Primary Factors Affecting the Efficiency of Thermoelectric Power Generation Sheets for Waste-Heat Recovery from the Ship’s Exhaust Gas

Abstract

:1. Introduction

2. Theory

2.1. Theoretical Foundations

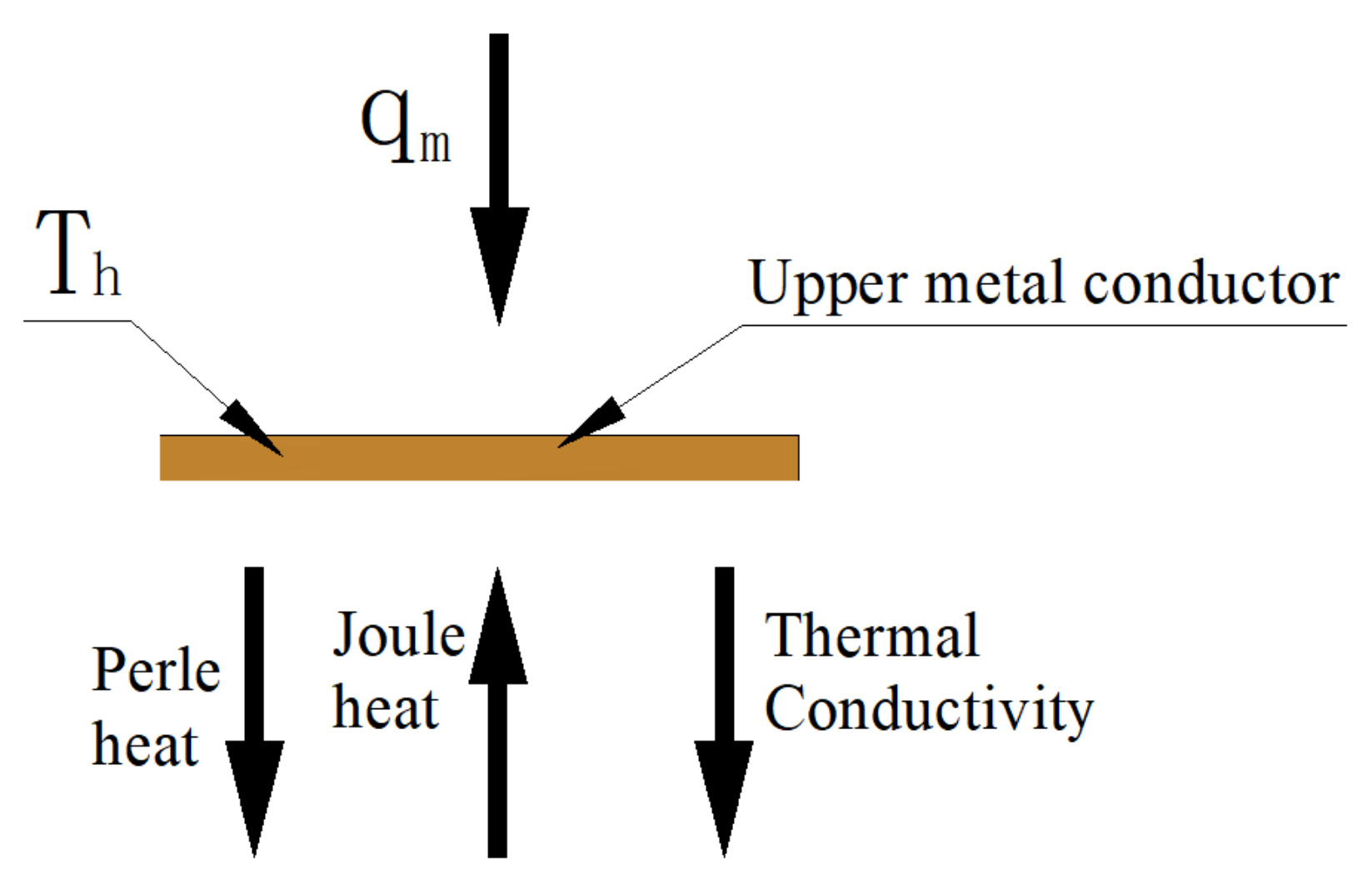

2.2. Theoretical Models and Calculations

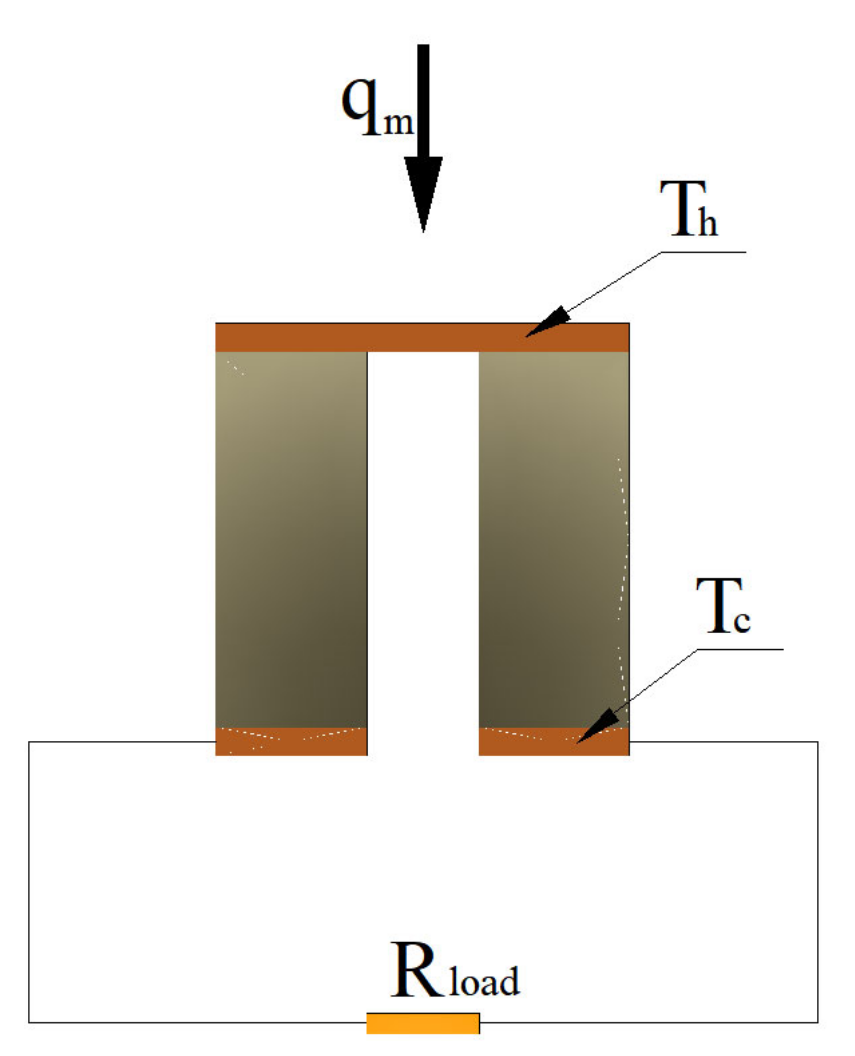

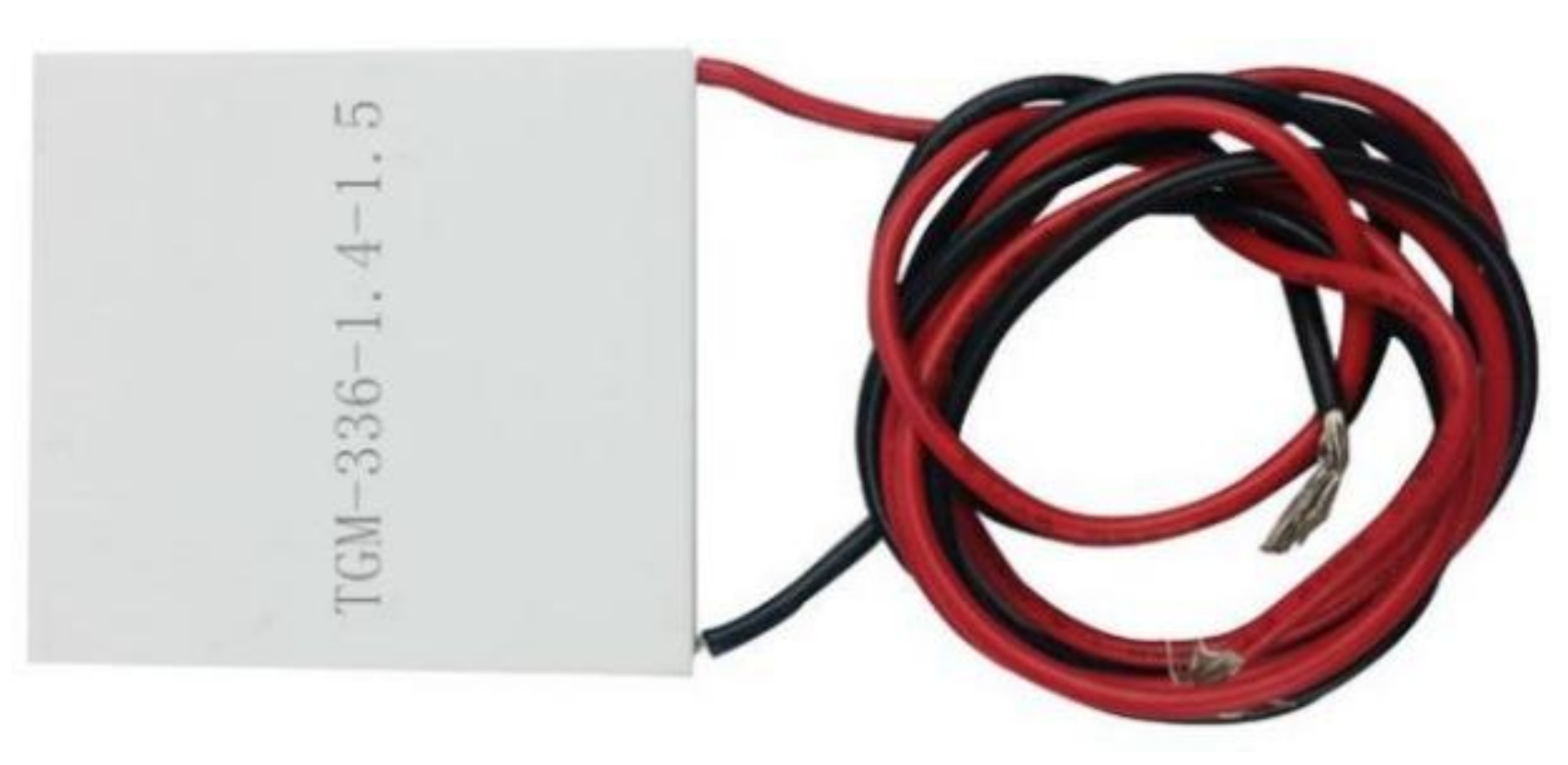

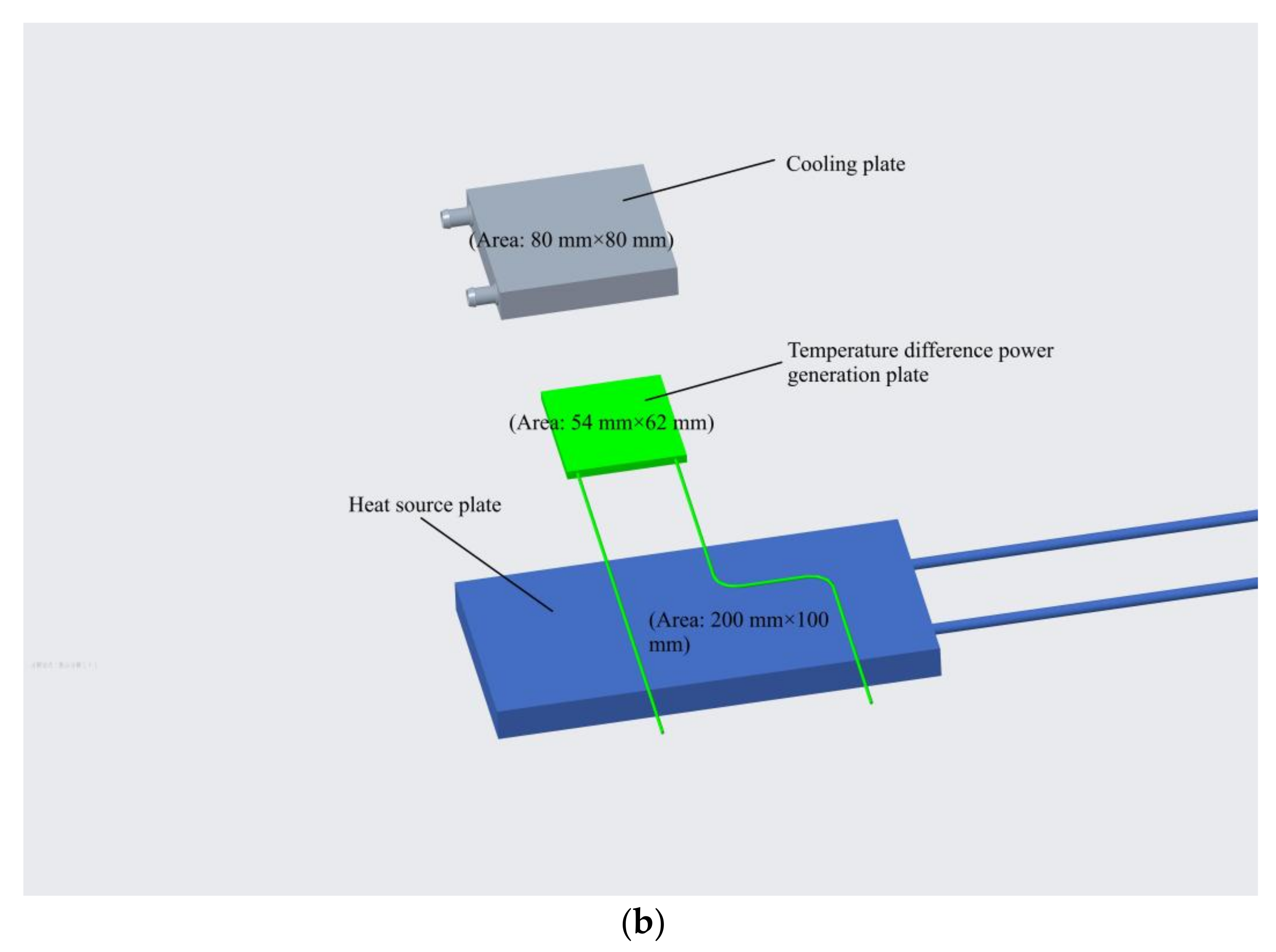

2.3. The Temperature-Difference Power Module

3. Performance of the Influencing Factors

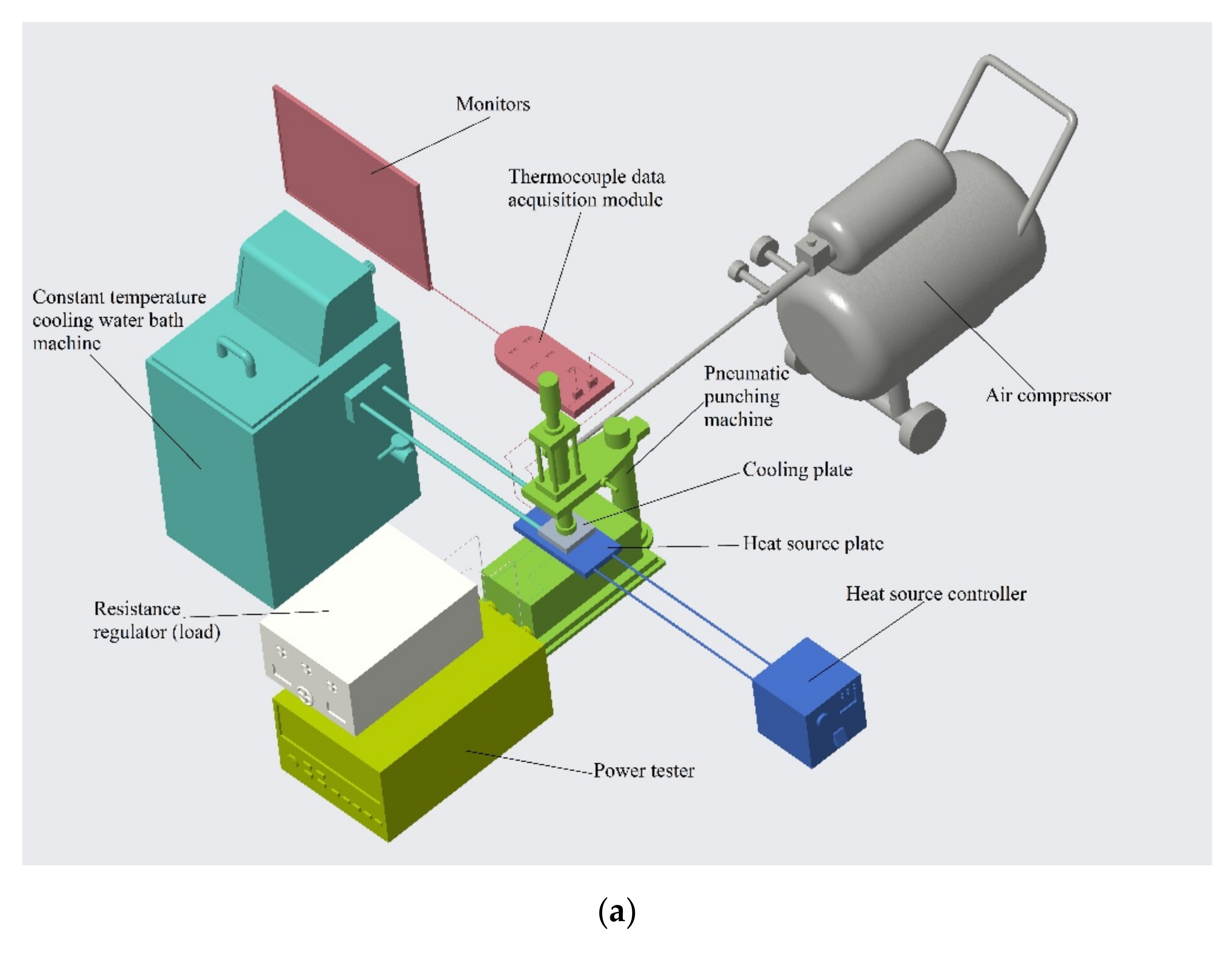

3.1. Experimental Platform

3.2. Experimental Conditions

3.3. Experimental Results and Analysis

3.3.1. Effect of Thermal Insulation

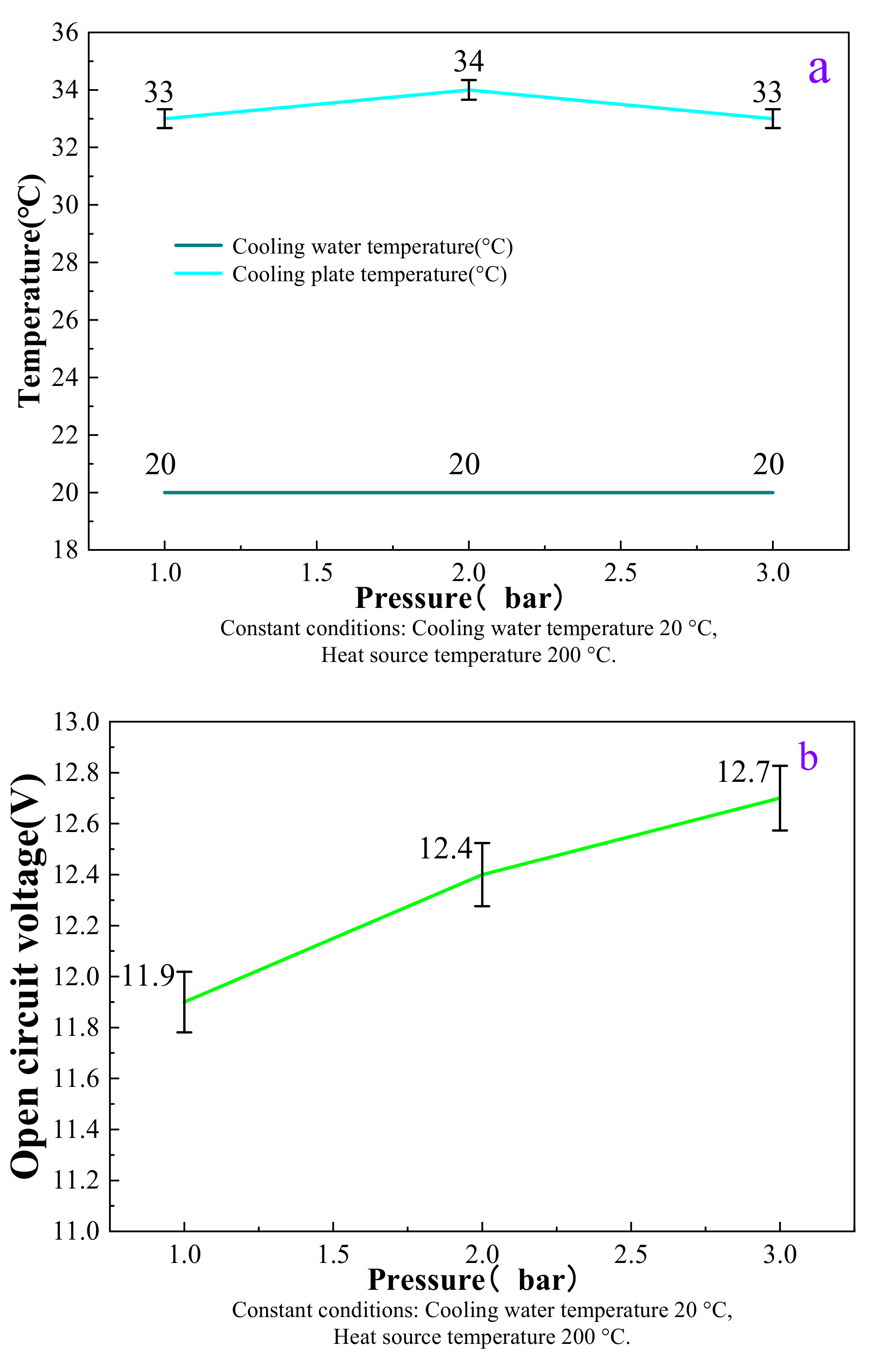

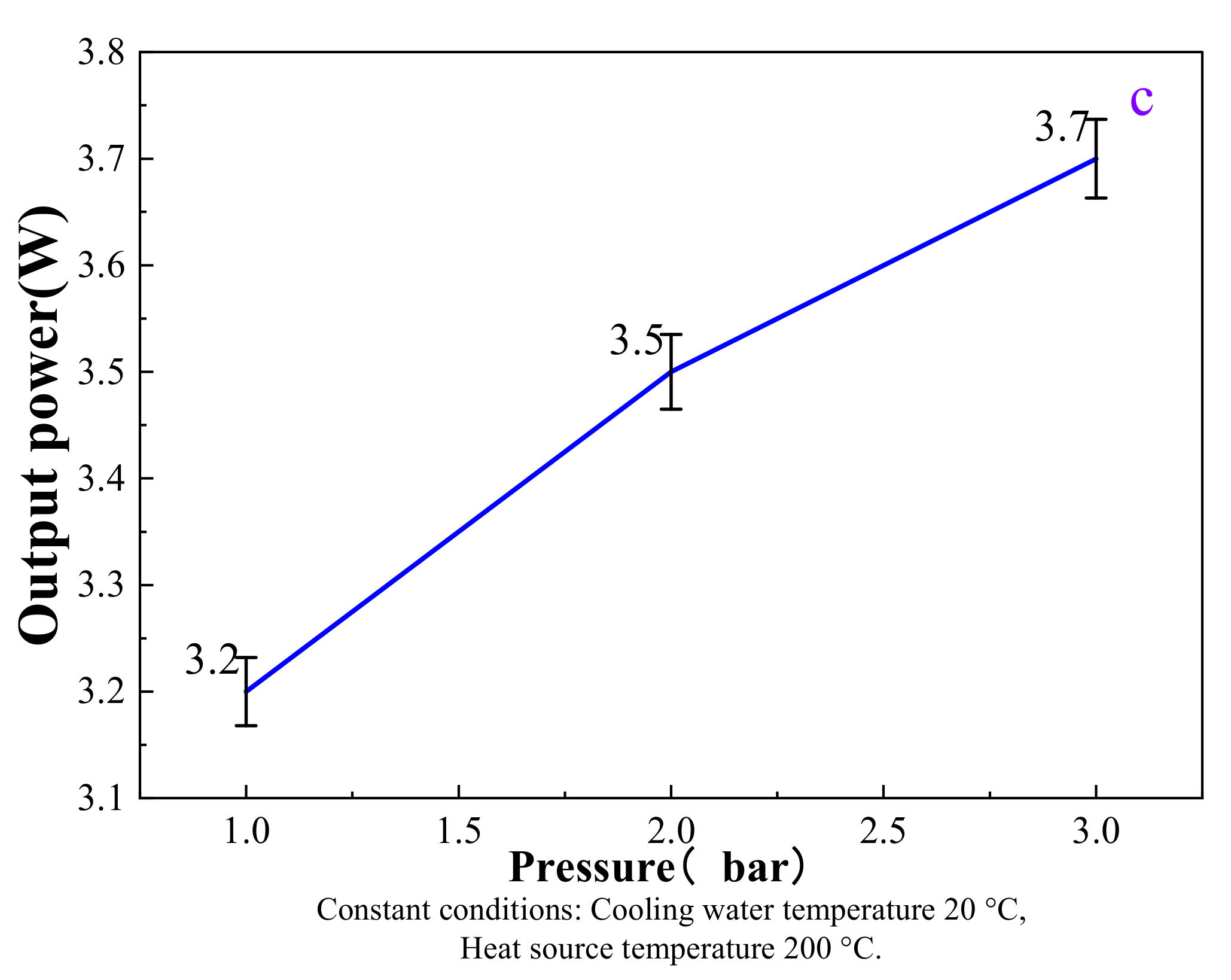

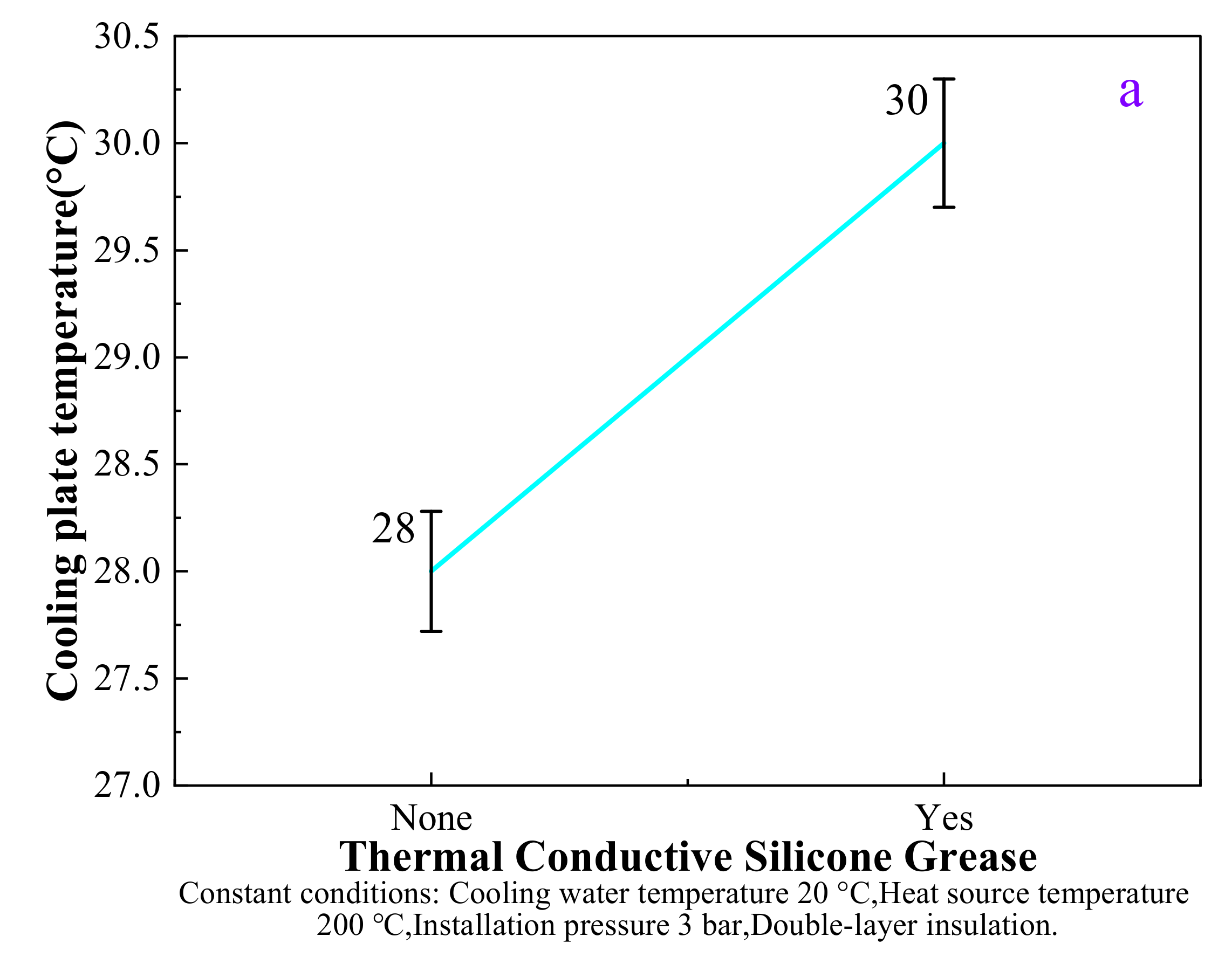

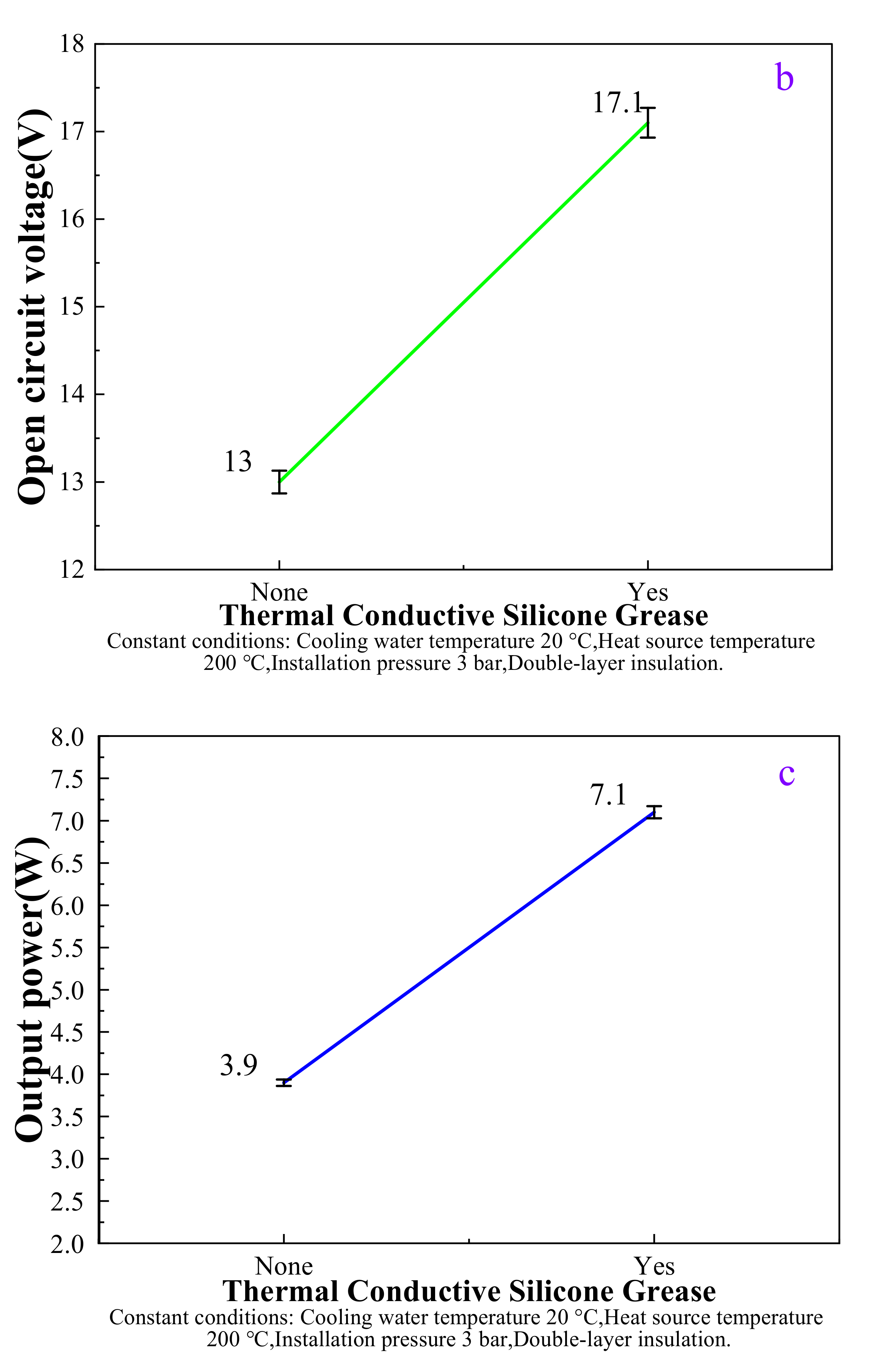

3.3.2. Effects of Installation Pressure and Thermal Grease

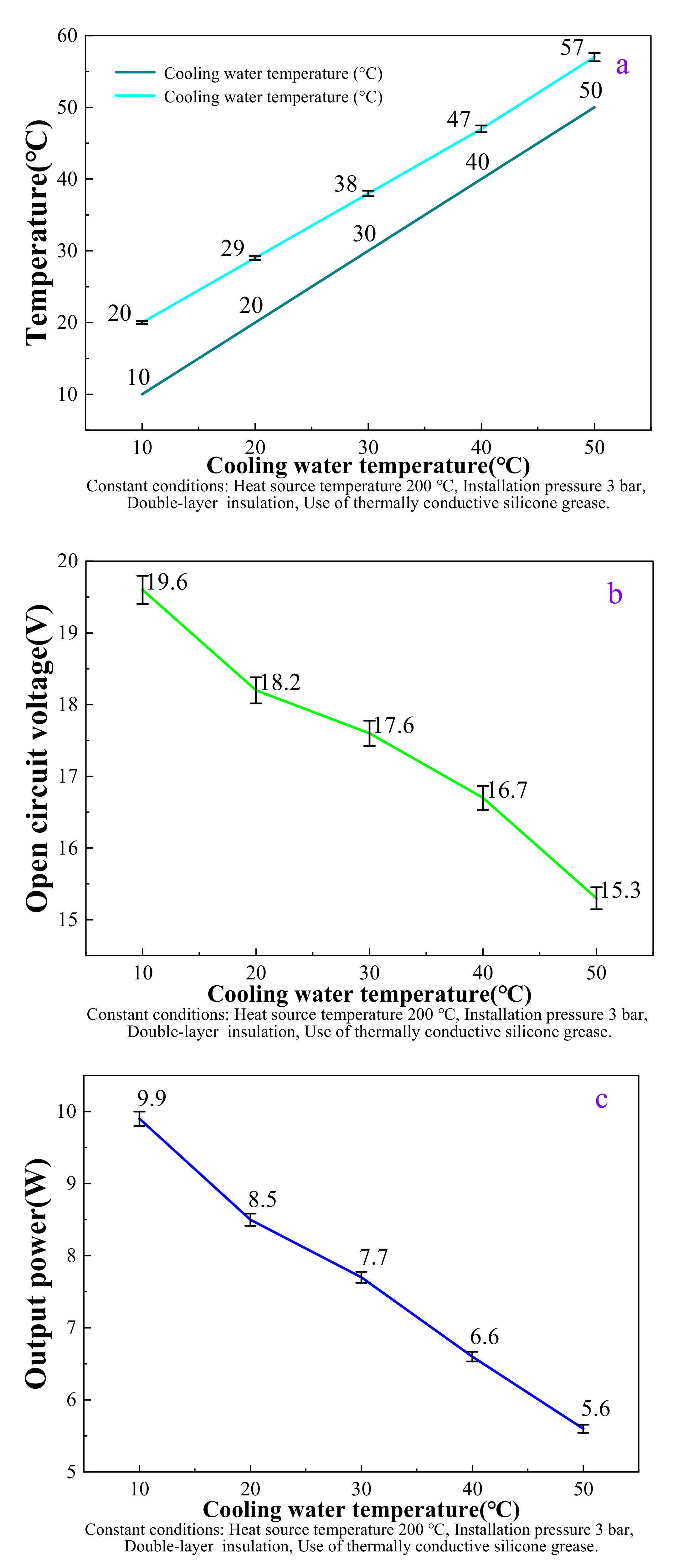

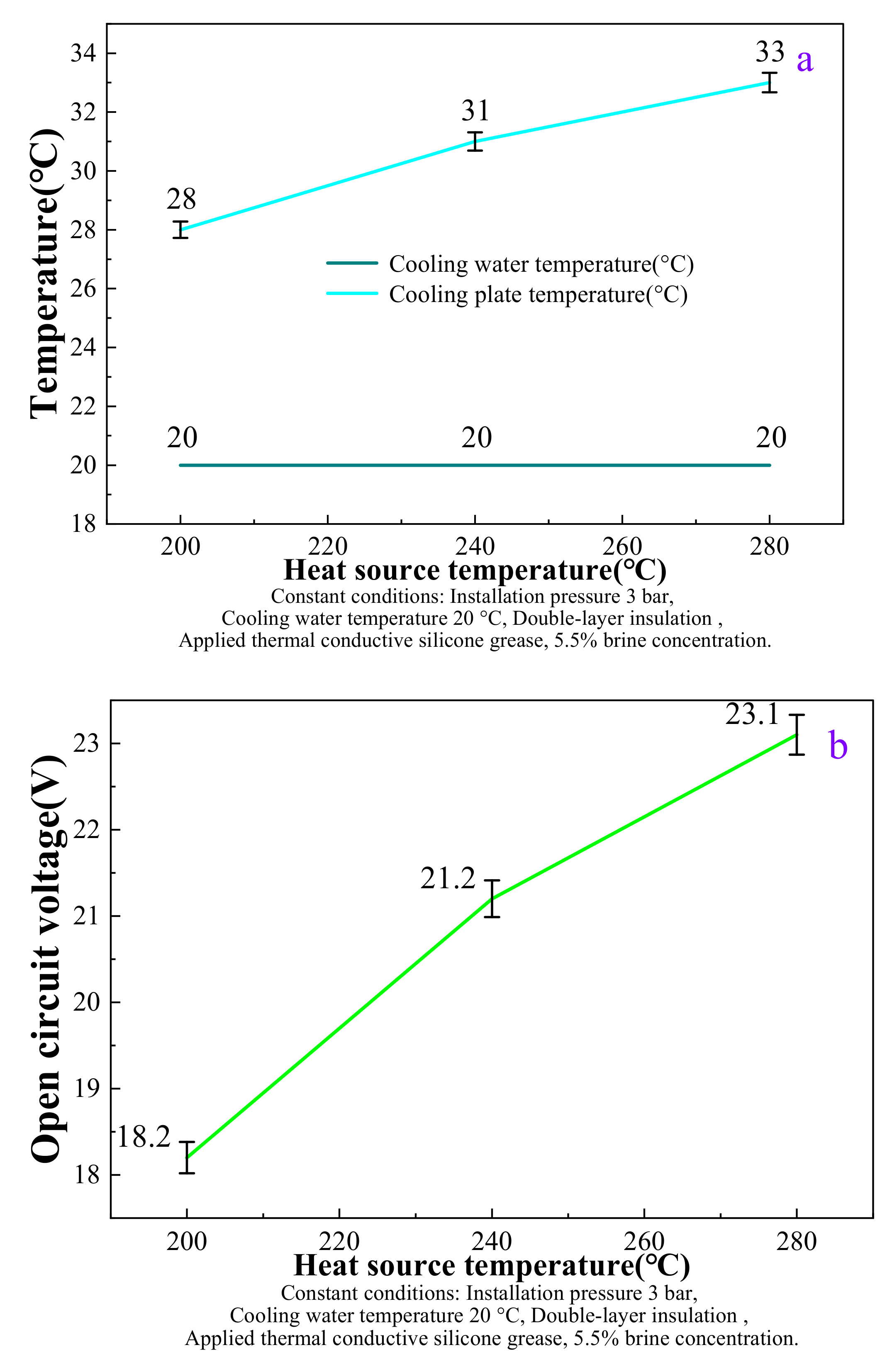

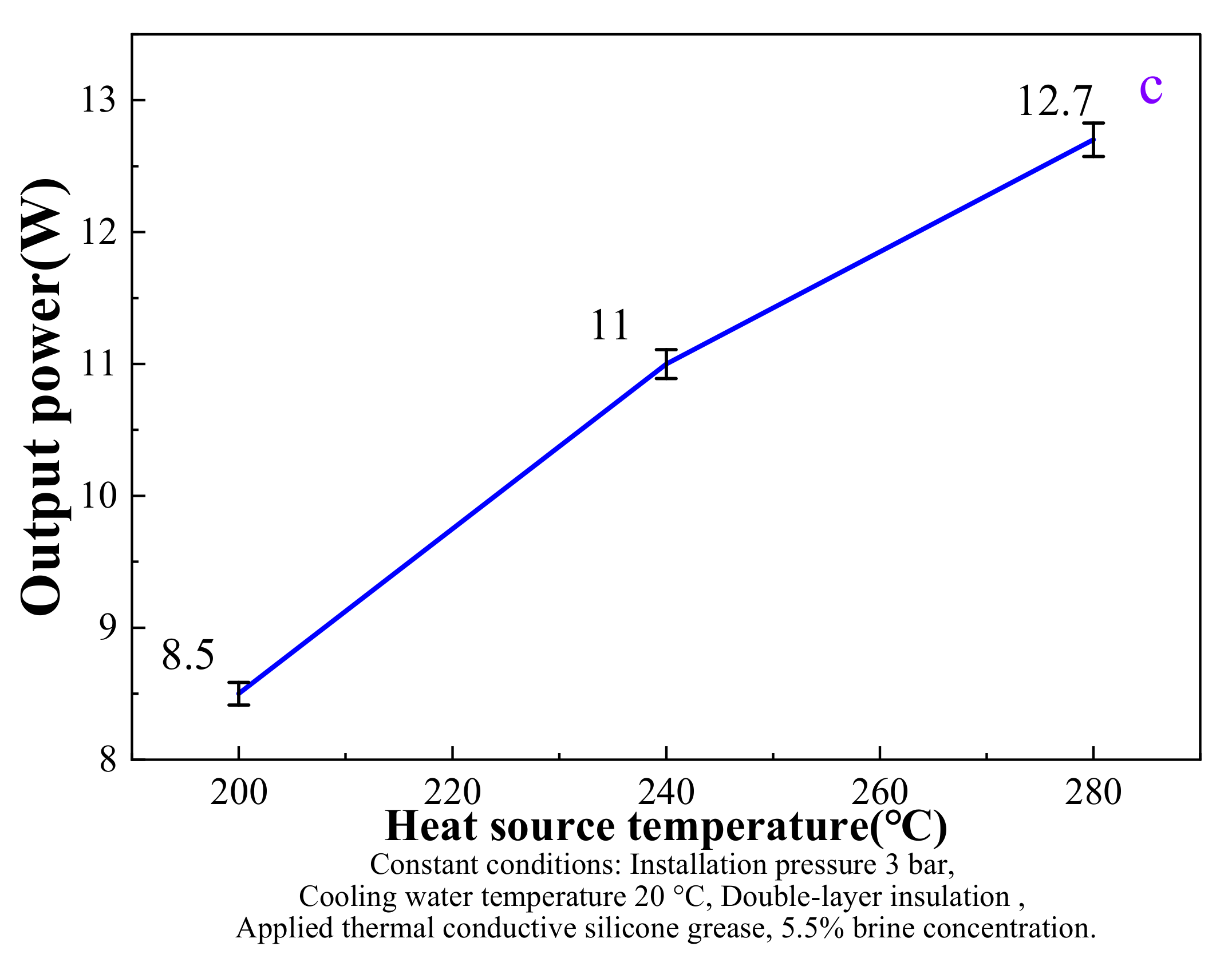

3.3.3. Effects of Cooling Water Temperature and Heat Source Temperature

4. Conclusions

- (1)

- The use of single-layer and double-layer thermal insulation improved the open-circuit voltage by 0.79% and 2.36%, respectively, and improved the maximum output power by 2.70% and 5.41%, respectively, compared to the case when no insulation layers were used.

- (2)

- Increasing the installation pressure to 2 and 3 bar increased the open-circuit voltage by 4.20% and 6.72% and the maximum output power by 9.38% and 15.63%, respectively, as compared to the case when 1 bar installation pressure was used.

- (3)

- Applying the thermally conductive silicone grease enhanced the open-circuit voltage by 31.54% and the output power of the temperature differential power generation unit by 82.05%.

- (4)

- Decreasing the cooling water temperature from 50 to 10 °C increased the open-circuit voltage growth rate from 9.15% to 28.10% and escalated the maximum output power growth rate from 17.86% to 76.79%. Increasing the heat source temperature from 200 to 280 °C enhanced the open-circuit voltage growth rate by 26.92% and the maximum output power growth rate by 49.41%.

- (5)

- Finally, the maximum output power of this temperature differential power generator reached 12.7 W when using an installation pressure of 3 bar, a cooling water temperature of 20 °C, double-layer aluminum insulation, and a thermally conductive silicone grease.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Tc | The temperature at the cold end (°C) |

| Th | The temperature at the hot end (°C) |

| ∆T (°C) | The temperature difference (°C) |

| αP | The Seebeck coefficient for P-type semiconductor materials (V/K) |

| αN | The Seebeck coefficient for N-type semiconductor materials (V/K) |

| αm | The Seebeck coefficient for temperature differential generation (V/K) |

| Z | The thermoelectric figure of merit (K−1) |

| σ | The electrical conductivity (S/m) |

| K | The thermal conductivity (W/m·k) |

| S | The Seebeck coefficient (mV/K) |

| T | The average temperature of the material (°C) |

| Rload | The external resistance (Ω) |

| Rint | The resistance (Ω) |

| qh | The amount of heat extracted per unit time (J) |

| qm | Heat flow per unit time per pair of semiconductors into the metal conductor (J) |

| qJ | Energy per unit time of a pair of semiconductors entering a metallic conductor (J) |

| qp | Energy of a pair of semiconductors flowing out of a metal conductor (J) |

| qc,o | The heat carried away by the heat conduction (J) |

| Q | The Peltier coefficient of the conductor (J) |

| πm | The Peltier factor (W/A) |

| I | Electric current (A) |

| αn | The Seebeck coefficient (V/K) |

| Rn | The thermal resistance of P-type and N-type semiconductors (K/W) |

| Pm,max | The output power is maximum (W) |

| qm,max | The amount of heat per unit time flowing into the deflector (J) |

| PT | The maximum output power (K/W) |

| qT | The heat flow per unit time into the temperature differential generator (J) |

| ηT | The maximum efficiency (%) |

References

- Ye, W.; Liu, C.; Liu, J.; Wang, H.; Yang, S.; Pan, X. Research on TEG–ORC Combined Bottom Cycle for Cascade Recovery from Various Vessel Waste Heat Sources. Arab. J. Sci. Eng. 2022, 47, 3151–3161. [Google Scholar] [CrossRef]

- Jayswal, R.S.; Pandit, D.; Prakashbhai, S.N.; Bhavsar, U.N.; Prajapati, R.G. Review Paper on Inverted Brayton Cycles. J. Sci. Technol. 2020, 5, 78–84. [Google Scholar] [CrossRef]

- Zhu, S.; Zhang, K.; Deng, K. A review of waste heat recovery from the marine engine with highly efficient bottoming power cycles. Renew. Sustain. Energy Rev. 2020, 120, 109611. [Google Scholar] [CrossRef]

- Mariani, A.; Mastellone, M.L.; Morrone, B.; Prati, M.V.; Unich, A. An organic Rankine cycle bottoming a diesel engine powered passenger car. Energies 2020, 13, 314. [Google Scholar] [CrossRef]

- Omam, S.H. Exhaust waste energy recovery using Otto-ATEG-Stirling engine combined cycle. Appl. Therm. Eng. 2021, 183, 116210. [Google Scholar] [CrossRef]

- Ng, P.S.C.W.; Tam, I. Overview of Waste Heat Recovery Technologies for Maritime Applications. Soc. Nav. Archit. Mar. Eng. Singap. 2019, 64. Available online: http://snames.org.sg/wp-content/uploads/38thAnnualJournal.pdf#page=64 (accessed on 29 August 2022).

- Luo, D.; Wang, R.; Yu, W.; Sun, Z.; Meng, X. Modelling and simulation study of a converging thermoelectric generator for engine waste heat recovery. Appl. Therm. Eng. 2019, 153, 837–847. [Google Scholar] [CrossRef]

- Lim, T.-W.; Choi, Y.-S. Thermal design and performance evaluation of a shell-and-tube heat exchanger using LNG cold energy in LNG fuelled ship. Appl. Therm. Eng. 2020, 171, 115120. [Google Scholar] [CrossRef]

- Tian, Z.; Zeng, W.; Gu, B.; Zhang, Y.; Yuan, X. Energy, exergy, and economic (3E) analysis of an organic Rankine cycle using zeotropic mixtures based on marine engine waste heat and LNG cold energy. Energy Convers. Manag. 2021, 228, 113657. [Google Scholar] [CrossRef]

- Yuan, T.; Song, C.; Zhang, R.; Zhang, X.; Zhang, N.; Bao, J. Energy and Economic Optimization of the Multistage Condensation Rankine Cycle That Utilizes LNG Cold Energy: Considerations on Working Fluids and Cycle Configurations. ACS Sustain. Chem. Eng. 2019, 7, 13505–13516. [Google Scholar] [CrossRef]

- Yu, H.; Kim, D.; Gundersen, T. A study of working fluids for Organic Rankine Cycles (ORCs) operating across and below ambient temperature to utilize Liquefied Natural Gas (LNG) cold energy. Energy 2019, 167, 730–739. [Google Scholar] [CrossRef]

- Kober, M.; Knobelspies, T.; Rossello, A.; Heber, L. Thermoelectric Generators for Automotive Applications: Holistic Optimization and Validation by a Functional Prototype. J. Electron. Mater. 2020, 49, 2902–2909. [Google Scholar] [CrossRef]

- Kober, M. The high potential for waste heat recovery in hybrid vehicles: A comparison between the potential in conventional and hybrid powertrains. J. Electron. Mater. 2020, 49, 2928–2936. [Google Scholar] [CrossRef]

- Ezzitouni, S.; Fernández-Yáñez, P.; Sánchez Rodríguez, L.; Armas, O.; de las Morenas, J.; Massaguer, E.; Massaguer, A. Electrical modelling and mismatch effects of thermoelectric modules on performance of a thermoelectric generator for energy recovery in diesel exhaust systems. Energies 2021, 14, 3189. [Google Scholar] [CrossRef]

- Heber, L.; Schwab, J. Modelling of a thermoelectric generator for heavy-duty natural gas vehicles: Techno-economic approach and experimental investigation. Appl. Therm. Eng. 2020, 174, 115156. [Google Scholar] [CrossRef]

- Lesage, F.J.; Pagé-Potvin, N. Experimental analysis of peak power output of a thermoelectric liquid-to-liquid generator under an increasing electrical load resistance. Energy Convers. Manag. 2013, 66, 98–105. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Zhao, C.; Guo, H.; Wang, Z. Primary Factors Affecting the Efficiency of Thermoelectric Power Generation Sheets for Waste-Heat Recovery from the Ship’s Exhaust Gas. J. Mar. Sci. Eng. 2022, 10, 1281. https://doi.org/10.3390/jmse10091281

Liu X, Zhao C, Guo H, Wang Z. Primary Factors Affecting the Efficiency of Thermoelectric Power Generation Sheets for Waste-Heat Recovery from the Ship’s Exhaust Gas. Journal of Marine Science and Engineering. 2022; 10(9):1281. https://doi.org/10.3390/jmse10091281

Chicago/Turabian StyleLiu, Xiaoyu, Chong Zhao, Hao Guo, and Zhongcheng Wang. 2022. "Primary Factors Affecting the Efficiency of Thermoelectric Power Generation Sheets for Waste-Heat Recovery from the Ship’s Exhaust Gas" Journal of Marine Science and Engineering 10, no. 9: 1281. https://doi.org/10.3390/jmse10091281

APA StyleLiu, X., Zhao, C., Guo, H., & Wang, Z. (2022). Primary Factors Affecting the Efficiency of Thermoelectric Power Generation Sheets for Waste-Heat Recovery from the Ship’s Exhaust Gas. Journal of Marine Science and Engineering, 10(9), 1281. https://doi.org/10.3390/jmse10091281