A Method for Measuring Hydrodynamic Force Coefficients Applied to an Articulated Concrete Mattress

Abstract

:1. Introduction

2. Load Balance Analysis for an ACM in Steady Current

3. Proposed Testing Method

4. Model Setup

5. Results

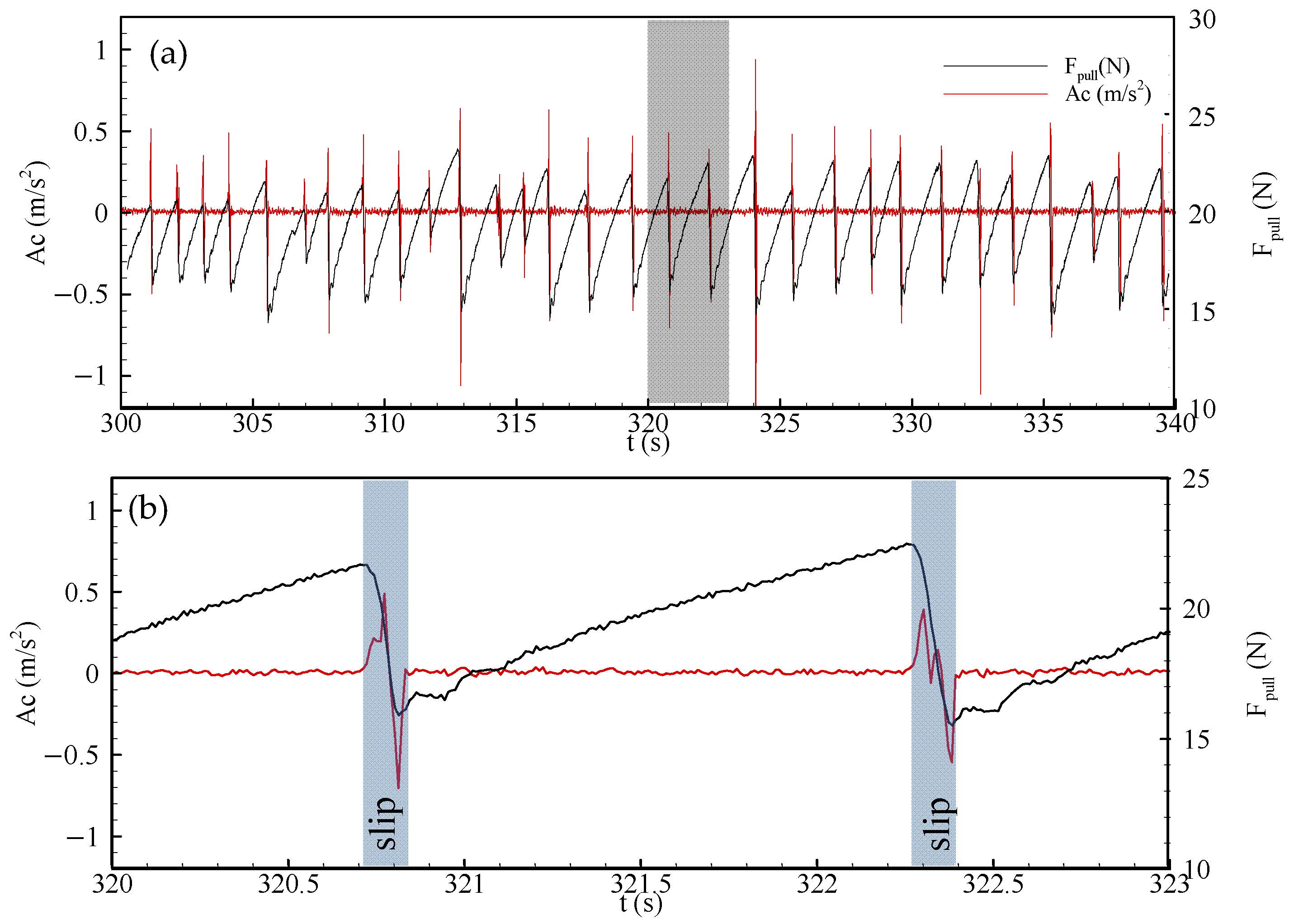

5.1. ACM Sliding Behaviour

5.2. Sliding Failure Mode

5.3. Edge Lifting Tests

5.4. Reynolds Number Effect

6. Conclusions and Recommendations for Further Work

6.1. Conclusions

6.2. Recommendations for Future Work

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Scope, C.; Vogel, M.; Guenther, E. Greener, cheaper, or more sustainable: Reviewing sustainability assessments of maintenance strategies of concrete structures. Sustain. Prod. Consum. 2021, 26, 838–858. [Google Scholar] [CrossRef]

- Hrabova, K.; Lehner, P.; Ghosh, P.; Konecny, P.; Teply, B. Sustainability Levels in Comparison with Me-chanical Properties and Durability of Pumice High-Performance Concrete. Appl. Sci. 2021, 11, 4964. [Google Scholar] [CrossRef]

- Zhang, Z.; Gong, R.; Zhang, H.; He, W. The Sustainability Performance of Reinforced Concrete Structures in Tunnel Lining Induced by Long-Term Coastal Environment. Sustainability 2020, 12, 3946. [Google Scholar] [CrossRef]

- Dardeau, E.A., Jr.; Ellis, S.W.; Collins, J.G. The articulated concrete mattress: History and use. Erosion and its control. In Proceedings of the Federal Interagency Sedimentation Conferences, Las Vegas, NV, USA, 18–21 March 1991. [Google Scholar]

- Gaeta, M.G.; Lamberti, A.; Galante, F.; Mongiorgi, M. Articulated concrete block mattresses (ACBM) for submarine pipeline protection and stabilization: A physical model study in a wave flume. In Proceedings of the Marine Waste Water Discharges and Coastal Environment + International Exhibition on Materials, Equipment and Services for Coastal Environmental Projects, Dubrovnik, Croatia, 27–31 October 2012. [Google Scholar]

- Yamini, O.A.; Kavianpour, M.R.; Mousavi, S.H. Wave run-up and rundown on ACB Mats under granular and geotextile filters’ condition. Mar. Georesources Geotechnol. 2018, 36, 895–906. [Google Scholar] [CrossRef]

- Yamini, O.A.; Mousavi, S.H.; Kavianpour, M. Experimental investigation of using geo-textile filter layer in articulated concrete block mattress revetment on coastal embankment. J. Ocean. Eng. Mar. Energy 2019, 5, 119–133. [Google Scholar] [CrossRef]

- Mclaren, R.W.G. Investigation of Hydrodynamic Forces on Articulated Concrete Block Mattresses in Fluid Flow from Various Horizontal Directions. Master’s Thesis, University of Tasmania, Churchill Ave, TAS, Australia, March 2019. [Google Scholar]

- NCMA (National Concrete Masonry Association). Design Manual for Articulating Concrete Block (ACB) Revetment Sys-Tems; Publication No. TR220A; NCMA (National Concrete Masonry Association): Herndon, VA, USA, 2010. [Google Scholar]

- Lagasse, P.F.; Clopper, P.E.; Pagán-Ortiz, J.E.; Zevenbergen, L.W.; Arneson, L.A.; Schall, J.D.; Girard, L.G. Bridge Scour and Stream Instability Countermeasures: Experience, Selection, and Design Guidance: Volume 2 (No. FHWA-NHI-09-112), 3rd ed.; National Highway Institute (US): Arlington, VA, USA, 2009.

- Melville, B.; Van Ballegooy, R.; Van Ballegooy, S. Flow-induced failure of cable-tied blocks. J. Hydraul. Eng. 2006, 132, 324–327. [Google Scholar] [CrossRef]

- Griggs, R. 3D CFD Investigation of Hydrodynamic Forces on Subsea Articulated Concrete Mattresses. Bachelor’s Thesis, Edith Cowan University, Joondalup, Australia, 2014. [Google Scholar]

- Yamamoto, K.; Hayasi, K.; Senkine, M.; Fujita, K.; Tamura, M.; Nisimura, S.; Hamaguchi, K. Measuring method of drag coefficient, lift coefficient and equivalent roughness of re-vetment block. J. Jpn. Soc. Civ. Eng. (Hydraul. Eng.) 2000, 44, 1053–1058. [Google Scholar]

- Hayashi, K. Fluid forces and stability for block with seaweed. J. Jpn. Soc. Civ. Eng. Ser. B3 (Ocean. Eng.) 2018, 74, 360. [Google Scholar] [CrossRef] [Green Version]

- Godbold, J.; Sackmann, N.; Cheng, L. Stability design for concrete mattresses. In Proceedings of the Twenty-fourth International Ocean and Polar Engineering Conference, Busan, Korea, 15–20 June 2014. [Google Scholar]

- An, H.; Luo, C.; Cheng, L.; White, D. A new facility for studying ocean-structure–seabed interactions: The O-tube. Coast. Eng. 2013, 82, 88–101. [Google Scholar] [CrossRef]

- Yang, F.; An, H.; Cheng, L. Drag crisis of a circular cylinder near a plane boundary. Ocean. Eng. 2018, 154, 133–142. [Google Scholar] [CrossRef]

- Byerlee, J.D. The mechanics of stick-slip. Tectonophysics 1970, 9, 475–486. [Google Scholar] [CrossRef]

- Thompson, P.A.; Robbins, M.O. Origin of stick-slip motion in boundary lubrication. Science 1990, 250, 792–794. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Thompson, D.; Hu, Z. Effect of wall proximity on the flow over a cube and the implications for the noise emitted. Phys. Fluids 2019, 31, 077101. [Google Scholar]

- Bai, H.; Alam, M.M. Dependence of square cylinder wake on Reynolds number. Phys. Fluids 2018, 30, 015102. [Google Scholar] [CrossRef]

| Model Number | Mass (kg) | Volume (m3) | Aggregate Material | |

|---|---|---|---|---|

| 1 | 7.55 | 2.34 | 3.23 | lead shot |

| 2 | 6.30 | 2.33 | 2.70 | lead shot |

| 3 | 5.16 | 2.34 | 2.21 | No |

| 4 | 4.02 | 2.31 | 1.72 | plastic bead |

| Test | |||||

|---|---|---|---|---|---|

| T1 | 1.0 | 8.6 | 14.1 | 0.65 | 0.15 |

| T2 | 1.0 | 8.4 | 13.9 | 0.65 | 0.17 |

| T3 | 0.8 | 10.2 | 13.3 | 0.60 | 0.18 |

| Average | 0.633 | 0.167 | |||

| Test | Measured | Predicted | ||

|---|---|---|---|---|

| T4 | −1.20 | 15.6 | 14.3 | −8.3% |

| T5 | −1.38 | 15.8 | 15.5 | −1.9% |

| Test | Ucr (m/s) | Error | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Measured | Average | Predicted | |||||||

| T6 | 3.23 | 1.80 | 1.75 | 1.76 | 1.75 | 1.76 | 1.76 | 1.81 | 2.5% |

| T7 | 2.69 | 1.61 | 1.62 | 1.60 | 1.55 | 1.55 | 1.59 | 1.57 | −1.0% |

| T8 | 2.21 | 1.37 | 1.38 | 1.34 | 1.41 | 1.42 | 1.38 | 1.33 | −4.0% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

An, H.; Hu, X.; Draper, S.; Cheng, L.; Lubis, B.; Kimiaei, M. A Method for Measuring Hydrodynamic Force Coefficients Applied to an Articulated Concrete Mattress. J. Mar. Sci. Eng. 2022, 10, 144. https://doi.org/10.3390/jmse10020144

An H, Hu X, Draper S, Cheng L, Lubis B, Kimiaei M. A Method for Measuring Hydrodynamic Force Coefficients Applied to an Articulated Concrete Mattress. Journal of Marine Science and Engineering. 2022; 10(2):144. https://doi.org/10.3390/jmse10020144

Chicago/Turabian StyleAn, Hongwei, Xiaoyuan Hu, Scott Draper, Liang Cheng, Binsar Lubis, and Mehrdad Kimiaei. 2022. "A Method for Measuring Hydrodynamic Force Coefficients Applied to an Articulated Concrete Mattress" Journal of Marine Science and Engineering 10, no. 2: 144. https://doi.org/10.3390/jmse10020144

APA StyleAn, H., Hu, X., Draper, S., Cheng, L., Lubis, B., & Kimiaei, M. (2022). A Method for Measuring Hydrodynamic Force Coefficients Applied to an Articulated Concrete Mattress. Journal of Marine Science and Engineering, 10(2), 144. https://doi.org/10.3390/jmse10020144