Abstract

Recent large-scale operations, including frequent maritime transportation and unauthorised as well as unlawful collisions of drainage wastes, have polluted the ocean’s ecology. Due to the ocean’s unsuitable ecology, the entire globe may experience drastic aberrant conditions, which will force illness onto all living things. Therefore, an advanced system is very necessary to remove the undesired waste from the ocean’s surface and interior. Through the use of progressive unmanned amphibious vehicles (UAV), this study provides a dynamic operational mode-based solution to damage removal. In order to successfully handle the heavy payloads of ravage collections when the UAV reveals centre of gravity concerns, a highly manoeuvrable-based design inspired by nature has been imposed. The ideal creatures to serve as the inspiration for this piece are tropical birds, which have a long tail for navigating tricky situations. The design initialization was carried out by focusing on the outer body of tropical birds. Following this, special calculations were conducted and the full design parameters of the UAV were established. This study proposes a unique mathematical formulation for the development of primary and secondary design parameters of an UAV. The proposed mission profile of this application is computationally tested with the aid of sophisticated computational methodologies after the modelling of this UAV. The computational methods that are required are one-way coupling-based hydro-structural interaction assessments and computational hydrodynamic analyses. Computing is used to determine the aerodynamic and hydrodynamic forces over the UAV, the lightweight materials to withstand high fluid dynamic loads, and the buoyancy forces to complete the UAV components. These computational methods have been used to produce a flexible and fine-tuned UAV design for targeted real-time applications.

1. Introduction

Maritime transport has emerged everywhere due to its flexible, huge, and low-cost platforms. Because of this huge implementation, sea wastes such as oil spills and marine debris form a major threat to the marine ecosystem. No permanent solution for cleaning up the ocean from these threats exists. This study established the idea of resolving such conditions through ravage removal with the help of unmanned amphibious vehicles (UAVs). An UAV is a kind of unmanned vehicle in which there is no need for a pilot. Instead of an onboard position, through remote control or program control, the UAV can be engaged in the execution of its mission. This study on UAVs deals with the major analysis of Aerodynamic, Aero-structural, Hydrodynamics and Hydro structural studies. An unmanned amphibious vehicle is an aircraft operated remotely by humans or autonomously by onboard computers. This type of vehicle can fly/swim in air and water. i.e., it can also be operated on the surface of the water to ocean depths and back. UAVs lighter than air possess lifted buoyancy, and those heavier than air have related motion against aerodynamics, up thrust-powered lifts with engine thrust or electric power. A powered lift is produced by directing the engine thrust vertically downwards. UAVs are classified into three types: seaplane, submarine-launched, and submersible. Overall, aquatic UAVs use an electric power or hybrid-powered propulsive system. The Seaplane UAVs follow aerodynamic and hydrodynamic principles, but submarine-launched UAVs plus submersible UAVs work only under the laws of hydrodynamics. Therefore, their design should always decrease the drag and increase hydrodynamic stability. Wing Configuration of aquatic UAVs is fixed wings, morphing wings, variable wings and Quadcopter.

Fixed-wing UAVs can take off and land on water but cannot dive in. This fixed-wing UAV is navigated through sea wave mode and flying mode. While in sea wave mode, the engine will be shut down. This type of wing maintains neutral buoyancy in water. At the same time, it reduces vehicles’ weight. Because of the lifting surface, it could achieve greater endurance: for example, a flying fish is an air-to-water transition wing, an electric motor and a single propeller. A morphing wing can fold its wing to increase underwater maneuverability. A quadcopter aquatic UAV generates lift force through the rotations of rotors, and it is easy to enter and exit the water. This type of rotor can be highly stable and good for maneuvering, but it has less efficiency and battery life. Variable wing structure includes folded swept wings and bio-inspired flapping wings; they can reduce friction and improve moving efficiency. Most of these types of UAVs are flapping wing UAVs inspired by bionics. A jellyfish aquatic UAV-inspired flapping wing concept was proposed, wherein the flapping wing is efficient only for small UAVs. The important applications include light reflection, research of microscopic life, observing creatures and inspecting ice situations, water sampling, deep-sea sampling, ocean oil pipes transportation, study diffusion, acoustic transmission, and submarine wakes have been executed by UAVs. From various studies, fixed-wing configurations can be operated on the surface of water and underwater. This wing type has a lift-producing component and is stable on the sea surface. This study extracted the design from a white tropic bird; the bird has high stability and lifts consideration. From an aerodynamic perspective, the authors used a double-tapered wing. From a hydrodynamics perspective, the authors used linear tapered wings with attached aerodynamic rotors or propellers to reduce the buoyancy and forward speed.

1.1. Aim

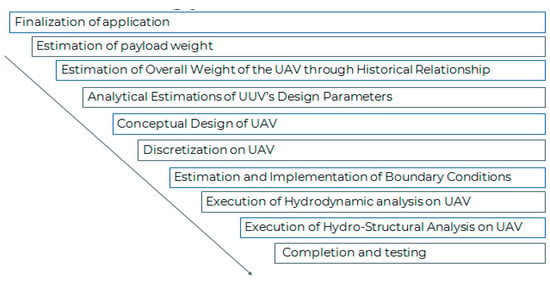

The aim of this study is to construct a conceptual design of an UAV and then analyze its working conditions according to the mission requirements. The study mainly focuses on design, i.e., flexible and efficient design. The mission of this work is to remove ravage and debris on the water surface and under the surface of the sea for further development. The work in this field of analysis will promote new trends and technology regarding air–water ecosystems. A preprint of this study has previously been published [1] and the procedures involved are shown in Figure 1.

Figure 1.

Workflow involved in this proposed research.

1.2. Literature Survey

Dylan K. Wainwright et al. (2020) presented three motion models based on fish and hydrodynamic performance. The methods included comparing three motion models, measuring fish hydrodynamic performance for distinct kinematic models, and studying a tuna’s motion model’s shape, coordinates, and mathematical form. The motion model uses a bionic tuna. In addition, the efficacy of high-speed photos of swimming fish was evaluated. Finally, hydrodynamic coefficients were compared after researching spline curve properties. The comparative approach and fish analysis [2] stand out. Meliha Bozkurttas et al. (2008) analysed the sunfish fin’s design, kinematics, and performance. Examined sunfish fins through the computational fluid dynamics (CFD) tool, the scaling influence of fish fins, and a fin prototype were used. First, sunfish fin mechanics were examined and used as a model. Next, a biorobotic fin propeller was prototyped. This study explored robotic fins to improve forward force, reduce effects, control the propulsive system, and manage manoeuvring forces. CFD analysis relies significantly on observations while constructing a prototype [3].

Negrello F et al. (2016) designed and researched a flapping-wing UAV, wherein the minimum UAV speed was fixed at 5 m/s for this application. This study used extensive mathematical simulations to determine the final design specifications for a flapping-wing UAV. CFD computations were carried out on and above the UAV using the pressure-based solver in ANSYS. Due to UAV complexity, unstructured mesh-based discretization was used. The computational processes used a high-velocity inlet, the pressure-velocity coupler PISO, the second order to obtain acceptable accuracy, and a hybrid initialization. We noted and imposed design calculations as well as computational approaches for CFD investigations [4]. Tae-Hwan Joung et al. (2006) addressed deep water UAVs’ structural design and analysis. The authors analysed and designed (remotely operated underwater vehicle) ROV and launcher systems in this study using an optimization technique. The launcher frames were made of galvanised steel, and the remote-controlled vehicle was made of 60-series of aluminium. The launcher’s submerged base for ROV operations helps reduce shock waves. In this scenario, the material’s yield stress determines the frames’ structural value, live load allowances, welding strength loss, and abnormal loading consequences. Displacement and stress are insufficient standard launcher and ROV reactions. The best design can accomplish these structural loads, and during structure analysis the finite elements-based approach was employed. Safety issues and stress data reduced the launcher and ROV mass. Maximum design stress has a safety factor of 8. Ti and Al alloys are recommended for the UAV’s pressure vessel. Pressure vessel analysis includes poison’s ratio, yielding stress, and ultimate stress [5].

This study is a submerged UAV-based concept that has spinning wings to allow it to float and fly. Whirling wings can minimize water resistance by lowering surface tension. By infusing water into the UAV’s “float bowl,” its density and submerged capacity are boosted. The CFD assessed aerodynamic and hydrodynamic features. The whirling wings boosted water performance [6]. This research examined an (autonomous underwater vehicle) AUV’s effectiveness. This AUV has wavy wings and its aspect ratio, propulsion efficiency, and power were investigated. Changes in aspect ratio affected AUV vortex formations. Thrust and propulsive efficiency increased linearly with the aspect ratio [7]. This study researched the viability of building a fish-inspired (unmanned underwater vehicle) UUV propeller. This study focused on the Bluegill sunfish’s complex pectoral fin. The morphology, hydrodynamics, and kinematics of sunfish pectoral fins were studied. These data imply that its fins are unique. Dimples and vortices in the leading edge can boost high-speed thrust. According to this study, a robotic fin could be used to propel UUVs, increasing their manoeuvrability [8].

This study conceptualised an AUV and so focused on hull resistance, which determines the AUV’s power needs and range. First, CFD estimated hull resistance and hydrodynamic characteristics. After that, the AUV’s shape was optimised with CFD and a ducted propeller [9]. This study compared fish movement models. Here, the authors tested three fish-swimming motion models. Three models were numerically analysed to compare their hydrodynamic performance and a suitable model for real-time implementation was found. The experiments suggested that amplitude beats frequency [10]. The authors aimed to develop a flying, swimming robot watercraft. So, this gizmo was inspired by flying fish’s predator-avoiding skills. This paper used mathematics to analyse the robotic fish’s hydrodynamic properties and mechanical design concepts. A mechanical model was built and tested to evaluate how closely the robotic fish matched the real one. This research supported several lasting concepts [11]. This research analysed and designed an underwater flying-wing glider. Because of their weak lift-to-drag ratio, underwater gliders have flying wings. This study used CFD to evaluate a flying wing design and explain its mathematics. Optimizing the flying wing design improved glide performance [12]. This study theoretically and quantitatively assessed an UAV. The flying fish’s glide ratio inspired this design. This clever creature can swim and fly. Retractable wings lower the UAV’s water profile and flying resistance. CFD and hydro structural interaction based computations helped lot on study five lightweight materials. Epoxy-E-Glass-Fabric provides improved hydrodynamic performance, according to research [13].

This study examined the hydrodynamics and dynamic stability of underwater glider wing shapes. The analysis used square and angled wing profiles. A tow tank test and CFD analysis determined the glider’s efficiency. A rectangular wing can create strong lift forces but is not stable. The tapered wing has a minimal lift but considerable dynamic stability [14]. The authors used an evolutionary technique to perfect the undersea vehicle’s plans. These approaches can handle single or multi-objective optimization problems. These computations yield a configuration with low movement resistance [15]. This study presented UAV designs and evaluations. It was inspired by flying fish and developed using submarine rules. When the UAV design is complete, CFD is utilised to determine its water performance. A cylindrical hull shape was analysed. CFD analyses pressure, velocity, and drag coefficient [16].

Models are utilised to build effective underwater feedback controls and navigation techniques. Back-stepping can be linearised feedback in a dynamic model. Situation dependent static or dynamic feedbacks were investigated. Control and stability problems are solved by deriving Lyapunov stability requirements for the designed controllers. Non-holonomic bounds complete the kinematic model. This technique reduces output vector-auxiliary input dependence. The controllers’ efficacy was evaluated by comparing simulation results [17]. This paper examined a coraciiform swimming robot with navigation and direction. The biomimetic vehicle construction is water and pressure-resistant yet less efficient. The gear mechanism propels the plane’s fin. Studying fish swimming patterns can increase AUV propeller efficiency and manoeuvrability. Comparing expected values to robot test results showed some agreement [18]. This article showed how autonomous underwater gliders aid ocean research. Oceans studied the effects of pollutants on fish, fish reproduction, and fish nutrition. Its military uses include sea mine-detecting. Oceanographers used these gliders for study. Sea gliders, deep gliders, sprays, Slocum batteries, electric gliders, and military vehicles are also proposed [19]. This research used a remote sensor system on an AUV to monitor water quality in real time. Due to the underwater environment, putting a water quality sensor in the AUV’s payload was not easy. This technique studied aquaculture nitrate discharge. According to [20], AUVs have limited technology interfaces for measuring systems. This study discussed submarines, AUVs, ROVs, and ship-towed instrument packages. All simulations used a steady-state 3D segregated RANS solver. CFD reduces costs and shortens development times, so analysts use it more frequently in AUV hydrodynamic designs. CFD solvers calculated drag and wave resistance. The military use AUVs for deep-sea exploration [21].

This article compared remote-controlled ROVs to AUVs. The author emphasised the need for underwater vehicle adaptability for avoiding obstacles, laying pipes, searching for resources, destroying mines, etc. The goal was to build a six-degrees-of-freedom (DOF) UUV control system. CFD may assist in the optimization of the propeller and generate a streamlined hull with little drag [22]. This study described several motion consequences such as rolling, single-axis rotation, and gliding, spiralling, drifting, hovering, and zigzagging. UAVs have a multi-rotor layout, which is inefficient in terms of manoeuvrability and longevity. This study described a UAV design with long service life, efficient construction, reliable flight, and low maintenance costs. Modern engineering software such as ANSYS-Fluent can reduce design complexity and it was also found that a stingray-inspired body shape allows UAVs to swim steadily. Before service, CFD software analysed the best UAVs’ water-flow properties [23]. In this analysis, the authors forecast the energy needed to propel a robotic fish like a real fish and the drag it would encounter. Simulating a fish’s swimming is tricky. A robot fish needs a flawless body and energy to swim like a real fish. A bottle-nose dolphin analyses drag, speed, and the boundary layer. Animal morphology and mobility help improve robot fish and underwater vehicles. The robotic fish should be streamlined to ensure a laminar boundary layer and flow pattern. Underwater individuals rarely suffer wave drag, unlike ships and animals [24].

This research introduced an implicit predictor-corrector method for the simultaneous integration of the six-degrees of freedom (DOF) submarine motion equations and the unstable Reynolds-Averaged Navier–Stokes (URANS) vehicle hydrodynamic equations. CFD solver ANSYS CFX is popular to use on submarines with tetrahedral mesh. The 6 DOF URANS simulations are coupled with a predictor-corrector approach that models emergency risers and horizontal zigzags. Due to relief parameter stability restrictions in fixed-point iteration, increasing the time step size is inefficient [25]. Here is a biomimetic robot jellyfish that looks and behaves like the real thing. Saora’s Polystructure and actuators are 95% polymer. When deployed in suitable structures and with optimal actuation settings, severely twisted and coiled silver-coated 6-ply TCP actuators can provide a robotic jellyfish with good swimming characteristics. Jellyfish have developed a low-cost, polymer-based actuation mechanism. The Poly-Saora jellyfish can swim 180 mm in a single stroke [26]. This article describes how to make a folding underwater glider. Angle of Attack and sweep can be modified for different motion types. AUGs are compact, have long battery lives, and may collect crucial oceanographic data, making them a desirable maritime observation platform. Various wing configurations are investigated in glide, spiral, and horizontal turn simulations. Simulations demonstrated that wing designs affect aeroplane performance. Field testing showed that the movable wing improves flight performance [27]. AUVs are cheaper than manned vessels for underwater search and survey activities. This study proposed a design framework to reduce AUV resistance, energy utilization, and maintenance costs. By adding additional framework modules, the developer may address serious optimization difficulties. Calculations computed in ANSYS ICEM and Fluent. This framework’s adaptability is shown by its ability to identify the finest preliminary AUV designs for diverse needs. Because of the framework’s production process and tools, each component is high-quality and reliable [28].

Advances in AUV modelling, control, and guidance are reviewed. The dynamics of a self-driving underwater vehicle are modelled to illustrate control synthesis. This topic focuses on formal models and analysis tools for synthesizing collaborative underwater robotic behaviour and developing accurate, resilient, cost-effective navigation technology for extended missions. AUVs can acquire long-range oceanographic data, while ROVs cannot. Shape design, wing design, cross-domain design, take-off and landing design, and other AUV challenges are explored. Air and water are the most difficult environments for an AUV [29]. The paper discusses bio-inspired underwater UAVs. Prototypes and applications are discussed. Unmanned boats and submarines are considered. It categorizes aquatic UAVs and investigates control, take-off, landing, and communication. This study introduces AUVs [30]. This paper presents a design for UUV using sturdy mechanical solutions. Water tightness, hull deflection, propulsion shaft guidance, and sensor protection are addressed. I-DEAS was employed using the Finite Element Method. Ballast tanks, propulsion assembly, and vertical and horizontal thrusters were covered. The miniature submarine inspired the design. Different experiments used rational behaviour mode and three-tiered software architecture. This study’s mechanical underpinning enabled autonomous submarine navigation [31]. This study examined growing deserts and sea levels due to global warming. AUVs were once considered. These types have advantages when support boats and tether cables are not needed. Deep-diving AUVs are useful for surveying large areas. The study team studied AUV technology. All issues include saltwater and water pressure, freshwater supply, a working toilet, and a closed gas station, fully charged battery, satellite and radio signal reception [32]. This research intended to construct a dolphin-inspired underwater robot vehicle. All three accelerations were examined to determine oscillation frequency and motion direction. Because of its dolphin-like look, the fish’s physical traits are categorised and examined in considerable detail. Size is a factor. Controls and physical systems allow the AUV to float and dive factors such as the centre of gravity and pitch angle were studied. It employed the avoidable collision function to reduce collision damage [33]. This article proposed an amphibious unmanned surface vehicle design to improve marine SAR. The goal was to construct a single underwater and airborne propulsion mechanism. Using the strategy mentioned earlier will make the cruise easier. Unmanned ship types are also compared and contrasted. Flying, hovering, and ground navigation is summarised. The major mechanical structure was carefully built after a force research of the aircraft’s flight posture. This research lays out a plan for how rescue and search vehicles should be designed and function [34].

Because of their considerable skills, the fish design is able to carry out in-depth studies. Signals can be optical, electrical, mechanical, chemical, and electromagnetic. The gap between natural and artificial behaviour is a key factor in ecologies. The findings suggested “situ exploration,” which reveals fish behaviours at 200 m or less. Researchers say they behave like coastal species. In response, habitat use and migration patterns were analysed. The case study used ten seafloor video transects. This study examined round-nose grenadier, orange roughly, and fake boarfish [35]. This study compared the anatomy of six groups of flying fish to their capacity to fly. When a species flies, its fins can transform into glider-like wings. Flight parameters, including aspect ratio and wing loading, were scaled. The authors optimised the wing’s design for lift and drag. Fin size was compared to wing size, wingspan, loading, and aspect ratio. The ultimate approach included data from flying species and flapping devices [36]. Here, researchers studied fish finlets, wherein short, non-tucking fins were found to make a major contribution. Society feeds them mackerels, bonitos, and tuna. The species swim well. Finlet hydrodynamics were determined experimentally and computationally. First, high-speed movies investigated fluid motion in vivo. The wake dynamics were then studied to show the underlying vortex formations and hydrodynamic functions. Finally, finlet models were built using yellowfin tuna video data, and modelling restrictions and generalizability were assessed [37]. This work offered a Caribbean-specific AUV layout. Deep-wave-based water diving can become dangerous, an important factor in developing structural failure. Due to deep water pressures, AUV hull performance is crucial. The hull was built to endure extreme circumstances while minimizing hydrodynamic drag. The hull’s water resistance was calculated using CFD and empirical approaches. The findings affect drag prediction. This study offers a revolutionary AUV torpedo body design that potentially impacts deep-sea exploration and operations [38]. Some marine flying vertebrates are aquatic. Despite these constraints, their aerodynamic design helps them move. The study of morphological and behavioural changes began with aerodynamics and flying. This article examined how a fish’s fin impacts the wind’s force on its body. Fins on planes increased lift versus drag. The authors estimated the ground effect g-forces per ton to reduce drag when flying low [39]. This study developed Tifone, an AUV, to monitor submerged archaeological sites. It was designed to execute high-profile functions. It can endure 5-knot winds and 300-m water pressure. From a hydrodynamic perspective, it is like a torpedo. Lateral and vertical thrusters are often utilised as control surfaces. The result is a more reliable system [40].

1.3. Summary

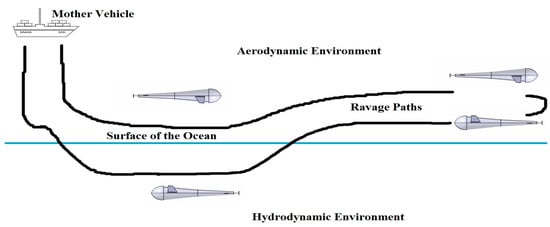

The relationship between the UAV’s payload and its total take-off weight has been determined by searching the relevant literature and examining the relevant historical data. For this reason, it is necessary to determine the UAV’s total take-off weight before choosing any other parts. The necessary parameters for the design of UAVs have been completed using conventional-cum-standard equations. The conceptual design of a UAV will be built using the modelling application CATIA. The Hydro-Structural Interactional Analyses are expected to be carried out using ANSYS Fluent and ANSYS Structural. In this study, a new platform of UAVs is combined with established methods, such as sea bins, to produce novel results. The cleaner, which specifies the machinery used to eliminate the mess, is thus incorporated into the UAV’s final design. Prediction of ravage or other wastages is crucial, so studying this in-depth is necessary to develop an effective ravage elimination system. Table 1 comprises essential design-based information, Table 2 contains computational data from CFD, Table 3 contains computational data from FEA, and Table 4 contains the components of UAVs. The appropriate materials and computational conditions for this investigation are derived from these tables. Figure 2 displays the intended work mission profile. As per the planned mission, the mother aircraft is located on the surface of the ocean.

Table 1.

Comparative information about design of unmanned underwater vehicle.

Table 2.

Comparative information about parameters of CFD analysis on unmanned underwater vehicles.

Table 3.

Comparative information about parameters of FEA analysis on unmanned underwater vehicles.

Table 4.

Comparative information about components involved in unmanned underwater vehicles.

Figure 2.

Mission profile of this proposed nature inspired UAV.

1.4. Symbols and Notations

Table 5 show the symbols used in this work.

Table 5.

Symbols and Notations.

2. Proposed Design—Tropic Bird Inspired UAV

The conceptual design of UAV was taken from the literature survey about existing species. The outer body of this proposed UAV design was captured from the tropic bird. The major fundamental requirement of this recommended UAV must have high stability to execute the mission without any disturbances and high manoeuvring capacity to execute the sudden depth variations with payload. The aforementioned two factors made the design of this proposed UAV complicated, so this work picked one of the perfect nature-based designs, which is tropicbird. From the field work, the length of the body, length of the long tail, and wingspan of the tropicbird are known as 40 cm, 40 cm, and 96 cm. This study was finalised to implement the outer boundary shape of the tropicbird, so the length of the UAV is attained as 80 cm and the wingspan is attained as 96 cm. Based on these inputs, the other design parameters are estimated, which are overall weight, chord length, and tail, etc. [41,42,43,44,45,46].

2.1. Design of UAV’s Wing at Aerodynamic Environments

Wing is the most important in UAV design. Wing plays a major role in lift production. Here the wing designs from the tropic bird which is the double tabard wing and the location of the wing is high wing. A large size fixed wing is designed for high lift generation, so that the lift and buoyancy force overcomes the gravity force to make the UAV float [47,48]. The wingspan of the UAV is taken from an adult tropic bird wing. In general, the Aspect Ratio (AR) of long-range UAV should be more than 15 and medium velocity UAVs aspect ratios vary between 8 and 15. For this case, the UAV works in medium velocity. As per the historical relation, the aspect ratio was fixed. Using aspect ratio and wingspan, the wing area was estimated using the following formula. From an historical relationship, the wing loading was fixed using those total weights estimated from the design nature of the tropic bird design,

Likewise, from an historical perspective, the taper ratio for forward and backward swept wing was estimated. Using known values and suitable formulae chord root, chord tip, swept angles, meaning aerodynamic chord and span wise chord were estimated. In general, the values AR of medium velocity-based drones were between 8 and 15, so for this case AR was assumed as 10,

Due to the historical relationship, the value of the wing loading for this UAV is assumed as 0.0062 kg/cm2.

The wing consists of two parts: a rectangular wing that is forward swept and a tapered wing that is backward swept. The forward swept wing helps to maintain the airflow over their surfaces at steeper climb angles than the conventional plane. The swept back wings give more lateral stability and less turbulence when the speed abruptly changes. From the literature survey, it was found that 40% of wingspan is allocated for constant chord forward swept wing and 60% of the wingspan is allocated for backward swept wing. Half of the wingspan is equal to 48 cm, in which 40% is allocated for the first portion, which is 19.2 cm and 60% is collocated for the second portion, which is 28.8 cm [49,50,51,52].

2.1.1. Design of Constant-Chord Swept-Forward (CCSF) Wing

The relationship between wingspan, chord length, and wing area for a constant-chord swept-forward wing is given in Equation (5) [13,16,23,47,53,54,55,56,57].

From Equation (1), is estimated as and is determined as ; Therefore, .

From Equation (3), the aspect ratio of ccsf wing is framed, which is, .

From the tropic bird, the primary design details concerning the first taper ratio is obtained, which is the slightly tilted constant-chord swept-forward wing. The swept angle formula is given in Equation (6) [13,16,23,47,53,54,55,56,57].

2.1.2. Design of Tapered with Backward Swept Wing

Since the next part of the overall wing is planned to impose tapered with backward swept, the conventional equations for such a wing configuration has been attained [13,16,23,47,53,54,55,56,57]. Especially, Equation (7) contains an analytical description of the planform area of the tapered with backward swept (TBS) wing and Equation (8) contains the analytical description of the aspect ratio of the TBS wing.

From the field work, the second taper ratio of this hybrid wing was obtained and also mentioned in Equation (9). Additionally, it was found that λ = 0.4 is the optimum value, so in this study λ = 0.4 is used [12].

The estimation of the mean aerodynamic centre (MAC) and its location always play an important role in the arrangement of wings at the right location. The calculating procedures of MAC and its positions are given in Equations (10) and (11) [13,16,23,47,53,54,55,56,57].

The span-wise chord estimations were estimated with the help of Equation (12).

At 25% of the span of both sides,

At 50% of the span of both sides,

At 75% of the span of both sides,

In Equation (13), chord length and vertical distance are used to calculate the sweep angle of a tapered backward wing.

2.2. Design of Wing at Hydrodynamic Environment

Under a hydrodynamic environment, the force equilibrium equation (Equation (14)) comprises the weight of the UAV, the lift force generated by the lifting surfaces of the UAV and the buoyancy force created by the hydro fluid. Thus,

The force required to immerse this proposed UAV under the hydrodynamic environment was easily calculated with the help of the above equation. Thus, this imposed lifting device (rectangular wing) needs to work well in order to maintain the UAV in the desired depth. Based on the lightweight material consideration and conventional relationships, the comparative force analyses on UAV under hydrodynamic conditions are calculated and the data are listed in Table 6 [13,16,23,47,53,54,55,56,57].

Table 6.

Comparative force analyses under the hydrodynamic environments on and over the UAV.

From Table 6, the force requirement by the wing immersed in hydro fluid is estimated, which lies between 23.2 N and 114 N. Since the hydro fluid is more complicated than an aerodynamic environment, the gust load effect and force generation due to the presence of hydrofoil are quite complicated. Thus, it is finalised that the constant cord-based wing configuration with symmetrical hydrofoil is more suitable to execute the mission inside the water up to 5 m depth. The first portion of the wing is finalised to remain the same as the main body and the next portion is flexible as per the requirement of the mission execution process [13,16,23,47,53,54,55,56,57].

Aerofoil Selection for Wing

From the conventional procedure, the coefficient of drag for five different symmetrical aerofoils are analysed, and the relevant data are listed in Table 7.

Table 7.

Comparative dynamic performance of various symmetrical aerofoils.

2.3. Design of Fuselage

The outer body of this proposed UAV is captured from tropic bird, so the design relationships are formed through previous relevant articles [13,16,23,47,53,54,55,56,57]. The first design relationship has been derived between the maximum fuselage diameter and length of the UAV, which is mentioned in Equation (15).

The second design relationship has been derived between the minimum fuselage diameter and length of UAV, which is mentioned in Equation (16).

The third design relationship has been derived between the nose tip to first connecting point of wing, fuselage and length of UAV, which is mentioned in Equation (17).

2.4. Propulsive System Design

Thrust requirement by the single propeller in a co-axial propulsive system, in which the maximum forward velocity is assumed as 10 m/s and minimum forward velocity is assumed as 5 m/s. Additionally, the diameter of the propeller is picked as 4.57 cm because of the working nature of this amphibious drone [13,16,23,47,53,54,55,56,57]. The major lifting device of this UAV is wing, which can tackle the weight of the UAV during movement of a steady level flight as well as take-off. Thus, this small proposed co-axial propulsive system can surely execute the focused mission through this nature-inspired UAV. As the assumed maximum velocity lies in a low regime, the workload on the propeller lies in a light manner. The conventional procedures involved in the development of this unique propeller and its developing relationships are provided in Equations (18)–(22).

The designed thrust at 5 m/s is calculated as 20.18 N and the designed thrust at 10 m/s is determined as 83.25 N. In which, the hydrodynamic fluid density is used as 1000 kg/m3. Equations (19)–(22) comprise the relationship data between the mechanical power required and the rotational speed of the propeller. Both dynamic and static conditional data are mentioned in Equations (19)–(22), wherein the major outcome of this analytical procedure is the pitch of the propeller.

The propeller pitch is estimated to be 4.65 cm with the help of the abovementioned formulae.

2.4.1. Estimation of Pitch Angle and Chord of the Propeller

This proposed UAV has a dependency factor similar to its mother vehicle such as aircraft, ship, and boat, in order to execute efficient manoeuvrings. So, this proposed UAV needs to move in a medium range and focus most of its attention on the locations of the ravage’s presence. Owing to this reason, the power requirement of this UAV is not as as high as conventional unmanned underwater vehicles. Thus, the Brushless Direct Current motor-based electric propulsion is enough to execute this targeted mission. Additionally, the standby batteries are also equipped in this unmanned system. The standard analytical formulae to design the UAV’s propellers are listed in Equations (23)–(25), in which pitch angle and chord length of the propellers are dealt. With the help of Equations (23)–(25), the design parameters of the UAV’s propeller are designed, and the design data are listed in Table 8 [13,16,23,47,53,54,55,56,57].

Table 8.

Calculated design data of four blade propeller.

2.4.2. Aerofoil Selection for Propeller

Aerofoil is the fundamental platform of a propeller, so it needs to be estimated through Reynolds Number, the maximum velocity of the UAV, and Coefficient of Lift. These predominant parameters were estimated with the help of a literature survey [13,16,23,47,53,54,55,56,57] and are listed in Table 9. The aerofoils, with respect to their coefficient of drag values, are combinedly revealed.

Table 9.

Comprehensive coefficient of drag (CD) analysis of various aerofoils.

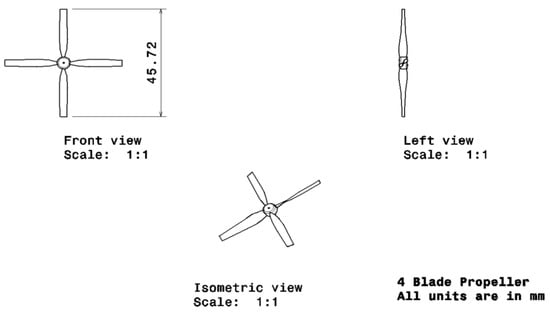

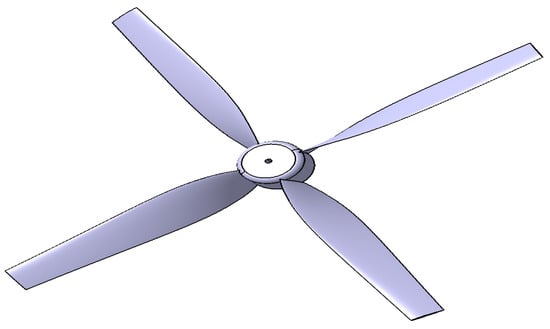

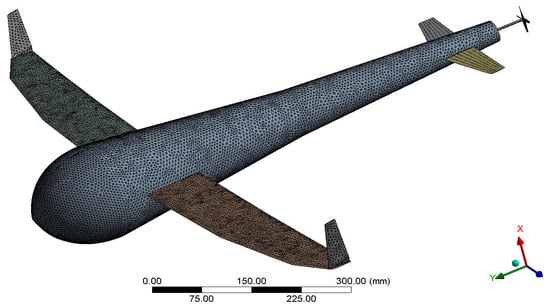

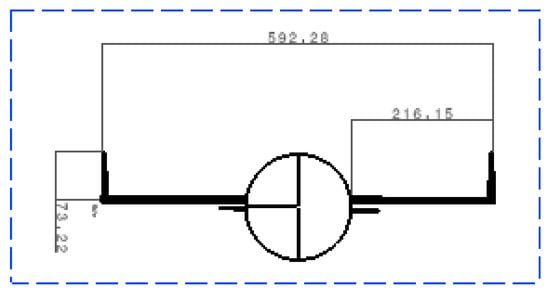

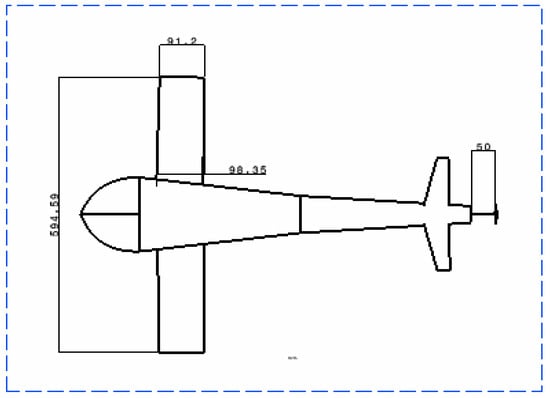

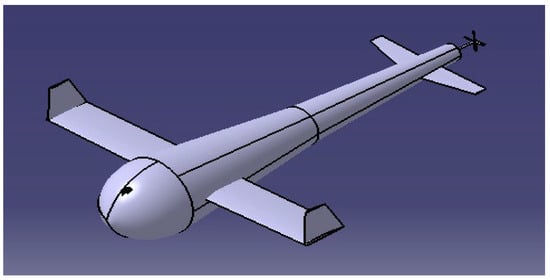

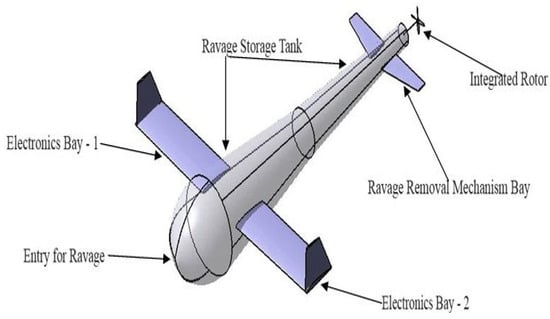

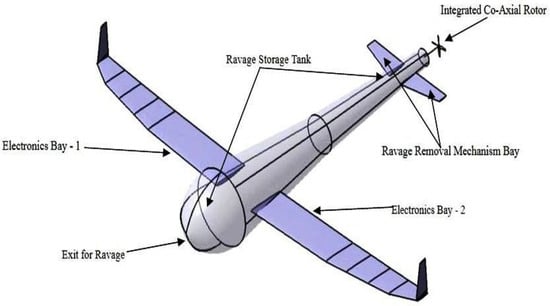

Through Table 9, the NACA 2408 aerofoil is selected as the best compared to others based on the low co-efficient of drag value. Thus, with the help of the obtained design data, the conceptual designs of UAV and its propeller are modelled [13,16,23,47,53,54,55,56,57]. The conceptual design of the propeller is revealed in Figure 3 and Figure 4, also the conceptual design of the advanced UAV is shown in Figure 5, Figure 6 and Figure 7. The numbers of blades are assumed as four for this construction because of the consideration of the higher, denser fluid-based working conditions. Additionally, mostly, this proposed UAV has been planned to survive in an aerodynamic environment only and it can also go up to 5 m depth for the purpose of collecting immersed ravages. So, the aerodynamic calculations-based propeller was developed and imposed in this UAV for both environmental mission executions. This proposed UAV can have the dependency factor with the mother vehicle such as aircraft, ship, and boat, in order to execute the high manoeuvrings. So, this proposed UAV needs to move in a medium range and focus primarily on the locations of the ravage’s presence. Owing to this reason, the power requirement of this UAV and its propellers are not as high as conventional UAVs. Thus, Brushless Direct Current motor-based electric propulsion is enough to execute this targeted mission. Additionally, the standby batteries are also equipped in this unmanned system. The weights of the primary and secondary batteries are included in the overall weight of the UAV.

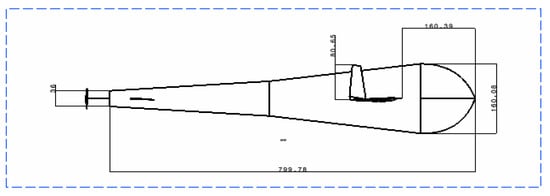

Figure 3.

Design of selected UAV’s Propeller.

Figure 4.

Conceptual design of selected UAV’s Propeller.

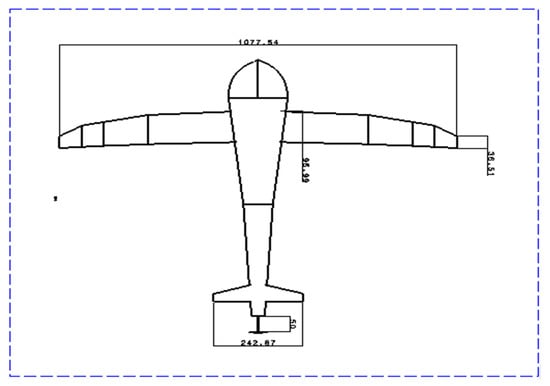

Figure 5.

Design draft of the complete nature-based UAV—A typical view—1.

Figure 6.

Design draft of the complete nature-based UAV—A typical view—1.

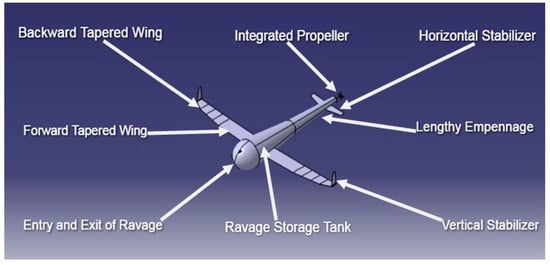

Figure 7.

Conceptual design of nature inspired UAV.

The estimated values for wing dimensions are tabulated in Table 10.

Table 10.

Final estimated data of UAV.

2.5. Design of UAV

Conceptual design of this advanced UAV is modelled with the help of CATIA. In the design, two-vertical stabilizers are fixed at the end of the wingtip in order to achieve easy manoeuvring. A propeller is fixed at the end of the fuselage using a connecting rod to prevent it from inflicting any damage. Since the propeller is an aerofoil shape, it creates considerable lift and controls buoyancy lift. The small size of the propeller withstands the hydrodynamic force imposed by the water. Furthermore, for the wing design, the respective sweep angle is made [13,16,23,47,53,54,55,56,57].

3. Proposed Methodology—Advanced Computational Analysis

The proposed methodology for this study is advanced computational analysis, in which the various environments such as aerodynamic, aero-structural, hydrodynamic, and hydro-structural are solved with the help of ANSYS Fluent and structural tools. Fluid and structural dynamics are predominant computational analyses imposed on the UAV to investigate its different manoeuvring conditions [58,59,60,61,62,63,64,65,66].

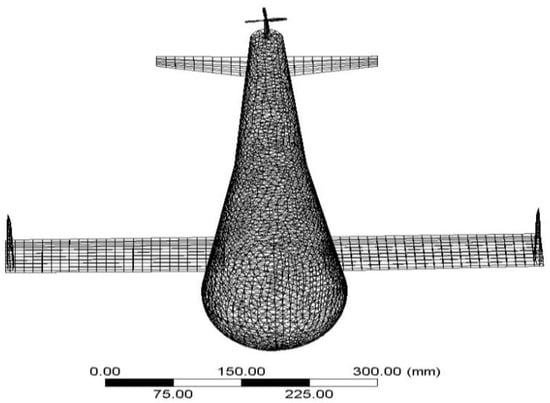

3.1. Computational Aerodynamic and Hydrodynamic Fluid Analyses

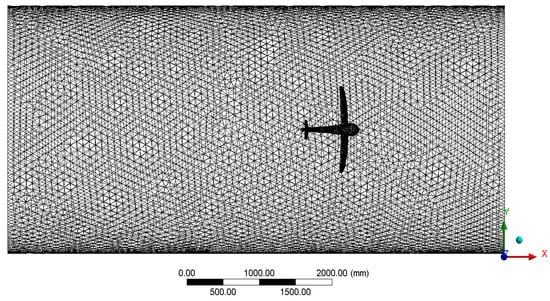

Fluid dynamic analysis provides a link between the pressure, velocity and geometry of channels or closed volume through which the flow occurs. The two main purposes of fluid dynamic analysis are to find whether our UAV can overcome the drag force, so that the required RPM of the propeller can be calculated, and to analyse how much impact the fluid has on the solid body of the UAV. A cylinder-shaped enclosure is used to enclose the bodies of the model. The respective dimension for enclosure is 250 cm radius. The flow direction is “X” axis, so in the positive direction 250 cm and for negative direction 7.5 m enclosure is created. The negative direction was longer than the positive in order to analyse the flow after the UAV. The reference length for the construction of this study’s control volume is chosen as the length of the UAV. For the main flow direction, the control volume was extended up to 9.375 times the length of the UAV. For the remaining directions, the control volume was extended up to 3.5 times the length of the UAV. Additionally, in this current study, the authors gave specified values at the exterior point of the control volumes instead of the pressure far field, so this constructed control volume is fit to provide reliable outcomes. Additionally, we referred to this paper when constructing the control volume, in which the referred paper executed the domain independence study, allowing us to obtain the optimised dimensions. Then, the Boolean operation was carried out in order to subtract the model from the enclosure because the nature of this analysis is external flow analysis. The updated control volume was discretised into small volumes, in which the compositional parts formed are nodes and elements. The type of mesh used for UAV was unstructured grid. Proximity and curvature were chosen for size function because the area varies depending on the location of the UAV. Fine relevance centre was used to obtain minute nodes, and medium smoothening was used. Finally, the quantity of mesh attained had a minimum value of 0.95 and a maximum value of 0.9925. The wireframe model of the discretised structure is revealed in Figure 8.

Figure 8.

Discretization of computational model.

After discretization, the boundary conditions must be given for the UAV model. The given boundary to a model can give the required result, which is highly reliable in nature. Therefore, four boundaries are given to the computational model. In the “X” direction, inlet and outlet are given using named selection, and the subtracted part is given as UAV. Finally, the rest of the parts are given as wall. For the inlet, the hydro fluid velocity is given as 5 m/s and the aero fluid velocity is given as 10 m/s. On outlet, 0-gauge pressure is maintained for both the cases. For the wall and UAV, no-slip and specified shear are given, respectively. A pressure-based solver was chosen, and the model used was k-epsilon to improve the accuracy of the results. Second order upwind was also chosen as the solution method in order to obtain accurate results. The material used was fluid with a density of 1025 kg/m3 for hydrodynamic computation and a fluid density of 1.2256 kg/m3 was used for aerodynamic computation. Three major fluid dynamic computations were investigated: aerodynamic studies on an UAV when it is flying above the ocean, aerodynamic-cum-hydrodynamic studies on an UAV when it is flying on the ocean’s surface, and hydrodynamic studies on an UAV when it is flying in the ocean at a depth of 5 m [60,61,62,63,64,65,66].

3.1.1. Grid Convergence Study—I

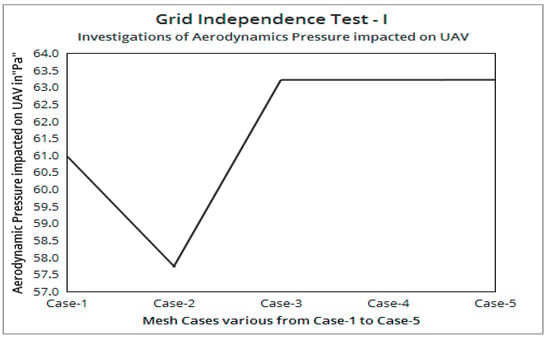

To select a suitable grid that will ensure a reliable outcome, the grid convergence test was conducted on various computational analyses. Therefore, this comprehensive investigation executed two different grid independent tests: the grid finalization test for aerodynamic fluid computation and the grid finalization test for equivalent stress-based hydro-structural computation. Figure 9 shows the comparative mesh outcomes of the first grid convergence test. A total of five different mesh cases were put under both tests, wherein unstructured fine, unstructured fine proximity, unstructured fine curvature, unstructured fine with adoptive mesh, and unstructured fine with inflation are the various five mesh cases used. The statistical data of mesh elements are listed in Table 11.

Figure 9.

Grid Independence Test-I.

Table 11.

Comparative statistical information of all the mesh cases.

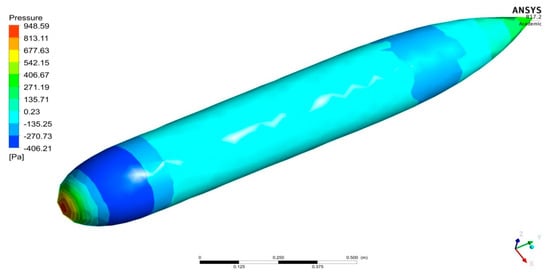

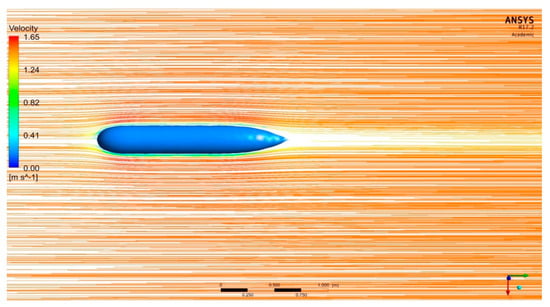

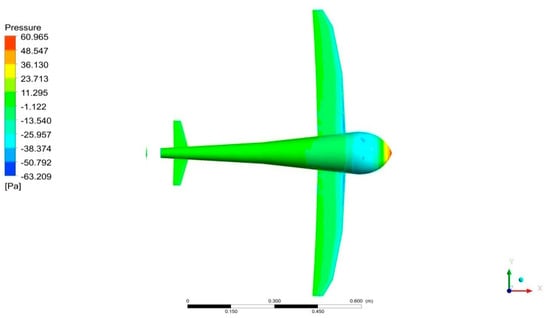

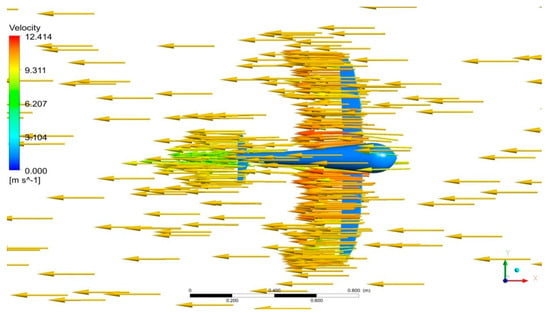

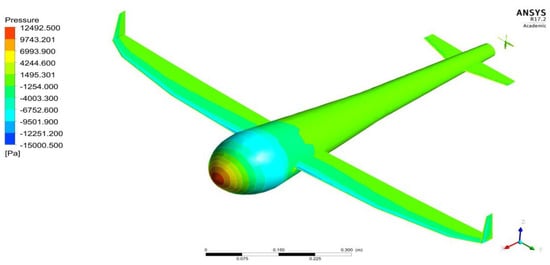

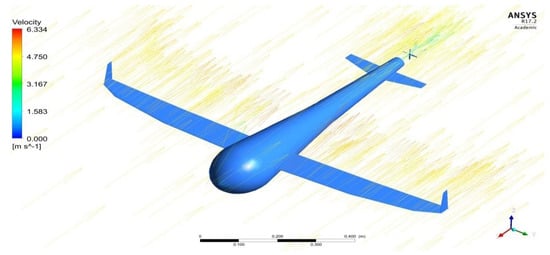

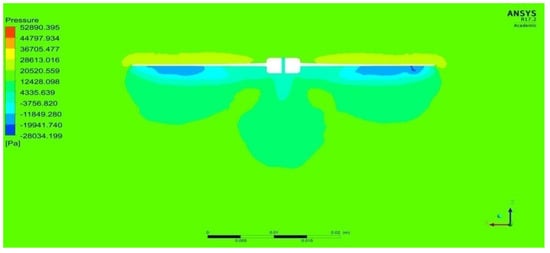

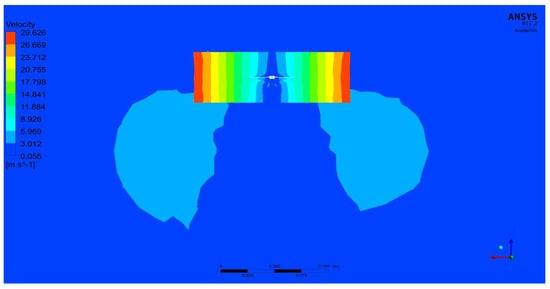

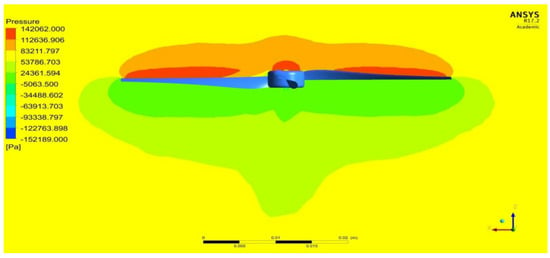

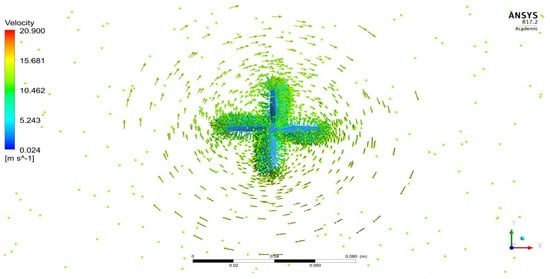

3.1.2. Experimental Validation

Since this suggested computational technique produces approximate results, the implementation of experimental validations and grid convergence tests is an important step. As a result, this work has been completed in order to compute both of the aforementioned outcome sensitivity tests. The relevant experimental outcome-based fuselage model of the UAV was derived by a complete literature review [50,51,52]. The same fuselage model was used for a computational hydrodynamic simulation using extracted beginning circumstances such as water velocity, design data, and so on. The current study’s authors’ finalised boundary conditions have been placed on the computations mentioned above to determine the computational outputs. The obtained computational outcomes are revealed in Figure 10 and Figure 11. The focused outcomes of this validation are the hydrodynamic pressure acting on the fuselage model, the hydrodynamic velocity variations over the fuselage, and the drag force induced on and over the fuselage. Figure 10 shows the hydrodynamic pressure distributions on the fuselage model, wherein the maximum pressure is acting on the nose of the UAV’s body. The velocity variations over the fuselage are shown in Figure 11, in which both vector and streamline-based representations have been used to understand the formation of turbulence in a clear manner.

Figure 10.

A typical representations of hydrodynamic pressure variations on the fuselage model—Validation study.

Figure 11.

A systematic representation of velocity variations over the fuselage model—Top view.

The comprehensive outcomes of drag force induced on the fuselage model of the experimental model [50,51,52] and the computational approaches of this work are computed, compared, and listed in Table 12. The error percentage has been obtained, which was around 2%. Thus, these proposed boundary conditions and computational procedures are validated to provide reliable outcomes on UAVs.

Table 12.

Comprehensive outcomes of drag for both computational and experimental outcomes [50,51,52].

3.2. Computational Aero-Structural and Hydro-Structural Analyses

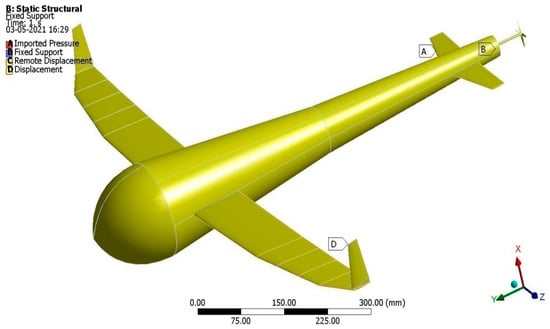

The pressure of the fluid can deform or translate the structures that interact with them. The fluid also changes the structural and thermal stresses in the structures, therefore the flow pattern after the structure and induced velocity may also differ. So, the hydro structural interaction (HSI) analysis helps to identify those impacts. Another purpose of this proposed HSI analysis is to estimate the suitable material to withstand the hydrodynamic impact load. Thus, the best lightweight material to resist the fluid loads for the UAV for all kinds of oceanic working environments can be estimated. For HSI, the computational fundamental model is the design of an UAV. The deformation, equivalent stress, and normal stress over an UAV are the major outcome of these HSI analyses. Computationally, meshing plays a major role that can help form better results and fast calculations. The type of mesh used for an UAV is unstructured mesh because the complicated curvature design of an UAV is directly linked with the generation of mesh. Proximity and curvature-based mesh features are chosen for size function, owing to the variations in the area of different locations of an UAV. The discretised structure of an UAV for structural simulation is clearly revealed in Figure 12. After discretization, the boundary conditions are applied on the UAV. Fixed support is given at the end of the UAV and the root face of the wing. Remote displacement is given to guide the deformation from a point on the hub region of the integrated propeller and finally the pressure load is imported through a one-way coupling approach-based HSI simulation. The detailed given boundary conditions of this advanced UAV are revealed in Figure 13.

Figure 12.

Meshed structure of UAV for HSI simulation.

Figure 13.

Boundary conditions imposed under HSI environment.

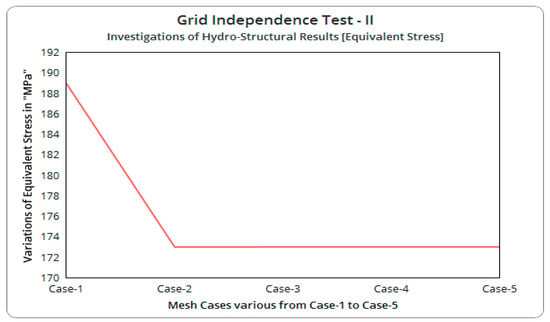

Grid Convergence Study—II

From Figure 9, it is observed that mesh case-3 performed better than other cases based on its low compositional elements and high reliability outcomes. In previous mesh studies, mesh case-3 had an unstructured fine curvature with area proximity. Figure 14 shows the comparative mesh outcomes of the second grid convergence test. From Figure 14, it is observed that mesh case-2 performed better than other mesh cases based on the equivalent stress-based outcomes of hydro-structural computation. Mesh case-2 is unstructured fine proximity. Hence the same shortlisted mesh cases are extended for all other simulations. The complete mesh data for this second study are listed in Table 13.

Figure 14.

Grid Convergence Test-2.

Table 13.

Comparative information of all the mesh cases.

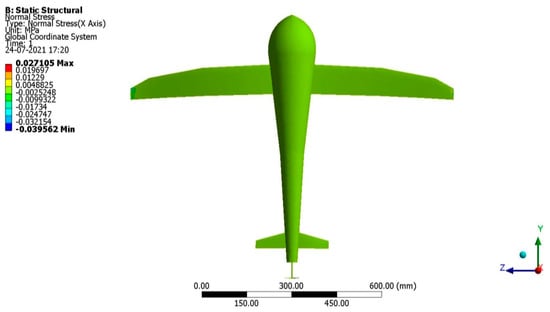

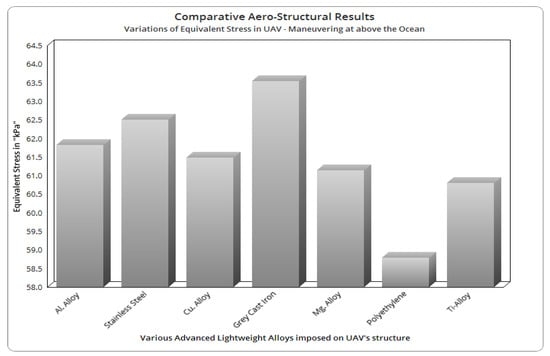

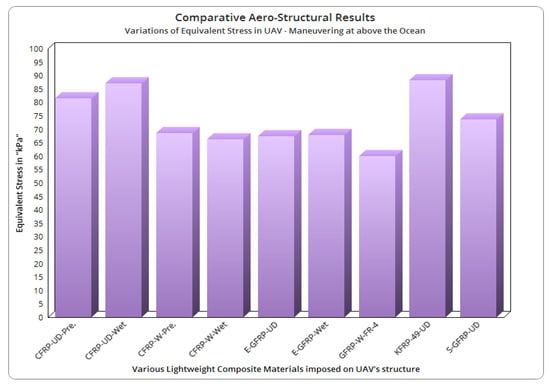

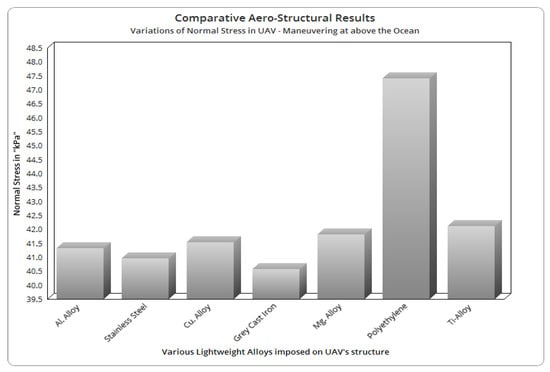

4. Results and Discussions

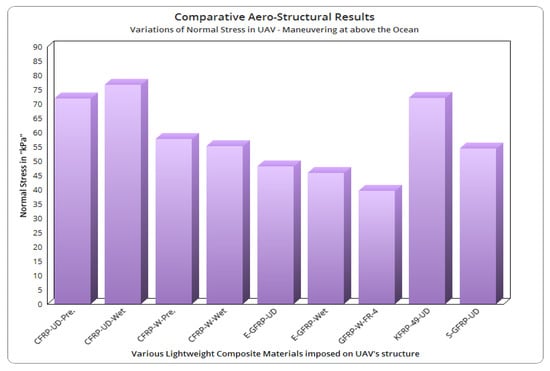

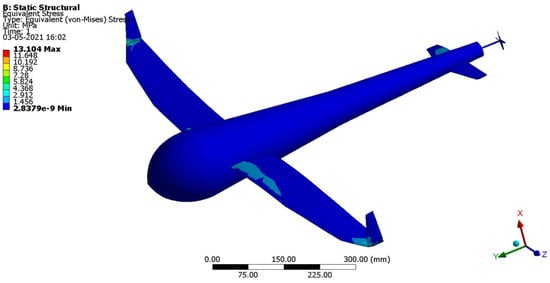

The major outcomes composed and discussed in these comparative investigations are aero and hydrodynamic forces acting on an UAV, aero and hydrodynamic pressure distributions on an UAV, velocity variations over the UAV, structural deformation of an UAV, and stresses induced in an UAV structure. All of the said outcomes predominantly contribute to the selection of lightweight material for an UAV and its overall efficiency. In total, three different oceanic in and above environments were subjected to these advanced computations: above the ocean surface, on the ocean surface, and in the ocean. The computational aerodynamic simulation is computed for above the surface of the ocean, the computational hydrodynamic simulation is computed for in the ocean, finally the combined simulation is computed for on the surface of the ocean. Figure 15, Figure 16 and Figure 17 reveal the results for above the ocean surface and the comprehensive results of the same conditions are revealed in Figure 18, Figure 19, Figure 20 and Figure 21. In which, the attained computational outcome of aerodynamic pressure on UAV for this first grid convergence test is also typically revealed in Figure 15. Computational investigations are extended to the interior of the ocean surface in the same way that they are performed outside of it, and the necessary computational findings are then captured.

Figure 15.

Aerodynamic Pressure variations on UAV when flying above the ocean.

Figure 16.

Velocity generation over the UAV when flying above the ocean.

Figure 17.

Stress induced in UAV—Manoeuvring at above the ocean.

Figure 18.

Comparative Equivalent Stress Variations for various alloys.

Figure 19.

Comparative Equivalent Stress Variations for various composites.

Figure 20.

Comparative Normal stress variations for various alloys.

Figure 21.

Comparative Normal stress variations for various composites.

4.1. CFD Results—Above the Surface of Oceans

4.2. HSI Results—Above the Surface of Oceans

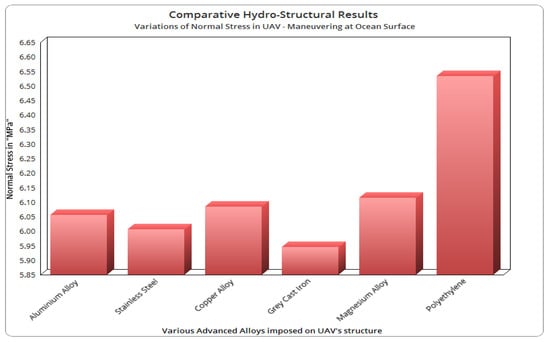

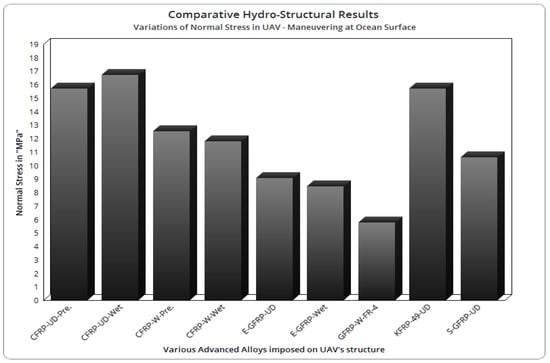

The normal stress induced in an UAV under a GFRP (Glass Fibre Reinforced Polymer)-W-FR4-based composite is revealed in Figure 16. Apart from this material, various other lightweight materials are also subjected to HSI simulations, in which the implemented materials are Aluminium Alloy, Stainless Steel, Grey Cast Iron, Magnesium Alloy, Polyethylene, Copper Alloy, Ti-Alloy, CFRP (Carbon Fibre Reinforced Polymer)-UD-Prepreg, CFRP-UD-Wet, CFRP-Woven-Prepreg, CFRP-Woven-Wet, E-Glass-UD, E-Glass-Wet, FR-4-Glass-Woven, S-Glass-UD, KFRP (Kevlar Fibre Reinforced Polymer)-49-UD. The best seven advanced alloys are picked and imposed for both of the aerodynamic and hydrodynamic impacted structural computations. Similarly, under the composite material category, the nine better lightweight materials are imposed above said HSI simulations. The selection factors involved in this study for the suitability of lightweight material to resist both aerodynamic and hydrodynamic loads are low reactance of deformation and low induction of stresses.

Equivalent stress and total deformations of various lightweight materials are comprehensively represented in Figure 18, Figure 19, Figure 20 and Figure 21. From Figure 18, Figure 19, Figure 20 and Figure 21, it is strongly observed that the GFRP-W-FR4-based composite has a lower reaction than other lightweight materials under aerodynamic load. Thus, the lifetime of this same GFRP composite is quite higher than other lightweight material.

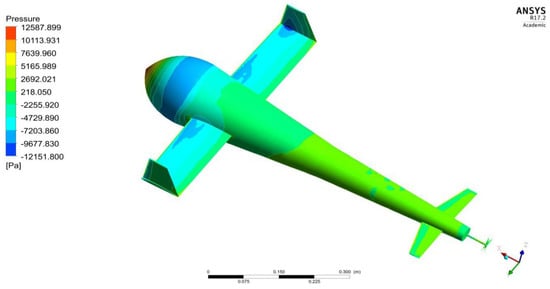

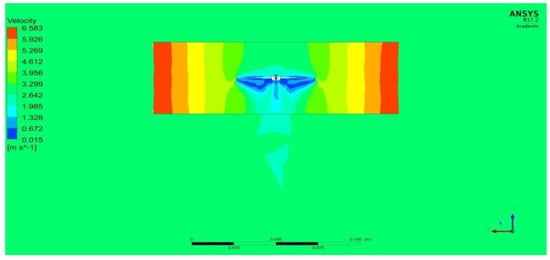

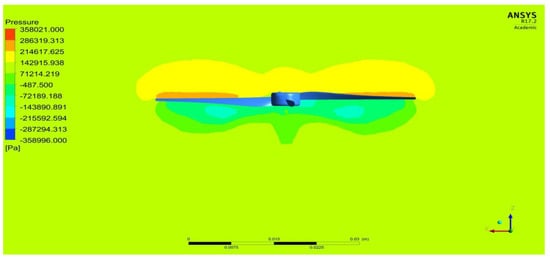

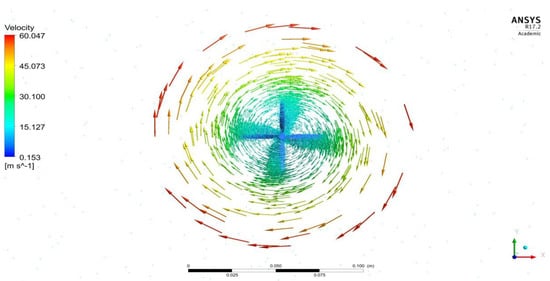

4.3. CFD Results—On Surface of the Oceans

Using ANSYS Fluent, the hydrodynamic-cum-aerodynamic forces of UAV when it is being manuvere on the surface of the ocean are computed and the pressure load on the UAV, velocity flow over the UAV are estimated for 0.1 m depth under the water. The maximum pressure on the UAV is obtained as 15,000.9 Pa and the minimum of pressure is predicted as 1254 Pa. The pressure variations in UAV are clearly expressed in Figure 22.

Figure 22.

Hydrodynamic pressure distributions on UAV.

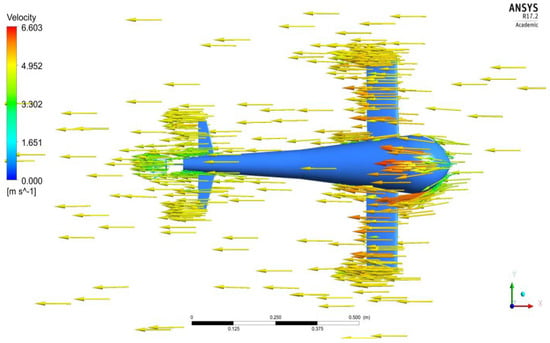

The velocity flow over a UAV is apparently the same at different locations. The different view of velocity over the UAV is shown in Figure 23. The input velocity on the surface is measured and given as 5 m/s and thereby the induced velocity increased by 1.334 m/s [58].

Figure 23.

Velocity variations over the UAV.

The hydrodynamic forces of Lift, Drag and Side forces are 66.91 N, 37.24 N and 0.18 N, respectively. The lift force is a little higher than the required amount. The reason for this is the span of the wing. Then, the drag force is acceptable. Using that value, the rpm of the propeller is fixed. Only then can it overcome the drag force. Additionally, the side force was also estimated for general purposes.

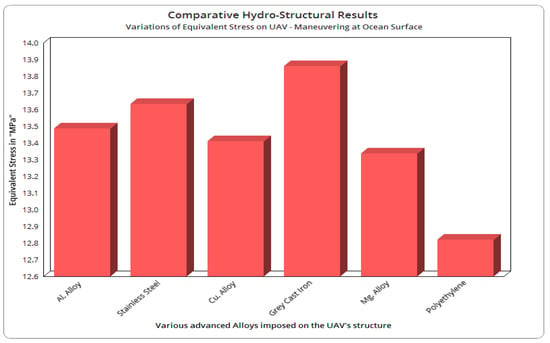

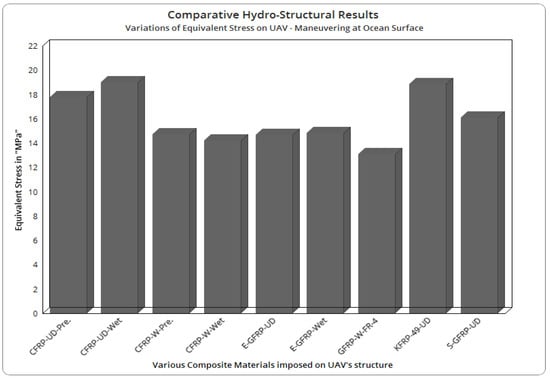

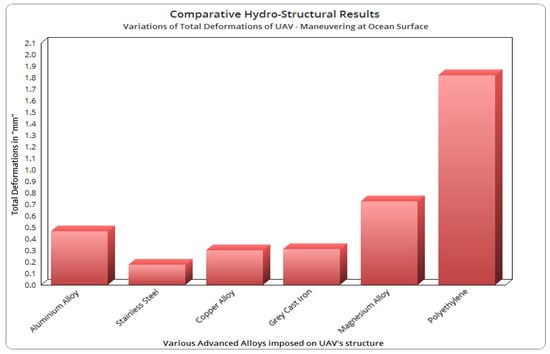

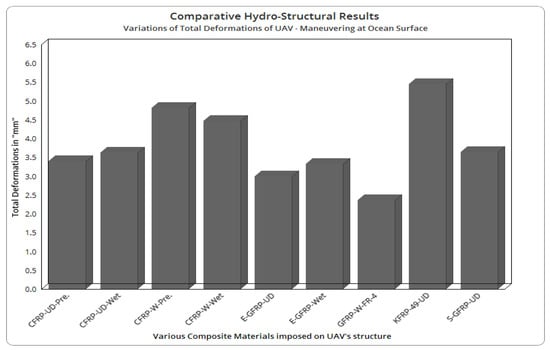

4.4. HSI Results—On Surface of the Oceans

As per the aerodynamic-based HSI simulation, the same sixteen lightweight materials are chosen for this hydrodynamic analysis. The pressure load, which is estimated at a 0.1 m depth, is given as the input to the structural simulation. For each material, the equivalent-elastic strain, equivalent stress, normal stress, elastic strain and total deformation values are estimated using the ANSYS structural tool. The typical equivalent stress variations induced in this proposed UAV under loaded with material properties of GFRP-FR-4-Woven is shown in Figure 24. Based on the low reactance of structural outcomes, the best material is picked to resist this environmental condition.

Figure 24.

Variations in Equivalent Stress of GFRP-FR-4-Woven.

The comprehensive results of this condition are revealed in Figure 25, Figure 26, Figure 27, Figure 28, Figure 29 and Figure 30, wherein the total deformation, equivalent stress, and normal stress are focally considered as selection parameters.

Figure 25.

Comparative equivalent stress variations for various alloys.

Figure 26.

Comparative equivalent stress variations for various composites.

Figure 27.

Variations of total deformations of different alloys.

Figure 28.

Variations of total deformations of different composite materials.

Figure 29.

Comparative normal stress variations for various alloys.

Figure 30.

Comparative normal stress variations for various composites.

In this study, aluminium alloys and stainless-steel were the already existing materials. With reference to the two other materials, the deformation values are compared. Grey cast iron has less equivalent-elastic strain value (0.00013542). Likewise, Polyethylene has less equivalent stress (12.821), FR-4-Glass-woven has less normal stress (5.7784), Copper alloy has less elastic strain (0.007857), and the Copper alloy had less deformation value (0.29923). The deformation of material is more important, therefore Copper alloy was selected for an UAV under the alloy category. From Figure 25, Figure 26, Figure 27, Figure 28, Figure 29 and Figure 30, it can be observed that the GFRP-W-FR4-based composite reacted lower than the other lightweight materials under both hydrodynamic and aerodynamic loads. Thus, the lifespan of this same GFRP composite is significantly longer than other lightweight material.

4.5. Final Optimised Design and its CFD Results—Inside the Oceans

Due to the high lift generation, the foldable wing is proposed for this advanced UAV. Thus, another part of the foldable wing is implemented in this condition, which is a rectangular wing based on symmetrical aerofoil. The optimised-cum-flexible wing system-supported UAV is modelled and revealed in Figure 31, Figure 32 and Figure 33.

Figure 31.

Design of optimised UAV—A typical view—1.

Figure 32.

Design of optimised UAV—A typical view—1.

Figure 33.

Conceptual design of optimised UAV.

Figure 34 and Figure 35 show the hydrodynamic velocity and pressure variations of the optimised UAV. The working environment picked for this condition is 5 m and the input velocity is assumed as 5 m/s. To clean the maximum number of unwanted ravages from the oceans, the surface of the ocean to a 5 m depth in the ocean is planned through this UAV. Therefore, this computation is mandatory, and the hydrodynamic forces of Lift, Drag and Side forces are estimated as172.8 N, 37.61 N and 0.54 N, respectively [20,21,22,23,24,25,26,27,28,29].

Figure 34.

Hydrodynamic velocity generation over the optimised UAV.

Figure 35.

Hydrodynamic Pressure variations of optimised UAV.

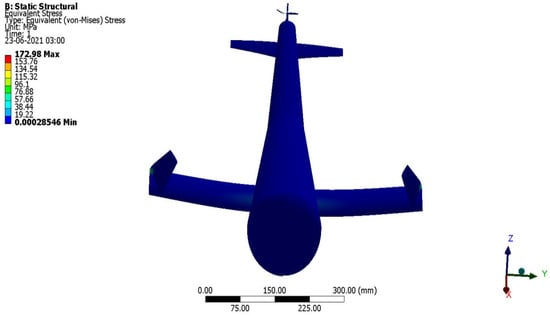

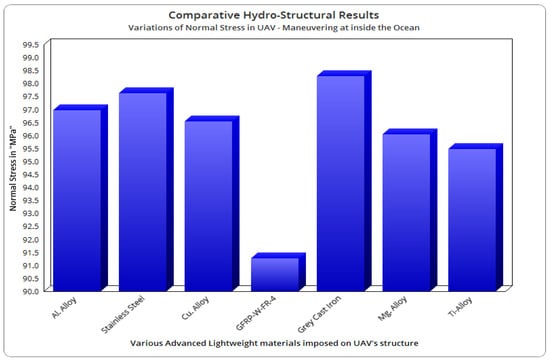

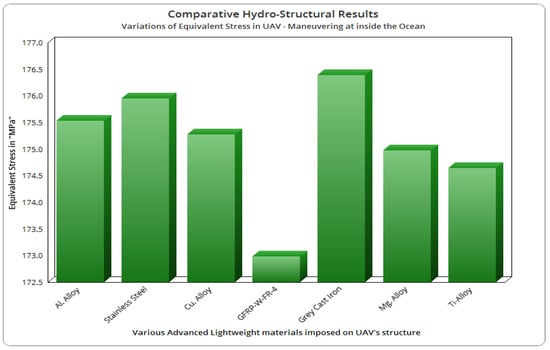

4.6. Final Optimised Design and Its HSI Results—Inside the Oceans

The HSI results on this condition are computed and the relevant outcomes are revealed in Figure 36, Figure 37, Figure 38, Figure 39 and Figure 40. Figure 36 reveals the unstructured feature-based discretised structure of an optimised UAV. Apart from discretization, the boundary condition plays the focal role, which is shown in Figure 37, wherein imposed hydrodynamic pressure and fixed support are mentioned clearly. In the first two investigations, the GFRP composite and all the alloys performed better than the other lightweight materials, so the best seven lightweight materials were chosen to undergo this complicated HSI simulation. The typical hydro-structural outcome of this proposed UAV inside the ocean is revealed in Figure 38, which is predominantly considered for the second grid convergence test of this work. The comprehensive results of normal and equivalent stresses are clearly shown in Figure 39 and Figure 40. From Figure 39 and Figure 40, it is strongly noted that the GFRP-W-FR4-based composite is reacted lower than other lightweight materials under both hydrodynamic loads. Thus, the lifetime of this same GFRP composite is quite higher than other lightweight material. So, the GFRP-Woven-FR4-based lightweight composite is perfect to implement in the structure of UAV because it is able to withstand both aerodynamic and hydrodynamic loads.

Figure 36.

Discretised structure of optimised UAV.

Figure 37.

Boundary conditions imposed in optimised UAV.

Figure 38.

Equivalent Stress of GFRP-W-FR-4 based optimised UAV.

Figure 39.

Comparative normal stress variations for various lightweight materials.

Figure 40.

Comparative equivalent stress variations for various lightweight materials.

5. Ravage Issue and Its Removal Application

The ravage focused on in this work is the debris/waste that forms on the surface of water and submerged to some extent under the water. The debris/waste includes all forms of plastic waste, sewage waste, oil spills, etc. Oil spills are liquid petroleum hydrocarbon released into ocean/water bodies due to manmade disasters, drilling rigs, offshore platforms, etc. The leakage of oil spills in the ocean is a form of pollution, especially marine. These oil spills have adverse effects on the marine ecosystem in such a way that it forms a blocking coat over the surface of the water. This blockade does not allow the oxygen to dissolve in and out of the water. This in turn causes marine species to suffer from insufficient dissolved oxygen, thus causing the death of living marine organisms. These oil spills not only affect the fish in the marine ecosystem but also birds and other mammals. More specifically, oil spills penetrate the anatomical structure of the plumage of birds and the fur of other mammals. Due to this penetration, they lose their insulating ability. This in turn will make them vulnerable to more temperature fluctuations. This will also make them denser and so they become less buoyant. These oil spills also have adverse effects on society. Unfortunately, the fact is that cleaning the oil spills is a difficult task and it depends on many factors such as the type of oil that is spilled, the water temperature, the type of shoreline, the type of beaches/ocean involved, etc. Cleaning the oil spills physically is also very expensive. The method of bioremediation using bacteria is a better method, but only to some extent, since abundant bacteria is needed and this method also requires support from external factors. The Seabin project can also be a possible solution, but that is a static model. Similar to these techniques, fewer advances have made to clean up the oil spills, but these were not cost efficient. By considering all these factors, the idea of building a dynamic movable model capable of locating the debris and cleaning up such spills was developed. This dynamic movable model is the UAV, which could prove to be a possible solution in the near future [20,21,22,23,24,25,26,27,28,29].

The collection and removal ravage system-based UAV phases and its corresponding components are revealed in Figure 41 and Figure 42. With the help of three different environmental conditions-based multi-disciplinary investigations, the proposed dynamic model of an UAV-based ravage collector has been constructed, with the inclusion of all the major conclusions from the abovementioned three comparative investigations. The constructed dynamic ravage collector UAV is ready for deployment.

Figure 41.

Components and arrangements of UAV at the stage of collection of ravage.

Figure 42.

Components and arrangements of UAV at the stage of removal of ravage.

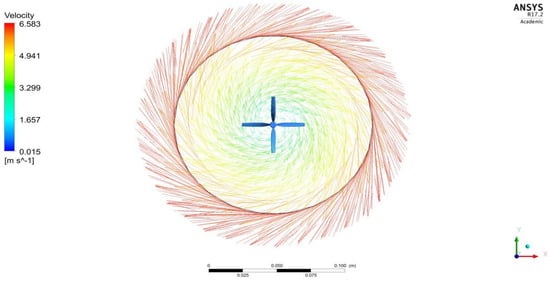

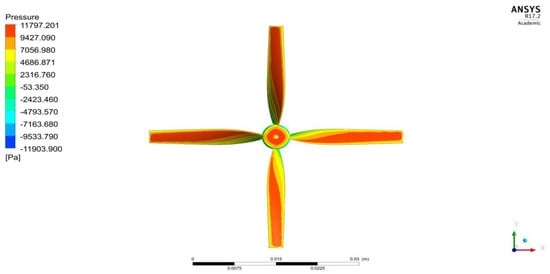

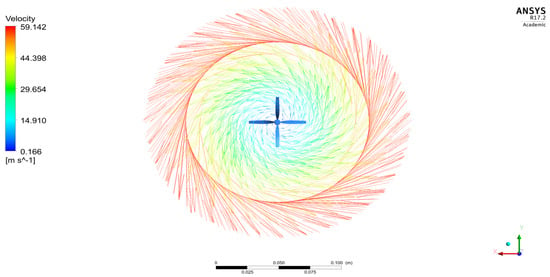

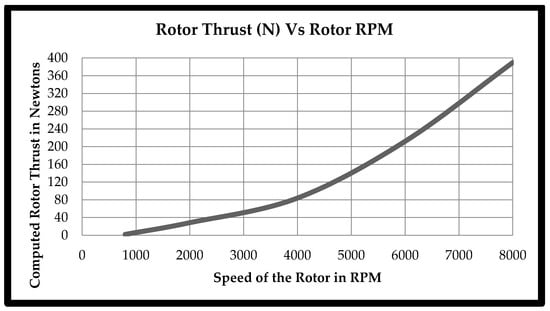

Comprehensive Investigation on Propeller

The minimum thrust requirement to move this proposed UAV is 55.92 N. This comprehensive investigation on propellers through CFD-SMRF has been executed in order to determine the suitable RPM condition for a propeller. With the known initial conditions and boundary conditions, comprehensive simulations were carried out. The fluid dynamic-based steady state with rotational speed outcomes are revealed in Figure 43, Figure 44, Figure 45, Figure 46, Figure 47 and Figure 48 and the comprehensive outcomes are revealed in Figure 49.

Figure 43.

A typical planar view-based variations of velocity in and over the different frames.

Figure 44.

Hydrodynamic fluid variations in and over the propeller—Top view.

Figure 45.

Hydrodynamic pressure distributions on the propeller—Front view.

Figure 46.

A typical planar representation of hydrodynamic pressure distributions on UAV propeller under the conditions of 3 m/s and 4000 RPM.

Figure 47.

A typical planar representation of hydrodynamic velocity variations over the UAV propeller under the conditions of 3 m/s and 4000 RPM.

Figure 48.

A typical vector representation of hydrodynamic velocity variations over the UAV propeller under the conditions of 3 m/s and 8000 RPM.

Figure 49.

Comprehensive outcomes between rotor thrust and rotor RPM.

Figure 49 is perfectly supported for the selection of the working speed of the proposed propeller. An additional computation is carried out with the help of ANSYS Fluent on the US propeller, wherein the needful wave energy-based input data are given as boundary conditions. The general relationships for intermediate depth wave are given below (Equations (26) and (27)) for the purpose of estimating the needful wave speed. This wave speed will serve as the major initial condition to the advanced computational simulation, which is based on wave energy-imposed computation. During an energetic swell, a wave buoy records a Significant Wave Height of 2.1 m and a Peak Period of 9.3 s. The mooring depth is 32 m [66].

With the help of known data and conditions, the simulations are carried out and thereby the important outcome, such as mean wavelength, is 96.78 m and wave celerity is 12.10 m/s. The wave energy impacted computational outcomes are revealed in Figure 50, Figure 51, Figure 52 and Figure 53.

Figure 50.

Hydrodynamic pressure variations over the UAV propeller under 800 RPM with wave celerity of 12.10 m/s.

Figure 51.

Hydrodynamic velocity variations on the UAV propeller under 800 RPM with wave celerity of 12.10 m/s.

Figure 52.

Hydrodynamic pressure variations over the UAV propeller under 8000 RPM with wave celerity of 12.10 m/s.

Figure 53.

Hydrodynamic velocity variations on the UAV propeller under 8000 RPM with wave celerity of 12.10 m/s.

The attained outcomes are affected by the forces of this proposed propeller, so to overcome this issue, the current study proposes a variable pitch propeller and flexible wing system. With the help of these flexible techniques along with servo, the controller of the US can change the angle of attacks of the wing and propeller by considering the wave inputs.

6. Conclusions

The paper includes a conceptual design of a flexible and efficient UAV. Bio-inspired species of this UAV have the high stability to withstand conditions on and under the water. Since the tropic bird can fly with high stability and high manoeuvring capacity, the bio-inspired UAV can implement the mission without any disturbances and execute the sudden depth variations with payload. Once the conceptual design of the UAV was modelled with the help of CATIA, the aerodynamic and hydrodynamic forces were estimated using ANSYS Fluent. The drag forces were monitored clearly, and the same forces were indented to design and select the suitable propulsive system for this highly manoeuvrable UAV. The velocity flows over an UAV at various working oceanic environments are apparently the same and linear in different locations because of this proposed UAV’s design. Therefore, the drag generated is quite lower than other conventional UAV models. Additionally, the HSI analyses are computed on an UAV in two different working environments (above and on the ocean surfaces) under the counts of sixteen lightweight materials and thereby the suitable materials are picked to withstand such conditions. A common observation is that alloys are able to withstand complicated fluid loads and the GFRP-Woven-FR4-based composite material is the overall best performer. The next HSI analysis was carried out on an UAV under the ocean at the depth of 5 m and so the suitable material was picked to resist such an environment. One major observation found that the GFRP-Woven-FR4-based composite material is the best lightweight material to resist all kinds of oceanic environments, thus the same material is strongly suggested for implementation in the UAV’s real-time application. The designed UAV is capable of providing good conditions for the cleaning mechanism to take place. The bio-inspired structure of the UAV when modelled gives extraordinary support to ravage removal. This will set the base for inventions in ravage removal.

Author Contributions

Conceptualization, V.R., S.G. and D.M.; methodology, V.R., S.G. and D.M.; software, V.R., S.G. and D.M.; validation, V.R., S.K.M. and H.A.Z.A.-b.; formal analysis, V.R. and H.A.Z.A.-b.; investigation, S.K.M. and P.R.; resources, V.R. and P.R.; data curation, V.R. and S.K.M.; writing—original draft preparation, V.R. and P.R.; writing—review and editing, M.A.-B., P.R. and V.R.; visualization, H.A.Z.A.-b., M.A.-B. and P.R.; supervision, P.R.; project administration, P.R.; funding acquisition, P.R. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by a Universiti Sains Malaysia, Bridging GRA with Project No: 304/PAERO/6316608.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The Aircraft Design and Analyses Laboratory, Department of Aeronautical Engineering, Kumaraguru College of Technology (KCT), Coimbatore-641049, Tamil Nadu, India, supports the computational resources used in this work. As a result, the authors of this article would like to thank all of the top management and professionals.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Madasamy, S.K.; Raja, V.; Ganesan, S.; Murugan, D.; Raji, A.P.; Jayaram, D.K. Conceptual Design, and Fluid-Structural Interaction Based Investigations on Highly Maneuverable Unmanned Amphibious Vehicle for Ravage Removal Applications at Various Oceanic Working Environments. Res. Sq. 2021; preprint. [Google Scholar] [CrossRef]

- Wainwright, D.K.; Lauder, G.V. Tunas as a high-performance fish platform for inspiring the next generation of autonomous underwater vehicles. Bioinspir. Biomim. 2020, 15, 035007. [Google Scholar] [CrossRef] [PubMed]

- Bozkurttas, M.; Tangorra, J.; Lauder, G.; Mittal, R. Understanding the Hydrodynamics of Swimming from Fish Fins to Flexible Propulsors for Autonomous Underwater Vehicles. Adv. Sci. Technol. 2008, 58, 193–202. [Google Scholar] [CrossRef]

- Negrello, F.; Silvestri, P.; Lucifredi, A.; Guerrero, J.; Bottaro, A. Preliminary design of a small-sized flapping UAV: II. Kinematic and structural aspects. Meccanica 2015, 51, 1369–1385. [Google Scholar] [CrossRef]

- Joung, T.-H.; Jae-Hwan, L.; Nho, I.; Jong-Moo, L.; Lee, P.-M. A Study on the Structural Design and Analysis of a Deep-sea Unmanned Underwater Vehicle. J. Ocean Eng. Technol. 2006, 20, 7–14. [Google Scholar]

- Wang, Q.; Wu, S.; Hong, W.; Zhuang, W.; Wei, Y. Submersible Unmanned Aerial Vehicle: Configuration Design and Analysis Based on Computational Fluid Dynamics. MATEC Web Conf. 2017, 95, 7023. [Google Scholar] [CrossRef]

- Li, Y.; Hu, J.; Zhao, Q.; Pan, Z.; Ma, Z. Hydrodynamic Performance of Autonomous Underwater Gliders with Active Twin Undulatory Wings of Different Aspect Ratios. J. Mar. Sci. Eng. 2020, 8, 476. [Google Scholar] [CrossRef]

- Tangorra, J.L.; Davidson, S.N.; Hunter, I.W.; Madden, P.G.A.; Lauder, G.V.; Dong, H.; Bozkurttas, M.; Mittal, R. The Development of a Biologically Inspired Propulsor for Unmanned Underwater Vehicles. IEEE J. Ocean. Eng. 2007, 32, 533–550. [Google Scholar] [CrossRef]

- Joung, T.-H.; Sammut, K.; He, F.; Lee, S.-K. Shape optimization of an autonomous underwater vehicle with a ducted propeller using computational fluid dynamics analysis. Int. J. Nav. Arch. Ocean Eng. 2012, 4, 44–56. [Google Scholar] [CrossRef]

- Xuel, G.; Liu, Y.; Chen, Z.; Li, S. Motion Model of Fish-like Underwater Vehicle and its Effect on Hydrodynamic Performance. In Proceedings of the International Symposium on Mechatronics and Its Applications, ISMA, Sharjah, United Arab Emirates, 4–6 March 2018; pp. 1–5. [Google Scholar] [CrossRef]

- Gao, A.; Techet, A.H. Design considerations for a robotic flying fish. In Proceedings of the OCEANS’11 MTS/IEEE KONA, Waikoloa, HI, USA, 19–22 September 2011. [Google Scholar] [CrossRef]

- Zihao, W.; Ye, L.; Aobo, W.; Xiaobing, W. Flying Wing Underwater Glider: Design, Analysis, and Performance Prediction. In Proceedings of the 2015 International Conference on Control, Automation and Robotics, Singapore, 20–22 May 2015. [Google Scholar] [CrossRef]

- Mathaiyan, V.; Murugesan, R.; Madasamy, S.K.; Gnanasekaran, R.K.; Sivalingam, S.; Jung, D.W. Conceptual Design and Numerical analysis of an Unmanned Amphibious Vehicle. In Proceedings of the AIAA 2021-1285 Session: Unmanned Systems IX, Nashville, TN, USA, 11–15 & 19–21 January 2021. [Google Scholar] [CrossRef]

- Javaid, M.Y.; Ovinis, M.; Hashim, F.B.; Maimun, A.; Ahmed, Y.M.; Ullah, B. Effect of wing form on the hydrodynamic characteristics and dynamic stability of an underwater glider. Int. J. Nav. Arch. Ocean Eng. 2017, 9, 382–389. [Google Scholar] [CrossRef]

- Alam, K.; Ray, T.; Anavatti, S.G. An Evolutionary Approach for the Design of Autonomous Underwater Vehicles. In Proceedings of the 25th Australasian Joint Conference on Advances in Artificial Intelligence (AI 2012), Sydney, NSW, Australia, 2–4 February 2022; LNCS 7691. pp. 279–290. [Google Scholar] [CrossRef]

- Kumar, V.P.; Kumar, S.K.; Pandian, K.S.; Ashraf, E.; Selvan, K.T.T.; Vijayanandh, R. Conceptual Design And Hydrodynamic Research On Unmanned Aquatic Vehicle. Int. J. Innov. Technol. Explor. Eng. 2019, 8, 121–127. [Google Scholar]

- Wadoo, S.; Kachroo, P. Autonomous Underwater Vehicles. Modeling, Control Design, and Simulation; Taylor and Francis Group, LLC: Abingdon, UK, 2011. [Google Scholar]

- Costa, D.; Palmieri, G.; Palpacelli, M.-C.; Panebianco, L.; Scaradozzi, D.; Costa, D. Design of a Bio-Inspired Autonomous Underwater Robot. J. Intell. Robot. Syst. 2017, 91, 181–192. [Google Scholar] [CrossRef]

- Wood, S. Autonomous Underwater Gliders, Underwater Vehicles Book; Intech: London, UK, 2009. [Google Scholar] [CrossRef]

- Eichhorn, M.; Ament, C.; Jacobi, M.; Pfuetzenreuter, T.; Karimanzira, D.; Bley, K.; Boer, M.; Wehde, H. Modular AUV System with Integrated Real-Time Water Quality Analysis. Sensors 2018, 18, 1837. [Google Scholar] [CrossRef] [PubMed]

- Vasudev, K.L. Review of Autonomous Underwater Vehicles, Autonomous Vehicles Book; Intech: London, UK, 2018. [Google Scholar] [CrossRef]

- Amin, O.M.; Karim, A.; Saad, A.H. Development of a highly maneuverable unmanned underwater vehicle on the basis of quad-copter dynamics. AIP Conf. Proc. 2017, 1919, 020009. [Google Scholar] [CrossRef]

- Pandian, R.S.; Vijayanandh, R.; Kumar, S.K.; Kumar, V.P.; Ramesh, M.; Kumar, M.S.; Kumar, G.R. Comparative Hydrodynamic Investigations on Unmanned Aquatic Vehicle for Ocean Applications. In Lecture Notes in Mechanical Engineering Book Series (LNME); Springer: Singapore, 2021; ISBN 978-981-16-2086-7. [Google Scholar] [CrossRef]

- Nesteruk, I.; Passoni, G.; Redaelli, A. Shape of Aquatic Animals and Their Swimming Efficiency. J. Mar. Biol. 2014, 2014, 470715. [Google Scholar] [CrossRef]

- Bettle, M.C.; Gerber, A.G.; Watt, G.D. Using reduced hydrodynamic models to accelerate the predictor–corrector convergence of implicit 6-DOF URANS submarine manoeuvring simulations. Comput. Fluids 2014, 102, 215–236. [Google Scholar] [CrossRef]

- Hamidi, A.; Almubarak, Y.; Rupawat, Y.M.; Warren, J.; Tadesse, Y. Poly-Saora robotic jellyfish: Swimming underwater by twisted and coiled polymer actuators. Smart Mater. Struct. 2020, 29, 045039. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Y.; Zhang, M.; Yang, Z.; Wu, Z. Design and flight performance of hybrid underwater glider with controllable wings. Int. J. Adv. Robot. Syst. 2017, 14, 1729881417703566. [Google Scholar] [CrossRef]

- Alam, K.; Ray, T.; Anavatti, S.G. Design and construction of an autonomous underwater vehicle. Neurocomputing 2014, 142, 16–29. [Google Scholar] [CrossRef]

- Budiyono, A. Advances in unmanned underwater vehicles technologies: Modeling, control and guidance perspectives. Indian J. Geo-Mar. Sci. 2009, 38, 282–295. [Google Scholar]

- Cui, W.; Suming, Q.; Weicheng, C. An Overview on Aquatic Unmanned Aerial Vehicles. Ann. Rev. Res. 2019, 5, 555663. [Google Scholar] [CrossRef]

- Garibal, S.B. Mechanical Design for a New Autonomous Underwater Vehicle (AUV); Project Report; The NPS Institutional Archive: Calhoun, Georgia, 1999; Available online: http://hdl.handle.net/10945/810 (accessed on 14 September 2022).

- Hyakudome, T. Design of Autonomous Underwater Vehicle. Int. J. Adv. Robot. Syst. 2011, 8, 122–130. [Google Scholar]

- Wang, Y.-L.; Tai, C.-H.; Huang, H.-R. Design and development of an autonomous underwater vehicle—Robot dolphin. J. Mar. Eng. Technol. 2015, 14, 44–55. [Google Scholar] [CrossRef]

- Wang, Z.-J.; Nie, Z.-Q.; Li, J.-X.; Ma, Y. Conceptual Design of a Water-air Amphibious Unmanned Vehicle. DEStech Trans. Comput. Sci. Eng. 2019. [Google Scholar] [CrossRef]

- Uiblein, F. Deep-Sea Fish Behavioral Responses to Underwater Vehicles: Differences among Vehicles, Habitats and Species, Autonomous Underwater Vehicles; Cruz, N., Ed.; IntechOpen Limited: London, UK, 2011; ISBN 978-953-307-432-0. [Google Scholar] [CrossRef]

- Fish, F.E. Wing design and scaling of flying fish with regard to flight performance. J. Zool. 1990, 221, 391–403. [Google Scholar] [CrossRef]

- Wang, J.; Wainwright, D.K.; Lindengren, R.E.; Lauder, G.V.; Dong, H. Tuna locomotion: A computational hydrodynamic analysis of finlet function. J. R. Soc. Interface 2020, 17, 20190590. [Google Scholar] [CrossRef]

- Ignacio, L.C.; Victor, R.R.; Francisco, D.R.R.; Pascoal, A. Optimized design of an autonomous underwater vehicle, for exploration in the Caribbean Sea. Ocean Eng. 2019, 187, 106184. [Google Scholar] [CrossRef]

- Park, H.; Choi, H. Aerodynamic characteristics of flying fish in gliding flight. J. Exp. Biol. 2010, 213, 3269–3279. [Google Scholar] [CrossRef]

- Allotta1, B.; Costanzi1, R.; Monni, N.; Pugi, L.; Ridolfi, A.; Vettori, G. Design And Simulation of An Autonomous Underwater vehicle. In Proceedings of the ECCOMAS 2012, Vienna, Austria, 10–14 September 2012. [Google Scholar]

- Kulandaiyaappan, N.K.; Gnanasekaran, R.K.; Raja, V.; Bernard, F.A.; Murugesan, R.; Madasamy, S.K.; Mathaiyan, V.; Raji, A.P.; KAsher, P.; Ponmariappan, J. Optimization of High Payload Unmanned Aerial Vehicle’s Propellers based on Energy Formation by using Computational Vibrational Analyses. In Proceedings of the AIAA Propulsion and Energy 2021 Forum, Virtual, 9–11 August 2021. [Google Scholar] [CrossRef]

- Du, X.-X.; Wang, H.; Hao, C.-Z.; Li, X.-L. Analysis of hydrodynamic characteristics of unmanned underwater vehicle moving close to the sea bottom. Def. Technol. 2014, 10, 76–81. [Google Scholar] [CrossRef]