New Steps to Deep-Water Hydrate Long-Term Mining by Formation Stabilization

Abstract

:1. Introduction

2. Risk Analysis of the Gas Hydrate Exploitation

2.1. Hydrate Trial Production Plan

- Thermal recovery [23]

- 2.

- Depressurization [24]

- 3.

- Chemical reagents [25]

- 4.

- Gas displacement [26]

2.2. Accidents Occurred in Hydrate Trial Production

2.3. Analysis of the Causes and Factors of Trial Production Accidents

- Mechanical properties

- 2.

- Hydrate decomposition during production

- Hydrate as cement

- Hydrate that occurs in pores

- 3.

- Hydrate saturation

3. Design Ideas and Methods

3.1. New Ideas for Long-Term Production of Deep-Water Hydrate Reservoirs

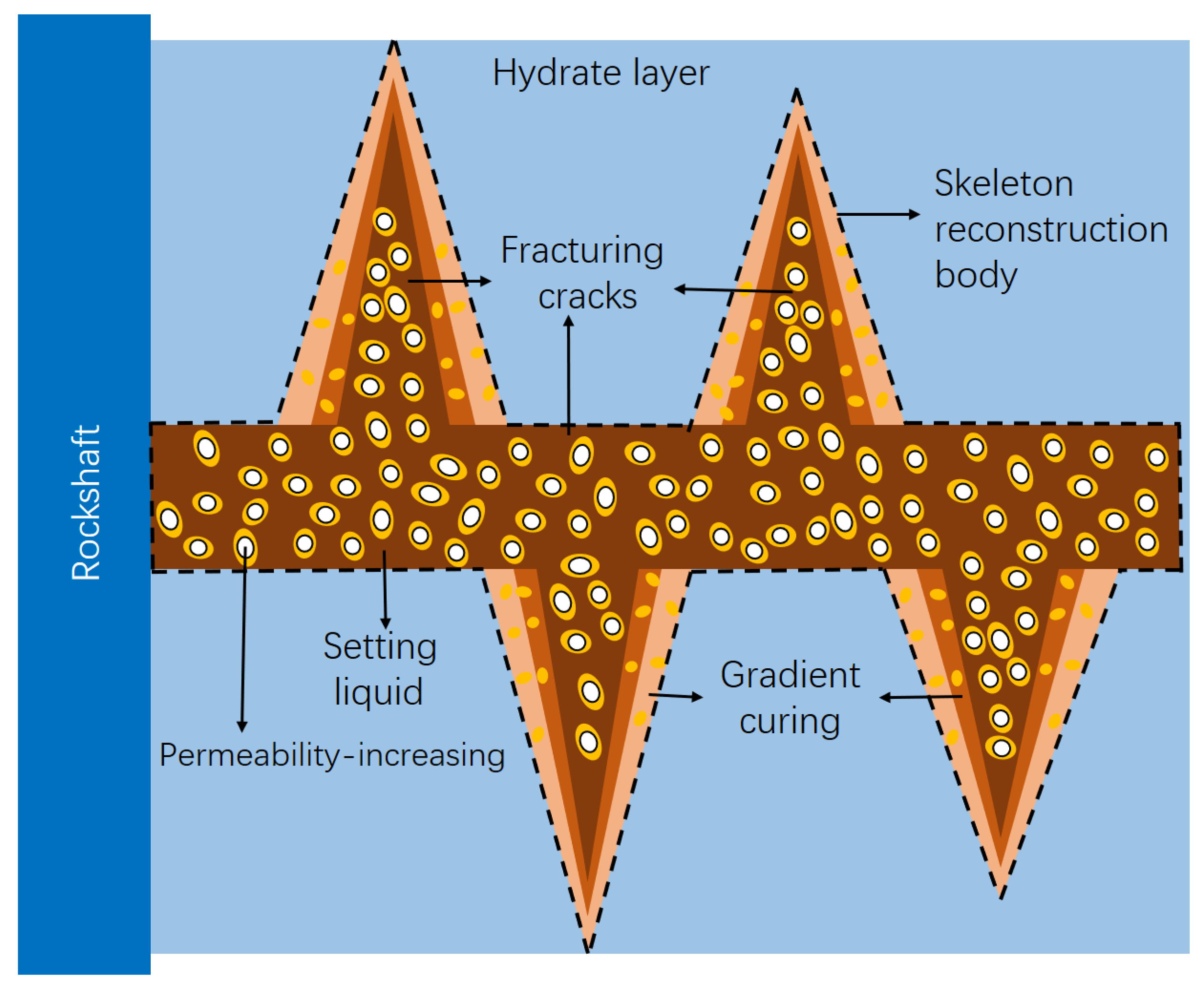

3.2. Effect of Skeleton Reconstruction Body on Sand Control and Collapse in Hydrate Layers

- Effect of the skeleton reconstruction body on sand control

- Safe

- Economical

- Controllable

- 2.

- Effect of the skeleton reconstruction body on collapse

4. Results and Discussion

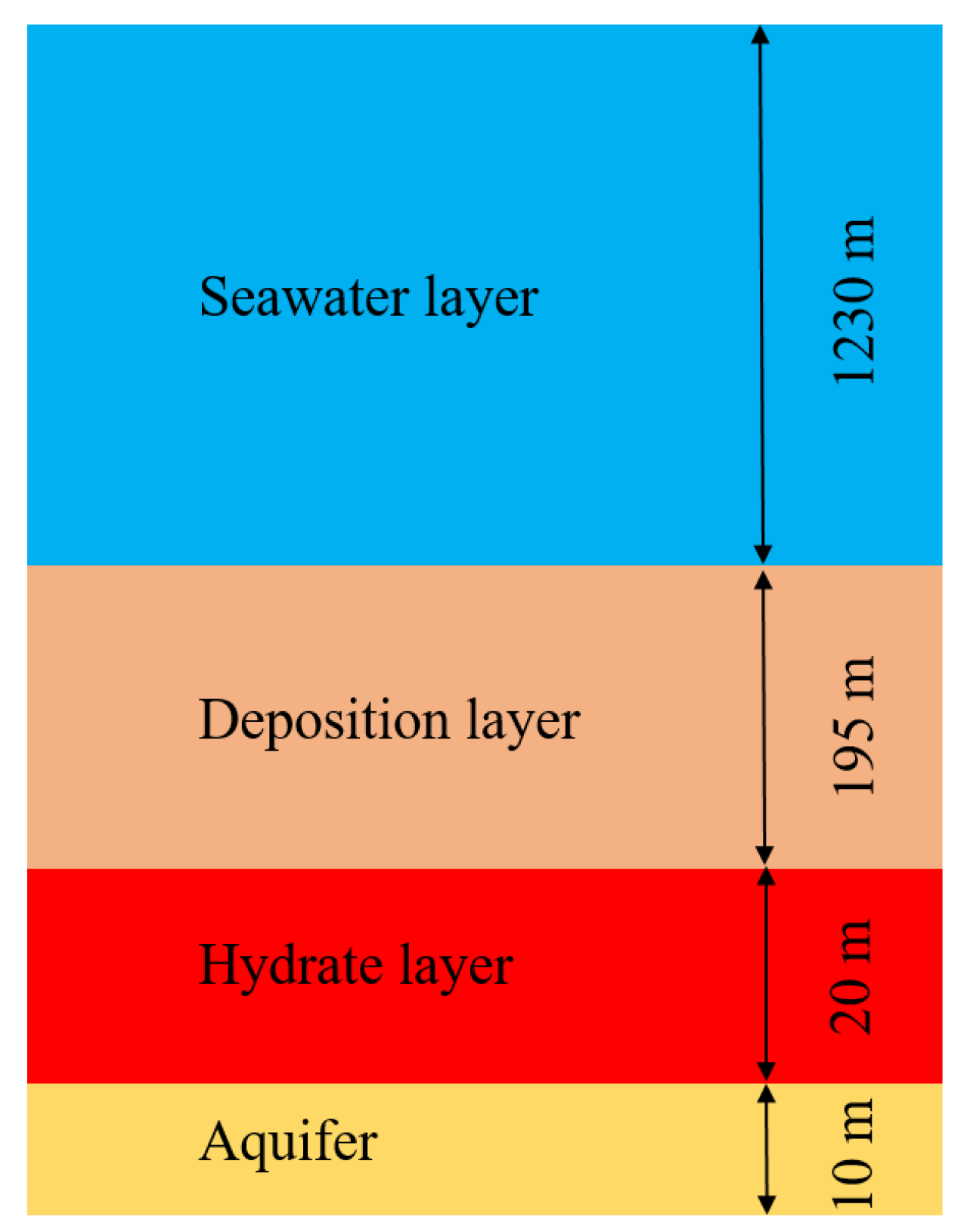

4.1. Overview of Study Strata

4.2. Design Method and Parameter Design for Performance Parameters of the Skeleton Reconstruction Body

- Pore pressure

- 2.

- Overburden pressure

- 3.

- Framework support stress of the hydrate layer

- 4.

- Design of key parameters for the skeleton reconstruction body

- Strength of the skeleton reconstruction body

- Permeability of the skeleton reconstruction body

- Pore size of the skeleton reconstruction body

4.3. Fracturing and Grouting Process

- Cycle and flush the pipeline to check the water supply and pipeline connection of the fracturing pump;

- High-pressure pipeline pressure test. Close the main gate of the wellhead and hold the pressure on the high-pressure pipeline, wellhead, connecting thread, oil union, etc., on the ground for 2–3 min without puncturing or leaking, which is considered qualified;

- After passing the pressure test, open the main gate and use a fracturing truck to squeeze the reagent solution into the target layer until the pressure stabilizes. The purpose is to check whether the downhole string and tools are normal;

- Calculate the overall amount of solidified liquid based on the reservoir operating conditions, which can be configured in batches based on the total amount and speed of pumping, combined with parameters such as the thickening time of the solidified liquid;

- Design the pump injection pressure based on the pressure of the hydrate reservoir and the strength of the hydrate layer;

- After the trial pressure and displacement are stabilized, fracturing fluid is injected into the well to rapidly increase the bottom hole pressure. When the bottom hole pressure exceeds the formation fracture pressure, fractures will form in the formation;

- After fracturing, the well needs to be shut in for a period of time, which depends on the final pumping time and initial setting time of the solidified liquid;

- After the solidification liquid solidifies, the displacement liquid will be immediately pumped in to displace all the liquid in the ground pipeline and wellbore into the cracks, preventing the remaining solidification liquid from depositing at the bottom of the well and forming blockages;

- Wash the well and clean the remaining solidified liquid system inside the well.

5. Conclusions

- A reinforcement theory for deep-water hydrate reservoirs is proposed, in which solidified liquid is injected into the hydrate formation through fracturing and grouting. The liquid solidifies to form a skeleton reconstruction body and simultaneously permeates and diffuses to the surrounding area in the fracturing crack, bonding with the hydrate layer, forming a gradient solidification zone, and achieving anti-collapse and sand control effects.

- A design method for the performance parameters of a hydrate reservoir reinforcement skeleton reconstruction body was proposed. This method can be used to design the parameters of the skeleton reconstruction body for different regions of hydrate layers, which is of great significance for achieving long-term, safe, and effective production of hydrate reservoirs.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, H.Y.; Ji, Q.; Fan, Y. An evaluation framework for oil import security based on the supply chain with a case study focused on China. Energy Econ. 2013, 38, 87–95. [Google Scholar] [CrossRef]

- Wu, X.; Huang, W.; Liu, W.; Xue, F.; Wang, M.; Lv, P. Evaluation of Global Natural Gas Hydrate Resource Potential and Progress in Exploration and Production. Mar. Geol. Front. 2017, 33, 63–78. [Google Scholar] [CrossRef]

- Cong, X.; Wu, N.; Su, M.; Yang, R.; Qiao, S.; Mao, X. New Progress and Outlook of Potential Resources Volume of Natural Gas Hydrate. Adv. New Renew. Energy 2014, 2, 462–470. [Google Scholar] [CrossRef]

- Shao, M.; Zhang, W.; Wu, X.; Sun, Z.; China National Geological Library; Geosciences Documentation Center, CGS. Natural Gas Hydrate Exploitation at Messoyakha Gas Field. Nat. Resour. Inf. 2016, 17, 17–19+31. [Google Scholar]

- Kurihara, M.; Sato, A.; Funatsu, K. Analysis of production data for 2007/2008 Mallik gas hydrate production tests in Canada. In Proceedings of the International Oil and Gas Conference and Exhibition in China, Beijing, China, 8–10 June 2010. SPE132155. [Google Scholar] [CrossRef]

- Hunter, R.B.; Collett, T.S.; Boswell, R. Mount Elbert Gas Hydrate StratigrapHic Test Well, Alaska North Slope: Overview of scientific and technical program. Mar. Pet. Geol. 2011, 28, 295–310. [Google Scholar] [CrossRef]

- Kvamme, B. Feasibility of simultaneous CO2 storage and CH4 production from natural gas hydrate using mixtures of CO2 and N2. WSEAS Trans. Heat Mass Transf. 2015, 93, 897–905. [Google Scholar] [CrossRef]

- Zuo, R.; Li, Y.; The Ministry of Land and Resources of the People’s Republic of China; The Institute of Exploration Techniques, CAGS; Editorial Board of Exploration Engineering. Japan’s Sampling Study and Successful Production Test for NGH in Nankai trough. Explor. Eng. (Rock Soil Drill. Tunn.) 2017, 44, 1–20. [Google Scholar]

- Zhang, G.; Liang, J.; Lu, J.; Yang, S.; Zhang, M.; Su, X.; Xu, H.; Fu, S.; Kuang, Z.; Key Laboratory of Marine Mineral Resources, Ministry of Land and Resources∥Guangzhou Marine Geological Survey; et al. Characteristics of Natural Gas Hydrate Reservoir on the Northeastern Slope of the South Sea. Nat. Gas Ind. 2014, 34, 1–10. [Google Scholar] [CrossRef]

- Liu, C.; Li, Y.; Sun, J.; Wu, N. Gas Hydrate Production TEST: FROM Experimental Simulation to Field Practice. Mar. Geol. Quat. Geol. 2017, 37, 12–26. [Google Scholar] [CrossRef]

- Johnson, J.E.; MacLeod, D.R.; Phillips, S.C.; Phillips, M.P.; Divins, D.L. Primary deposition and early diagenetic effects on the high saturation accumulation of gas hydrate in a silt dominated reservoir in the Gulf of Mexico. Mar. Geol. 2022, 444, 106718. [Google Scholar] [CrossRef]

- Bazaluk, O.; Sai, K.; Lozynskyi, V.; Petlovanyi, M.; Saik, P. Research into Dissociation Zones of Gas Hydrate Deposits with a Heterogeneous Structure in the Black Sea. Energies 2021, 14, 1345. [Google Scholar] [CrossRef]

- Dong, C.; Yan, Q.; Li, Y.; Xu, H.; Zhou, Y.; Shang, X.; Chen, Q.; Song, Y. Numerical simulation of particle scale micro sand production in natural gas hydrate reservoirs. J. China Univ. Pet. (Ed. Nat. Sci.) 2019, 43, 77–87. [Google Scholar]

- Murphy, A.; Soga, K.; Yamamoto, K. A laboratory investigation of sand production simulating the 2013 Daini-Atsumi Knoll gas hydrate production trial using a high pressure plane strain testing apparatus. In Proceedings of the 9th International Conferences on Gas Hydrate, Denver, CO, USA, 25–27 June 2017. ICGH9. [Google Scholar] [CrossRef]

- House, K.Z.; Schrag, D.P.; Harvey, C.F.; Lackner, K.S. Permanent carbon dioxide storage in deep-sea sediments. Proc. Natl. Acad. Sci. USA 2006, 103, 12291–12295. [Google Scholar] [CrossRef]

- Sasaki, K.; Akibayashi, S. A calculation model for liquid CO2 injection into shallow sub-seabed aquifer. Ann. N. Y. Acad. Sci. 2000, 912, 211–225. [Google Scholar] [CrossRef]

- Koide, H.; Shindo, Y.; Tazaki, Y.; Iijima, M.; Ito, K.; Kimura, N.; Omata, K. Deep sub-seabed disposal of CO2—The most protective storage. Energy Convers. Manag. 1997, 38, S253–S258. [Google Scholar] [CrossRef]

- Benson, S.M.; Cole, D.R. CO2 Sequestration in Deep Sedimentary Formations. Elements 2008, 4, 325–331. [Google Scholar] [CrossRef]

- Bu, Y.; Du, J.; Liu, H.; Guo, S.; Tian, L. A Integrated Liquid of Cementing—Formation Welding Integrated Fluid to Weakly Cemented Strata in Deep Water. China Patent CN201710844706.X, 19 September 2017. [Google Scholar]

- Bu, Y.; Dong, L.; Liu, H. Theory and Implementation Method of Strengthening and Preventing Collapse and Sand Control in Natural Gas Hydrate Formation. China Patent CN202110972005.0, 21 September 2021. [Google Scholar]

- Du, J.; Bu, Y.; Liu, H.; Tian, L. A Equipment for Simulating the Gradient Layer of Cementing Strength in Weak Cemented Formations in Deep Water. China Patent CN201610808893.1, 21 September 2018. [Google Scholar]

- Bu, Y.; Du, J.; Guo, S. Effects of formation water influx on the bonding strength between oil well cement and the formation. Constr. Build. Mater. 2020, 251, 118989. [Google Scholar] [CrossRef]

- ErDing, C. Research on Technology for Sand Control of Permeable Microfine Cement System; Southwest Petroleum University: Beijing, China, 2002. [Google Scholar]

- Mc Guire, P.L. Methane Hydrate Gas Production by Thermal Stimulation. In Proceedings of the Fourth Canadian Permafrost Conference, Calgary, AB, Canada, 2 March 1981. [Google Scholar]

- Holder, G.D.; Angert, P.F. Simulation of Gas Production from a Reservoir Containing both Gas Hydrates and Free Natural Gas. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 26–29 September 1982. SPE11105. [Google Scholar] [CrossRef]

- Kamath, V.A.; Godbole, S.P. Evaluation of Hot-Brine Stimulation Technique for Gas Production from Natural Gas Hydrates. J. Pet. Technol. 1985, 39, 1379–1388. [Google Scholar] [CrossRef]

- Ohgaki, K.; Takano, K.; Sangawa, H. Methane Exploitation by Carbon Dioxide from Gas Hydrates—Phase Equilibria for CO2-CH4 Mixed Hydrate System. J. Chem. Eng. Jpn. 1996, 29, 478–483. [Google Scholar] [CrossRef]

- Waite, W.F.; Santamarina, J.C.; Cortes, D.D. Physical properties of hydrate-bearing sediments. Rev. Geophys. 2009, 47, 3–40. [Google Scholar] [CrossRef]

- Li, Y.; Liu, L.; Liu, C.; Sun, J.; Ye, Y.; Chen, Q. Sanding Prediction and Sand—Control Technology in Hydrate Exploitation: A Review and Discussion. Mar. Geol. Front. 2016, 32, 36–43. [Google Scholar] [CrossRef]

- Huang, G.; Zheng, S.; Xia, M.; Wu, D. Study on Sand Production in a Natural Gas Hydrate Production Well. Mar. Geol. Quat. Geol. 2017, 37, 174–183. [Google Scholar] [CrossRef]

- Ning, Q. Research on Sand Control and Increasing Production Technique in the Unconsolidated Sand Reservoirs; China University of Petroleum: Beijing, China, 2007. [Google Scholar]

- Gang, L.; Xiao, S.L.; Qi, C.R. Numerical Simulation of Gas Production from Gas Hydrate Zone in Shenhu Area, South China Sea. Acta Chim. Sin. 2010, 78, 1083–1092. [Google Scholar] [CrossRef]

- Guan, Z.; Chen, T. Drilling Engineering Theory and Technology; Petroleum University Press: Qingdao, China, 2000; pp. 8–10. [Google Scholar]

- Cheng, Y.; Li, L. Fluid-Solid Coupling Numerical Simulation on Natural Gas Production from Hydrate Reservoirs by Depressurization; China University of Petroleum (East China): Beijing, China, 2009. [Google Scholar]

- Yalamas, T.; Nauroy, J.F.; Bemer, E.; Dormieux, L.; Garnier, D. Sand Erosion in Cold Heavy-oil Production. In Proceedings of the SPE International Thermal Operations and Heavy Oil Symposium and Western Regional Meeting, Bakersfield, CA, USA, 16–18 March 2004. SPE86949. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, D.; Bu, Y.; Xiang, C.; Lu, C.; Liu, H.; Guo, S. New Steps to Deep-Water Hydrate Long-Term Mining by Formation Stabilization. J. Mar. Sci. Eng. 2023, 11, 2225. https://doi.org/10.3390/jmse11122225

Lin D, Bu Y, Xiang C, Lu C, Liu H, Guo S. New Steps to Deep-Water Hydrate Long-Term Mining by Formation Stabilization. Journal of Marine Science and Engineering. 2023; 11(12):2225. https://doi.org/10.3390/jmse11122225

Chicago/Turabian StyleLin, Dong, Yuhuan Bu, Changyou Xiang, Chang Lu, Huajie Liu, and Shenglai Guo. 2023. "New Steps to Deep-Water Hydrate Long-Term Mining by Formation Stabilization" Journal of Marine Science and Engineering 11, no. 12: 2225. https://doi.org/10.3390/jmse11122225

APA StyleLin, D., Bu, Y., Xiang, C., Lu, C., Liu, H., & Guo, S. (2023). New Steps to Deep-Water Hydrate Long-Term Mining by Formation Stabilization. Journal of Marine Science and Engineering, 11(12), 2225. https://doi.org/10.3390/jmse11122225