Effect of Variation in the Mass Ratio on Vortex-Induced Vibration of a Circular Cylinder in Crossflow Direction at Reynold Number = 104: A Numerical Study Using RANS Model

Abstract

:1. Introduction

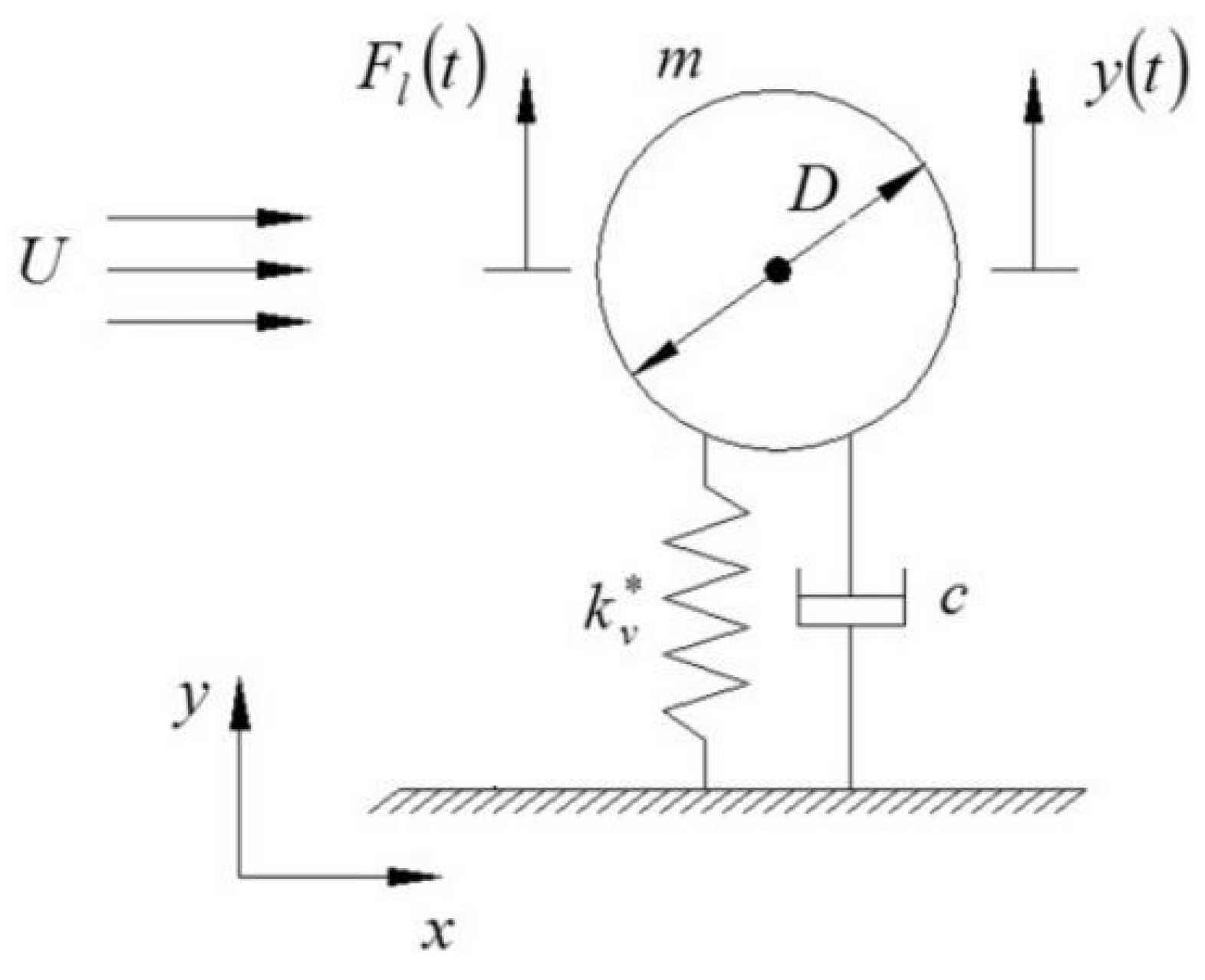

2. Numerical Approach

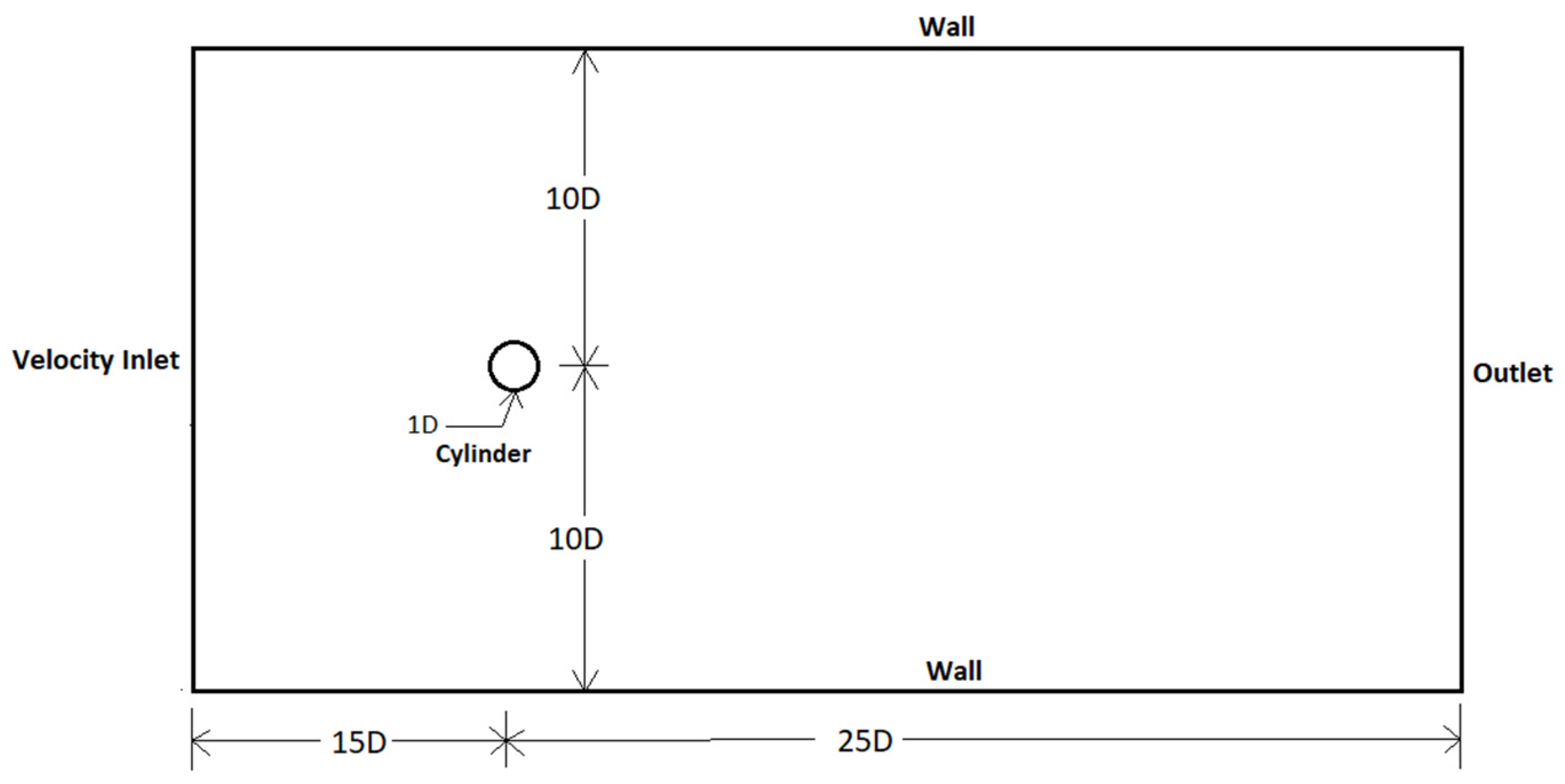

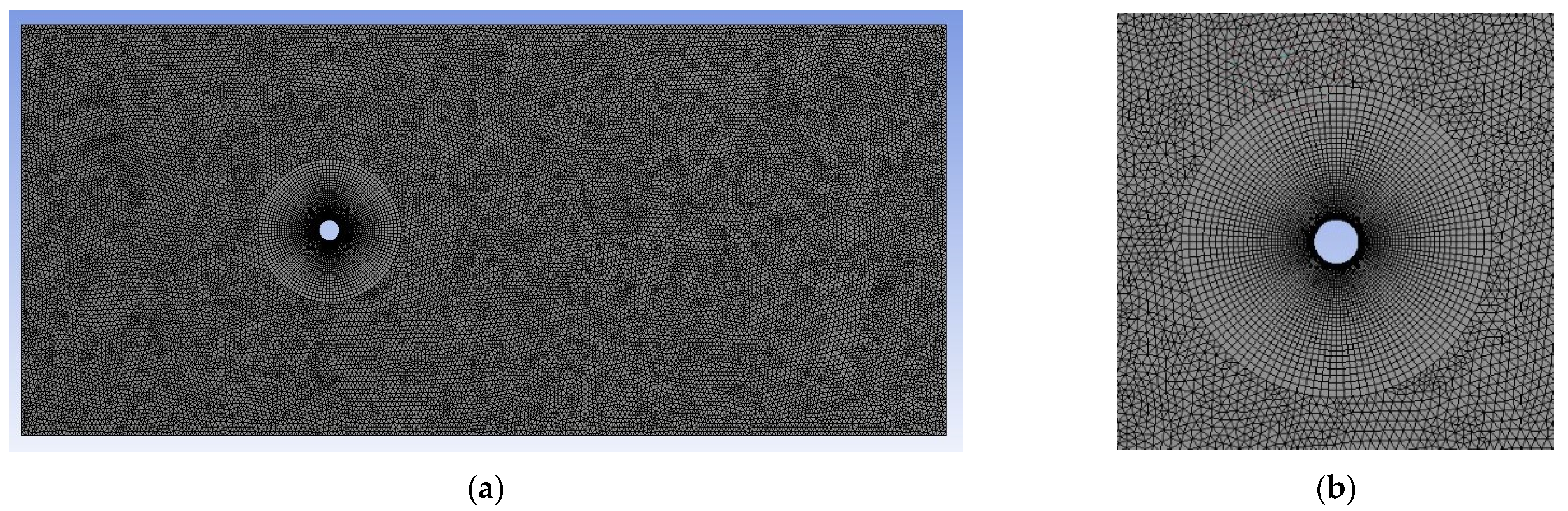

3. Computational Domain and Mesh

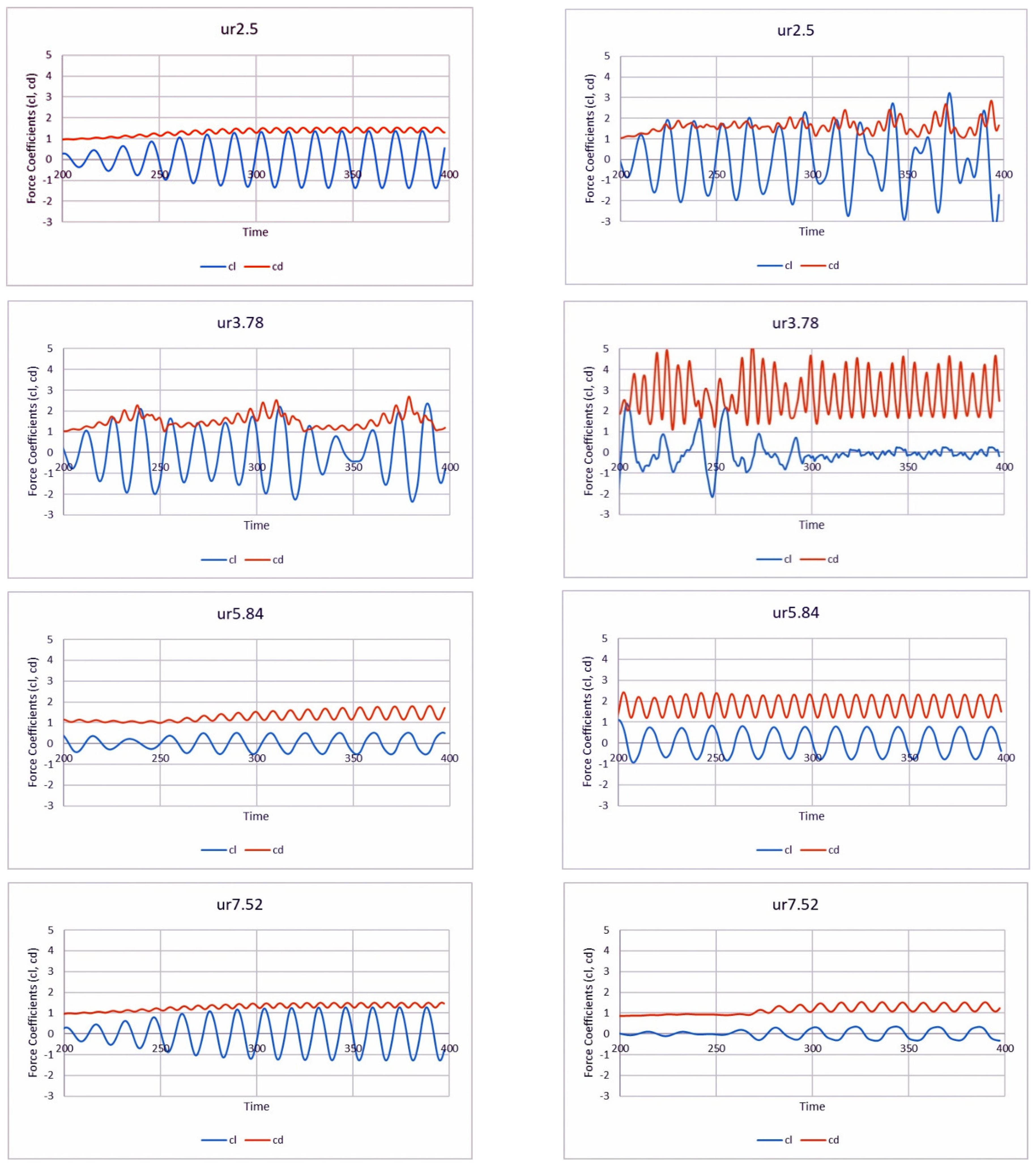

4. Results & Discussion

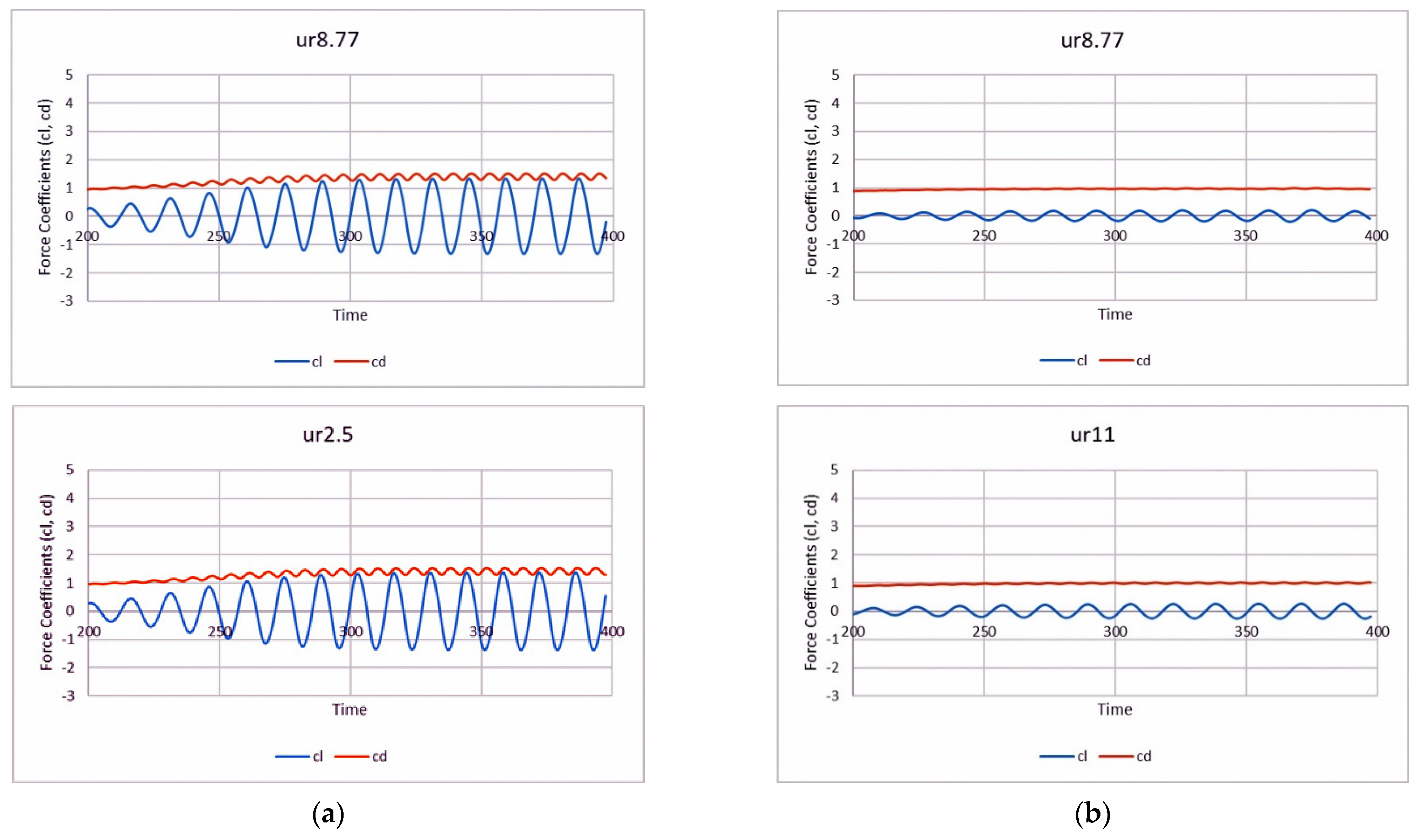

Smooth Circular Cylinder with Mass Ratio, m* = 11

5. Conclusions

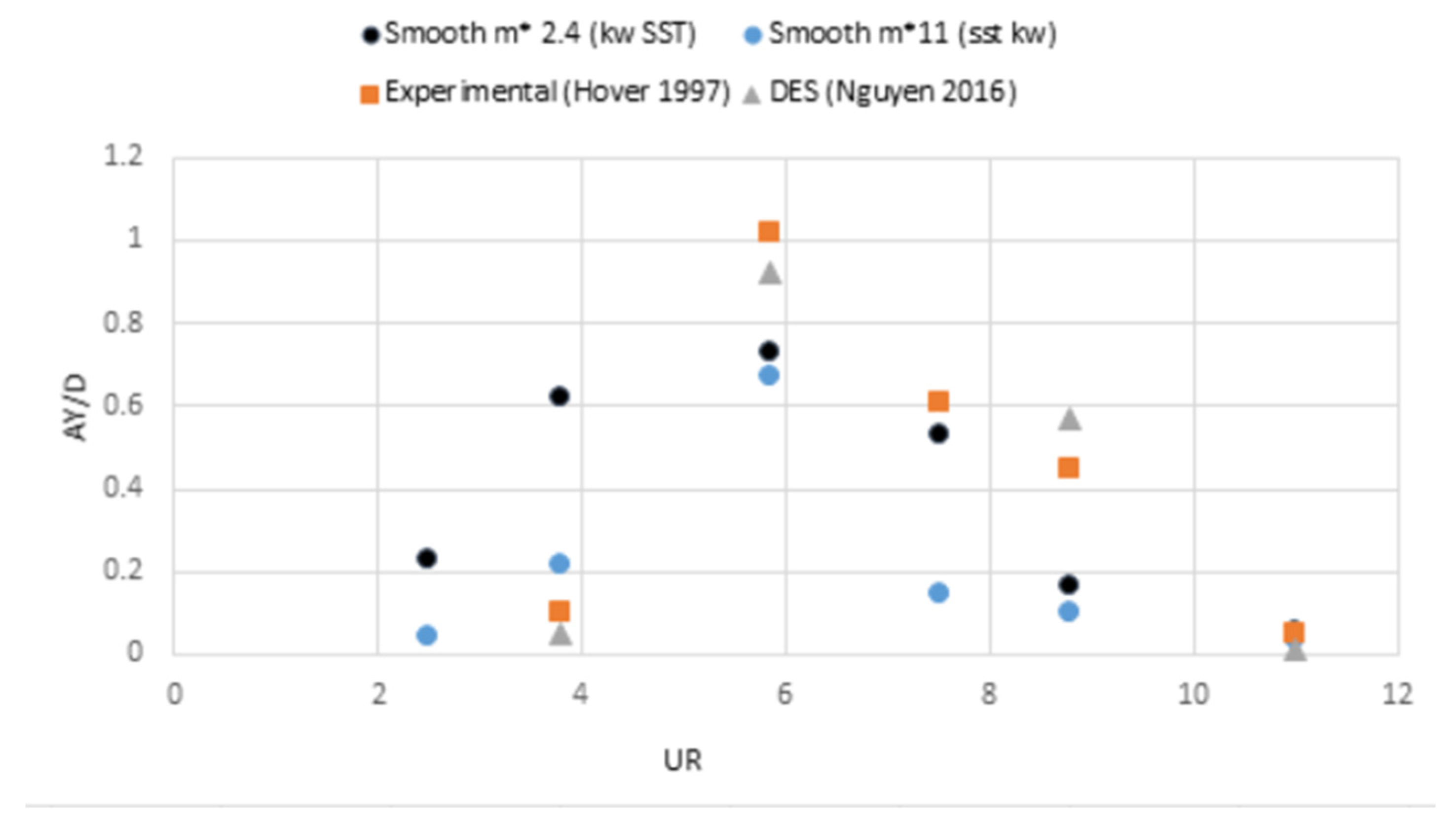

- At the same range of Reynold number and damping ratio, decrease in mass ratio results in widened lock-in region. Furthermore, low mass ratio results in comparatively higher amplitude response and the difference becsme more significant (more than twice) at the beginning and end of the lock-in region. However, the peak amplitude response at reduced velocity 0.73 was slightly higher (8%) in the case of low mass ratio.

- Overall, comparatively high amplitude and widened synchronization region were computed at the low mass ratio.

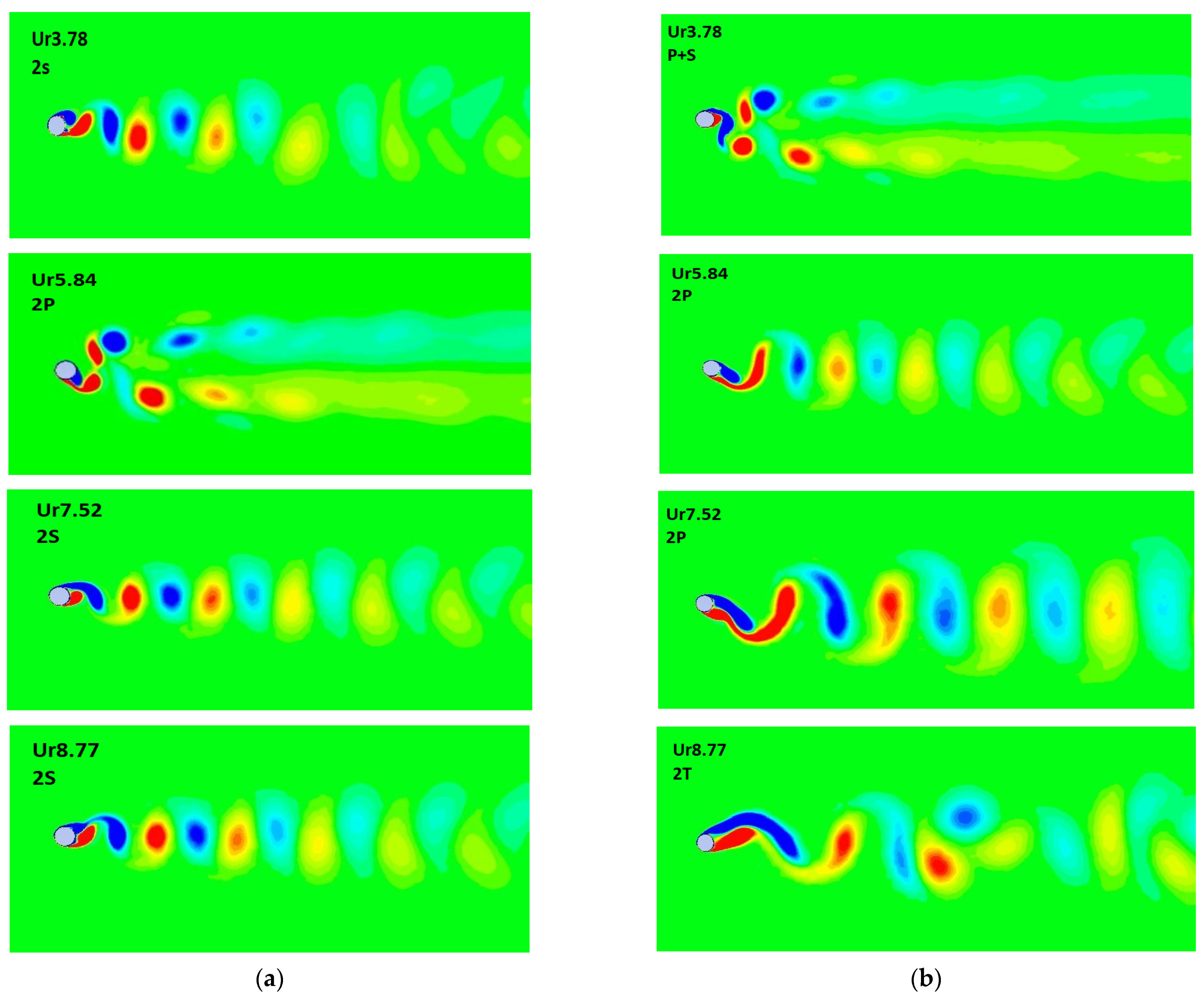

- For a cylinder with m* = 11, it was found from the study that kw-SST was successful in capturing all three branch responses (initial branch, upper branch, and lower branch) and it also successfully captured 2S & 2P vortex modes for the corresponding amplitude responses and their branches.

- At peak amplitude inside the lock-in region, the vortex mode of 2P was captured in both cases of low and high mass ratio. However, vortex shape captured at a low mass ratio at reduced velocity 8.77was 2T, whereas, at high mass ratio, a vortex mode of 2S was captured.

- Peak amplitude responses were lower in comparison to the numerical (DES model) and experimental study which could be due to a lower blockage ratio. However, comparatively, the study was computationally less expensive and was also less time-consuming, which leads us to conclude that the 2D RANS approach and kw-SST turbulent model are quite reliable and capable of the resolution of complex fluid flow problems.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sarpkaya, T. A critical review of the intrinsic nature of vortex-induced vibrations. J. Fluids Struct. 2004, 19, 389–447. [Google Scholar] [CrossRef]

- Breuer, M. Large eddy simulation of the subcritical flow past a circular cylinder: Numerical and modeling aspects. Int. J. Numer. Methods Fluids 1998, 28, 1281–1302. [Google Scholar] [CrossRef]

- Bearman, P. Circular cylinder wakes and vortex-induced vibrations. J. Fluids Struct. 2011, 27, 648–658. [Google Scholar] [CrossRef]

- Placzek, A.; Sigrist, J.-F.; Hamdouni, A. Numerical simulation of an oscillating cylinder in a cross-flow at low Reynolds number: Forced and free oscillations. Comput. Fluids 2009, 38, 80–100. [Google Scholar] [CrossRef]

- Zhao, M.; Cheng, L.; An, H.; Lu, L. Three-dimensional numerical simulation of vortex-induced vibration of an elastically mounted rigid circular cylinder in steady current. J. Fluids Struct. 2014, 50, 292–311. [Google Scholar] [CrossRef]

- Khan, N.B.; Jameel, M.; Badry, A.B.B.M.; Ibrahim, Z.B. Numerical study of flow around a smooth circular cylinder at Reynold number = 3900 with large eddy simulation using CFD code. In Proceedings of the ASME 2016 35th International Conference on Ocean, Offshore and Arctic Engineering, Busan, Korea, 19–24 June 2016; American Society of Mechanical Engineers Digital Collection: New York, NY, USA, 2016. [Google Scholar]

- Khalak, A.; Williamson, C. Dynamics of a hydroelastic cylinder with very low mass and damping. J. Fluids Struct. 1996, 10, 455–472. [Google Scholar] [CrossRef]

- Guilmineau, E.; Queutey, P. Numerical simulation of vortex-induced vibration of a circular cylinder with low mass-damping in a turbulent flow. J. Fluids Struct. 2004, 19, 449–466. [Google Scholar] [CrossRef]

- Pan, Z.; Cui, W.; Miao, Q. Numerical simulation of vortex-induced vibration of a circular cylinder at low mass-damping using RANS code. J. Fluids Struct. 2007, 23, 23–37. [Google Scholar] [CrossRef]

- Li, W.; Li, J.; Liu, S. Numerical simulation of vortex-induced vibration of a circular cylinder at low mass and damping with different turbulent models. In Proceedings of the OCEANS 2014, Taipei, Taiwan, 7–10 April 2014; IEEE: Manhattan, NY, USA, 2014; pp. 1–7. [Google Scholar]

- Nguyen, V.-T.; Nguyen, H.H. Detached eddy simulations of flow induced vibrations of circular cylinders at high Reynolds numbers. J. Fluids Struct. 2016, 63, 103–119. [Google Scholar] [CrossRef]

- Hover, F.; Miller, S.; Triantafyllou, M. Vortex-induced vibration of marine cables: Experiments using force feedback. J. Fluids Struct. 1997, 11, 307–326. [Google Scholar] [CrossRef]

- Khan, N.B.; Ibrahim, Z.; Nguyen, L.T.T.; Javed, M.F.; Jameel, M. Numerical investigation of the vortex-induced vibration of an elastically mounted circular cylinder at high Reynolds number (Re = 104) and low mass ratio using the RANS code. PLoS ONE 2017, 12, e0185832. [Google Scholar] [CrossRef] [PubMed]

- Williamson, C.; Govardhan, R. Vortex-induced vibrations. Annu. Rev. Fluid Mech. 2004, 36, 413–455. [Google Scholar] [CrossRef]

- Stappenbelt, B.; Lalji, F.; Tan, G. Low mass ratio vortex-induced motion. In Proceedings of the 16th Australasian Fluid Mechanics Conference, Gold Coast, Australia, 3–7 December 2007. [Google Scholar]

- Bahmani, M.; Akbari, M. Effects of mass and damping ratios on VIV of a circular cylinder. Ocean Eng. 2010, 37, 511–519. [Google Scholar] [CrossRef]

- Modir, A.; Kahrom, M.; Farshidianfar, A. Mass ratio effect on vortex induced vibration of a flexibly mounted circular cylinder, an experimental study. Int. J. Mar. Energy 2016, 16, 1–11. [Google Scholar] [CrossRef]

- Pigazzini, R.; Contento, G.; Martini, S.; Morgut, M.; Puzzer, T. An investigation on VIV of a single 2D elastically-mounted cylinder with different mass ratios. J. Mar. Sci. Technol. 2019, 24, 1078–1091. [Google Scholar] [CrossRef]

- Zhao, J.; Leontini, J.; Jacono, D.L.; Sheridan, J. The effect of mass ratio on the structural response of a freely vibrating square cylinder oriented at different angles of attack. J. Fluids Struct. 2019, 86, 200–212. [Google Scholar] [CrossRef]

- Tang, Z.; Zhou, B. The effect of mass ratio and spring stiffness on flow-induced vibration of a square cylinder at different incidence angles. Ocean Eng. 2020, 198, 106975. [Google Scholar] [CrossRef]

- Chen, D.; Marzocca, P.; Xiao, Q.; Zhan, Z.; Gu, C. Vortex-induced vibration on a low mass ratio cylinder with a nonlinear dissipative oscillator at moderate Reynolds number. J. Fluids Struct. 2020, 99, 103160. [Google Scholar] [CrossRef]

- Mittal, S. The critical mass phenomenon in vortex-induced vibration at low. J. Fluid Mech. 2017, 820, 159–186. [Google Scholar]

- Kinaci, O.K.; Demirhan, A.E.; Duranay, A. Vortex-induced vibrations of a single-degree-of-freedom circular cylinder in the vicinity of the free surface. Appl. Ocean Res. 2022, 124, 103202. [Google Scholar] [CrossRef]

- Guo, T.; Zhang, W.-h.; Wang, W.-q.; Luo, Z.-m. Effects of high mass and damping ratio on VIV of a circular cylinder with low Reynolds number based on IBM. Eng. Mech. 2022, 39, 222–232. [Google Scholar]

- Zhang, B.; Li, B.; Fu, S.; Mao, Z.; Ding, W. Vortex-Induced Vibration (VIV) hydrokinetic energy harvesting based on nonlinear damping. Renew. Energy 2022, 195, 1050–1063. [Google Scholar] [CrossRef]

- Lin, J.; Zhao, D.; Guo, C.; Zhang, Z.; Su, Y. Numerically Modeling the Effect of Flexibility on Flow around Marine Engineering Structures: Using the Shape of the Saguaro Cactus. J. Coast. Res. 2020, 36, 628. [Google Scholar] [CrossRef]

- Lin, J.-F.; Han, Y.; Su, Y.-M.; Wang, Y.; Zhang, Z.-T.; Jiang, R.-Q. Hydrodynamic performance of a Magnus anti-rolling device at zero and low ship speeds. Ocean Eng. 2021, 229, 109008. [Google Scholar] [CrossRef]

- Zhang, M.; Fu, S.; Ren, H.; Ma, L.; Xu, Y. A hybrid FEM-DNN-based vortex-induced Vibration Prediction Method for Flexible Pipes under oscillatory flow in the time domain. Ocean Eng. 2022, 246, 110488. [Google Scholar] [CrossRef]

- Salhi, J.E.; Ajarostaghi, S.S.M.; Zarrouk, T.; Pour, M.S.; Salhi, N.; Salhi, M. Turbulence and thermo-flow behavior of air in a rectangular channel with partially inclined baffles. Energy Sci. Eng. 2022. Available online: https://onlinelibrary.wiley.com/doi/full/10.1002/ese3.1239 (accessed on 1 May 2022). [CrossRef]

- Kurushina, V.; Pavlovskaia, E.; Postnikov, A.; Wiercigroch, M. Calibration and comparison of VIV wake oscillator models for low mass ratio structures. Int. J. Mech. Sci. 2018, 142–143, 547–560. [Google Scholar] [CrossRef]

- Khan, N.B.; Ibrahim, Z. Numerical investigation of vortex-induced vibration of an elastically mounted circular cylinder with One-degree of freedom at high Reynolds number using different turbulent models. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2019, 233, 443–453. [Google Scholar] [CrossRef]

- Khan, N.B.; Ibrahim, Z.; Badry, A.B.B.M.; Jameel, M.; Javed, M.F. Numerical investigation of flow around cylinder at Reynolds number = 3900 with large eddy simulation technique: Effect of spanwise length and mesh resolution. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2018, 233, 417–427. [Google Scholar] [CrossRef]

- Khan, N.B.; Ibrahim, Z.; Khan, M.I.; Hayat, T.; Javed, M.F. VIV study of an elastically mounted cylinder having low mass-damping ratio using RANS model. Int. J. Heat Mass Transf. 2018, 121, 309–314. [Google Scholar] [CrossRef]

- Fluent, A.J.I.C. R2 User’s Manual; ANSYS: Canonsburg, PA, USA, 2020. [Google Scholar]

- Shao, J.; Zhang, C. Numerical analysis of the flow around a circular cylinder using RANS and LES. Int. J. Comput. Fluid Dyn. 2006, 20, 301–307. [Google Scholar] [CrossRef]

- Fang, Y.Y.; Han, Z.L. Numerical experimental research on the hydrodynamic performance of flow around a three dimensional circular cylinder. In Applied Mechanics and Materials; Trans Tech Publication: Bäch, Switzerland, 2011. [Google Scholar]

- Franke, J.; Frank, W. Large eddy simulation of the flow past a circular cylinder at ReD = 3900. J. Wind Eng. Ind. Aerodyn. 2002, 90, 1191–1206. [Google Scholar] [CrossRef]

- Zdravkovich, M. Conceptual overview of laminar and turbulent flows past smooth and rough circular cylinders. J. Wind Eng. Ind. Aerodyn. 1990, 33, 53–62. [Google Scholar] [CrossRef]

- Navrose; Mittal, S. Free vibrations of a cylinder: 3-D computations at Re = 1000. J. Fluids Struct. 2013, 41, 109–118. [Google Scholar] [CrossRef]

- Zhao, M.; Tong, F.; Cheng, L. Numerical Simulation of Two-Degree-of-Freedom Vortex-Induced Vibration of a Circular Cylinder between Two Lateral Plane Walls in Steady Currents. J. Fluids Eng. 2012, 134, 104501. [Google Scholar] [CrossRef]

- Bishop, R.E.D.; Hassan, A.Y.; Sciences, P. The lift and drag forces on a circular cylinder oscillating in a flowing fluid. Proc. R. Soc. London Ser. A Math. Phys. Sci. 1964, 277, 51–75. [Google Scholar]

| Mesh | No. of Elements | Maximum Ay/d |

|---|---|---|

| M1 | 28,050 | 0.52 |

| M2 | 34,980 | 0.581 |

| M3 | 51,094 | 0.6702 |

| M4 | 64,364 | 0.6771 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Anwar, M.U.; Lashin, M.M.A.; Khan, N.B.; Munir, A.; Jameel, M.; Muhammad, R.; Guedri, K.; Galal, A.M. Effect of Variation in the Mass Ratio on Vortex-Induced Vibration of a Circular Cylinder in Crossflow Direction at Reynold Number = 104: A Numerical Study Using RANS Model. J. Mar. Sci. Eng. 2022, 10, 1126. https://doi.org/10.3390/jmse10081126

Anwar MU, Lashin MMA, Khan NB, Munir A, Jameel M, Muhammad R, Guedri K, Galal AM. Effect of Variation in the Mass Ratio on Vortex-Induced Vibration of a Circular Cylinder in Crossflow Direction at Reynold Number = 104: A Numerical Study Using RANS Model. Journal of Marine Science and Engineering. 2022; 10(8):1126. https://doi.org/10.3390/jmse10081126

Chicago/Turabian StyleAnwar, Muhammad Usman, Maha M. A. Lashin, Niaz B. Khan, Adnan Munir, Mohammed Jameel, Riaz Muhammad, Kamel Guedri, and Ahmed M. Galal. 2022. "Effect of Variation in the Mass Ratio on Vortex-Induced Vibration of a Circular Cylinder in Crossflow Direction at Reynold Number = 104: A Numerical Study Using RANS Model" Journal of Marine Science and Engineering 10, no. 8: 1126. https://doi.org/10.3390/jmse10081126

APA StyleAnwar, M. U., Lashin, M. M. A., Khan, N. B., Munir, A., Jameel, M., Muhammad, R., Guedri, K., & Galal, A. M. (2022). Effect of Variation in the Mass Ratio on Vortex-Induced Vibration of a Circular Cylinder in Crossflow Direction at Reynold Number = 104: A Numerical Study Using RANS Model. Journal of Marine Science and Engineering, 10(8), 1126. https://doi.org/10.3390/jmse10081126