ARIMA-Kriging and GWO-BiLSTM Multi-Model Coupling in Greenhouse Temperature Prediction

Abstract

1. Introduction

2. Experimental Design and Model Development

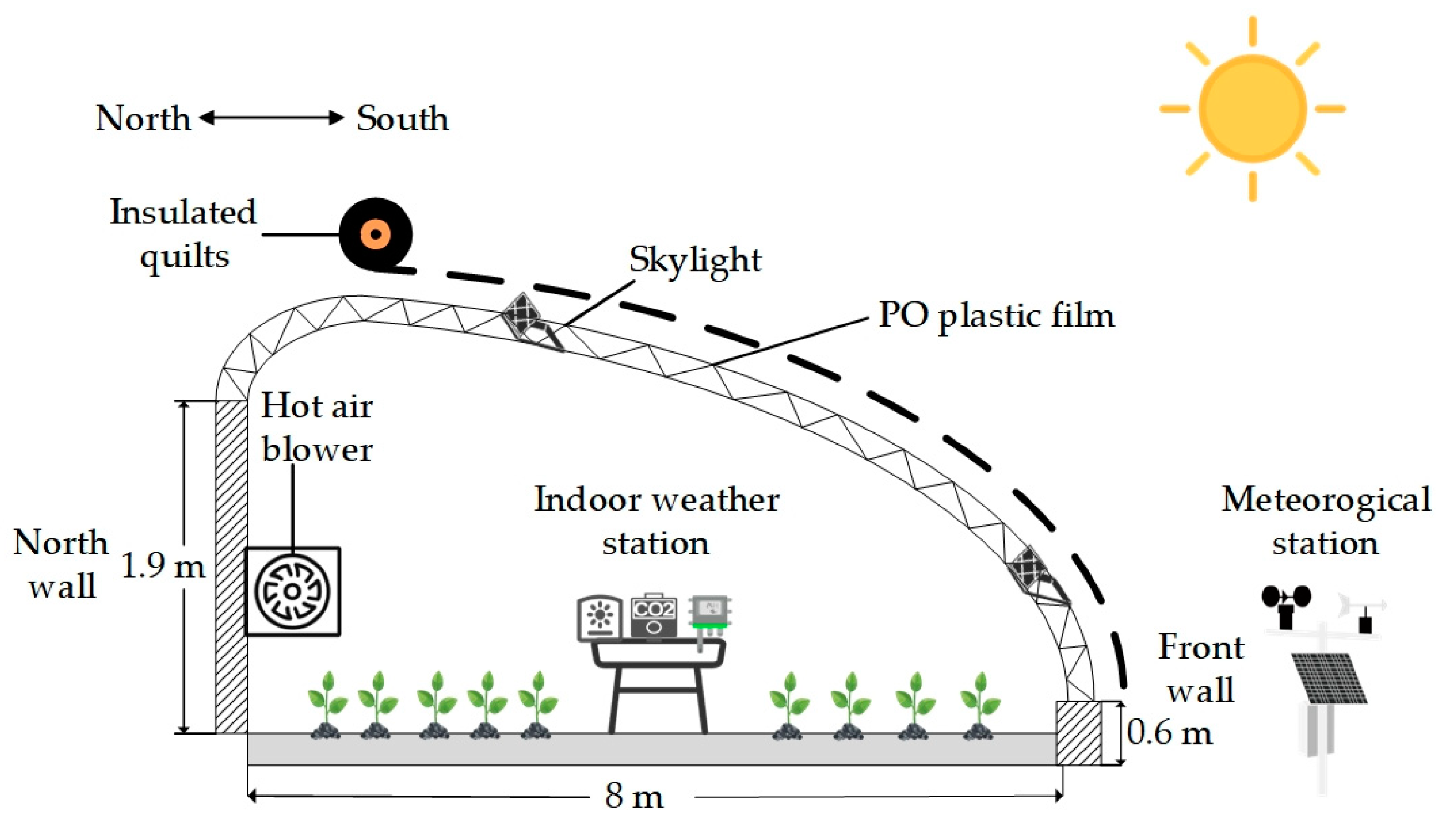

2.1. Experimental Greenhouse

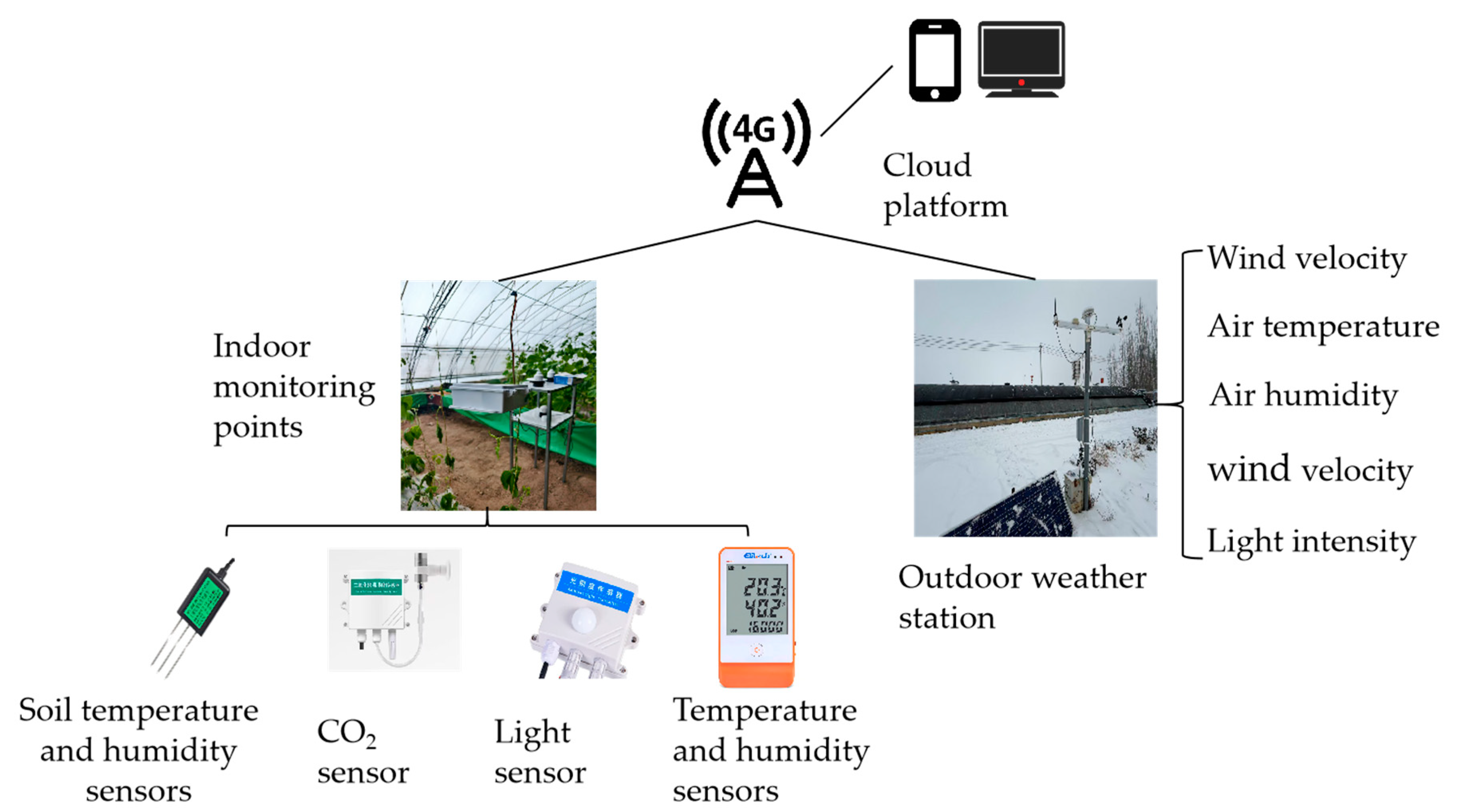

2.2. Data Acquisition Platform

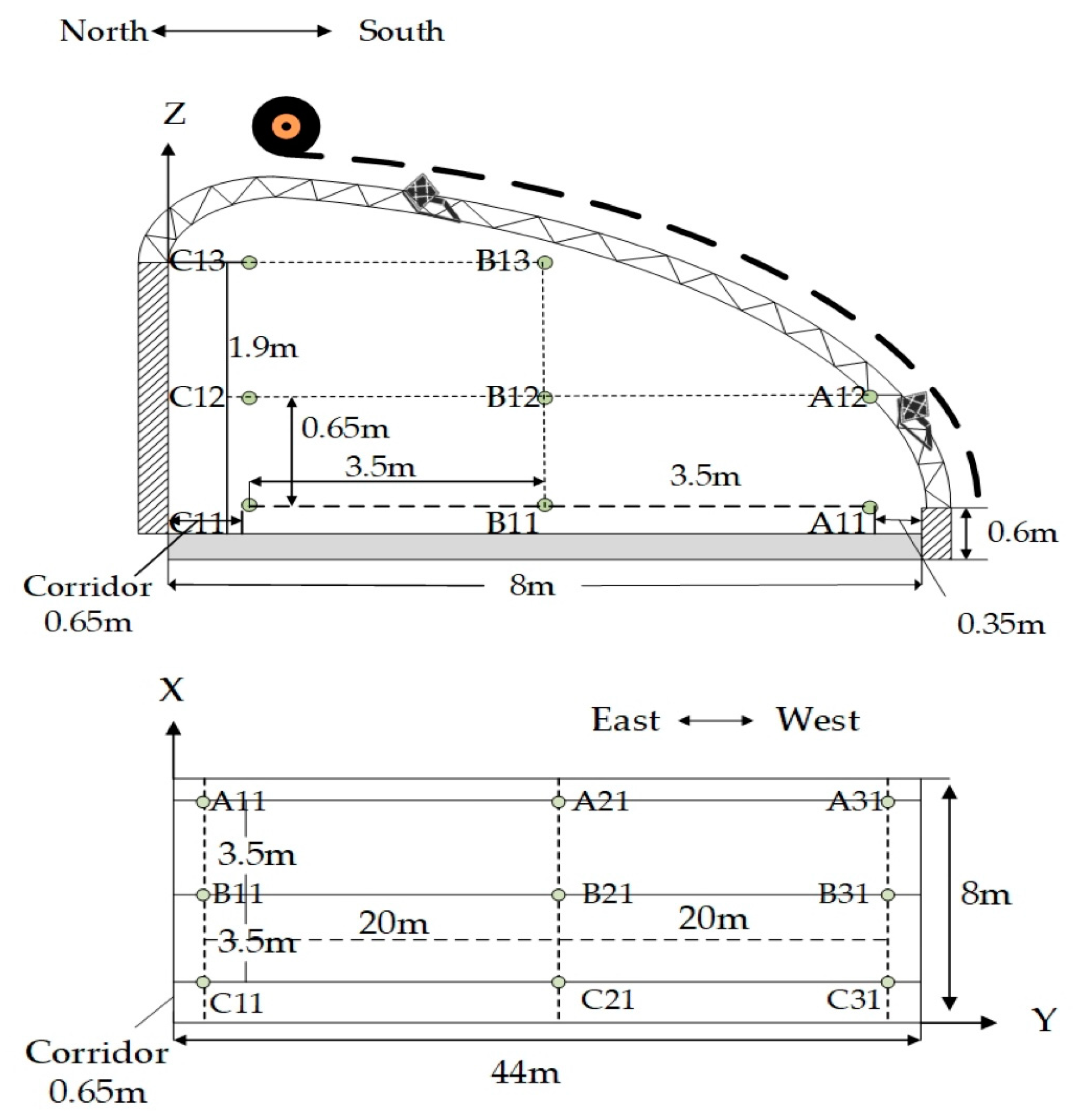

2.3. Greenhouse Temperature Sensor Arrangement

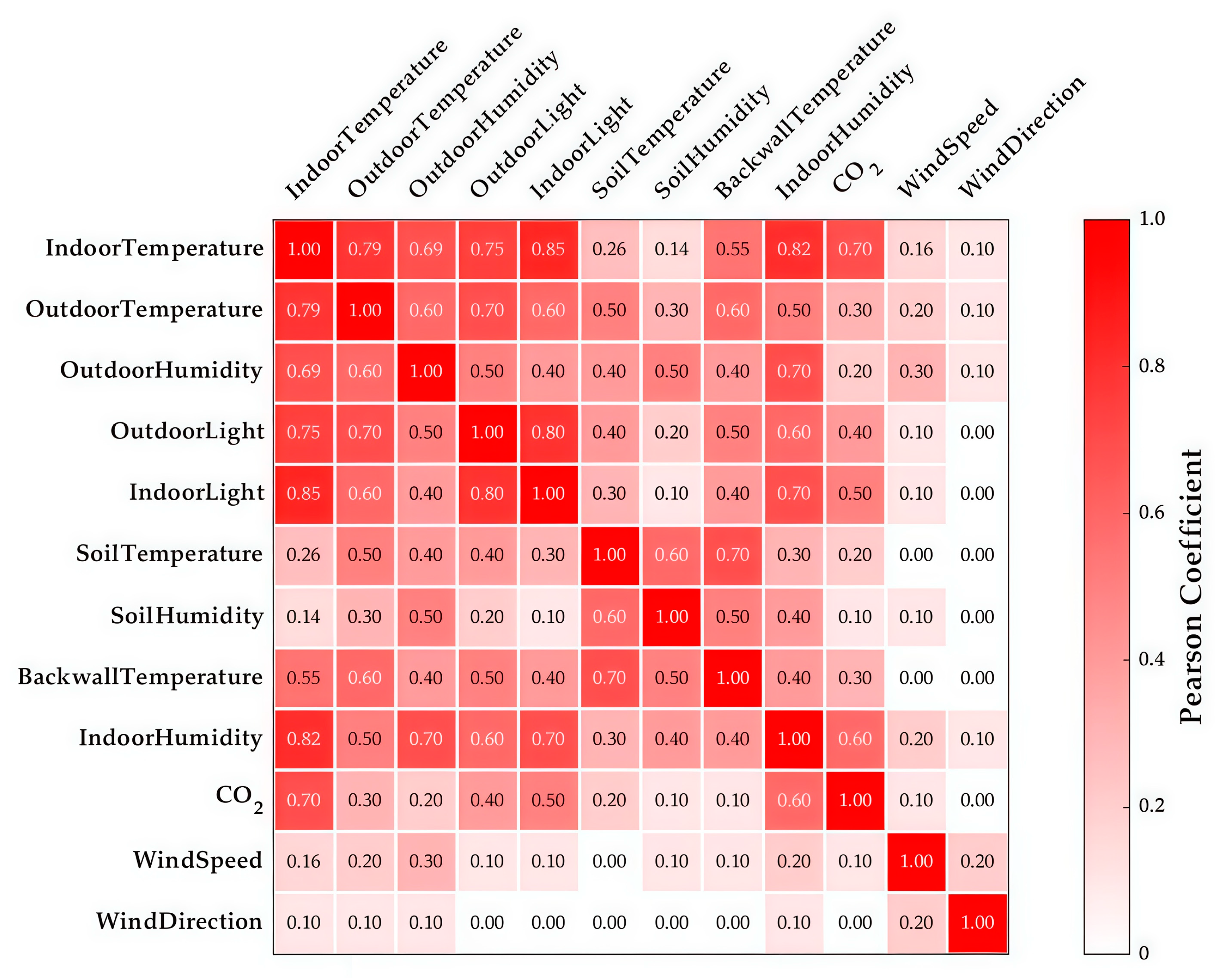

2.4. Data Preprocessing and Feature Volume Selection

2.4.1. Data Preprocessing

2.4.2. Feature Quantity Selection

2.5. Algorithmic Principle

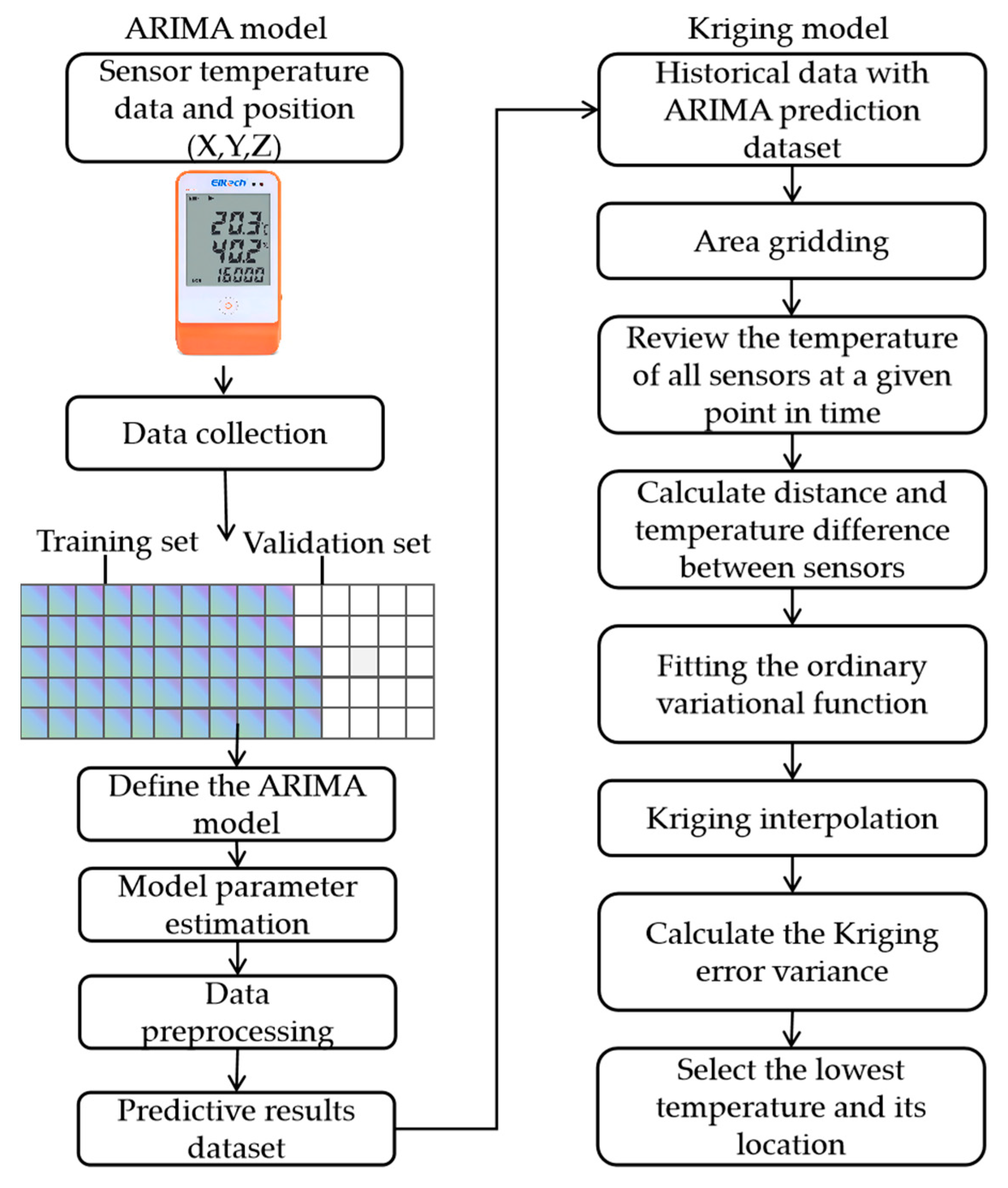

2.5.1. Principle of ARIMA-Kriging Algorithm

- (1)

- Time series feature extraction analysis. An autoregressive integral sliding average model (ARIMA) is used to capture the time-domain evolution pattern of temperature data. For any monitoring point si, its time series is modeled as follows:

- (2)

- Spatiotemporal data fusion. The Kalman filter is introduced to realize the dynamic fusion of predicted values and historical observations.

- (3)

- Spatial interpolation optimization. A spatially optimal interpolation model based on the ordinary kriging method.

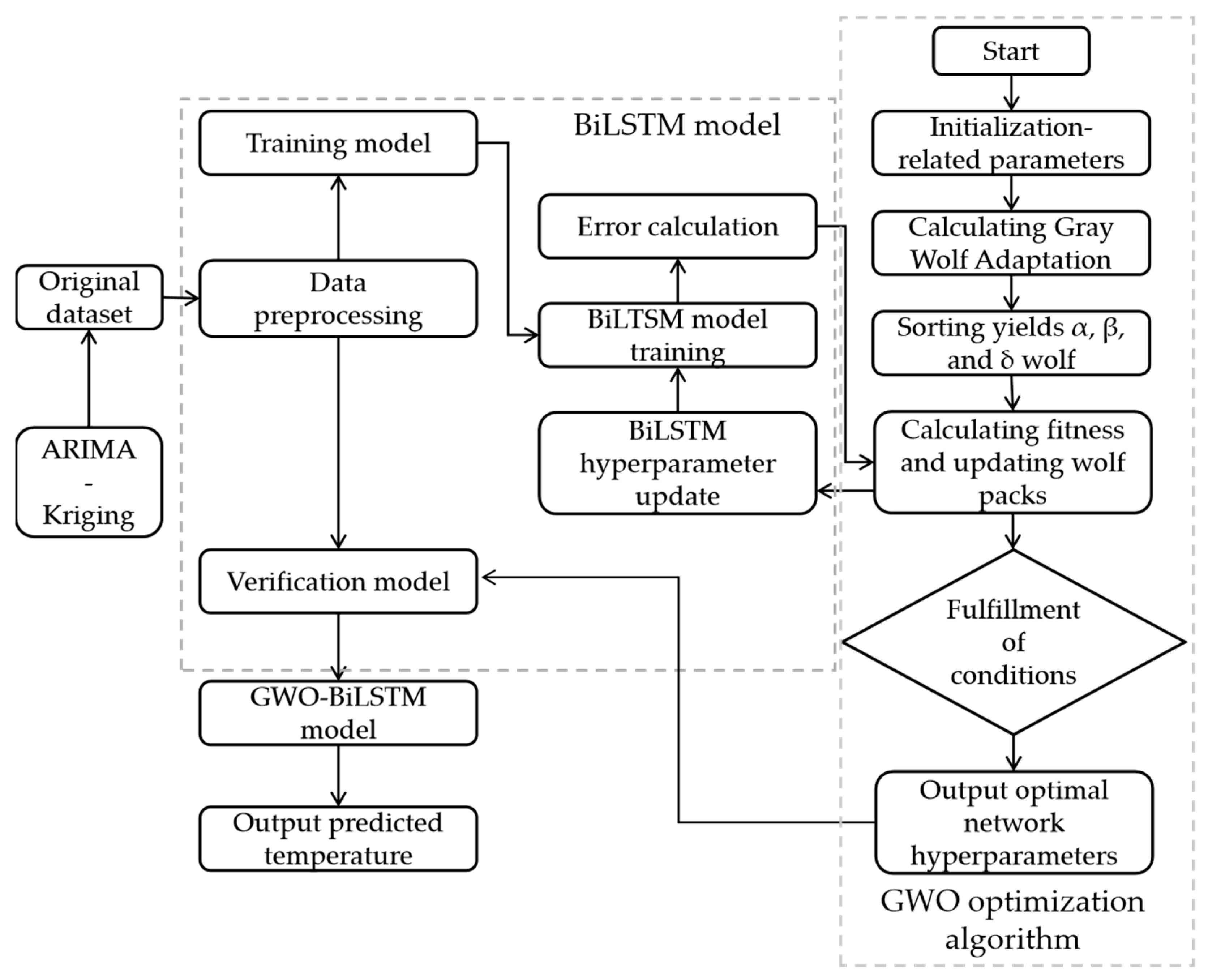

2.5.2. Grey Wolf Optimization Algorithm (GWO)

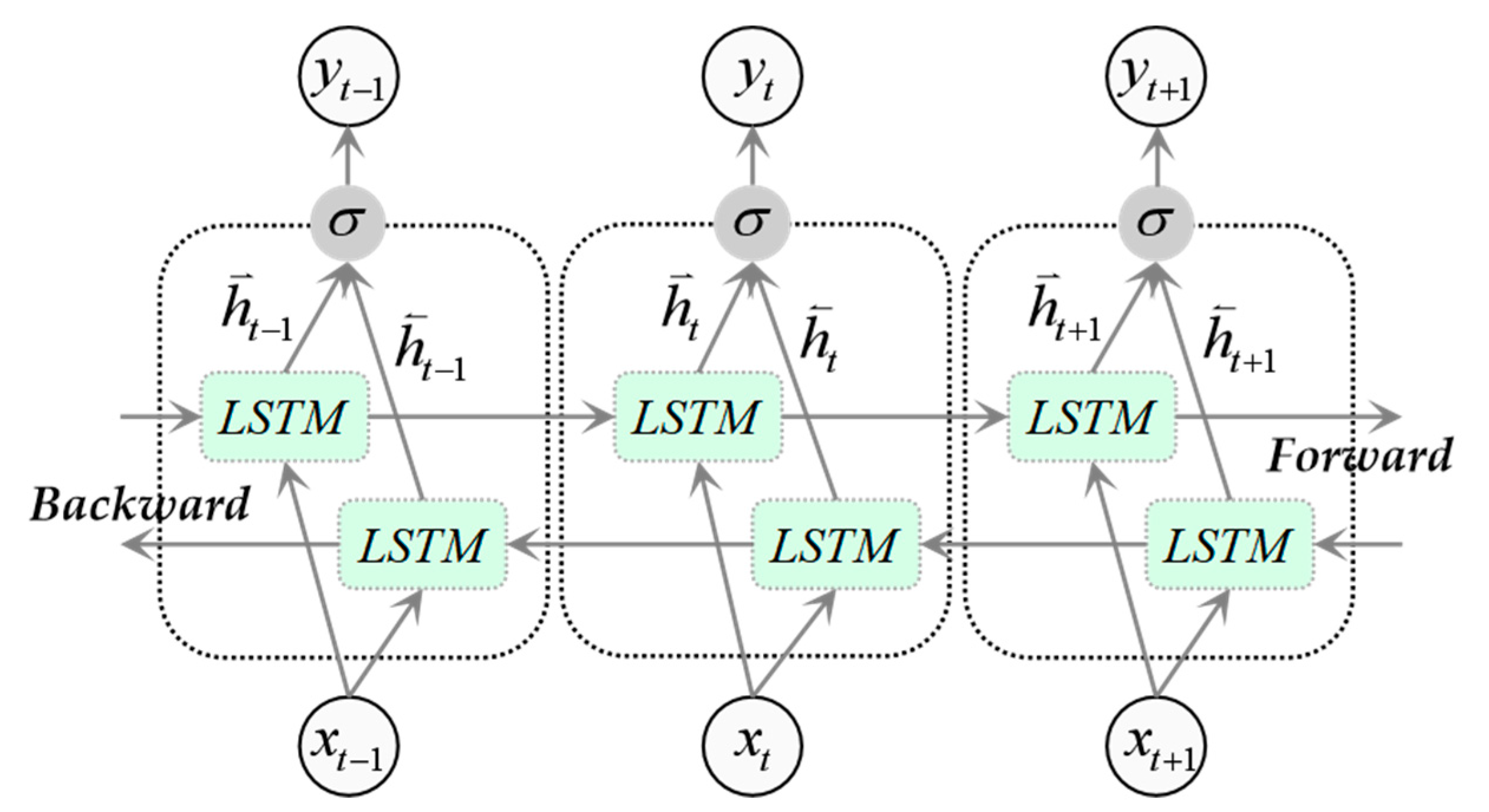

2.5.3. Bidirectional Long Short-Term Memory Network (BiLSTM)

2.6. ARIMA-Kriging Temperature Interpolation Modeling

2.7. GWO-BiLSTM Model Construction

2.8. Model Evaluation Indicators

3. Results and Analysis

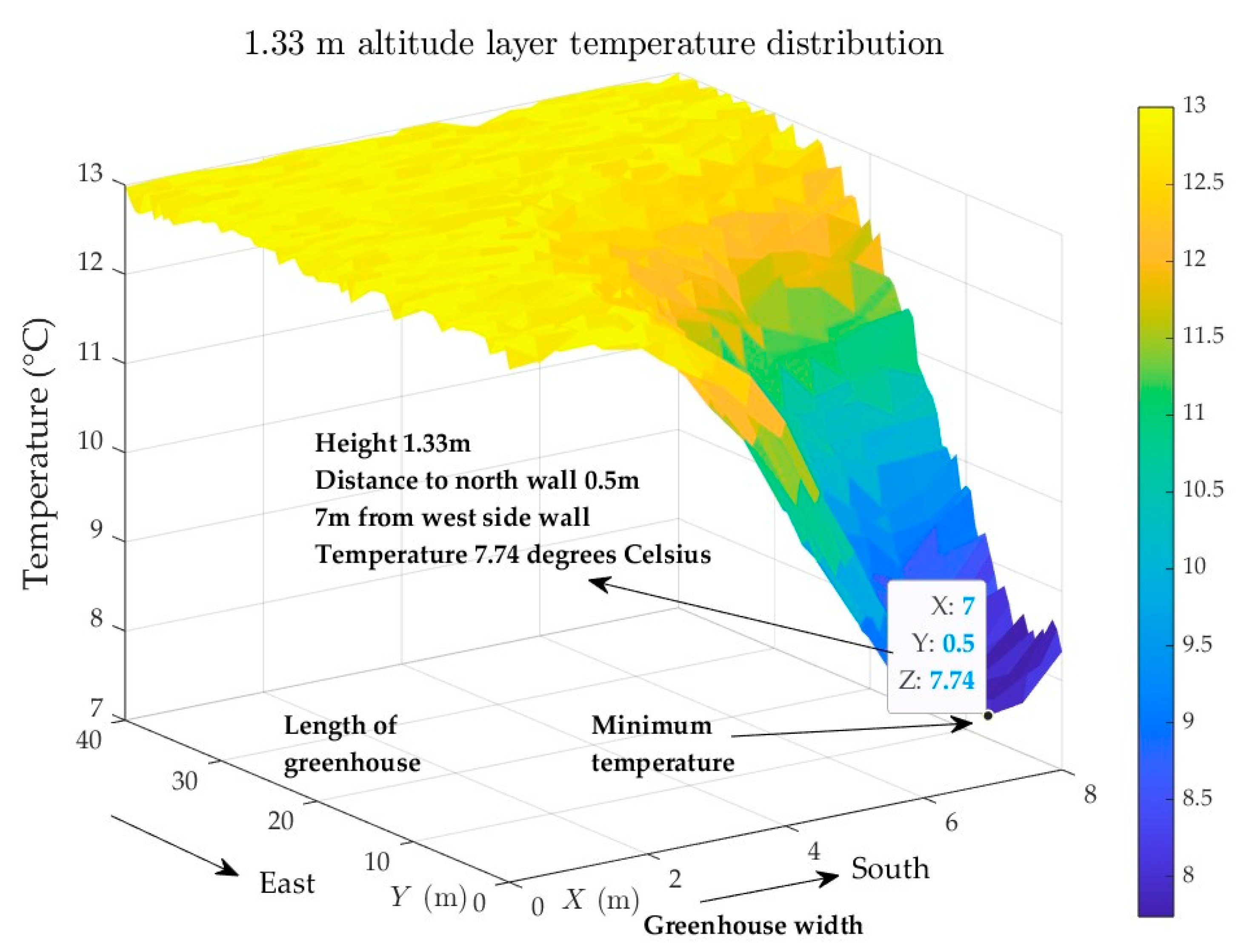

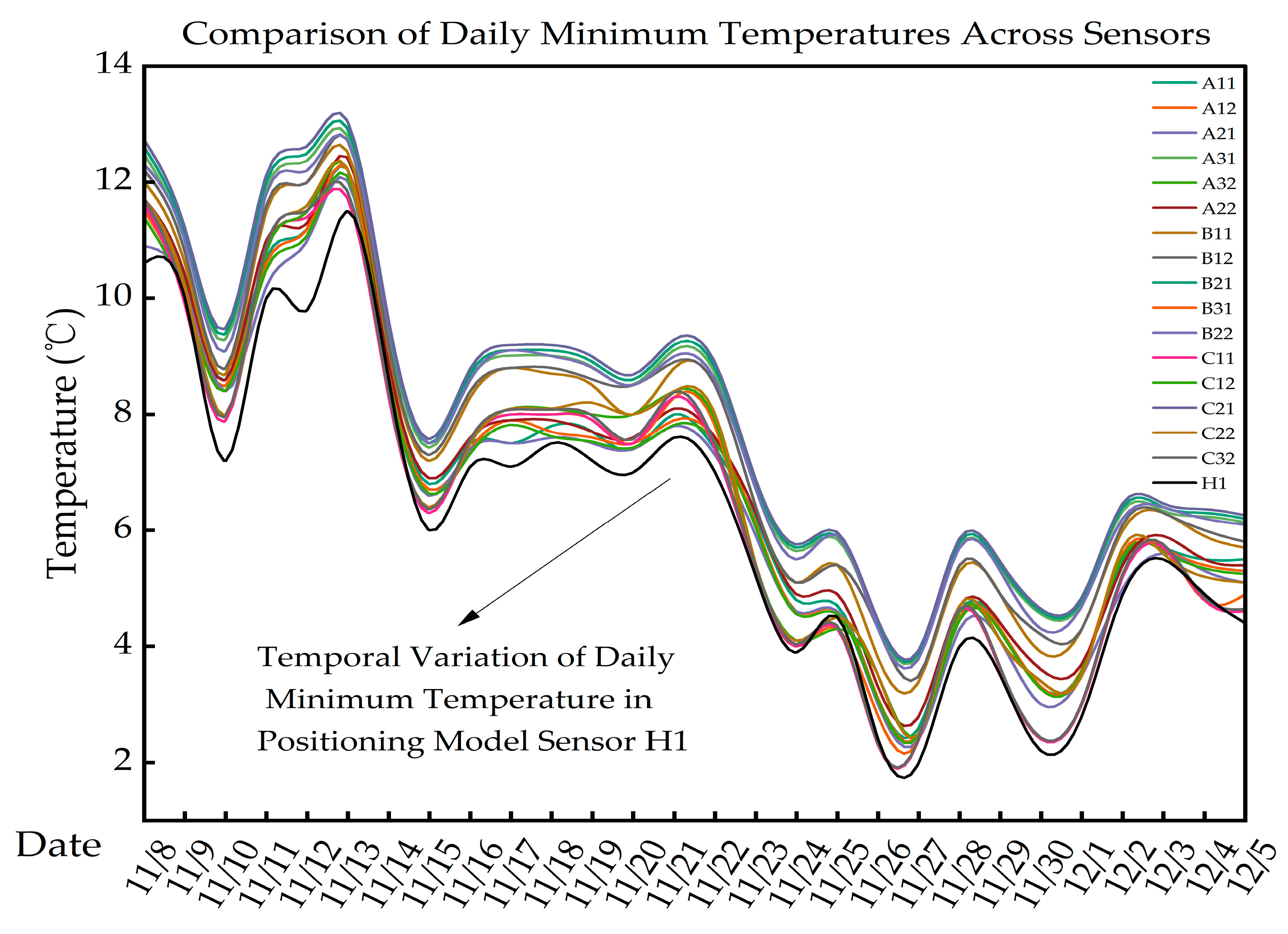

3.1. ARIMA-Kriging Model Validation

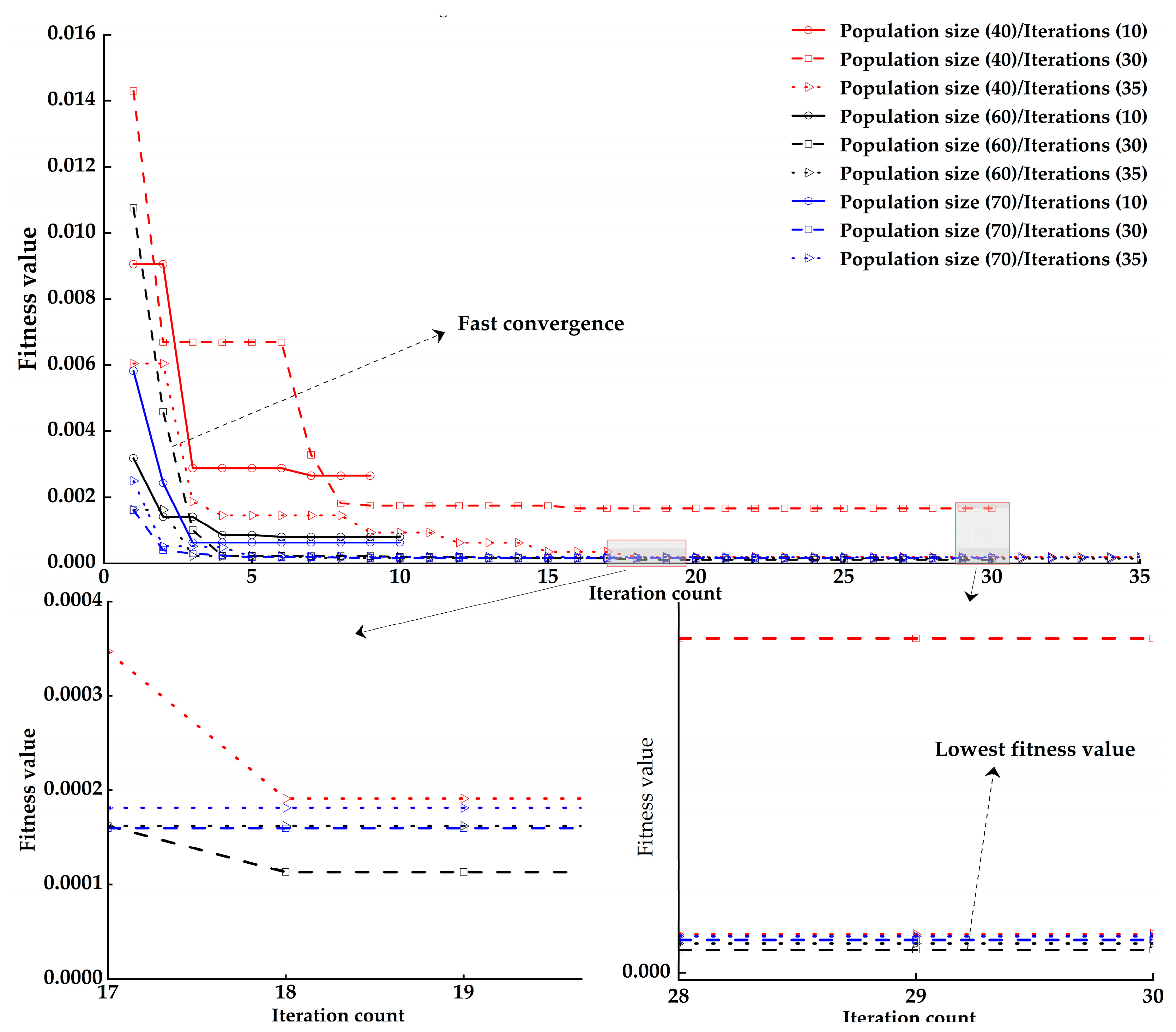

3.2. GWO-BiLSTM Model Parameter Selection

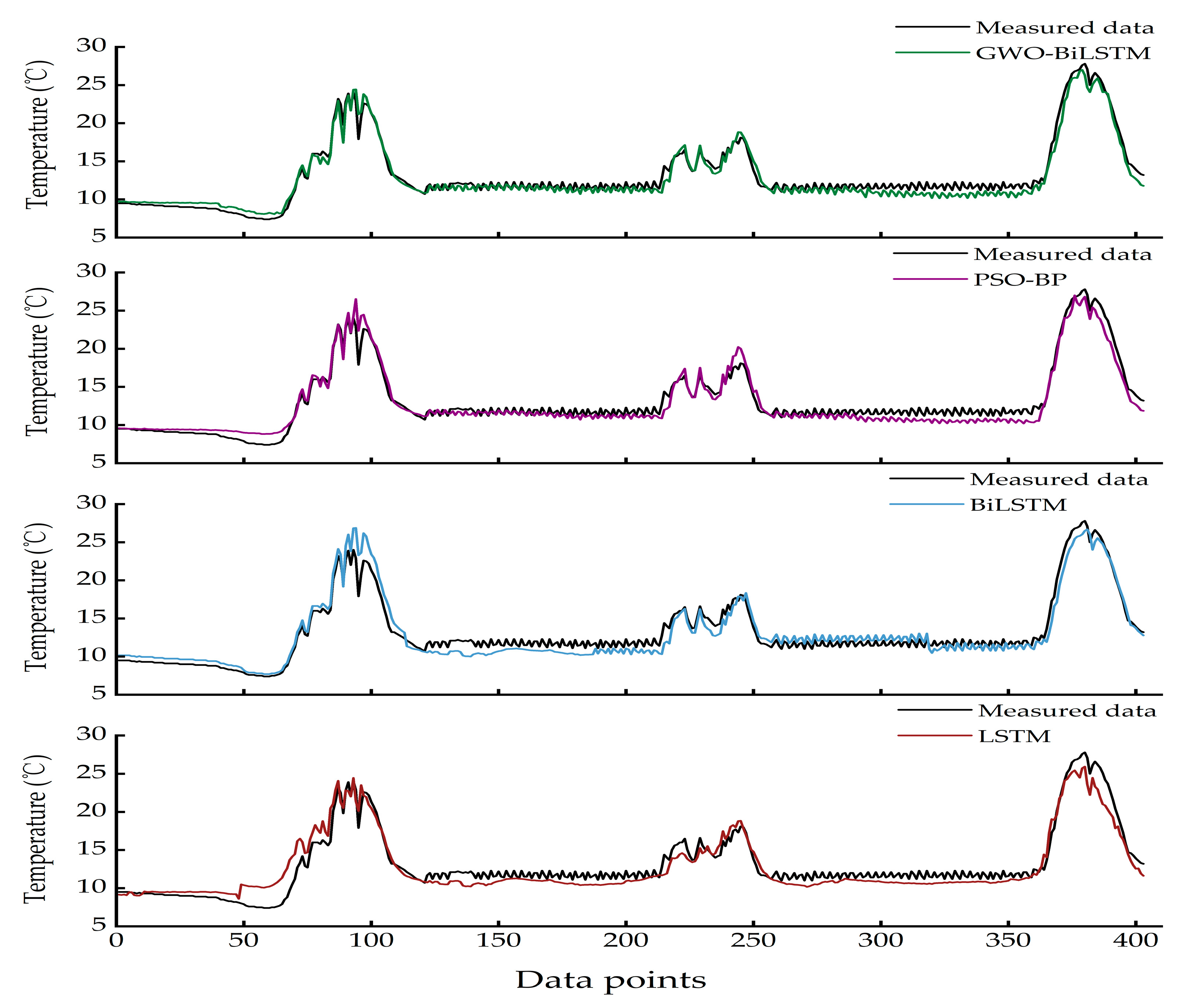

3.3. Multi-Temporal Performance Evaluation and Comparison of Greenhouse Temperature Prediction Models

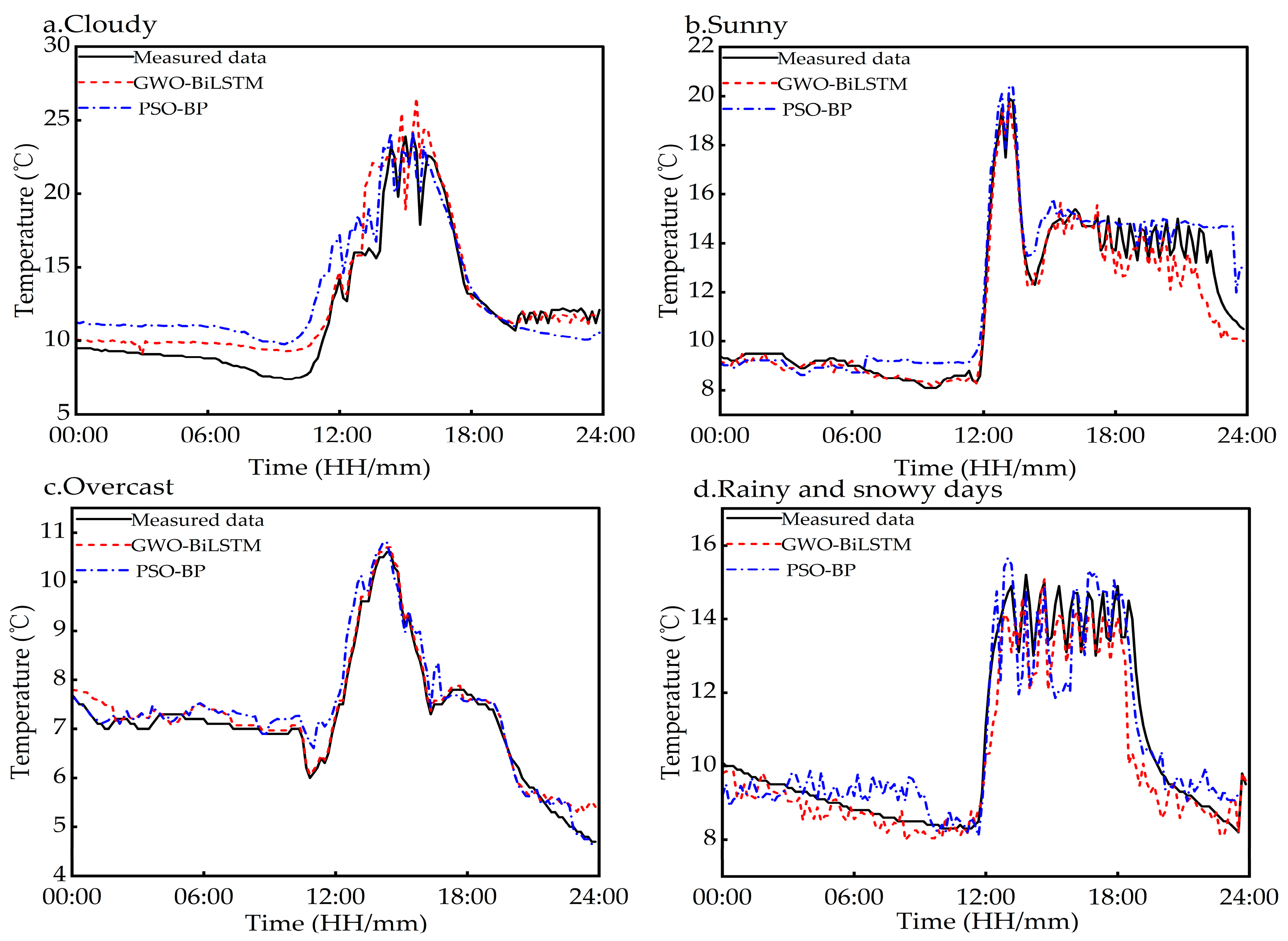

3.4. Comparison of Model Adaptation and Performance Under Different Weather Conditions

3.5. Analysis of Computational Efficiency

4. Discussion

5. Conclusions

- (1)

- The ARIMA-Kriging model reconstructs greenhouse temperature fields through spatiotemporal data fusion and Kriging interpolation, identifying the vertical 1.33 m layer as a low-temperature core zone and pinpointing an extreme low-temperature point (7.74 °C). Compared with traditional uniform sensor deployment, this approach reduces key monitoring nodes while significantly lowering hardware costs, thereby providing high-value temperature time-series data for subsequent GWO-BiLSTM algorithms.

- (2)

- The GWO-BiLSTM model is optimized by the Grey Wolf algorithm for Bidirectional Long- and Short-Term Memory networks, and the key indexes are better than those of the three models of BiLSTM, LSTM, and PSO-BP under different prediction steps. Multi-weather validation shows that the model exhibits strong temperature prediction ability under various meteorological conditions, is robust to sudden environmental changes, and can be used for long-term greenhouse air temperature prediction. Further analysis of the lack of sufficient multi-cloud weather data in the training data leads to the relatively weak generalization ability of the models to multi-cloud weather.

- (3)

- The current study only validated the model in a single sample of greenhouses in Urumqi (43.92° N), and there are still challenges in generalizing the model to other types of greenhouses. The parameters of the ARIMA-Kriging model need to be optimized for different greenhouses to adapt to the differences in their structures and cover materials. In extreme climatic regions, external meteorological fluctuations are more significant in perturbing the heat balance of greenhouses, and the model needs to be further coupled with regional meteorological forecast data as model inputs to enhance the responsiveness to extreme environmental events.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hu, J.; Yang, Y.X.; Li, Y.F. Research Status Analysis and Prospects of Greenhouse Environmental Control Methods. Trans. Chin. Soc. Agric. Eng. 2024, 40, 112–128. [Google Scholar]

- Pi, Y.X.; Zhang, J.S.; Ma, R. Instance Recognition and Model Transfer of Greenhouses Based on Deep Learning. Trans. Chin. Soc. Agric. Eng. 2023, 39, 185–195. [Google Scholar]

- Fan, L.; Ji, Y.; Wu, G. Research on Temperature Prediction Model in Greenhouse Based on Improved SVR. J. Phys. Conf. Ser. 2021, 1802, 042001. [Google Scholar] [CrossRef]

- Kavga, A.; Thomopoulos, V.; Pischinas, E.; Tsipianitis, D.; Nikolakopoulos, P. Design and Simulation of a Greenhouse in a Computational Environment (ANSYS/FLUENT) and an Automatic Control System in a LABVIEW Environment. Simul. Model. Pract. Theory 2023, 129, 102837. [Google Scholar] [CrossRef]

- Li, X.; Zhang, L.; Wang, X.; Liang, B. Forecasting Greenhouse Air and Soil Temperatures: A Multi-Step Time Series Approach Employing Attention-Based LSTM Network. Comput. Electron. Agric. 2024, 217, 108602. [Google Scholar] [CrossRef]

- Gao, P.; Li, B.; Bai, J.; Lu, M.; Feng, P.; Wu, H.; Hu, J. Method for Optimizing Controlled Conditions of Plant Growth Using U-Chord Curvature. Comput. Electron. Agric. 2021, 185, 106141. [Google Scholar] [CrossRef]

- Cai, W.; Wei, R.; Xu, L.; Ding, X. A Method for Modeling Greenhouse Temperature Using Gradient Boost Decision Tree. Inf. Process. Agric. 2022, 9, 343–354. [Google Scholar]

- Jung, D.H.; Kim, H.S.; Jhin, C.; Kim, H.-J.; Park, S.H. Time-Serial Analysis of Deep Neural Network Models for Prediction of Climatic Conditions Inside a Greenhouse. Comput. Electron. Agric. 2020, 173, 105402. [Google Scholar] [CrossRef]

- Vanthoor, B.H.E. A Model-Based Greenhouse Design Method. Ph.D. Thesis, Wageningen University, Wageningen, The Netherlands, 2011. [Google Scholar]

- Yang, S.; Liu, X.; Liu, S.; Chen, X.; Cao, Y. Real-Time Temperature Distribution Monitoring in Chinese Solar Greenhouse Using Virtual LAN. Agronomy 2022, 12, 1565. [Google Scholar] [CrossRef]

- Cheng, X.; Li, D.; Shao, L.; Ren, Z. A Virtual Sensor Simulation System of a Flower Greenhouse Coupled with a New Temperature Microclimate Model Using Three-Dimensional CFD. Comput. Electron. Agric. 2021, 181, 105934. [Google Scholar] [CrossRef]

- Lee, S.; Lee, I.; Yeo, U.; Kim, R.; Kim, J. Optimal Sensor Placement for Monitoring and Controlling Greenhouse Internal Environments. Biosyst. Eng. 2019, 188, 190–206. [Google Scholar] [CrossRef]

- Yuan, M.; Zhang, Z.; Li, G.; He, X.; Huang, Z.; Li, Z.; Du, H. Multi-Parameter Prediction of Solar Greenhouse Environment Based on Multi-Source Data Fusion and Deep Learning. Agriculture 2024, 14, 1245. [Google Scholar] [CrossRef]

- Qin, L.L.; Ma, J.; Huang, Y.M.; Guang, W. Predictive Control of Greenhouse Temperature Hybrid System Based on Accumulated Temperature Theory. Trans. Chin. Soc. Agric. Mach. 2018, 49, 347–355. [Google Scholar]

- Jia, W.; Wei, Z. Short-Term Prediction Model of Environmental Parameters in Typical Solar Greenhouse Based on Deep Learning Neural Network. Appl. Sci. 2022, 12, 12529. [Google Scholar] [CrossRef]

- Chen, L.J.; Du, S.F.; Li, J.P.; He, Y.; Liang, M. Online Identification Method for Adaptive Mechanism Model Parameters of Greenhouse Environmental Temperature Prediction. Trans. Chin. Soc. Agric. Eng. 2017, 33, 315–321. [Google Scholar]

- Chouab, N.; Allouhi, A.; El Maakoul, A.; Kousksou, T.; Saadeddine, S.; Jamil, A. Review on Greenhouse Microclimate and Application: Design Parameters, Thermal Modeling and Simulation, Climate Controlling Technologies. Sol. Energy 2019, 191, 109–137. [Google Scholar] [CrossRef]

- Zhang, G.S.; Li, T.H.; Hou, J.L. Temperature Prediction Model for Glass Greenhouse Cover Layer Considering Dynamic Absorption Rate. Trans. Chin. Soc. Agric. Eng. 2020, 36, 201–211. [Google Scholar]

- Xu, K.; Guo, X.; He, J.; Yu, B.; Tan, J.; Guo, Y. A study on temperature spatial distribution of a greenhouse under solar load with considering crop transpiration and optical effects. Energy Convers. Manag. 2022, 254, 115277. [Google Scholar] [CrossRef]

- Lopez, C.I.; Fitz, R.E.; Salazar, M.R.; Rojano-Aguilar, A.; Kacira, M. Development and Analysis of Dynamical Mathematical Models of Greenhouse Climate: A Review. Eur. J. Hortic. Sci. 2018, 83, 269–279. [Google Scholar] [CrossRef]

- Chen, Z.; Zhao, H.; Zhang, Y.; Shen, S.; Shen, J.; Liu, Y. State of health estimation for lithium-ion batteries based on temperature prediction and gated recurrent unit neural network. J. Power Sources 2022, 521, 230892. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, F.; Zhao, Y. Data-driven approaches for greenhouse climate prediction: A review. Comput. Electron. Agric. 2022, 193, 106637. [Google Scholar]

- Yao, Z.; Lum, Y.; Johnston, A.; Mejia-Mendoza, L.M.; Zhou, X.; Wen, Y.; Aspuru-Guzik, A.; Sargent, E.H.; Seh, Z.W. Machine learning for a sustainable energy future. Nat. Rev. Mater. 2023, 8, 202–215. [Google Scholar] [CrossRef] [PubMed]

- Ding, J.; Tu, H.; Zang, Z.; Huang, M.; Zhou, S.-J. Precise control and prediction of the greenhouse growth environment of Dendrobium candidum. Comput. Electron. Agric. 2018, 151, 453–459. [Google Scholar] [CrossRef]

- Wang, H.; Li, L.; Wu, Y.; Meng, F.; Wang, H.; Sigrimis, N.A. Recurrent neural network model for prediction of microclimate in solar greenhouse. IFAC-PapersOnLine 2018, 51, 790–795. [Google Scholar]

- Qi, P.; Yao, X.; Liu, Q.; Xu, K.; Ren, H.; Xu, K. Prediction of ash melting characteristics temperature for biomass and bituminous coal co-firing based on multiple linear regression model. Agric. Eng. 2024, 40, 174–182. [Google Scholar]

- Jose, D.M.; Vincent, A.M.; Dwarakish, G.S. Improving multiple model ensemble predictions of daily precipitation and temperature through machine learning techniques. Sci. Rep. 2022, 12, 4678. [Google Scholar] [CrossRef]

- Grégoire, G.; Fortin, J.; Ebtehaj, I.; Bonakdari, H. Forecasting Pesticide Use on Golf Courses by Integration of Deep Learning and Decision Tree Techniques. Agriculture 2023, 13, 1163. [Google Scholar] [CrossRef]

- Hoomod, H.K.; Amory, Z.S. Temperature prediction using recurrent neural network for Internet of Things room controlling application. In Proceedings of the 2020 5th International Conference on Communication and Electronics Systems (ICCES), Coimbatore, India, 10–12 June 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 973–978. [Google Scholar]

- Hao, H.; Yu, F.; Li, Q. Soil temperature prediction using convolutional neural network based on ensemble empirical mode decomposition. IEEE Access 2020, 9, 4084–4096. [Google Scholar] [CrossRef]

- Zhang, G.; Ding, X.; He, F.; Yin, Y.; Li, T.; Ren, J.; Zhou, J.; Qi, F. Construction of greenhouse air temperature prediction model based on LSTM-AT. Agric. Eng. 2024, 40, 194–201. [Google Scholar]

- Liu, Y.; As’arry, A.; Hassan, M.K.; Hairuddin, A.A.; Mohamad, H. Review of the grey wolf optimization algorithm: Variants and applications. Neural Comput. Appl. 2024, 36, 2713–2735. [Google Scholar] [CrossRef]

| Instrument | Model Number | Sensor Name | Measuring Range | Accuracy |

|---|---|---|---|---|

| Outdoor PH automatic weather station | PH-CJ1 | Temperature sensor | −50~100 °C | ±0.5 °C |

| Humidity sensor | 0~100% RH | ±5% | ||

| Wind speed sensor | 0~45 m/s | ±0.3 m/s | ||

| Light intensity sensor | 0~200,000 lux | ±7% | ||

| Indoor wireless agricultural detection system | BNL-GPRS-10G | CO2 concentration sensor | 0~5000 ppm | ±50 ppm |

| Soil temperature sensors | −40~80 °C | ±0.2 °C | ||

| Light intensity sensor | 0~200,000 lx | ±1% | ||

| Jingchuang temperature and humidity recorder | GSP-6 | Temperature sensor | −40~+85 °C | ±0.3 °C |

| Humidity sensor | 10~99% RH | ±3% RH |

| Model | Forecast Time | Evaluation | ||||

|---|---|---|---|---|---|---|

| RMSE/°C | MAPE/% | R2 | MSE | MAE | ||

| GWO-BiLSTM | 10 min | 0.7889 | 4.94 | 0.97 | 0.63 | 0.62 |

| 30 min | 0.8863 | 8.5 | 0.97 | 0.68 | 0.65 | |

| BiLSTM | 10 min | 1.1064 | 6.92 | 0.93 | 1.22 | 0.91 |

| 30 min | 1.593 | 12.8 | 0.92 | 1.61 | 1.21 | |

| LSTM | 10 min | 1.3557 | 10.8 | 0.90 | 1.84 | 1.07 |

| 30 min | 1.8872 | 10.2 | 0.90 | 2.13 | 1.11 | |

| PSO-BP | 10 min | 0.9467 | 5.8 | 0.95 | 0.90 | 0.73 |

| 30 min | 1.1268 | 8.6 | 0.94 | 1.65 | 0.89 | |

| Weather | GWO-BiLSTM | PSO-BP | ||||

|---|---|---|---|---|---|---|

| R2 | RMSE/°C | MAPE/% | R2 | RMSE/°C | MAPE/% | |

| Cloudy | 0.95 | 1.59 | 9.8 | 0.93 | 2.02 | 17.49 |

| Sunny | 0.97 | 0.71 | 3.59 | 0.96 | 0.99 | 7.35 |

| Overcast | 0.96 | 0.86 | 7.21 | 0.95 | 1.1 | 6.74 |

| Sleet | 0.95 | 0.91 | 8.53 | 0.93 | 1.41 | 9.93 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, W.; Liu, S.; Guo, J.; Liu, N.; Li, Z.; Xie, C. ARIMA-Kriging and GWO-BiLSTM Multi-Model Coupling in Greenhouse Temperature Prediction. Agriculture 2025, 15, 900. https://doi.org/10.3390/agriculture15080900

Zhou W, Liu S, Guo J, Liu N, Li Z, Xie C. ARIMA-Kriging and GWO-BiLSTM Multi-Model Coupling in Greenhouse Temperature Prediction. Agriculture. 2025; 15(8):900. https://doi.org/10.3390/agriculture15080900

Chicago/Turabian StyleZhou, Wei, Shuo Liu, Junxian Guo, Na Liu, Zhenglin Li, and Chang Xie. 2025. "ARIMA-Kriging and GWO-BiLSTM Multi-Model Coupling in Greenhouse Temperature Prediction" Agriculture 15, no. 8: 900. https://doi.org/10.3390/agriculture15080900

APA StyleZhou, W., Liu, S., Guo, J., Liu, N., Li, Z., & Xie, C. (2025). ARIMA-Kriging and GWO-BiLSTM Multi-Model Coupling in Greenhouse Temperature Prediction. Agriculture, 15(8), 900. https://doi.org/10.3390/agriculture15080900