Seaport Terminals Risks Prioritization Using a Structural Modeling-Based Approach: A Real Case Study

Abstract

1. Introduction

1.1. Literature Review

1.2. Objective of the Study

2. Materials and Methods

2.1. MICMAC Method

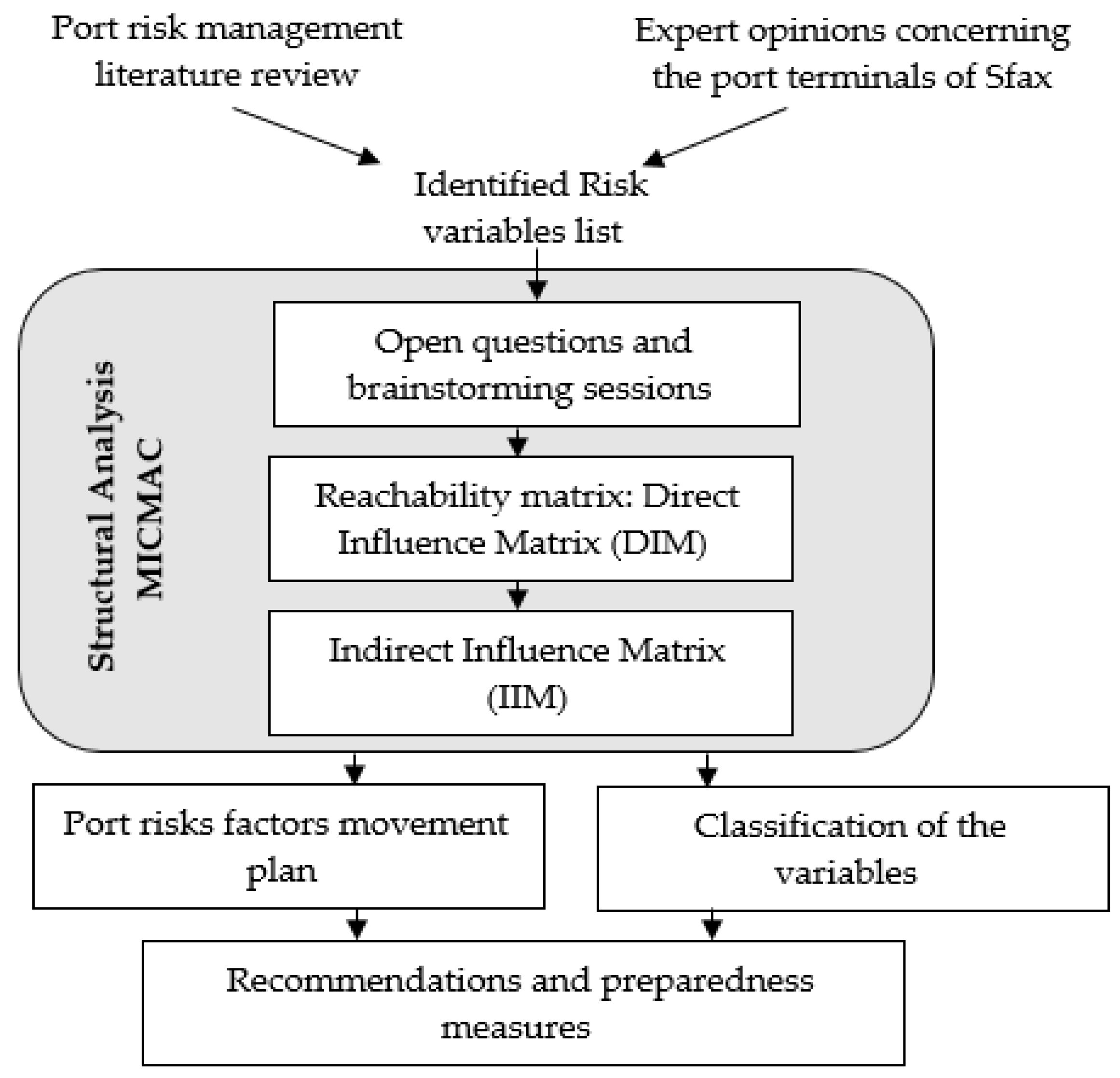

2.2. The Proposed Approach

3. Results

3.1. Identification of Risk Variables

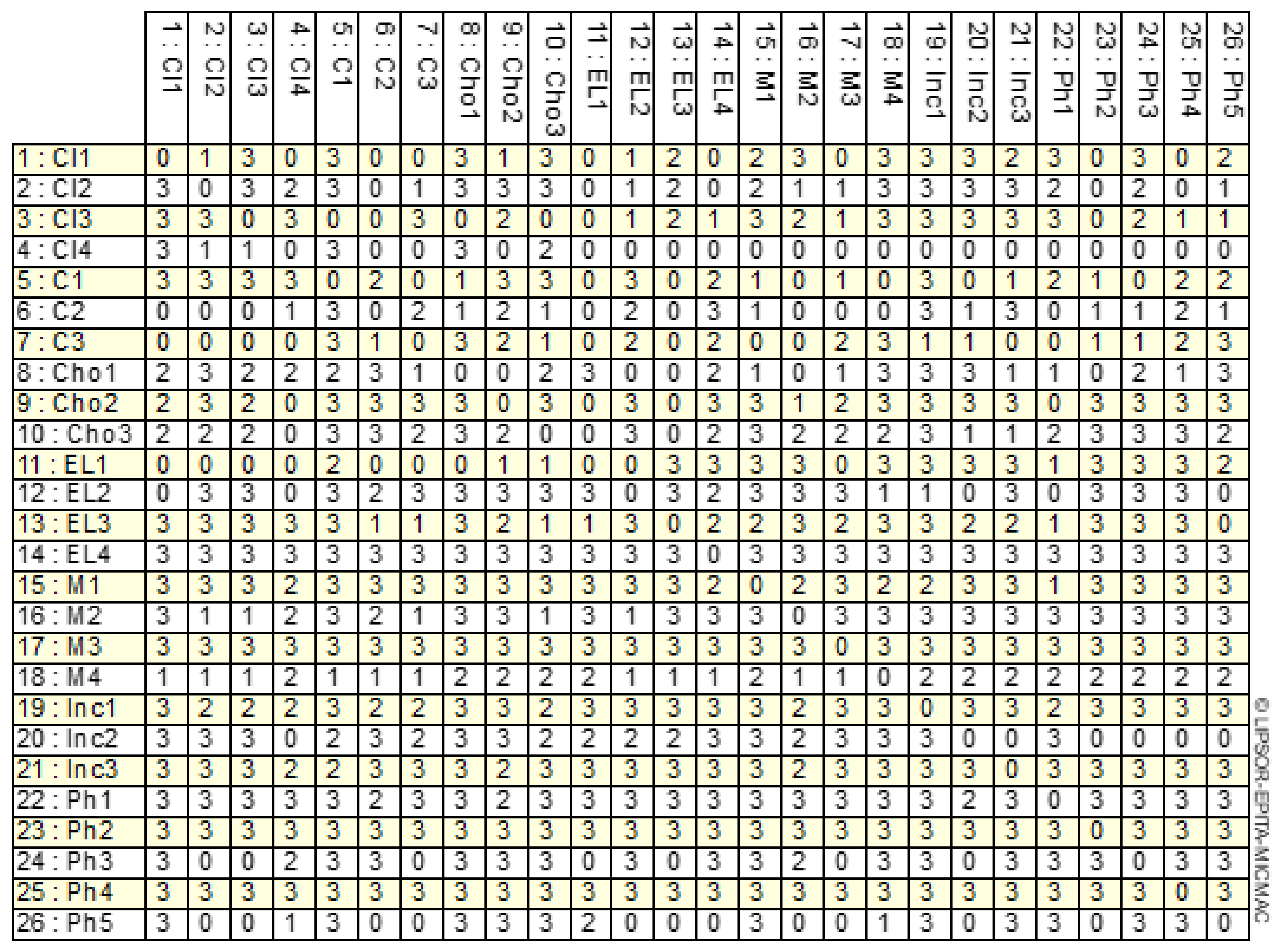

3.2. MICMAC Matrix

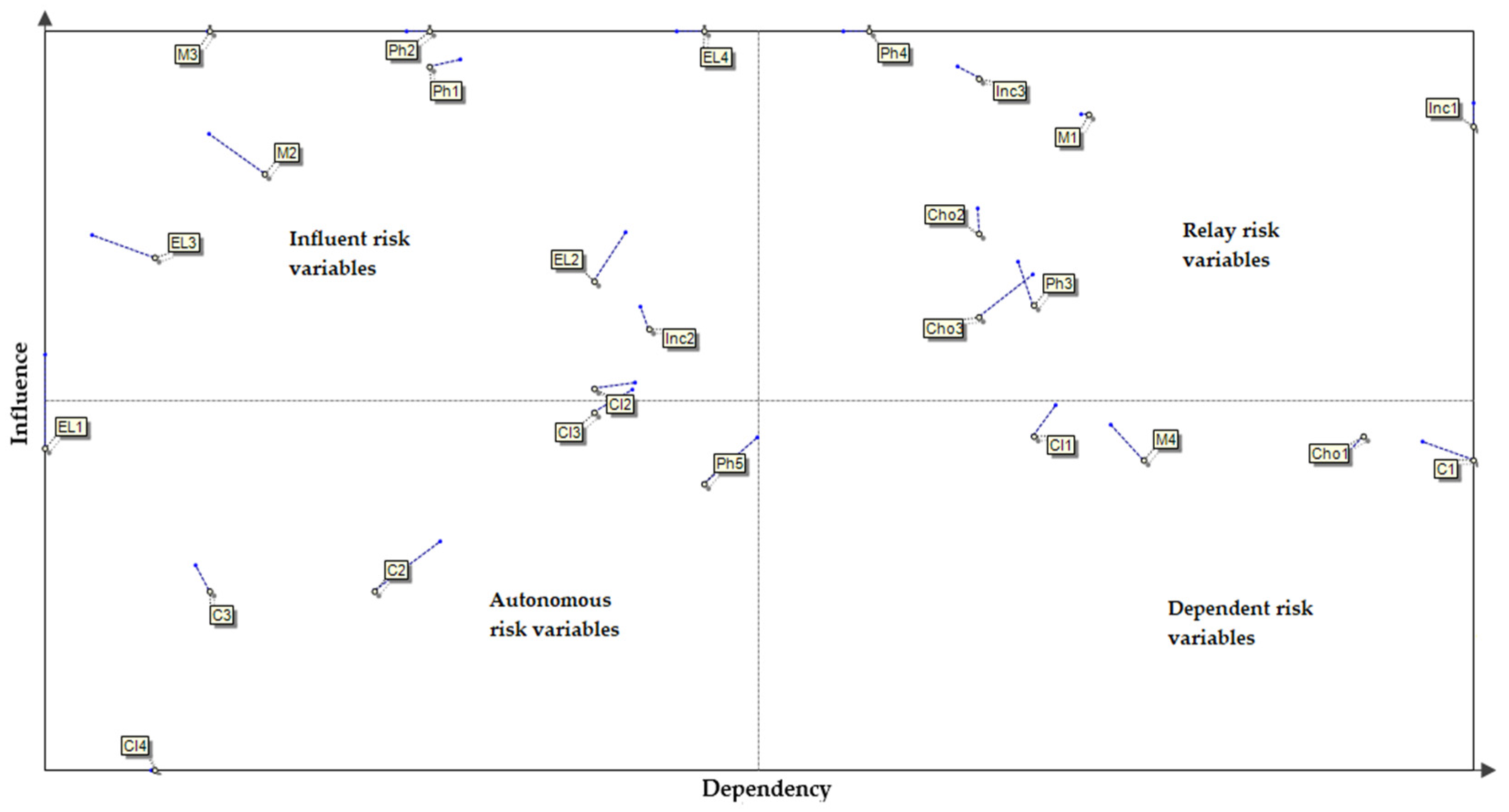

3.3. MICMAC results

- The input or influential variables, located to the northwest are: M3 (lack of supervision), EL4 (neglect of regulatory aspects (periodic inspection)), EL2 (lack of work equipment and individual protection equipment (EPI)), M2 (lack of lighting (visual management)), Ph1 (bad arrangement of the stations), Ph2 (lack of training) and EL3 (faulty electrical installation). These are highly influential variables and are less dependent than the other variables in the PRM system. They are also explanatory variables of the system under study and are the most crucial elements. These variables cannot be controlled.

- The relay variables are highly influential and highly dependent variables: Inc3 (neglect of regulatory aspects: the requirements of safety code and prevention against fire, explosion, and panic risks), Ph3 (manual handling), Ph4 (disregard of safety aspects (lack of procedures, instructions, supervision, roles and responsibilities, job description), Inc1 (unsafe storage of the goods (non-respect of thermal flows, domino rule, bow tie, etc.), CI3 (neglect of the EPI (gloves, mask, etc.) by the workers exposed to the risk (absence of discipline), ChO2 (ignorance of the good practices of handling (slinging of the goods) during the operation of loading and unloading), ChO3 (inadequate lifting accessories (chains, slings, ropes, shackles, hooks, lifting straps) and noncompliance with the regulatory aspects of the Tunisian Decree 62–129 (periodic inspection required)) and M1 (neglect of the regulatory aspects of handling equipment (periodic inspection).

- The outcome or dependent variables are both weakly influential and highly dependent. The evolution of these variables is explained by the evolution of the input and relay variables. These are the output variables of the PRM system: CI1 (poor layout of the workplaces), M4 (fault from heights (of drivers: forklift operators, crane operators, etc.), ChO1 (instability and bad storage of the goods), C1 (poor handling of chemicals), etc.

- The autonomous variables are variables with little influence and little dependency. They have little impact on the evolution of the PRM system: CI4 (deficient and irregular ground), C2 (absence of a Safety Data Sheet (SDS) for the goods), C3 (no wearing of the EPI (gloves, mask, etc.) by workers exposed to the risk (absence of discipline).

- The platoon variables are more influential in the medium than the dependent variables. It is not possible to determine their role in the PRM system: CI2 (lack of signage of the aisles of circulation of various flows (pedestrians, carts, materials, etc.), EL1 (lack of training for electricians), CI3 (absence of plan, instruction, traffic display), Ph5 (poor posture and physical condition).

4. Discussion

- Respect of general obligations of the competent authority of the flag state:

- Respect of general obligations and responsibilities of ship owners: The ship owner is primarily responsible for the safety and health of all seafarers on board ships. However, the daily duty rests with the captain who has to adhere to the reporting approaches set through ship owners. These should establish an adequate seafarer health and safety policy, under the law national and international, and provide the means necessary for the execution of these policies. The policy and software must set out the obligations of all parties, such as shore employees and contractors. Ship owners should offer and keep or replace vessels, gadget, units, manuals, and other files, and prepare all coaching and sports in the sort of way that, to the fullest extent possible, seafarers are not exposed to any chance of twist of fate or damage. The planning, preparation, and implementation of activities should take the following requirements: (1) All dangers that may arise on the port must be avoided. (2) Excessively or unnecessarily painful working postures and movements must be avoided. (3) The organization of work must consider the safety and health of the sea worker. (4) The materials and products used must be safe and do not endanger the health of seafarers. (5) The working methods employed must ensure the protection of seafarers against the harmful effects of chemical, physical, and biological agents. (6) Shipowners should take a look at the applicable national and international regulations while setting the level of staffing and thinking about the requirements necessary in phases of bodily fitness, state of health, level of competence, and language skills to ensure the protection and health of seafarers in keeping their obligations onboard the ship.

- Respect of general obligations and responsibilities of the owner;

- Respect of general obligations and responsibilities of employees;

- Respect of the general obligations and responsibilities of the safety and health committee on board which include the following. (1) Ensure that the requirements of the competent authority and the ship owner in the safety and health sector are satisfied. (2) Address, through the captain, complaints and recommendations to the owner on behalf of the crew. (3) Examine matters of concern to the crew in matters of safety and health, and take the necessary measures on this basis to assess the safety and protection, including life-saving devices. (4) Study accident reports.

- Respect of general duties and responsibilities of the security officer. They include the following: (1) He should educate the crew members on safety issues. (2) Investigate safety lawsuits brought to its attention and seize the safety and fitness committee and individuals if vital.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Elmsalmi, M.; Hachicha, W.; Aljuaid, A.M. Prioritization of the Best Sustainable Supply Chain Risk Management Practices Using a Structural Analysis Based-Approach. Sustainability 2021, 13, 4608. [Google Scholar] [CrossRef]

- Shahbaz, M.S.; Sohu, S.; Khaskhelly, F.Z.; Bano, A.; Soomro, M.A. A Novel Classification of Supply Chain Risks: A Review. Eng. Technol. Appl. Sci. Res. 2019, 9, 4301–4305. [Google Scholar] [CrossRef]

- Dias, G.C.; Leal Junior, I.C. Rébula de Oliveira, U. Supply chain risk management at seaport container terminals. Gest. Prod. 2019, 26, 1–14. [Google Scholar] [CrossRef]

- Nagi, A.; Schroeder, M.; Kersten, W. Risk management in seaports: A community analysis at the port of Hamburg. Sustainability 2021, 13, 8035. [Google Scholar] [CrossRef]

- Roux, P. Guide pour la conception et l’exploitation de silos de stockage de produits agro-alimentaires vis-à-vis des risques d’explosion et d’incendie ». Ministère de l’Aménagement du territoire et de L’environnement; Institut National de l’Environnement Industriel et des Risques INERIS: Paris, France, 2000. [Google Scholar]

- Hachicha, W.; Elmsalmi, M. An integrated approach based-structural modeling for risk prioritization in supply network management. J. Risk Res. 2014, 17, 1301–1324. [Google Scholar] [CrossRef]

- Jha, K.N.; Devaya, M.N. Modelling the risks faced by Indian construction companies assessing international projects. Constr. Manag. Econ. 2008, 26, 337–348. [Google Scholar] [CrossRef]

- Pfohl, H.; Gallus, P.; Thomas, D. Interpretive structural modeling of supply chain risks. Int. J. Phys. Distrib. Logist. Manag. 2011, 41, 839–859. [Google Scholar] [CrossRef]

- Elmsalmi, M.; Hachicha, W. Risk Mitigation Strategies According to the Supply Actors’ Objectives by Using the MACTOR Method. In Proceedings of the International Conference on Advanced Logistics and Transport (ICALT’2014), Hammamet, Tunisia, 1–3 May 2014; pp. 362–367. [Google Scholar]

- Elmsalmi, M.; Hachicha, W.; Aljuaid, A.M. Modeling Sustainable Risks Mitigation Strategies Using a Morphological Analysis-Based Approach: A Real Case Study. Sustainability 2021, 13, 12210. [Google Scholar] [CrossRef]

- Pandey, A.K.; Sharma, R.K. FMEA-based interpretive structural modelling approach to model automotive supply chain risk. Int. J. Logist. Syst. Manag. 2017, 27, 395–419. [Google Scholar]

- Godet, M.; Durance, P.; Gerber, A. Strategic Foresight la Prospective; Cahiers du LIPSOR: Paris, France, 2008. [Google Scholar]

- Maruster, L.; Gijsenberg, M.J. Qualitative Research Methods; Sage Publications Ltd.: New York, NY, USA, 2013; Available online: https://www.amazon.com/Qualitative-Research-Gijsenberg-compilation-Maruster/dp/1446272370/ref=monarch_sidesheet (accessed on 2 February 2022).

- Centemeri, L. «Enquêter la mémoire disctréte de desastre de Soveso». Le gouvernement des Catastrophes 2013, 217–249. [Google Scholar] [CrossRef]

- Bertazzi, P.A. Future prevention and handling of environmental accidents. Scand. J. Work. Environ. Health 1999, 1999, 580–588. [Google Scholar] [CrossRef] [PubMed][Green Version]

- ElGharbawi, T.; Zarzoura, F. Damage detection using SAR coherence statistical analysis, application to Beirut, Lebanon. ISPRS J. Photogramm. Remote Sens. 2021, 173, 1–9. [Google Scholar] [CrossRef]

- Smari, S.; Noumen, R. Port risk assessment in container terminals: The case of Tunisia. Int. J. Transp. Dev. Integr. 2020, 4, 42–50. [Google Scholar]

- Pallis, P.L. Port Risk Management in Container Terminals. Transp. Res. Procedia 2017, 25, 4411–4421. [Google Scholar] [CrossRef]

- Wiegel, M.; de Boer, W.; van Koningsveld, M.; van der Hout, A.; Reniers, A. Global mapping of seaport operability risk indicators using open-source metocean data. J. Mar. Sci. Eng. 2021, 9, 695. [Google Scholar] [CrossRef]

- John, A.; Paraskevadakis, D.; Bury, A.; Yang, Z.; Riahi, R.; Wang, J. An integrated fuzzy risk assessment for seaport operations. Saf. Sci. 2014, 68, 180–194. [Google Scholar] [CrossRef]

- Pileggi, S.F.; Indorf, M.; Nagi, A.; Kersten, W. CoRiMaS—An Ontological Approach to Cooperative Risk Management in Seaports. Sustainability 2020, 12, 4767. [Google Scholar] [CrossRef]

- Ding, J.F.; Tseng, W.J. Fuzzy risk assessment on safety operations for exclusive container terminals at Kaohsiung port in Taiwan. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2013, 227, 208–220. [Google Scholar] [CrossRef]

- Wan, C.; Yan, X.; Zhang, D.; Qu, Z.; Yang, Z. An advanced fuzzy Bayesian-based FMEA approach for assessing maritime supply chain risks. Transp. Res. Part E Logist. Transp. Rev. 2019, 125, 222–240. [Google Scholar] [CrossRef]

- Bellsolà Olba, X.; Daamen, W.; Vellinga, T.; Hoogendoorn, S.P. Risk Assessment Methodology for Vessel Traffic in Ports by Defining the Nautical Port Risk Index. J. Mar. Sci. Eng. 2020, 8, 10. [Google Scholar] [CrossRef]

- Loh, H.S.; Thai, V.V. Managing port-related supply chain disruptions (PSCDs): A management model and empirical evidence. Marit. Policy Manag. 2016, 43, 436–455. [Google Scholar] [CrossRef]

- Loh, H.S.; Thai, V.V.; Wong, Y.D.; Yuen, K.F.; Zhou, Q. Portfolio of port-centric supply chain disruption threats. Int. J. Logist. Manag. 2017, 28, 1368–1386. [Google Scholar] [CrossRef]

- John, A.; Yang, Z.; Riahi, R.; Wang, J. A risk assessment approach to improve the resilience of a seaport system using Bayesian networks. Ocean. Eng. 2016, 111, 136–147. [Google Scholar] [CrossRef]

- Ocampo, L.A.; Villegas, Z.V.A.; Carvajal, J.A.T.; Apas, C.A.A. Identifying significant drivers for sustainable practices in achieving sustainable food supply chain using modified fuzzy decision-making trial and evaluation laboratory approach. Int. J. Adv. Oper. Manag. 2018, 10, 51–89. [Google Scholar]

- Ahmad, M.; Tang, X.-W.; Qiu, J.-N.; Ahmad, F. Interpretive Structural Modeling and MICMAC Analysis for Identifying and Benchmarking Significant Factors of Seismic Soil Liquefaction. Appl. Sci. 2019, 9, 233. [Google Scholar] [CrossRef]

- Romano, A.L.; Ferreira, L.M.D.F.; Caeiro, S.S.F.S. Modelling Sustainability Risk in the Brazilian Cosmetics Industry. Sustainability 2021, 13, 13771. [Google Scholar] [CrossRef]

- Hassan, A.; Cui-Xia, L.; Ahmad, N.; Iqbal, M.; Hussain, K.; Ishtiaq, M.; Abrar, M. Safety Failure Factors Affecting Dairy Supply Chain: Insights from a Developing Economy. Sustainability 2021, 13, 9500. [Google Scholar] [CrossRef]

- Ullah, S.; Ahmad, N.; Khan, F.U.; Badulescu, A.; Badulescu, D. Mapping Interactions among Green Innovations Barriers in Manufacturing Industry Using Hybrid Methodology: Insights from a Developing Country. Int. J. Environ. Res. Public Health 2021, 18, 7885. [Google Scholar] [CrossRef]

- Sonar, H.; Khanzode, V.; Akarte, M. Investigating additive manufacturing implementation factors using integrated ISM-MICMAC approach. Rapid Prototyp. J. 2020, 26, 1837–1851. [Google Scholar] [CrossRef]

- Godet, M. Manuel de la Prospective Strategiques: Tome 2, l’art de la Method; Dunod: Paris, France, 2007. [Google Scholar]

| Category | Num. | Code | Risk Variables |

|---|---|---|---|

| Internal organization | 1 | (CI1) | Poor workplace design. |

| 2 | (CI2) | Lack of signage for the circulation of various flows (pedestrians, carts, materials, etc.). | |

| 3 | (CI3) | Absence of plan, instruction, traffic display | |

| 4 | (CI4) | Defective and uneven floor. | |

| Chemical hazards | 5 | (C1) | Improper handling of chemicals. |

| 6 | (C2) | Absence of a Safety Data Sheet (SDS) for the goods. | |

| 7 | (C3) | Not wearing the EPI (gloves, mask, …) by the workers exposed to the risk | |

| Failing objects | 8 | (Cho1) | Instability and poor stowage of goods. |

| 8 | (Cho2) | Ignorance of good handling practices (slinging of the goods) during the operation of loading and unloading. | |

| 10 | (Cho3) | Inadequate lifting accessories. (Chains, slings, ropes, shackles, hooks, lifting straps) and non-compliance with the regulatory aspects of Tunisian decree 62-129 (periodic inspection required). | |

| Electrical hazards | 11 | (EL1) | Lack of training for electricians. |

| 12 | (EL2) | Lack of work equipment and personal protective equipment (PPE). | |

| 13 | (EL3) | Faulty electrical installation. | |

| 14 | (EL4) | Neglect of regulatory aspects (periodic inspection). | |

| Machine risks | 15 | (M1) | Neglect of the regulatory aspects of handling equipment (periodic inspection). |

| 16 | (M2) | Lack of lighting (Visual management). | |

| 17 | (M3) | Lack of supervision. | |

| 18 | (M4) | Falling from heights (of drivers: forklift operators, crane operators, …), lack of instruction (climbing down ladder). | |

| Fire, explosions and paric | 19 | (Inc1) | Unsafe storage of goods (no-respect of thermal flows, domino rule, bow tie,...). |

| 20 | (Inc2) | Absence of a prevention system and a rescue organization (prevention certificate, first intervention team, emergency exit, assembly point, …). | |

| 21 | (Inc3) | Neglect of the regulatory aspects (the requirements of the safety code and prevention of fire, explosion and panic risks). | |

| Physical hazards | 22 | (Ph1) | Poor layout of workstations. |

| 23 | (Ph2) | Lack of training | |

| 24 | (Ph3) | Manual handling. | |

| 25 | (Ph4) | Disregard for safety aspects (lack of procedures, instructions, supervision, roles and responsibilities, job description). | |

| 26 | (Ph5) | Poor posture and physical condition. |

| Rank | Label | Direct Influence | Label | Direct Dependency | Label | Indirect Influence | Label | Indirect Dependency |

|---|---|---|---|---|---|---|---|---|

| 1 | EL4 | 553 | C1 | 486 | EL4 | 541 | Inc1 | 484 |

| 2 | M3 | 553 | Inc1 | 486 | M3 | 541 | C1 | 477 |

| 3 | Ph2 | 553 | Cho1 | 471 | Ph2 | 541 | Cho1 | 467 |

| 4 | Ph4 | 553 | M4 | 442 | Ph4 | 541 | M4 | 436 |

| 5 | Ph1 | 530 | M1 | 435 | Ph1 | 523 | M1 | 433 |

| 6 | Inc3 | 523 | CI1 | 427 | Inc3 | 518 | CI1 | 429 |

| 7 | M1 | 501 | Ph3 | 427 | Inc1 | 496 | Cho3 | 426 |

| 8 | Inc1 | 494 | Cho2 | 420 | M1 | 488 | Ph3 | 424 |

| 9 | M2 | 464 | Cho3 | 420 | M2 | 476 | Cho2 | 419 |

| 10 | Cho2 | 427 | Inc3 | 420 | Cho2 | 430 | Inc3 | 416 |

| 11 | EL3 | 412 | Ph4 | 405 | EL2 | 414 | Ph4 | 401 |

| 12 | EL2 | 398 | EL4 | 383 | EL3 | 413 | Ph5 | 390 |

| 13 | Ph3 | 383 | Ph5 | 383 | Ph3 | 395 | EL4 | 380 |

| 14 | Cho3 | 376 | Inc2 | 376 | Cho3 | 388 | Inc2 | 375 |

| 15 | Inc2 | 368 | CI2 | 368 | Inc2 | 368 | CI2 | 374 |

| 16 | CI2 | 331 | CI3 | 368 | EL1 | 337 | CI3 | 374 |

| 17 | CI3 | 317 | EL2 | 368 | CI2 | 319 | EL2 | 373 |

| 18 | CI1 | 302 | Ph1 | 346 | CI3 | 315 | Ph1 | 351 |

| 19 | Cho1 | 302 | Ph2 | 346 | CI1 | 306 | C2 | 349 |

| 20 | EL1 | 294 | C2 | 339 | M4 | 293 | Ph2 | 344 |

| 21 | C1 | 287 | M2 | 324 | Ph5 | 285 | M2 | 318 |

| 22 | M4 | 287 | C3 | 317 | C1 | 283 | M3 | 318 |

| 23 | Ph5 | 272 | M3 | 317 | Cho1 | 275 | C3 | 317 |

| 24 | C2 | 206 | CI4 | 309 | C2 | 219 | CI4 | 311 |

| 25 | C3 | 206 | EL3 | 309 | C3 | 205 | EL3 | 303 |

| 26 | CI4 | 95 | EL1 | 294 | CI4 | 76 | EL1 | 297 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dhahri, M.; Elmsalmi, M.; Aljuaid, A.M.; Hachicha, W. Seaport Terminals Risks Prioritization Using a Structural Modeling-Based Approach: A Real Case Study. J. Mar. Sci. Eng. 2022, 10, 217. https://doi.org/10.3390/jmse10020217

Dhahri M, Elmsalmi M, Aljuaid AM, Hachicha W. Seaport Terminals Risks Prioritization Using a Structural Modeling-Based Approach: A Real Case Study. Journal of Marine Science and Engineering. 2022; 10(2):217. https://doi.org/10.3390/jmse10020217

Chicago/Turabian StyleDhahri, Maryam, Manel Elmsalmi, Awad M. Aljuaid, and Wafik Hachicha. 2022. "Seaport Terminals Risks Prioritization Using a Structural Modeling-Based Approach: A Real Case Study" Journal of Marine Science and Engineering 10, no. 2: 217. https://doi.org/10.3390/jmse10020217

APA StyleDhahri, M., Elmsalmi, M., Aljuaid, A. M., & Hachicha, W. (2022). Seaport Terminals Risks Prioritization Using a Structural Modeling-Based Approach: A Real Case Study. Journal of Marine Science and Engineering, 10(2), 217. https://doi.org/10.3390/jmse10020217