Experimental and Numerical Resistance Analysis for a Cruise Ship W/O Fin Stabilizers

Abstract

:1. Introduction

1.1. Review of the Fin Stabilizers Development

1.2. Current Work

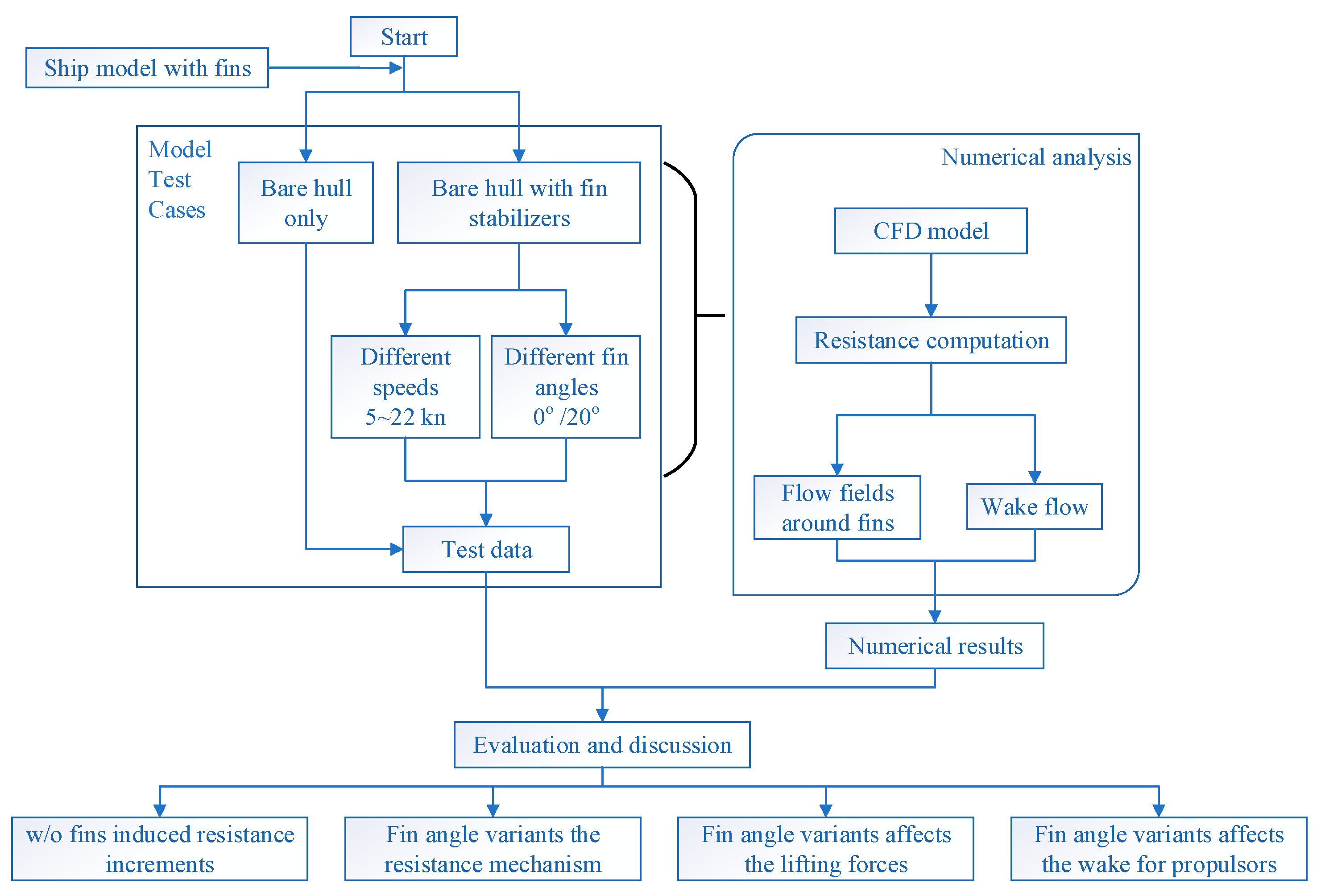

1.3. Methodology

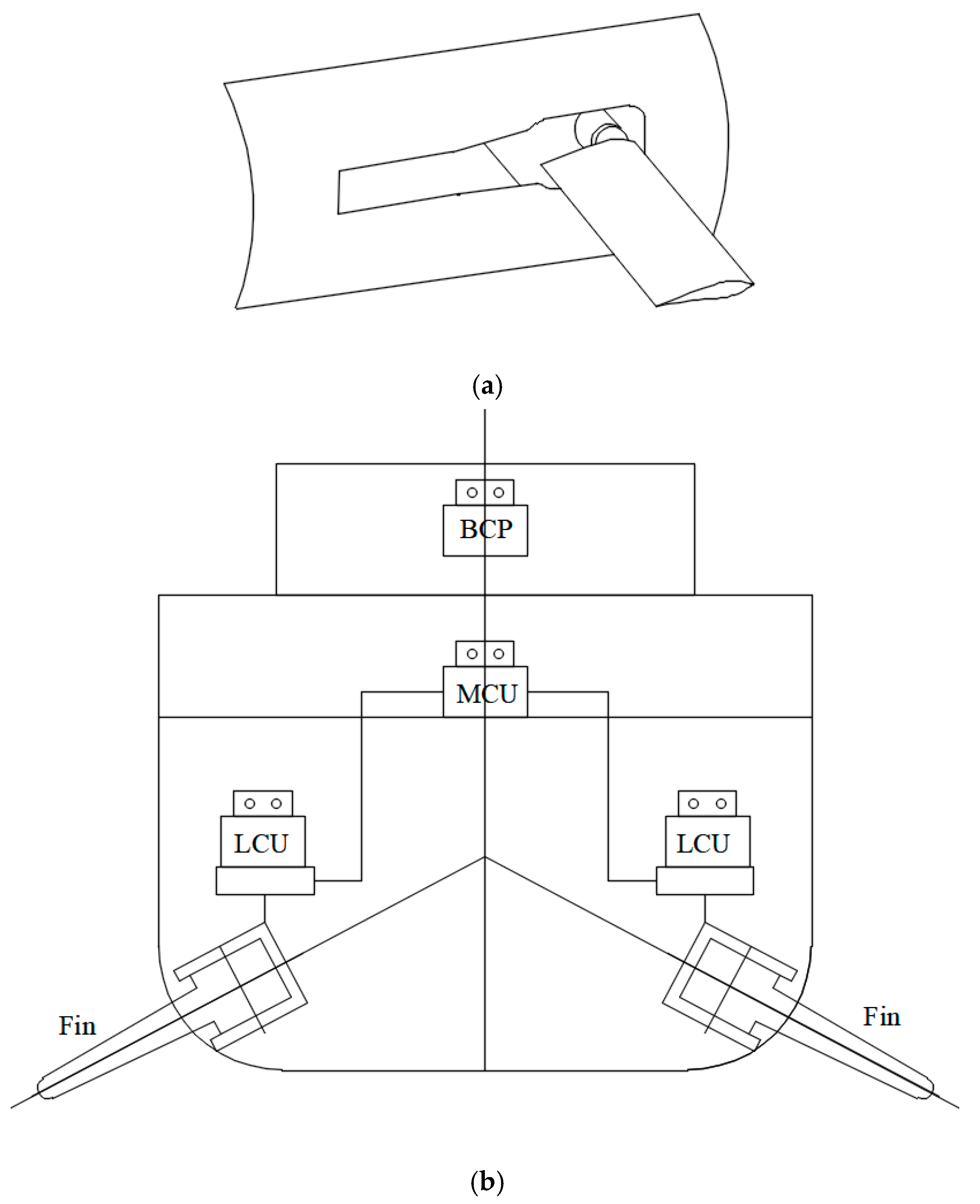

2. Experiment Setup

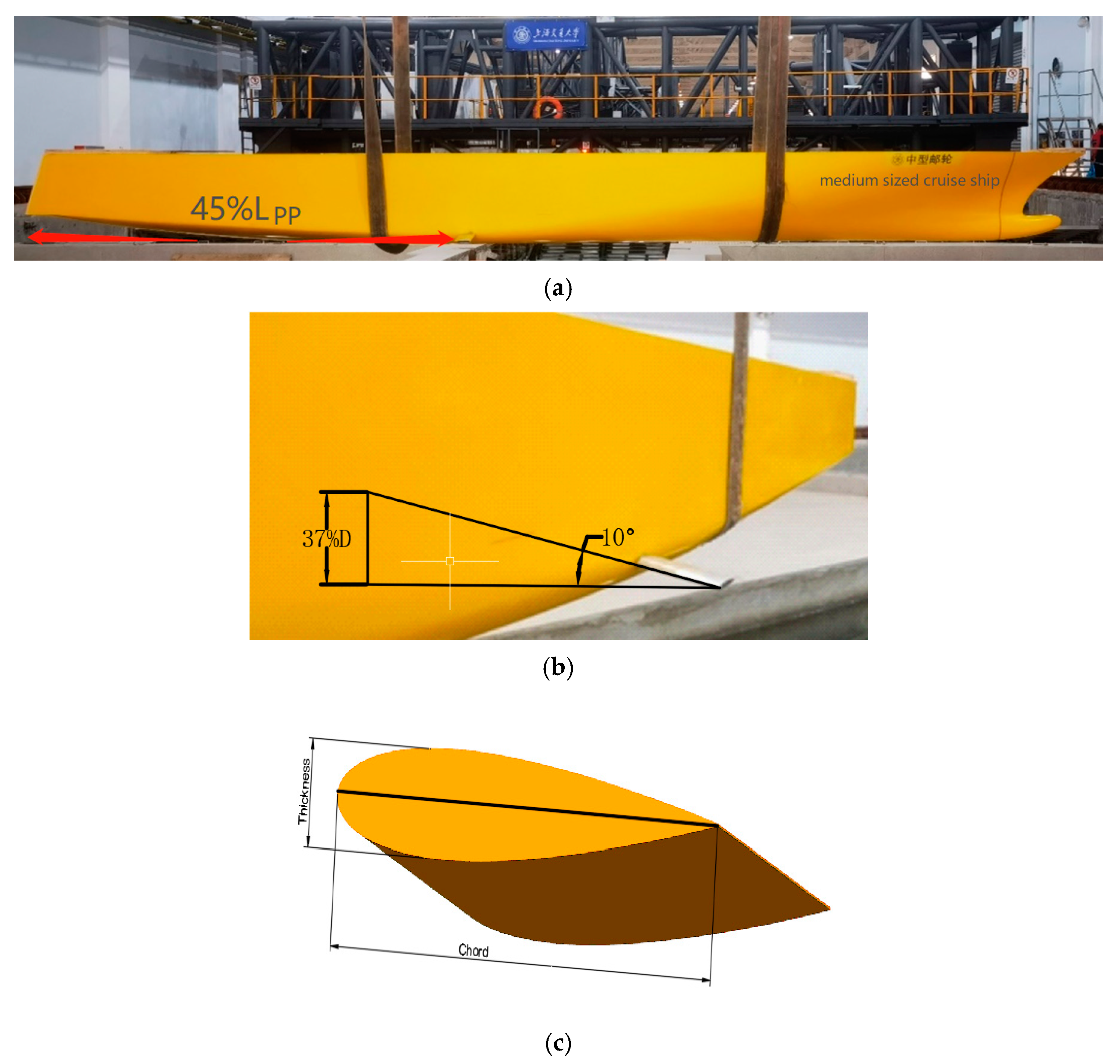

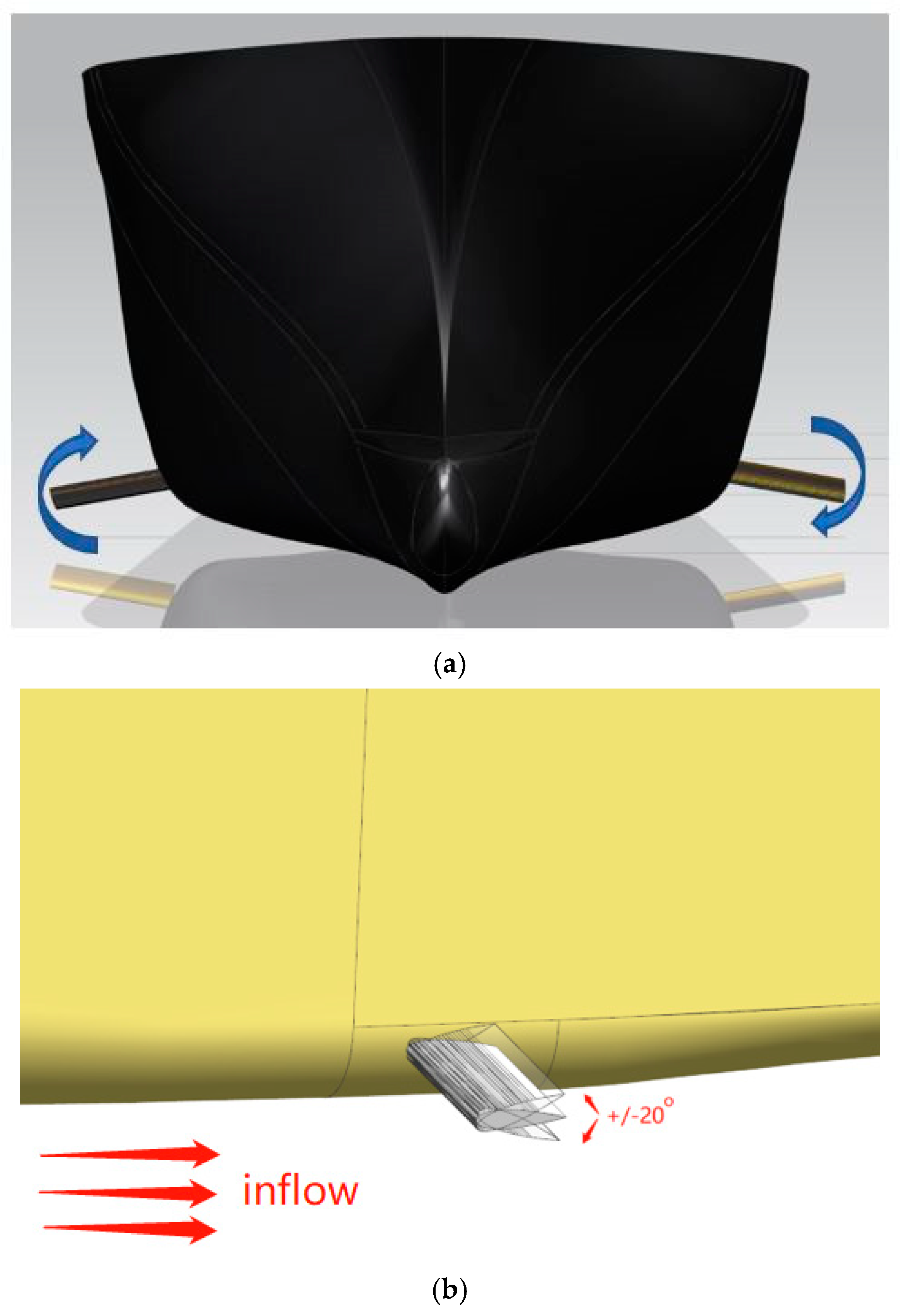

2.1. Test Preparation

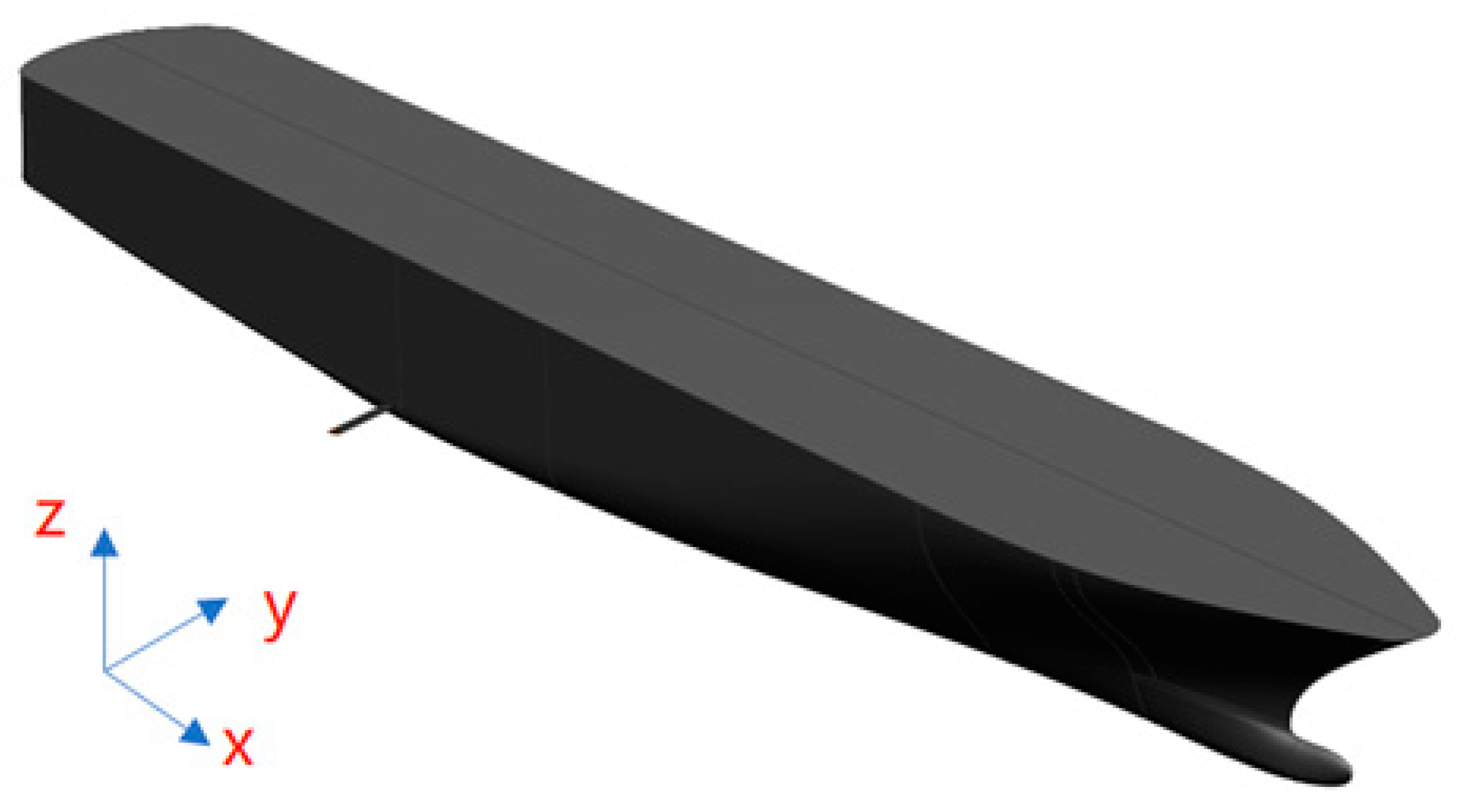

2.2. Geometry Model

3. The Numerical Analysis

3.1. Governing Equations

3.2. Calculation Setup

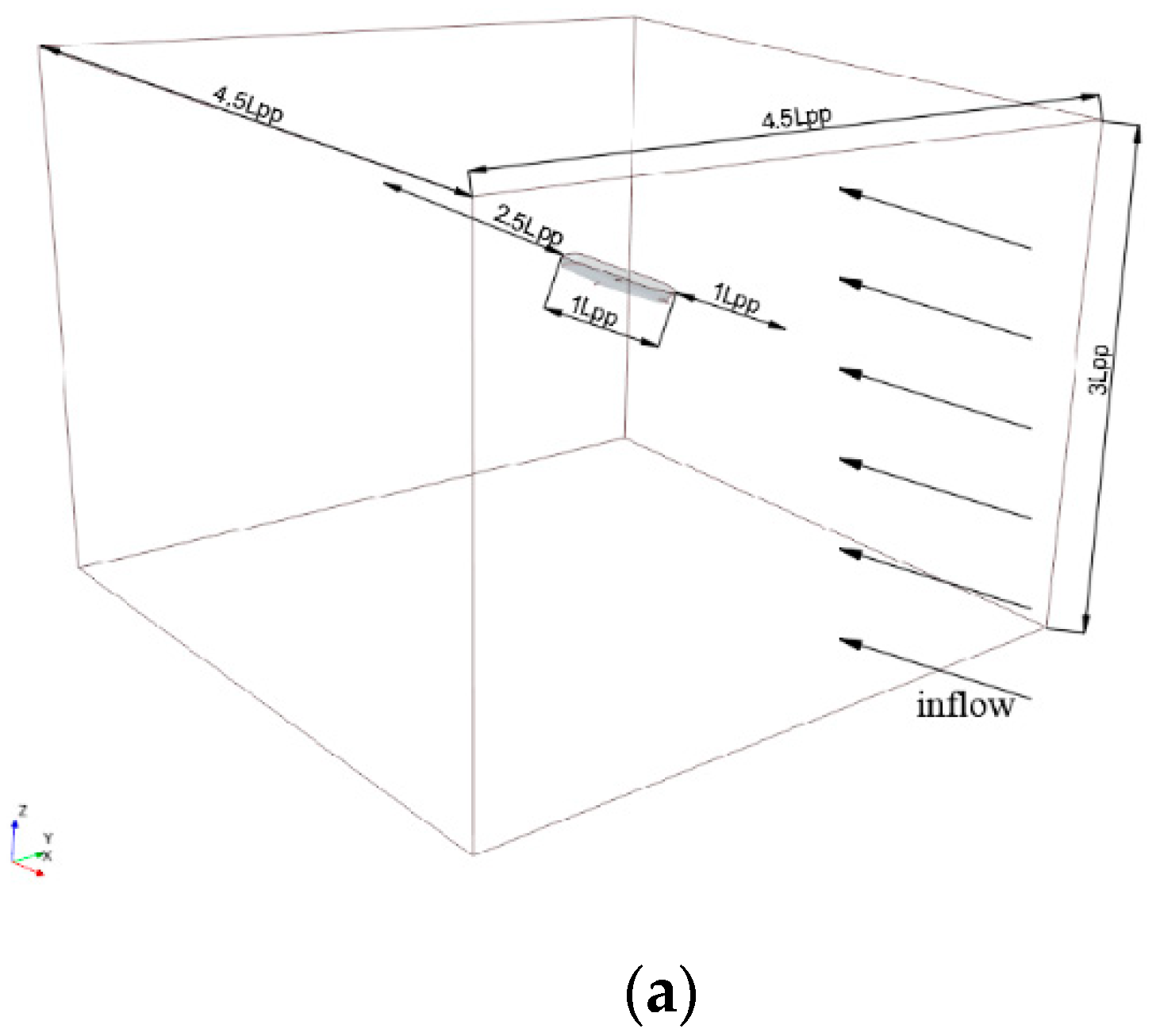

3.2.1. Computational Domain

3.2.2. To Avoid Wave Reflection

3.2.3. Air and Water Interface

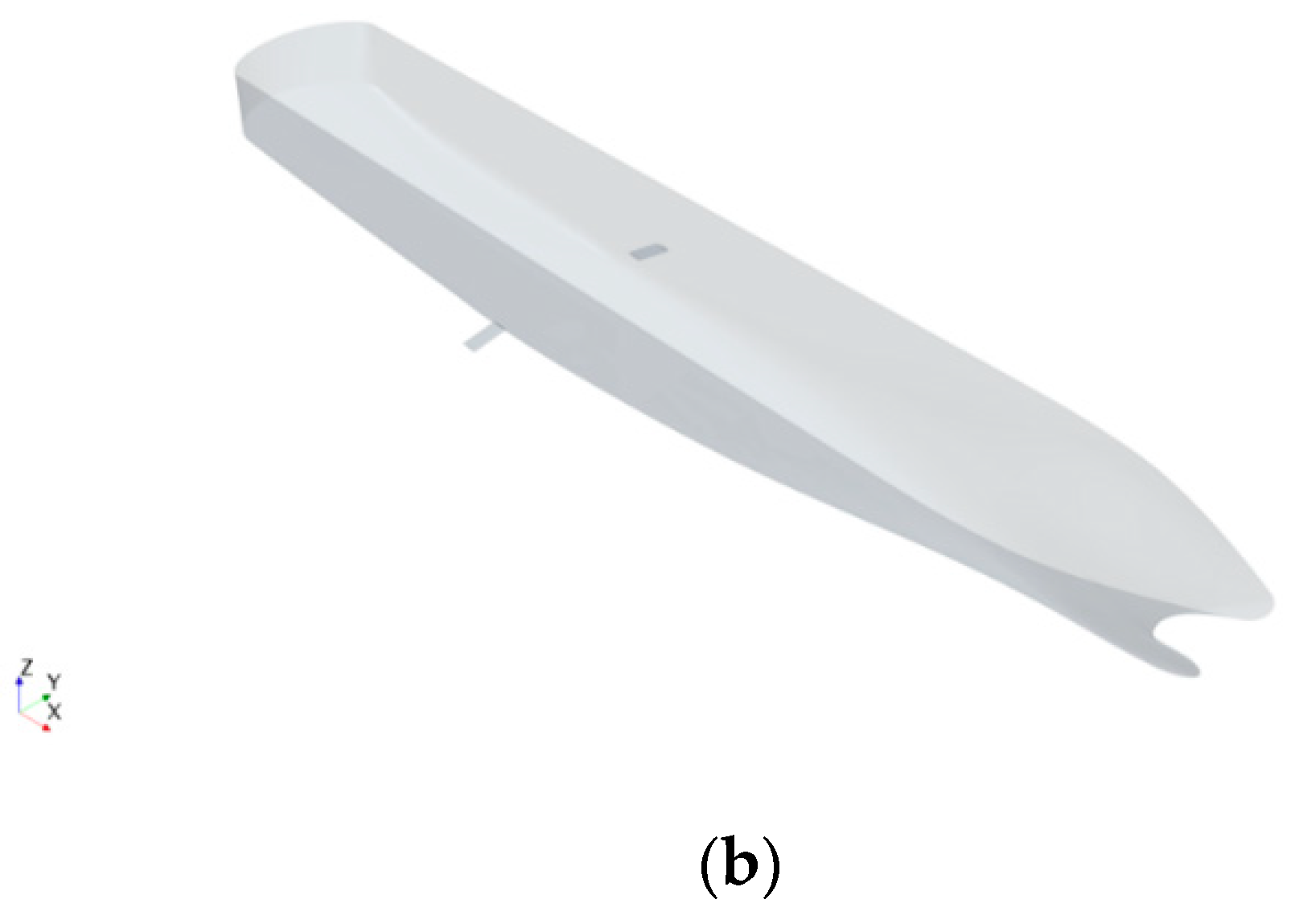

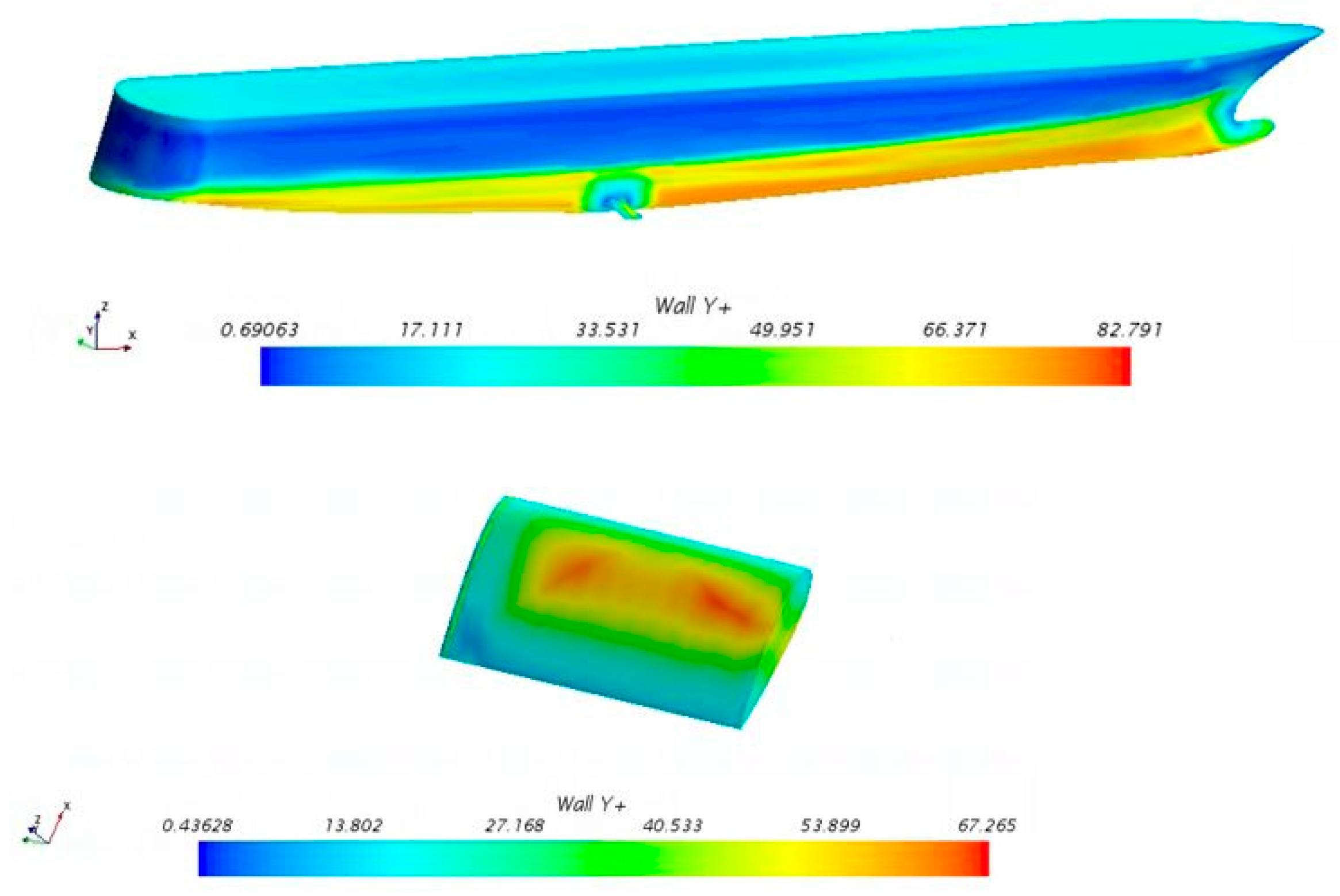

3.3. Mesh Generation

4. Results and Discussions

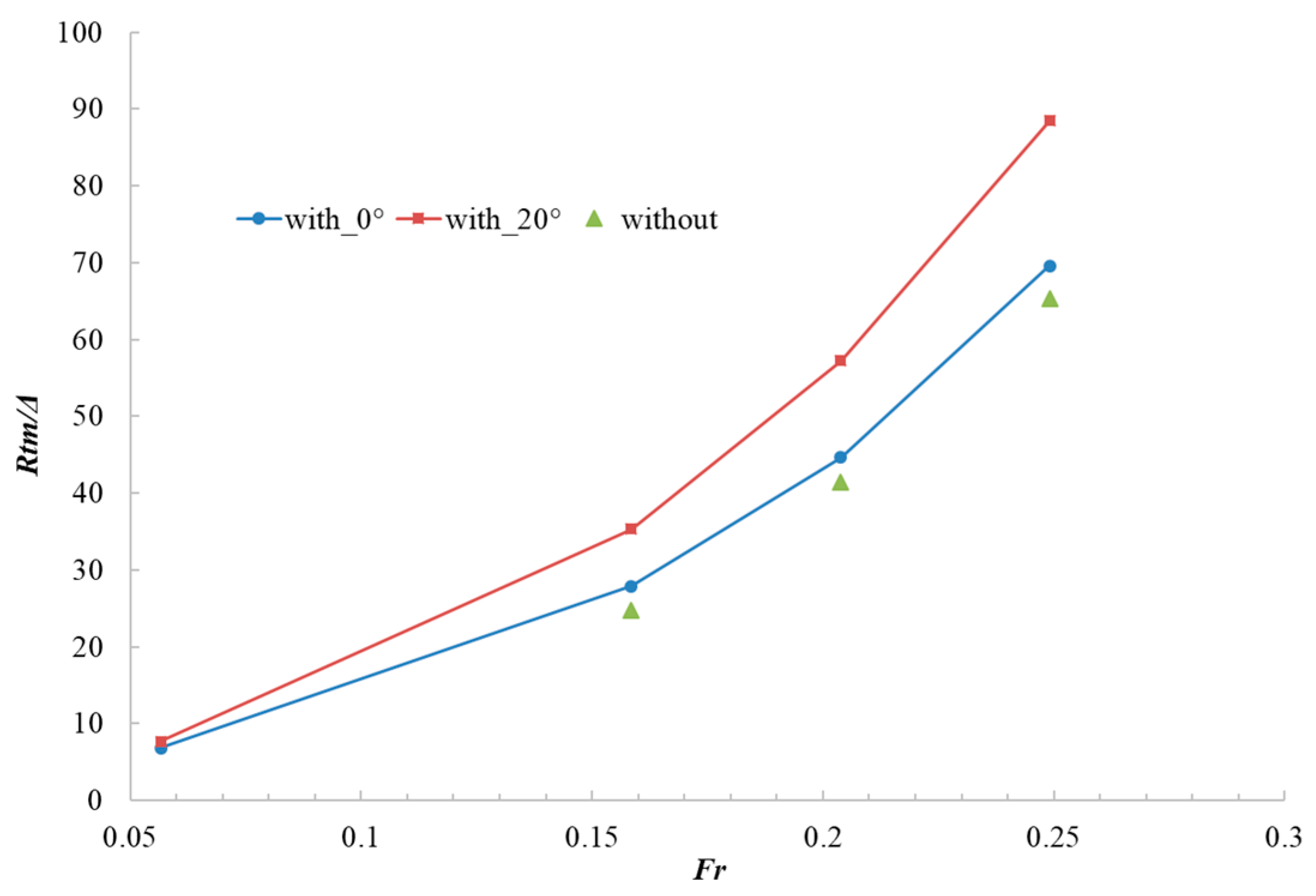

4.1. Experimental Results

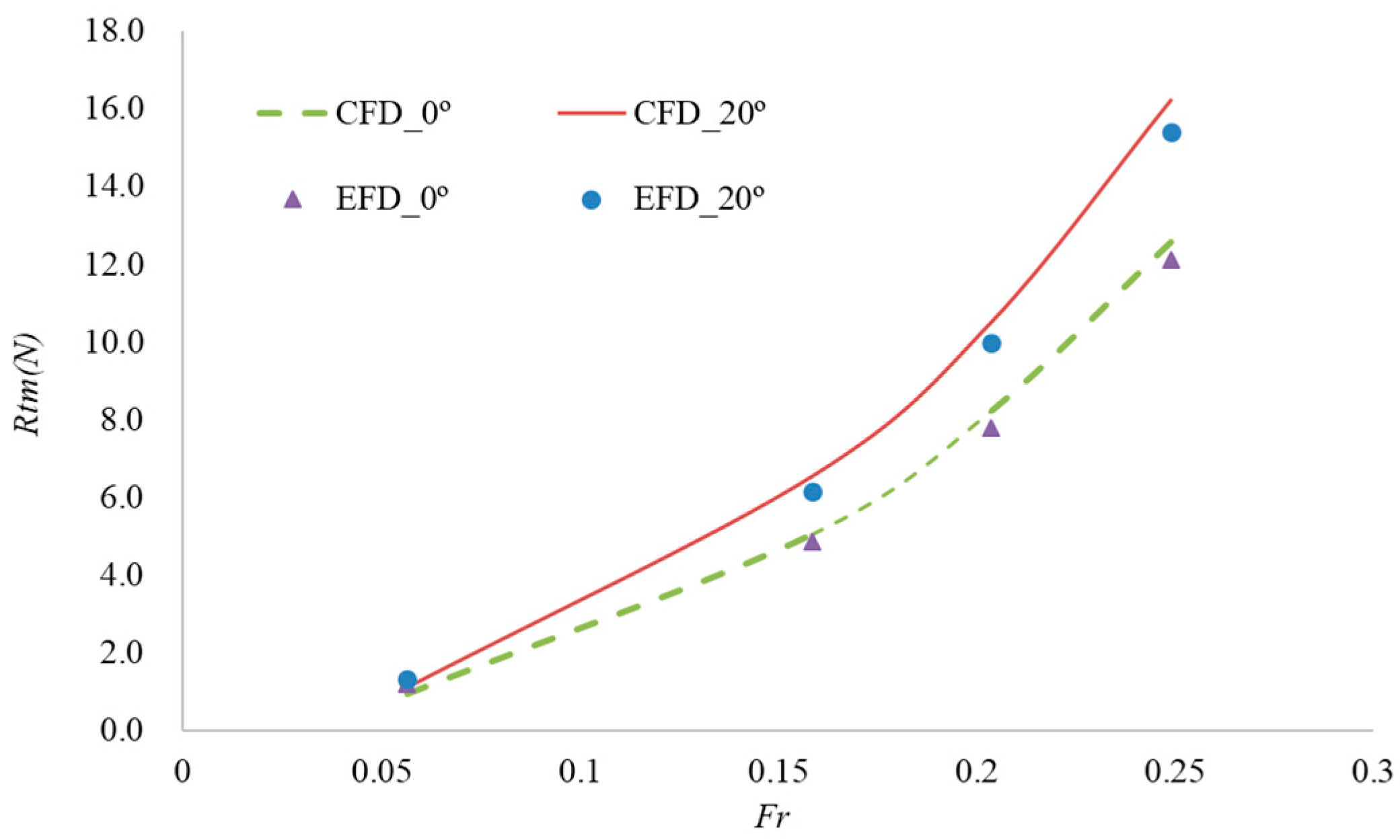

4.2. Verifications for EFD and CFD

4.2.1. W/O Fin Comparisons

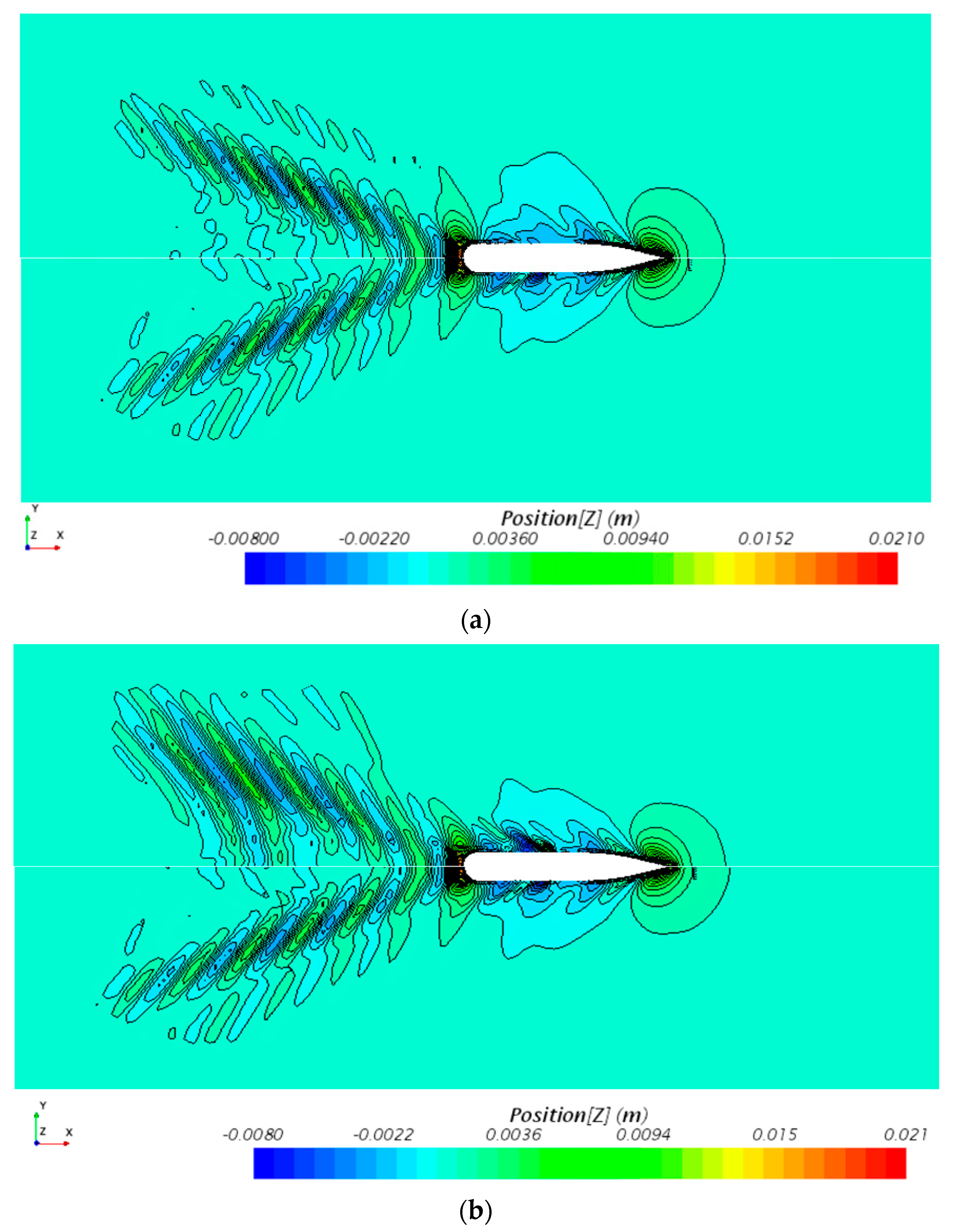

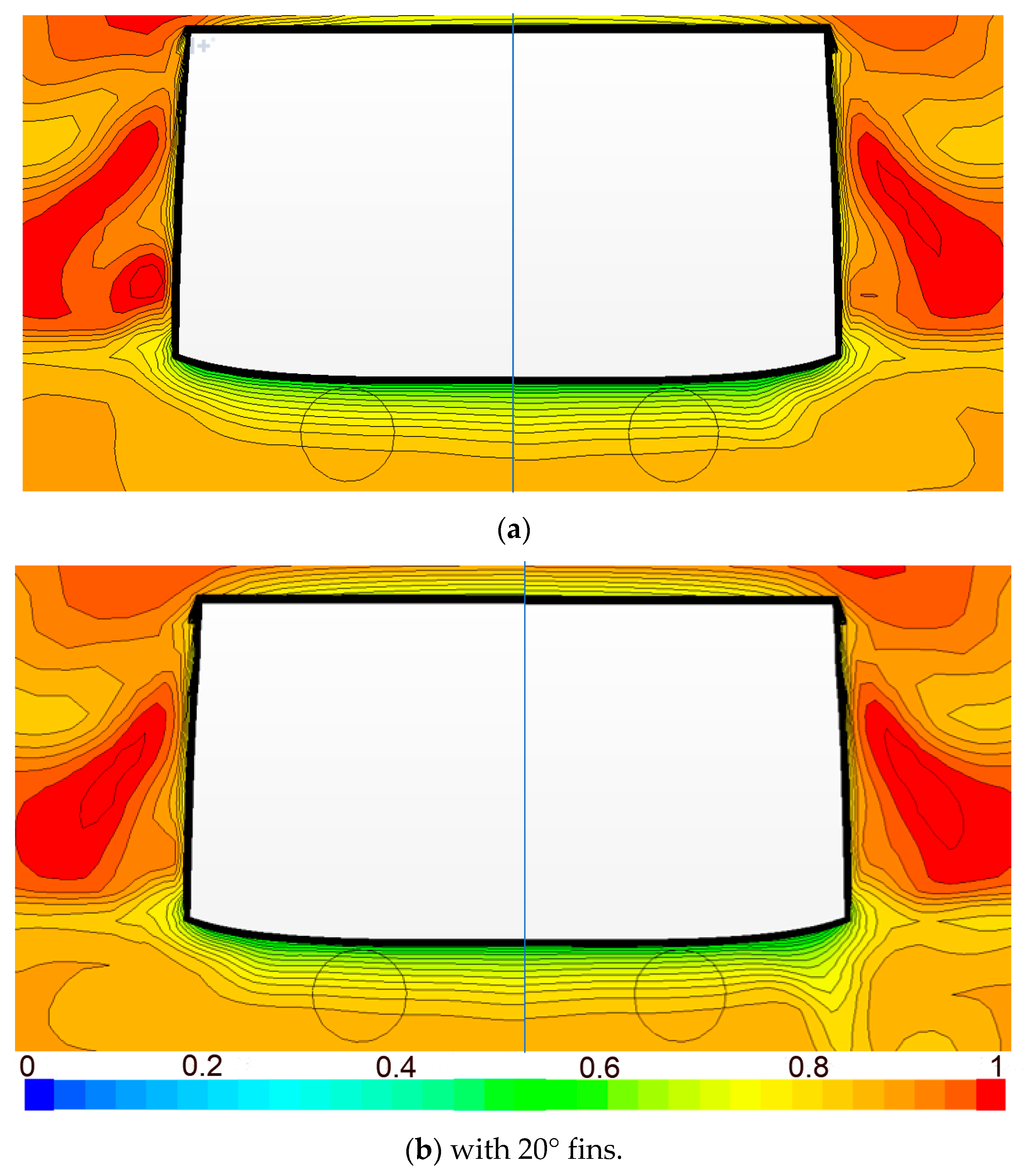

4.2.2. Free Surface Comparisons

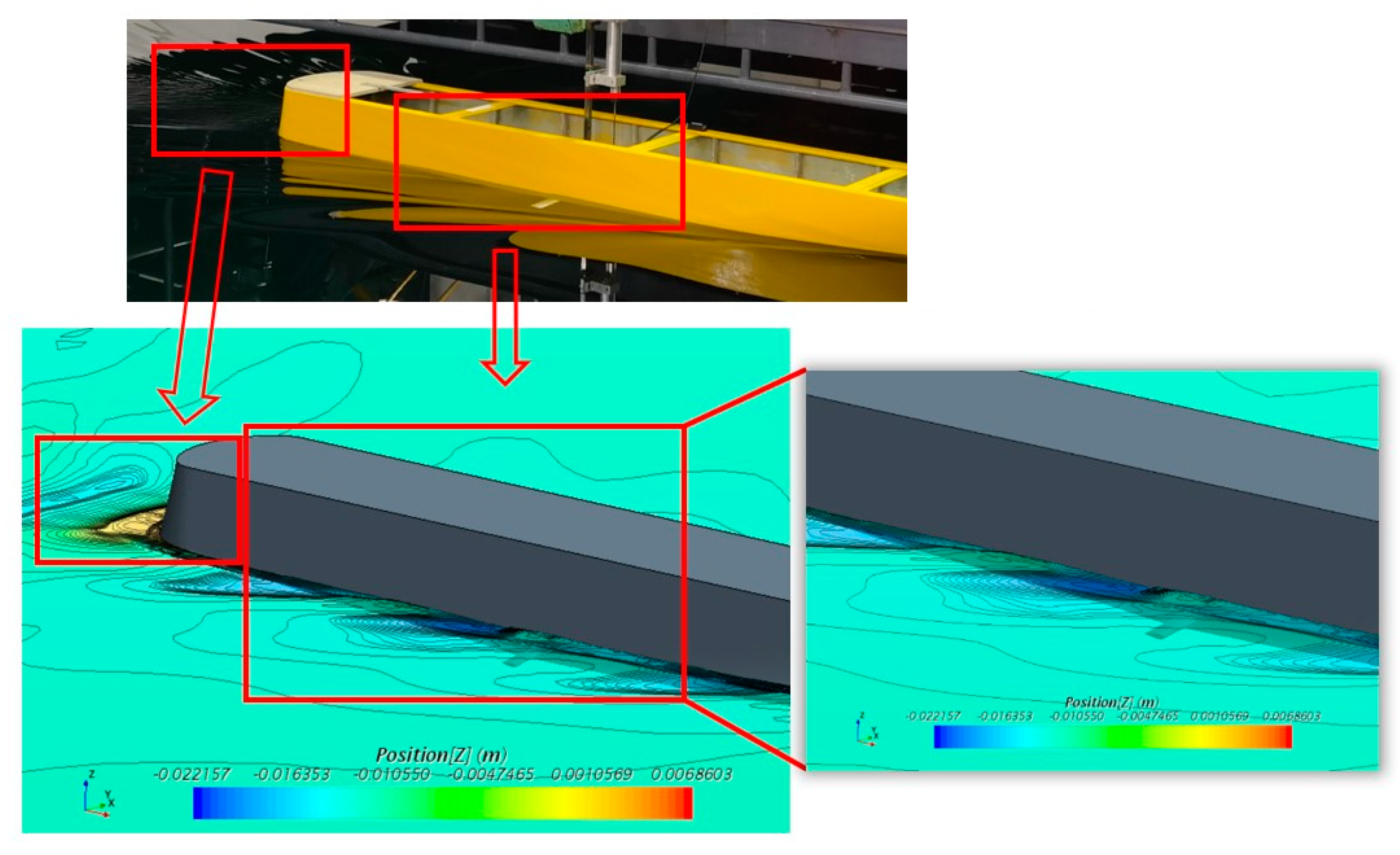

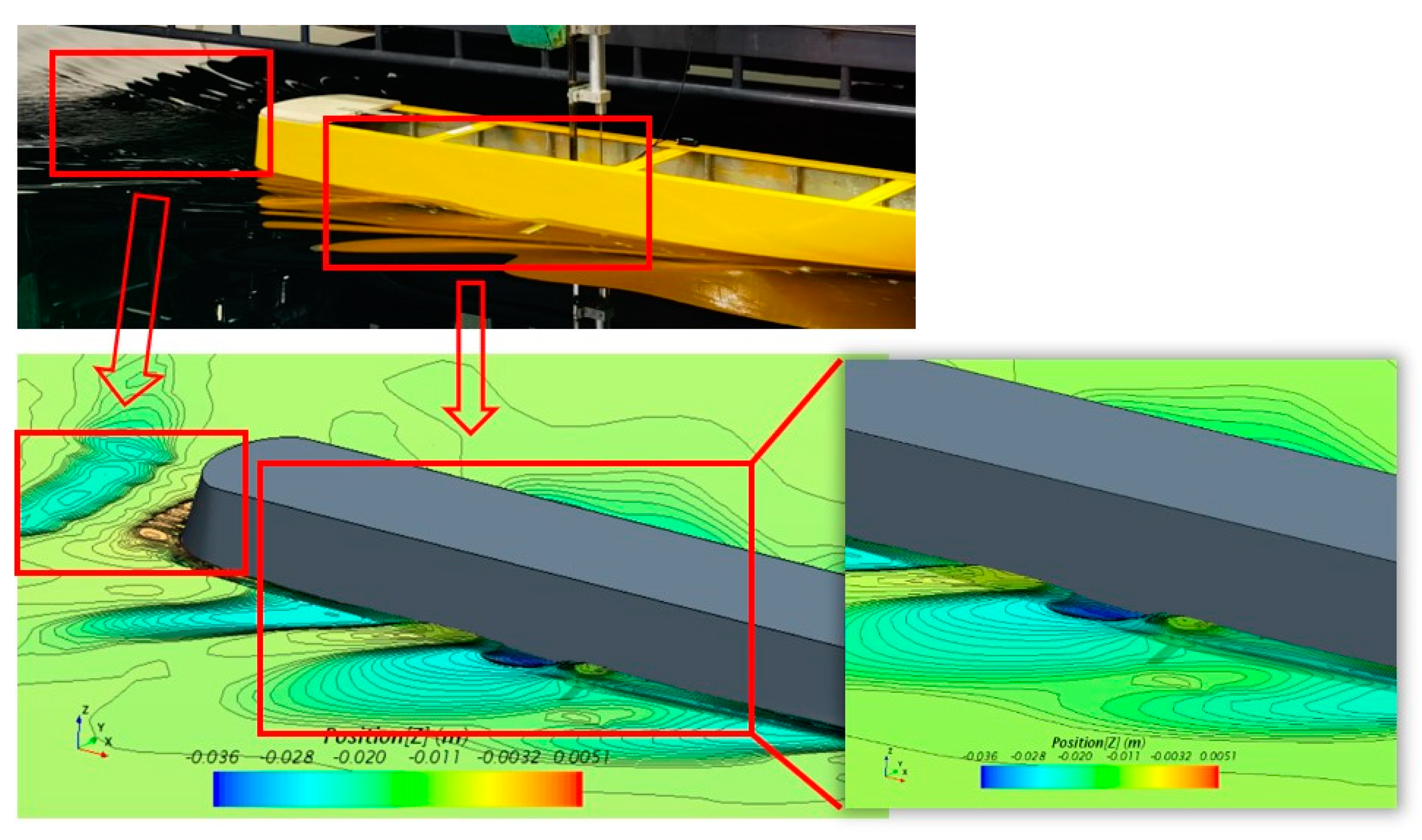

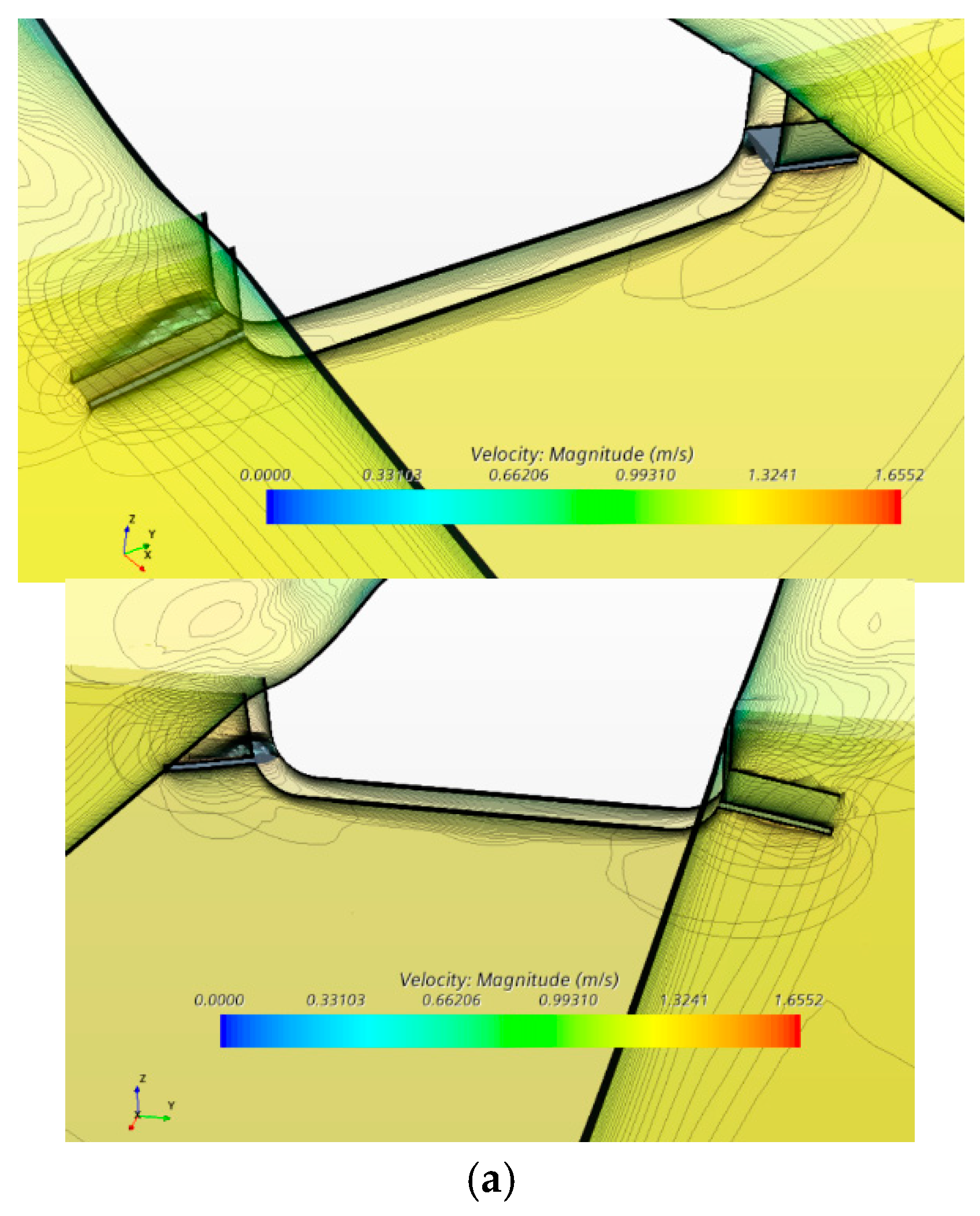

4.2.3. With 20° Fins—Asymmetry Condition

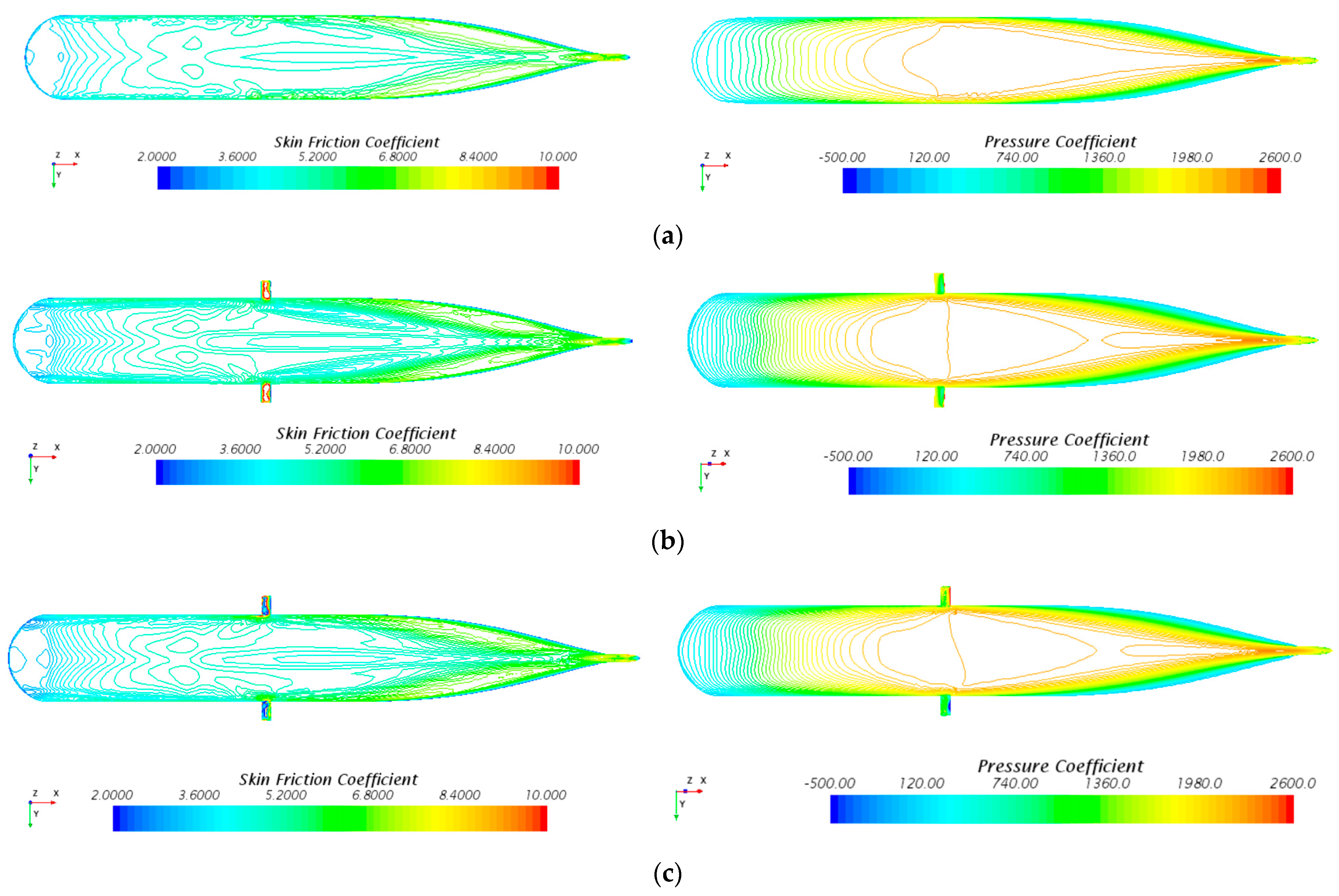

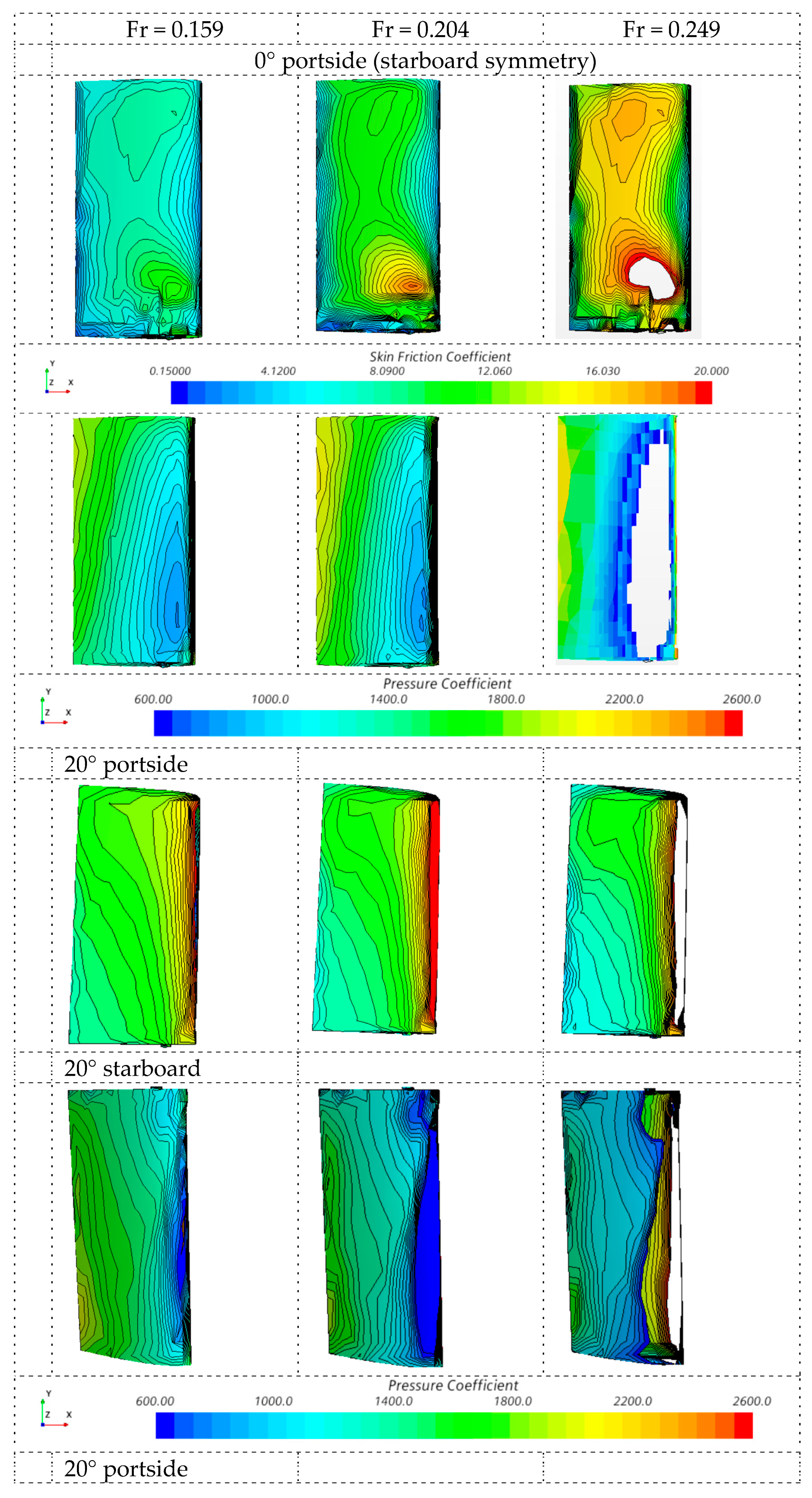

4.3. Fin Drag Evaluation

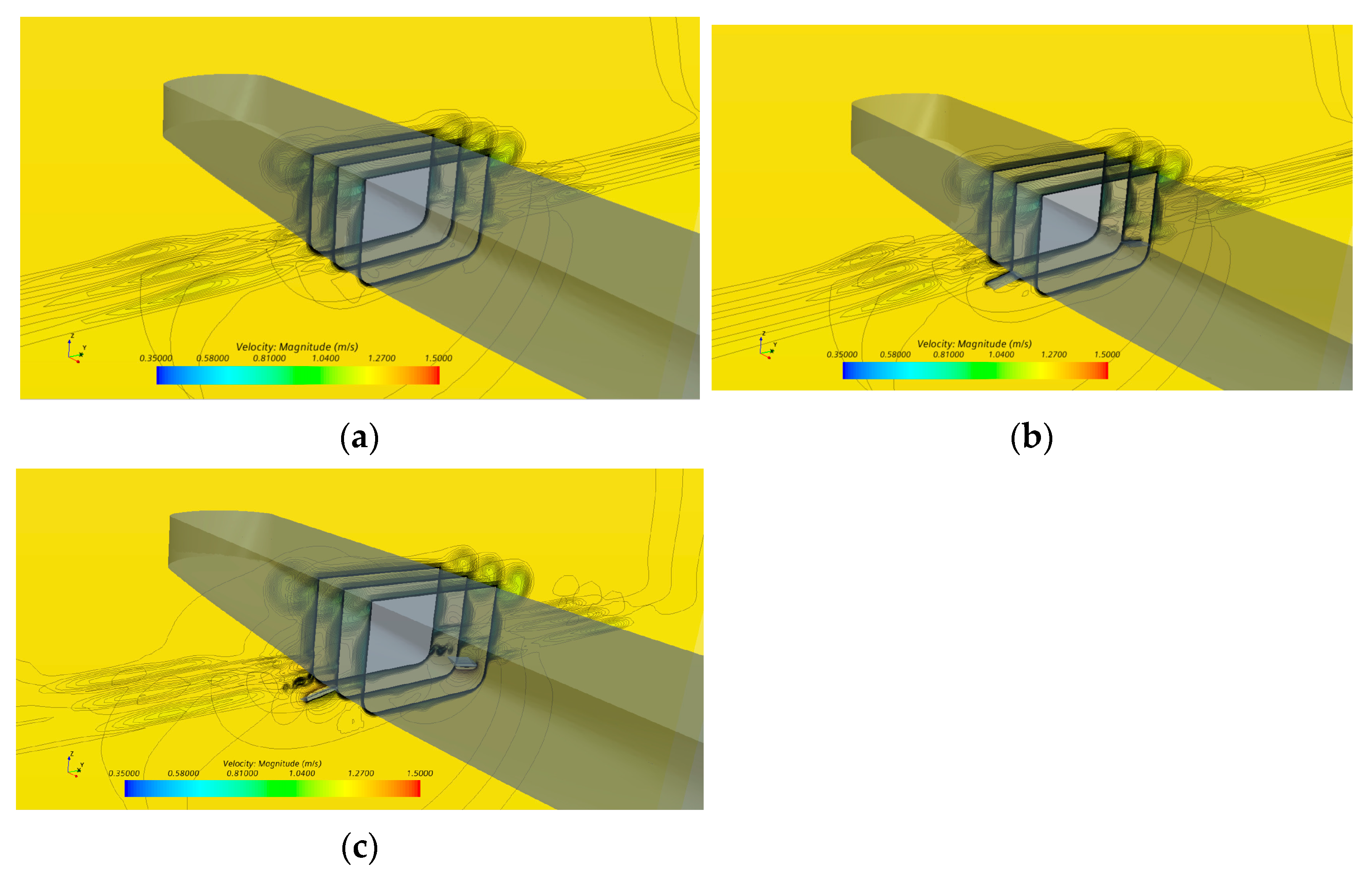

4.4. Propulsor Inflow Analysis

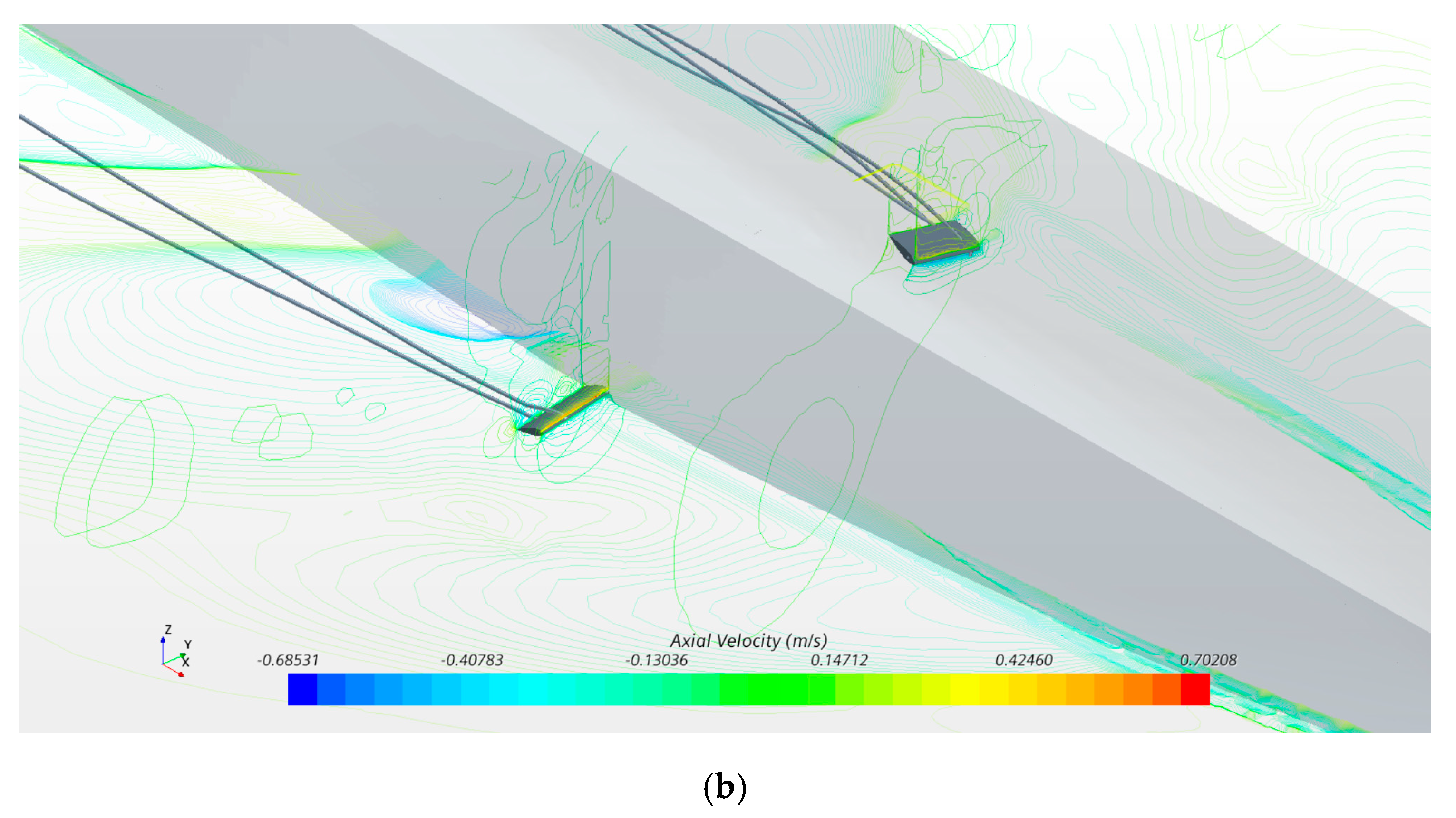

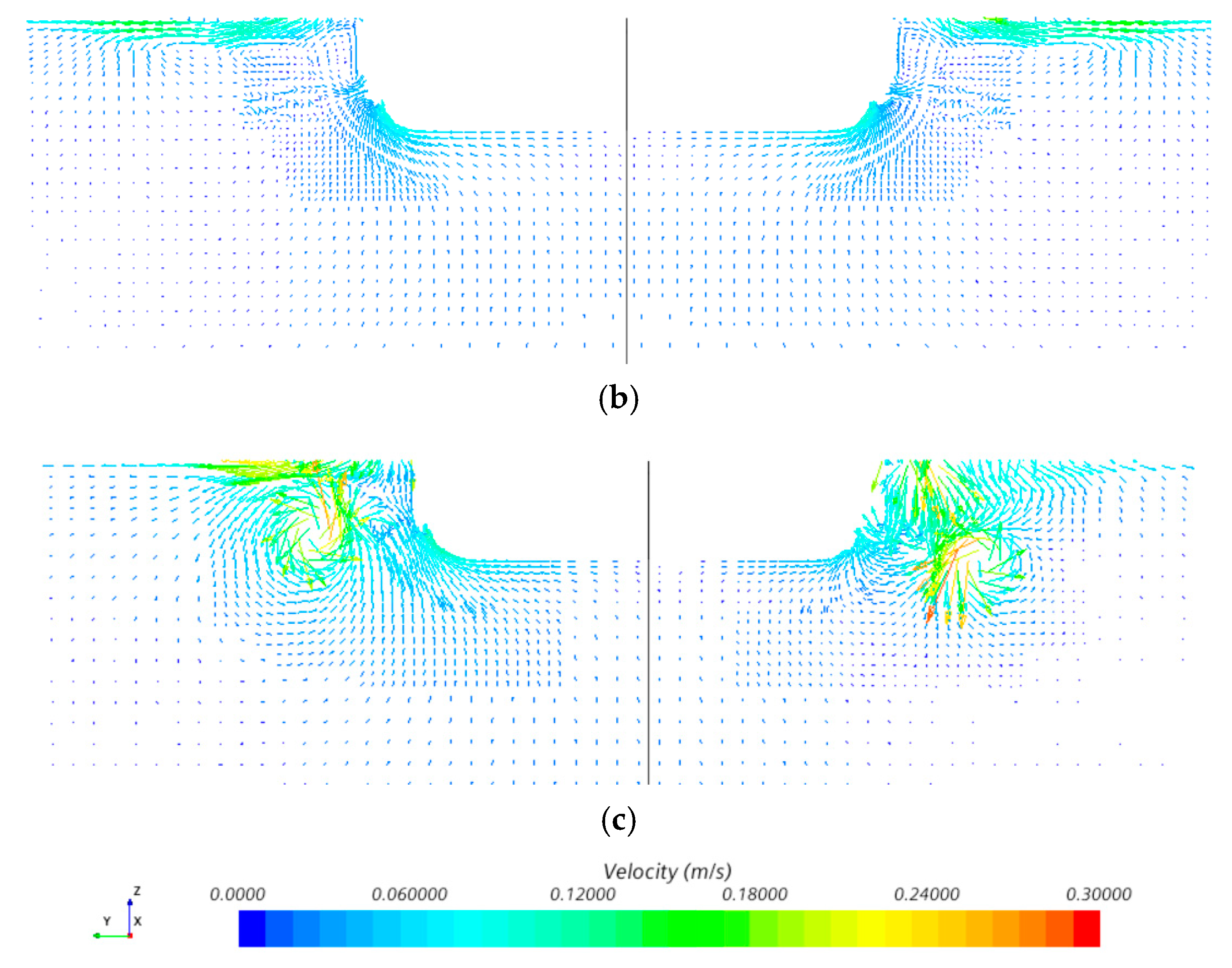

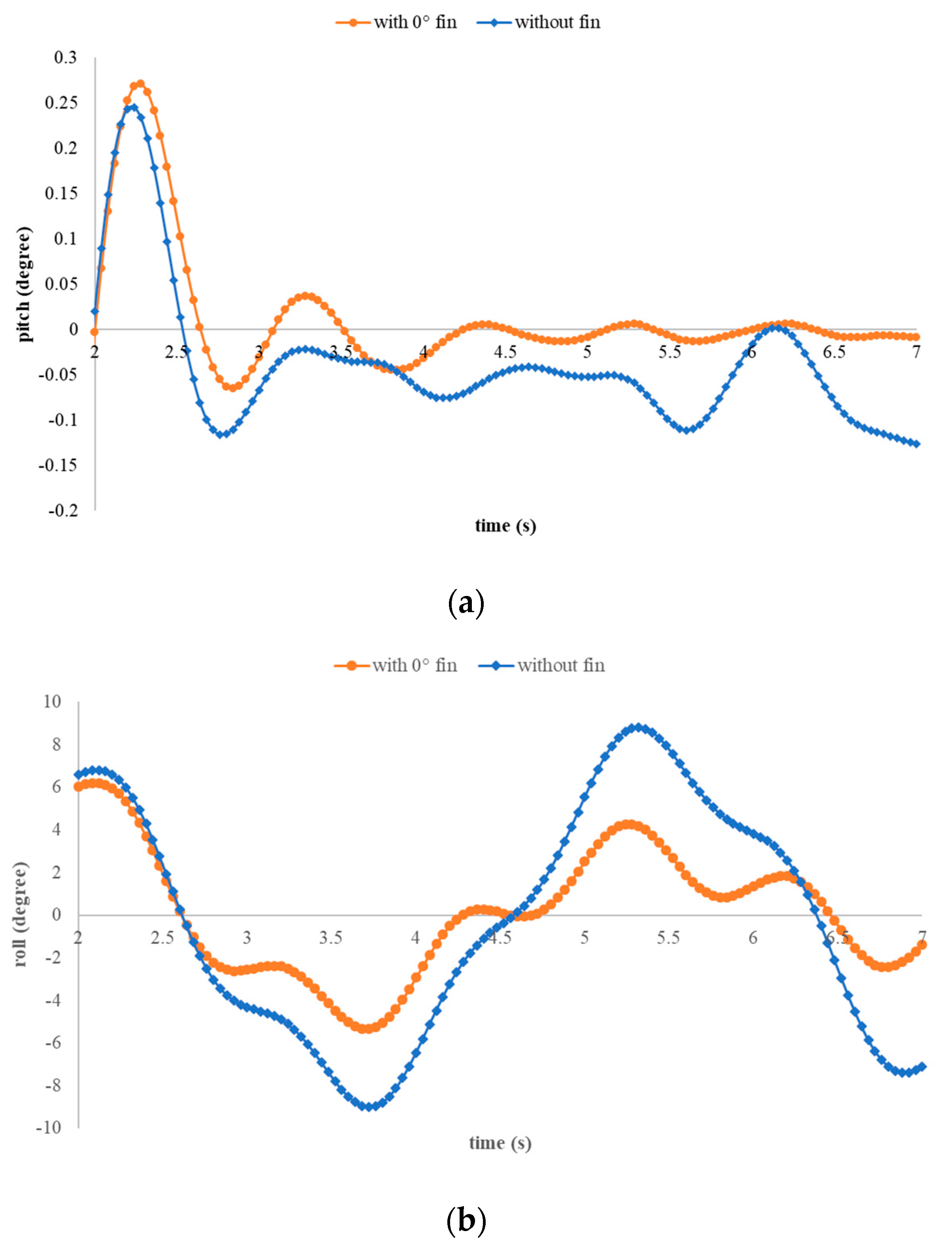

4.5. Fin Effect in Waves

5. Conclusions

- (1)

- The EFD provided reliable qualitative resistances, with various overhang fins at different angles at various ship speeds. The average resistance increment was 8.252%, whereas it increased by up to 19% at the largest fin angle. The test data proposed a new understanding of the fin-induced resistance.

- (2)

- CFD analysis details the fins’ resistance characteristics at various ship speeds and fin angles. The numerical methods that predicted the resistance increments agreed with EFD, with an average error margin within 5%.

- (3)

- The CFD computation captured the ship wave in good accord with the EFD, especially ship waves near the fin area with the same crest and trough. The flow characteristics of the maximum fin angle of 20° was investigated, and the two sides with different velocity distributions were compared with EFD results.

- (4)

- The fin drags derived by EFD can reach four times at the 20° fin angle, the significance of which cannot be neglected. The CFD, as an unsteady and steady method, was employed for fin drags, compared with the EFD. The CFD provided high-fidelity results, whereas the steady method overestimated by about 50%. From detailed computation, the high-pressure area moved to the leading edge with higher speeds, while the frictional area moved to the trailing edge.

- (5)

- The velocity distribution at the propulsor disk was calculated and compared. The fin-induced inflow change cannot be ignored, especially circumferential velocities at different fin angles.

- (6)

- The fin effect in waves has been investigated. The added resistance of the hull with fins increases less than that without fins. The roll reduction by the uncontrolled fins is up to 52.6%, while that of pitch is 88% at 22 kn.

Author Contributions

Funding

Conflicts of Interest

References

- Holden, C.; Perez, T.; Fossen, T. A Lagrangian approach to nonlinear modeling of anti-roll tanks. Ocean Eng. 2011, 38, 341–359. [Google Scholar] [CrossRef]

- Dreyfusi, E.D.; Brunsell, P.A. Moving Weight Ship Stabilizer. U.S. Patent 3,557,735A, 26 January 1971. [Google Scholar]

- Townsend, N.C.; Murphy, A.J.; Shenoi, R.A. A new active gyrostabiliser system for ride control of marine vehicles. Ocean Eng. 2007, 34, 1607–1617. [Google Scholar] [CrossRef]

- Surendran, S.; Kiran, V. Technical note Studies on the feasibilities of control of ship roll using fins. Ships Offshore Struct. 2006, 1, 357–365. [Google Scholar] [CrossRef]

- Liu, W.; Demirel, Y.K.; Djatmiko, E.B.; Nugroho, S.; Tezdogan, T.; Kurt, R.E.; Supomo, H.; Baihaqi, I.; Yuan, Z.; Incecik, A. Bilge keel design for the traditional fishing boats of Indonesia’s East Java. Int. J. Nav. Archit. Ocean. Eng. 2019, 11, 380–395. [Google Scholar] [CrossRef]

- Liang, L.; Zhao, P.; Zhang, S.; Yuan, J.; Wen, Y. Simulation and analysis of magnus rotating roll stabilizer at low speed. Ocean Eng. 2017, 142, 491–500. [Google Scholar] [CrossRef]

- Kongsberg Maritime. Available online: https://www.kongsberg.com/maritime/products/positioning-and-manoeuvring/fin-stabilisers (accessed on 22 June 2022).

- Sellars, F.H.; Martin, J.P. Selection and evaluation of ship roll stabilization systems. Mar. Technol. 1992, 29, 84–101. [Google Scholar] [CrossRef]

- Gaillarde, G. Dynamic Behavior and Operation Limits of Stabilizer Fins; International Maritime Association of the Mediterranean (IMAM): Creta, Greece, 2002. [Google Scholar]

- Gaillarde, G. Dynamic stall and cavitation of stabiliser fins and their influence on the ship behavior. In Proceedings of the 7th International Conference on Fast Sea Transportation (FAST), Ischia, Italy, 7–10 October 2003. [Google Scholar]

- Perez, T.; Blanke, M. Ship roll damping control. Annu. Rev. Control 2012, 36, 129–147. [Google Scholar] [CrossRef] [Green Version]

- Della Rosa, S.; Maceri, S.; Viola, I.M.; Bartesaghi, S. Design and optimization of a fin stabilizer using CFD codes and optimization algorithms. In Proceedings of the 16th International Conference of Ship and Shipping Research, Messina, Italy, 26–27 November 2009. [Google Scholar]

- Ram, B.R.R.; Surendran, S.; Lee, S.K. Computer and experimental simulations on the fin effect on ship resistance. Ships Offshore Struct. 2015, 10, 122–131. [Google Scholar] [CrossRef]

- Giallanza, A.; Elms, T. Interactive roll stabilization comparative analysis for large yacht: Gyroscope versus active fins. Int. J. Interact. Des. Manuf. 2020, 14, 143–151. [Google Scholar] [CrossRef]

- Kusdiana, W.; Semin; Ariana, I.M.; Kusuma, C.; Ali, B. Location Analysis of Patrol Boat Fin Stabilizer Based on Numerical Method. IOP Conf. Ser. Earth Environ. Sci. 2022, 972, 12002. [Google Scholar] [CrossRef]

- Jin, H.Z.; Zhang, X.F.; Luo, Y.M.; Li, D.S. Research on lift model of zero speed fin stabilizer. Ocean. Eng. 2007, 25, 83–87. [Google Scholar]

- Dallinga, R.P.; Rapuc, S. Merits of Flapping Roll Stabilizer Fins. In Proceedings of the HISWA Amsterdam Boat Show, Amsterdam, The Netherlands, 2–7 September 2014. [Google Scholar]

- Jin, H.Z.; Pan, Y.; Yang, B. Theoretical analysis of humpback whale fin stabilizer at a small angle of attack. J. Ship Mech. 2010, 14, 1219–1226. [Google Scholar]

- Song, J.; Jin, H.; Meng, L. Optimum Design of Aerofoil for Fin Stabilizer at Whole Speed Range. Shipbuild. China 2013, 54, 1–10. [Google Scholar]

- Koop, M.T. Method for Actively Damping a Ship’s Motion as Well as Such an Active Roll Stabilization System. U.S. Patent 9,527,557 B2, 27 December 2016. [Google Scholar]

- Liang, L.; Jiang, Y.L.; Zhang, Q.; Le, Z.W. Aspect ratio effects on hydrodynamic characteristics of Magnus stabilizers. Ocean Eng. 2020, 216, 107699. [Google Scholar] [CrossRef]

- Ye, X.; Wang, X.; Wang, Y.; Luo, Y.; Yang, G.; Sun, R. Design Features and Construction Enlightenments of Oasis-Class Luxury Cruise Ships. In Report on the Development of Cruise Industry in China; Wang, H., Ed.; Springer: Singapore, 2018. [Google Scholar] [CrossRef]

- Zhu, W. Study on stabilization system for large ships. Chin. Water Transp. 2012, 12, 69–70. [Google Scholar]

- Düz, B. Sensitivity Analysis in Parametric Rolling of a Modern Cruise Ship Using Numerical Simulations in 6-DOF. In Proceedings of the 39th International Conference on Ocean, Offshore and Arctic Engineering, Online, 28 June–3 July 2020. [Google Scholar]

- Kim, J.H.; Kim, Y.H. Motion control of a cruise ship by using active stabilizing fins. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2011, 225, 311–324. [Google Scholar] [CrossRef]

- Lee, S.; Rhee, K.P.; Choi, J.W. Design of the roll stabilization controller, using fin stabilizers and pod propellers. Appl. Ocean. Res. 2011, 33, 229–239. [Google Scholar] [CrossRef]

- Ozturk, D. Performance of a Magnus effect-based cylindrical roll stabilizer on a full-scale Motor-yacht. Ocean Eng. 2020, 218, 108247. [Google Scholar] [CrossRef]

- John, S.; Khan, K.; Praveen, P.C.; Korulla, M.; Panigrahi, P.K. Ship Hull Appendages: A Case Study. Int. J. Innov. Res. Dev. 2012, 1, 74–89. [Google Scholar]

- Fenton, J.D. A Fifth-Order Stokes Theory for Steady Waves. J. Waterw. Port Coast. Ocean Eng. 1985, 111, 216–234. [Google Scholar] [CrossRef] [Green Version]

| Items | Symbols | Value |

|---|---|---|

| Length between perpendiculars | LPP/m | 3.725 |

| Breadth | B/m | 0.564 |

| Draft | T/m | 0.1173 |

| Displacement | Δ/t | 0.1742 |

| Wetted surface | Sw/m2 | 2.362 |

| Center of gravity | LCG/m | 1.611 |

| Center of gravity | KG/m | 0.287 |

| Fin sectional hydrofoil | NACA0021 | |

| Fin chord length | m | 0.06 |

| Aspect ratio | 2.05 | |

| Fin length | m | 0.12376 |

| No. | Vs (kn) | Fr | Vm (m/s) | W/O Condition | ||

|---|---|---|---|---|---|---|

| Without | With Fin Angle | |||||

| 0° | 20° | |||||

| 1 | 5 | 0.057 | 0.3468 | ~ | ④ | ⑧ |

| 2 | 14 | 0.159 | 0.9711 | ① | ⑤ | ⑨ |

| 3 | 18 | 0.204 | 1.2485 | ② | ⑥ | ⑩ |

| 4 | 22 | 0.249 | 1.5260 | ③ | ⑦ | ⑪ |

| Items | Volume Meshes (Unit: M) | Rtm (N) | |

|---|---|---|---|

| G1 | 1.02 | 8.4 | −1.31% |

| G2 | 1.36 | 8.29 | −0.72% |

| G3 | 1.80 | 8.23 | −0.49% |

| G4 | 3.08 | 8.19 | −0.12% |

| G5 | 7.02 | 8.18 |

| No. | Fr | ||

|---|---|---|---|

| 1 | 0.057 | ~ | 11.70% |

| 2 | 0.159 | 11.25% | 20.96% |

| 3 | 0.204 | 7.33% | 21.97% |

| 4 | 0.249 | 6.18% | 21.38% |

| Average | 8.25% | 19% |

| No. | Fr | (0°–20°)/20° | Error (%) | |

|---|---|---|---|---|

| Rtm_EFD (%) | Rtm_CFD (%) | EFD—FD | ||

| 1 | 0.057 | −11.70% | −14.65% | 2.94% |

| 2 | 0.159 | −20.96% | −22.84% | 1.88% |

| 3 | 0.204 | −21.97% | −21.84% | −0.13% |

| 4 | 0.249 | −21.38% | −20.27% | −1.11% |

| Fr | Re | Fin Drags by EFD (a) | Fin Drags by CFD (b) | Steady Estimation (c) |

|---|---|---|---|---|

| 0.159 | 1.19 × 105 | 1.834 | 1.749 | 2.598 |

| 0.204 | 1.53 × 105 | 2.7596 | 2.7617 | 3.946 |

| 0.249 | 1.87 × 105 | 4.0437 | 4.0648 | 6.098 |

| Fr | |||

|---|---|---|---|

| 0.159 | 183.40 | −4.63 | 48.54 |

| 0.204 | 275.96 | 0.08 | 42.88 |

| 0.249 | 404.37 | 0.52 | 50.02 |

| Condition | Drag in Calm Water (N) | Drag in Waves (N) | |

|---|---|---|---|

| Without | 7.42 | 7.672 | 3.29% |

| 0° fin | 7.926 | 8.020 | 1.17% |

| 20° fin | 10.11 | 10.244 | 1.31% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, R.; Yu, L.; Fan, Q.; Wang, X. Experimental and Numerical Resistance Analysis for a Cruise Ship W/O Fin Stabilizers. J. Mar. Sci. Eng. 2022, 10, 1054. https://doi.org/10.3390/jmse10081054

Yao R, Yu L, Fan Q, Wang X. Experimental and Numerical Resistance Analysis for a Cruise Ship W/O Fin Stabilizers. Journal of Marine Science and Engineering. 2022; 10(8):1054. https://doi.org/10.3390/jmse10081054

Chicago/Turabian StyleYao, Rulin, Long Yu, Qidong Fan, and Xuefeng Wang. 2022. "Experimental and Numerical Resistance Analysis for a Cruise Ship W/O Fin Stabilizers" Journal of Marine Science and Engineering 10, no. 8: 1054. https://doi.org/10.3390/jmse10081054

APA StyleYao, R., Yu, L., Fan, Q., & Wang, X. (2022). Experimental and Numerical Resistance Analysis for a Cruise Ship W/O Fin Stabilizers. Journal of Marine Science and Engineering, 10(8), 1054. https://doi.org/10.3390/jmse10081054