Assessing Fire Risks in Agricultural Balers: A Comprehensive Study

Abstract

1. Introduction

2. Materials and Methods

2.1. Questionnaire Data Analysis of Baler Users and Owners

2.2. Temperature Records Under Working Conditions

2.3. Analysis of Residues Generated in the Balers

3. Results and Discussion

3.1. Questionnaire Results: Fire Incidence and Risk Factors

3.2. Influence of Variables on Fire Risk

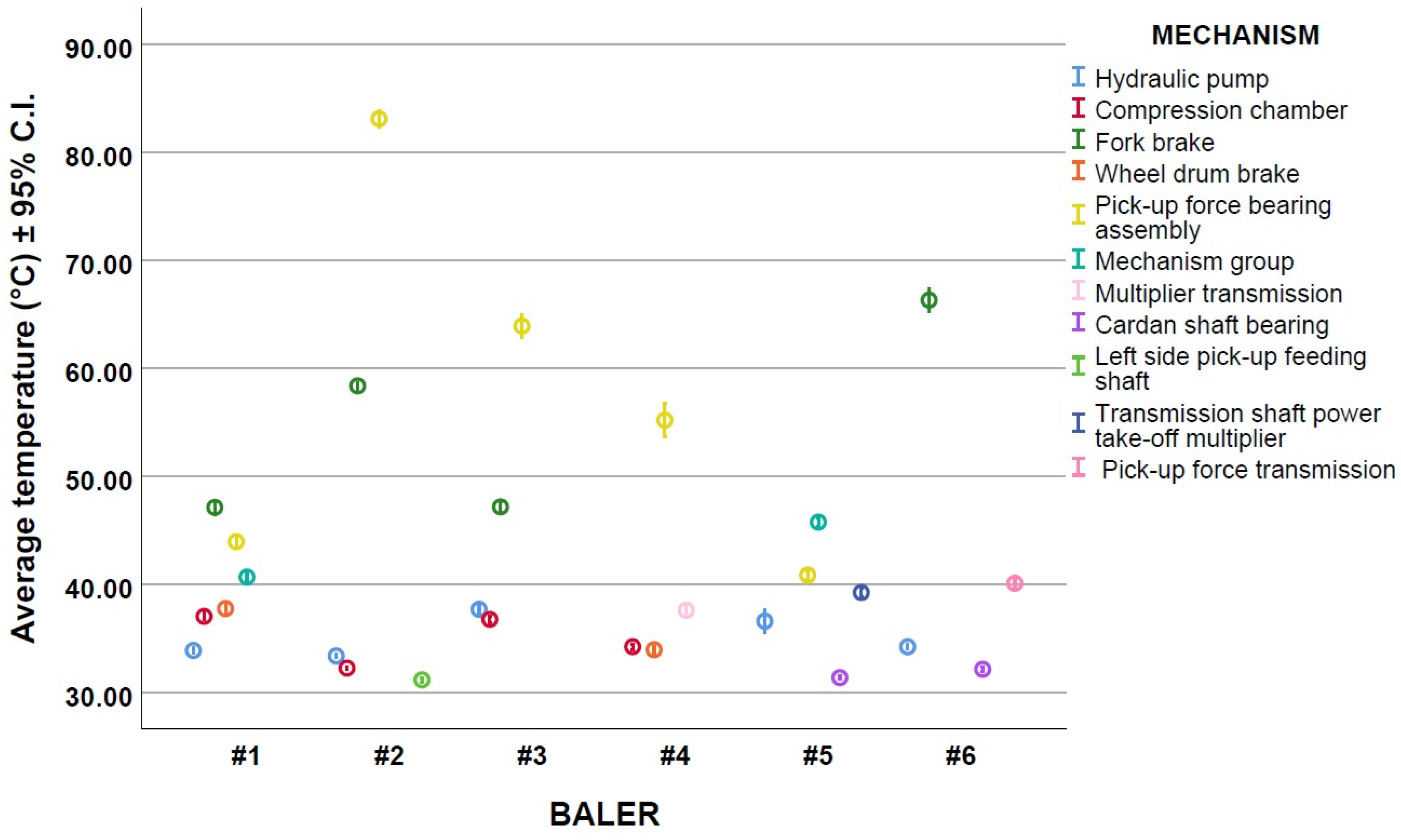

3.3. Temperature Records

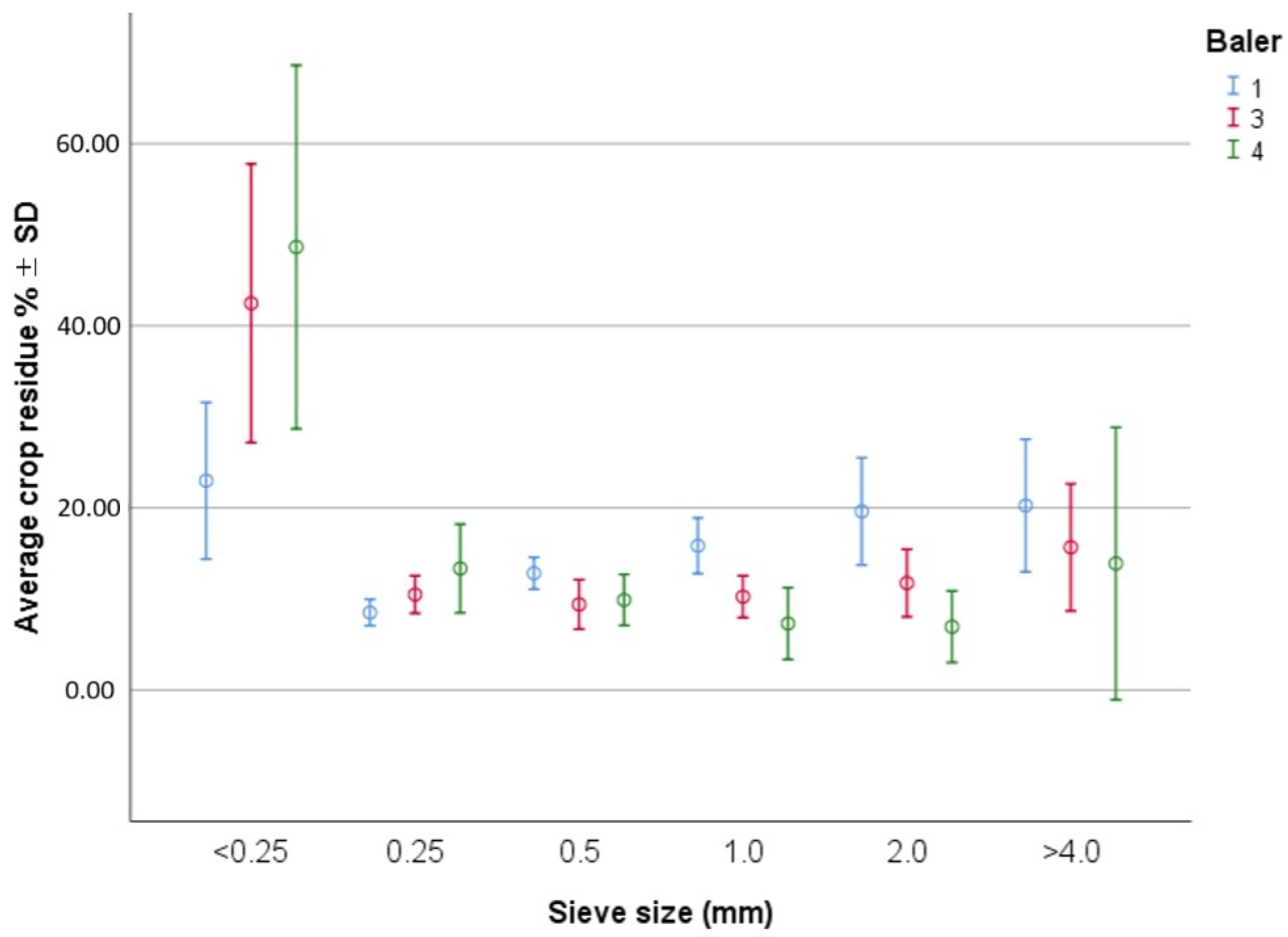

3.4. Generated Residues

4. Conclusions

- Enhanced cleaning and maintenance protocols, focusing on high-risk areas prone to residue accumulation.

- Real-time temperature monitoring systems in critical baler components to detect early warning signs of excessive heating.

- Optimization of mechanical designs to reduce the retention of fine residues.

- Developing operational guidelines for baler users that emphasize the role of environmental conditions (e.g., temperature, humidity, wind speed) in fire risk.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tomasková, M.; Matisková, D.; Baláziková, M. Case study to determine the causes of fire in agriculture. Adv. Sci. Technol. Eng. Syst. J. 2020, 5, 11–15. [Google Scholar] [CrossRef]

- Martínez, J.; Vega-Garcia, C.; Chuvieco, E. Human-caused wildfire risk rating for prevention planning in Spain. J. Environ. Manag. 2009, 90, 1241–1252. [Google Scholar] [CrossRef] [PubMed]

- Gobierno de España. Ministerio para la Transición Ecológica y el Reto Demográfico. Avance Informativo de Incendios Forestales del 1 de Enero al 31 de Noviembre de 2024. 2024. Available online: https://www.miteco.gob.es/content/dam/miteco/es/biodiversidad/temas/incendios-forestales/Avance%20informativo%2030%20de%20noviembre%202024.pdf (accessed on 1 March 2025).

- Gobierno de Aragón. Estadísticas de incendios forestales en Aragón 2024. Available online: https://www.aragon.es/-/estadisticas-de-incendios (accessed on 1 March 2025).

- Pasovets, V.N.; Lakhvich, V.V.; Antonenko, M.A. Fires on agricultural machinery and their causes. J. Civ. Prot. 2021, 5, 193–205. [Google Scholar] [CrossRef]

- Cardil, A.; Salis, M.; Spano, D.; Delogu, G.; Molina Terrén, D. Large wildland fires and extreme temperatures in Sardinia (Italy). iForest—Biogeosci. For. 2014, 7, 162–169. [Google Scholar] [CrossRef]

- Venem, M.; Shutske, J.M. Combine Fire Prevention and Control Summit. CIGR XVth World Congress; American Society of Agricultural Engineers: Chicago, IL, USA, 2002. [Google Scholar]

- Visser, R.; MacDell, S.L.; Obi, O.F. Forest machinery fires: Trends in New Zealand forest harvesting sector. Croat. J. For. Eng. 2021, 42, 9. [Google Scholar] [CrossRef]

- Quick, G.R. An Investigation into Combine Harvester Fires; Grains Research and Development Corporation: Barton, Australia, 2010; 20p. [Google Scholar]

- Val-Agüasca, J.P.; Videgain-Marco, M.; Martín-Ramos, P.; Vidal-Cortés, M.; Boné Garasa, A.; García-Ramos, F.J. Fire risk associated with combine harvesters: Analysis of machinery critical points. Agronomy 2019, 9, 877. [Google Scholar] [CrossRef]

- Shutske, J.M.; Field, W.E. An Integrated Loss Control Strategy for Grain Combine Fires; International Winter Meeting of the American Society of Agricultural Engineers: Chicago, IL, USA, 1988. [Google Scholar]

- Shutske, J.M.; Field, W.E.; Gaultney, L.D.; Parsons, S.D. Agricultural machinery fire losses: A preventative approach. Appl. Eng. Agric. 1990, 10, 175–192. [Google Scholar] [CrossRef]

- Guerrieri, A.S.; Anifantis, A.S.; Santoro, F.; Pascuzzi, S. Study of a large square baler with innovative technological systems that optimize the baling effectiveness. Agriculture 2019, 9, 86. [Google Scholar] [CrossRef]

- Kuta, L. Sources of accident risk in harvesting work. J. Res. Appl. Agric. Eng. 2013, 58, 87–91. [Google Scholar]

- Mickan, F. Hay Balers: A Hidden Fire Danger; Department of Environment and Primary Industries, State Government of Victoria (Australia): Victoria, Australia, 2013; pp. 1–3. [Google Scholar]

- ISO 4254-11:2011/A1:2020; Agricultural Machinery-Safety. Part 11: Pick-Up Balers. International Organization for Standardization: Geneva, Switzerland, 2020.

- Pilarczyk, M.; Ulewicz, R. Evaluating Risk in the Operation of Agricultural Machinery Based on Farm Size; Organization and Management Series No. 198; Scientific Papers of Silesian University of Technology: Gliwice, Poland, 2024. [Google Scholar] [CrossRef]

- Pilarczyk, M.; Ulewicz, R. Sustainable Farm Management: Integrating Safety, Efficiency, and Environmental Practices. Mater. Res. Proc. 2024, 45, 185–194. [Google Scholar] [CrossRef]

- Radicioni, G.; Bono, F.M.; Cinquemani, S. On the Use of Vibrations and Temperatures for the Monitoring of Plastic Chain Conveyor Systems; Mechanical Systems and Signal Processing; Elsevier: Amsterdam, The Netherlands, 2024. [Google Scholar] [CrossRef]

- Barač, M.; Juric, M.; Plasčak, I.; Juric, T.; Markovic, M. Assessing Whole-Body Vibrations in an Agricultural Tractor Based on Selected Operational Parameters: A Machine Learning-Based Approach. AgriEngineering 2025, 7, 72. [Google Scholar] [CrossRef]

- Tamboli, I.I.; Sambhaji, S. Machine Accident Analytics and Protection System (MAAPS): An IoT and Data Analytics Based Approach to Enhance Safety in Agricultural Machinery. Int. J. Sci. Res. Eng. Manag. 2024, 8, 1–5. [Google Scholar] [CrossRef]

- Ayudán, C. Estudio del Riesgo de Incendio en Empacadoras Agrícolas. Trabajo Fin de Máster en Ingeniería Agronómica. 2021. Available online: https://zaguan.unizar.es/record/109740 (accessed on 20 March 2025).

- ISO/IEC 80079-20-2:2016; Explosive Atmospheres-Part 20-2: Material Characteristics-Combustible Dusts Test Methods. International Organization for Standardization: Geneva, Switzerland, 2016.

- ISO/IEC 80079-36:2016; Explosive Atmospheres-Part 36: Non-Electrical Equipment for Explosive Atmospheres-Basic Method and Requirements. International Organization for Standardization: Geneva, Switzerland, 2016.

- ATEX Guidelines; European Commission: Brussels, Belgium, 2013.

- Fernández-Anez, N.; García-Torrent, J. Influence of particle size and density on the hot surface ignition of solid fuel layers. Fire Technol. 2019, 55, 175–191. [Google Scholar] [CrossRef]

| Baler ID | Manufacturer ID | Rake Equipment | Initial Number of Bales | Final Number of Bales | Monitoring Period |

|---|---|---|---|---|---|

| #1 | 1 | Yes | 40 | 18.020 | 02/07/20–04/08/20 |

| #2 | 2 | Yes | 8.100 | 19.000 | 09/07/20–22/09/20 |

| #3 | 3 | No | 8.900 | 17.000 | 06/07/20–27/07/20 |

| #4 | 3 | Yes | 84.970 | 87.954 | 22/07/20–18/08/20 |

| #5 | 3 | Yes | 5.033 | 8.580 | 29/07/20–02/09/20 |

| #6 | 1 | Yes | 146.000 | 157.898 | 23/06/21–07/09/21 |

| #2 | 2 | Yes | 26.200 | 40.950 | 21/06/21–08/10/21 |

| #5 | 3 | Yes | 11.000 | 18.200 | 23/06/21–16/09/21 |

| Probe Location | 2020 | 2021 | ||||||

|---|---|---|---|---|---|---|---|---|

| Baler ID | ||||||||

| #1 | #2 | #3 | #4 | #5 | #6 | #2 | #5 | |

| (1) Compression chamber | X | X | X | X | X | |||

| (2) Pick-up force bearing assembly | X | X | X | X | X | |||

| (3) Hydraulic pump | X | X | X | X | X | |||

| (4) Fan shaft bearings | X | X | ||||||

| (5) Feeder fork brake for compression chamber | X | X | X | X | X | X | ||

| (6) Baling mechanism group | X | X | X | |||||

| (7) Cardan shaft bearing for mechanism group transmission | X | |||||||

| (8) Baling wheel drum brake | X | X | X | |||||

| (9) Left side bearing of pick-up feeding shaft | X | |||||||

| (10) Transmission shaft power take-off multiplier | X | |||||||

| (11) Pick-up force transmission | X | X | ||||||

| Number of responded questionnaires | Baler owners | 105 |

| Baler users | 39 | |

| Total | 144 | |

| Number of balers | 1 | 53 |

| 2 | 11 | |

| 3 | 8 | |

| >3 | 10 | |

| Total | 144 | |

| Fire incidents | Yes | 40 |

| No | 104 | |

| Number of fires per user/owner | 1 | 9 |

| 2 | 9 | |

| 3 | 3 | |

| >3 | 1 | |

| Number of fires per machine | 1 | 36 |

| 2 | 3 | |

| 3 | 1 | |

| Fire origin areas | Bearings | 13 |

| Pick-up | 9 | |

| Clutch | 10 | |

| Transmission | 4 | |

| Others | 4 | |

| Fire incidents and notation of packed cereal | Barley | 9 |

| Wheat | 29 | |

| Balers with fire prevention systems | Fire extinguisher | 100 |

| Water tank | 25 | |

| Both | 12 | |

| Others | 3 | |

| Total | 140 |

| Variable | Variable Level | Fire (N) | No Fire (N) | % Fire Cases | χ2 Value | df | p-Value |

|---|---|---|---|---|---|---|---|

| Ownership Type | Owner | 29 | 76 | 27.6 | 0.005 | 1 | 0.944 |

| User | 11 | 28 | 28.2 | ||||

| Business Type | Company | 3 | 10 | 23.1 | 0.253 | 2 | 0.881 |

| Multiservice | 20 | 48 | 29.4 | ||||

| Private | 17 | 46 | 27.0 | ||||

| Baler Age (years) | ≤3 | 19 | 36 | 34.5 | 6.488 | 7 | 0.484 |

| 4–8 | 12 | 37 | 24.5 | ||||

| 9–13 | 4 | 15 | 21.1 | ||||

| ≥14 | 5 | 16 | 23.8 | ||||

| Annual Bale Production | ≤4500 | 12 | 33 | 26.7 | 5.827 | 6 | 0.443 |

| 4501–7500 | 12 | 20 | 37.5 | ||||

| 7501–10,500 | 5 | 19 | 20.8 | ||||

| ≥10,501 | 11 | 32 | 25.6 | ||||

| Use of Rake | No | 10 | 51 | 16.4 | 6.837 | 1 | 0.009 |

| Yes | 30 | 53 | 36.1 | ||||

| Manufacturer | 1 | 8 | 13 | 38.1 | 24.240 | 10 | 0.007 |

| 2 | 8 | 3 | 72.7 | ||||

| 3 | 1 | 5 | 16.7 | ||||

| 4 | 0 | 1 | 0.0 | ||||

| 5 | 2 | 1 | 66.7 | ||||

| 6 | 5 | 7 | 41.7 | ||||

| 7 | 15 | 52 | 22.4 | ||||

| Others | 1 | 6 | 14.3 | ||||

| Maintenance Level | No | 2 | 2 | 50.0 | 2.610 | 2 | 0.271 |

| Yes | 2 | 13 | 13.3 | ||||

| Daily | 36 | 89 | 28.8 | ||||

| Component Replacement | Original | 6 | 8 | 42.9 | 1.758 | 1 | 0.185 |

| Nonoriginal | 34 | 96 | 26.2 | ||||

| Fire prevention system | Fire Extinguisher | 24 | 78 | 23.5 | 3.376 | 2 | 0.185 |

| Water Tank | 10 | 25 | 28.6 | ||||

| Fire Extinguisher + Water Tank | 6 | 12 | 33.3 |

| <250 µm | 250 µm | 500 µm | 1 mm | 2 mm | 4 mm |

|---|---|---|---|---|---|

| 39.09 | 11.03 | 10.61 | 10.74 | 12.18 | 16.32 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Videgain-Marco, M.; Ayudán-Ibarz, C.; Vidal-Cortés, M.; Boné-Garasa, A.; García-Ramos, F.J. Assessing Fire Risks in Agricultural Balers: A Comprehensive Study. Agriculture 2025, 15, 908. https://doi.org/10.3390/agriculture15080908

Videgain-Marco M, Ayudán-Ibarz C, Vidal-Cortés M, Boné-Garasa A, García-Ramos FJ. Assessing Fire Risks in Agricultural Balers: A Comprehensive Study. Agriculture. 2025; 15(8):908. https://doi.org/10.3390/agriculture15080908

Chicago/Turabian StyleVidegain-Marco, María, Carlos Ayudán-Ibarz, Mariano Vidal-Cortés, Antonio Boné-Garasa, and Francisco Javier García-Ramos. 2025. "Assessing Fire Risks in Agricultural Balers: A Comprehensive Study" Agriculture 15, no. 8: 908. https://doi.org/10.3390/agriculture15080908

APA StyleVidegain-Marco, M., Ayudán-Ibarz, C., Vidal-Cortés, M., Boné-Garasa, A., & García-Ramos, F. J. (2025). Assessing Fire Risks in Agricultural Balers: A Comprehensive Study. Agriculture, 15(8), 908. https://doi.org/10.3390/agriculture15080908