Objective Prediction Tracking Control Technology Assisted by Inertial Information

Abstract

:1. Introduction

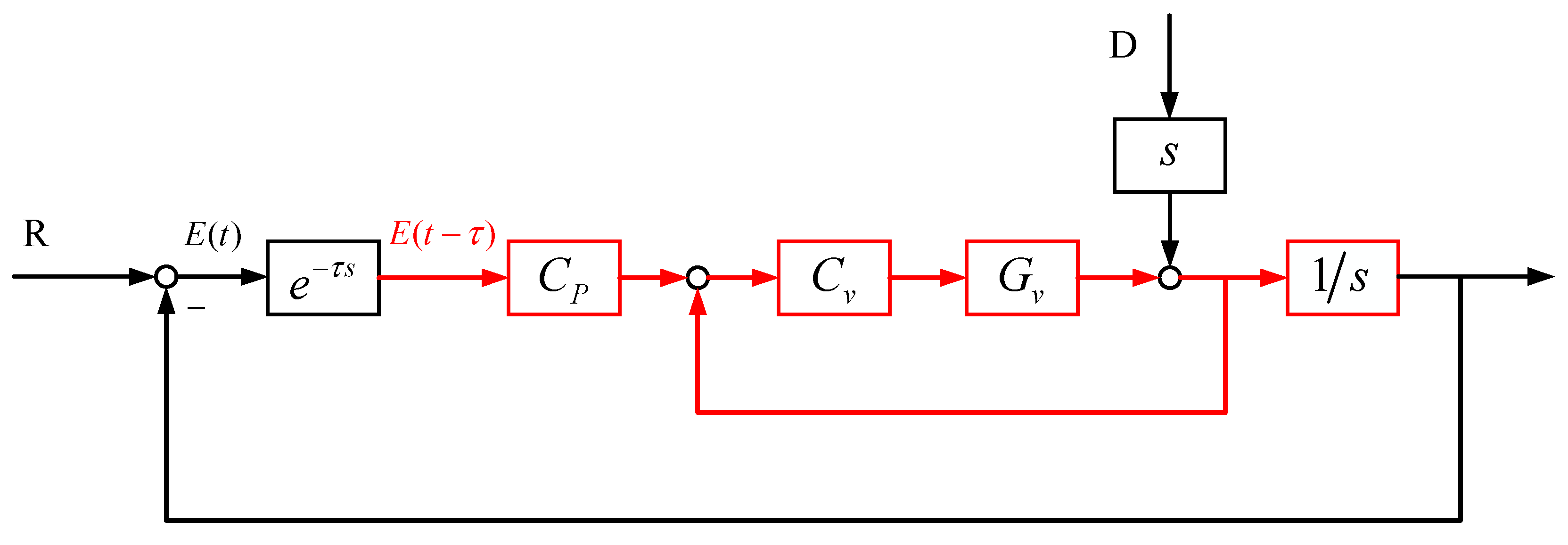

- R: Angular position command of the tracking control system, representing the actual angular position of the target relative to the tracking control system in the geographic coordinate system.

- Y: Angular position response of the tracking control system.

- : Position loop controller of the tracking control system.

- : Off-target error delay time.

- : Velocity loop controller of the tracking control system.

- D: Attitude disturbance of the motion carrier, measured and obtained through inertial navigation.

- : Controlled object model for the velocity loop.

2. Principles of Target Prediction and Tracking Control Technology Based on Multi-Space Reference Fusion

2.1. Fusion of Attitude Information in a Multi-Space Basis

- : The target coordinate system, along the direction facing the target, is defined as left, down, and rear.

- : The pitch-axis fixed-coordinate system coincides with and is defined as right, forward, and up.

- : The pitch-axis zero coordinate system is aligned with , differing from the pitch angle , and defined in the same manner as the azimuth-zero coordinate system: forward, left, and up.

- : The azimuth-axis coordinate system is defined as forward, left, and up.

- : The azimuth-zero coordinate system is defined as forward, left, and up.

- : The installation base coordinate system is aligned with .

- : The IMU carrier coordinate system is defined as right, front, and up.

- : The geographical coordinate system is defined as east, north, and up.

2.1.1. Projection Transformation from Target Surface Frame to Geographical Frame

2.1.2. Interpolation and Resampling of Off-Target Deviation in the Geographical Frame

2.1.3. Generation of High-Sampling-Rate Elevation and Azimuth Angles

2.2. Target Prediction Algorithm

3. Control System Design and Analysis of Target Prediction Algorithm Based on Multi-Spatial Frame Attitude Information Fusion

3.1. Control System Design for Target Prediction Algorithm Based on Multi-Spatial Frame Fusion

- E: Control error in angular position.

- : Estimated target angular position relative to the geodetic reference frame at a lag, τ.

- : Estimated target angular position relative to the geodetic reference frame at the current time t.

- : Pre-measured time delay associated with the off-target measurements. The discussion in this paper is based on the condition of having lag, .

3.2. Algorithm Stability and Error Analysis

3.2.1. Control System Stability Analysis

3.2.2. Algorithm Error Analysis and Comparison

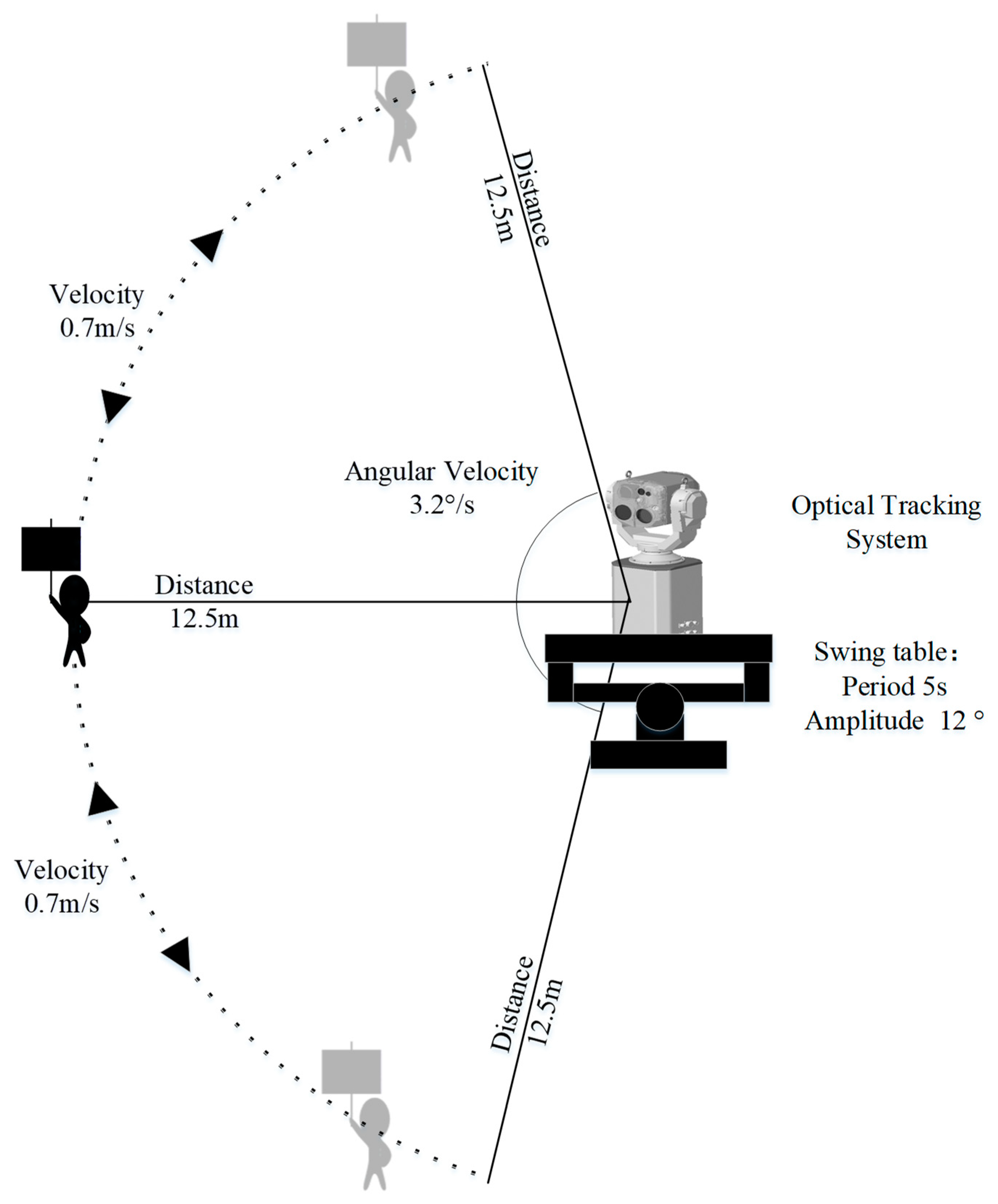

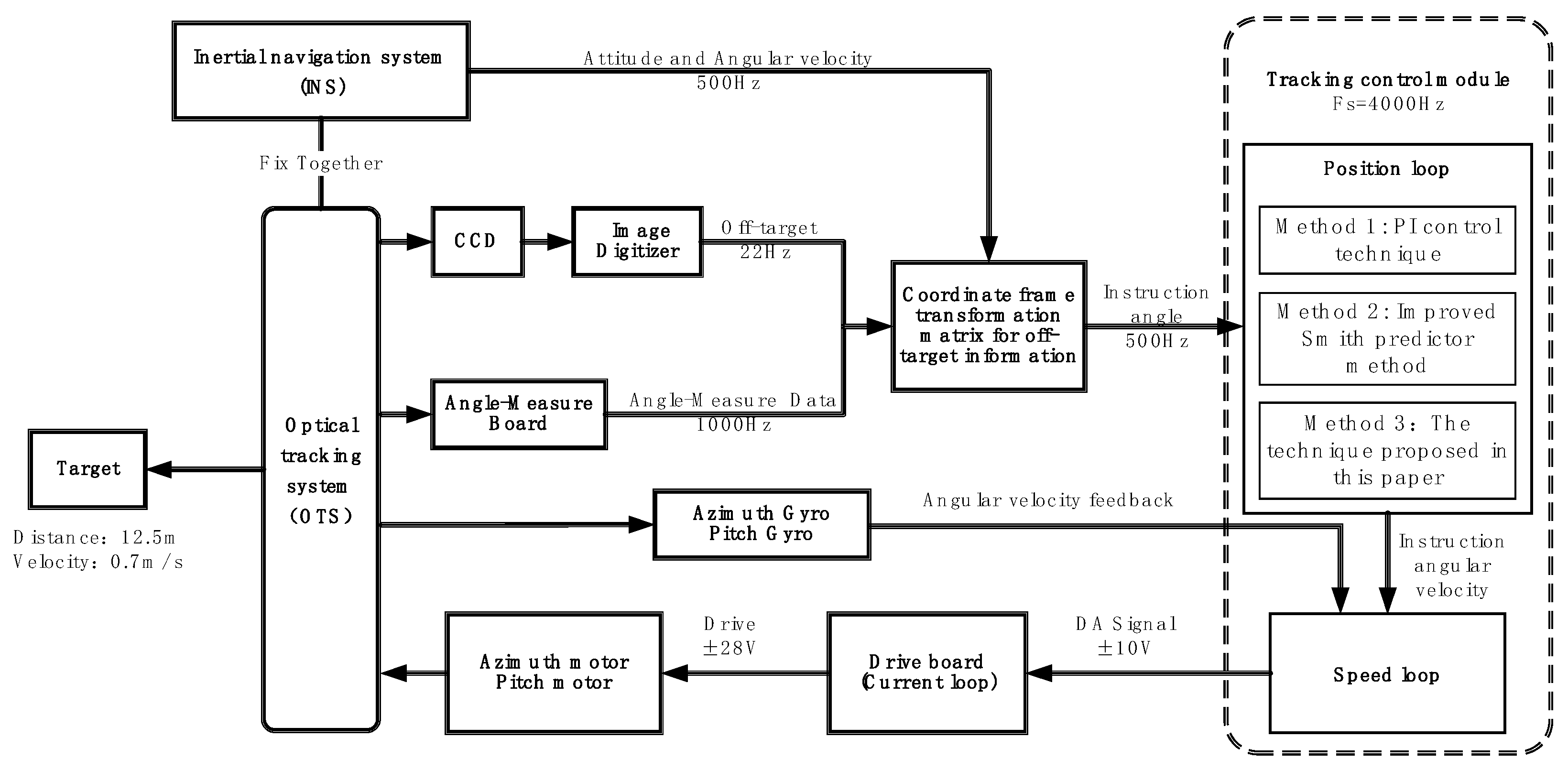

4. Experimental Testing

4.1. Test Conditions

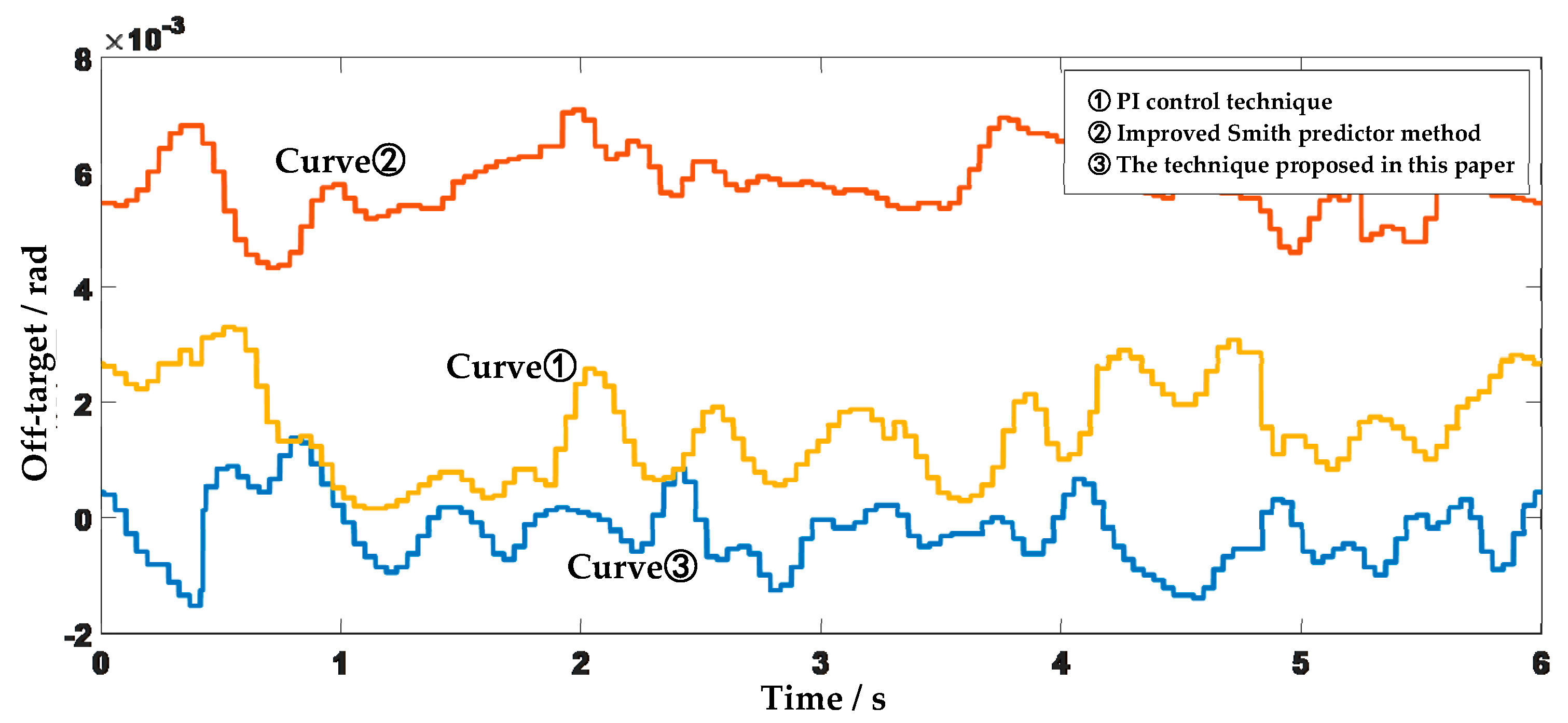

4.2. Test Results

- The target prediction and tracking control technique proposed in this paper, based on multi-space-based attitude fusion, is significantly superior to the other two control techniques. With PI control and the improved Smith predictor technique, when the target is moving at a constant speed, there is a consistent deviation in the target tracking error curve, indicating a noticeable tracking lag.

- In the case of PI control, during the off-target measurement update time, both the angular motion of the optical-electronic device itself and the linear motion of the target can result in angular displacement errors that conventional feedback controllers are unable to compensate for.

- For the improved Smith predictor technique, using gyro information for external disturbance estimation can suppress the interference caused by the angular motion of the optical-electronic device itself. However, since there is no prediction of the target’s linear motion trajectory, when tracking high-speed moving targets, it can actually reinforce the tracking of the lagged target position, resulting in more noticeable tracking lag errors.

- The technique proposed in this paper has advantages over PI control and the improved Smith predictor technique. It leverages real-time measurements from inertial navigation information to compensate for the impact of the angular motion of the optical-electronic device on tracking accuracy. Additionally, it establishes a target motion trajectory model in the relatively stable geodetic coordinate system to compensate for the impact of target movement on tracking accuracy.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hou, M.L.; Liu, Y.R.; Xing, S.B.; Su, L.Y. Study of intelligent diagnosis system for photoelectric tracking devices based on multiple knowledge representation. Adv. Mater. Res. 2011, 179, 602–607. [Google Scholar] [CrossRef]

- Li, T.H.; Xiang, D.Q. Research and Design of Photoelectric Solar Tracking System. Adv. Eng. Forum 2012, 4, 115–120. [Google Scholar] [CrossRef]

- Masten, M.K. Inertially stabilized platforms for optical imaging systems. IEEE Control Syst. Mag. 2008, 28, 47–64. [Google Scholar]

- Hilkert, J.M. Inertially stabilized platform technology concepts and principles. IEEE Control Syst. Mag. 2008, 28, 26–46. [Google Scholar]

- Tang, T.; Mao, J.; Chen, H.; Fu, C.; Yang, H.; Ren, G.; Yang, W.; Qi, B.; Cao, L.; Zhang, M.; et al. A review on precision control methodologies for optical-electric tracking control system. Opto-Electron. Eng. 2020, 47, 200315. [Google Scholar]

- Ekstrand, B. Tracking filters and models for seeker applications. IEEE Trans. Aerosp. Electron. Syst. 2001, 37, 965–977. [Google Scholar] [CrossRef]

- Tao, T.; Ma, J.; Ren, G. PID-I controller for of charge coupled device-based tracking loop for fast-steering mirror. Opt. Eng. 2011, 50, 043002. [Google Scholar]

- Srivastava, S.; Pandit, V.S. A PI/PID controller for time delay systems with desired closed loop time response and guaranteed gain and phase margins. J. Process Control 2016, 37, 70–77. [Google Scholar] [CrossRef]

- Amini, E.; Rahmani, M. Stabilizing PID controller for time-delay systems with guaranteed gain and phase margins. Int. J. Syst. Sci. 2022, 53, 1004–1016. [Google Scholar] [CrossRef]

- Ren, W.; Luo, Y.; He, Q.N. Stabilization Control of Electro-optical Tracking System with Fiber-Optic Gyroscope Based on Modified Smith Predictor Control Scheme. IEEE Sens. J. 2018, 99, 1. [Google Scholar]

- Böhm, M.; Pott, J.U.; Kürster, M.; Sawodny, O.; Defrere, D.; Hinz, P. Delay compensation for Real time Disturbance estimation at extremely large telescope. IEEE Trans. Control Syst. Technol. 2016, 25, 1384–1394. [Google Scholar] [CrossRef]

- Luo, Y.; Xue, W.; He, W.; Nie, K.; Mao, Y.; Guerrero, J.M. Delay-Compound-Compensation Control for Photoelectric Tracking System Based on Improved Smith Predictor Scheme. IEEE Photonics J. 2022, 14, 6625708. [Google Scholar] [CrossRef]

- Sariyildiz, E.; Ohnishi, K. A guide to design disturbance observer. J. Dyn. Syst. Meas. Control 2014, 136, 11–21. [Google Scholar] [CrossRef]

- Wang, L.; Su, J. Robust disturbance rejection control for attitude tracking of an air-craft. IEEE Trans. Control Syst. Technol. 2015, 23, 2361–2368. [Google Scholar] [CrossRef]

- İçmez, Y.; Can, M.S. Smith Predictor Controller Design Using the Direct Synthesis Method for Unstable Second-Order and Time-Delay Systems. Processes 2023, 11, 941. [Google Scholar] [CrossRef]

- Ghorbani, M.; Tavakoli-Kakhki, M.; Tepljakov, A. Robust stability analysis of smith predictor-based interval fractional-order control systems: A case study in level control process. IEEE/CAA J. Autom. Sin. 2022, 10, 762–780. [Google Scholar] [CrossRef]

- Tang, T.; Cai, H.; Huang, Y.; Ren, G. Combined line-of-sight error and angular position to generate feedforward control for a charge-coupled device–based tracking loop. Opt. Eng. 2015, 54, 105107. [Google Scholar] [CrossRef]

- Tang, T.; Tian, T.; Zhong, D.J.; Fu, C.Y. Combining Charge Couple Devices and Rate Sensors for the Feedforward Control System of a Charge Coupled Device Tracking Loop. Sensors 2016, 16, 968. [Google Scholar] [CrossRef]

- Xie, R.; Zhang, T.; Li, J.; Dai, M. Compensating Unknown Time-Varying Delay in Opto-Electronic Platform Tracking Servo System. Sensors 2017, 17, 1071. [Google Scholar] [CrossRef]

- Luo, Y.; Ren, W.; Huang, Y.; He, Q.J.; Wu, Q.; Zhou, X.; Mao, Y. Feedforward Control based on Error and Disturbance Observation for the CCD and Fiber-Optic Gyroscope-Based Mobile Optoelectronic Tracking System. Electronics 2018, 7, 223. [Google Scholar] [CrossRef]

- Li, X.R.; Jilkov, V.P. Survey of maneuvering target tracking. Part I. Dynamic models. IEEE Trans. Aerosp. Electron. Syst. 2004, 39, 1333–1364. [Google Scholar]

- Lee, B.J.; Joo, Y.H.; Park, J.B. An intelligent tracking method for a maneuvering target. Int. J. Control. Autom. Syst. 2003, 1, 93–100. [Google Scholar]

- Yu, Y.H.; Cheng, Q.S. Particle filters for maneuvering target tracking problem. Signal Process 2006, 86, 195–203. [Google Scholar] [CrossRef]

| Off-Target Deviation Sampling Time (Low-Frequency) | IMU Sampling Time (High-Frequency) | Off-Target Deviation before Resampling | Equivalent Target Angular Position Vector after Resampling |

|---|---|---|---|

| … | … | ||

| … | … | ||

| … | … | … | … |

| … | … | ||

| Current Time | Time Corresponding to the Off-Target Deviation | Off-Target Deviation Values | Target Angular Vector Projected into the Geographical Frame during forward Projection | Target Angular Vector after Back-Projection into the Carrier Frame |

|---|---|---|---|---|

| … | … | … | ||

| Physical Quantities | Spatial Reference Frame | Time Reference Frame | Remark |

|---|---|---|---|

| R: Angle position of the target | Geographic frame | The present moment | Cannot be directly obtained. |

| E: Angle position error of the target | Geographic frame | The present moment | Cannot be directly obtained. |

| Off-target deviation | Target frame | The delayed time | The actual inputs to the system are subject to sampling and lag delay. |

| Estimated target angular position | Geographic frame | The delayed time | After the forward projection transformation from the target surface frame to the carrier frame and then to the geographic frame, the lagged angular measurements and inertial navigation data are used. |

| Estimated target angle position | Geographic frame | The present moment | After applying the target prediction algorithm |

| Estimated target angular position error | Carrier frame | The present moment | Following the transformation from the geographic frame to the carrier frame, utilizing the current moment’s inertial navigation information, the subsequent control inputs for tracking are determined. |

| Position Loop | ||||

|---|---|---|---|---|

| Control Parameters | PI Control Technique | Improved Smith Predictor Method | The Control Technique Proposed in This Paper | |

| Pitch axis | 0.15 | 0.15 | 0.15 | |

| 11.5 | 46 | 137.5 | ||

| Azimuth axis | 0.15 | 0.15 | 0.15 | |

| 11.5 | 46 | 137.5 | ||

| Velocity Loop | ||||

| Pitch axis | 8 | 8 | 8 | |

| 100 | 100 | 100 | ||

| Azimuth axis | 30 | 30 | 30 | |

| 400 | 400 | 400 | ||

| Control Technique | Tracking Accuracy (RMS) |

|---|---|

| PI control technique | 1.8 mrad |

| Improved Smith predictor | 5.8 mrad |

| Target prediction and tracking control technique based on multi-space frame attitude fusion | 633 μrad |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leng, Y.; Zhong, S. Objective Prediction Tracking Control Technology Assisted by Inertial Information. J. Mar. Sci. Eng. 2023, 11, 2175. https://doi.org/10.3390/jmse11112175

Leng Y, Zhong S. Objective Prediction Tracking Control Technology Assisted by Inertial Information. Journal of Marine Science and Engineering. 2023; 11(11):2175. https://doi.org/10.3390/jmse11112175

Chicago/Turabian StyleLeng, Yue, and Sheng Zhong. 2023. "Objective Prediction Tracking Control Technology Assisted by Inertial Information" Journal of Marine Science and Engineering 11, no. 11: 2175. https://doi.org/10.3390/jmse11112175

APA StyleLeng, Y., & Zhong, S. (2023). Objective Prediction Tracking Control Technology Assisted by Inertial Information. Journal of Marine Science and Engineering, 11(11), 2175. https://doi.org/10.3390/jmse11112175