, C.; Varelas, T.J.; Varlamis, I. A Big Data Approach for Fuel Oil Consumption Estimation in the Maritime Industry. In Proceedings of the 2022 IEEE Eighth International Conference on Big Data Computing Service and Applications (BigDataService), Newark, CA, USA, 15–18 August 2022; pp. 39–47. [Google Scholar]

- Kaklis, D.; Varelas, T.J.; Varlamis, I.; Eirinakis, P.; Giannakopoulos, G.; Spyropoulos, C. V From STEAM to Machine: Emissions Control in the Shipping 4.0 Era. In Proceedings of the SNAME 8th International Symposium on Ship Operations, Management and Economics, Athens, Greece, 7–8 March 2023. [Google Scholar]

- Kaklis, D.; Varlamis, I.; Giannakopoulos, G.; Spyropoulos, C.; Varelas, T.J. Online Training for Fuel Oil Consumption Estimation: A Data Driven Approach. In Proceedings of the 2022 23rd IEEE International Conference on Mobile Data Management (MDM), Paphos, Cyprus, 6–9 June 2022; pp. 394–400. [Google Scholar]

| No. | Sampling Frequency | Long-Term Characteristics | Short-Term Characteristics | Prediction Step |

|---|---|---|---|---|

| 1 | 2 Hz | 400 s × 2 Hz | 2 s × 2 Hz | 4 |

| 2 | 5 Hz | 400 s × 5 Hz | 2 s × 5 Hz | 10 |

| 3 | 10 Hz | 400 s × 10 Hz | 2 s × 10 Hz | 20 |

| 4 | 20 Hz | 400 s × 20 Hz | 2 s × 20 Hz | 40 |

| 5 | 40 Hz | 400 s × 40 Hz | 2 s × 40 Hz | 80 |

| 6 | 50 Hz | 400 s × 50 Hz | 2 s × 50 Hz | 100 |

| 7 | 100 Hz | 400 s × 100 Hz | 2 s × 100 Hz | 200 |

| 8 | 200 Hz | 400 s × 200 Hz | 2 s × 200 Hz | 400 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, C.; Hu, X. A Prediction Method of Ship Motion Based on LSTM Neural Network with Variable Step-Variable Sampling Frequency Characteristics. J. Mar. Sci. Eng. 2023, 11, 919. https://doi.org/10.3390/jmse11050919

Han C, Hu X. A Prediction Method of Ship Motion Based on LSTM Neural Network with Variable Step-Variable Sampling Frequency Characteristics. Journal of Marine Science and Engineering. 2023; 11(5):919. https://doi.org/10.3390/jmse11050919

Chicago/Turabian StyleHan, Chongyang, and Xiong Hu. 2023. "A Prediction Method of Ship Motion Based on LSTM Neural Network with Variable Step-Variable Sampling Frequency Characteristics" Journal of Marine Science and Engineering 11, no. 5: 919. https://doi.org/10.3390/jmse11050919

APA StyleHan, C., & Hu, X. (2023). A Prediction Method of Ship Motion Based on LSTM Neural Network with Variable Step-Variable Sampling Frequency Characteristics. Journal of Marine Science and Engineering, 11(5), 919. https://doi.org/10.3390/jmse11050919