Equivalent Aerodynamic Design of Blade for Offshore Floating Wind Turbine Model

Abstract

:1. Introduction

2. Scaling Laws and RNE

2.1. Scaling Laws

2.2. RNE

3. Airfoil Selection

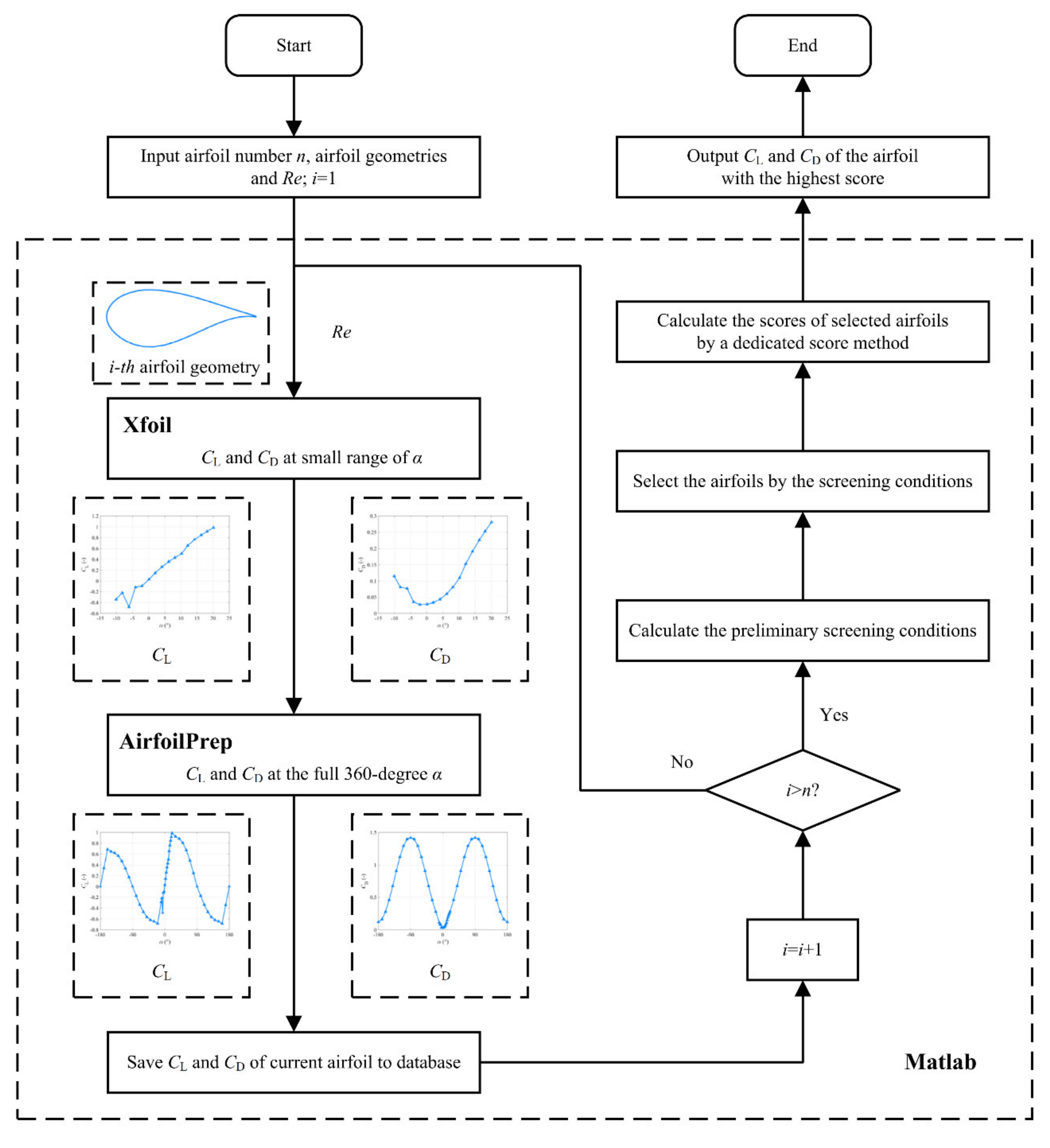

3.1. XAM System

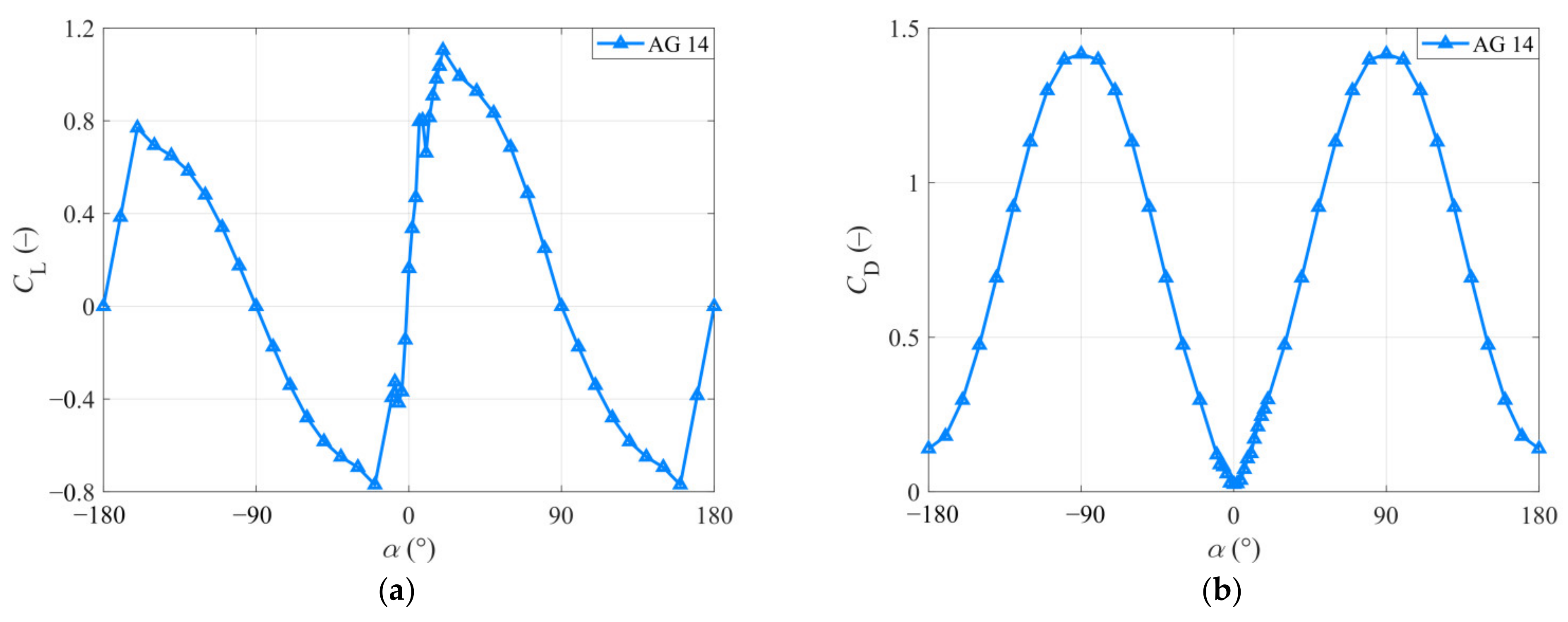

3.2. Result and Discussion of Airfoil Performance

4. Redesigning Blade Solution

4.1. WTSM

4.2. Some Modifications in GOA

4.3. Results and Discussion

4.4. Aerodynamic Analysis with Different Pitch Angle

5. Conclusions

- (1)

- A XAM system is constructed to guide the airfoil selection. Based on the XAM system, 767 airfoils are compared with each other according to the preliminary screening conditions and the dedicated score method. Finally, the AG 14 airfoil is selected out as the best airfoil.

- (2)

- A WTSM is proposed for a wide TSR thrust-match blade. Based on the WTSM, the blade chord and twist of the redesigned blade with AG 14 airfoil is optimized for a better thrust performance. The CT-TSR curve of the redesigned blade is compared with the RWT blade. Moreover, most of the relative errors are less than 5%, except for the working conditions that TSR = 3 (8%) and TSR = 5 (6%). It proves the thrust performance of the redesigned blade matches that of the RWT blade well at a 0 pitch angle.

- (3)

- The thrust coefficients of the proposed redesigned blade in other pitch angles are calculated and compared to those of the RWT blade. Results show that the variations are consistent with the RWT blade. It means that the redesigned blade has great potential in the studies related to control strategy.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Global Wind Energy Council. GWEC Global Wind Report; Global Wind Energy Council (GWEC): Brussels, Belgium, 2021. [Google Scholar]

- Ju, S.; Huang, Y.; Huang, Y. Study of optimal large-scale offshore wind turbines. Renew. Energy 2020, 154, 161–174. [Google Scholar] [CrossRef]

- Finnegan, W.; Jiang, Y.; Dumergue, N.; Davies, P.; Goggins, J. Investigation and Validation of Numerical Models for Composite Wind Turbine Blades. J. Mar. Sci. Eng. 2021, 9, 525. [Google Scholar] [CrossRef]

- Medina, C.; Álamo, G.M.; Quevedo-Reina, R. Evolution of the Seismic Response of Monopile-Supported Offshore Wind Turbines of Increasing Size from 5 to 15 MW including Dynamic Soil-Structure Interaction. J. Mar. Sci. Eng. 2021, 9, 1285. [Google Scholar] [CrossRef]

- Chatterjee, J.; Dethlefs, N. Deep learning with knowledge transfer for explainable anomaly prediction in wind turbines. Wind Energy 2020, 23, 1693–1710. [Google Scholar] [CrossRef]

- Ghigo, A.; Cottura, L.; Caradonna, R.; Bracco, G.; Mattiazzo, G. Platform optimization and cost analysis in a floating offshore wind farm. J. Mar. Sci. Eng. 2020, 8, 835. [Google Scholar] [CrossRef]

- Dao, C.; Kazemtabrizi, B.; Crabtree, C. Wind turbine reliability data review and impacts on levelised cost of energy. Wind Energy 2019, 22, 1848–1871. [Google Scholar] [CrossRef] [Green Version]

- Crabtree, C.J.; Zappalá, D.; Hogg, S.I. Wind energy: UK experiences and offshore operational challenges. Proc. Inst. Mech. Eng. Part A J. Power Energy 2015, 229, 727–746. [Google Scholar] [CrossRef] [Green Version]

- Lalonde, E.; Vischschraper, B.; Bitsuamlak, G.; Dai, K. Evaluation of a neural network-based surrogate aerodynamic wind turbine model. In Proceedings of the International Conference on Advances in Wind and Structures, Seoul, Korea, 8 July 2020. [Google Scholar]

- Martin, H.R. Development of a Scale Model Wind Turbine for Testing of Offshore Floating Wind Turbine Systems; University of Maine: Orono, ME, USA, 2011; pp. 1–181. [Google Scholar]

- Lee, H.; Lee, D.J. Low Reynolds number effects on aerodynamic loads of a small scale wind turbine. Renew. Energy 2020, 154, 1283–1293. [Google Scholar] [CrossRef]

- Gueydon, S.; Judge, F.M.; O’shea, M.; Lyden, E.; Le Boulluec, M.; Caverne, J.; Ohana, J.; Kim, S.; Bouscasse, B.; Thiebaut, F.; et al. Round robin laboratory testing of a scaled 10 mw floating horizontal axis wind turbine. J. Mar. Sci. Eng. 2021, 9, 988. [Google Scholar] [CrossRef]

- Meng, L.; He, Y.; Zhao, Y.; Peng, T.; Yang, J. Experimental Study on Aerodynamic Characteristics of the Model Wind Rotor System and on Characterization of a Wind Generation System. China Ocean Eng. 2019, 33, 137–147. [Google Scholar] [CrossRef]

- Fowler, M.J.; Kimball, R.W.; Thomas, D.A.; Goupee, A.J. Design and testing of scale model wind turbines for use in wind/wave basin model tests of floating offshore wind turbines. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Nantes, France, 9–14 June 2013; Volume 8, pp. 1–11. [Google Scholar]

- Duan, F.; Hu, Z.; Niedzwecki, J.M. Model test investigatiaon of a spar floating wind turbine. Mar. Struct. 2016, 49, 76–96. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.; Hu, Z.; Wan, D.; Xiao, Q. Comparisons of the dynamical characteristics of a semi-submersible floating offshore wind turbine based on two different blade concepts. Ocean Eng. 2018, 153, 305–318. [Google Scholar] [CrossRef] [Green Version]

- Duan, F.; Hu, Z.; Liu, G.; Wang, J. Experimental comparisons of dynamic properties of floating wind turbine systems based on two different rotor concepts. Appl. Ocean Res. 2016, 58, 266–280. [Google Scholar] [CrossRef] [Green Version]

- Tahir, A.; Elgabaili, M.; Rajab, Z.; Buaossa, N.; Khalil, A.; Mohamed, F. Optimization of small wind turbine blades using improved blade element momentum theory. Wind Eng. 2019, 43, 299–310. [Google Scholar] [CrossRef]

- Timmer, W.A.; van Rooij, R.P.J.O.M. Summary of the Delft University Wind Turbine Dedicated Airfoils. J. Sol. Energy Eng. 2003, 125, 488–496. [Google Scholar] [CrossRef]

- Zhang, S.; Li, H.; Abbasi, A.A. Design methodology using characteristic parameters control for low Reynolds number airfoils. Aerosp. Sci. Technol. 2019, 86, 143–152. [Google Scholar] [CrossRef]

- Martin, H.R.; Kimball, R.W.; Viselli, A.M.; Goupee, A.J. Methodology for wind/wave basin testing of floating offshore wind turbines. J. Offshore Mech. Arct. Eng. 2014, 136, 020905. [Google Scholar] [CrossRef]

- Bayati, I.; Belloli, M.; Bernini, L.; Zasso, A. Aerodynamic design methodology for wind tunnel tests of wind turbine rotors. J. Wind Eng. Ind. Aerodyn. 2017, 167, 217–227. [Google Scholar] [CrossRef] [Green Version]

- Chen, Z.; He, Y.; Zhao, Y.; Meng, L.; He, C.; Yang, H.; Han, Z.; Liu, Y. High-order redesign method for wind turbine blade optimization in model test considering aerodynamic similarity. Ocean Eng. 2020, 202, 107156. [Google Scholar] [CrossRef]

- Wen, B.; Tian, X.; Dong, X.; Li, Z.; Peng, Z. Design approaches of performance-scaled rotor for wave basin model tests of floating wind turbines. Renew. Energy 2020, 148, 573–584. [Google Scholar] [CrossRef]

- Du, W.; Zhao, Y.; He, Y.; Liu, Y. Design, analysis and test of a model turbine blade for a wave basin test of floating wind turbines. Renew. Energy 2016, 97, 414–421. [Google Scholar] [CrossRef]

- Wang, Y.; Lin, J.; Duan, H.; Zhang, J. Investigation on Thrust Characteristics of a Downstream Offshore Floating Wind Turbine under Yawed Inflow Conditions. J. Mar. Sci. Eng. 2021, 9, 1215. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, J.; Zhang, J. Effects of Wind Rotor Tilt Angle on Aerodynamic Power of Wind Turbine under Typical Periodic Disturbances. Mech. Mach. Sci. 2019, 73, 3459–3468. [Google Scholar]

- Wang, Y.; Lin, J.; Zhang, J. Investigation of a new analytical wake prediction method for offshore floating wind turbines considering an accurate incoming wind flow. Renew. Energy 2022, 185, 827–849. [Google Scholar] [CrossRef]

- Li, S.; Han, Y.; Pan, W.; Liu, S.; Hou, M. Variable-Gain Higher-Order Sliding Mode Pitch Control of Floating Offshore Wind Turbine. J. Mar. Sci. Eng. 2021, 9, 1172. [Google Scholar] [CrossRef]

- Ruzzo, C.; Muggiasca, S.; Malara, G.; Taruffi, F.; Belloli, M.; Collu, M.; Li, L.; Brizzi, G.; Arena, F. Scaling strategies for multi-purpose floating structures physical modeling: State of art and new perspectives. Appl. Ocean Res. 2021, 108, 102487. [Google Scholar] [CrossRef]

- Jonkman, J.; Butterfield, S.; Musial, W.; Scott, G. Definition of a 5-MW Reference Wind Turbine for Offshore System Development; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2009. [Google Scholar]

- Macháček, M.; Pospíšil, S.; Kozmar, H. Scaling of wind turbine aerodynamics: Wind tunnel experiments. MATEC Web Conf. 2020, 313, 00053. [Google Scholar] [CrossRef]

- Gajardo, D.; Escauriaza, C.; Ingram, D.M. Capturing the development and interactions of wakes in tidal turbine arrays using a coupled BEM-DES model. Ocean Eng. 2019, 181, 71–88. [Google Scholar] [CrossRef] [Green Version]

- Drela, M. XFOIL: An Analysis and Design System for Low Reynolds Number Airfoils. In Proceedings of the Conference on Low Reynolds Number Airfoil Aerodynamics, Notre Darre, IN, USA, 5–7 June 1989; pp. 1–12. [Google Scholar]

- Hansen, C. AirfoilPrep: An Excel Workbook for Generating Airfoil Tables for AeroDyn and WT_Perf. Available online: https://www.nrel.gov/wind/nwtc/airfoil-prep.html (accessed on 3 December 2021).

- Zhang, J.; Zhang, J.; Zhong, M.; Zheng, J.; Yao, L. A GOA-MSVM based strategy to achieve high fault identification accuracy for rotating machinery under different load conditions. Meas. J. Int. Meas. Confed. 2020, 163, 108067. [Google Scholar] [CrossRef]

- Chen, F.; Tang, B.; Song, T.; Li, L. Multi-fault diagnosis study on roller bearing based on multi-kernel support vector machine with chaotic particle swarm optimization. Meas. J. Int. Meas. Confed. 2014, 47, 576–590. [Google Scholar] [CrossRef]

| Airfoil | Peak CL | Valley CD | Peak CL/CD | Score |

|---|---|---|---|---|

| AG 04 | 1.0498 | 0.0250 | 10.3591 | 0.3347 |

| AG 08 | 1.0606 | 0.0248 | 11.1918 | 0.4629 |

| AG 09 | 1.0675 | 0.0244 | 11.8643 | 0.5784 |

| AG 10 | 1.0717 | 0.0244 | 11.9592 | 0.5983 |

| AG 11 | 1.0588 | 0.0256 | 10.4947 | 0.3291 |

| AG 12 | 1.0808 | 0.0246 | 11.2672 | 0.5307 |

| AG 13 | 1.0922 | 0.0245 | 11.8873 | 0.6305 |

| AG 14 | 1.1047 | 0.0245 | 12.5317 | 0.7286 |

| AG 16 | 1.0731 | 0.0252 | 10.4601 | 0.3852 |

| AG 17 | 1.0862 | 0.0249 | 11.2889 | 0.5250 |

| AG 18 | 1.0992 | 0.0247 | 12.1169 | 0.6576 |

| AG 26 | 1.1010 | 0.0256 | 10.9973 | 0.4796 |

| AG 27 | 1.1182 | 0.0260 | 11.9633 | 0.5960 |

| BE6453B | 1.1774 | 0.0292 | 12.1544 | 0.5340 |

| GOE492 | 1.0931 | 0.0293 | 12.5829 | 0.3811 |

| GRANTX16 | 1.0468 | 0.0255 | 11.0466 | 0.3681 |

| HN-1070 | 1.0482 | 0.0253 | 11.0657 | 0.3870 |

| HN-998 | 1.1063 | 0.0282 | 10.7751 | 0.2909 |

| HN-999 | 1.1124 | 0.0286 | 10.6772 | 0.2670 |

| MA409(original) | 1.1514 | 0.0279 | 11.6869 | 0.5126 |

| MA409(smoothed) | 1.1154 | 0.0288 | 11.8652 | 0.3885 |

| Ritz2-30-5 | 1.0567 | 0.0248 | 12.0982 | 0.5518 |

| Ritz2-30-6 | 1.0313 | 0.0252 | 10.4219 | 0.2857 |

| Ritz3-30-5 | 1.0947 | 0.0257 | 11.5023 | 0.5130 |

| SIMPLEX5 | 1.0529 | 0.0258 | 12.2410 | 0.4906 |

| SIMPLEX6 | 1.0497 | 0.0278 | 10.4016 | 0.1486 |

| STCYR-53 | 1.0315 | 0.0283 | 13.4464 | 0.4018 |

| USA46 | 1.0677 | 0.0259 | 10.4566 | 0.3249 |

| lb | −1.5 | 0 | −2.5 | −0.1 | 0 | 6 | −30 |

| ub | 1 | 3 | −0.5 | 1 | 0.5 | 15 | −16 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, J.; Duan, H.; Xu, B.; Wang, Y.; Zhang, J. Equivalent Aerodynamic Design of Blade for Offshore Floating Wind Turbine Model. J. Mar. Sci. Eng. 2022, 10, 132. https://doi.org/10.3390/jmse10020132

Lin J, Duan H, Xu B, Wang Y, Zhang J. Equivalent Aerodynamic Design of Blade for Offshore Floating Wind Turbine Model. Journal of Marine Science and Engineering. 2022; 10(2):132. https://doi.org/10.3390/jmse10020132

Chicago/Turabian StyleLin, Jiahuan, Huawei Duan, Baoming Xu, Yangwei Wang, and Jun Zhang. 2022. "Equivalent Aerodynamic Design of Blade for Offshore Floating Wind Turbine Model" Journal of Marine Science and Engineering 10, no. 2: 132. https://doi.org/10.3390/jmse10020132

APA StyleLin, J., Duan, H., Xu, B., Wang, Y., & Zhang, J. (2022). Equivalent Aerodynamic Design of Blade for Offshore Floating Wind Turbine Model. Journal of Marine Science and Engineering, 10(2), 132. https://doi.org/10.3390/jmse10020132