Modeling and Optimization of Fuel-Mode Switching and Control Systems for Marine Dual-Fuel Engine

Abstract

1. Introduction

1.1. The Research Background

1.2. Technical Parameters and Characteristics of Dual-Fuel Engines

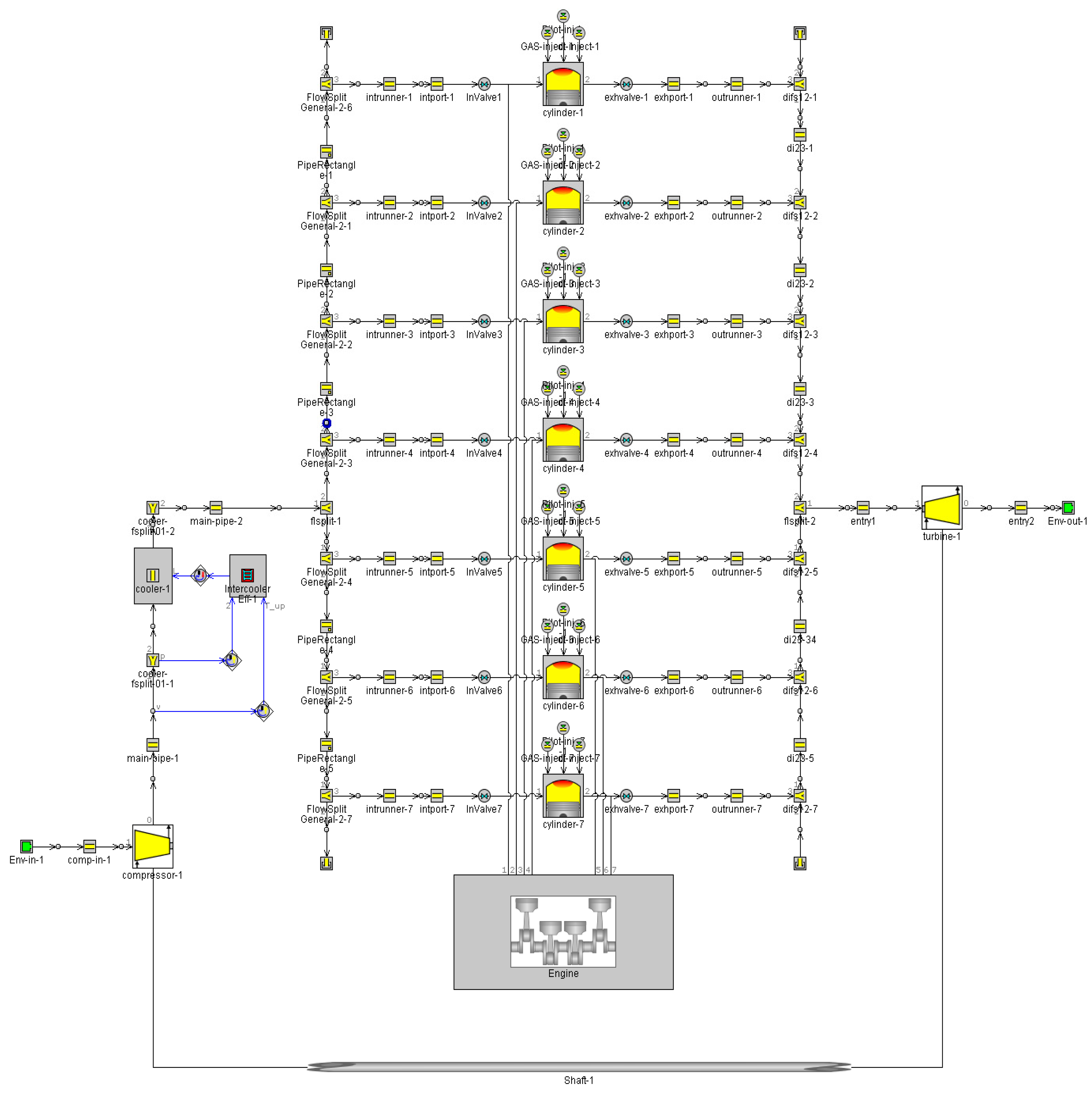

2. Dual-Fuel Engine Model

2.1. Simulation Theory and Mathematical Models

2.2. Basic Equations for In-Cylinder Processes

2.3. Mathematical Model of Intake and Exhaust Processes

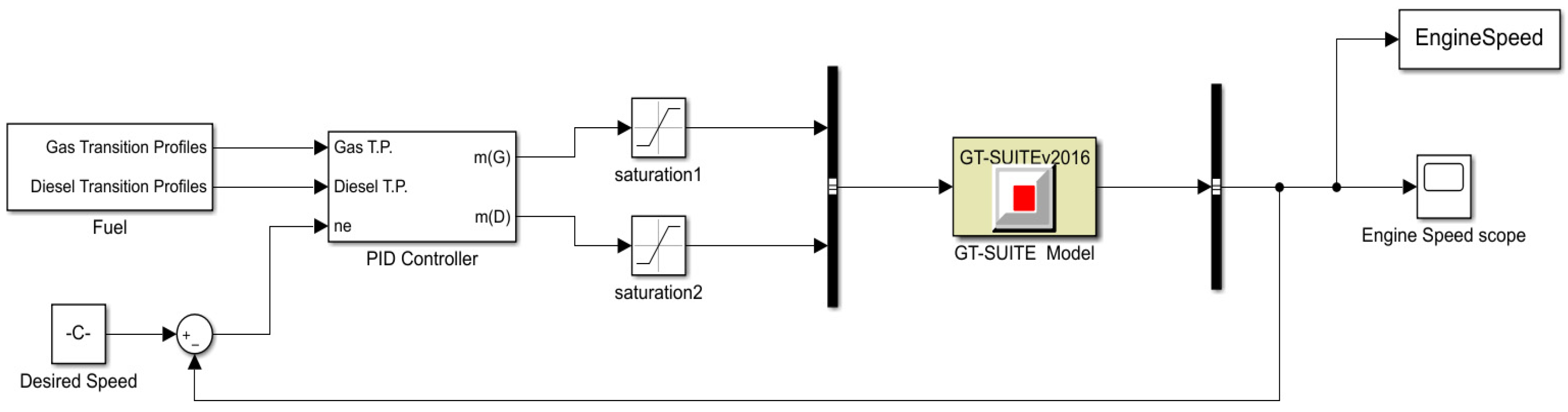

2.4. Engine Speed Control Principle

2.5. Joint Simulation Modeling

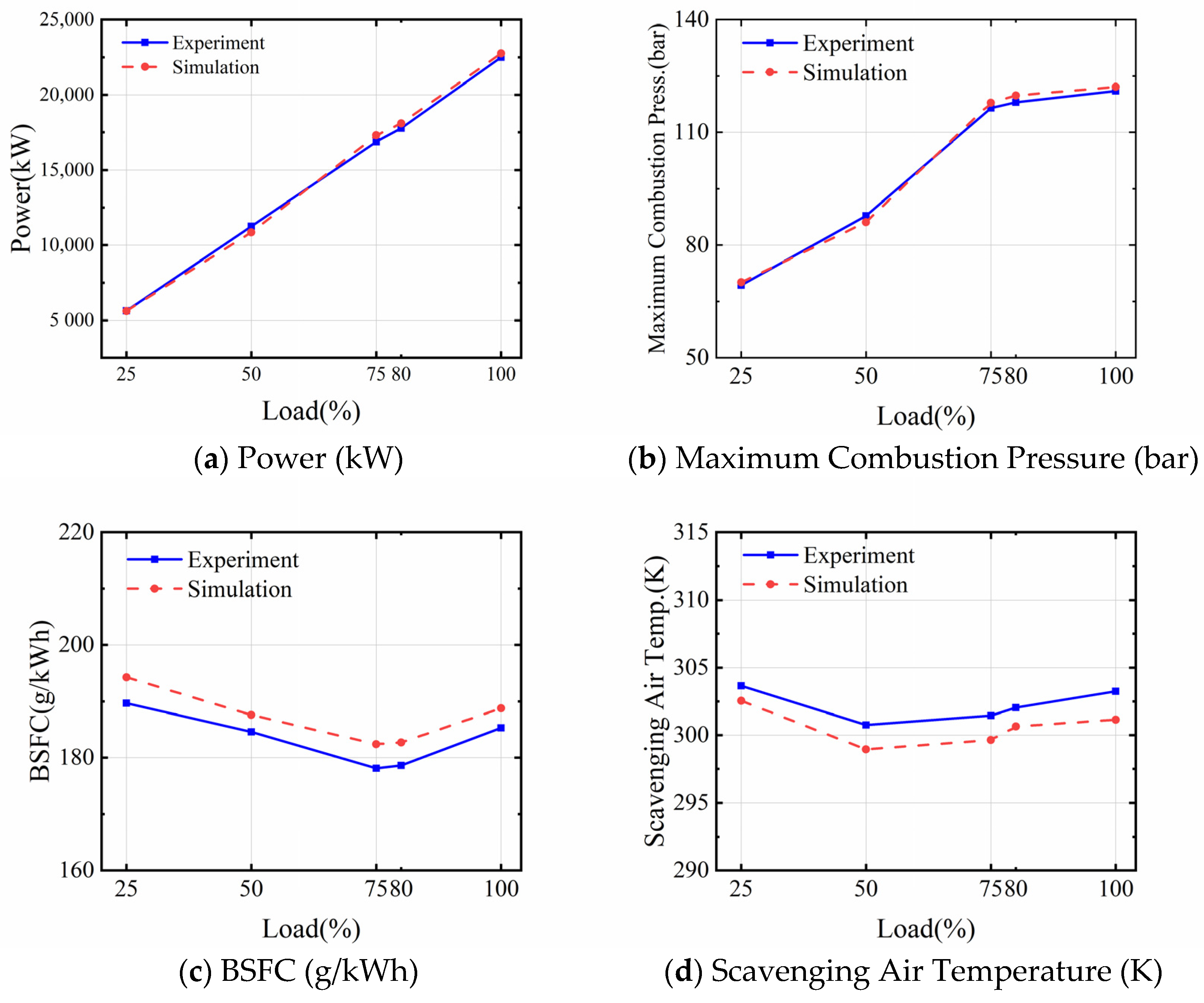

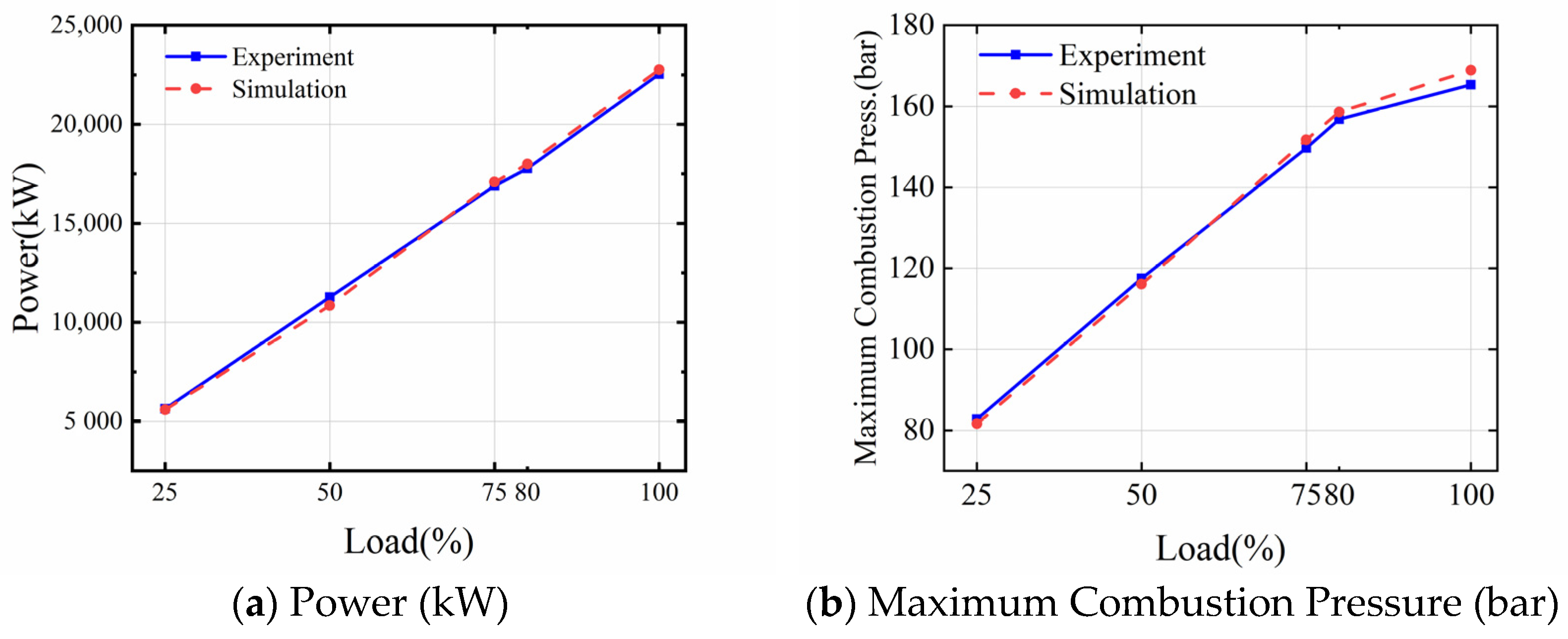

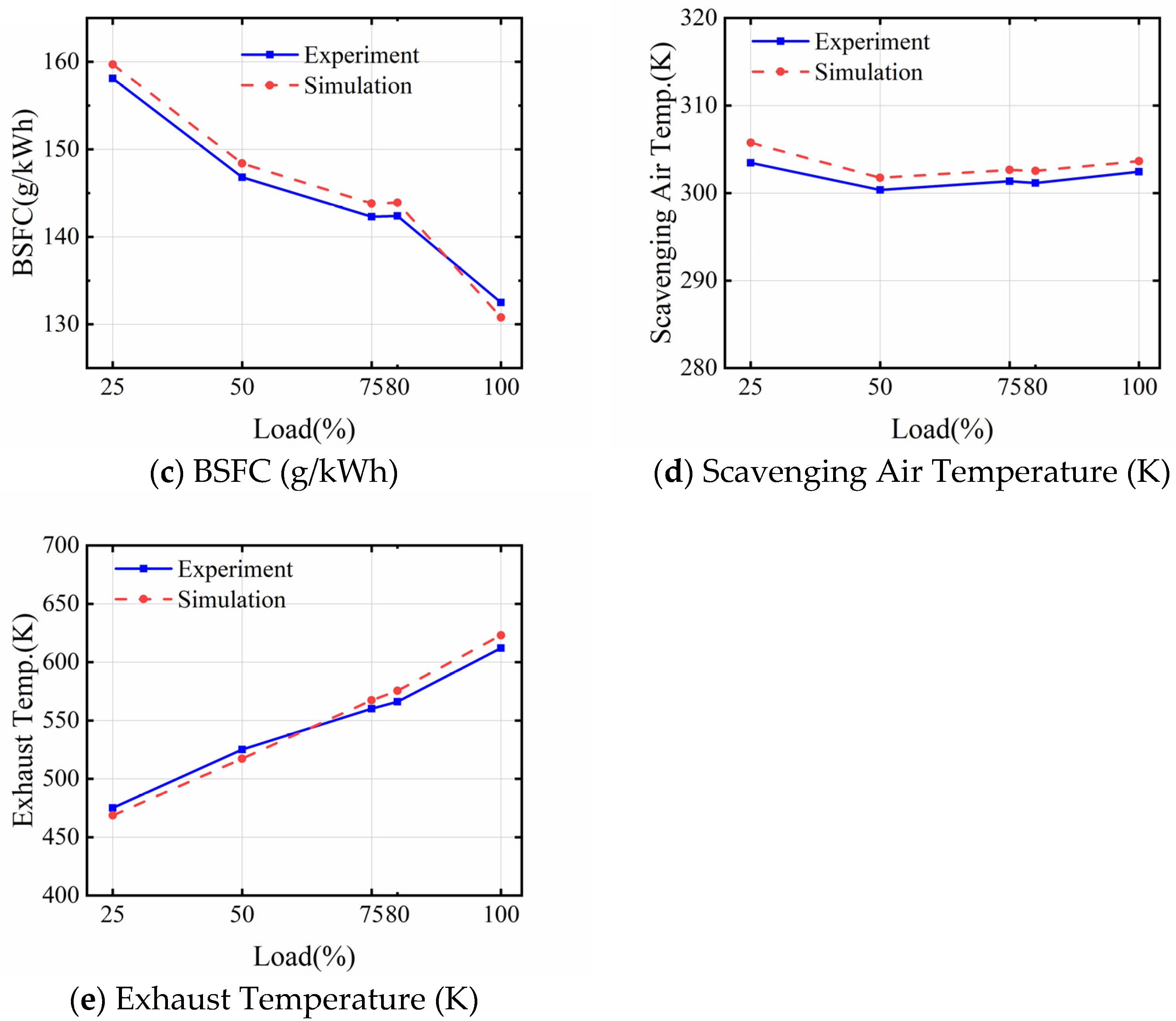

2.6. Simulation Model Calibration

3. Simulation of a Dual-Fuel Engine Fuel-Mode Switching Process

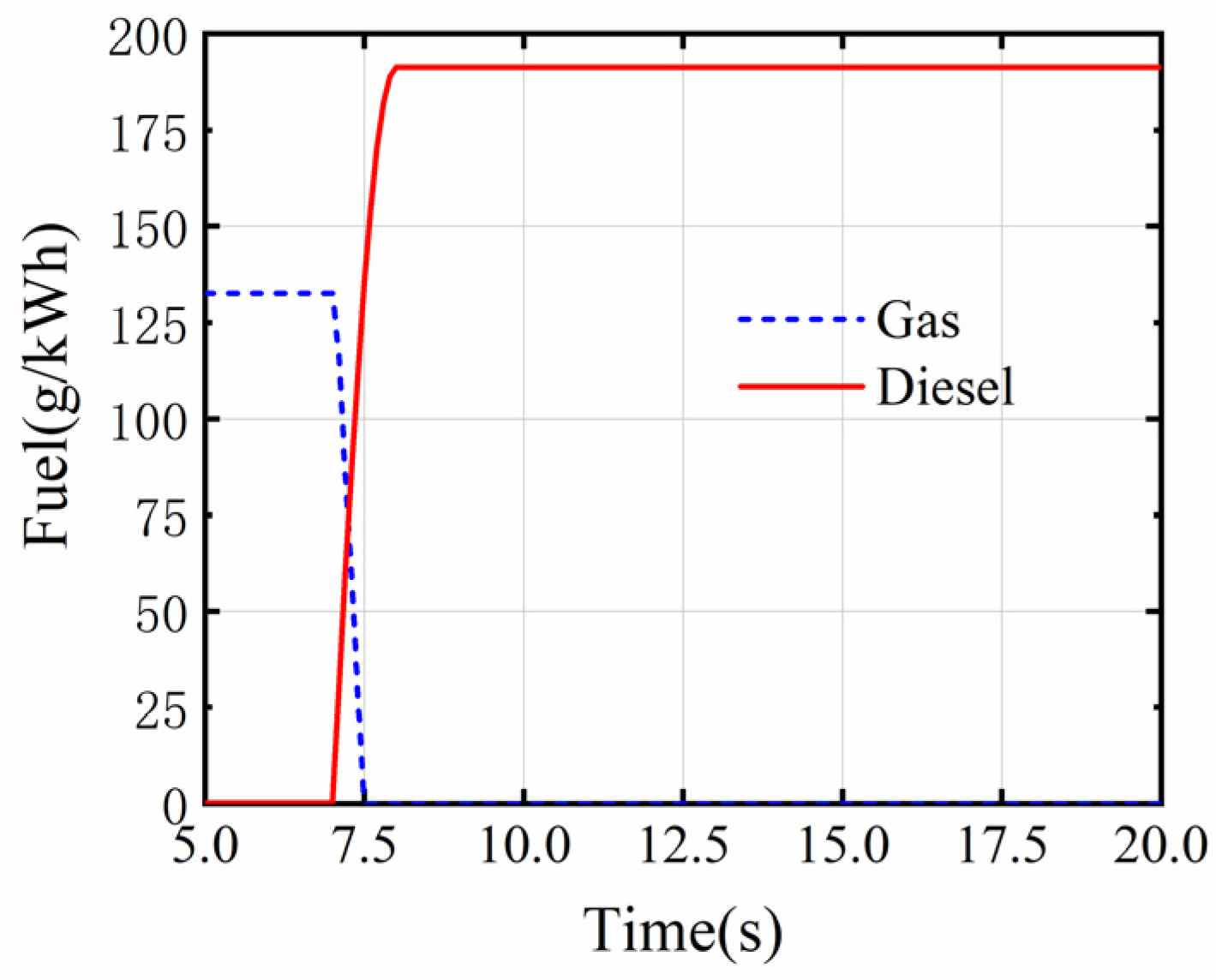

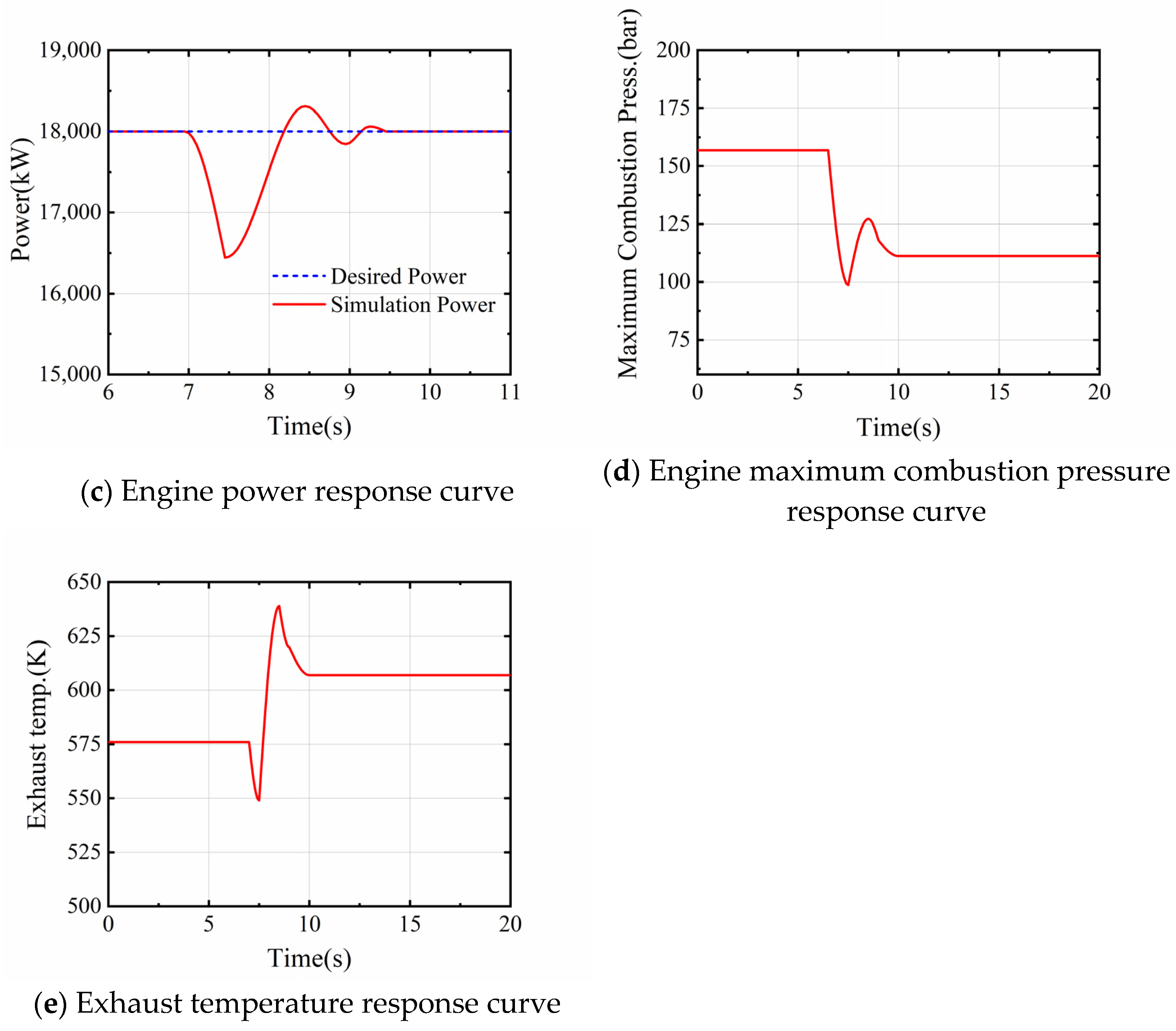

3.1. Switching from Gas Mode to Diesel Mode

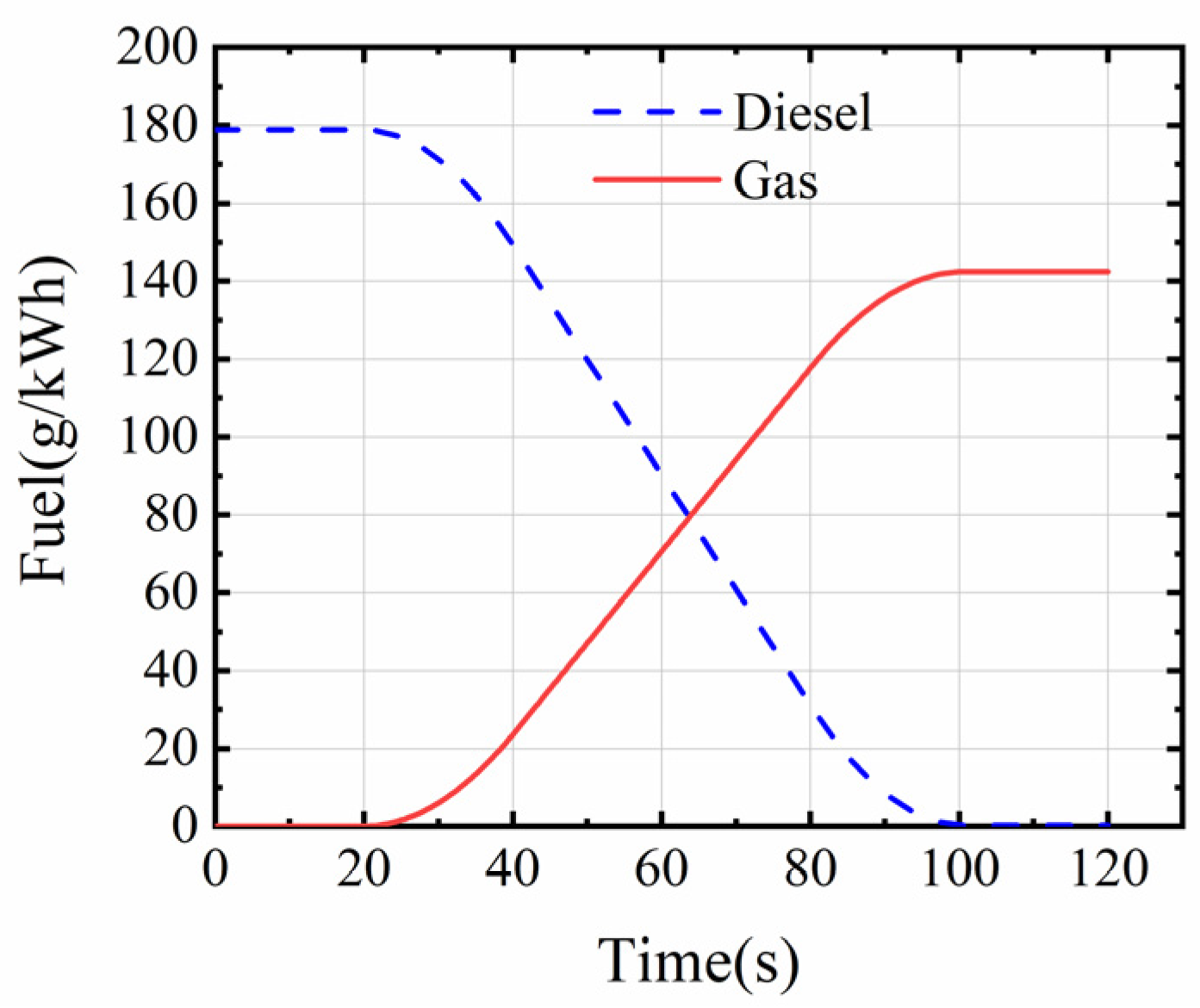

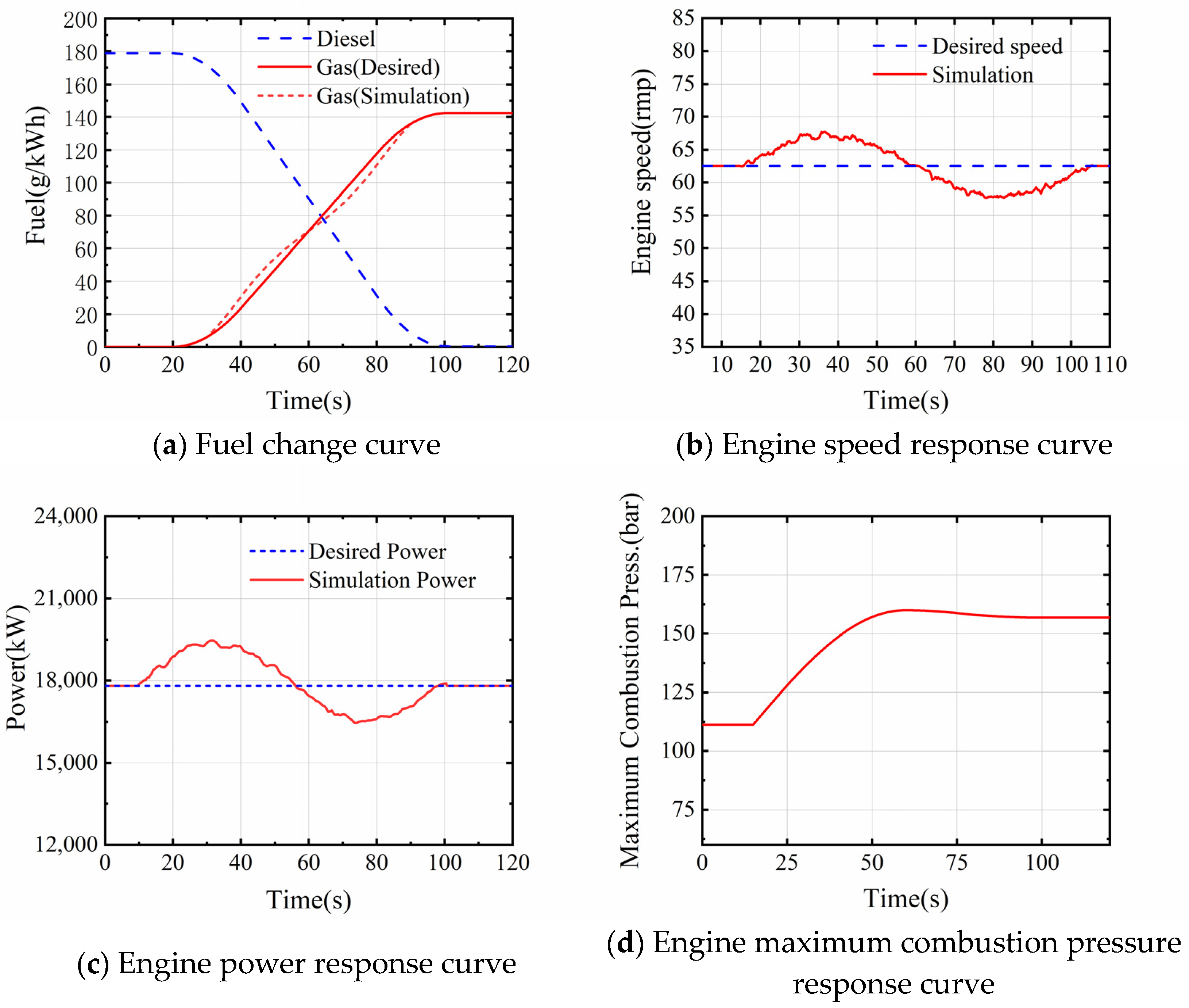

3.2. Switching from Diesel Mode to Gas Mode

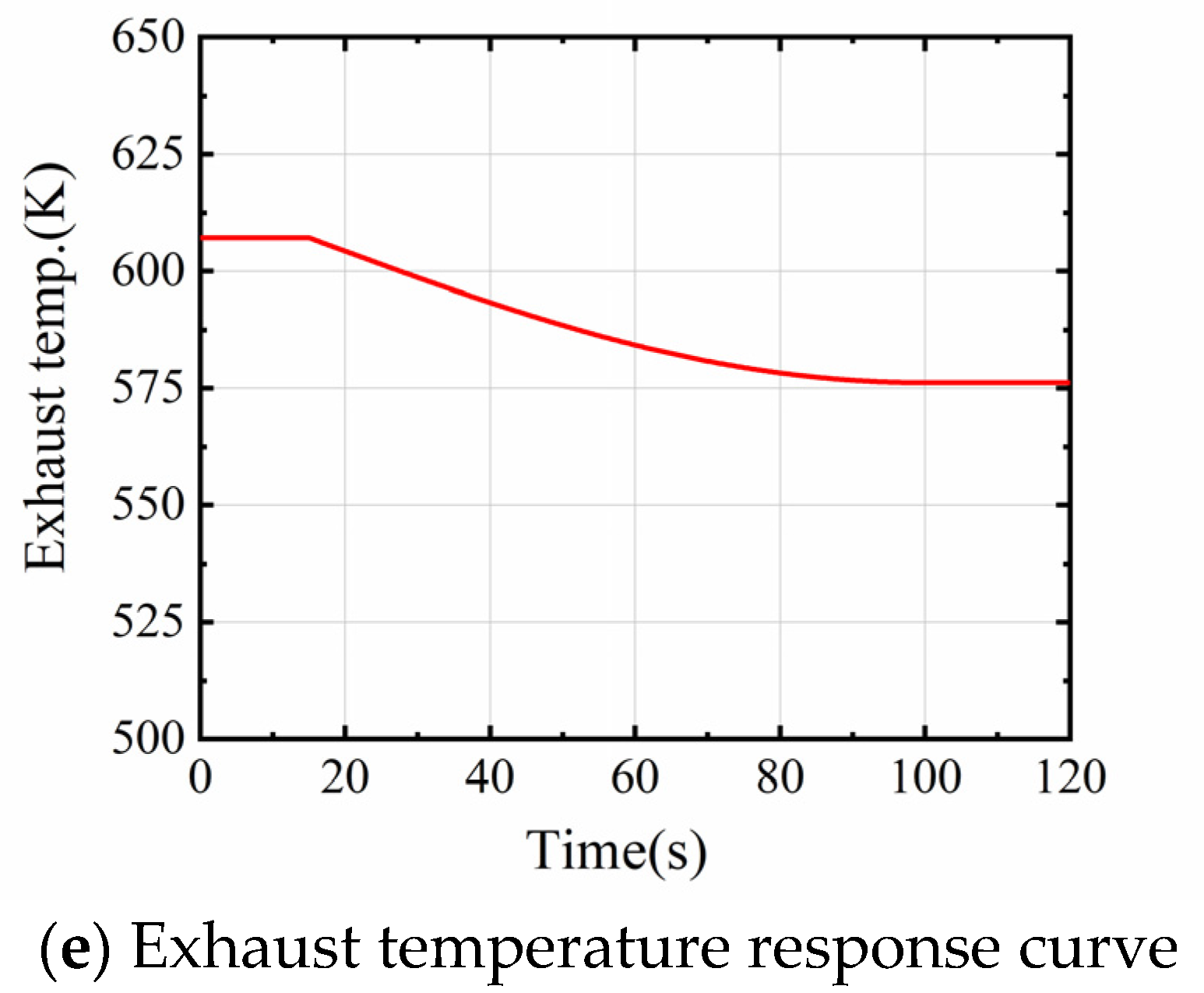

4. Cuckoo-Search-Algorithm-Based Control Parameter Tuning

4.1. Cuckoo Search Algorithm

- (a)

- The cuckoo chooses a random nest location and lays only one egg in a single nest at a time.

- (b)

- Eggs in the better-placed nests will be kept and hatched.

- (c)

- The number of nests available to cuckoos and the probability that each nest owner will find an intrusive egg is fixed.

- (a)

- The initial definition of the algorithm parameters: for the number of nests, Q, the larger the Q, the greater the number of nest options for the cuckoo to lay eggs; in this paper, Q = 500. The problem dimension, H, also known as the number of optimization parameters, is the three control parameters in the controller; in this paper, H is taken as 3, 2, and 1 in this order. The discovery probability, Pa, refers to the likelihood of the original nest owner finding exotic cuckoo eggs; in this paper Pa = 0.25. The number of iterations is C; in this paper C = 100. The nest’s location is randomly initialized, and the fitness function is defined.

- (b)

- The fitness function values for each existing nest location are calculated and compared with each other to select the current optimal function value.

- (c)

- In addition to the optimal nest, the nest location and nest state are updated using Levy flight for the other nest locations while generating a random number of r(r ∈ [0,1]).

- (d)

- The value of the function calculated in step (c) is compared with the optimal function value in step (b) to generate a new optimal function value. The random number r generated in step (c) is compared with the discovery probability, Pa, defined in step (a). If r > Pa, a new nest position is generated randomly; otherwise, the nest position remains unchanged. In addition, add one to the number of iterations.

- (e)

- If the maximum number of iterations set in step (a) has been met, the global optimal nest position is output at that point; if the maximum number of iterations is not satisfied, return to step (c).

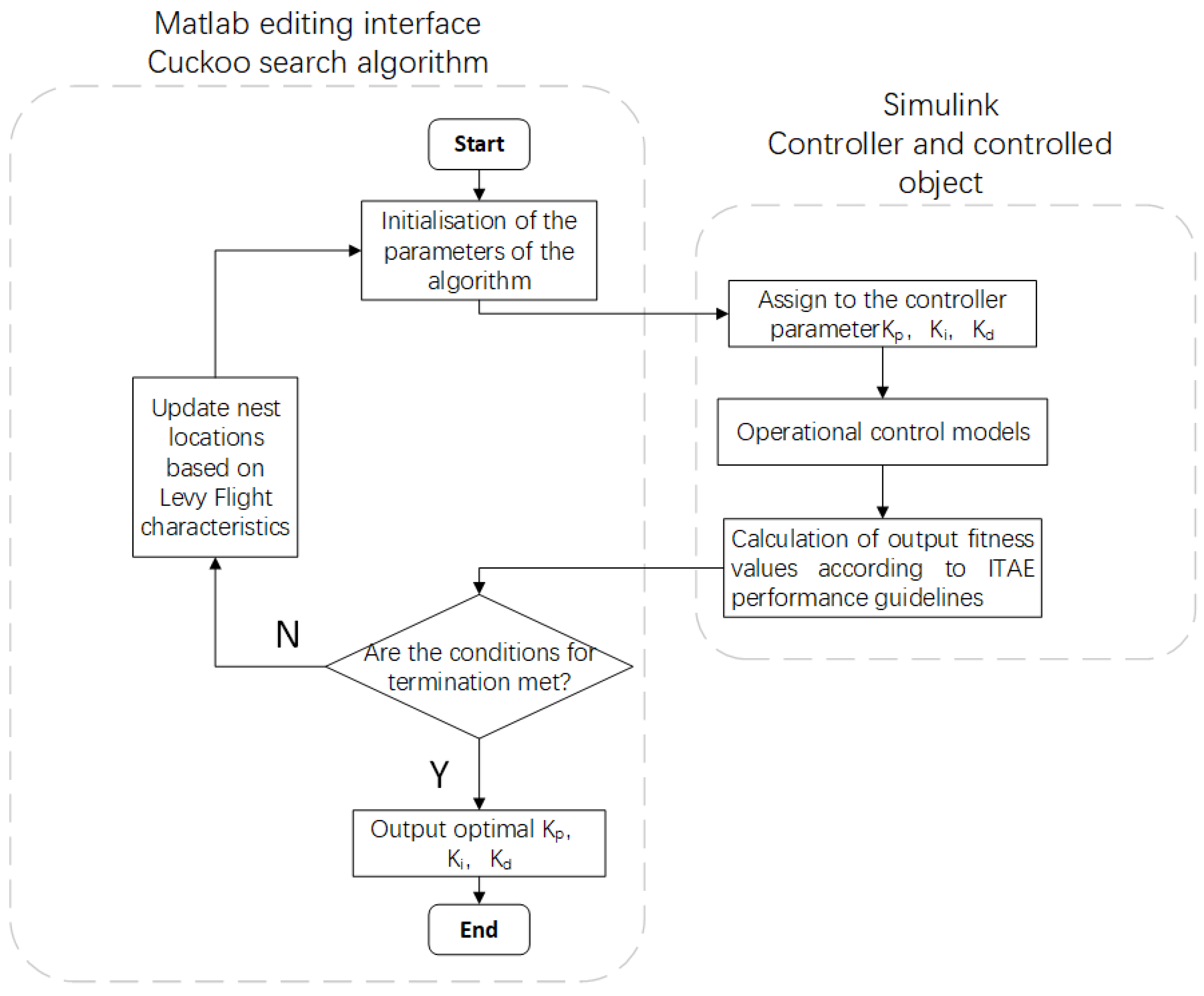

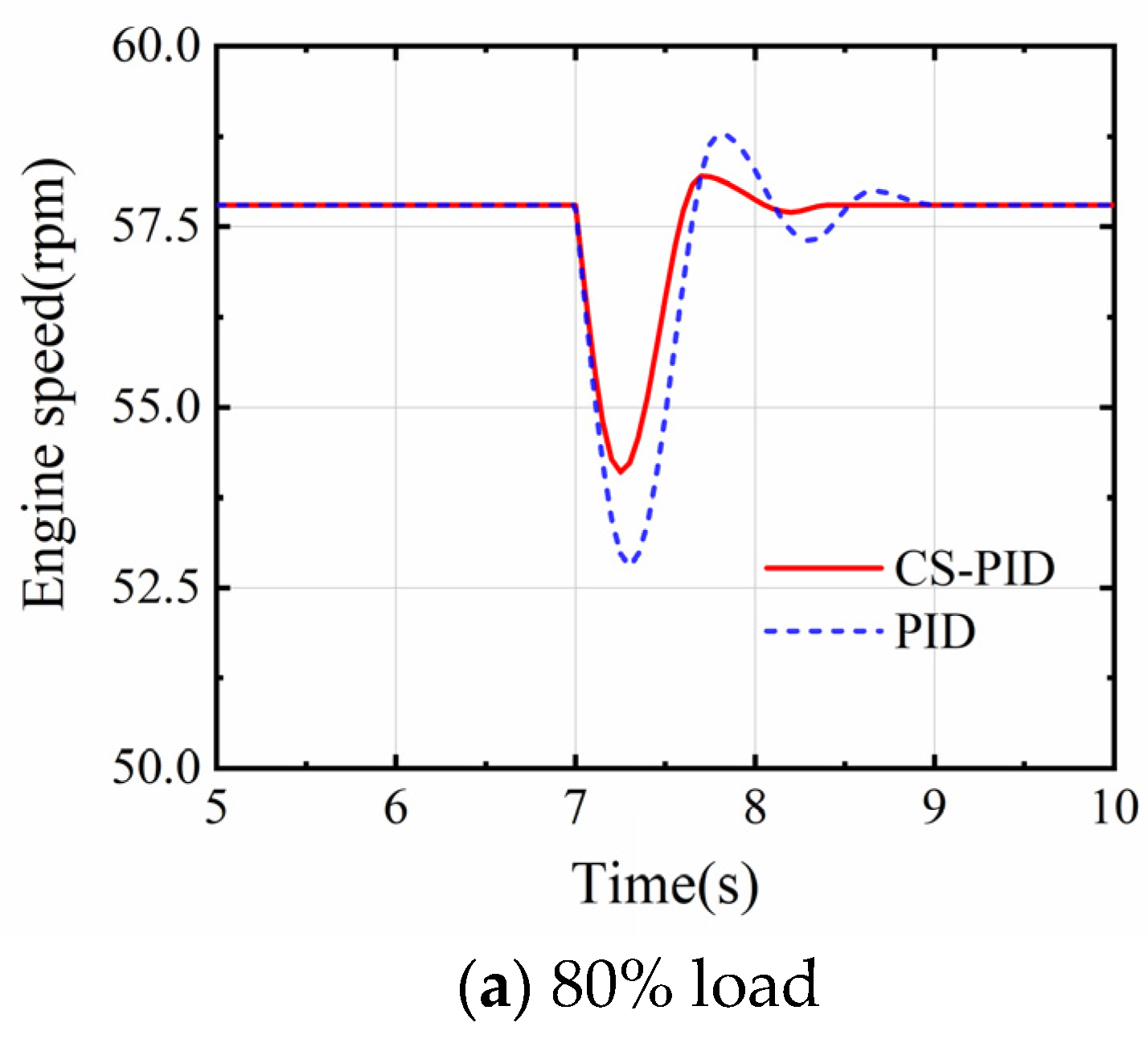

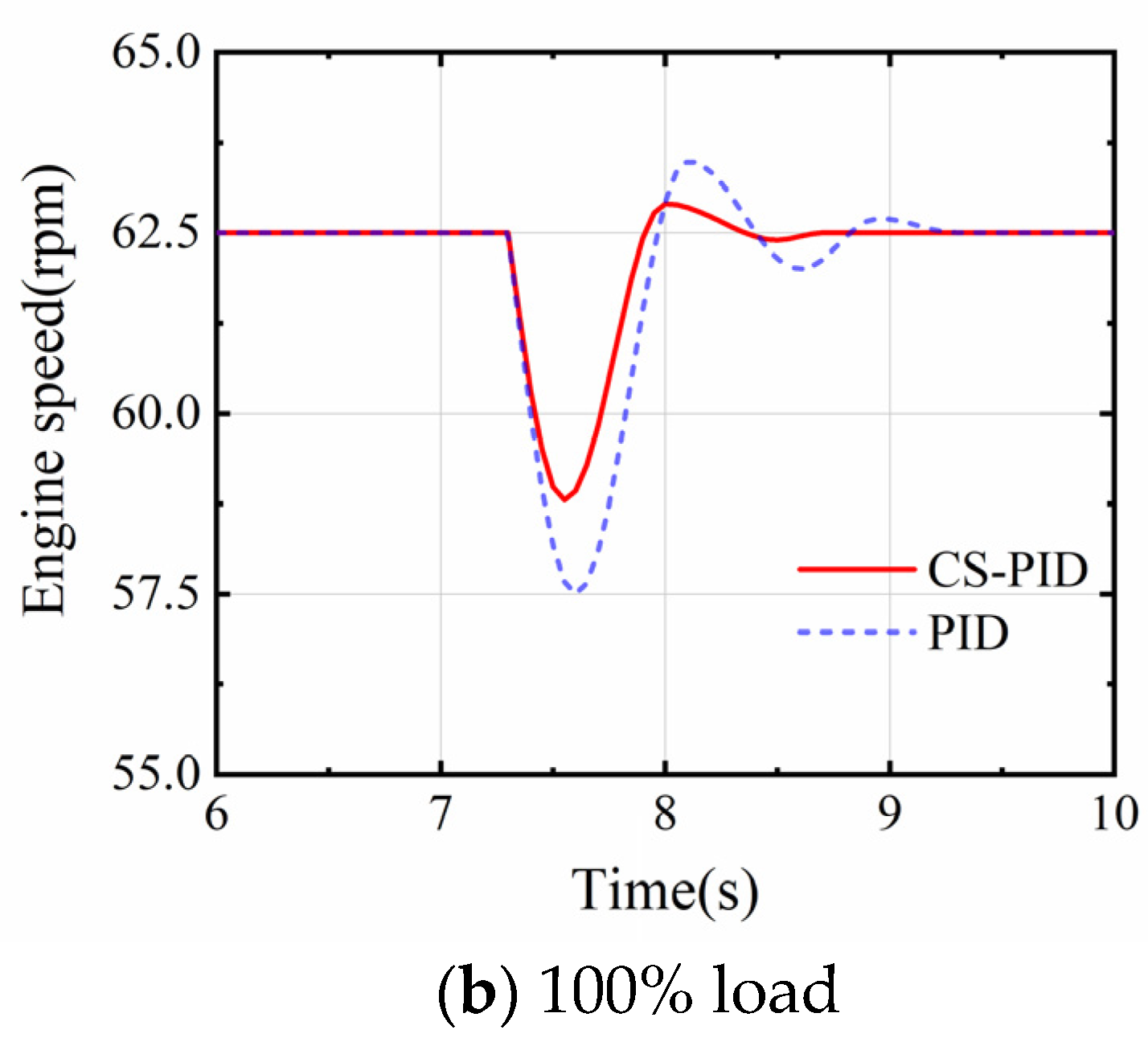

4.2. Simulation Verification of PID Parameter Tuning Based on the Cuckoo Search Algorithm

5. Conclusions

- A simulation model of the 7X82DF dual-fuel engine was built using GT Power and MATLAB/Simulink coupling. The model was calibrated and verified by using the steady-state data of the engine running in diesel and gas modes and the bench report provided by the shipyard. Each error was within 5%, which verified the model’s accuracy. It was demonstrated that the developed model met the requirements for further research.

- According to the manufacturer’s requirements, the engine needs to be switched from running in gas mode to diesel mode within 2 s, which places high demands on the engine and its control system. The rapid cut-off of the gas and the lag in the diesel supply cause an instantaneous lack of engine power, which results in an instantaneous drop in engine speed. In order to quickly restore engine power and speed, the control system increases the diesel supply and overshoots the speed, after which the engine gradually stabilizes. This process is more prone to safety accidents as the engine speed fluctuates due to the short switching time and the high mechanical and thermal loads on the engine components.

- The changeover from diesel to gas mode is longer, and the change in fuel supply is smoother, so the simulation gives a smoother transition in engine parameters. The changeover process is less volatile and less demanding on the engine and its control system than the changeover from gas to diesel mode. Therefore, the possibility of a safety incident during this process is also low.

- The cuckoo search algorithm was introduced and used to optimize the parameters of a PID controller for a conventional fuel supply system. The optimized controller is then used to simulate the switching process from gas to diesel mode at 80% and 100% loads on the main engine. The results show that the optimized controller is able to significantly suppress the engine speed fluctuations when performing the fuel-mode switch.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| PID | Proportion Integral Differential |

| CS | Cuckoo search algorithm |

| LNG | Liquefied natural gas |

| IMO | International Maritime Organization |

| PID | Proportional–Integral–Derivative controller |

| TDC | Top dead center |

| ATDC | After top dead center |

| Fuel inject timing | |

| Ignition delay time | |

| P | Pressure in the cylinder |

| T | Temperature in the cylinder |

| k | Chemical kinetic rate constant |

| m | Mass of oil and gas mixture generated during the ignition delay |

| Calibration factor | |

| Taylor microscale length | |

| , | GT Power built-in function |

| Volume of cylinders | |

| Concentration of oxygen | |

| Diffusion combustion coefficient | |

| Energy that enters or exits the system | |

| Heat exchanged through the system boundary | |

| W | Mechanical work of the gas in the cylinder acting on the piston |

| Specific enthalpy | |

| U | Internal energy of the system |

| V | Working volume of the air cylinder |

| Crank angle | |

| Heat enters or leaves the walls of the cylinder | |

| Heat release of fuel into the cylinder | |

| Specific enthalpy at the intake valve and exhaust valve | |

| Mass of the working substance flowing into and out of the cylinder | |

| Instantaneous fuel mass in the cylinder | |

| V | Volume of the working substance in the system |

| n | Amount of substance of the working substance in the system |

| T | Temperature of the working substance in the system |

| R | Gas constant |

| Mass flow through the control body boundary | |

| Density | |

| A | Area cross section |

| u | Velocity of the working substance crossing the boundary |

| Surface area of the heat transfer surface | |

| e | Internal energy per unit mass |

| H | Enthalpy per unit mass |

| h | Heat transfer coefficient |

| Temperature of the fluid and the temperature of the wall | |

| Pressure loss coefficient | |

| Surface friction coefficient | |

| dx | Mass element length in the flow direction |

| dp | Pressure difference before and after dx |

| D | Equivalent diameter |

| Output value | |

| Difference between the target value and the measured value | |

| Proportionality coefficient | |

| Integral coefficient | |

| Differential coefficient | |

| MCR | Maximum continuous rating |

| BSFC | Brake-specific fuel consumption |

| ITAE | Time-multiplied absolute error integration criterion |

References

- Karimi, M.; Wang, X.L.; Hamilton, J.; Negnevitsky, M.; Lyden, S. Status, challenges and opportunities of dual fuel hybrid approaches-a review. Int. J. Hydrogen Energy 2021, 46, 34924–34957. [Google Scholar] [CrossRef]

- Iannaccone, T.; Landucci, G.; Tugnoli, A.; Salzano, E.; Cozzani, V. Sustainability of cruise ship fuel systems: Comparison among LNG and diesel technologies. J. Clean. Prod. 2020, 260, 121069. [Google Scholar] [CrossRef]

- Thomson, H.; Corbett, J.J.; Winebrake, J.J. Natural gas as a marine fuel. Energy Policy 2015, 87, 153–167. [Google Scholar] [CrossRef]

- Abadie, L.M.; Goicoechea, N. Powering newly constructed vessels to comply with ECA regulations under fuel market prices uncertainty: Diesel or dual fuel engine? Transp. Res. Part D-Transp. Environ. 2019, 67, 433–448. [Google Scholar] [CrossRef]

- Boeckhoff, N.; Heider, G.; Hagl, P. Operational experience of the 51/60 DF from MAN Diesel SE. In Proceedings of the 26th CIMAC World Congress on Combustion Engine Technology, Bergen, Norway, 10–14 June 2019. Paper No. 37. [Google Scholar]

- Xianquan, Z.; Jianguo, Y.; Lufeng, H.; Shulin, Z.; Zhengyan, Q. Experimental research of fuel mode switch-over for a marine micro-pilot-ignition dual-fuel engine. J. Harbin Eng. Univ. 2021, 42, 541–547. [Google Scholar]

- Enzhe, S.; Zhongzhou, J.; Chong, Y.; Guofeng, Z. Research on Mode Switch Control Strategy of Marine Diesel/Natural Gas Dual Fuel Engine. J. China Mech. Eng. 2022, 33, 388–396. [Google Scholar]

- Reitz, R.D.; Ogawa, H.; Payri, R.; Fansler, T.; Kokjohn, S.; Moriyoshi, Y.; Agarwal, A.K.; Arcoumanis, D.; Assanis, D.; Bae, C.; et al. IJER editorial: The future of the internal combustion engine. Int. J. Engine Res. 2020, 21, 3–10. [Google Scholar] [CrossRef]

- Nwafor, O.M.I. Knock Characteristics of Dual-Fuel Combustion in Diesel Engines Using Natural Gas As Primary Fuel. Sadhana-Acad. Proc. Eng. Sci. 2002, 27, 375–382. [Google Scholar] [CrossRef]

- Srinivasan, K.K.; Krishnan, S.R.; Qi, Y.; Asme. Cyclic Combustion Variations in Dual Fuel Partially Premixed Pilot-Ignited Natural Gas Engines. In Proceedings of the ASME Internal Combustion Engine Division Spring Technical Conference, Politecn Torino, Torino, Italy, 6–9 May 2012; p. 133. [Google Scholar]

- Wartsila. Wartsila 31DF Product Guide [DB/OL]. [2019–3]; Wartsila: Helsinki, Finland, 2019. [Google Scholar]

- Stoumpos, S.; Theotokatos, G.; Mavrelos, C.; Boulougouris, E. Towards Marine Dual Fuel Engines Digital Twins—Integrated Modelling of Thermodynamic Processes and Control System Functions. J. Mar. Sci. Eng. 2020, 8, 200. [Google Scholar] [CrossRef]

- Gaurav, T.; Priybrat, S.; Atul, D. Computational study of diesel injection strategies for methane-diesel dual fuel engine. J. Clean. Eng. Technol. 2022, 6, 100393. [Google Scholar]

- Lounici, M.S.; Benbellil, M.A.; Loubar, K.; Niculescu, D.C.; Tazerout, M. Knock characterization and development of a new knock indicator for dual-fuel engines. Energy 2017, 141, 2351–2361. [Google Scholar] [CrossRef]

- Tripathi, G.; Sharma, P.; Dhar, A.; Sadiki, A. Computational investigation of diesel injection strategies in hydrogen-diesel dual fuel engine. Sustain. Energy Technol. Assess. 2019, 36, 100543. [Google Scholar] [CrossRef]

- Mavrelos, C.; Theotokatos, G. Numerical investigation of a premixed combustion large marine two-stroke dual fuel engine for optimising engine settings via parametric runs. Energy Convers. Manag. 2018, 160, 48–59. [Google Scholar] [CrossRef]

- Murphy, A.J.; Norman, A.J.; Pazouki, K.; Trodden, D.G. Thermodynamic simulation for the investigation of marine Diesel engines. Ocean Eng. 2015, 102, 117–128. [Google Scholar] [CrossRef]

- Stoumpos, S.; Theotokatos, G.; Boulougouris, E.; Vassalos, D.; Lazakis, I.; Livanos, G. Marine dual fuel engine modelling and parametric investigation of engine settings effect on performance-emissions trade-offs. Ocean Eng. 2018, 157, 376–386. [Google Scholar] [CrossRef]

- Sui, W.B.; Gonzalez, J.P.; Hall, C.M. Combustion Phasing Modelling of Dual Fuel Engines. In Proceedings of the 5th International-Federation-of-Automatic-Control (IFAC) Conference on Engine and Powertrain Control, Simulation and Modeling (E-COSM), Changchun, China, 20–22 September 2018; pp. 319–324. [Google Scholar]

- Xu, S.N.; Anderson, D.; Hoffman, M.; Prucka, R.; Filipi, Z. A phenomenological combustion analysis of a dual-fuel natural-gas diesel engine. Proc. Inst. Mech. Eng. Part D-J. Automob. Eng. 2017, 231, 66–83. [Google Scholar] [CrossRef]

- Tang, J.; Zhu, G.M.G.; Men, Y. Review of engine control-oriented combustion models. Int. J. Engine Res. 2022, 23, 347–368. [Google Scholar] [CrossRef]

- Kwak, K.H.; Borgnakke, C.; Jung, D.; Asme. Fuel sensitive ignition delay models for a local and global description of direct injection internal combustion engines. In Proceedings of the ASME Internal Combustion Engine Division Fall Technical Conference, Columbus, IN, USA, 19–22 October 2014. [Google Scholar]

- Ma, F.K.; Zhao, C.L.; Zhang, F.J.; Zhao, Z.F.; Zhang, Z.Y.; Xie, Z.Y.; Wang, H. An Experimental Investigation on the Combustion and Heat Release Characteristics of an Opposed-Piston Folded-Cranktrain Diesel Engine. Energies 2015, 8, 6365–6381. [Google Scholar] [CrossRef]

- Ithnin, A.M.; Ahmad, M.A.; Abu Bakar, M.A.; Rajoo, S.; Yahya, W.J. Combustion performance and emission analysis of diesel engine fuelled with water-in-diesel emulsion fuel made from low-grade diesel fuel. Energy Convers. Manag. 2015, 90, 375–382. [Google Scholar] [CrossRef]

- Kang, Z.; Wu, Z.J.; Fu, L.Z.; Deng, J.; Hu, Z.J.; Li, L.G. Experimental Study of Ion Current Signals and Characteristics in an Internal Combustion Rankine Cycle Engine Based on Water Injection. J. Eng. Gas Turbines Power-Trans. ASME 2018, 140, 111506. [Google Scholar] [CrossRef]

- Chalet, D.; Chesse, P.; Hetet, J.F. Boundary conditions modelling of one-dimensional gas flows in an internal combustion engine. Int. J. Engine Res. 2008, 9, 267–282. [Google Scholar] [CrossRef]

- Yu, R.; Bai, X.S. A semi-implicit scheme for large Eddy simulation of piston engine flow and combustion. Int. J. Numer. Methods Fluids 2013, 71, 13–40. [Google Scholar] [CrossRef]

- Qinghua, S.; Dandan, W. Neural Network Ship PID Control and Simulation Based on Grey Prediction. J. Coast. Res. 2020, 110, 299–303. [Google Scholar]

- Nakatani, T.; Ohtsu, K.; Okazaki, T.; Moriyoshi, N. On Automatic Tuning of Ship’s PID Regulators. Trans. Soc. Instrum. Control. Eng. 1998, 34, 689–691. [Google Scholar] [CrossRef]

- Shen, X.Q.; Su, Y.X. Marine Diesel Engine Speed Control System Based on Fuzzy-PID. In Proceedings of the International Conference on Mechanical Engineering and Materials (ICMEM), Melbourne, Australia, 15–16 January 2012; pp. 1589–1594. [Google Scholar]

- Yang, X.S.; Deb, S. Cuckoo Search via Levey Flights. In Proceedings of the World Congress on Nature and Biologically Inspired Computing, Coimbatore, India, 9–12 December 2009; p. 210. [Google Scholar]

- Soneji, H.; Sanghvi, R.C. Towards the Improvement of Cuckoo Search Algorithm. In Proceedings of the World Congress on Information and Communication Technologies (WICT), Trivandrum, India, 30 October–2 November 2012; pp. 878–883. [Google Scholar]

- Boeckhoff. Operational Experience of the 51/60 DF from MAN Diesel SE. In Proceedings of the 26th CIMAC World Congress on Combustion Engine Technology, Bergen, Norway, 14–15 May 2010; pp. 1867–1872. [Google Scholar]

- Das, S.; Dasgupta, P.; Panigrahi, B.K. Inter-species Cuckoo Search via Different Levy Flights. In Proceedings of the 4th International Conference on Swarm, Evolutionary, and Memetic Computing (SEMCCO), SRM Univ., Chennai, India, 19–21 December 2013; pp. 515–526. [Google Scholar]

- Gandomi, A.H.; Yang, X.S.; Alavi, A.H. Cuckoo search algorithm: A metaheuristic approach to solve structural optimization problems. Eng. Comput. 2013, 29, 17–35. [Google Scholar] [CrossRef]

- Tang, H.L.; Xue, F. Cuckoo search algorithm with different distribution strategy. Int. J. Bio-Inspired Comput. 2019, 13, 234–241. [Google Scholar] [CrossRef]

- Quoc, H.D.; The, L.N.; Doan, C.N.; Thanh, T.P.; Ieee. New Cuckoo Search Algorithm for the Resource Constrained Project Scheduling Problem. In Proceedings of the RIVF International Conference on Computing and Communication Technologies (RIVF), RMIT University, Ho Chi Minh City, Vietnam, 14–15 October 2020; pp. 376–378. [Google Scholar]

- Mudi, R.K.; Pal, N.R. A robust self-tuning scheme for PI- and PD-type fuzzy controllers. IEEE Trans. Fuzzy Syst. 1999, 7, 2–16. [Google Scholar] [CrossRef]

- Gozde, H.; Taplamacioglu, M.C.; Kocaarslan, I. Comparative performance analysis of Artificial Bee Colony algorithm in automatic generation control for interconnected reheat thermal power system. Int. J. Electr. Power Energy Syst. 2012, 42, 167–178. [Google Scholar] [CrossRef]

- Maurya, A.K.; Bongulwar, M.R.; Patre, B.M.; Ieee. Tuning Of Fractional Order PID Controller For Higher Order Process Based On ITAE Minimization. In Proceedings of the 12 IEEE International C Elect Energy Environmental Communications Computer Control, New Delhi, India, 17–20 December 2015. [Google Scholar]

- Jin, Q.B.; Qi, L.F.; Jiang, B.Y.; Wang, Q. Novel improved cuckoo search for PID controller design. Trans. Inst. Meas. Control. 2015, 37, 721–731. [Google Scholar] [CrossRef]

| Engine Parameters | Unit | Values |

|---|---|---|

| Cylinder | - | 7 |

| Bore | mm | 820 |

| Stroke | mm | 3375 |

| Compression ratio | - | 12.4 |

| Power | kW | 22,531 |

| Speed | rpm | 62.5 |

| Firing order | - | 1-6-3-4-5-2-7 |

| Pilot-injection pressure | bar | 755 |

| Gas-injection pressure | bar | 14.8 |

| Pilot timing | °CA ATDC | −8.5 |

| Gas-valve timing | °CA ATDC | 224 |

| Load (%) | 25 | 50 | 75 | 80 | 100 |

| Pilot consumption (g/kWh) | 1.0 | 0.5 | 0.4 | 0.3 | 0.3 |

| Load (%) | 25 | 50 | 75 | 80 | 100 |

| Pilot consumption (g/kWh) | 1.9 | 0.4 | 0.3 | 0.3 | 0.3 |

| Load (%) | 25 | 50 | 75 | 80 | 100 |

|---|---|---|---|---|---|

| Error (%) | |||||

| Power (kW) | −0.267 | −3.556 | 2.518 | 1.828 | 1.133 |

| Maximum Combustion Pressure (bar) | 1.154 | −1.936 | 1.201 | 1.525 | 0.909 |

| BSFC (g/kWh) | 2.425 | 1.625 | 2.414 | 2.295 | 1.889 |

| Scavenging Air Temperature (K) | −0.362 | −0.599 | −0.597 | −0.463 | −0.692 |

| Exhaust Temperature (K) | 1.357 | −1.003 | 1.231 | 0.988 | 1.4 |

| Load (%) | 25 | 50 | 75 | 80 | 100 |

|---|---|---|---|---|---|

| Error (%) | |||||

| Power (kW) | −0.781 | −3.759 | 1.124 | 1.289 | 1.025 |

| Maximum Combustion Pressure (bar) | −1.445 | −1.191 | 1.336 | 1.148 | 2.178 |

| BSFC (g/kWh) | 1.012 | 1.089 | 1.054 | 1.623 | −0.128 |

| Scavenging Air Temperature (K) | 0.758 | 0.466 | 0.431 | 0.465 | 0.397 |

| Exhaust Temperature (K) | −1.378 | −1.485 | 1.285 | 1.660 | 1.781 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shu, Z.; Gan, H.; Ji, Z.; Liu, B. Modeling and Optimization of Fuel-Mode Switching and Control Systems for Marine Dual-Fuel Engine. J. Mar. Sci. Eng. 2022, 10, 2004. https://doi.org/10.3390/jmse10122004

Shu Z, Gan H, Ji Z, Liu B. Modeling and Optimization of Fuel-Mode Switching and Control Systems for Marine Dual-Fuel Engine. Journal of Marine Science and Engineering. 2022; 10(12):2004. https://doi.org/10.3390/jmse10122004

Chicago/Turabian StyleShu, Zepeng, Huibing Gan, Zhenguo Ji, and Ben Liu. 2022. "Modeling and Optimization of Fuel-Mode Switching and Control Systems for Marine Dual-Fuel Engine" Journal of Marine Science and Engineering 10, no. 12: 2004. https://doi.org/10.3390/jmse10122004

APA StyleShu, Z., Gan, H., Ji, Z., & Liu, B. (2022). Modeling and Optimization of Fuel-Mode Switching and Control Systems for Marine Dual-Fuel Engine. Journal of Marine Science and Engineering, 10(12), 2004. https://doi.org/10.3390/jmse10122004