Design and Experiment of a Universal Harvesting Platform for Cabbage and Chinese Cabbage

Abstract

1. Introduction

2. Universal Harvesting Strategy and Overall Scheme

2.1. Cabbage and Chinese Cabbage Varieties and Their Main Cultivation Patterns

2.1.1. Cabbage and Chinese Cabbage Varieties

2.1.2. Cabbage and Chinese Cabbage Main Cultivation Patterns

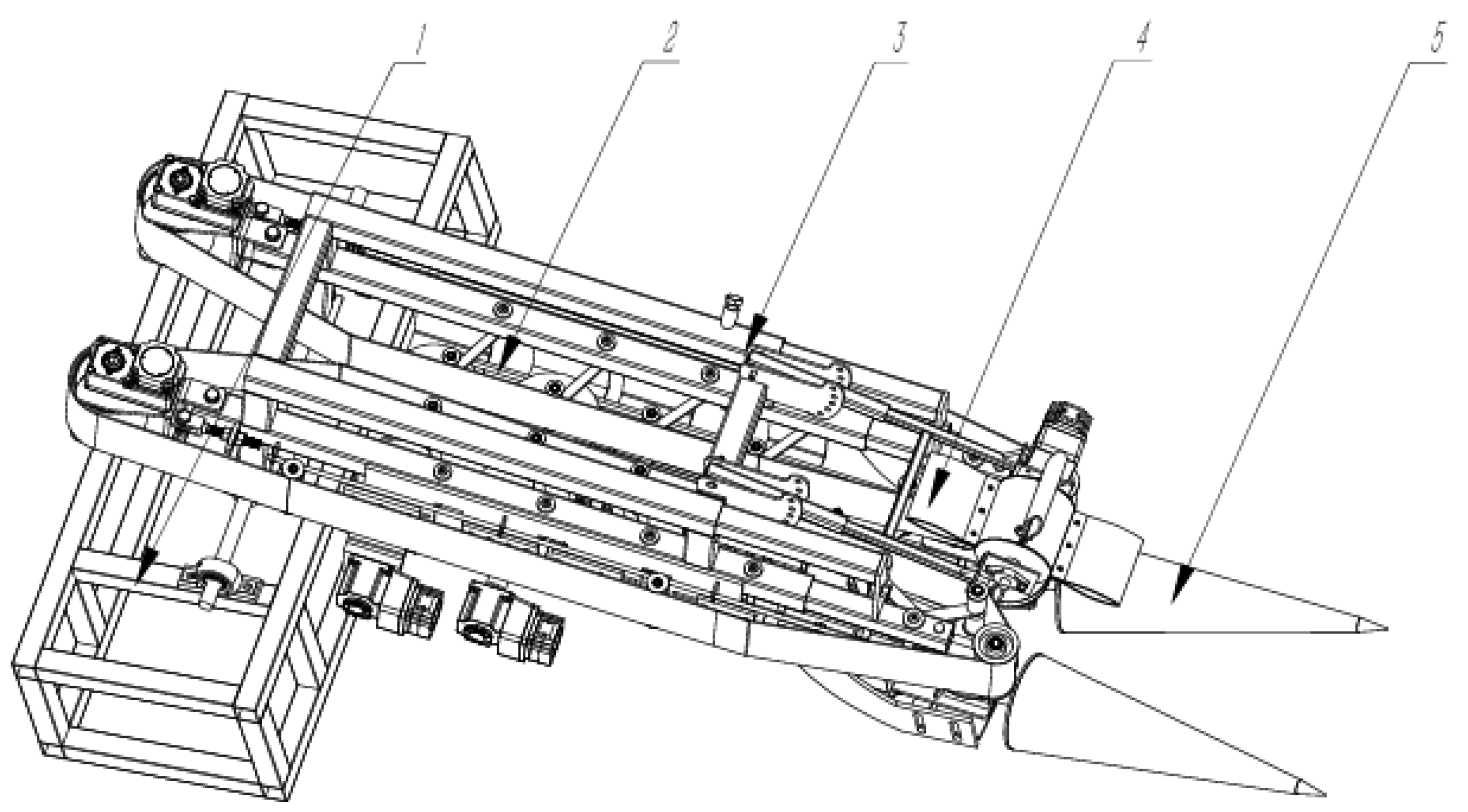

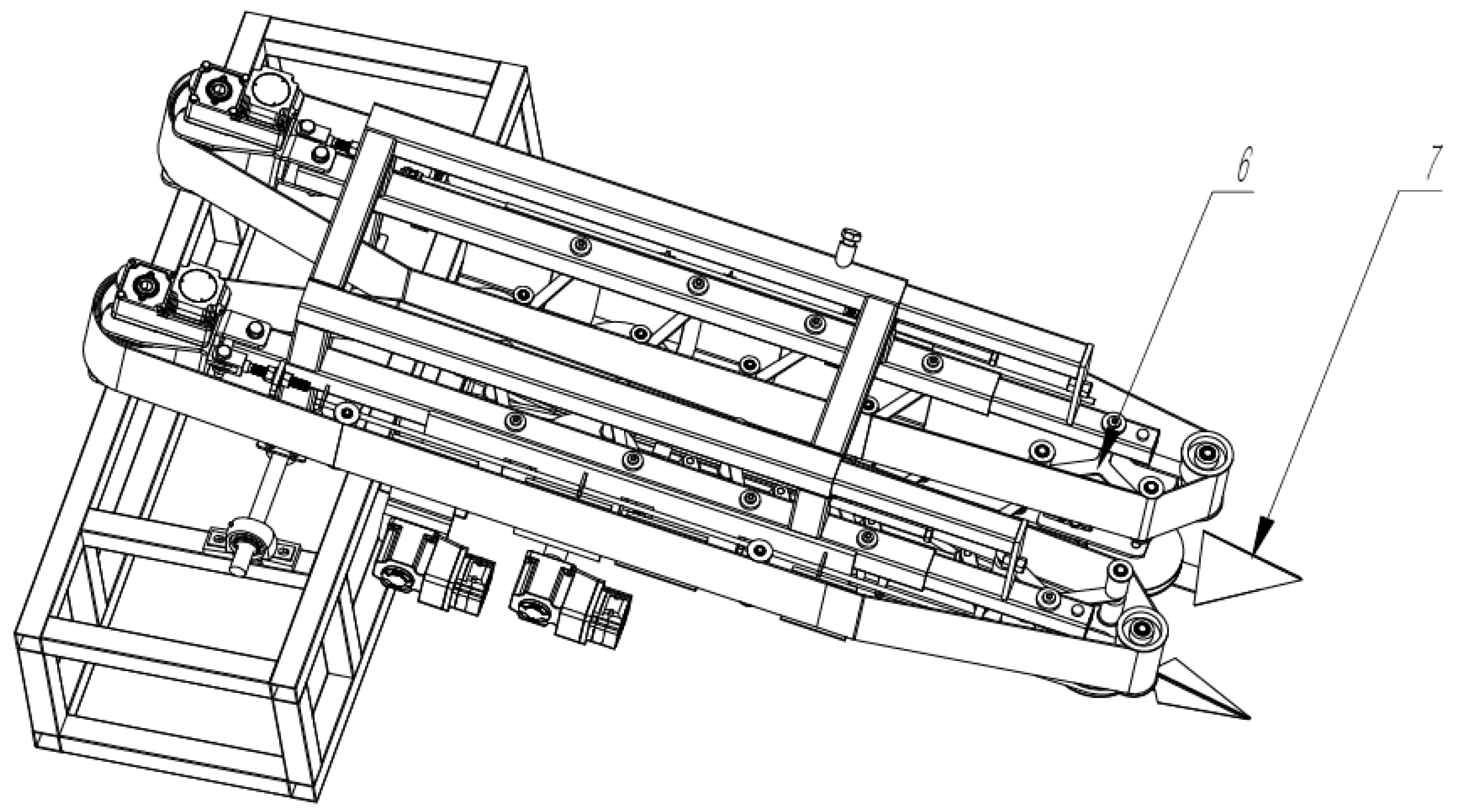

2.2. Overall Structure and Working Principle

2.2.1. Cabbage Harvesting

2.2.2. Chinese Cabbage Harvesting

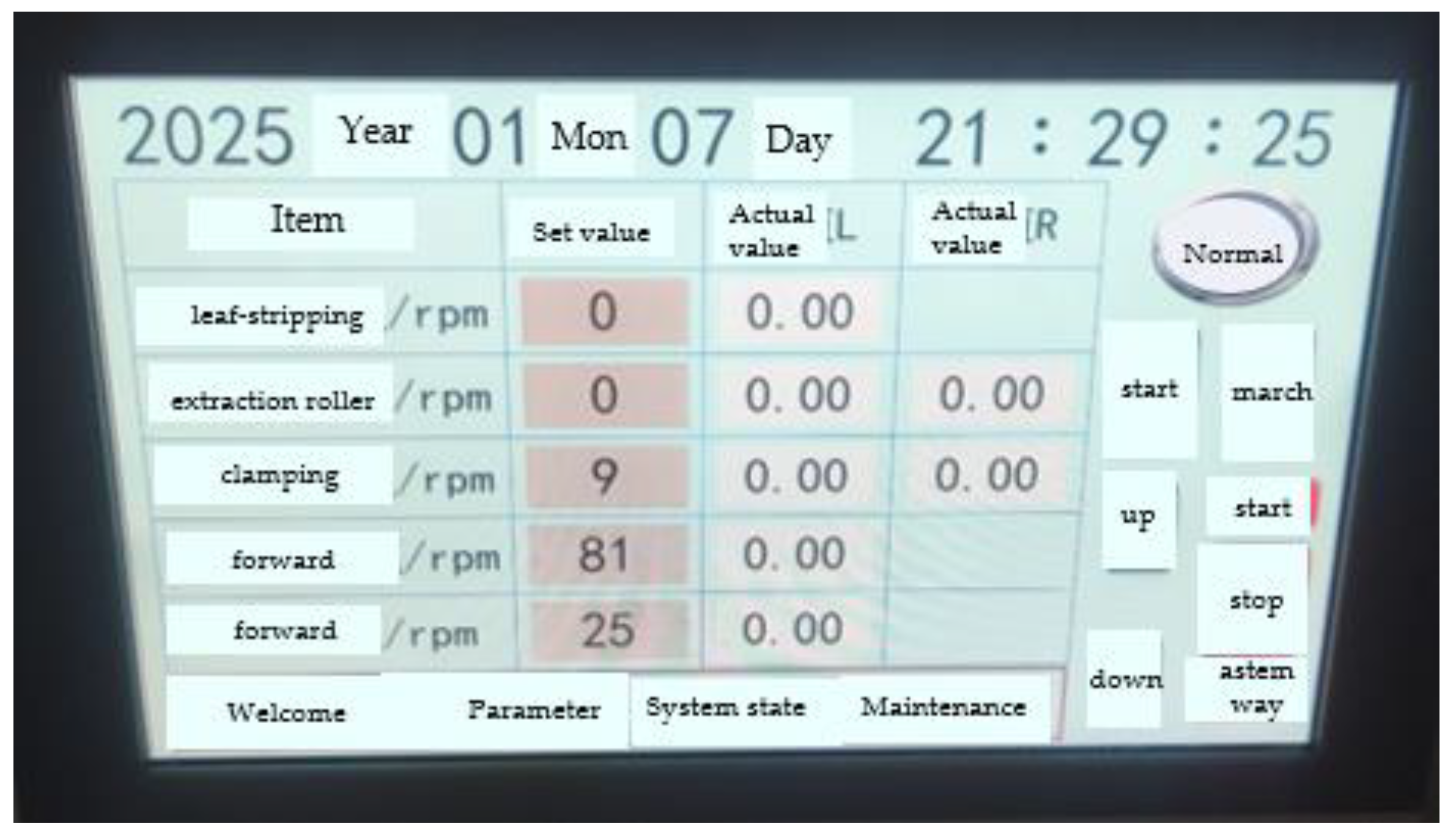

2.3. Technical Parameters

3. Structure Design and Motion Analysis of Key Components

3.1. Cabbage Extraction Device

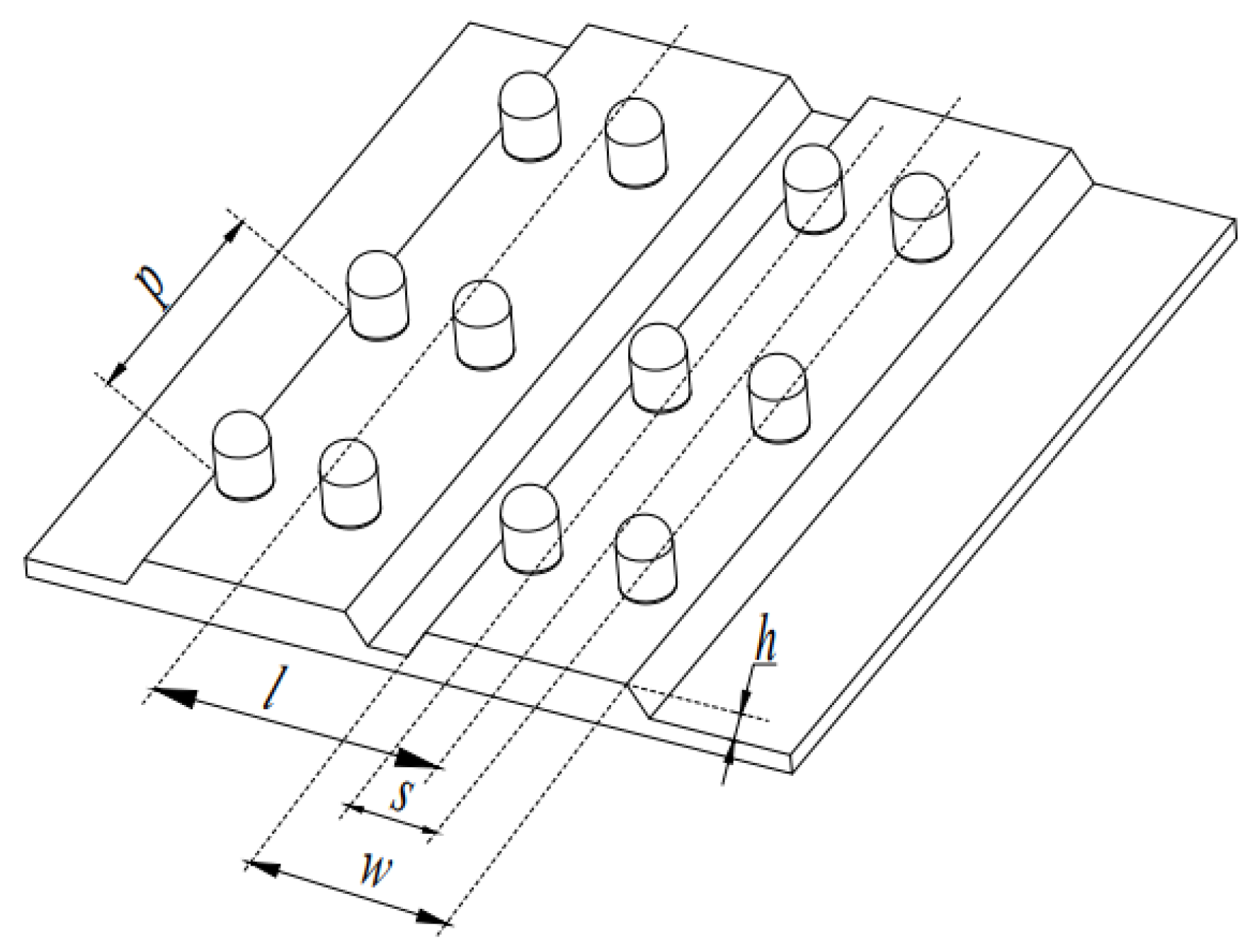

3.1.1. Structural Design of the Leaf-Stripping Wheel

3.1.2. Force Analysis of the Leaf-Stripping Wheel

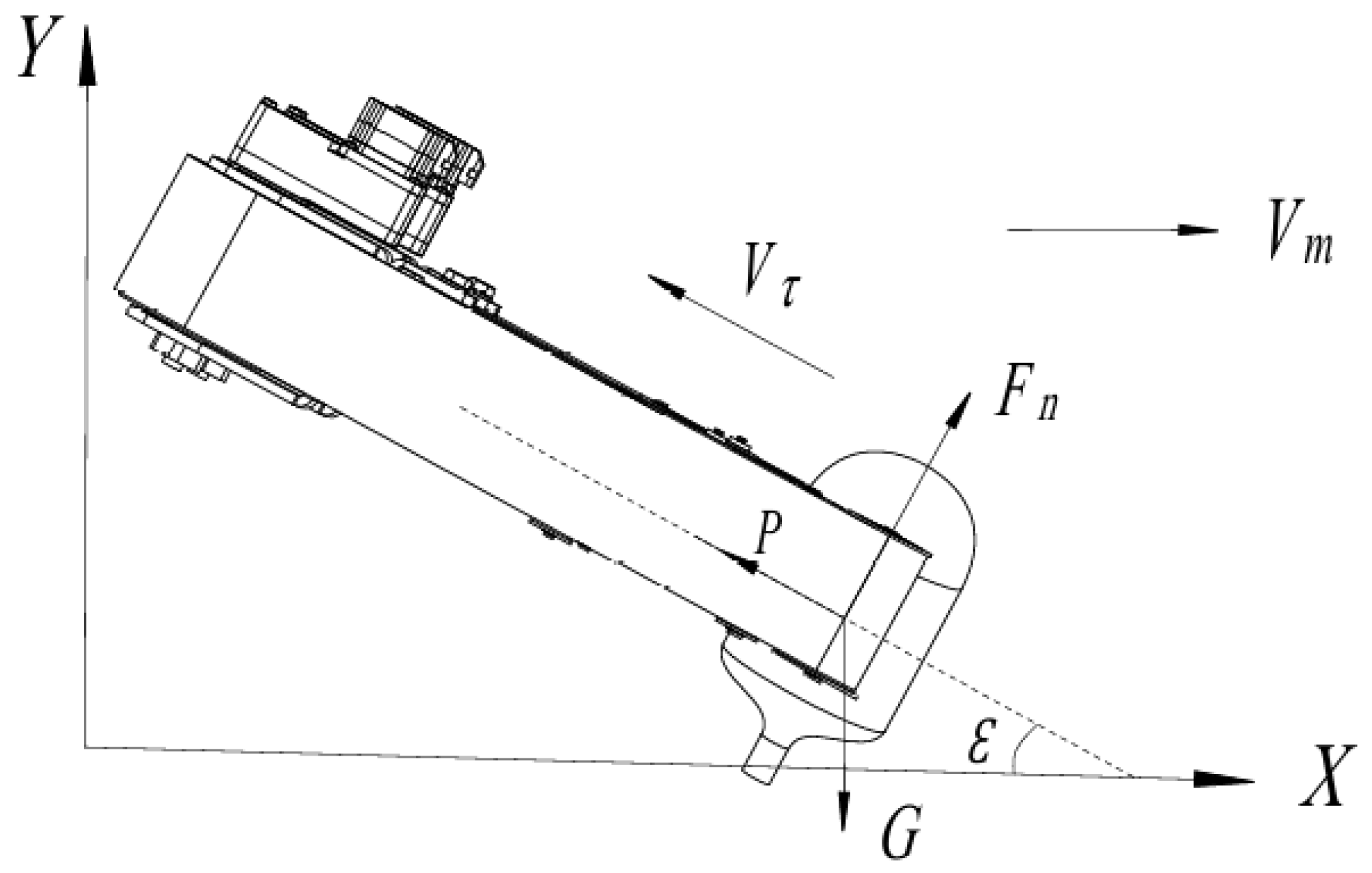

3.1.3. Design of the Extraction Roller Structure

3.1.4. Force Analysis of the Extraction Roller

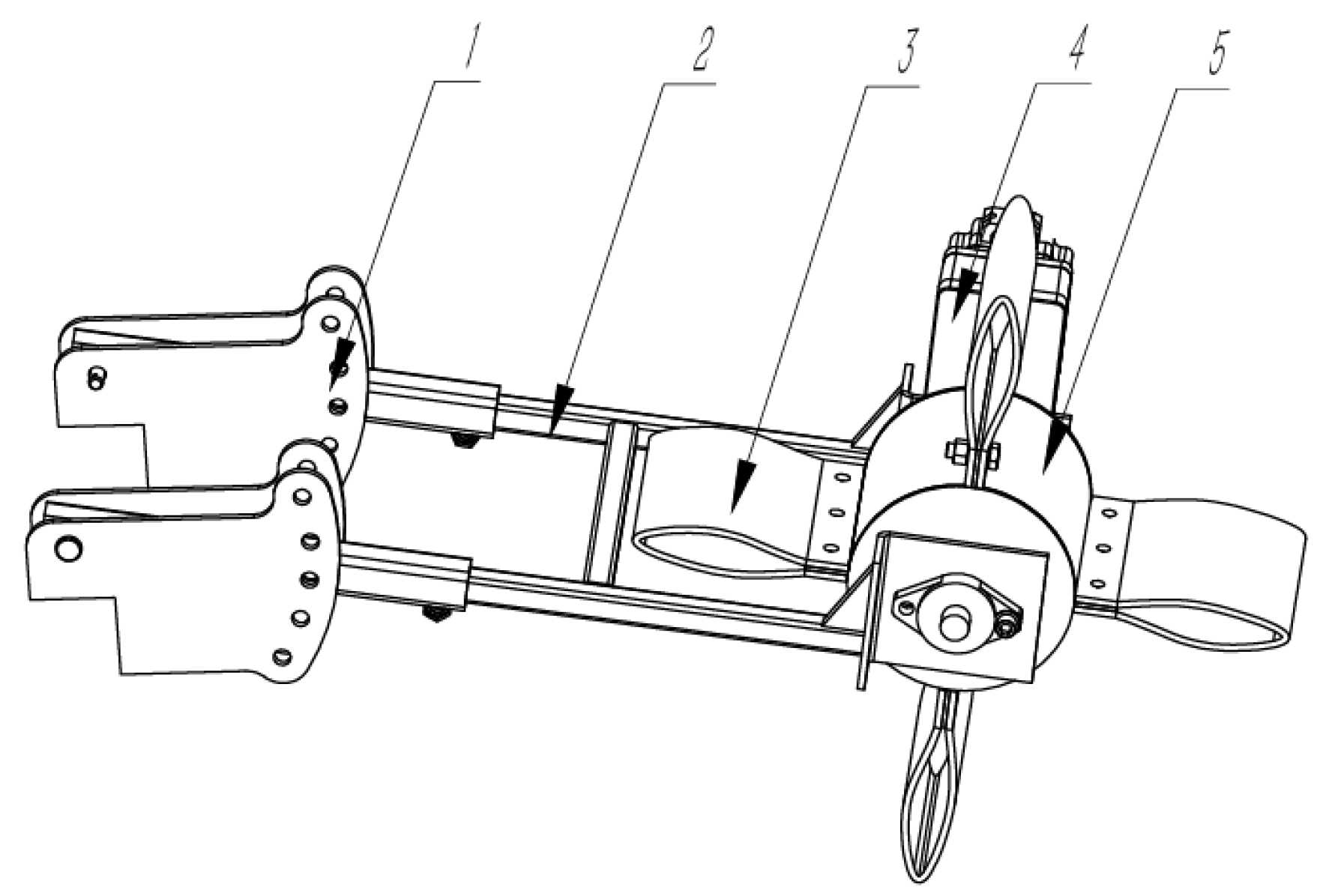

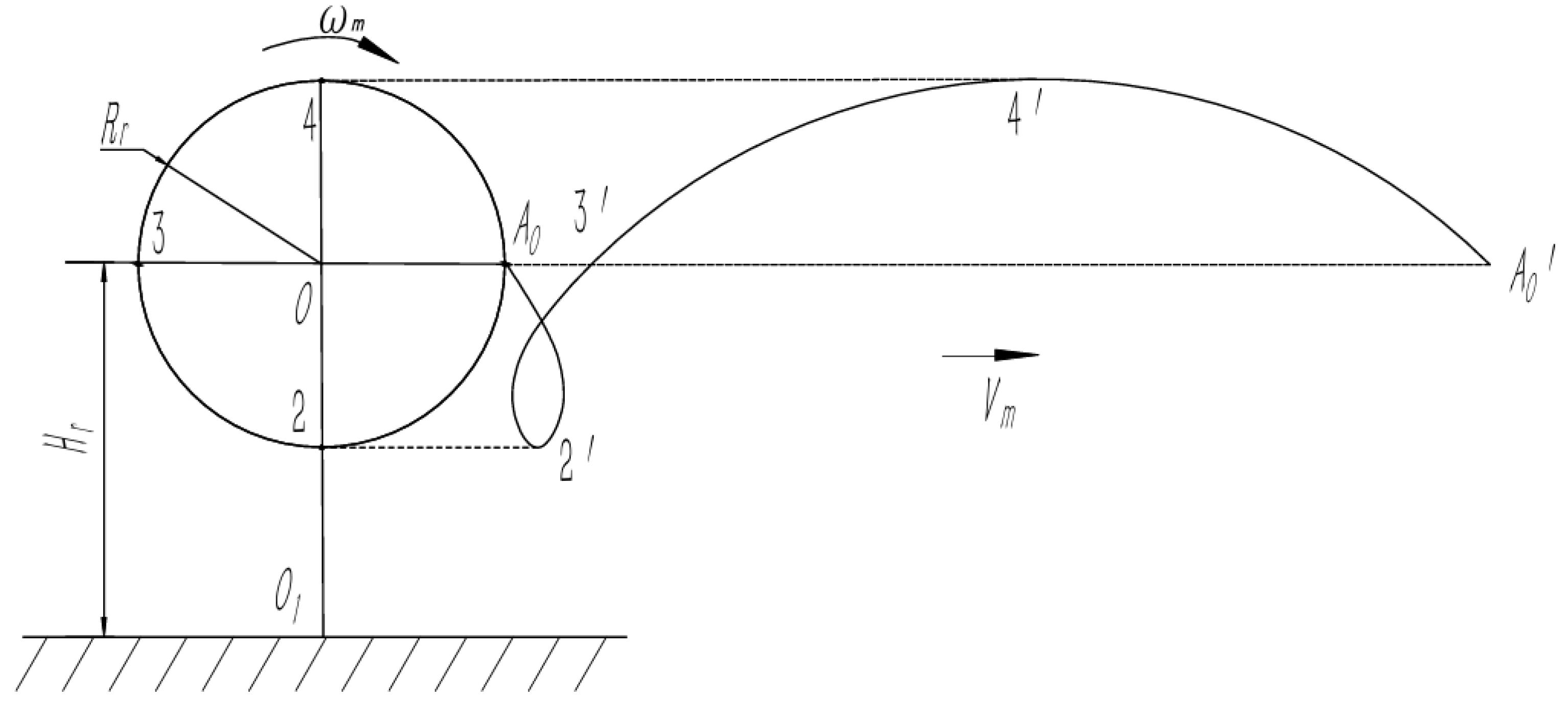

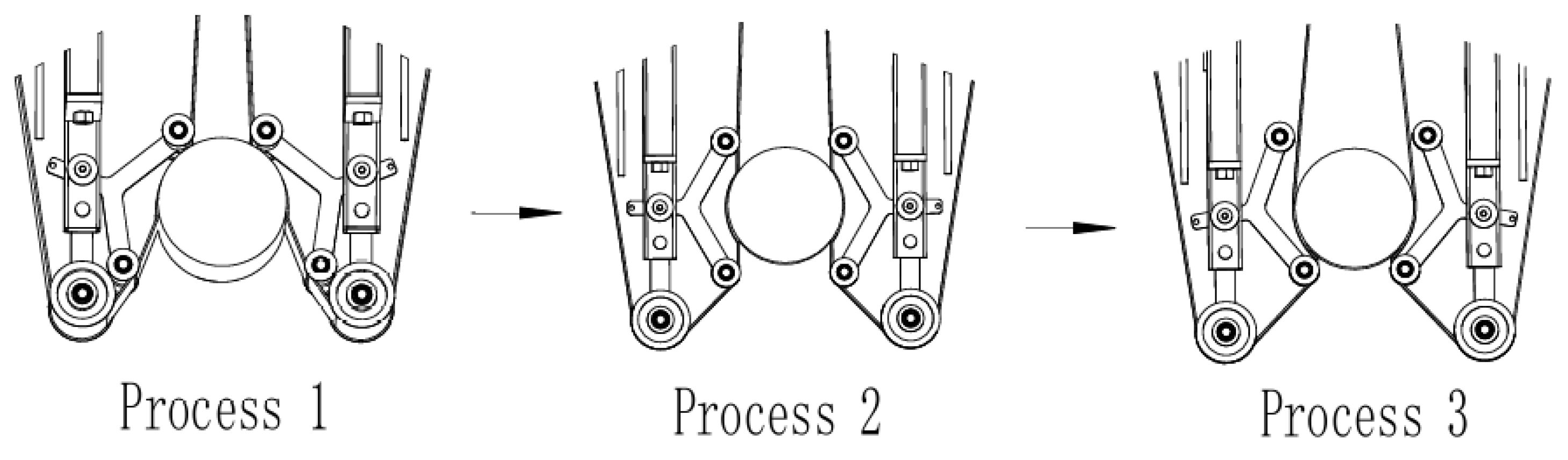

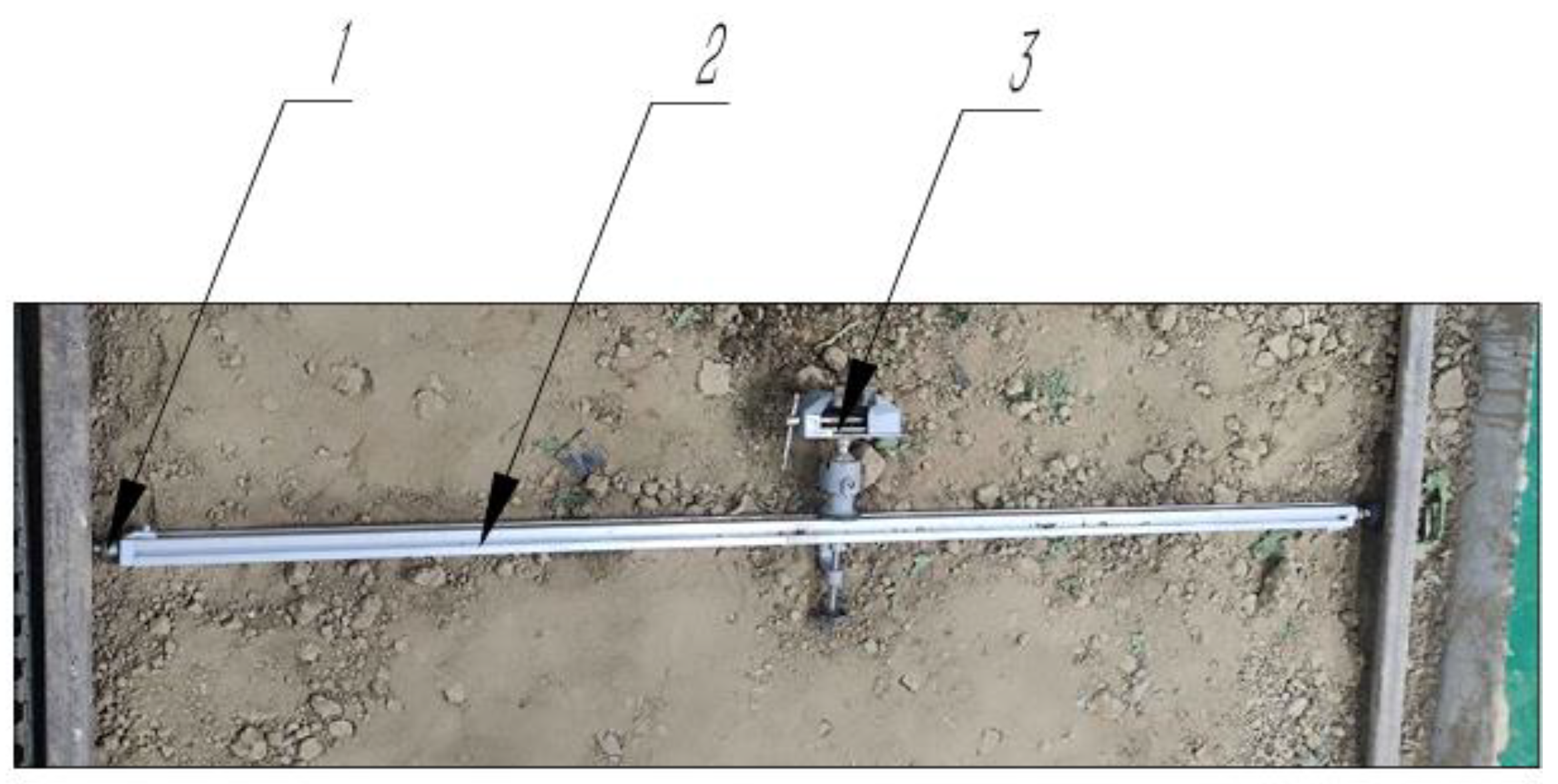

3.2. Chinese Cabbage Extraction Device

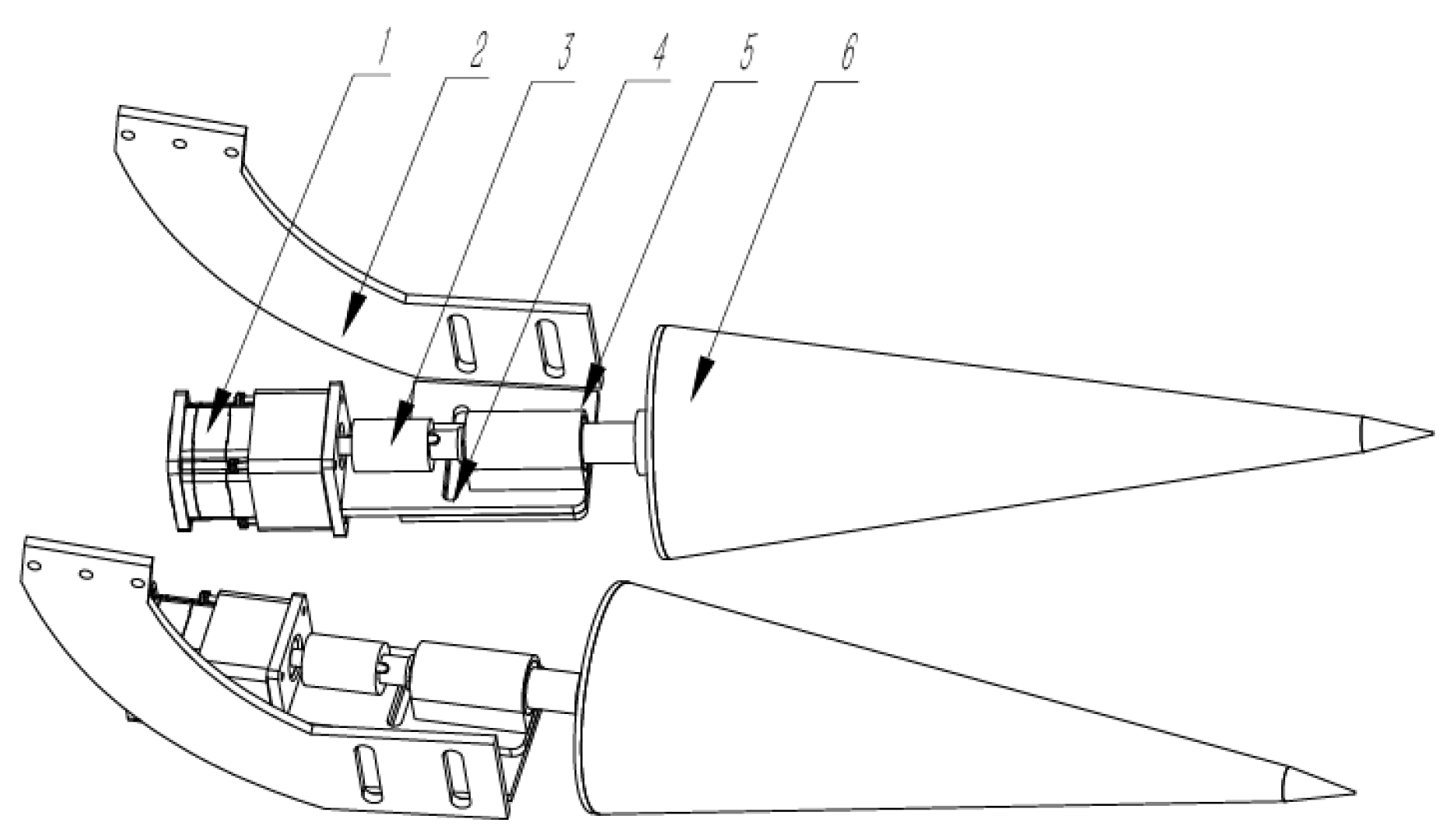

3.2.1. Design of the Y-Type Extraction Device Structure

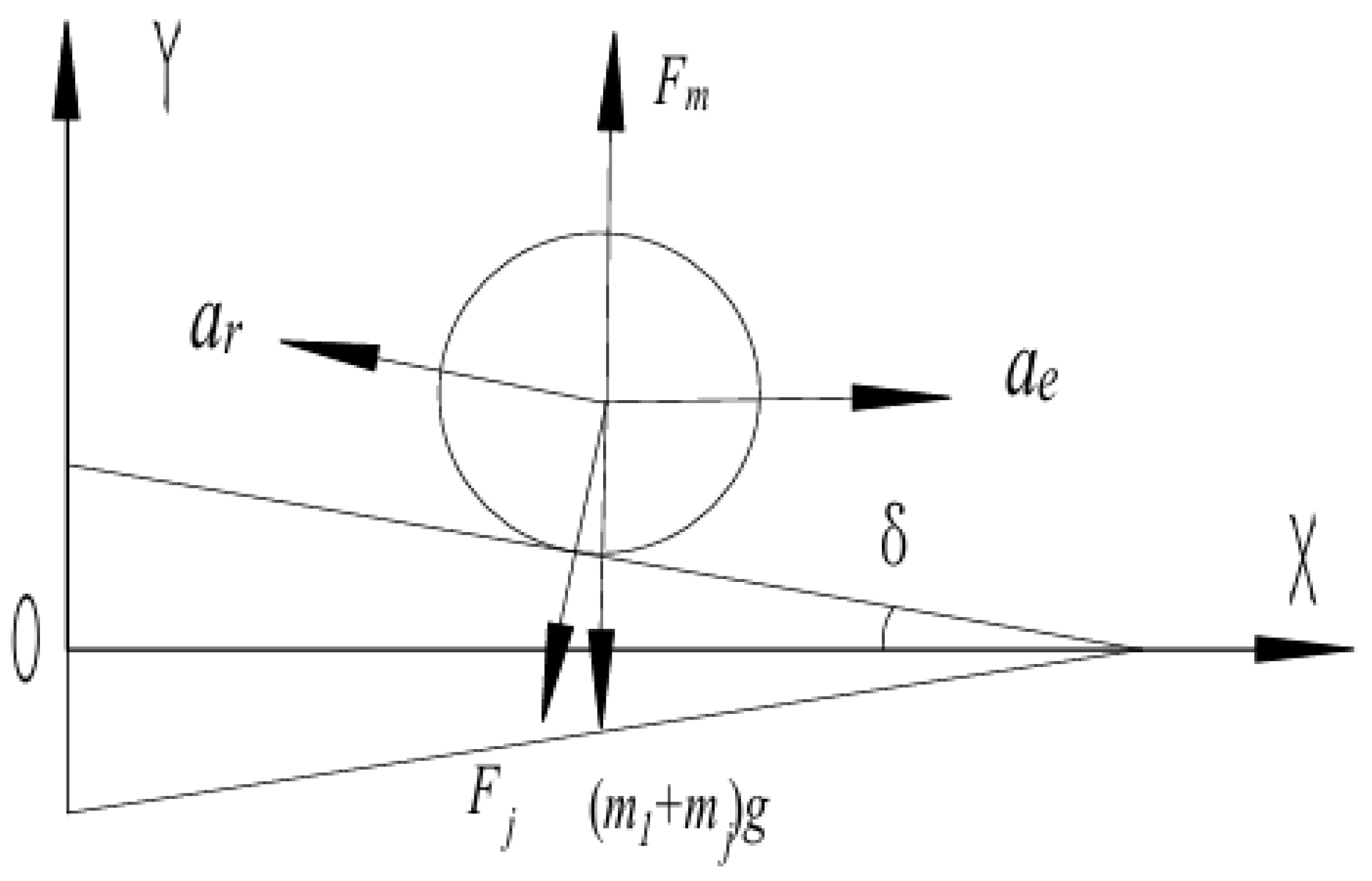

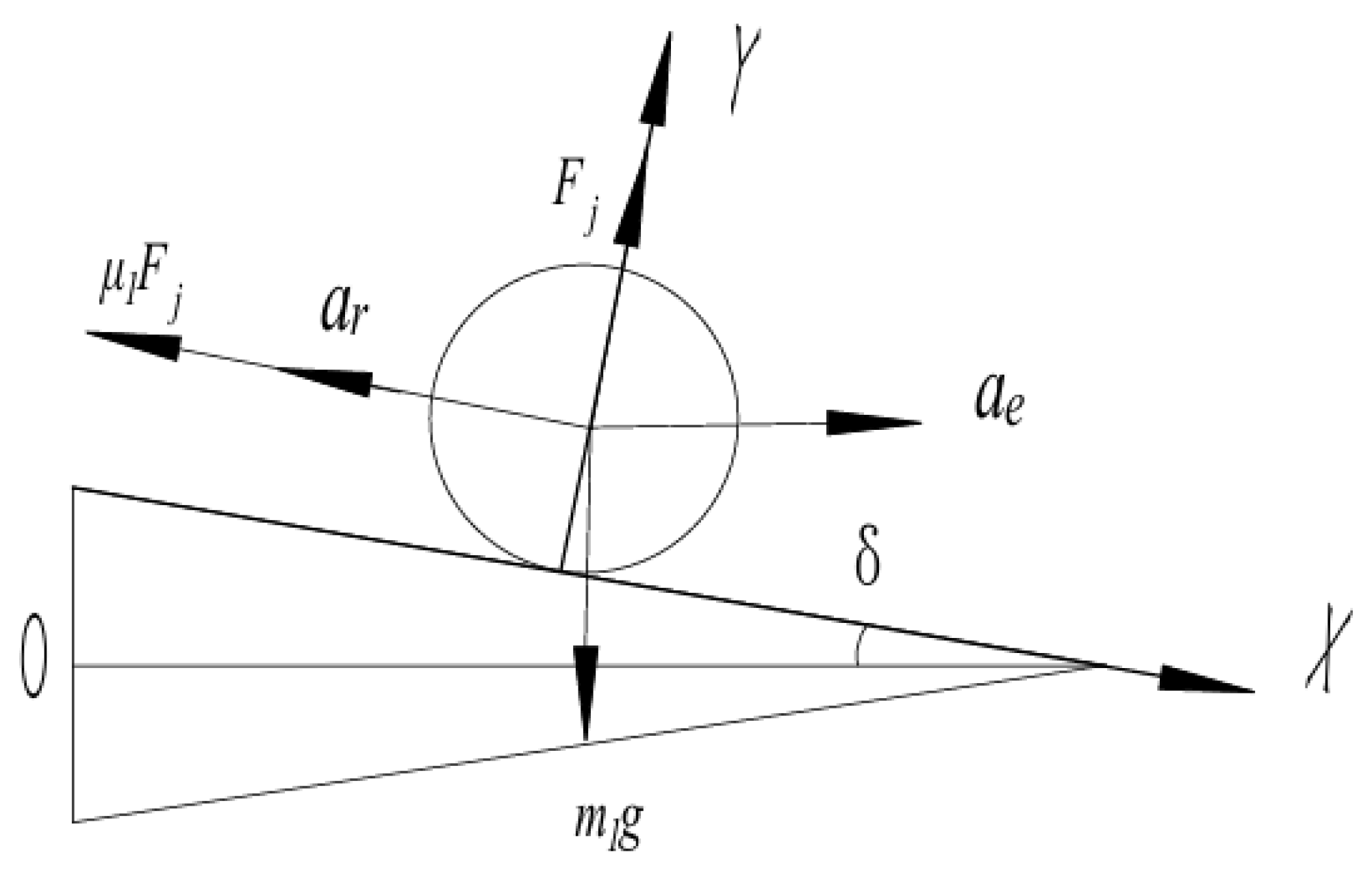

3.2.2. Mechanical Analysis of the Y-Type Extraction Device

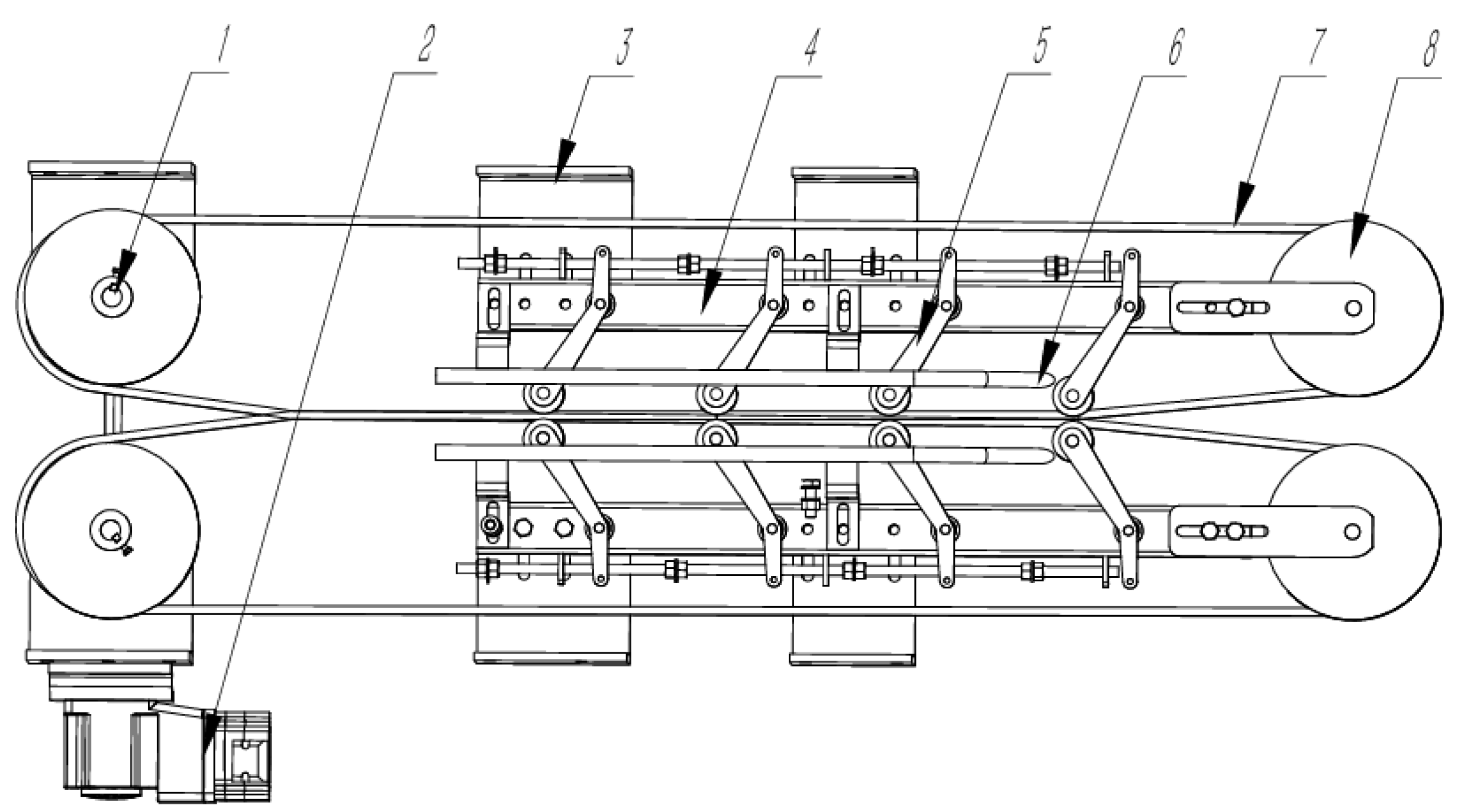

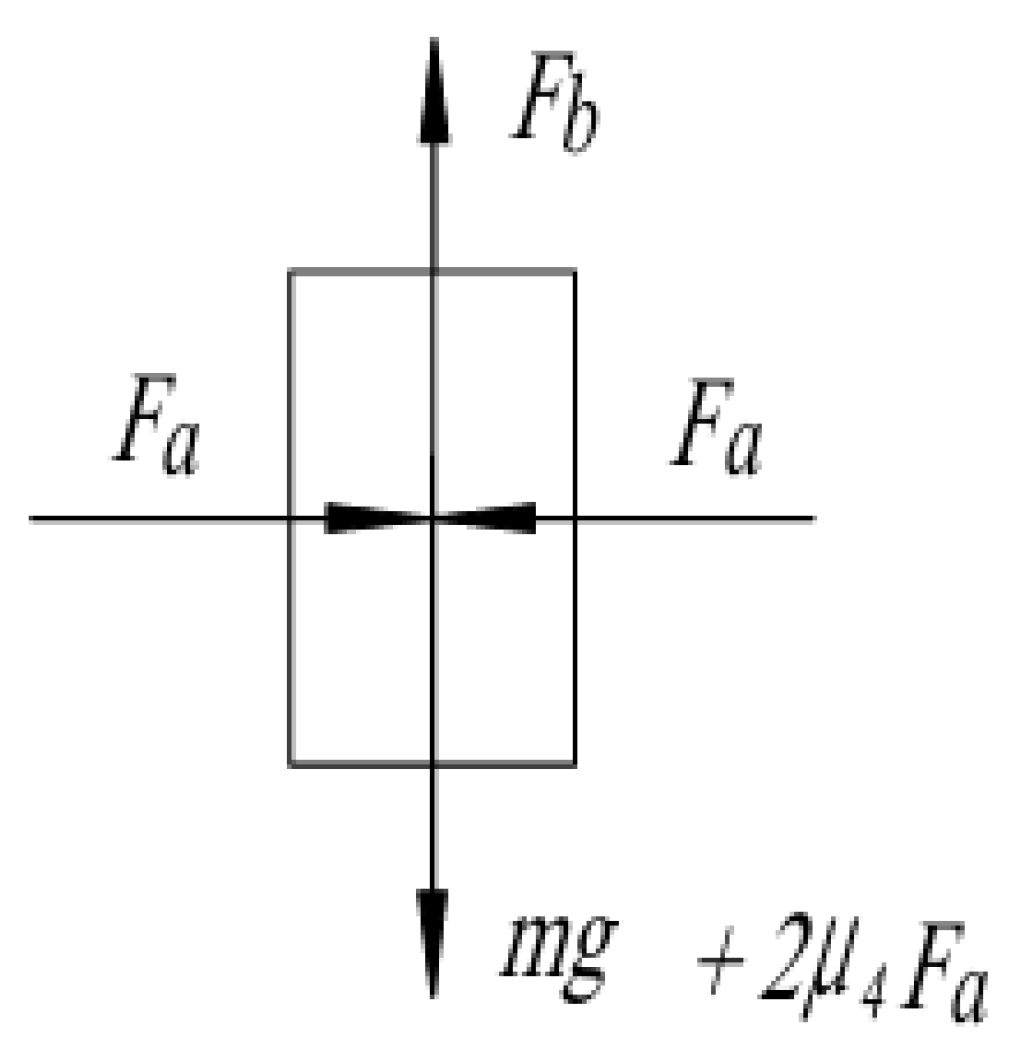

3.3. Clamping and Conveying Device Design and Analysis

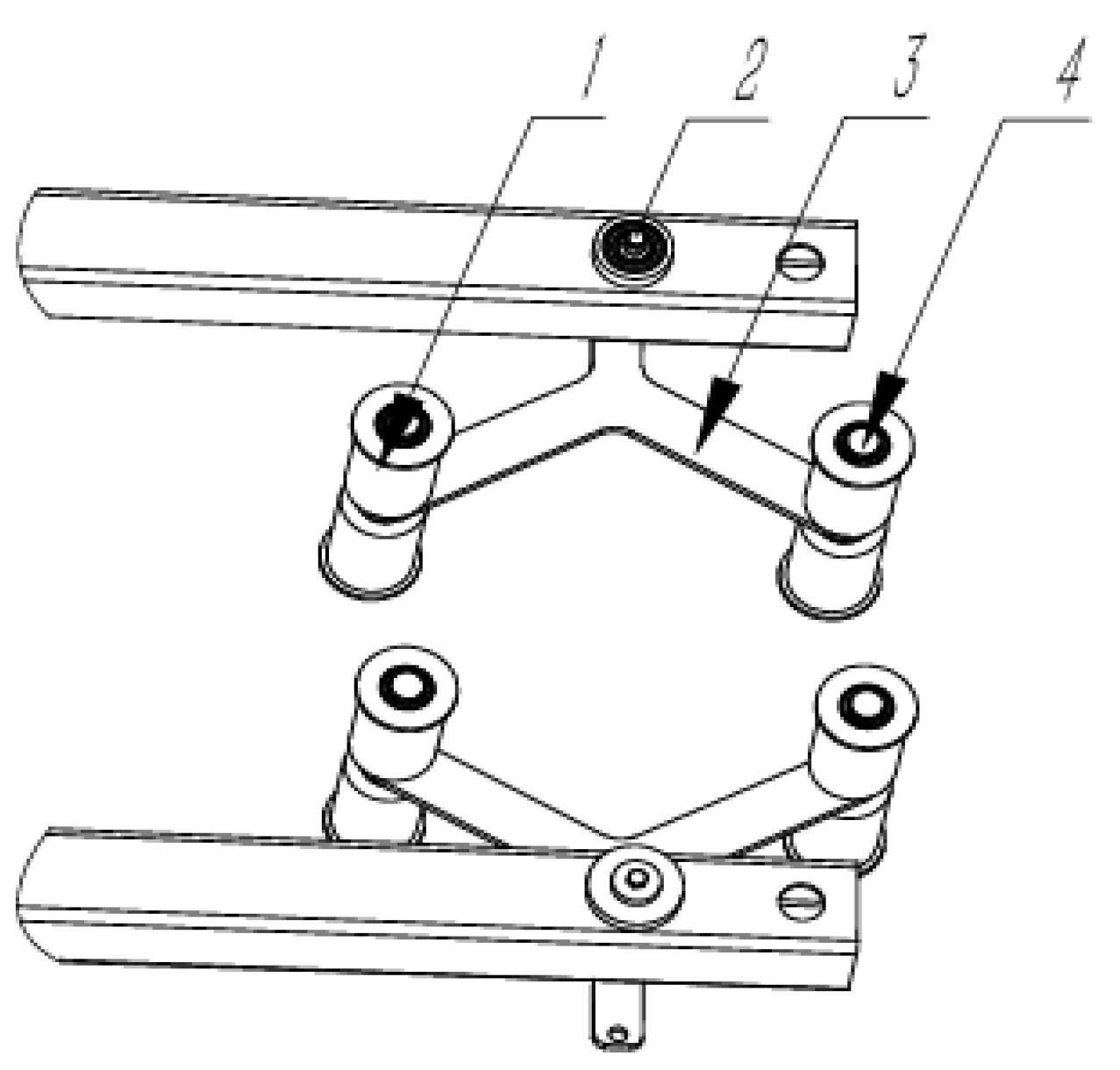

3.3.1. Structural Design of the Clamping Device

3.3.2. Structural Design of the Root-Clamping Device

3.3.3. Mechanical Analysis of the Clamping and Conveying Device

4. Soil-Trough Harvesting Experiment

4.1. Soil-Trough Experimental Conditions

4.2. Experimental Conditions, Methods, and Results for Chinese Cabbage

4.2.1. Experimental Conditions for Chinese Cabbage

4.2.2. Experimental Methods for Chinese Cabbage

- (1)

- Extraction Success Rate

- (2)

- Clamping and Conveying Success Rate

- (3)

- Operational Damage Rate

- (1)

- Single-factor experiment for forward speed: During the experiment, the conveyor belt speed was fixed at 60 RPM. The forward speed started at 0.8 km·h−1, and in each experiment, the forward speed was increased by 0.1 km·h−1. A total of five groups of experiments were conducted, with the maximum forward speed reaching 1.2 km·h−1;

- (2)

- Single-factor experiment for conveyor belt speed: During the experiment, the forward speed was fixed at 1 km·h−1. The conveyor belt speed started at 40 RPM, and in each experiment, the speed was increased by 10 RPM. A total of five groups of experiments were conducted, with the maximum conveyor belt speed reaching 80 RPM.

4.2.3. Experimental Results and Analysis for Chinese Cabbage

4.3. Experimental Conditions, Methods, and Results for Cabbage

4.3.1. Experimental Conditions for Cabbage

4.3.2. Experimental Methods for Cabbage

- (1)

- Extraction and Feeding Success Rate

- (2)

- Conveying Success Rate

- (3)

- Operational loss rate

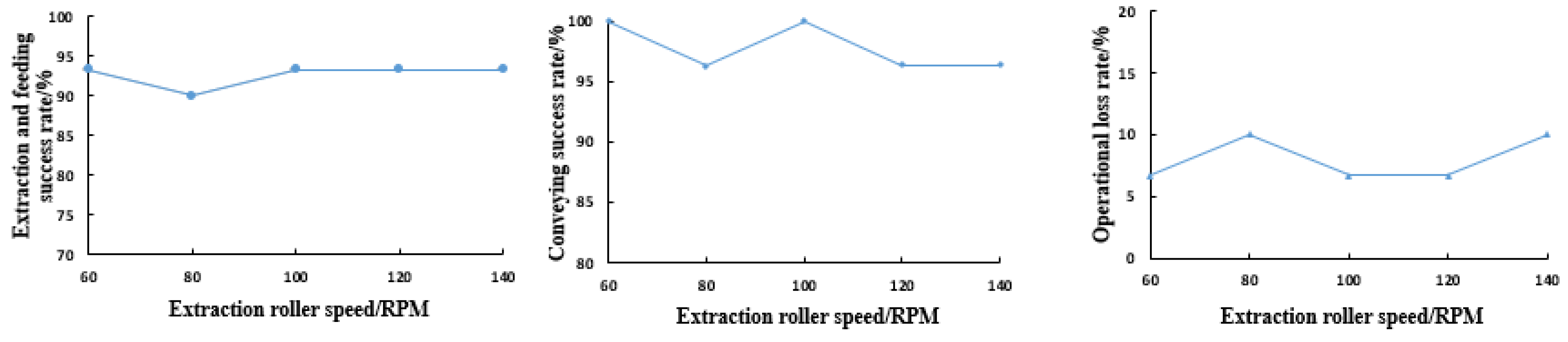

- (1)

- Single-factor experiment for extraction roller speed: During the experiment, the conveyor belt speed was set to 60 RPM, the root-clamping belt speed to 50 RPM, and the forward speed to 1 km·h−1. The extraction roller speed started at 60 RPM, with increments of 20 RPM for each experiment. A total of five experimental groups were conducted, with a maximum extraction roller speed of 140 RPM;

- (2)

- Single-factor experiment for conveyor belt speed: During the experiment, the extraction roller speed was set to 100 RPM and the forward speed to 1 km·h−1. The conveyor belt speed started at 40 RPM, with increments of 10 RPM for each experiment. A total of five experimental groups were conducted, with a maximum conveyor belt speed of 80 RPM;

- (3)

- Single-factor experiment for forward speed: During the experiment, the transport belt speed was set to 60 RPM, the root-clamping belt speed to 50 RPM, and the extraction roller speed to 100 RPM. The forward speed started at 0.8 km·h−1, with increments of 0.1 km·h−1 for each experiment. A total of five experimental groups were conducted, with a maximum forward speed of 1.2 km·h−1.

4.3.3. Experimental Results and Analysis for Cabbage

5. Discussion

- (1)

- Study on matching the clamping device speed and the root-clamping device speed for regulating Chinese cabbage posture: In this study, the soil-trough harvesting experiment for Chinese cabbage relied solely on matching the forward speed with the conveyor belt speed to achieve optimal performance of the universal harvesting platform. However, the primary factor affecting the extraction success rate is the change in the posture of Chinese cabbage during the extraction process, which is a key challenge in the harvesting method that involves extraction followed by conveying and root-cutting. By matching the rotation speeds of the clamping device and the root-clamping device, the posture variation during the extraction process can be minimized, greatly improving the harvesting efficiency of the machine;

- (2)

- Determination of core parameters: The universal harvesting platform for cabbage and Chinese cabbage designed in this study features many adjustable parameters to achieve universality in harvesting. However, the soil-trough harvesting experiment revealed that having too many adjustable parameters increases the unreliability of the platform. Reducing the number of adjustable parameters can enhance the overall reliability of the platform;

- (3)

- Design of an adjustable root-cutting device: Due to various issues, the universal harvesting platform for cabbage and Chinese cabbage designed in this study does not include a root-cutting device. In future work, an adjustable root-cutting device that can be moved up and down could be designed. Its floating stroke should meet the root-cutting requirements for both cabbage and Chinese cabbage, thereby further enhancing the completeness of the platform;

- (4)

- Multi-factor optimization experiments for the root-clamping device: The designed root-clamping device incorporates an important root-clamping limiting function. That is, during installation, an angular difference is maintained between the clamping belt and the limit guide rail. As the clamping belt moves backward, it pulls down the lotus seats of the cabbage and Chinese cabbage, causing them to fall onto the limit guide rail. This mechanism addresses the issue of inconsistent optimal root-cutting positions after extraction, which can reduce the qualified root-cutting rate. However, due to time constraints, this aspect was not further explored in this current study. Future work may involve multi-factor optimization experiments to determine the optimal parameters for the root-clamping device.

6. Conclusions

- (1)

- In response to the problem that existing cabbage and Chinese cabbage harvesters can only harvest a single variety of vegetable and lack universality, a modular design was developed for a universal cabbage–Chinese cabbage harvesting platform. Based on common cabbage and Chinese cabbage varieties and main cultivation patterns in the Jiangsu–Zhejiang region of China, the harvesting platform can achieve simultaneous harvesting of both cabbage and Chinese cabbage by replacing components and adjusting parameters;

- (2)

- In response to the insufficient research on the extraction-first method for Chinese cabbage harvesting in China, a Y-shaped extraction device was designed to cooperate with the conveyor belt for the extraction process. The flexible conveyor belt can deform along the direction of the cabbage ball, increasing the contact area with the cabbage. This reduces the force per unit area, thereby minimizing damage during the extraction process. Additionally, a dual clamping method using both the clamping device and the root-clamping device was adopted. The posture of the cabbage can be adjusted by matching the speeds of the conveyor belt and the root-clamping belt, helping to reduce posture changes during the extraction stage and minimizing damage caused by these changes;

- (3)

- The results of the Chinese cabbage soil-trough harvesting experiment showed that when the forward speed was set to 1 km·h−1 and the conveyor belt speed was set to 60 RPM, the universal harvesting platform exhibited optimal overall performance. The extraction success rate was 86.7%, the clamping and conveying success rate was 92.3%, and the operational damage rate was 6.7%. For the cabbage soil-trough harvesting experiment, when the extraction roller speed was set to 100 RPM, the conveyor belt speed to 60 RPM, and the forward speed to 1 km·h−1, the best overall performance was achieved. The extraction and feeding success rate was 93.3%, the conveying success rate was 100%, and the operational loss rate was 6.7%.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, Y.S.; Liu, X.C. Development Report of China Vegetable Mechanization in 2009. J. Chin. Agric. Mech. 2020, 41, 46–53. (In Chinese) [Google Scholar] [CrossRef]

- Yang, J.H.; Fang, X.; Ma, L.X. Research Status and Direction of Knotting Vegetable Harvesting Machinery. J. Agric. Mech. Res. 2023, 45, 10–17. (In Chinese) [Google Scholar]

- Hansen, C.J. Harvesting Machine for Cabbage, or the Like. U.S. Patent 3827503, 6 August 1974. [Google Scholar]

- Lenker, D.H.; Nascimento, D.F.; Adrian, P.A. Apparatus for Harvesting Vegetable Heads. U.S. Patent 4136509, 30 January 1979. [Google Scholar]

- Chagnon, R.; Eng, P.; Charles, M.T. Development of a Cabbage harvester. In Proceedings of the 2004 ASAE/CSAE Annual International Meeting, Ottawa, ON, Canada, 1–4 August 2004. [Google Scholar]

- Zhang, J.; Cao, G.; Jin, Y.; Tong, W.; Zhao, Y.; Song, Z. Parameter Optimization and Testing of a Self-Propelled Combine Cabbage Harvester. Agriculture 2022, 12, 1610. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, E.; Mao, H.; Zuo, Z.; Peng, H.; Zhao, M.; Yu, Y.; Li, Z. Design and Testing of an Electric Side-Mounted Cabbage Harvester. Agriculture 2024, 14, 1741. [Google Scholar] [CrossRef]

- Kanamitsu, M.; Kenji, Y. Development of Chinese cabbage harvester. JARQ 1996, 30, 35–41. [Google Scholar]

- Kim, H.; Yeongsoo, C. Pulling Performance of a Self-Propelled Chinese cabbage Harvester and Design of a Preprocessing Unit. J. Agric. Life Sci. 2020, 54, 99–108. [Google Scholar] [CrossRef]

- Yang, K.W. Development and Performance Test of Prototype Chinese Cabbage Harvester(I). J. Agric. Life Sci. 2022, 56, 113–123. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, J. Design and experiment of crawler self-propelled single-row harvester for Chinese Cabbage. Trans. Chin. Soc. Agric. Mach. 2022, 53, 134–146. (In Chinese) [Google Scholar]

- Du, D.D. Research on Crawler Self-Propelled Cabbage Harvester Equipment and Development of Its Weighing System. Ph.D. Thesis, Zhejiang University, Hangzhou, China, 2017. (In Chinese). [Google Scholar]

- Yang, Y.T.; Cui, Z.C.; Gao, Q.S. Current Status and Development Recommendations for the Mechanized Production of Chinese Cabbage in China. Chin. Veg. 2020, 11, 9–16. (In Chinese) [Google Scholar]

- Zhang, J.F.; Xiao, H.R.; Cao, G.Q. Cabbage harvester header design and test. J. Chin. Agric. Mech. 2020, 41, 39–44. (In Chinese) [Google Scholar] [CrossRef]

- Yang, Y. Design and Research of the 4LZY-7 Rapeseed Combine Harvester. Master’s Thesis, Gansu Agricultural University, Lanzhou, China, 2019. (In Chinese). [Google Scholar]

- Guo, X.; Wang, S.; Chen, S.; Li, B.; Tang, Z.; Hu, Y. Impact of Structural Parameters on the Collision Characteristics and Coefficient of Restitution of Soybean Particles on Harvester’s Cleaning Screens. Agriculture 2024, 14, 1201. [Google Scholar] [CrossRef]

- Ma, Z.; Zhu, Y.; Li, J. Study on the performance of detection air duct and evaluation index of agricultural cleaning centrifugal fans. Biosyst. Eng. 2024, 239, 81–97. [Google Scholar] [CrossRef]

- Zhang, Q.; Fang, H.; Xu, G.; Niu, M.; Li, J. Experimental and Numerical Analysis of Straw Motion under the Action of an Anti-Blocking Mechanism for a No-Till Maize Planter. Agriculture 2024, 14, 1001. [Google Scholar] [CrossRef]

- Song, C.H.; Qu, G.Y.; Liu, Q.T. Effect of friction between spiral component and sugarcane on sugarcane lifting. J. Hunan Agric. Univ. (Nat. Sci.) 2012, 38, 330–332. (In Chinese) [Google Scholar] [CrossRef]

- Jia, H.W.; Wen, B.; Wang, X.F. Design and experiments of the electro-mechanical integrated measurement device for a grain friction coefficient. Trans. CSAE 2025, 41, 31–41. (In Chinese) [Google Scholar]

- Yuan, L.; Tang, Z.; Liu, S.; Wang, T.; Ding, Z. Design for Copying Grouser and Bionic Convex Hull Patterns on Track Surfaces of Crawler Combine Harvesters. Agriculture 2024, 14, 1079. [Google Scholar] [CrossRef]

- Wang, S.Y. Design and Experimental Research of Self-Propelled Cabbage Harvesting Test Platform. Master’s Thesis, Jiangsu University, Zhenjiang, China, 2019. (In Chinese). [Google Scholar]

- Kou, T.H.; Yang, Y.; Wang, C. Analysis of clamping force and experimental study of mechanical characteristics of onion. J. Chin. Agric. Mech. 2020, 42, 174–180. (In Chinese) [Google Scholar]

- Zhou, L.L. Research on the Key Technologies of Low Damage and Orderly Harvest for Spinach with Root. Ph.D. Thesis, Shandong Agricultural University, Taian, China, 2022. (In Chinese). [Google Scholar]

- Zhang, J. Research on Physical and Mechanical Properties of Headed Chinese Cabbage and Its Crawler Self-Propelled Harvesting Machine. Ph.D. Thesis, Zhejiang University, Hangzhou, China, 2022. (In Chinese). [Google Scholar]

- Cao, Y.; Yu, Y.; Tang, Z.; Zhao, Y.; Gu, X.; Liu, S.; Chen, S. Multi-Tooth Cutting Method and Bionic Cutter Design for Broccoli Xylem (Brassica oleracea L. var. Italica Plenck). Agriculture 2023, 13, 1267. [Google Scholar] [CrossRef]

- Shi, Y.Y.; Zhang, Y.N.; Wang, X.C. Design of Orderly Harvester in Stems-leafy Vegetables Based on Pro/E. J. Chin. Agric. Mech. 2017, 39, 139–143. (In Chinese) [Google Scholar]

- Xu, H.G.; Zhang, C.X.; Zhang, X.J. Development and Application of Corn Harvester for Hilly Area. Trans. CSAE 2021, 11, 102–107. (In Chinese) [Google Scholar]

- Liu, J.; Liang, J.; Zhao, S.; Jiang, Y.; Wang, J.; Jin, Y. Design of a Virtual Multi-Interaction Operation System for Hand–Eye Coordination of Grape Harvesting Robots. Agronomy 2023, 13, 829. [Google Scholar] [CrossRef]

- Gao, Y.; Hu, Y.; Yang, Y.; Feng, K.; Han, X.; Li, P.; Zhu, Y.; Song, Q. Optimization of Operating Parameters for Straw Returning Machine Based on Vibration Characteristic Analysis. Agronomy 2024, 14, 2388. [Google Scholar] [CrossRef]

- GB/Z 26582-2011; Production Technical Practice for Cabbage. China National GB Standard Research: Shenzhen, China, 2011.

- JB/T 6276-2007; Test Method for Sugar Beet Harvesting Machinery. Ministry of Machinery and Electronics Industry of the People’s Republic of China: Beijing, China, 2007.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual aut`hor(s) and contributor(s) and not of MDPI and/or the editor(s) MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

| Variety | Plant Height (mm) | Root Length (mm) | Head Diameter (mm) | Head Weight (kg) | Total Weight (kg) |

|---|---|---|---|---|---|

| Zhegan 85 | 318 ± 25.6 | 122 ± 22.8 | 210 ± 18.2 | 1.88 ± 0.26 | 2.45 ± 0.28 |

| Aoqina | 232 ± 39.9 | 198 ± 22.2 | 243 ± 36.1 | 3.82 ± 0.35 | 4.02 ± 0.77 |

| Chunqiu Wang | 150 ± 14.5 | 135 ± 12.6 | 1.28 ± 0.15 | ||

| Lanzhou Bao | 190 ± 19.5 | 143 ± 13.6 | 1.16 ± 0.12 | ||

| Chunfeng | 300 ± 25.6 | 130 ± 12.5 | 1.45 ± 0.21 |

| Variety | Plant Height (mm) | Root Length (mm) | Head Diameter (mm) | Head Weight (kg) | Total Weight (kg) |

|---|---|---|---|---|---|

| Zaoshu 5 | 300~320 | 75~92 | 140~180 | 1~1.5 | |

| Huangxin | 290 ± 19.2 | 138 ± 24.7 | 183 ± 17.4 | 2.34 ± 0.39 | |

| Xiayang | 287 ± 6.1 | 158 ± 18.8 | 185 ± 19.8 | 3.19 ± 0.78 |

| Parameter Name | Unit | Value (Range) |

|---|---|---|

| Suitable cabbage and Chinese cabbage head diameter | mm | 50~280 |

| Number of harvesting rows | row | 1 |

| Overall dimensions (L × W × H) | mm | 2920 × 1380 × 1140 |

| Conveyor belt speed | RPM | 0~300 |

| Root-clamping belt speed | RPM | 0~300 |

| Leaf-stripping wheel speed | RPM | 0~100 |

| Extraction roller speed | RPM | 0~500 |

| Platform angle with ground | ° | 5~30 |

| Statistical Indicator | Total Mass (kg) | Spherical Diameter (mm) | Plant Height (mm) | Root Diameter (mm) | Root Length (mm) |

|---|---|---|---|---|---|

| Minimum | 1.57 | 155 | 254 | 16.35 | 85 |

| Maximum | 2.98 | 315 | 326 | 22.46 | 201 |

| Average | 2.43 | 186.4 | 292.1 | 19.72 | 138.4 |

| Standard Deviation | 0.44 | 44.26 | 20.58 | 1.94 | 27.81 |

| Coefficient of Variation | 0.18 | 0.24 | 0.07 | 0.11 | 0.22 |

| Statistical Indicator | Total Weight (kg) | Head Diameter (mm) | Plant Height (mm) | Root Diameter (mm) | Root Length (mm) |

|---|---|---|---|---|---|

| Minimum | 2.19 | 152 | 254 | 16.35 | 85 |

| Maximum | 3.74 | 249 | 326 | 22.46 | 201 |

| Average | 2.71 | 194.5 | 292.06 | 19.72 | 138.41 |

| Standard Deviation | 0.42 | 44.26 | 20.58 | 1.94 | 27.8 |

| Coefficient of Variation | 0.16 | 0.24 | 0.07 | 0.1 | 0.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Mao, H.; Wang, Y.; Jiang, T.; Zuo, Z.; Chai, J.; Liu, C.; Shen, L.; Wei, S.; Ma, G. Design and Experiment of a Universal Harvesting Platform for Cabbage and Chinese Cabbage. Agriculture 2025, 15, 935. https://doi.org/10.3390/agriculture15090935

Liu Z, Mao H, Wang Y, Jiang T, Zuo Z, Chai J, Liu C, Shen L, Wei S, Ma G. Design and Experiment of a Universal Harvesting Platform for Cabbage and Chinese Cabbage. Agriculture. 2025; 15(9):935. https://doi.org/10.3390/agriculture15090935

Chicago/Turabian StyleLiu, Ze, Hanping Mao, Yana Wang, Tao Jiang, Zhiyu Zuo, Jiajun Chai, Chengyi Liu, Lei Shen, Shuocheng Wei, and Guoxin Ma. 2025. "Design and Experiment of a Universal Harvesting Platform for Cabbage and Chinese Cabbage" Agriculture 15, no. 9: 935. https://doi.org/10.3390/agriculture15090935

APA StyleLiu, Z., Mao, H., Wang, Y., Jiang, T., Zuo, Z., Chai, J., Liu, C., Shen, L., Wei, S., & Ma, G. (2025). Design and Experiment of a Universal Harvesting Platform for Cabbage and Chinese Cabbage. Agriculture, 15(9), 935. https://doi.org/10.3390/agriculture15090935