Abstract

Ocean energy is an underutilized renewable energy source compared with hydropower and wind power. Therefore, the development of economical and efficient wave energy converters (WECs) is important and crucial for offshore power generation. The mooring tensioner is a critical device that can be used in point-absorber-type WECs, semisubmersible floats for oil and gas drilling, and floating wind turbines. A mooring tensioner is a system used to create, reduce, or maintain tension within the mooring lines by applying a force to the mooring line. Composite springs as mooring tensioners have several advantages compared to metal springs, such as corrosion resistance, high specific strain energy, appropriate fatigue performance, and the ability to flexibly adjust the spring constant without changing the overall dimensions. This paper reviews in detail the fatigue performance, seawater durability, and manufacturing methods of different composite materials as well as the current and potential applications of composites springs. In addition, recommendations for future research and opportunities for composite mooring tensioners are presented.

1. Introduction

Recently, the replacement of conventional steel springs with polymer matrix composite springs has gained momentum due to their beneficial engineering attributes, such as high corrosion resistance, high strength-to-weight ratio, long fatigue life, and larger design space. Many of these attributes are particularly beneficial when targeting springs as mooring tensioners in offshore applications, such as offshore platforms, wave energy converters, wind farms, and even for securing large vessels. Due to the abovementioned benefits of fiber-reinforced polymer (FRP) composites, the offshore oil and gas industry has started to use FRP composite risers to replace steel drilling risers that require depths exceeding 3000 m [1]. According to an estimation [2], a one-pound increase in platform payload costs USD 4–7. Therefore, by using composite materials, the total system weight, top-tension, and mooring pretentions can be reduced, and therefore FRP composite risers are more cost-effective [1]. This highlights the willingness of the offshore industry to adopt composites solutions where there is a clear performance or cost benefit. With respect to mooring tensioners, it is important to point out that currently, wave energy converter companies are investigating composite springs as mooring tensioners, and the oil and gas industries have not yet considered the applications of composite mooring tensioners.

In contrast to the automotive industry, where composite springs have already been commercialized, the potential of composite springs in mooring tensioner applications remains largely untapped. Future generations of composite helical springs are likely to be lighter and have a higher energy storage capacity. According to Jun Ke et al. [3], in automotive applications, suspension springs made of composite materials can provide the same spring constant and are at least 50% lighter than a traditional steel spring. For instance, the Audi A6 and R8 models have used composite helical springs in their suspension systems to achieve the desired spring rate and reduce the weight to achieve better driving performance [3].

An elastic spring can store energy and release the stored energy while recovering its original position. There are different types of springs, namely compression springs, extension springs, torsion springs, and flat springs. Typically, springs are classified as constant-rate (linear), variable-rate, and constant-force. Based on the loading nature and the spring performance, these springs are used in different applications. Composite springs have outstanding properties compared with metal springs, and therefore metals can potentially be replaced by composites in some applications.

Composite springs can provide a larger design space, which enables engineers to tune the spring stiffness across a wide range so that it is specific to the application. For example, the spring constant of a composite spring can be modified without changing its geometry by altering the fiber type, laminate sequence, and fiber volume fraction [4]. Compared to steel springs, composite springs are typically less stiff and therefore generally offer a lower spring stiffness than an equivalently sized steel spring. However, since the reduced material stiffness of a composite spring is typically accompanied by a high strain capacity, composite springs offer unique features that make them very useful in a range of applications. For example, composite springs are the ideal choice for mooring tensioners of WECs because they enable designs that offer a low but tunable spring stiffness, large displacement, high strain energy storage efficiency, excellent fatigue performance, and scalability (including very large springs).

Furthermore, composite springs as mooring tensioners can avoid the issue of corrosion that is commonly encountered in metals. The weight of mooring tensioners can also be reduced by using composite materials, due to their high strength-to-weight ratio. As a result, the payload of offshore platforms or vessels can be increased to optimize their efficiency.

Due to the above-highlighted advantages of composite springs, this paper provides an overview of the key aspects relevant to the realization of composite springs for mooring tensioners. The paper first introduces different mooring systems and their applications and discusses in detail the opportunities created by using composite springs. Subsequently, information is provided on the properties and performance of different FRP composites, and a comparison is drawn with conventional spring materials. The paper then discusses the design and performance attributes of composite springs, such as their mechanical properties, fatigue strength, and environmental durability. Next, the different manufacturing methods of composite springs and their advantages and disadvantages are presented. Finally, recommendations for future research and opportunities are provided.

2. Mooring Systems and Mechanical Mooring Tensioners

A mooring system is a device that secures a float, such as a ship or a platform, at a certain position in changing wave and weather conditions. A common mooring system consists of mooring lines, catenary chains, and a mooring anchor. Mooring systems are widely used in different marine industries, such as WECs, offshore wind turbines, offshore oil rigs, boats, and offshore fish cages [5,6]. Section 2.1 introduces the current configurations of mooring tensioners in the offshore oil gas industry, and their drawbacks are discussed in Section 2.2. Then, Section 2.3 explains potential innovations for mooring tensioners in wave energy converters, and the potential applications of taut-leg mooring systems are discussed in Section 2.4.

2.1. Current Configuration of Mooring Tensioners

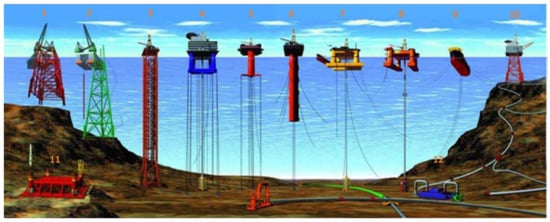

Figure 1 [7] shows the different types of fixed platforms and offshore semisubmersible floats for oil and gas drilling, storage, and offloading. (Please refer to the operating range of sea depths provided in the caption). Ma et al. [8] recommended that a compliant tower should be used for production in water depths ranging from 1200 ft to 1800 ft. Floating production systems are required for deeper water applications (e.g., tension-leg platforms (TLPs); semisubmersible platforms (semis); and floating production, storage, and offloading (FPSO) units) [8]. A floating production system requires a mooring tensioner system to secure it in position while it floats above sea level [8]. Mooring tensioner systems for offshore floats have been upgraded over time. The first generation of mooring tensioners comprised rotary windlasses on ships. Nowadays, different types of mooring tensioner systems have been developed, including fixed, linear, or rotary movable chain jacks that are driven by hydraulic and electric systems [9].

Figure 1.

Examples of deep-water offshore production facilities. (1, 2) conventional fixed platforms (150–412 m); (3) compliant tower (457–914 m); (4, 5) tension-leg platform (TLP) (457–2134 m); (6) truss SPAR (610–3048 m); (7, 8) semisubmersibles platforms (semis) (457–1920 m); (9) floating production, storage, and offloading (FPSO) unit (1345–1500 m); (10) jacket platform (150–412 m); (11) subsea completion and tieback to a host facility; (12) subsea manifold [7]. Reproduced with permission from Chiemela et al., Journal of Marine Science and Engineering, published by MDPI, 2022.

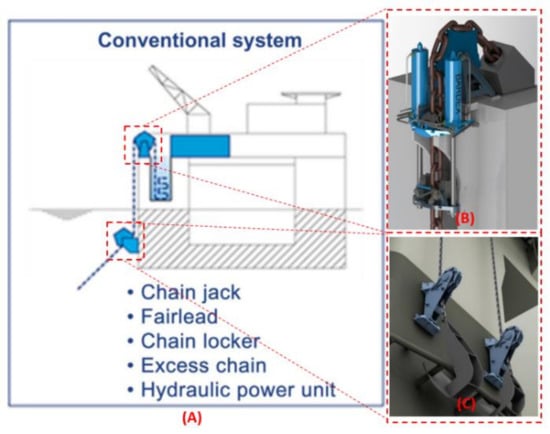

As Figure 1 and Figure 2 show, the floating platform is anchored to the seabed using steel chains, which act as the current station-keeping mooring tensioner. As Figure 2B shows, steel chains are pulled in or let out by one or more hydraulic cylinders attached to the platform. Tension forces are applied to the chain using a chain jack to keep the floating platform stable [8].

Figure 2.

(A) Conventional chain jack tensioning system installed on a floating platform. (B) Schematic of a chain jack. (C) Schematic of fairleads [8]. Reproduced with permission from Ma et al., Mooring system engineering for offshore structures, published by Gulf Professional Publishing, 2019.

2.2. Failures of Current Mooring Systems

According to Majihi et al. [10], floating production systems (FPSs) are used for offshore oil and gas production. There were 23 FPS mooring failure accidents documented between 2000 and 2012 around the world [10]. Each failure was caused by the failure of one or more mooring lines. At least 150 mooring lines were replaced or repaired within the same period, but they were not counted as failure accidents [10]. The total number of floating production and storage systems in service was 365 in 2012 [11].

Integrity issues of mooring systems are responsible for shortening the designed lifespan of mooring systems. Permanent mooring systems are designed for 15 to 25 years of service [10]. However, many mooring systems have failed within the first 2 years. The premature mooring failures of spar platforms; floating production, storage, and offloading (FPSO) units; submerged turret loading (STL) buoys; and catenary anchor leg mooring (CALM) buoys were reported by Majihi et al. [10]. Ma et al. [11] recorded that polyester ropes, wire ropes, yokes, connectors, steel chain failures, and column collapses were the causes of the 42 mooring line breaks from 2001 to 2011 globally. Forty-two mooring breaks were caused by steel chain failures, wire rope breaks, connector failures, polyester rope breaks, and yoke column failures, which accounted for 52%, 33%, 10%, 3%, and 2% of the breaks, respectively [11]. The main reasons for mooring failures are listed below:

- Manufacturing defects: the strength of the manufactured component is lower than the designed value, which can cause failures.

- Wear and corrosion: steel catenary chains experience wear and corrosion at different rates in different water conditions. Corrosion caused by sulfate-reducing bacteria (SRB) and the interlink wear of steel chains can accelerate the corrosion and wear rate by up to 10 times [12].

- Fatigue loading: interlink rotation is inhibited by the friction and yielding between the links of chains because the frictional forces are proportional to the applied tension force. As a result of this friction, out-of-plane bending fatigue has caused failures such as the taut-moored CALM buoy in West Africa [13].

- Installation damage: the designed installation procedures have not been strictly followed, which causes twists and the wear of mooring lines during installation.

2.3. Mooring System of Wave Energy Converters

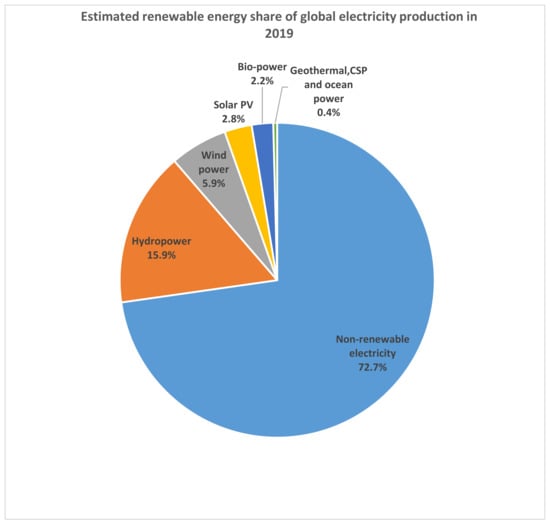

Ocean wave energy is an underutilised renewable energy source. As shown in Figure 3 [14], it was estimated that in 2019, only 27.3% of global electricity produced was generated from renewable energy. In 2019, less than 0.4% of electricity produced was estimated to be generated from ocean wave energy, which was significantly smaller than the estimated proportion of 15.9% for hydropower and 5.9% for wind [14]. Therefore, the development of an economical and efficient WEC is important and critical for offshore power generation.

Figure 3.

Estimated renewable energy share, adapted from [14].

WECs are devices that convert the energy of moving ocean waves into mechanical or electrical energy. There are different types of WECs, such as point absorbers, oscillating water columns, and attenuators [15]. This paper focuses on point-absorber-type WECs. According to the literature review of patents, as shown in Table 1, the oil and gas industries have developed mooring tensioners for the tensioning/re-tensioning of mooring lines. However, there currently appears to be no patent literature describing a mooring tensioner that can be used in point-absorber-type WECs to convert wave energy into mechanical energy.

Table 1.

Existing patents for mooring tensioners.

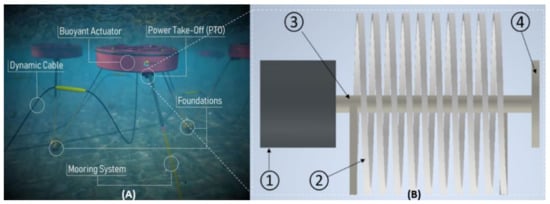

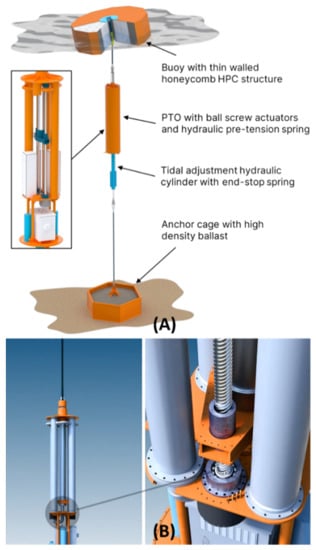

Therefore, new designs and technologies need to be developed for the mooring tensioners of WECs. As shown in Figure 4A, Carnegie Clean Energy is developing a point-absorber-type WEC that consists of a power take-off (PTO) system and other devices. The wave energy can be extracted using the PTO device. The relative motion between the buoyant actuator and the seabed can be stored as mechanical energy using a mechanical mooring tensioner and then converted to electricity by the PTO system [6].

In Figure 4A, the mooring system is anchored from the seabed to the drum of the PTO device. The buoyant actuator is buoyed and pulled by tight mooring lines. Different sea waves generate a buoyancy force on the buoyant actuator, which is transferred through mooring lines to the PTO device to generate electricity.

In this operation, the continuous changes in the direction and magnitude of the buoyancy force under different wave conditions result in differential lift forces for the PTO device to generate electricity. The mooring tensioner in the PTO system (Figure 4B) generates torque from the differential lift forces to turn the generator and produce electricity while maintaining pre-tension and ensuring that the mooring lines are taut.

Figure 4.

(A) Schematic of WEC designed by Carnegie Clean Energy [6]. Reproduced with permission from Sam Neilson, CETO Technology; published by Carnegie Clean Energy, 2022. (B) Schematic of PTO system: ① electric generator; ② mooring tensioner; ③ drive shaft; ④ drum.

Other mooring tensioner systems in WECs are being used by different developers. For example, as shown in Figure 5A [20], Ocean Harvesting Technologies (OHT) uses a pre-tension gas spring system as a mooring tensioner, which consists of a standard gas piston with a double-sided piston rod to provide a constant pre-tension force on the mooring line. As shown in Figure 5B, the differential lift force drives the ball nuts to move vertically and then causes the ball screws in the PTO hull to rotate, which drives the frameless torque generators that are directly connected to the ball screws.

As shown in Figure 6 [21], Corpower uses a hydraulic system to provide pre-tension loading on mooring lines. Compared with the gas spring and hydraulic mooring tensioner, a mechanical mooring tensioner might provide good reliability and cost effectiveness due to the simplicity of the spring mechanism. However, gas and hydraulic mooring tensioner systems can be remotely controlled to adjust the pre-tension spring forces by changing the pressure, which can be an advantage that mechanical tensioners do not have. In conclusion, for better commercial value, the cost effectiveness and energy loss of different systems should be analyzed quantitatively by researchers in the future.

If a mechanical mooring tensioner is used in a WEC to increase its efficiency, materials with a lower modulus of elasticity need to be considered. This is necessary to ensure that the tensioning system provides a sufficient range of motion to cope with the sea state. The finetuning of the spring rate is required for a cost-effective WEC mooring tensioner. Using traditional metal springs for these applications is hindered by the high inherent material stiffness, requiring higher stress levels to achieve the same strain value, which can cause buckling instability. The details will be explained in Section 3.1 and Section 3.3.

Figure 5.

Infinity WEC. (A) Schematic of WEC designed by OHT. Explanation of abbreviations: high-strength concrete (HPC) and power take-off (PTO). (B) Schematic of ball nuts, ball screws, and a frameless torque generator, adapted from [20]. Reproduced with permission from Mikael Sidenmark and Markus Wallentin, InfinityWEC—at the forefront of wave power technology; published by Ocean Harvesting Technologies, 2022.

Figure 6.

Corpower’s wave energy concept. ① WEC system, ② mooring system, ③ foundation, ④ offshore grid connection, adapted from [21].

2.4. Potential Innovation of Mooring Systems

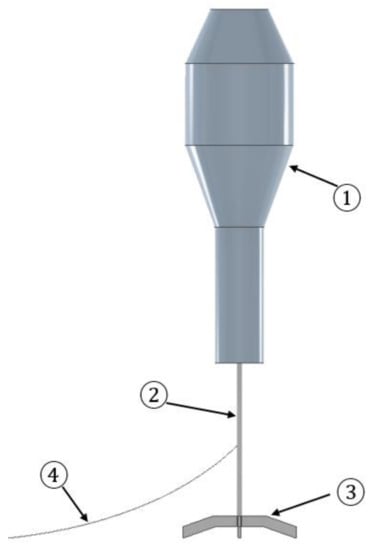

According to Tension Technology International (TTI) [22], a synthetic rope has been analyzed as a mooring line that could outperform steel mooring systems in terms of corrosion resistance, weight, and cost. Moreover, TTI analyzed the differences between catenary and taut mooring systems and the potential application of the synthetic rope in the taut mooring systems of offshore oil platforms. The differences and potential applications are discussed in the following section.

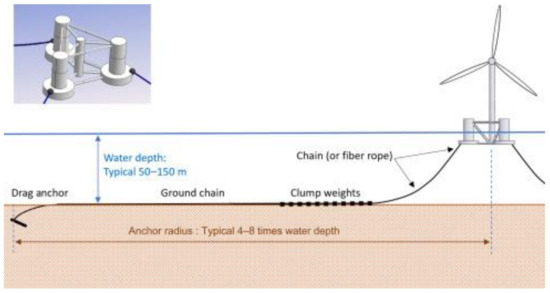

The traditional steel catenary mooring system is a common mooring method used in the offshore oil and gas industry [22]. Figure 7A shows the float connected to the seabed through catenaries, with part of them hanging horizontally across the seabed. Therefore, the length of the catenary is greater than the depth of the sea, and the anchor point of this system is subjected to horizontal forces. This system provides restoring forces for the motion of ships or floats through the weight of the catenaries.

Compared with steel catenary mooring systems, taut-leg mooring systems have advantages in terms of their linear load-excursion characteristic and cost-effectiveness. Taut-leg mooring systems provide a linear restoring force to control the motion of a float instead of non-linear control through the weight of the catenary.

Moreover, the cost of the mooring system can be reduced dramatically because the length of the taut leg used is about 60% shorter than a typical catenary system. In comparison, the total length of one steel catenary line needs to be 4–8 times the depth of the water [8]. The weight of the steel catenary is large in deep-water applications, and therefore the payload of the vessel is reduced. TTI has performed experiments using a synthetic rope as a taut leg to achieve a more effective mooring system. However, there are a few obstacles with respect to the durability of such systems that must be addressed. The obstacles are summarized below [22]:

- The taut-leg mooring system requires adequate elasticity to absorb energy generated by the motion of the float caused by waves.

- The current taut-leg mooring systems can only be implemented at locations with low wave energy.

Figure 7.

(A) Synthetic rope use in mooring. (B) Taut and catenary mooring [22]. Reproduced with permission from Stephen Banfield, TensionTech; published by Tension Technology International, 2022.

As discussed in Section 2.3, composite springs could be considered as a potential novel component that could be connected to synthetic or wire ropes to overcome the shortfalls of the taut-leg mooring system. Composite springs considered for a wave energy harvesting system would have the ability to provide high fatigue strength and suitable elasticity, achieving highly efficient power production. In terms of other applications, composite springs could be modified to achieve a desired spring constant and attached to a synthetic rope to act as a taut-leg mooring system for offshore floats. The system could be designed to either dissipate energy or recover the stored energy.

Such an improved taut-leg mooring system could be employed in a variety of applications, including taut-leg mooring systems in offshore wind turbines and marine vessels. These applications will be discussed in Section 2.4. and Section 2.4.2. However, detailed investigations are needed to confirm the feasibility and efficiency of the proposed system.

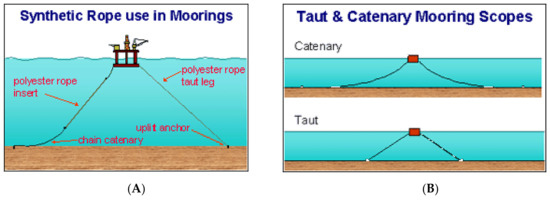

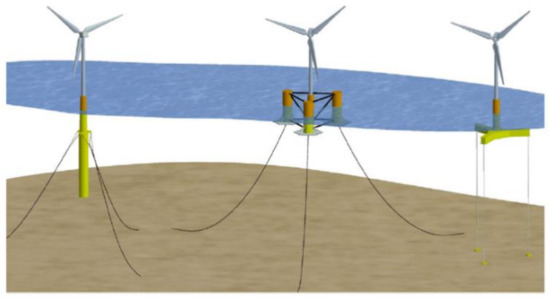

2.4.1. Potential Taut-Leg Mooring System for Offshore Wind Turbines

The promising example of the application of mooring tensioners in offshore wind farms is discussed in this subsection. As shown in Figure 8 [8], spar buoys, semisubmersibles, and tension-leg platforms are three common types of floats that are used. All types of floats require a mooring system to make them stable in seawater under different weather conditions.

The spar-buoy system consists of a floating foundation, a tower, a rotor nacelle assembly, and a mooring system. The floating foundation consists of a concrete cylinder filled with gravel at the bottom of the float to ensure that the center of gravity is below the center of buoyancy, which allows the wind turbine tower to float and stay upright [8].

Semisubmersible wind turbine floats consist of large column floats fitted with a tubular truss structure, which provides stability to the float in different weather conditions. The wind turbine sits on one of the columns or the geometric center of the columns [8].

The tension leg is a mooring system that can be used to secure the turbine tower by applying a linear restoring force. Vertical steel tethers are used to hold the tension-leg platform stable, and they are anchored by driven piles or suction piles at the seabed [8].

Taut-leg moorings with mechanical tensioner mooring systems can potentially be used in all spar-buoy and semisubmersible float systems. As shown in Figure 9, the length of the catenary mooring lines needs to be 4–8 times the water depth. This contributes to the high cost of such systems. Taut-leg mooring is more cost-effective for offshore wind turbine floats, especially in water deeper than 200 m [8].

Furthermore, the length of the vertical steel tethers in tension-leg platforms is dramatically shorter than the catenary mooring line. However, the low elasticity of the steel tethers can cause failure, and the platform may lose its stability in a harsh environment, such as high sea states. Therefore, using a mechanical tensioner, such as a composite spring that can be attached to the tethers, could be an option to buffer the energy caused by the high sea states and increase the reliability of tension-leg platforms [8].

Figure 8.

Three types of wind turbine floaters: spar buoy, semisubmersible, tension-leg platform [8]. Reproduced with permission from Ma et al., Mooring system engineering for offshore structures; published by Gulf Professional Publishing, 2019.

Figure 9.

Catenary lines spread-mooring design [8]. Reproduced with permission from Ma et al., Mooring system engineering for offshore structures; published by Gulf Professional Publishing, 2019.

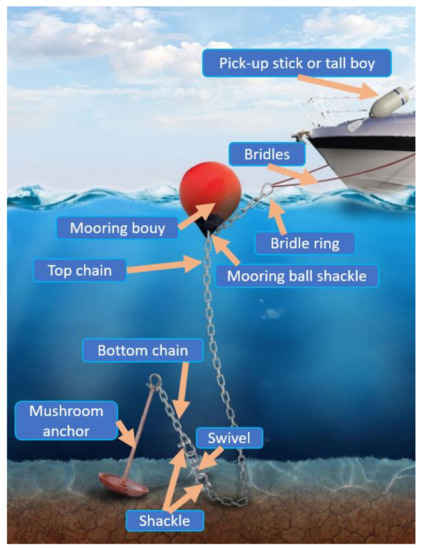

2.4.2. Potential Taut-Leg Mooring System for Marine Vessels

Figure 10 shows the traditional mooring system of a boat that relies on a heavy chain of at least twice the water depth to anchor it to the seabed. The heavy chain touches the seabed and is dragged across it, and this can result in significant damage to the seabed and the marine ecosystem. A composite spring fitted with a synthetic rope could be considered as a potential mooring system that could be installed on a boat to avoid contact between the mooring and the seabed and reduce the damage caused by the mooring system [23]. Such a mooring system may also position the ship more accurately relative to other marine installations or other vessels. For example, this is advantageous for supply barges in aquaculture or offshore oil and gas.

Figure 10.

Traditional steel-chain mooring system, adapted from [23]. Reproduced with permission from Larry Berger, Moorings; published by Twocs Marine, 2022.

This section has provided a general overview of the benefits that a composite mooring tensioner can provide. To conclude, composite mooring tensioners represent a promising novel solution, particularly for a taut-leg mooring system. In the next section, the material selection is discussed with a particular focus on mooring tensioners for WECs.

3. Material Selection

Offshore applications such as mooring tensioners for WECs, offshore wind farms, and platforms have varying design requirements. As Table 2 shows, a mooring tensioner for a WEC requires a relatively higher specific strain energy to maximize the efficiency of the electricity generation. In contrast, mooring tensioners for other applications such as wind farms, fish pens, and boats are required to dissipate the energy to increase the durability of the mooring system. Material selection is critical for an adequate design. This section will first review the research relating to key design aspects such as the spring constant and specific strain energy and then review the mechanical properties such as the static strength, fatigue performance, and property reduction due to aging in seawater.

Table 2.

Design requirements of mooring tensioner in different industries.

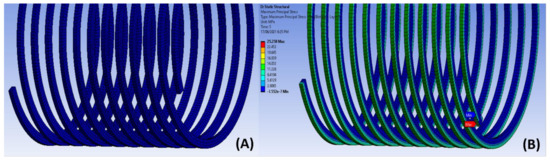

3.1. Loading Conditions of Mooring Tensioner

In the design of WECs, the mooring tensioner is connected to the mooring lines and the buoy. The wave energy drives the mooring tensioner to extend and rotate the shaft, which is connected to the PTO device to generate electricity. As shown in Figure 11, one end of the helical spring is fixed, and the other end is loaded. The spring wire in a helical torsion spring is loaded in bending and experiences a compression load on the inner surface and a tension load on the outer surface while it is subjected to cyclical external forces generated from the wave. The applied loads vary from minimum to maximum loading conditions, including a pre-tension load to keep the mooring line taut. Generally, the static mechanical properties, fatigue strength, and environmental durability of the composite in seawater conditions should satisfy the design requirements. The factors that are mentioned above are critical material selection criteria.

Figure 11.

Example of helical torsion spring: (A) unloaded conditions, (B) loaded with torque.

3.2. Adjustment of Spring Constant

In the application of a WEC, the geometric size of the mooring tensioner is constrained due to the limited space in the buoyant actuator. Typically, peak efficiencies of electric generators close to 99% can be achieved at a high rotating speed [24]. The efficiency decreases significantly (down to 60–70% depending on the generator) when the speed is low and the torque is high [24].

Therefore, a mooring tensioner with a relatively low stiffness and a constant geometric size is required to maximize the rotating speed of the shaft. The stiffness and strength properties of candidate spring materials are presented in Table 3. The tensile modulus of composite materials such as S-2 glass/epoxy and E glass/epoxy are much lower than copper or spring steel. In this regard, composite materials seem to be more suitable than steel springs with the same size and geometry.

In other applications, such as the automotive industry, springs with a higher stiffness are required to achieve the desired ride and handling performance. Composite springs made of a carbon-fiber-reinforced polymer can provide a similar modulus of elasticity and strength but at a lighter weight than the steel spring; therefore, they have started to replace steel springs. For example, as shown in Table 3, carbon fiber/epoxy has a tensile modulus of 140 GPa, which is similar to the stiffness of metal materials such as copper and stainless steel.

To sum up, the spring constants of composite springs can be flexibly adjusted to be similar to or lower than those of metal springs by selecting different types of fibers and matrices and different fiber volume fractions [4]. This will help engineers select different composite springs to achieve different spring constants for different applications with sizing and flexibility constraints.

Table 3.

Tensile modulus and strength of different spring materials.

Table 3.

Tensile modulus and strength of different spring materials.

| Type of Material | Fiber Volume Fraction | Tensile Modulus (GPa) | Ultimate Tensile Strength (MPa) | Density (g/cm3) | Fatigue Strength at 106 Cycles (MPa) |

|---|---|---|---|---|---|

| Copper wire (Phosphor Bronze Grade A ASTM B 159) [25] | N/A | 128 | 724 | 8.86 | 241 [26] |

| Stainless-steel wire (17–7 PH ASTM A 313 (631)) [25] | N/A | 203 | 1620 | 7.92 | 842.4 1 |

| High-carbon spring steel (Hard Drawn ASTM A 227) [25] | N/A | 207 | 1014 | 7.85 | 920 [27] |

| Gurit SparPreg unidirectional E glass/epoxy [28] | 68% | 44 | 935 | 2.14 2 | 420.8 3 |

| Gurit SparPreg unidirectional carbon fiber/epoxy [28] | 66% | 140 | 2234 | 1.55 | 720.6 4 |

| AGY unidirectional S-2 glass/epoxy [29] | 57–63% | 53–59 | 1590–2000 | 1.96–2.02 | 552.0 |

1 No data available in the datasheet. The reduction factor of stainless-steel wire is assumed to be the same as that of Si-Cr spring steel (JIS G3561, SWOSC-V) [30]. 2 No data available in the datasheet. Calculation of the value is based on the rule of mixture and the assumption that the epoxy density is 1.2 g/cm3. 3 No data available in the datasheet. The reduction factor of E glass/epoxy is assumed to be −55% [31]. 4 No data available in the datasheet. The reduction factor of carbon fiber/epoxy is assumed to be −70% [32].

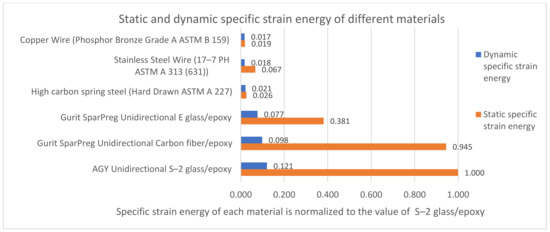

3.3. Specific Strain Energy

One of the important factors for a spring is its specific strain energy. The specific strain energy of a spring can be calculated using Equation (1):

where σ is the static strength or fatigue strength when the formula used to calculate static specific strain energy or dynamic specific strain energy, respectively; E is the Young’s modulus; and ρ is the density [3,33]. As discussed in Section 3.1, tension and compression loads are the critical loading conditions of helical torsion springs that are used in WECs, and therefore, for the purpose of comparison, the static and fatigue tensile strengths are analyzed in this section as material selection criteria. According to Equation (1), a composite material with a higher strength-to-weight ratio, lower modulus, and lower density provides a higher specific strain energy compared to a metal spring. This allows composite springs to absorb more energy when they are loaded under the same stress conditions within the allowable stress range [34]. Hence, a composite spring, as a mooring tensioner, can provide higher specific strain energy than a metal spring.

U = σ2/ρE

Figure 12 compares the static and dynamic specific strain energy of the spring materials that were discussed in Table 3. The static ultimate strength was used to calculate the static specific strain energy, which is represented by the orange bars in the chart. They show that a stainless-steel spring only has 6.7% of the static specific strain energy compared with S-2 glass/epoxy. The blue bars represent dynamic specific strain energy based on fatigue strengths at 106 cycles. They show that the S-2 glass/epoxy has the highest dynamic specific strain energy of all the materials.

Figure 12.

The specific strain energy (unidirectional properties under static and fatigue loads) of spring materials. The orange and blue bars represent the static specific strain energy and the dynamic specific strain energy of the materials, respectively, which were normalized to the static specific strain energy value of the S–2 glass/epoxy.

In summary, S-2 glass/epoxy can absorb more energy under static and dynamic load conditions compared with copper wire, stainless steel, carbon steel, and E glass/epoxy. Therefore, S-2 glass/epoxy can be a more efficient material for constructing a mooring tensioner to convert kinetic energy to electricity.

Table 3 shows the density of typical composite and metal materials. Carbon-fiber epoxy can provide an 80% and S-2 glass a 75% weight reduction compared to the same volume of mechanical tensioner made from stainless-steel wire. This weight reduction reduces the buoyancy required. For instance, a smaller volume of buoy is required to generate enough buoyancy to balance the weight of a composite spring compared with a metal spring.

3.4. Static Strength

In Table 3, the ultimate tensile strengths of common thermoset FRPs are compared with common metal spring materials. The table shows that unidirectional carbon/epoxy and unidirectional S-2 glass/epoxy have a higher static strength, lower density, and lower tensile modulus than the common metal spring materials, which explains why they have a higher static specific strain energy.

Therefore, material selection of FRP for the WECs is the main objective of the material selection section of this paper. The material selection section focuses on static strength, fatigue performance, seawater effects and a combination of seawater and fatigue loading perspectives of FRP.

3.5. Fatigue Performance

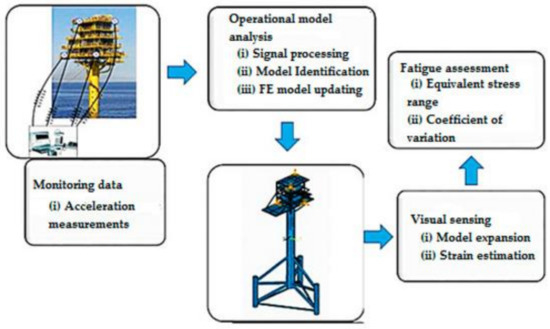

The fatigue failure of offshore oil and gas platforms is caused by dynamic loading conditions. This type of failure can happen without prior awareness and visibility. Therefore, as shown in Figure 13, offshore oil and gas industries have developed the following procedures to assess fatigue life and consider fatigue failure as a critical design factor [35]. However, Du et al. [36] reported that fatigue life evaluation can have an error of up to 35% if the simultaneous effects of marine corrosion and wave climate change are overlooked.

Figure 13.

Flowchart of fatigue analysis [35]. Reproduced with permission from Nima et al., Journal of Marine Science and Engineering; published by MDPI, 2021.

In the case of composite mooring tensioners, a similar approach to fatigue life assessment has been used. To minimize the error of fatigue life evaluation, the following factors of FRPs are analyzed: fiber orientation, stress ratio, and fiber volume fraction, which are discussed in the subsections below. The effect of water/seawater is discussed in Section 3.6.

The stress ratio or R ratio is an important concept in fatigue characterization. It is defined as the ratio of the minimum stress (σmin) to the maximum stress (σmax) experienced during one load cycle. For example, R = 0.1 represents tension–tension cycles where σmin = 0.1 × σmax, and R = 0 represents pulsating tension cycles where σmin = 0.

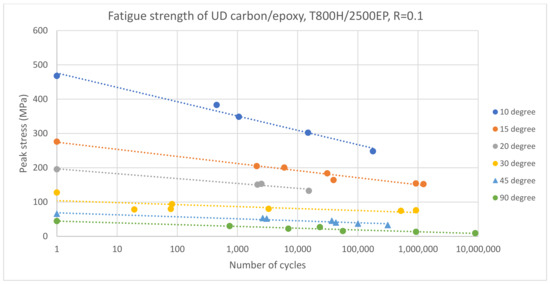

3.5.1. Effect of Fiber Orientation on Fatigue Strength of Composites

As shown in Figure 14, six different fiber directions of unidirectional (UD) T800H/epoxy composite with a 64% fiber volume fraction were analyzed at R = 0.1 and a frequency of 10 Hz for fatigue strength tests [37]. As the angle of fiber orientation increased from 10° to 90°, the tensile fatigue strength reduced. The fatigue strength of the composite with 10° fiber orientation at 105 cycles was reduced by around 39.1% compared with the static strength. In contrast, the fatigue strength for the 90° fiber orientation dropped by around 60% compared with the static strength. The range of the strength reduction factor was between 23.1–60% for these fiber orientations [37].

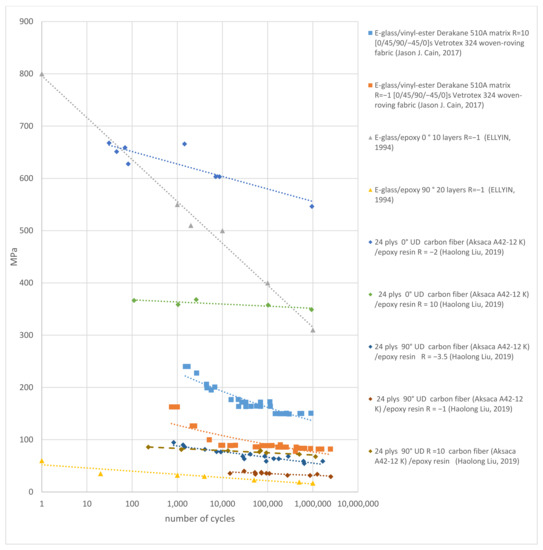

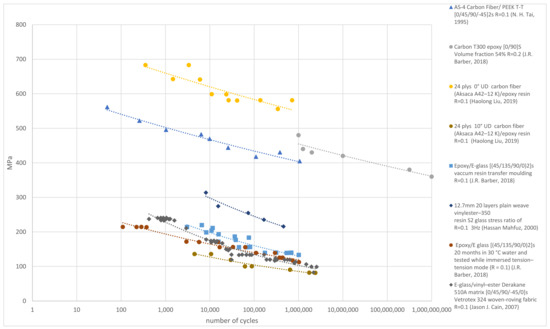

Experimental results for E glass/vinyl-ester, E glass/epoxy, carbon fiber/epoxy, carbon fiber/PEEK, S2 glass/vinyl ester, and E glass/vinyl ester are summarized in Figure 15 and Figure 16 to compare the fatigue performance of laminates with different fiber orientations. The figures show that laminates with fibers at a 0° orientation had higher fatigue strength than laminates with fibers at 90° in both compression–compression (C–C) and tension–compression (T–C) fatigue cycles for the different types of composites. Not only glass/epoxy and carbon/epoxy but also short-glass-fiber-reinforced polyamide-6 exhibited this trend [31,38,39,40]

In summary, many researchers have concluded that the principal loading direction could be designed in line with the direction of fibers to achieve higher fatigue strength, and that it is worth considering the different fatigue reduction factors of different fiber directions in engineering designs.

Figure 14.

Fatigue strength of UD carbon/epoxy with different fiber orientations at room temperature, adapted from [37].

Figure 15.

Summary of literature for tension–compression (T–C) and compression–compression (C–C) fatigue of E glass/vinyl-ester, E glass/epoxy, and carbon fiber/epoxy with different fiber orientations, adapted from [31,39,40].

Figure 16.

Tension–tension (T–T) fatigue data of carbon fiber/PEEK, carbon fiber/epoxy, E glass/epoxy, and S2 glass/vinyl ester, adapted from [3940414243].

3.5.2. Effect of Stress Ratios on Fatigue Strength of Composites

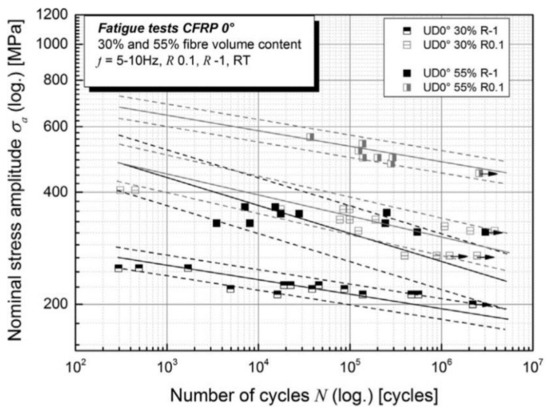

By comparing Figure 15 and Figure 16, one can conclude that the fatigue strength of composites under tension–tension (T–T) load conditions is higher than the fatigue strength under C–C and T–C load conditions [32,40]. For instance, the fatigue strength of Aksaca A42-12K carbon fiber under a stress ratio of 10 (R = 10) is around 41% lower than the strength under a stress ratio of 0.1 (R = 0.1) at 106 loading cycles [40]. Furthermore, as shown in Figure 17, the fatigue strength at approximately 2.5 million cycles of 0° UD carbon/epoxy with a 55% fiber volume fraction at R = −1 is 33.3% smaller than at a stress ratio of R = 0.1 [32]. According to research [32,40], it can be concluded that the fatigue strength of the same 0° UD carbon/epoxy is higher in T–T cycles compared to T–C and C–C cycles.

Figure 17.

Comparison of fatigue strength between two loading conditions and two fiber volume fractions [32]. Reproduced with permission from Julia Brunbauer and Gerald Pinter, International Journal of Fatigue; published by Elsevier, 2015.

3.5.3. Effect of Fiber Volume Fraction on Fatigue Strength of Composites

The effect of the fiber volume fraction has been analyzed by Ansari et al. [44] and Brunbauer and Pinter [32]. Different failure modes might occur with different fiber volume fractions. The damage mode observed in samples with a 30% fiber volume fraction was dominated by matrix cracking and fiber–matrix debonding in the T–T test [32]. In contrast, fiber pull-out was the main failure mode of the 55% sample under the same test conditions [32]. According to Ansari et al. [44], it should be noted that relatively high fiber volume fractions (45–60%) are ideal for superior fatigue durability. However, very high percentages (e.g., >70%) of fiber volume fractions will decrease the fatigue strength due to the lack of sufficient resin to secure the fibers [44].

In conclusion, previous studies on the influence of the fiber orientation, stress ratio. and fiber volume fraction on the absolute fatigue strength and fatigue strength reduction ratio suggest that the fiber direction and laminate sequence of the torsion spring should be designed to be in line with the principle loading direction to increase the fatigue performance. High fiber volume fractions between 45 and 60% should be targeted for applications requiring a long fatigue life.

3.6. Comparison of Mechanical Properties between Different Types of Fibers and Matrices in Dry and Seawater Conditions

Understanding the reasons why different types of fibers and matrices degrade at different rates when exposed to or immersed in seawater is critical for the design of offshore composite structures. In this subsection, the seawater degradation of the mechanical properties of composite materials is reviewed.

3.6.1. Comparison of Different Fibers in Dry Conditions

The properties of both the matrix and the fibers will affect the seawater durability and fatigue strength of a composite. This subsection analyzes how different FRPs respond differently under the same fatigue loading conditions in dry conditions. Munoz-Guijosa et al. [45] summarized the fatigue strengths of epoxy reinforced with unidirectional (UD) fibers but did not consider different brands and types of epoxy as a factor, which could have affected the accuracy of the comparison. The authors summarized the mechanical properties and fatigue strengths in a table, which was modified and is shown in Table 4 [45]. As shown in this table, S-2 glass and R glass had higher static ultimate tensile strength (UTS) than E glass. The fatigue strengths with stress ratios of R = 0 and R = 10 for AGY S-2 glass/epoxy at 3 × 105 cycles were higher than those of E glass/epoxy by 37% and 58%, respectively, in dry conditions.

Table 4.

Summary of mechanical properties of different fibers and spring steel in dry conditions at room temperature, adapted from [45].

3.6.2. Comparison of Different Fibers in Seawater Conditions

E glass, S glass, R glass, alkali-resistant (AR) glass fibers, and carbon fibers are typical fibers used in the composite industry. E-glass is an alumino-borosilicate glass with less than 1% alkali content. S-glass is a type of aluminosilicate glass without added calcium oxide that contains around 10% magnesium oxide. R-glass is a type of aluminosilicate glass without added calcium and magnesium oxides. AR glass contains zirconium oxide to increase alkali resistance [64].

It is critical to consider the degradation of the mechanical properties of composite materials in seawater. In the above case for E-glass fibers, the likely culprits are chloride ions, which diffuse through the resin and react with the E-glass. This causes the formation of fiber surface microcracks as stress concentrators, reducing the strength [65]. The chemical reaction is described in Table 5, and the degradation of strength occurs at all temperatures in seawater. Therefore, it is not recommended to use E-glass in submerged seawater conditions for long periods of time [65].

Table 5.

The degradation of mechanical properties for different composites.

The pH of sea water is within the range of 7.5 to 8.4, which is considered slightly or moderately alkaline [69]. R-glass, S-glass, and AR-glass have a similar modulus of elasticity, but AR-glass experiences less degradation of its mechanical properties in alkaline solution [64]. Broughton [65] found that the strength of E-glass composite was reduced by 30% in caustic solutions within 2 weeks. AR-glass has superior alkaline resistance, and it is widely used in glass-fiber-reinforced concrete in the civil industry [68,70]. Oh et al. [71] found that the optimum mix ratio of milled AR-glass fibers in milled E glass/epoxy can increase the durability of GFRP rebars in an alkaline environment. Research has also been conducted on the durability of AR-glass-fiber-reinforced cement in seawater [70,71,72].

S-2 glass and R-glass have better resistance to mineral acids and alkaline solution compared with E-glass [65]. However, there is a lack of research on the mechanical properties, fatigue strength, and seawater durability of AR-glass-, S-2-glass-, and R-glass-reinforced epoxy or other polymers.

It is also worth noting that the fatigue strength of S-glass varies from one grade to another. Research carried out by Tobler and Reads [73] in 1975 showed that the static tensile strength of UD S-901 glass/epoxy was 1330 MPa, and the T–T fatigue strength with R = 0.1 was around 279 MPa (21% of UTS) at 1 × 106 cycles, which is significantly lower than the 540 MPa fatigue strength of AGY S-2 glass/epoxy with R = 0.05 under the same fatigue cycles [48].

In contrast, carbon fiber has good chemical resistance, does not react with water or seawater, and is only affected by harsh environments, such as H2S solution [43]. As shown in Table 4, with the same void content of the samples and same type of resin, UD carbon fiber/epoxy generally exhibits a higher fatigue strength than glass/epoxy in dry conditions. As shown in Table 5, carbon fibers also have better stability in seawater compared with other fibers. However, carbon fiber/epoxy has a higher Young’s Modulus than glass/epoxy, and therefore it may not be an ideal material to provide a relatively high static specific strain energy.

3.6.3. Comparison of Different Matrices in Seawater Conditions

The mechanical properties of composites in seawater are affected by fiber and matrix durability. Current evidence shows that different types of matrices absorb seawater at different rates, and some will leach out organic species [74]. Thus, when designing composite mechanical mooring tensioners, it is important to select composite materials that have superior durability in seawater.

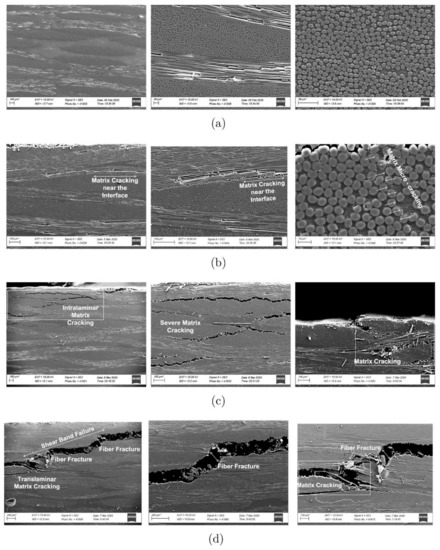

Matrix strength plays an important role in the fatigue performance of a composite. Figure 18 shows the stages of fatigue failure progression under dry conditions. Inset (a) shows a composite sample that has not been tested yet and inset (b) indicates that a crack in the matrix is initiated at the composite surface and progresses through the matrix in between rows of fibers. An intralaminar matrix fracture caused by further matrix cracking is shown in inset (c), indicating that the crack growth rate is dependent on the applied strain. The crack propagates through different layers of the matrix when the applied strain is increased. Finally, as shown in inset (d), translaminar matrix cracking and fiber fracture occur, resulting in a shear band failure mode and sample fracture. Compared with the dry sample, the seawater-saturated sample displays similar stages of fatigue failure but also exhibits a lower fatigue life than the dry sample [75]. It is also noteworthy that seawater immersion conditions can lower the matrix and fiber resistance to intralaminar and translaminar fracture [75,76], confirming the importance of careful material selection.

Figure 18.

Scanning electron microscopy images of fatigue failure of composites in dry conditions (a) untested sample without damage, (b) stage 1: matrix micro-crack and matrix crack at interface of fine bundles was (c) stage 2: interlaminar matrix cracking (d) stage 3: translaminar matrix cracking and shear band formation with fiber fracture [75]. Reproduced with permission from Pavana et al., International Journal of Fatigue; published by Elsevier, 2020.

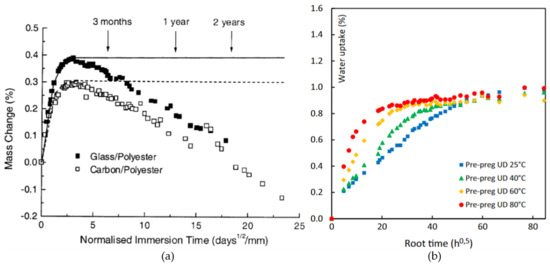

Kootsookos and Mouritz [74] demonstrated that, for samples of 1.5−1.6 mm thickness (Figure 19a), the maximum water absorption of E glass/polyester is higher than that of carbon/polyester at 3 days^(1/2)/mm, resulting in a 0.4% and 0.3% mass change, respectively. The thickness of E glass/polyester and carbon/polyester specimens varies from 1.5–1.6 mm. Therefore, days^(1/2)/mm was used to normalize the thickness to correct the seawater uptake performance. The authors also found that the mass change percentage of both composites reduced at a similar rate, whereby the mass of carbon/polyester declined below the original mass at 18 days^(1/2)/mm. These findings indicate that both E-glass/polyester and carbon/polyester absorb seawater until saturation and meanwhile leach out organic species at a similar rate at room temperature.

As discussed in Section 3.6.2, E-glass reacts with chloride ions and leaches out alkali oxides due to the diffusion of seawater through resin. If the chemical attack on the E-glass were significant, then the mass gain curve of the E-glass/polyester would be lower than that of the carbon/polyester. However, as shown in Figure 19, this was not the case, because the mass change was primarily attributed to the reaction between water and polyester, and the mass change caused by the weight change of the E-glass was negligible [74]. Kootsookos and Mouritz [74] explained that the reason for the mass change difference was that the moisture uptake at the interphase region of the glass/polyester was higher than that at the interphase region of the carbon/polyester.

Figure 19.

Seawater uptake conditions of (a) glass/polyester and carbon/polyester. Degree of polyester cure was 88% [74]. Reproduced with permission from Kootsookos and Mouritz, Composites Science and Technology; published by Elsevier, 2004. (b) Carbon/epoxy prepreg 2 mm thickness at 25, 40, 60, and 80 °C [77]. Reproduced with permission from Tual et al., Composites Part A: Applied Science and Manufacturing; published by Elsevier, 2015.

In contrast, a mass change of around 0.55% in both fully cured glass/vinyl ester and carbon/vinyl ester is typically measured within one year of immersion and remains at that level for the next two years, indicating that both composites do not leach out after reaching full saturation [74]. Moreover, as shown in Figure 19b, unidirectional carbon epoxy prepreg absorbs around 0.9% of water to reach saturation and does not leach out within 267 days [77]. As shown in Table 6, carbon/acrylic does not leach out after saturation conditions of 0.8% weight gain within 540 days of immersion [78].

In summary, vinyl ester, epoxy, and acrylic matrices do not leach out once full saturation has been achieved within the first year of seawater immersion. However, polyester continues to leach out even after reaching saturation. Therefore, matrices that leach out in seawater should not be utilized in marine environments. Moreover, the fatigue strength of the chosen composite should be analyzed to ensure the durability of its structures in seawater.

Table 6.

Literature pertaining to composite water absorption.

Table 6.

Literature pertaining to composite water absorption.

| Type of Composite | Saturation and Leaching Conditions | Change in Mechanical Properties | |||||

|---|---|---|---|---|---|---|---|

| Max Water Uptake % at Immersion Time | Leaching Conditions | Duration of Immersion Test | Reference | Flexural Strength at Duration of Seawater Immersion (MPa) | Flexural Strength under Dry Conditions (MPa) | Reference | |

| Carbon/polyester 88% cured | 0.3 at 2 months | Leaching after max saturation | 3 years | [74] | 624 at 52 days 1 [74] | 833 | [79] |

| E glass/polyester 88% cured | 0.4 at 2 months | Leaching after max saturation | 3 years | [74] | 72 at 52 days 1 [74] | 120 | [80] |

| Carbon/vinyl ester 88% cured | 0.55 at 12 months | Does not leach out | 2 years | [74] | 150 at 450 days | 280 | [81] |

| E glass/vinyl ester 88% cured | 0.55 at 3 months | Does not leach out | 2 years | [74] | 62 at 450 days | 80 | [81] |

| Carbon/epoxy | 0.9 at around 150 days | Does not leach out | 267 days | [77] | 180 at 450 days | 260 | [81] |

| E glass/epoxy | 0.88 at around 365 days | Does not leach out | 450 days | [81] | 55 at 450 days | 85 | [81] |

| Carbon/acrylic | 0.8 at around 70 days | Does not leach out | 540 days | [78] | N/A | N/A | |

1 Flexural strength of seawater-immersed carbon/polyester and E glass/polyester samples is calculated using reduction factors of 25% and 40%, respectively (reduction factors provided by Kootsookos and Mouritz [74].

3.7. Effect of Moisture on the Fatigue Strength of Composites

Different fibers reinforce epoxy responses differently under the same fatigue loading conditions in dry conditions. As shown in Table 7, dry carbon fiber/epoxy experiences a lower strength degradation compared to dry E glass fiber/epoxy for the same range of T–T cycles from 100 to 106 [40,43]. Exposure to water can influence the properties of different types of composites at different rates.

Not only fatigue loading but also exposure to water contribute to the impairment of composite properties. According to J.R. Barber [43] and Davies and Rajapakse [82], identical E-glass-reinforced epoxy samples were conditioned in water and dry conditions and tested under the same fatigue cycles to investigate the effect of water on the static and fatigue strength. As shown in Table 7, dry E glass/epoxy laminate and samples immersed in 30 °C water for 20 months were tested under fatigue loading. The fatigue strength of the water-conditioned samples at 106 was reduced by 50% compared with the strength at 102 cycles, while the fatigue strength of dry E glass/epoxy was reduced by 43% compared with the strength at 102 cycles. The fatigue strength reduction of the conditioned E glass/epoxy was 7% greater than that of the dry E glass/epoxy, clearly highlighting the significance of aging in water.

Based on the literature, not only E glass/epoxy, but also many other composites degrade in seawater, such as carbon fiber/vinyl-ester, carbon fiber/epoxy, and carbon fiber/PEEK [54,75]. Even though, as discussed in Section 3.6.2, carbon fiber has good chemical resistance and does not react with water or seawater, many polymers degrade in seawater, causing a fatigue strength reduction in carbon-fiber-reinforced polymers. For example, a [±45]2S carbon fiber/vinyl-ester that was immersed in seawater at 40 °C for 6 months showed an 80% reduction in the number of tension–tension fatigue cycles compared to the dry samples under the conditions of 2/3 ultimate strength loading [54]. In another study, the flexural fatigue life of saturated carbon fiber/vinyl-ester immersed in seawater for 140 days at room temperature was reduced by 62% compared to the dry samples [75].

Mao Zhou [83] showed that UD carbon/samples that were immersed in seawater for 1 month reached fatigue loading at 0.5 million cycles at 65% of the ultimate flexural strength (UFS). However, the dry UD samples could retain 90% of the UFS after 1 million cycles [83]. For further explanation, Section 3.6 discussed how seawater affects the fatigue performance of different fibers and matrices.

It is worth mentioning that the composite manufacturing process and laminate sequences are different for the majority of examples discussed here. This decreases the accuracy of the comparison. Therefore, it is recommended that more experimental research is conducted on the fatigue performance of different types of fibers and matrices to understand how each type of fiber or matrix performs in fatigue loading while keeping other variables such as the fiber volume fraction, laminate sequence, and fiber direction the same. Successful mooring tensioner FRP product development relies on the fatigue characteristics of the composite material in seawater conditions. As discussed, the available data relating to the fatigue performance of seawater-conditioned composites are currently very sparse, and significant research is required to fill this gap.

Table 7.

Tension–tension and tension–compression fatigue of typical composite materials.

Table 7.

Tension–tension and tension–compression fatigue of typical composite materials.

| Reference | Fiber/Matrix Type | Laminates | Conditions | UTS MPa | Fatigue Strength at 106 Cycles MPa | Load Conditions | Fatigue Strength Reduction for the Range of Cycles |

|---|---|---|---|---|---|---|---|

| [31] | E glass/epoxy 3 M Type 1003 | 0° UD 10 layers | Dry/room temperature | 800 | 350 | Tension–compression, R = −1 | −55% (from UTS to 106) |

| [43] | E glass/epoxy Ahlstrom#42,007 | [(45°/135°/90°/0°)2] s | Dry | N/A | 130 | T–T, R = 0.1 | −43% (from 102 to 106) |

| [43] | E glass/epoxy Ahlstrom#42,007 | [(45°/135°/90°/0°)2] s | 20 months immersed 30 °C water | N/A | 115 | T–T, R = 0.1 | −50% (from 102 to 106) |

| [39] | E glass/vinyl-ester Derakane 510 A matrix and Vetrotex 324 woven-roving fabric | [0/45/90/−45/0] s | Dry/room temperature | N/A | 100 | T–T, R = 0.1 | −58% (from 103 to 106) |

| [41] | S2 glass vinylester-350 resin | 12.7 mm thickness, 20 layers plain weave | Dry/room temperature | N/A | 210 | T–T, R = 0.1 | −33% (from 104 to 106) |

| [40] | Carbon fiber/epoxy resin Aksaca A–42 | 24 ply 0° UD | Dry/room temperature | N/A | 510 | T–T, R = 0.1 | −26% (from 102 to 106) |

| [40] | Carbon fiber/epoxy resin Aksaca A–42 | 24 ply 0° UD | Dry/room temperature | N/A | 450 | T–C, R = −2 | −33% (from 102 to 106) |

| [42] | AS-4 carbon fiber/PEEK | [0/45/90/−45]2 s | Dry/room temperature | N/A | 406 | T–T, R = 0.1 | −22% (from 102 to 106) |

3.8. Comparison between Composites and Metal Materials

Composite springs may exceed the performance of conventional steel springs by the flexible adjustment of the spring constant and better corrosion resistance. However, since they are a relatively new technology, their long-term structural performance and fatigue behavior is not well understood. To achieve an appropriate level of reliability, the long-term fatigue performance must be understood.

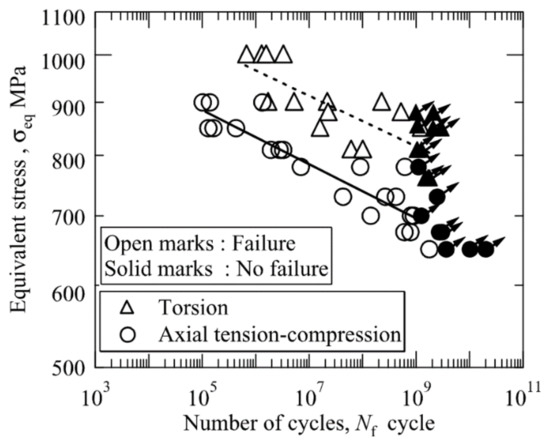

With respect to metal springs, the most commonly used spring steels are high-carbon steels, alloy spring steels, stainless spring steels, copper-based spring alloys, and nickel-based spring alloys. Alloy spring steels have advantages in terms of their long fatigue life compared with other types of steel springs. As an example, silicon chromium (Si-Cr) alloy steel is a type of heat-treated alloy spring steel that is designed to have a long fatigue life at a relatively high stress level [84]. Akiniwa et al. [30] used oil-tempered Si-Cr spring steel (JIS G3561, SWOSC-V) and conducted axial and torsional tests. In both tests, a stress ratio of −1 and a cycling frequency of 20 kHz were used. According to the datasheet provide by the Japanese Industrial Standard [63], the ultimate tensile strength (UTS) of JIS G3561 is 1660 MPa. Figure 20 shows that the equivalent stress is around 800 MPa at 106 axial tension–compression cycles and 650 MPa at 109 cycles. A 52% reduction from the UTS was observed for 106 cycles [30].

Figure 20.

Axial tension–compression and torsion data in terms of equivalent stresses [30]. Reproduced with permission from Akiniwa et al., International Journal of Fatigue; published by Elsevier, 2008.

In general, the percentage of fatigue strength degradation for oil-tempered Si-Cr steel and for 3 M type 1003 E glass/epoxy is similar, reaching about 50% of the UTS [30, 43]. However, 0° UD carbon fiber/epoxy has a lower percentage reduction [40]. Comparing Figure 20 with Figure 15, it can be concluded that the fatigue strength of Si-Cr spring steel is higher than that reported for E glass/epoxy and carbon/epoxy at 106 cycles. However, there is a lack of data available for the fatigue strength of S-2 glass/epoxy and R glass/epoxy at 106 cycles.

4. Overview of Spring Types and Manufacturing Methods

To the knowledge of the authors, there are currently no commercial composite mooring tensioner springs in existence. Despite the many advantageous properties discussed above, the challenge that needs to be overcome is their manufacturing. The subsequent section reviews a number of composite springs with respect to their applications and manufacturing processes. This section may serve as an inspiration and guide for the selection of suitable manufacturing processes for composite mooring tensioner springs. In Table 8, the different types of composite springs used in different industries and their related advantages are summarized. Composite spiral springs are designed to be used as energy storage systems [45]. Composite tape springs have been developed as a novel type of spring [85]. Composite semi-elliptical springs, elliptic springs, helical springs, disk springs, and leaf springs were designed for automotive suspension applications [3,4,86,87,88,89,90,91].

Table 8.

Different types of composite spring and related manufacturing methods.

For the production of composite springs that have a curved surface or coil shape, only certain manufacturing methods are available. Therefore, four of the most promising manufacturing methods for large mooring tensioner springs are discussed next. The manufacturing methods are summarized with respect to their advantages, disadvantages, and limitations in Table 9. Each method has different advantages, such as quality or cost effectiveness. Therefore, each method suits a different spring design and a different level of volume production.

Table 9.

Summary of advantages, disadvantages, and limitations of typical manufacturing methods of composite springs.

5. Conclusions and Recommendations for Future Studies

5.1. Conclusions

The application of composite springs as mooring tensioners has been discussed in this paper as a potential innovation to be used in WECs, offshore wind farms, offshore platforms, and vessels. Composite springs could potentially be applied as mooring tensioners in mooring systems to dissipate the energy caused by harsh environments and maximize the efficiency of the power generation of WECs. Composite springs offer many advantages, such as a wide range of achievable spring constants, corrosion resistance, a higher specific strain energy, and a lighter weight. The key findings of this review paper are summarized as follows:

- The fatigue strength of composite materials is affected by the type of fiber and matrix, the fiber volume fraction, and the fiber orientation. A fiber volume fraction of 45–60% provides superior fatigue strength. The fatigue strength starts to decrease when the fiber fraction is greater than 70%.

- Carbon fiber has superior seawater resistance and does not react with seawater. However, carbon fibers with a relatively high modulus might not be suitable for applications requiring high elasticity.

- It is not recommended to use E-glass-reinforced composites in submerged seawater conditions due to their low chemical resistance and seawater resistance.

- It was found that R glass and S glass have a higher strength and seawater resistance than E glass. Thus, glass fibers such as AR glass, R glass, and S glass could be the desired material options for applications requiring high elasticity in offshore environments.

- Epoxy, acrylics, and vinyl esters reached saturation conditions and did not leach out within the experimental duration in water-immersion conditions.

- Polyester was found to leach out organic species after it reached maximum weight gain at around 2 months immersed in seawater at room temperature. Leaching could cause the severe degradation of the mechanical properties of composites, and therefore polyester may not be suitable for applications in seawater for long-term service.

- Potential composite mooring tensioner manufacturing methods such as the vacuum-assisted resin infusion of composite multistrand springs, high-pressure resin transfer molding, filament winding, and automated fiber placement may be suitable manufacturing methods for large composite springs.

5.2. Recommendations for Future Studies

The main challenge facing the design of future composite springs for offshore applications is accurately determining the fatigue performance of composite springs under seawater conditions. Research that compares the fatigue performance of different resin types, fibers, and structural features under realistic fatigue cycles and conditioning regimes is very sparse. For example, carefully designed experiments to develop constant-life diagrams for composite materials used in seawater conditions are required to de-risk the development and application of composite springs in marine environments.

Many toughening methods have been analyzed by researchers [101,102]. The inclusion of a thermoplastic phase to increase the impact and post-impact of fiber-reinforced thermosetting composites has been investigated. The inclusion of thermoplastic phases can be achieved using toughening methods such as adding nanoparticles, bulk resin modification by blending thermoplastics with thermosets, and interlaminar modification [101,102]. However, there is a lack of research regarding the use of toughening methods to improve the environmental durability and fatigue performance of FRPs in seawater conditions. Some recommendations for future study are listed below:

- The comparison of mechanical property degradation for E-glass-, S-glass-, AR-glass, and R-glass-reinforced epoxy in seawater immersion conditions. Understanding how R glass, S glass, AR glass fiber/epoxy perform in fatigue loading under seawater immersion.

- The development of toughening methods for the matrix to increase the fatigue strength of composite materials in seawater environments.

- The development of an efficient and durable composite mechanical tensioner to provide a desired specific strain energy and compact configuration for offshore applications.

- Additive manufacturing methods are gaining popularity across many industries. With respect to the manufacture of composite spring elements discussed in this paper, a potential benefit of additive composite manufacture is the ability to produce large structures without the need for large molds. This research area is still in its infancy, and currently the structural properties of additively manufactured composites cannot compete with those of traditional manufacturing processes. Consequently, research efforts are required to develop new additive composite manufacturing properties targeting the manufacture of high-quality large structures.

Author Contributions

Conceptualization and methodology, Y.C., M.B. and M.T.H.; software, Y.C., M.B. and M.T.H.; formal analysis, Y.C.; investigation, Y.C.; writing—original draft preparation, Y.C.; writing—review and editing, Y.C., M.B., A.P.B., M.V. and M.T.H.; supervision, M.B., M.V. and M.T.H.; project administration and funding acquisition, M.T.H. All authors have read and agreed to the published version of the manuscript.

Funding

The authors acknowledge the financial support of the Blue Economy CRC, established and supported under the Australian Government’s CRC Program, grant number CRC-20180101. The CRC Program supports industry-led collaborations between industry, researchers, and the community.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors gratefully acknowledge the assistance provided by Rodney Thomson (Advanced Composite Structures Australia) and Alexandre Pichard (Carnegie Clean Energy). Their insight, guidance, and feedback during the writing of this review was highly appreciated.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Amaechi, C.V.; Chesterton, C.; Butler, H.O.; Gillet, N.; Wang, C.; Ja’e, I.A.; Reda, A.; Odijie, A.C. Review of Composite Marine Risers for Deep-Water Applications: Design, Development and Mechanics. J. Compos. Sci. 2022, 6, 96. [Google Scholar] [CrossRef]

- Saad, P.; Salama, M.M.; Jahnsen, O. Application of Composites to Deepwater Top Tensioned Riser Systems. In Proceedings of the ASME 2002 21st International Conference on Offshore Mechanics and Arctic Engineering, Oslo, Norway, 23–28 June 2002. [Google Scholar]

- Ke, J.; Wu, Z.; Chen, X.; Ying, Z. A review on material selection, design method and performance investigation of composite leaf springs. Compos. Struct. 2019, 226, 2–14. [Google Scholar] [CrossRef]

- Wu, L.; Chen, L.; Fu, H.; Jiang, Q.; Wu, X.; Tang, Y. Carbon fiber composite multistrand helical springs with adjustable spring constant: Design and mechanism studies. J. Mater. Res. Technol. 2020, 9, 5067–5076. [Google Scholar] [CrossRef]

- Huang, C.-C.; Tang, H.-J.; Liu, J.-Y. Dynamical analysis of net cage structures for marine aquaculture: Numerical simulation and model testing. Aquac. Eng. 2006, 35, 258–270. [Google Scholar] [CrossRef]

- Carnegie Clean Energy. CETO Technology. 2020. Available online: https://www.carnegiece.com/ceto-technology/ (accessed on 13 June 2021).

- Amaechi, C.V.; Reda, A.; Butler, H.O.; Ja’e, I.A.; An, C. Review on fixed and floating offshore structures. Part I: Types of platforms with some applications. J. Mar. Sci. Eng. 2022, 10, 1074. [Google Scholar] [CrossRef]

- Ma, K.-T.; Luo, Y.; Kwan, C.-T.T.; Wu, Y. Mooring System Engineering for Offshore Structures; Gulf Professional Publishing: Houston, TX, USA, 2019. [Google Scholar]

- Wu, Y.; Wang, T.; Ma, K.-T.; Heyl, C.; Garrity, R.; Shelton, J. Mooring Tensioning Systems for Offshore Platforms: Design, Installation, and Operating Considerations. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 30 April–3 May 2018. [Google Scholar]

- D’Souza, R.; Majhi, S. Application of Lessons Learned From Field Experience to Design, Installation and Maintenance of FPS Moorings. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 6–9 May 2013. [Google Scholar]

- Ma, K.-T.; Shu, H.; Smedley, P.; L’Hostis, D.; Duggal, A. A Historical Review on Integrity Issues of Permanent Mooring Systems. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 6–9 May 2013. [Google Scholar]

- ExxonMobil. Mooring Rapid Response Plan Front End Study; Granherne: Houston, TX, USA, 2010. [Google Scholar]

- Brown, M.G.; Hall, T.D.; Marr, D.G.; English, M.; Snell, R.O. Floating Production Mooring Integrity JIP—Key Findings. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 2–5 May 2005. [Google Scholar]

- RRD Team. Renewables 2020 Global Status Report; 2020. Available online: https://www.ren21.net/wp-content/uploads/2019/05/gsr_2020_full_report_en.pdf (accessed on 12 May 2021).

- Al Shami, E.; Zhang, R.; Wang, X. Point Absorber Wave Energy Harvesters: A Review of Recent Developments. Energies 2019, 12, 47. [Google Scholar] [CrossRef]

- Leverette, S.J.; Pollack, J. In-Line Mooring Connector and Tensioner. U.S. Patent 2014/0026796, 30 January 2014. [Google Scholar]

- Taylor, R. Mooring Tensioner and Methods Thereof. U.S. Patent 10,974,792, 13 April 2017. [Google Scholar]

- Lisland, T. Mooring Pulley Tensioning System. U.S. Patent 10,577,056, 3 March 2017. [Google Scholar]

- Bauer, T.C. Systems and Methods for Tensioning Mooring Lines at the Seafloor. U.S. Patent 9,487,272, 8 November 2015. [Google Scholar]

- Technologies, O.H. Introduction to InfinityWEC. Available online: https://www.oceanharvesting.com/infinitywec-technology/ (accessed on 10 February 2022).

- CorPower Ocean. Corpower’s Wave Energy Concept. 2019. Available online: https://www.corpowerocean.com/technology/ (accessed on 18 September 2021).

- Tension Technology International. Marine Mooring System Services. Available online: https://www.tensiontech.com/services/mooring (accessed on 21 February 2022).

- Two C’s Marine. Moorings 101. 2020. Available online: https://www.twocsmarine.com/moorings-101/ (accessed on 12 August 2021).

- Mahmoudi, A.; Soong, W.L.; Pellegrino, G.; Armando, E. Efficiency maps of electrical machines. In Proceedings of the IEEE Energy Conversion Congress and Exposition (ECCE), Montreal, QC, Canada, 20–24 September 2015. [Google Scholar]

- Ace Wire Spring & Form. Properties of Common Spring Materials. 2005. Available online: https://www.tribology-abc.com/calculators/properties_of_common_spring_materials.pdf (accessed on 28 August 2021).

- Copper Development Association Inc. 2013. Available online: https://www.copper.org/applications/industrial/DesignGuide/performance/fatigue03.html#:~:text=The%20standard%20fatigue%20strength%20for,withstand%20more%20cycles%20before%20failure (accessed on 28 April 2021).

- Hayes, M. Fatigue of Springs. In Fatigue and Fracture; ASM International: Almere, The Netherlands, 1996. [Google Scholar]

- Gurit. Carbon & Glass SparPregTM UD Prepreg Spar Solution. 2019. Available online: https://www.gurit.com/-/media/gurit/datasheets/sparpreg.pdf (accessed on 28 August 2021).

- AGY. High Strength Glass Fibers; AGY: 1996. Available online: https://www.agy.com/wp-content/uploads/2014/03/Advanced_Materials_Brochure-Technical.pdf (accessed on 28 July 2021).

- Akiniwa, Y.; Stanzl-Tschegg, S.; Mayer, H.; Wakita, M.; Tanaka, K. Fatigue strength of spring steel under axial and torsional loading in the very high cycle regime. Int. J. Fatigue 2008, 30, 2057–2063. [Google Scholar] [CrossRef]

- El Kadi, H.; Ellyin, F. Effect of stress ratio on the fatigue of unidirectional glass fibre/epoxy composite laminae. Composites 1994, 25, 917–924. [Google Scholar] [CrossRef]

- Brunbauer, J.; Pinter, G. Effects of mean stress and fiber volume content on the fatigue-induced damage mechanisms in CFRP. Int. J. Fatigue 2015, 75, 28–38. [Google Scholar] [CrossRef]

- Yu, W.-J.; Kim, H.-C. Double tapered FRP beam for automotive suspension leaf spring. Compos. Struct. 1988, 9, 279–300. [Google Scholar] [CrossRef]

- Chiu, C.-H.; Hwan, C.-L.; Tsai, H.S.; Lee, W.P. An experimental investigation into the mechanical behaviors of helical composite springs. Compos. Struct. 2007, 77, 331–340. [Google Scholar] [CrossRef]

- Amiri, N.; Shaterabadi, M.; Reza Kashyzadeh, K.; Chizari, M. A Comprehensive Review on Design, Monitoring, and Failure in Fixed Offshore Platforms. J. Mar. Sci. Eng. 2021, 9, 1349. [Google Scholar] [CrossRef]

- Du, J.; Wang, H.; Wang, S.; Song, X.; Wang, J.; Chang, A. Fatigue damage assessment of mooring lines under the effect of wave climate change and marine corrosion. Ocean. Eng. 2020, 206, 107303. [Google Scholar] [CrossRef]

- Kawai, M.; Yajima, S.; Hachinohe, A.; Takano, Y. Off-Axis Fatigue Behavior of Unidirectional Carbon Fiber-Reinforced Composites at Room and High Temperatures. J. Compos. Mater. 2001, 35, 545–576. [Google Scholar] [CrossRef]

- Bernasconi, A.; Davoli, P.; Basile, A.; Filippi, A. Effect of fibre orientation on the fatigue behaviour of a short glass fibre reinforced polyamide-6. Int. J. Fatigue 2007, 29, 199–208. [Google Scholar] [CrossRef]

- Cain, J.J.; Post, N.L.; Case, S.W.; Lesko, J.J. R-Ratio Effects on Glass-Reinforced Polymer Composite Life and Remaining Strength. In Proceedings of the 16th International Conference on Composite Materials, Kyoto, Japan, 8–13 July 2007. [Google Scholar]

- Liu, H.; Ojha, A.; Li, Z.; Engler-Pinto, C.C.; Su, X.; Sun, Q.; Kang, H.; Wen, W.; Cui, H. Fatigue modeling for carbon/epoxy unidirectional composites under various stress ratios considering size effects. Int. J. Fatigue 2019, 120, 184–200. [Google Scholar] [CrossRef]

- Mahfuz, H.; Zaman, K.; Haque, A.; Foy, C.; Mohamed, H.; Jeelani, S. Fatigue Life Prediction of Thick-Section S2-Glass/Vinyl-Ester Composites Under Flexural Loading. J. Eng. Mater. Technol. 2000, 122, 402–408. [Google Scholar] [CrossRef]

- Tai, N.H.; Ma, C.C.M.; Wu, S.H. Fatigue behaviour of carbon fibrePEEK laminate composites. Composites 1994, 26, 551–559. [Google Scholar] [CrossRef]

- Barber, A.A.J.R. Durability of Composites in a Marine Environment; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Ansari, M.T.A.; Singh, K.K.; Azam, M.S. Fatigue damage analysis of fiber-reinforced polymer composites—A review. J. Reinf. Plast. Compos. 2018, 37, 636–654. [Google Scholar] [CrossRef]

- Munoz-Guijosa, J.M.; Zapico, G.F.; de la Peña, J.; Echávarri, J. Using FRPs in elastic regime for the storage and handling of mechanical energy and power: Application in spiral springs. Compos. Struct. 2019, 213, 317–327. [Google Scholar] [CrossRef]

- DowAksa. Continuous Carbon Fiber Properties. 2020. Available online: https://www.dowaksa.com/aksaca/ (accessed on 3 May 2021).

- Toray. Toray Composite Materials Datasheet. 2020. Available online: www.toraycma.com (accessed on 28 April 2021).

- AGY. AGY Advanced Materials Datasheet. Available online: https://www.agy.com/wpcontent/uploads/2014/03/Advanced_Materials_Brochure-Technical.pdf (accessed on 28 April 2021).

- Wu, Z.; Wang, X.; Iwashita, K.; Sasaki, T.; Hamaguchi, Y. Tensile fatigue behavior of FRP and hybrid FRP sheets. Compos. B Eng. 2010, 41, 396–402. [Google Scholar] [CrossRef]

- Michel, S.A.; Kieselbach, R.; Martens, H.J. Fatigue strength of carbon fibre composites up to the gigacycle regime. Int. J. Fatigue 2006, 28, 261–270. [Google Scholar] [CrossRef]

- Toray. Toray T700S Datasheet. Available online: www.toraycma.com (accessed on 28 April 2021).

- Department Of Defense Handbook. Composite Materials Handbook, Polymer Matrix Composites Materials Properties; U.S. Government Bookstore: Washington, DC, USA, 1999; p. 2.

- Toray. Datasheet Toray T800H. Available online: www.toraycma.com (accessed on 28 April 2021).

- Siriruk, A.; Penumadu, D. Degradation in fatigue behavior of carbon fiber–vinyl ester based composites due to sea environment. Compos. Part B Eng. 2014, 61, 94–98. [Google Scholar] [CrossRef]

- APCM. DA 4518U/E-Glass Unidirectional E-glass epoxy prepreg. Available online: http://www.prepregs.com/wp-content/uploads/2016/06/da4518eglassdatasheet.pdf (accessed on 18 June 2021).

- Koricho, E.G.; Belingardi, G.; Beyene, A.T. Bending fatigue behavior of twill fabric Eglass/epoxy composite. Compos. Struct. 2014, 111, 169–178. [Google Scholar] [CrossRef]

- Mandell, J.F.; Samborsky, D.D. DOE/MSU Composite Material Database, Version 19.0. Master’s Thesis, Montana State University, Bozeman, MT, USA, 2010. [Google Scholar]

- AGY. High Strength Glass Fibes. In R2 AGY Technical Paper; AGY: Aiken, SC USA, 2006. [Google Scholar]

- Kinsella, M.; Murray, D.; Crane, D.; Mancinelli, J.; Kranjc, M. Mechanical properties of polymeric composites reinforced with high strength glass fibers. In Proceedings of the 33th International SAMPE Technical Conference, Seattle, WA, USA, 5–8 November 2001. [Google Scholar]

- Mandell, J.F. Recent Fatigue Test Result For Blade Materials. In 2008 Wind Turbine Blade Workshop; Department of Chemical and Biological Engineering, Montana State University: Bozeman, MT, USA, 2008. [Google Scholar]

- HiPer-tex. HiPer-texTM W2020 Rovings. 2019. Available online: https://www.3b-fibreglass.com/sites/default/files/products-data-sheets/TDS-HiPer-tex-W-2020-Rovings-for-Epoxy-Resin-2015-sans-trame-LR.pdf (accessed on 18 May 2021).

- Wilson ML, J.G. Comparison of Flexural Properties of Aramid-Reinforced Pultrusions Having Varied Matrices, Pretreatments and Postcures. In NASA Tech Memorandum; University of Michigan Library: Ann Arbor, MI, USA, 1997. [Google Scholar]