Study of a Large Square Baler with Innovative Technological Systems that Optimize the Baling Effectiveness

Abstract

:1. Introduction

- The spores contained in vegetable products dirtied with soil influence the number of spores present in the preserved alimony (dried fodder);

- The number of spores present in food affects the number present in the stools, which inevitably contaminate the rearing environment, the animals, the milking equipment and consequently the milk;

- The stools in turn, that come back to the soil as organic fertilizers, return the spores to the soil and may induce contamination phenomena.

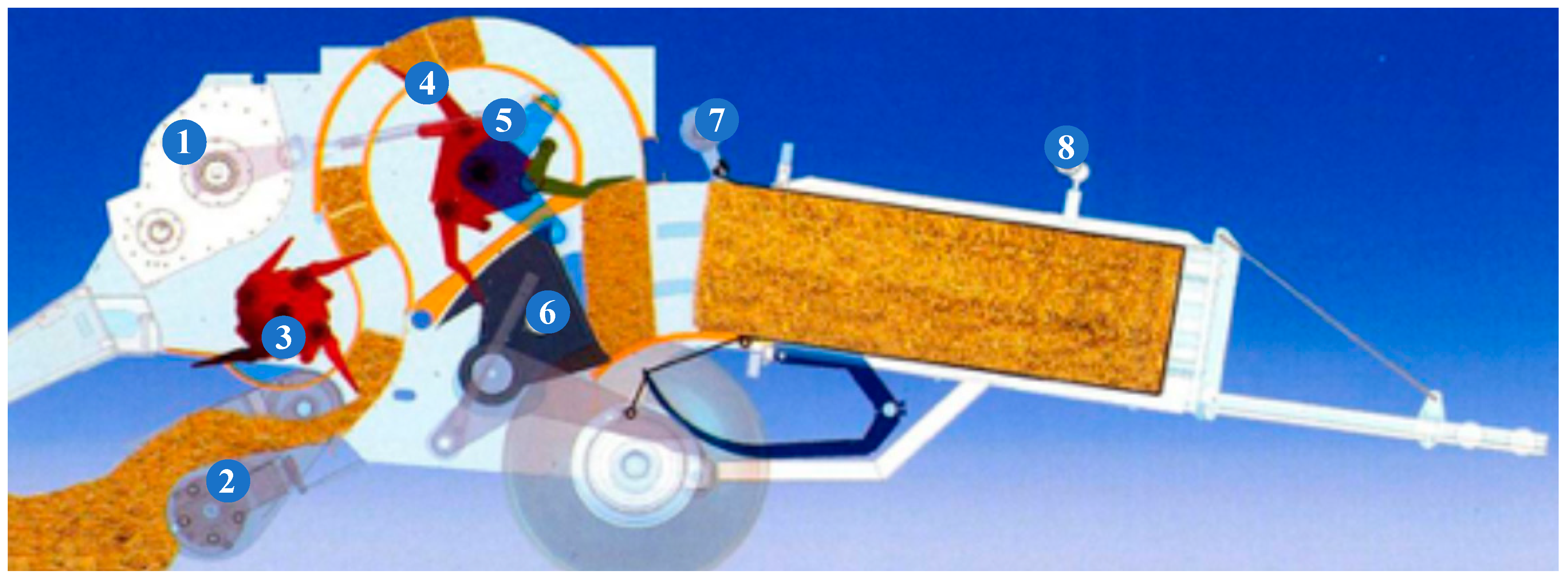

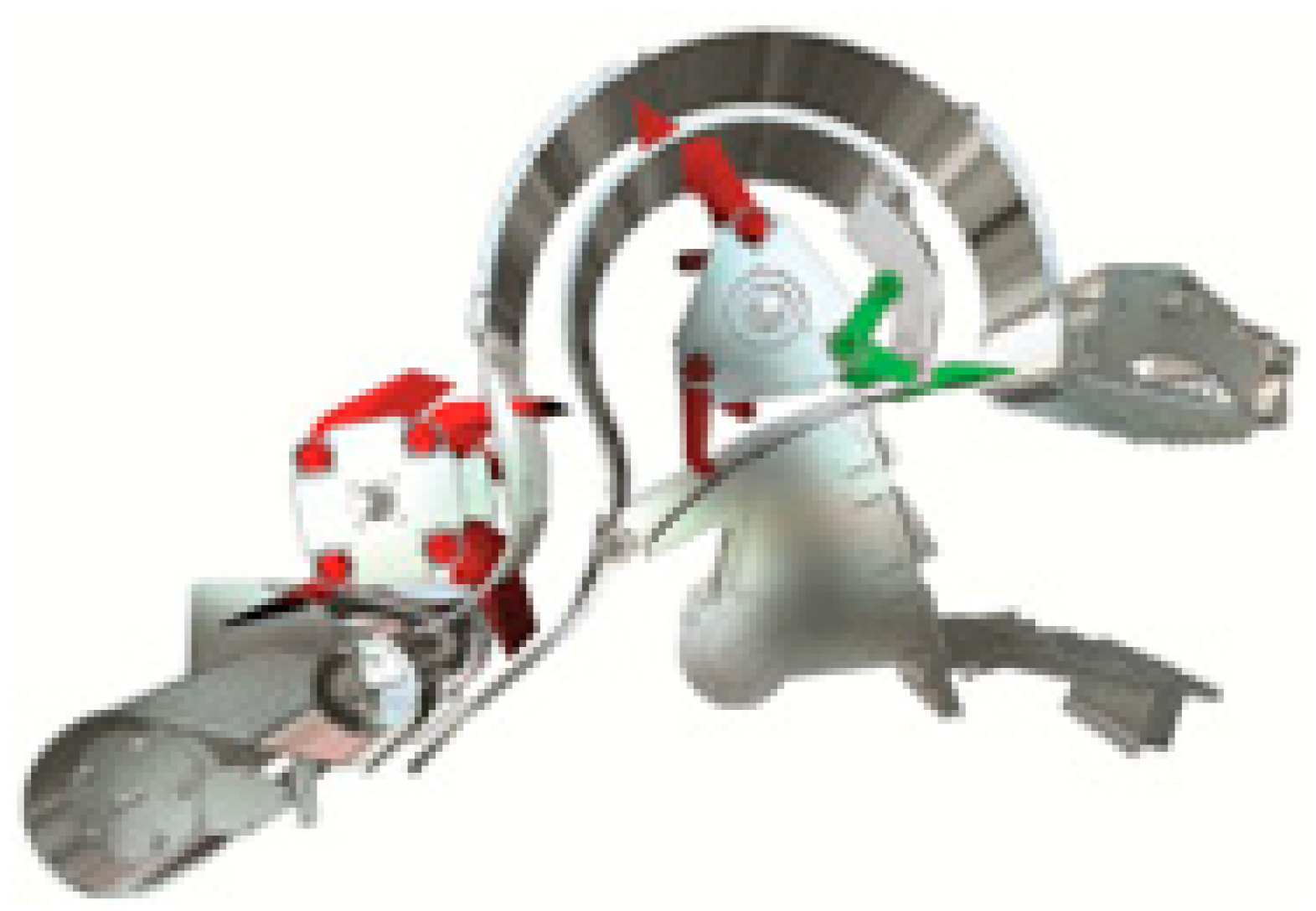

2. Large Square Baler from “Cicoria Square Bales” Manufacturer

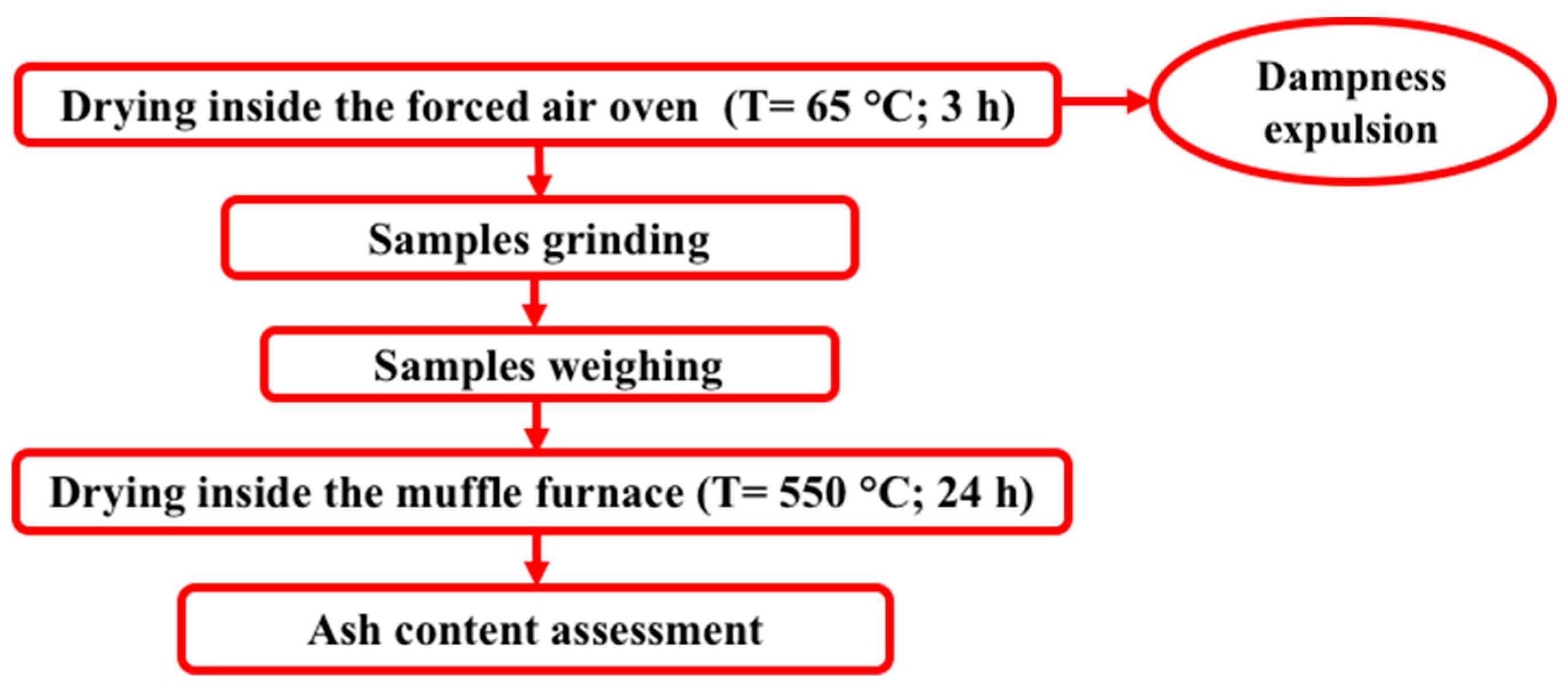

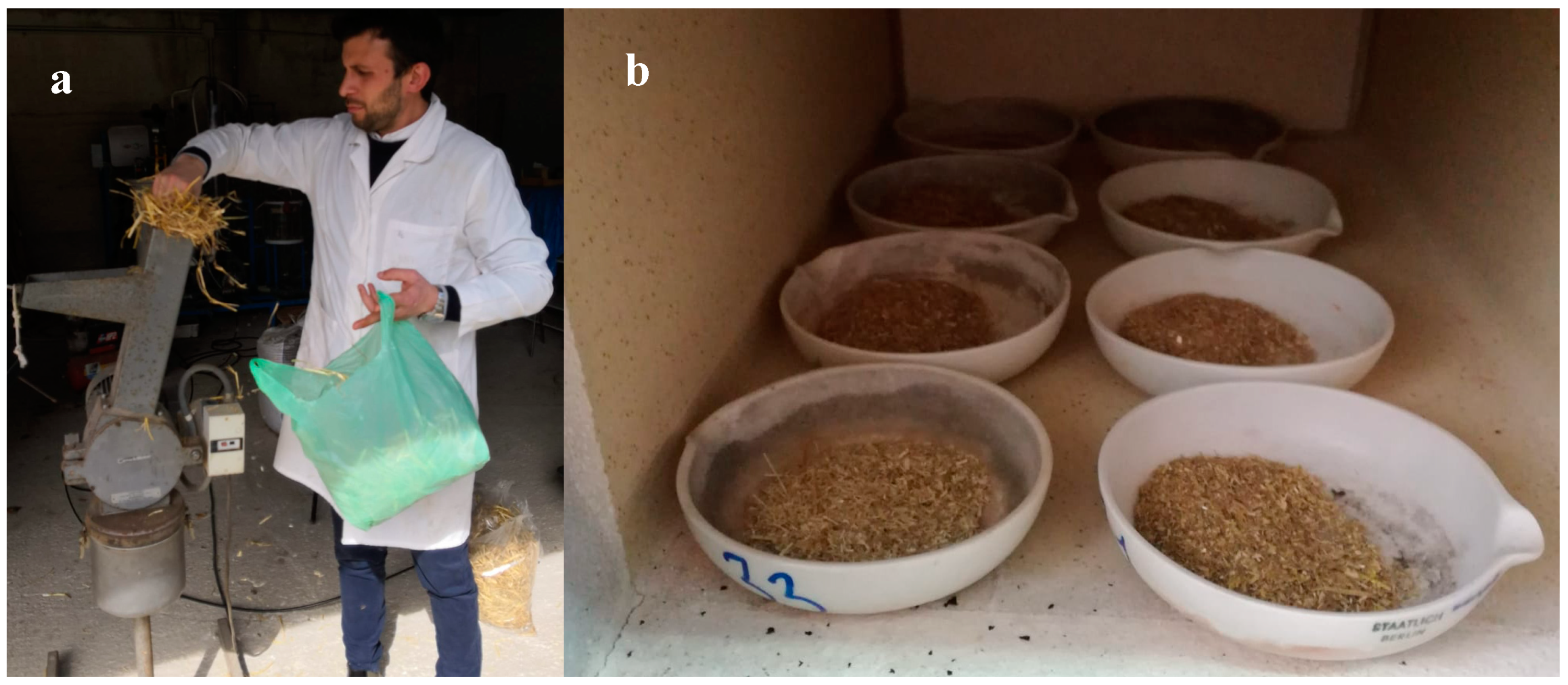

3. Materials and Methods

4. Results and Discussion

5. Conclusions

Author Contributions

Conflicts of Interest

References

- Pöllinger, A. Vergleich unterschiedlicher Heutrocknungsverfahren. In Gumpensteiner Bautagung; Bundesanstalt für alpenländische Landwirtschaft Gumpenstein: Irdning, Austria, 2003; pp. 63–68. [Google Scholar]

- Van Soest, P.J.; Robertson, J.B. Analysis of forages and fibrous feeds. In Laboratory Manual for Animal Science 613; Cornell University: Ithaca, NY, USA, 1985; p. 18. [Google Scholar]

- Shinners, K.J.; Huenink, B.M.; Muck, R.E.; Albrecht, K.A. Storage Characteristics of large round and square Alfalfa: Low moisture wrapped bales. Trans. ASABE 2009, 52, 401–407. [Google Scholar] [CrossRef]

- Amours, L.D.; Savoie, P. Density profile of corn silage in bunker silos. CBE 2005, 47, 221–228. [Google Scholar]

- Manetto, G.; Cerruto, E.; Pascuzzi, S.; Santoro, F. Improvements in citrus packing lines to reduce the mechanical damage to fruit. Chem. Eng. Trans. 2017, 58, 391–396. [Google Scholar] [CrossRef]

- Maguire, S.M.; Godwin, R.J.; O’Dogherty, M.J.; Blackburn, K. A dynamic weighing system for determining individual square bale weights during harvesting. Biosyst. Eng. 2007, 98, 138–145. [Google Scholar] [CrossRef]

- D’Alessandro, F.; Bianchi, F.; Baldinelli, G.; Rotili, A.; Schiavoni, S. Straw bale constructions: Laboratory, in field and numerical assessment of energy and environmental performance. J. Build. Eng. 2017, 11, 56–68. [Google Scholar] [CrossRef]

- Maraldi, M.; Molari, L.; Molari, G.; Regazzi, N. Time-dependent mechanical properties of straw bales for use in construction. Biosyst. Eng. 2018, 172, 75–83. [Google Scholar] [CrossRef]

- Maraldi, M.; Molari, L.; Regazzi, N.; Molari, G. Analysis of the parameters affecting the techanical behaviour of straw bales under compression. Biosyst. Eng. 2017, 160, 179–193. [Google Scholar] [CrossRef]

- Sun, Y.; Buescher, W.; Lin, J.; Schulze Lammers, P.; Ross, F.; Maack, C.; Cheng, Q.; Sun, W. An improved penetrometer technique for determining bale density. Biosyst. Eng. 2010, 105, 273–277. [Google Scholar] [CrossRef]

- Cazzato, E.; Laudadio, V.; Tufarelli, V. Effects of harvest period, nitrogen fertilization and mycorrhizal fungus inoculation on triticale (xTriticosecale Wittmack) forage yield and quality. Renew. Agric. Food Syst. 2012, 27, 278–286. [Google Scholar] [CrossRef]

- Adler, A. Qualität von Futterkonserven und mikrobielle Kontamination. In 8. Alpenländisches Expertenforum; Bundesanstalt für alpenländische Landwirtschaft Gumpenstein: Irdning, Austria, 2002; pp. 17–26. [Google Scholar]

- Li, M.; Sun, Y.; Cheng, Q.; Jungbluth, K.H.; Buescher, W.; Maack, C.; Cheng, H.; Wang, Z. Mapping oxygen-induced temperature patterns of round bale silage based on 3D stepwise-profiling measurement. Measurement 2016, 82, 115–122. [Google Scholar] [CrossRef]

- Román, F.D.; Hensel, O. Numerical simulations and experimental measurements on the distribution of air and drying of round hay bales. Biosyst. Eng. 2014, 122, 1–15. [Google Scholar] [CrossRef]

- Cazzato, E.; Tufarelli, V.; Laudadio, V.; Stellacci, A.M.; Selvaggi, M.; Leoni, B.; Troccoli, C. Forage yield and quality of emmer (Triticum dicoccum Schübler) and spelt (Triticum spelta L.) as affected by harvest period and nitrogen fertilization. Acta Agric. Scand. Sect. B Soil Plant Sci. 2013, 63, 571–578. [Google Scholar]

- Wilkinson, J.M.; Davies, D.R. The aerobic stability of silage: Key findings and recent developments. Grass Forage Sci. 2013, 68, 1–19. [Google Scholar] [CrossRef]

- Pascuzzi, S.; Cerruto, E.; Manetto, G. Foliar spray deposition in a “tendone” vineyard as affected by airflow rate, volume rate and vegetative development. Crop Prot. 2017, 91, 34–48. [Google Scholar] [CrossRef]

- Pascuzzi, S.; Santoro, F. Exposure of farm workers to electromagnetic radiation from cellular network radio base stations situated on rural agricultural land. Int. J. Occup. Saf. Ergon. 2015, 21, 351–358. [Google Scholar] [CrossRef] [PubMed]

- Cerruto, E.; Manetto, G.; Santoro, F.; Pascuzzi, S. Operator Dermal Exposure to Pesticides in Tomato and Strawberry Greenhouses from Hand-Held Sprayers. Sustainability 2018, 10, 2273. [Google Scholar] [CrossRef]

- Pascuzzi, S.; Blanco, I.; Anifantis, A.S.; Scarascia Mugnozza, G. Hazards assessment and technical actions due to the production of pressured hydrogen within a pilot photovoltaic-electrolyzer-fuel cell power system for agricultural equipment. J. Ag. Eng. 2016, 47, 88–93. [Google Scholar] [CrossRef]

- Baldoin, C.; Balsari, P.; Cerruto, E.; Pascuzzi, S.; Raffaelli, M. Improvement in pesticide application on greenhouse crops: Results of a survey about greenhouse structures in Italy. Acta Hortc. 2008, 801, 609–614. [Google Scholar] [CrossRef]

- Anifantis, A.S.; Colantoni, A.; Pascuzzi, S.; Santoro, F. Photovoltaic and Hydrogen Plant Integrated with a Gas Heat Pump for Greenhouse Heating: A Mathematical Study. Sustainability 2018, 10, 378. [Google Scholar] [CrossRef]

- Pascuzzi, S.; Blanco, I.; Anifantis, A.S.; Scarascia Mugnozza, G. Electrolyzer Performance Analysis of an Integrated Hydrogen Power System for Greenhouse Heating. A Case Study. Sustainability 2016, 8, 629. [Google Scholar] [CrossRef]

- Pascuzzi, S.; Santoro, F. Analysis of Possible Noise Reduction Arrangements inside Olive Oil Mills: A Case Study. Agriculture 2017, 7, 88. [Google Scholar] [CrossRef]

- Santoro, F.; Anifantis, A.S.; Ruggiero, G.; Zavadsky, V.; Pascuzzi, S. Lightning Protection Systems Suitable for Stables: A Case Study. Agriculture 2019, 9, 72. [Google Scholar] [CrossRef]

- Langer, T.H.; Ebbesen, M.K.; Kordestani, A. Experimental analysis of occupational whole-body vibration exposure of agricultural tractor with large square baler. Int. J. Ind. Ergon. 2015, 47, 79–83. [Google Scholar] [CrossRef]

- Bell, B. Farm. Machinery, 5th ed.; Old Pond Publishing: Ipswich, UK, 2005. [Google Scholar]

- Gomez, K.A.; Gomez, A.A. Statistical Procedures for Agricultural Research, 2nd ed.; Wiley-Interscience: New York, NY, USA, 1984; ISBN 978-0471870920. [Google Scholar]

| Thesis 1 | Thesis 2 | Thesis 3 | |

|---|---|---|---|

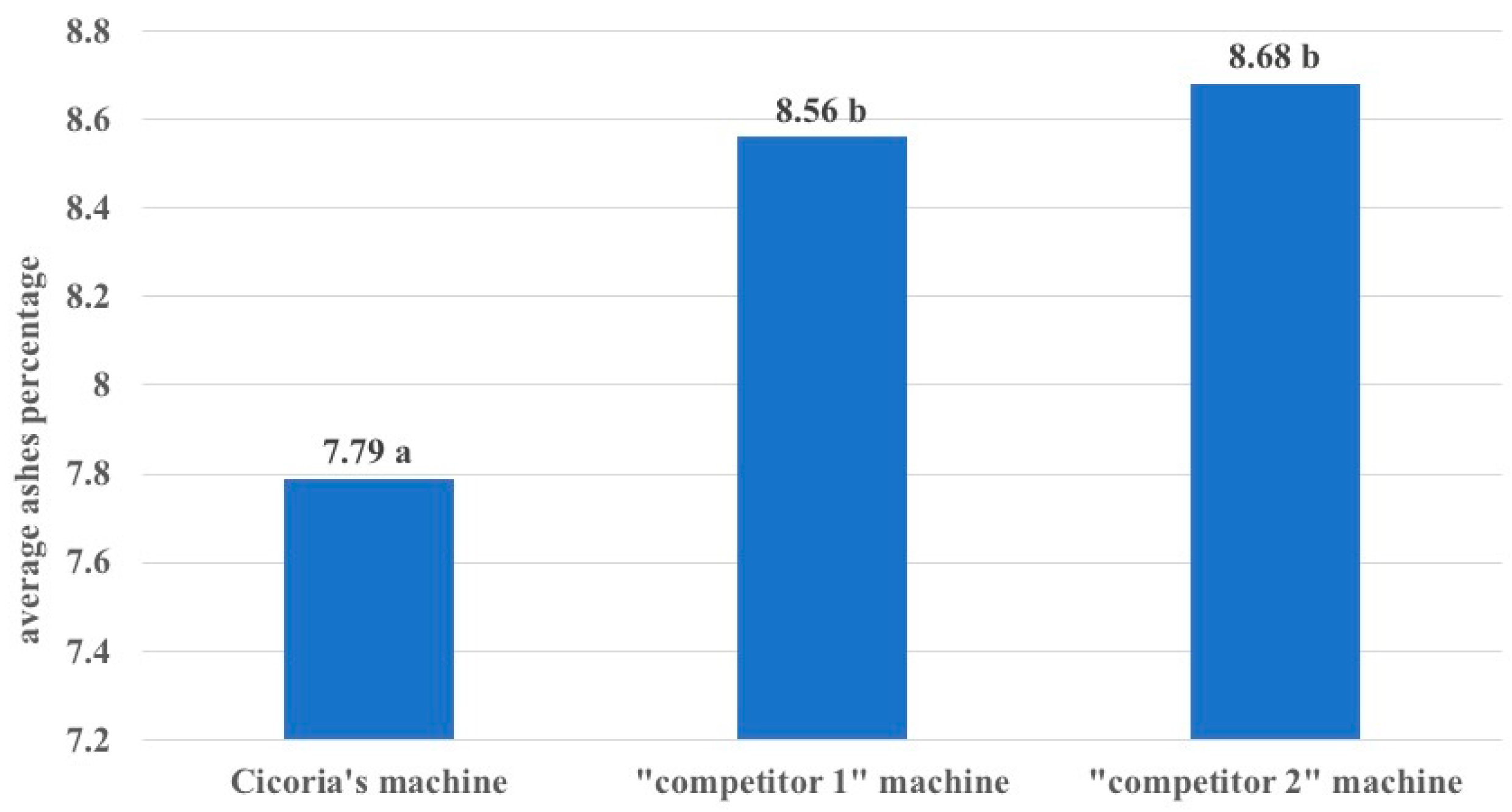

| straw | Cicoria’s machine | “competitor 1” machine | “competitor 2” machine |

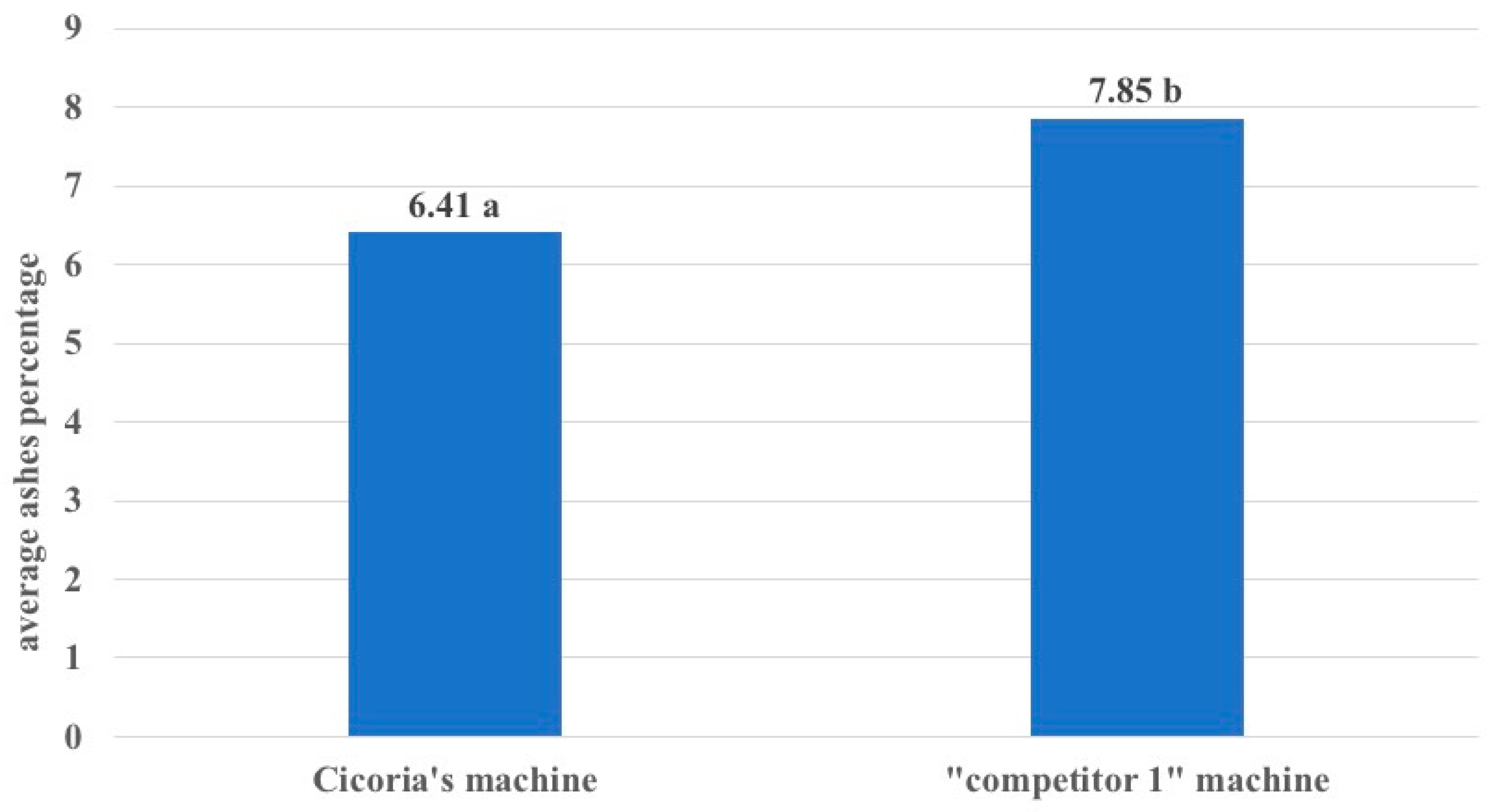

| hay | Cicoria’s machine | “competitor 1” machine |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guerrieri, A.S.; Anifantis, A.S.; Santoro, F.; Pascuzzi, S. Study of a Large Square Baler with Innovative Technological Systems that Optimize the Baling Effectiveness. Agriculture 2019, 9, 86. https://doi.org/10.3390/agriculture9050086

Guerrieri AS, Anifantis AS, Santoro F, Pascuzzi S. Study of a Large Square Baler with Innovative Technological Systems that Optimize the Baling Effectiveness. Agriculture. 2019; 9(5):86. https://doi.org/10.3390/agriculture9050086

Chicago/Turabian StyleGuerrieri, Arrigo Salvatore, Alexandros Sotirios Anifantis, Francesco Santoro, and Simone Pascuzzi. 2019. "Study of a Large Square Baler with Innovative Technological Systems that Optimize the Baling Effectiveness" Agriculture 9, no. 5: 86. https://doi.org/10.3390/agriculture9050086

APA StyleGuerrieri, A. S., Anifantis, A. S., Santoro, F., & Pascuzzi, S. (2019). Study of a Large Square Baler with Innovative Technological Systems that Optimize the Baling Effectiveness. Agriculture, 9(5), 86. https://doi.org/10.3390/agriculture9050086