Abstract

A conventional method for wrapping round bales of agricultural materials by wrappers with a rotating table or with rotating arms is considered. In contemporary agriculture, the demand for minimal consumption of the film used to wrap bales is very high, in order to apply this method with lower cost and less damage to the environment. A combined model-based problem of such a design, focusing on the width of stretch film and the overlap between adjacent film strips that minimizes film consumption, was mathematically formulated and solved. It was proven that the complete set of optimal film widths is defined by a simple algebraic equation described in terms of film, bale, and wrapping parameters. The optimal overlap ratios were found to be irreducible fractions in which the dividend is the divisor minus one; however, only the first three factions,

, are practically significant. Next, the robustness to disturbances in the functioning of an actual bale wrapper, which leads to overlap ratio uncertainty, is examined. It was shown that, unfortunately, the optimal film widths applied together with the optimal overlaps do not provide any robustness to overlap variations. To overcome this inconvenience, the problems of a choice of the best commercially available film width guaranteeing minimal film consumption or maximal tolerance on the overlap uncertainty were formulated and solved. A new algorithm for a robust design of wrapping parameters was developed, motivated, and numerically verified to achieve a trade-off between satisfactory robustness and low film usage. For the resulting wrapping parameters, near-optimal film usage was achieved; the relative errors of the minimal film consumption approximation did not exceed 4%. It was proven that for the overlap, slightly more than 50%, i.e., 51% or 52%, provides both optimality and robustness of the overlap over disturbances, which are ensured regardless of the number of film layers. Moreover, it was found that for these overlaps and for the commercially available film widths selected according to the algorithm, the film consumption was more than twice as small than the film usage for exactly 50% overlap, if the actual overlap was smaller than pre-assumed. Similarly, an overlap of slightly more than the commonly used 67% will result in about 30% to 40% reduction in film usage in the presence of unfavorable disturbances, depending on the number of film layers and wrapping parameters.

1. Introduction

Baling technology has been widely used in storing agricultural materials, both at large feed factories and small-scale farms, due to the mechanization of the production chain, low labor requirements, ease of the manipulation and transport of bales, and low requirements for bale storage [1,2,3]. A persistently exciting bale wrapping application is that of silage conservation. Bales are wrapped in plastic film to ensure proper fermentation in anaerobic conditions without the need to build dedicated structures [4,5]. Comprehensive reviews of the literature, substantial and multifaceted, concerning physical and biochemical characteristics of baled silages with fermentation and nutritive quality [6,7,8] provide detailed information about the progress in bale silage conservation techniques [7,9,10], recent experimental studies [6,7], and future perspectives [7,8,10]. Although other silage conservation technologies are poised to replace baled silage for the primary purpose of providing good silage at low cost, it is likely to remain popular in the foreseeable future [7,11].

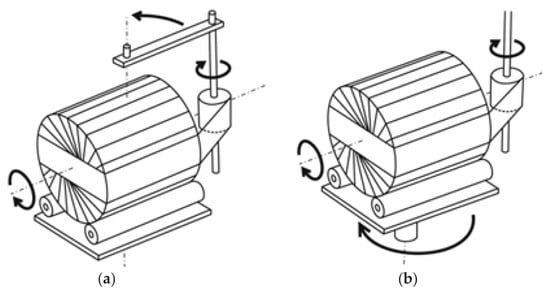

Today’s silage conservation in many regions of Europe [9,12], America [9], and China [1,11], especially for small and mid-sized producers, prefers round (i.e., cylindrical) bales wrapped individually. Since its origin in the 1980s, the conventional wrapping technique, according to which film strips are wrapped along the longitudinal axis of a bale, from the base to the top or vice versa, resulting in successive film layers, has been at the heart of the modern bale silage technique. Two main types of such round-bale wrappers are available [13,14]. In the first type, the film is applied by a pre-stretching unit mounted on an arm rotating around the bale (Figure 1a); see also [15]. The second type uses a rotating table on which the bale is rotated around its longitudinal axis, as seen in Figure 1b. For effective winding, the tension of the film has to be appropriately set [5]. Distribution of the film strips wrapped around the bale is illustrated in Figure 1, and is the same for the two types of round-bale wrappers; see also the bale wrapper documentation [16].

Figure 1.

Two types of round-bale wrappers: (a) with non-rotating table, (b) with rotating table, pre-stretchers in vertical position wrapping the film strips; figure is reprinted from [17].

However, silage wrap-film represents additional cost and environment damage [7,18]. Financial expenditures on the purchase of stretch film constitute a high percentage of the total costs of this technology [12,19]. The decrease in the usage of plastic film means cost reduction, a decrease in working time [9,20], and less damage to the environment. An appropriate choice of the wrapping variables and parameters may guarantee the assumed conservation quality of wrapped bales without increasing the consumption of plastic film [9], especially if the optimal wrapping parameters are applied and the uniform or near-uniform film coverage on the bale’s lateral surface is obtained [21].

To reduce film consumption, researchers have incorporated experimental methods; several strategies have been tested for the conventional wrapping method [11,20,22], for the alternative technique of three-dimensional (3D) film wrapping using biaxial rotation of the film applicators [14], and for a polyethylene tying-film system used to replace the typical net wrapping [23]. Simultaneously, a limited number of studies have been concerned with model-based optimization of film consumption by an appropriate choice of the film and wrapping process parameters. In [12], the mathematical models describing film usage for wrapping round and square bales were given, which take into account bale dimensions, film width, and the width of the overlap between successive film strips. A mathematical model describing film consumption as a function of the bale and film dimensions, and taking into account the mechanical properties of the stretch film described by the Poisson ratio and unit deformation, were presented, for the first time, in [24]. A mathematical model describing the distribution and consumption of stretch film used for bale wrapping, which captures more features of a realistic description of the wrapping process than previously existing models, was derived in [21]. Bale and film dimensions, mechanical properties of the stretch film, the overlap between adjacent film strips, and the pre-assumed number of basic film layers were taken into account. The minimization of film consumption gained by optimal design of the film width and the bale dimensions was conducted, for a fixed overlap ratio, in two papers [25,26], under the assumption that the number of bale rotations, rather than the pre-assumed number of film layers, is known. In [21], the complete set of the overlaps determining the width of the contact area between adjacent film strips guaranteeing, for the assumed film width, minimal film consumption was determined.

The proposed approach is model-based, and thus, is bound to be affected both by the inevitable inaccuracies of the model as well as the non-nominal values of wrapping parameters. The new IntelliWrap™ systems use sophisticated electronics to monitor the wrapping process and continuously control the film overlap [16]. However, when disturbances appear that yield an overlap ratio different than what was pre-assumed, severe consequences may result, in particular, the loss of the uniformity of film distribution or the increase of film usage. Therefore, it is of interest to evaluate the robustness of the design method into modeling inaccuracies and uncertainties caused by the disturbances in the functioning of an actual bale wrapper. The robustness of the overlap over disturbances was examined in [21], where two algorithms for robustly optimal overlap ratio design were developed.

The objective of the present paper was to find such film widths and overlap ratios, jointly, for which the consumption of the film used to wrap the bale is minimal, with an emphasis on robustness issues, and to propose a design approach.

2. Materials and Methods

2.1. Mathematical Model

In this section, a model describing film consumption is provided based on previous papers [21,24,25]. Symmetry of the bale was assumed and thickness of the film was ignored; for example, polyethylene film is 25 μm thick. Following [21,25], it was assumed that the bale’s rotation speed and the baler rotation speed were taken so that the subsequent strips of film overlap one another, creating the overlap , where is a dimensionless relative ratio determining the width of the contact area between adjacent film strips and is the film width after stretching described by the following formula [24]:

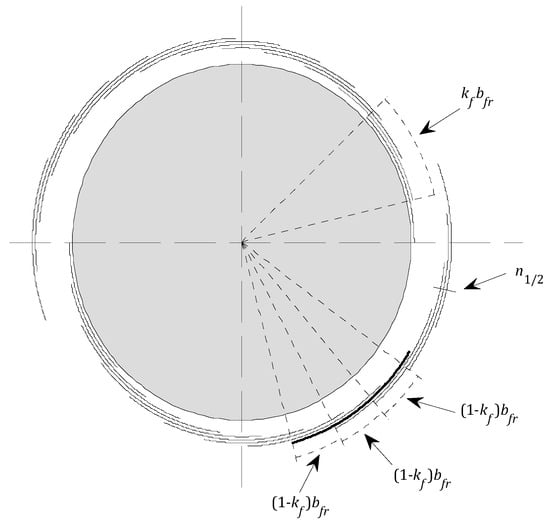

where is the width of un-stretched film and Poisson’s ratio and unit deformation describe the mechanical properties of the film. The main symbols are summarized, mostly with the references to respective equations, where they are defined or used for the first time, in Appendix B.1. The above assumption means that all film strips were equally overlapped by successive strips; the cross-section of the bale with overlapping film strips of width and exemplary overlap are presented in Figure 2. For the selected film strip (marked with a bold line) and two subsequent strips, the parts of the stretched film strips that were non-overlapped by the next film strip, are also indicated in Figure 2.

Figure 2.

Distribution of the film strips for bales’ half-rotation and illustration of the overlap , the complementary fragments of film strip, and the number of minimal ‘half-rotation’ film layers.

We assumed that the bale was wrapped correctly when the last applied strip of film overlaps the preceding strip with overlap and ‘overlaps’ the first applied film strip with the overlap not less than [25]. This means that the number of entire wrappings obtained directly for rotations of the bale is the smallest integer, such that [21,25]:

where is the outer bale diameter, and from which the following direct formula results:

where denotes the ceiling function, i.e., the least integer greater than or equal to [27], see Appendix B.2. This formula, derived in [25], was first reported in [24]. During wrapping of one film strip, the film is also wrapped on the opposite side of the bale; thus, during a half-rotation of the bale, the bale’s whole lateral surface is wrapped, as seen in Figure 2. Thus, the number , depicted in Figure 2, of minimal film layers on a bale’s lateral surface achieved during half-rotation of the bale is the largest integer, such that [21]:

An immediate consequence of the above inequality is that [21]:

where denotes the floor function, i.e., the greatest integer less than or equal to [27]. Thus, is uniquely determined by the overlap ratio . From this, the number of basic (i.e., minimal on the bale’s whole surface) film layers achieved during bale rotations is described as follows [21]:

provided that is an integer multiple of half-rotation, i.e., , ; henceforth, denotes the set of positive integer numbers. Thus, the applicability condition for Equation (3) and all the resulting formulas follows [21]:

Note that arbitrary satisfies the applicability condition for any , while for , the applicability is not so evident. Note also that the applicability condition does not depend on bale and film parameters.

Combining Equations (3) and (2) results in the final rule [21],

where the number of entire wrappings is directly described, ensuring the pre-assumed number of basic film layers , where the following function is introduced for brevity of the notation:

The dependence of the total number of wrappings on the film width from the range m and is shown in [25] (Figure 4), while the dependence of on the overlap ratio is illustrated in [21] (Figure 5) for fixed and .

The surface area of the film used to wrap the bale can be directly expressed as [21,24]:

where is bale height. A useful measure of film consumption is the surface area to volume of silage ratio [12,25,28], where is the volume of the bale, which for a cylindrical bale is described by the following function:

This formula indicates the dependence of the index on the overlap ratio , the number of film layers , and the bale and film parameters. It was assumed that the bale dimensions, the number of pre-assumed film layers , and the parameters and were given. Thus, only the width of the film and the overlap ratio are decision variables.

2.2. Model Development

In this paper, a model-based approach was applied, which addressed the goals (film usage optimization and robustness on overlap ratio uncertainties) by using mathematical tools.

Firstly, two problems of the optimal, in the sense of minimal film consumption, selection of the film width and the overlap ratio were mathematically formulated and solved, separately. Both problems were continuous programming tasks, and the goal functions were non-continuous due to piecewise constant ceiling and floor functions in the formula given by the right hand side of Equation (8). The optimal solutions were derived based on the specific properties of the film consumption index as a function of the film width and the overlap ratio , which are reported in Section 3.1 and Section 3.2. The problem of the optimal film width design was solved before in a previous paper [26]; however, under the less detailed assumption that the number of bale rotations, not the number of film layers, is given. Thus, the result abstracted in Proposition 1 was a generalization of the previously known results [26] for a more detailed model of the film consumption considered in this article. Similarly, the results concerning the choice of the optimal overlap ratio, abstracted in Proposition 2, came directly from the previous paper [21]; however, the film consumption per unit of the bale volume index Equation (8) was used here as a measure of film usage, while in [21], the surface area Equation (7), was treated as the film usage index. The solutions of the two separate optimization problems formed the basis for solving the new problem of the film width and overlap ratio combined design; therefore, they were briefly presented here. They were also significant for the robustness analysis of the overlap uncertainties caused by disturbances in the real wrappers work.

Next, the solution of the combined problem of optimal design of film width and overlap ratio was derived. This problem was stated and solved here for the first time, to the author’s best knowledge. The complete set of the optimal film widths, which were defined by simple algebraic equation, was indicated and it was shown that the complete set of the optimal overlap ratios is composed of irreducible fractions in which the dividend is the divisor minus one. The optimal overlap ratios also guarantee uniform stretch wrap-film coverage on the bale’s lateral surface.

As the next step in the study of the wrapping parameters’ effect on film consumption, the robustness to disturbances in the functioning of an actual bale wrapper, which leads to overlap ratio uncertainty, was examined. Robustness is crucial to ensure the pre-assumed number of film layers, which is fundamental to obtaining appropriate tightness of the wrappings; acceptable anaerobic conditions for fermentation; and an acceptable risk of internal and external puncture. The above indicates that not only should the film usage be minimal, but also that the tolerance to uncertainties of the overlap ratio should be guaranteed. It was found that, unfortunately, the optimal film widths applied together with the optimal overlap ratios did not provide any robustness to overlap ratio variations, which caused the need for optimal film width disappeared from the robustness point of view. Simultaneously, it was found that this inconvenience could be overcome by using an appropriately selected commercially available film of non-optimal width.

The problems of the choice of the best commercially available film width to guarantee minimal film consumption or maximal tolerance on uncertainty of the overlap were stated and solved. It was found that these requirements were not congruent. Consequently, design requires a careful trade-off between satisfactory robustness and the small consumption of the film. Simple mathematical formulas were derived to compute the optimal overlap ratio and to select the best film width, on the basis of which a new algorithm for wrapping parameters design was developed, executed, and numerically verified. For the wrapping parameters determined according to the algorithm, only near-optimal film usage was achieved, from which the analytical and numerical analyses of the relative errors for such approximations of the minimal film consumption were carried out.

Typical assumptions concerning the bale, film, and wrapping parameters were taken; no specific assumptions were made concerning the assumed number of film layers. Additionally, typical assumptions concerning the mechanical properties of the stretch film suggested that the results obtained can be applied both for the bales wrapped with a conventional PE film and with plastic stretch films with enhanced oxygen impermeability, which have been intensively studied in recent years [9]. The main developments were illustrated by figures and supporting discussions. The proposed approach was also exemplified through a case study, which was aimed at optimizing the consumption of the stretch film of typical mechanical properties for wrapping a cylindrical bale of commonly used dimensions [16,29].

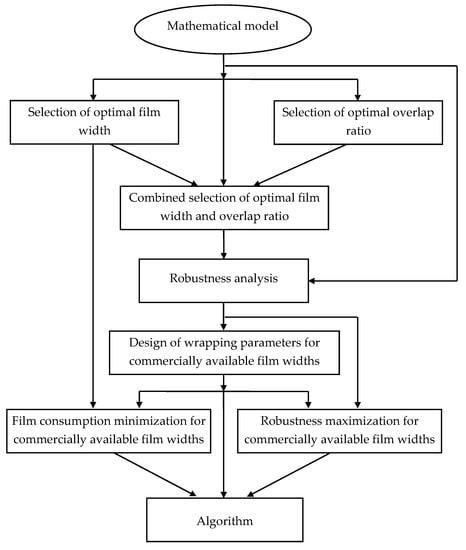

Summarizing, the solution of the problems of optimal and robustly optimal consumption of the film used for wrapping cylindrical bales was carried out in several stages. These stages are discussed individually in successive subsections.

The research framework is graphically shown in Figure 3, which also illustrates the relations between these tasks.

Figure 3.

Schematic framework for the tasks of designing optimal and robustly optimal wrapping parameters.

3. Results

3.1. Optimal Design of the Film Width

Assume additionally that the overlap ratio is given. Then, the problem of the optimal film width design consists of minimizing the index by solving the following optimization problem:

where, locally, the notation , indicating the dependence of on the film width , is used. The index is a piecewise linearly increasing function of in the intervals determined by discontinuity points such that:

Figure 4 shows the course of for exemplary bale silage from Example 1 given below. From Equations (10) and (8) in discontinuity points we have:

Figure 4.

The film consumption index as a function of the width of un-stretched film for six basic film layers; the solid dot indicates here and further on the value of the function at the discontinuity point.

Due to the right-continuity of the function in discontinuity points and its lower semi-continuity, is the minimal value of with respect to . Thus, every is, simultaneously, the local and global minimum of . The following result can be stated.

Proposition 1.

Assume the bale diameter, the pre-assumed number of film layers, and the overlap ratio are given, such that the applicability condition expressed by Equation (4) holds. The solution of the problem of film consumption minimization, Equation (9), there exists and is not unique. Every optimal film width is defined by Equation (10). The optimal film consumption is given by the right-hand side of Equation (11).

A similar result has been proven in [26] (Corollary 1); however, under less detailed assumptions that the number of bale rotations, not the number of film layers, is given. For by Equations (10) and (5) we have:

thus, every can be written more succinctly as:

The relation between and the respective number of entire film wrappings is uniquely described by Equation (13) or Equation (12).

Example 1

The main concern in this example is determination of the complete sets of optimal film widths for a few exemplary overlap ratios. The bale silage of diameter m [5,30] is considered. Conventional wrappers are adjusted to wrap cylindrical bales up to 1.6 m diameter and up to 1.2 m height [16,29]; or are capable of wrapping round bales up to 1.2 m height and 1.5 m diameter [29]. However, typical bales are 1.2–1.25 m in diameter and height [12,14]. The Poisson’s ratio and unit deformation of the stretch film are assumed to be the same for all examples and figures, which characterize, among others, commercial polyethylene (PE) film used traditionally because of its mechanical characteristics and low costs. Assume . The function is illustrated in Figure 4 for in the range m for the exemplary overlap ratios .

Assume that the film widths from the interval are considered; meters in the example. According to the formula from Equation (13), only such that the related numbers of film strips satisfy inequalities:

there are in the assumed range, from which direct estimations for are as follows:

Since the closed interval contains exactly integers [27] Equation (3.12), the number of optimal film widths is uniquely given by:

This number depends on bale and wrapping parameters as well as on the mechanical properties of the stretch film.

In the range from to m for , there are 19 optimal film widths ; all of them are summarized in the first column of Table 1. Having in mind Equation (10), note that for any overlap such that the ‘integer’ points are identical to those given in the first column of Table 1, whenever six film layers are pre-assumed. Optimal film widths for and , which yield , are given in the second column of Table 1; there are 21 such values. In the next columns of Table 1, the same data is summarized for the next two overlap ratios: (23 ) and (until 27 ). Different values, and yield different points . It should also be noted that, for example, if , then the results are identical to those obtained for , because . Additionally, Figure 4 shows that the overlap ratio influences the number of optimal film widths .

Table 1.

The optimal widths of un-stretched film in the range from to m for selected overlap ratios ; pre-assumed film layers.

It is evident that none of the from Table 1 is identical to commonly used film widths: and [16,29]. Some of the are in the near neighborhood of these ; however, a small difference does not guarantee near optimal film consumption. This can be easily confirmed by a quick inspection of data in Table 2, where the optimal , the nearest neighborhood of , i.e.:

and the film consumption are summarized for . For example, for and the small difference, results in the sub-optimality relative error:

Table 2.

The optimal and the nearest neighborhood of bf,s= 0.5, 0.75 m for selected overlap ratios ; pre-assumed film layers.

However, for , a bigger difference yields error equal only to:

The problem of the selection of the best commercially available film width is discussed later (Section 3.5, Section 3.6).

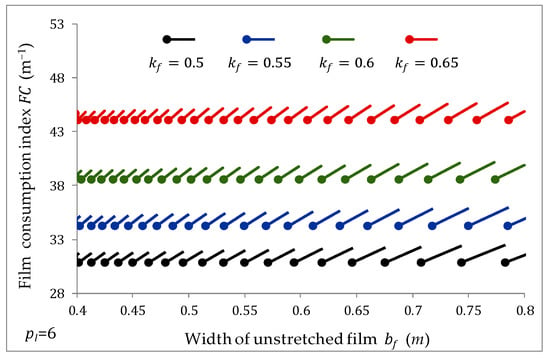

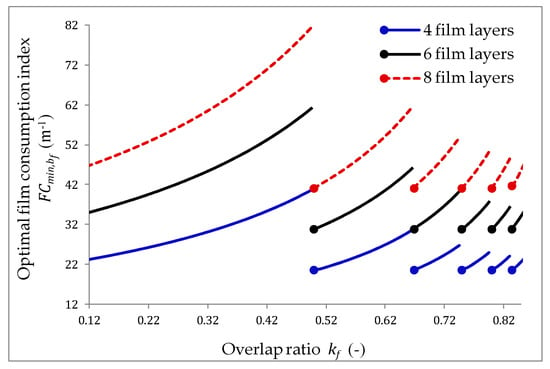

Both every optimal as well as the optimal described by Equation (11) depend on the overlap ratio, which is evident when comparing the successive columns of Table 1. Figure 5 shows as a function of the ratio for four, six, and eight basic film layers. For variability, according to the applicability condition expressed by Equation (4), the intervals and are chosen for , and also both applicability intervals and are considered for . For . the ranges and result from the applicability condition; the interval for which this condition is also satisfied is omitted here to make the figure more readable.

Figure 5.

The film consumption index , optimal with respect to the width of un-stretched film, as a function of the overlap ratio for basic film layers.

3.2. Optimal Design of the Overlap Ratio

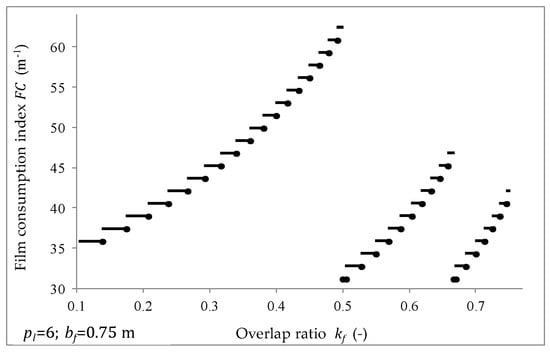

Assume now that the film width is given. The subject is to find the overlap ratio such that the film consumption index takes the minimal value. Now, locally, the notation indicating the dependence of given by Equation (8) on the overlap ratio, is used. Both the ceiling and inside nested floor functions make the function hard to analyze. The exemplary course of for bale silage from Example 1 is depicted in Figure 6; six film layers and are assumed. For variability, only the interval is considered, according to the applicability condition; the range is omitted here to make the figure more readable.

Figure 6.

The film consumption index for the overlap ratio ; film layers, film width .

The index is a piecewise-constant function of the ratio , which is left-continuous in the discontinuity points , such that:

i.e., the expression under ceiling function brackets in Equation (8) is an integer. It is proven in [21] that under the rationale condition:

every overlap ratio

where , being discontinuity points of (see Figure 8 in [21]), is also a discontinuity point of , in which this function is right-continuous. We denote by the set of all irreducible fractions in which the dividend is the divisor minus one. For , the condition expressed by Equation (14) is in general not satisfied. The index is a piecewise-constant in the intervals determined by discontinuity points and a non-decreasing function in the intervals determined by discontinuity points . In any interval defined by two successive there are many discontinuity points , as shown in Figure 6. The points are independent of , while are dependent of . Figure 7 shows how influences and better illustrates the piecewise-constant character of in the near neighbourhood of ; is depicted here for restricted to the interval for three popular film widths . As the values of are equal in some subintervals, they are slightly differentiated in Figure 7, in order to better illustrate the co-linearity of these subintervals.

Figure 7.

The film consumption for and ; .

Note that for the applicability condition expressed by Equation (4) means that:

i.e., that is the multiplicity of integer uniquely determining the overlap ratio .

In [21], the problem of film area , Equation (7), minimization with respect to the overlap ratio is solved. Since does not influence the volume of the bale, the solution of minimization task is identical; it is summarized in the next result following directly from Proposition 3 in [21].

Proposition 2.

Assume the bale and film dimensions , , and are given and are such that the inequality expressed by Equation (15) is satisfied. The solution of the problem of film usage minimization with respect to the overlap ratio there exists and is not unique. Let:

Then:

- (i)

- if , then every defined by Equation (16), for which the applicability condition expressed by Equation (17) holds, is an optimal overlap ratio;

- (ii)

- if , then for any , satisfying the applicability condition from Equation (17) and any , where is defined by:the ratio results in optimal film usage. In both cases the optimal film usage is calculated by:

Note that for the exemplary bale, the inequality expressed by Equation (15) is equivalent to the obvious requirement that . For an arbitrary , the minimal film consumption is reached regardless of the film width value. The optimal film usage is independent of ; however, it depends on . For the exemplary bale assuming six film layers for we have , yields , while results, again, in .

In view of the above proposition, a natural way to describe this set of the optimal overlap ratios is through the representation of values in the form of closed intervals ; Equations (18)–(20) permit us to determine them. For any if , then the ratio is identical to the discontinuity point , which is the nearest right neighbor of (see Figure 6 and Figure 7). The coefficient , and consequently, also and , depend on the film width. The optimal overlaps are referred to as , which for fixed belongs to the set-sum of intervals for every . Obviously, for an arbitrary fixed film width. From a practical perspective, however, only four such parameters are worth considering; 50%, 67%, and 75% overlaps, especially, are commonly used [5,10,13,14,16]. For a fixed film width, all are equivalent in the sense of optimal film consumption. A simple scheme for determining the set of the optimal overlap ratios, for given film and bale parameters, is presented in [21] (Algorithm 1). It is also proven in [21] that is the complete set of overlap ratios that guarantee uniform film distribution on the lateral surface of the cylindrical bale; however, the applicability condition expressed by Equation (17) must be simultaneously satisfied. Thus, there exists parallelism between the uniform film distribution and minimal film consumption. For any both properties are guaranteed regardless of the dimensions of the bale and film, with or without optimal width. However, the optimal film consumption does not necessarily guarantee the uniform distribution of film layers.

3.3. Optimal Design of the Film Width and Overlap Ratio

Combining the two problems considered above leads to the following task of simultaneous choice of the optimal film width and overlap ratio by solving the following minimization problem:

The notation , indicating the dependence of on both the film width and the overlap ratio, is used, locally. The goal function is a lower semi-continuous function of both arguments.

In view of Proposition 1, for any fixed overlap ratio, every optimal film width is defined by Equation (10). The -optimal quality index depends on the overlap ratio according to the formula of Equation (11), as indicated in Figure 5. Since is the right-continuous function of , increasing in the intervals determined by discontinuity points , for any such that the applicability condition holds index takes the minimal value equal to:

On the other hand, the results of Proposition 2 state that for any film width being fixed, every satisfying Equation (4), is an optimal overlap ratio, and the optimal film usage is given by Equation (21). This function is minimal if and only if the film width is such that:

Substituting Equation (24) into Equation (21) gives the optimal , Equation (23). Thus, we have . For brevity, we denote by the set of all in the range of practically meaningful film widths, for which Equation (24) is satisfied. Note that Equation (24) is, in fact, Equation (10), for . Since for an arbitrary the coefficient given by Equation (18) is an integer, thus and Equation (20) yield . The set of optimal overlap ratios reduces to , i.e., for optimal film width only the overlap ratios result in minimal film usage. The next result is valid.

Proposition 3.

Assume the bale dimensions and and the number of film layers are given. The solution of the film consumption minimization task stated in Equation (22) there exists and is not unique. Every , for which the applicability condition expressed by Equation (17) is satisfied, is the optimal overlap ratio; is the set of optimal widths of un-stretched film. The optimal film consumption is given by Equation (23).

Since for every the ratio introduced by Equation (18) is an integer, by Equations (5), (18) and (24) we have:

thus, every can be expressed as:

Thus, similar to the separate problem of the optimal film width selection, the relation between and the resulting number of entire film wrappings is described by Equation (25) or, equivalently, by Equation (26). From the computational point of view, the formula given by Equation (26) is more useful than directly solving the definitional Equation (24).

In view of the above proposition, only exact and the film widths are, simultaneously, optimal. However, even the smallest disturbance in any of the wrapping process parameters may result in the loss of the optimality. In particular, an overlap ratio other than the assumed may result from inaccuracies in the functioning of the wrapper. From a mathematical perspective, such variability entails uncertainty in the overlap ratio. The following section addresses some robustness issues.

3.4. Robustness

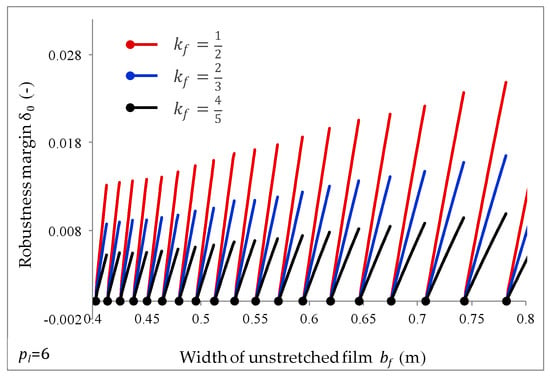

As we ascertained above, for any optimal , only the overlaps result in optimal film consumption. Thus, the optimal does not provide any robustness to overlap ratio variations. A non-optimal , for which , implies the non-one-point intervals of optimal overlaps for every applicable . Both larger than as well as smaller than overlap ratios imply the growth of film consumption. Thus, the length of this interval, which is estimated by , can be treated as a measure of robustness to parameter uncertainty—robustness margin [21]. The larger is, the greater robustness with respect to uncertainty is achieved. For the exemplary bale and a few widths of the film, the robustness margins are shown in Table 3 for two to ten pre-assumed film layers. Mostly, four, six, or eight layers of film are applied [5,14,31]; however, two, 10, and even 16 film layers in which the silages are wrapped have also been considered [22,31]. Naturally, only , which satisfies the applicability condition, Equation (17), for a given is considered. The formula from Equation (20) means that the smaller is, i.e., the smaller is, the bigger the resulting robustness margin is. This rule can be confirmed by an inspection of data in the columns of Table 3, for any fixed , separately. Increasing reduces the lengths of the intervals of optimal overlap ratios. However, the difference between and subsequent , equal to , also decreases for an increasing .

Table 3.

The lengths of the intervals of the optimal overlap ratios (robustness margins) for pre-assumed film layers.

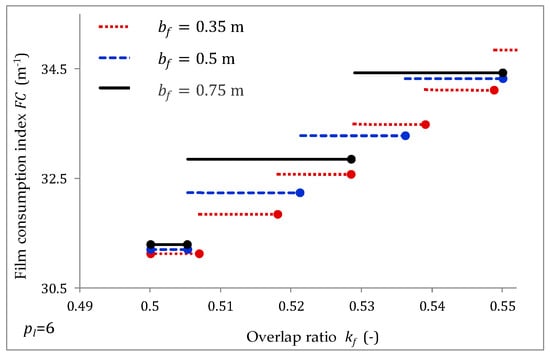

The selection of the film width and the respective overlap ratio, to guarantee the best robustness on uncertainty, is now the subject of interest. For fixed the robustness margin depends on the film width. By Equations (18)–(20), we have:

where we conclude that is a semi-continuous increasing right-continuous function of the film width in the intervals determined by discontinuity points , Equation (24). The margin is illustrated by Figure 8, where is depicted as a function of for three overlap ratios . The upper bound of for the range , where is a direct successor of in the set , results immediately as the left-hand sided limit:

for derivation see Appendix A.1. Thus, the larger is, the longer the interval of -optimal overlap ratios may be, if the width of the film is chosen in the nearest left neighborhood of . The above rules are also illustrated in Figure 8.

Figure 8.

The robustness margin described by Equation (27) as a function of the width of un-stretched film for overlap ratios and six pre-assumed film layers.

3.5. Robustly Optimal Design of Wrapping Parameters

The optimal film usage is never achieved if . Other than , film width means a larger than optimal film consumption, even if the overlap ratio is optimal; however, the robustness is guaranteed in such a case. The selection of the best commercially available film width is resolved by the following result proven in Appendix A.2. In various regions of the world, different film widths dominate (see, e.g., [11]). Both the film consumption and the robustness with respect to the overlap ratio uncertainties are taken into account.

Proposition 4.

Let be the set of all considered film widths that may be commercially available. Assume is the direct successor of in the set . Let:

where is commercially available width of the film such that:

Then:

- (i)

- The -optimal film consumption index expressed by Equation (21) takes the minimal value in the set if and only if the quotient:is minimal in the set . The increase of the index :is described by:

- (ii)

- For the length of the interval of overlap ratios ensuring -optimal film usage is given by:The length takes the maximal value in the set if and only if the quotient is maximal in .

By the above proposition, the requirements concerning minimal film usage and significant robustness are not consistent. To choose the compromise is necessary, which must be resolved on a case by case basis having in mind both the value of and the relative percentage error, calculated by the following:

Proposition 4 clearly shows that the quotient is significant to synthesis of the algorithm for optimal and robust design of the wrapping parameters. This quotient allows one to choose the best film width , estimate the film consumption deterioration according to formula from Equation (33), and also enable easy determination of both the robustness margin , as characterized by Equation (34), and the relative error given by Equation (35), on the basis of which the overlap ratio is chosen according to the design scheme presented below.

3.6. Algorithm

- (1)

- Take initially such that the applicability condition expressed by Equation (17) is fulfilled, i.e., is an integer.

- (2)

- For any commercially available find optimal being the nearest lower neighbours of using the direct formula from Equation (26) or solving Equation (24).

- (3)

- If a is identical to , then reject this from consideration, i.e., consider only .

- (4)

- For any pair compute the quotient according to Equation (31), and next estimate robustness margin according to Equation (34).

- (5)

- Select such for which both respective robustness margin and the relative error of film consumption described by Equation (35) are satisfactory.

- (6)

- Choose the overlap ratio from inside of the interval , e.g., .

By Equations (27) and (34), the overlap ratio , which means that , can be recommended to maximize the robustness margin. In this case the applicability condition is fulfilled for any even . Now, on the basis of the quotient , this for which the film consumption is minimal, or such that the margin is maximal, or such that the trade-off between these requirements is achieved, can be chosen. The following example illustrates the use of Proposition 4 and motivates the above algorithm for wrapping parameter robust design. The example is also aimed at illustrating the process of the best film width selection.

Example 2

The bale from the previous example is considered; bale height m is assumed [5], and is taken together with for film wrapping layers. We assume that the film widths , given in the second column of Table 4, are integer multiples of 5 cm from the range . Since , the film widths and are identical for any fixed ; they depend on the number of film layers. In the range from to m for , there are 12 optimal film widths; for nineteen are given in the first column of Table 1, while for in this range, there are 25 optimal film widths, and for there are as many as 31 . For any there are only nine values of such that the inequalities expressed in Equation (30) hold, and only these , which are necessary to estimate the quotient , Equation (31), are given in Table 4 for . Furthermore, in the first row, the largest smaller than are specified in order to estimate for . The quotients are given in the third column in Table 4, where also the robustness margins and the indices are added. Additionally, the left-hand sided limits (for derivation, see Appendix A.3) are as follows:

where , which characterize the film consumption if the actual overlap ratio is smaller than the assumed . The right-hand sided limits of film consumption, expressed as:

which are also given in Table 4. Here, is the direct successor of in the set of overlap ratios satisfying Equation (14) for . The limit defined by Equation (37) characterizes the film usage, if the actual overlap is greater than . In the last column, the errors , Equation (35), are given. The globally optimal film consumptions are as follows: for we have , for the respective , film layers means , while entails .

Table 4.

The optimal and commercially available widths of un-stretched film, the quotient Equation (31), the robustness margin Equation (27), (–optimal film consumption), sided estimations of , left-hand Equation (36), right-hand Equation (37), the relative errors , Equation (35); , .

By an inspection of the third column data in Table 4, it is evident that for all the considered numbers of film layers, there are two film width, and , for which the quotient is minimal, i.e., minimal film consumption is achieved. For also results in minimal , while for this minimum is also achieved for . In all these cases, .

The maximal robustness margin is guaranteed by for , while for , the film width results in the maximal . For the popular film width [12,14] also yields the maximal . The maximal robustness margin for implies an increase of film consumption measured by , while for the other numbers of basic film layers this error is smaller than .

From these data, it follows, for example, that if and robustness margin are assumed in the case of there are no practically accessible film widths satisfying these requirements, while for the respective slightly exceeds the assumed level. For the errors are such that ; however, none of the film widths ensure the pre-assumed robustness margin. Subsequently, and are assumed. Now, a recommendation for the film width based on the data states that a well-chosen for can be ; for there are three acceptable film widths, , of which results in the maximal robustness margin. Two film widths, are acceptable for and only one, seems to be acceptable for . Note that model-based simulations like this are helpful in understanding more deeply the impact of the model variables and parameters on film usage.

3.7. Error Analysis

Taking into account the inequalities expressed by Equations (29) and (30), the increase can be bounded as follows:

where, by Equation (26) and an analogous equation describing :

which also results directly from Equation (A3), the distance:

Having in mind Equation (26) and the last expression in Equation (35), we see that the following upper bound holds:

which means that the bigger is, i.e., the smaller and the bigger are, the smaller error for the film width may arise. Simultaneously, by Equation (39), decreasing and increasing reduces the distance between successive discontinuity points, and , from which the estimation resulting from inequality expressed in Equation (38) is closer (more accurate) for smaller . These rules can be confirmed by an inspection of data in Table 5, where the upper bounds are given for three to 16 film layers, which are reachable for the first five overlap ratios , i.e., for which the applicability condition expressed by Equation (17) holds, and being an integer multiple of 5 cm. Note that for not only the original , but also its upper bound do not exceed 4%.

Table 5.

The upper bounds defined in Equation (40) of the relative errors Equation (35), for the commercially available film widths of un-stretched film for film layers.

4. Discussion

As previously stated, disturbance in the functioning of an actual bale wrapper is the main justification for robustness studies. In view of Equation (A5), which can be rewritten as:

there is greater tolerance to overlap ratio uncertainty when the film width is increased between and its successor in the set of optimal film widths. Increasing the overlap above or decreasing them below causes a loss of optimality, even for very small uncertainties. A value smaller than may lead, especially for , to dramatically big increases in film usage, which is estimated and characterized by the left-hand sided limit described in Equation (36). The values of given for the commercially available in Table 4 for are more than twice as large as and almost twice as for respective film widths, regardless of the number of film layers. It may be observed that the bigger is, the smaller the increase in film consumption is, if the overlap ratio decreases below . For the limit is about one and a half times bigger than and . Additionally, Figure 6 shows how the overlap ratio uncertainty in the near left-neighborhood of an arbitrary influences film consumption. Simultaneously, the robustness margin is reduced for larger . A quick inspection of the data in Table 4 also leads to the conclusion that a small increase of the overlap ratio above the right margin of the ‘optimality’ interval results in significantly smaller increases in film usage, because the right-hand sided limit , Equation (37), is such that for , where the ratio is:

For , this ratio is characterized by ; for and the estimations are and , respectively. Thus, paradoxically, optimal parameters may lead to dramatically unfavorable film consumption if any disturbance appears, which, therefore, must be absolutely avoided, while near-optimal parameters, not much bigger than , may result in almost optimal film usage. Both the reported properties suggest that, since the intervals of optimal overlap ratios contain only the right neighborhood of , it is reasonable to take , rather than the exact , or such overlaps that belong to the interior of the interval , as in the Algorithm.

Proposition 4 demonstrates that the optimal and robust design of the film width and overlap ratio generally lead to conflicting requirements. Based on the results of numerical studies conducted for the exemplary bale, as seen in Table 6, the widths of practically available film from the range , which guarantee minimal film consumption or maximal robustness margins , are summarized for three to 10 basic film layers. Since does not depend on the specific , also the quotient is -independent. Thus, the analysis concerning the choice of the film width and, in particular, the recommendations summarized in Table 6, are suitable for any satisfying the applicability condition for the assumed . However, the value of the margin depends on , as stated previously.

Table 6.

The minimal film consumption or maximal robustness margins attainable for the commercially available film widths of un-stretched film (marked by the sign ‘x’) for film layers.

5. Conclusions

The combined problem of the optimal selection, in the film consumption sense, of the overlap ratio and film width, jointly, was stated and solved for the first time; Proposition 3 abstracts this solution. Complete sets of the optimal film widths and optimal overlap ratios were determined. These parameters, although optimal, did not provide any robustness to overlap ratio variations, even for very small uncertainties. It was shown that the robustness was achieved if non-optimal film widths were applied. From a practical perspective, only commercially available film widths were to be taken into account, for which this approach leads to an approximate value of the optimal . Thus, the problem of the robustly optimal design of the wrapping parameters in the set of commercially available film widths was stated and solved; Proposition 4 abstracts this solution. However, it was proven that the requirements of the minimal film consumption and maximal robustness are incompatible. Subsequently, to achieve both satisfactory robustness and small film usage, a new algorithm for wrapping parameter design was proposed. What we must keep in mind, from a film consumption minimization point of view, is that the numerical studies indicate that choosing an appropriate overlap ratio affects film consumption more than choosing an optimal film width.

Usually, it is difficult to guarantee the robustness of the process design for parameter disturbances. One large benefit of the presented model-based approach is that it allows for showing that small uncertainties in the overlap ratios do not result in the increase of the film consumption with some robustness margin. This is due to the properties of the ceiling and floor functions in the model describing the film consumption. In particular, it was proven that the optimal overlap ratio does not need to be exactly in a rational irreducible number form stated in Equation (16). Consequently, slight increases of the commonly used 50%, 67%, and 75% overlaps did not result in the loss of the optimality and guarantee desired robustness. Additionally, this fortunate result follows from the fact that the ceiling function is a piecewise-constant.

Note that the optimality conditions and design rules were obtained under general and not limiting assumptions concerning the bale and film dimensions, which can be chosen arbitrarily.

Funding

This research received no external funding.

Conflicts of Interest

The author declares no conflict of interest.

Appendix A

Appendix A.1. Derivation of the Limit Stated in Equation (28)

For fixed by Equation (27), in order to estimate the left-hand sided limit of as tends to , it is enough to find:

By virtue of Equation (24), for any , the equality holds:

which yields:

Since for , by Equations (24) and (25) we have:

where is the number if entire film wrappings; then, for , the next equation is satisfied:

Combining Equations (A2) and (A3) yields:

whence, in view of Equations (A1) and (27), the limit result is:

which by Equation (A2) is equivalent to that described by Equation (28).

Appendix A.2. Proof of Proposition 4

To prove the first result of the Proposition, the increase , defined by Equation (32), of the index described by Equation (21) must be estimated. By Equations (23) and (21) we have:

The conditions from Equations (30) and (24) imply:

Including Equation (29), after simple algebraic manipulations, we obtain:

whence the validity of thesis (i) follows immediately; by Equation (23) the rule stated in Equation (33) results.

In order to prove thesis (ii) the overlap ratio given by Equation (27) for the film width , defined by Equation (29), is estimated. From Equations (27) and (29), having in mind Equation (A4), we have:

which immediately yields Equation (34). Thus, maximal in the set relative increase described by Equation (31) results in the largest (in this set) coefficient and thesis (ii) is proven.

Appendix A.3. Derivation of the Limit Expressed by Equation (36)

First the left-sided limit of at discontinuity point described by Equation (16) will be determined. Since for:

where is direct predecessor of in the set , the inequalities hold:

which yields:

Thus, this left-sided limit there exists and in view of Equations (6), (A6), and (16) is as follows:

from which, by Equation (8), we have:

The limit expressed by Equation (36) follows immediately.

Appendix B

Appendix B.1. Nomenclature

| width of un-stretched film, m | |

| width of stretched film, Equation (1), m | |

| discontinuity points of the function with respect to film width, Equations (10) and (13), m | |

| commercially available width of the film, m | |

| set of all film widths that may be commercially available | |

| difference between and , Equation (29), m | |

| film width optimal in the sense of the function , Equations (24) and (26), m | |

| direct successor of in the set , m | |

| set of all optimal film widths | |

| bale diameter, m | |

| bale height, m | |

| film consumption index, Equation (8), m−1 | |

| film consumption optimal with respect to the film width, Equation (11), m−1 | |

| film consumption optimal with respect to the overlap ratio , Equation (21), m−1 | |

| film consumption optimal with respect to film width and overlap ratio, Equation (23), m−1 | |

| increase of the film consumption index with respect to , m−1 | |

| left-hand sided limit of film consumption index in the point , Equation (36), m–1 | |

| right-hand sided limit of film consumption index in the point , Equation (37), m−1 | |

| relative error of the increase of film usage with respect to , Equation (35), % | |

| the upper bound of expressed by Equation (40), % | |

| number of entire wrappings, Equation (5) | |

| overlap ratio | |

| discontinuity point of the function with respect to the overlap ratio, Equation (14) | |

| overlap ratio in the form of irreducible fraction expressed by Equation (16) | |

| the set of all overlap ratios | |

| direct successor of in the set | |

| set of the optimal overlap ratios for fixed film width | |

| integer number; twice the number of entire wrappings | |

| number of rotations of the bale around its axis | |

| set of all positive integer numbers | |

| pre-assumed number of basic film layers | |

| surface area of the film used to wrap the bale, Equation (7), m2 | |

| Poisson’s ratio of the stretch film | |

| bale volume, m3 | |

| unit deformation of the stretch film | |

| function of the overlap ratio defined by Equation (6) | |

| coefficient defined by Equation (19) | |

| robustness margin of the optimal overlap ratio, Equations (20) and (27), m | |

| increment of the overlap ratio , m | |

| upper bound of the robustness margin described by Equation (28), m | |

| coefficient defined by Equation (18) |

Appendix B.2. Mathematical Terminology

| the smallest integer not less than , ceiling function | |

| the largest integer not greater than , floor function | |

| find the value of , which minimizes the function |

References

- Wang, J.; Wang, J.; Bu, D.; Guo, W.J.; Song, Z.T.; Zhang, J.Y. Effect of storing total mixed rations anaerobically in bales on feed quality. Anim. Feed Sci. Technol. 2010, 161, 94–102. [Google Scholar] [CrossRef]

- Guerrieri, A.S.; Anifantis, A.S.; Santoro, F.; Pascuzzi, S. Study of a large square baler with innovative technological systems that optimize the baling effectiveness. Agriculture 2019, 9, 86. [Google Scholar] [CrossRef]

- Schmitz, A.; Moss, C.B. Mechanized Agriculture: Machine Adoption, Farm Size, and Labor Displacement. AgBioForum 2015, 18, 278–296. [Google Scholar]

- Buxton, D.R.; Muck, R.E.; Harrison, J.H. Silage Science and Technology; Agronomy Series Monograph No. 42; American Society of Agronomy, Inc.: Madison, WI, USA; Crop Science Society of America, Inc.: Madison, WI, USA; Soil Science Society of America: Madison, WI, USA, 2003. [Google Scholar]

- Bortolini, M.; Cascini, A.; Gamberi, M.; Mora, C. Environmental assessment of an innovative agricultural machinery. Int. J. Oper. Quant. Manag. 2014, 20, 243–258. [Google Scholar]

- Queiroz, O.C.M.; Ogunade, I.M.; Weinberg, Z.; Adesogan, A.T. Silage review: Foodborne pathogens in silage and their mitigation by silage additives. J. Dairy Sci. 2018, 101, 4132–4142. [Google Scholar] [CrossRef]

- Coblentz, W.K.; Akins, M.S. Silage review: Recent advances and future technologies for baled silages. J. Dairy Sci. 2018, 101, 4075–4092. [Google Scholar] [CrossRef]

- Grant, R.J.; Ferraretto, L.F. Silage review: Silage feeding management: Silage characteristics and dairy cow feeding behaviour. J. Dairy Sci. 2018, 101, 4111–4121. [Google Scholar] [CrossRef]

- Borreani, G.; Tabacco, E. New concepts on baled silage. In Proceedings of the 2nd International Conference on Forages, Lavras, Brazil, 28–30 May 2018; pp. 49–73. [Google Scholar]

- Wilkinson, J.M.; Rinne, M. Highlights of progress in silage conservation and future perspectives. Grass Forage Sci. 2018, 73, 40–52. [Google Scholar] [CrossRef]

- Li, L.; Wang, D.; Yang, X. Study on round rice straw bale wrapping silage technology and facilities. Int. J. Agric. Biol. Eng. 2018, 11, 88–95. [Google Scholar] [CrossRef]

- Ivanovs, S.; Gach, S.; Skonieczny, I.; Adamovičs, A. Impact of the parameters of round and square haylage bales on the consumption of the sealing film for individual and in-line wrapping. Agron. Res. 2013, 11, 53–60. [Google Scholar]

- Gaillard, F. L’ensilage en balles rondes sous film étirable. Fourrages 1990, 123, 289–304. [Google Scholar]

- Borreani, G.; Bisaglia, C.; Tabacco, E. Effects of a new-concept wrapping system on alfalfa round-bale silage. Trans. ASABE 2007, 50, 781–787. [Google Scholar] [CrossRef]

- Angelov, I.; Slavov, V.; Kalym, K.; Karaivanov, D. Kinematics of haylage bale in 3D space as a body of one fix point and two rotations. Meccanica 2014, 49, 739–747. [Google Scholar] [CrossRef]

- Round Balers. I-Bio+. Bale and Wrap in One Go. Available online: http://www.kuhn.com.pl/internet/webpl.nsf/0/C12577680057083DC12579990053A8ED/$File/i-BIO_GB.pdf/ (accessed on 29 August 2019).

- Balsari, P. La tecnica della fasciatura delle rotoballe per l’insilamento del foraggio. L’Inf. Agrar. 1990, 22, 33–47. [Google Scholar]

- Muise, I.; Adams, M.; Cote, R.; Price, G.W. Attitudes to the recovery and recycling of agricultural plastics waste: A case study of Nova Scotia, Canada. Resour. Conserv. Recycl. 2016, 109, 137–145. [Google Scholar] [CrossRef]

- Nowak, J. Analysis and Evaluation of the Round Bale Silage Production; AR Publishing House: Lublin, Poland, 1997. (In Polish) [Google Scholar]

- Baldasano, J.M.; Gassó, S.; Pérez, C. Environmental performance review and cost analysis of MSW landfilling by baling-wrapping technology versus conventional system. Waste Manag. 2003, 23, 795–806. [Google Scholar] [CrossRef]

- Stankiewicz, A. On the uniform distribution and optimal consumption of stretch film used for wrapping cylindrical baled silage. Grass Forage Sci. 2019, 74, 584–595. [Google Scholar] [CrossRef]

- Hong, S.; Kang, D.; Kim, D.; Lee, S. Analysis of bale surface pressure according to stretch film layer changes on round bale wrapping. J. Biosyst. Eng. 2017, 42, 136–146. [Google Scholar] [CrossRef]

- Bisaglia, C.; Tabacco, E.; Borreani, G. The use of plastic film instead netting when tying round bales for wrapped baled silage. Biosyst. Eng. 2011, 108, 1–8. [Google Scholar] [CrossRef]

- Stępniewski, A.; Nowak, J.; Stankiewicz, A. Analytical model of foil consumption for cylindrical bale wrapping. Econtechmod 2016, 5, 78–82. [Google Scholar]

- Stankiewicz, A.; Stępniewski, A.A.; Nowak, J. On the mathematical modelling and optimization of foil consumption for cylindrical bale wrapping. Econtechmod 2016, 5, 101–110. [Google Scholar]

- Stankiewicz, A.; Nowak, J.; Stępniewski, A.A. Two problems of foil consumption optimization for cylindrical bales wrapping. Econtechmod 2018, 7, 97–106. [Google Scholar]

- Graham, R.L.; Knuth, D.E.; Patashnik, O. Concrete Mathematics: A Foundation for Computer Science; Addison-Wesley Publishing Company: Massachusetts Menlo Park, CA, USA; New York, NY, USA, 1989. [Google Scholar]

- Stankiewicz, A. Model-based analysis of stretch film consumption for wrapping cylindrical baled silage using combined 3D technique. Trans. ASABE 2019, 62, 803–820. [Google Scholar] [CrossRef]

- Round and Square Bale Wrappers, RW-SW SERIES. Available online: https://www.kuhn-usa.com/sites/default/files/media-nextpage-doc/706439US_RWSW_WEB.pdf (accessed on 29 August 2019).

- Coblentz, W.K.; Ogden, R.K.; Akins, M.S.; Chow, E.A. Nutritive value and fermentation characteristics of alfalfa-mixed grass forage wrapped with minimal stretch film layers and stored for different lengths of time. J. Dairy Sci. 2017, 100, 5293–5304. [Google Scholar] [CrossRef] [PubMed]

- McEniry, J.; Forristal, P.D.; O’Kiely, P. Factors influencing the conservation characteristics of baled and precision-chop grass silages. Ir. J. Agric. Food Res. 2011, 50, 175–188. [Google Scholar]

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).