Development and Testing of the Adaptive Control System for Profiling Grain Header

Abstract

1. Introduction

- Based on the harvester’s motion laws during the harvesting operation, a profiling mathematical model for the vertical lifting motion, horizontal rotation motion of the profiling header, and the angle of the cutting knife is constructed, and an adaptive profiling control strategy is proposed.

- According to the profiling control strategy, an adaptive profiling hydraulic control system for the header suitable for hilly and mountainous areas is designed. It mainly consists of a profiling mechanism, a sensor unit, a profiling adjustment device, an adaptive controller, and a hydraulic drive device. The profiling mechanism and the sensor unit can sense and collect real-time information about the uneven field terrain. The hydraulic drive device controls the on–off of the solenoid valve through the electrical signals transmitted by the adaptive controller, thereby controlling the profiling adjustment device to perform accurate, stable, and real-time profiling of the header.

- The developed system is subjected to simulation and field tests. The results show that the adaptive profiling control system is highly accurate and stable and can achieve horizontal profiling. This system improves the intelligence level of the grain combine harvester to a certain extent. It will also have practical applications in other agricultural machinery.

2. Materials and Methods

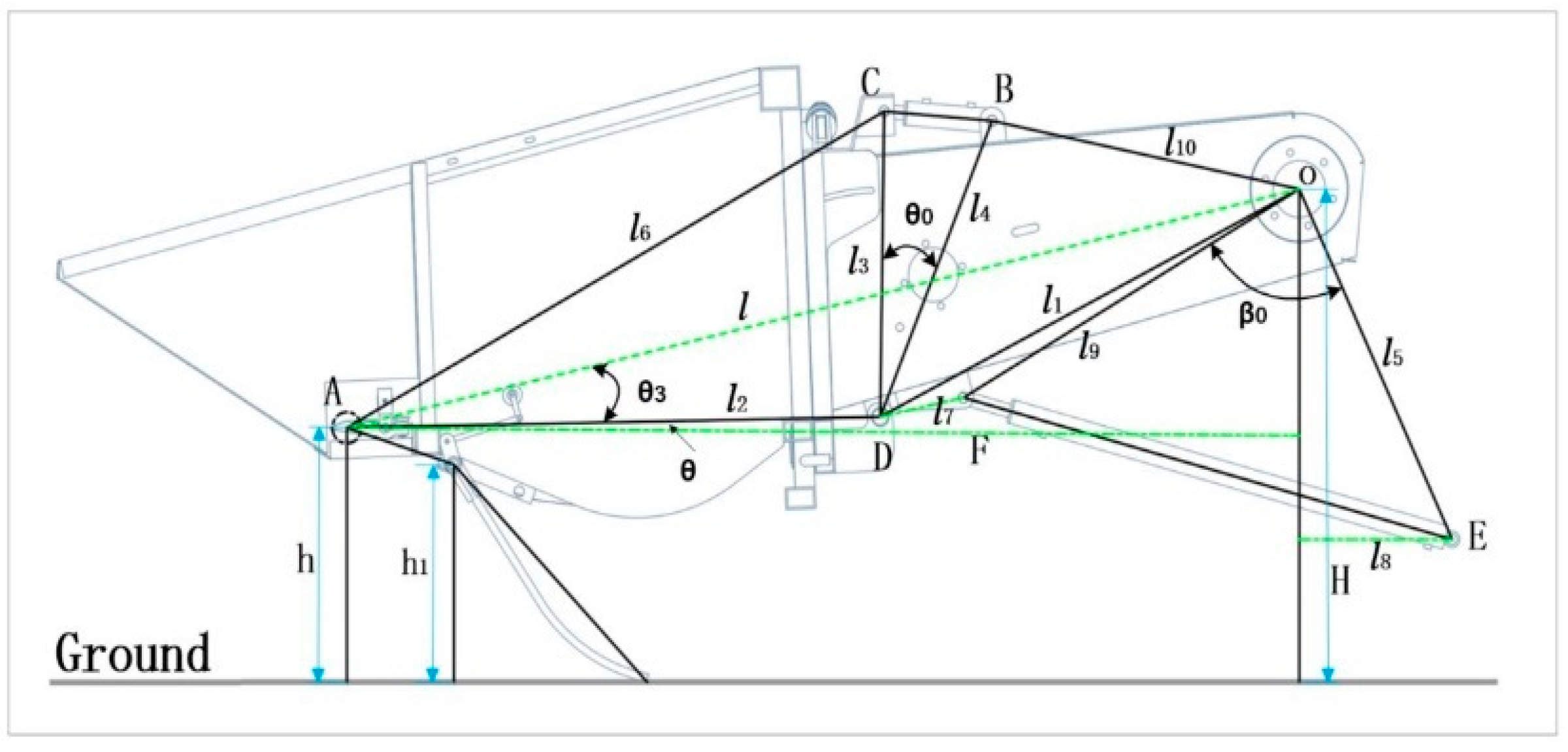

2.1. Adaptive Conformal Adjustment Mechanism Design

2.2. Modeling of Adaptive Conformal Adjustment Mechanisms

2.2.1. Vertical Lifting Motion and Cutting Angle Adjustment

2.2.2. Horizontal Rotary Oscillating Motion

2.3. Overall Design of Adaptive Profiling Control System

2.3.1. Analysis of Affine Control Strategies

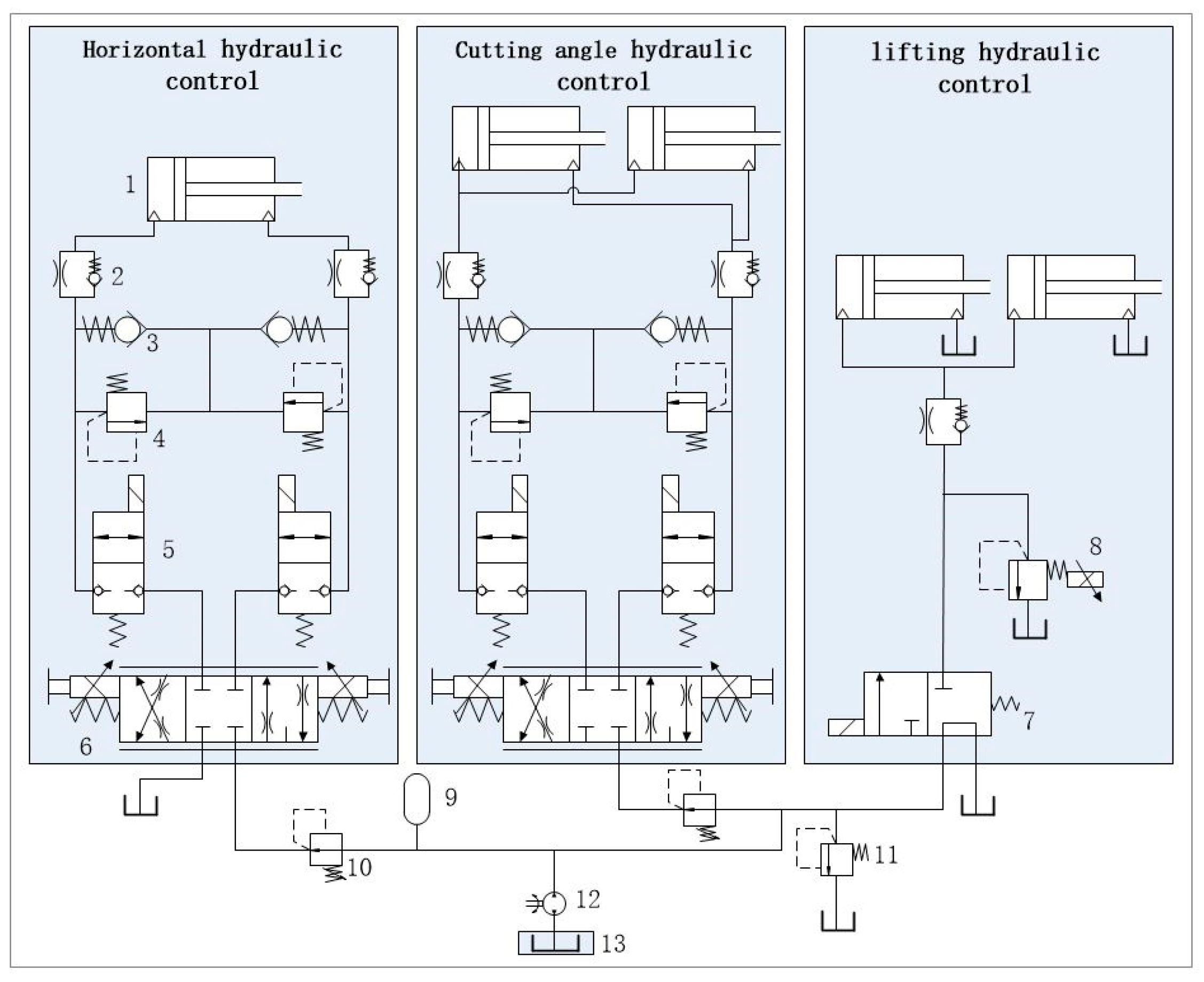

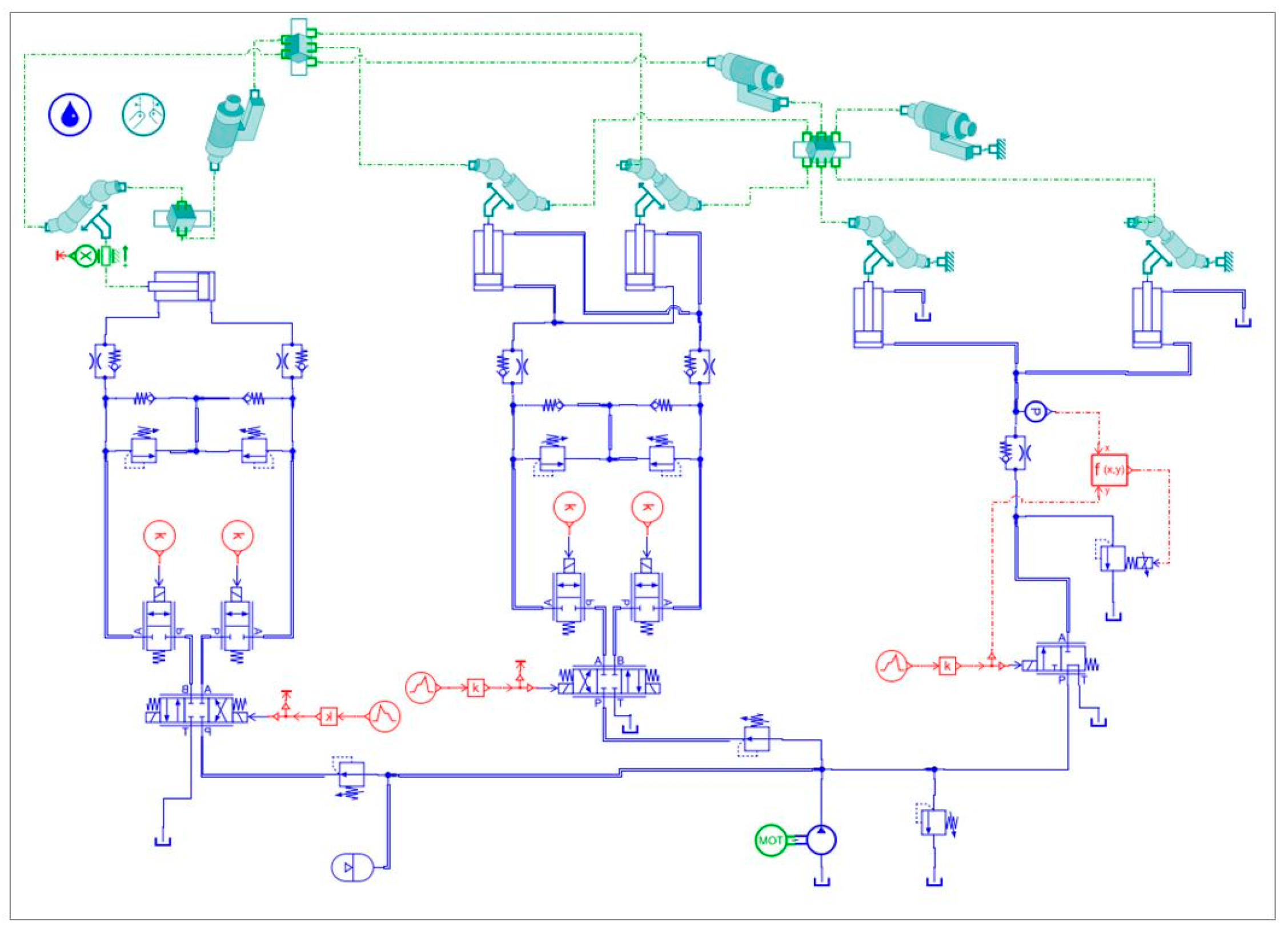

2.3.2. Analysis of Hydraulic Drive Systems

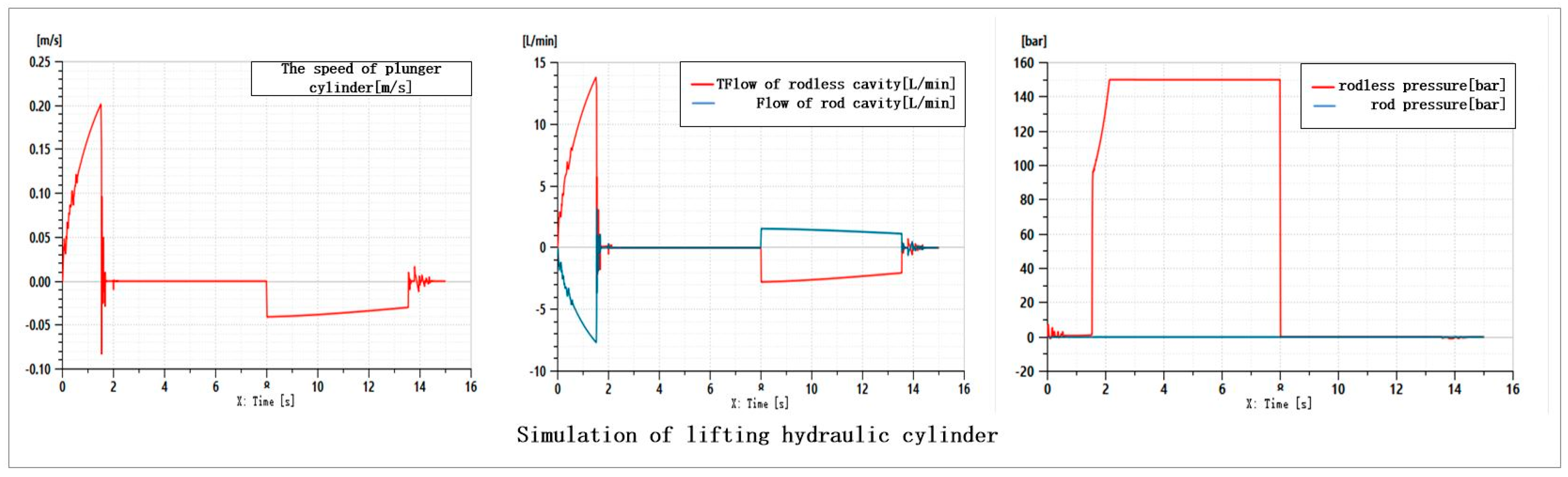

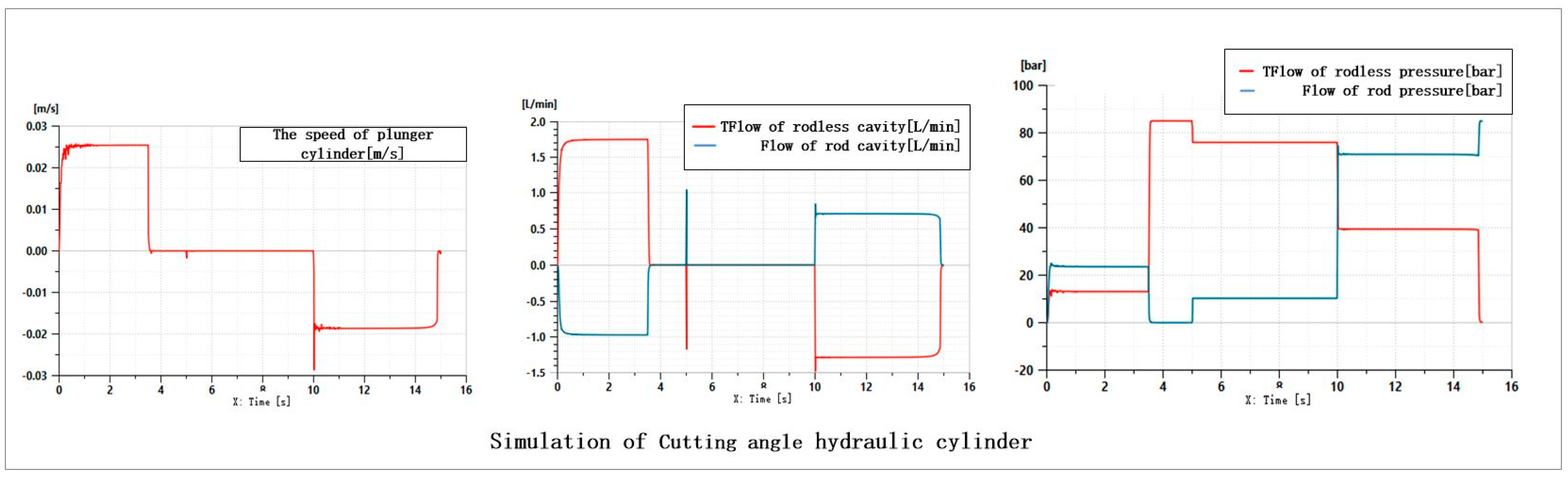

2.3.3. Simulation and Analysis of Hydraulic Systems

Vertical Elevation of the Header Imitates Rows

Header Front and Back Floating Imitation Line

Horizontal Oscillation of the Header Imitates Rows

3. Results

3.1. Static Test

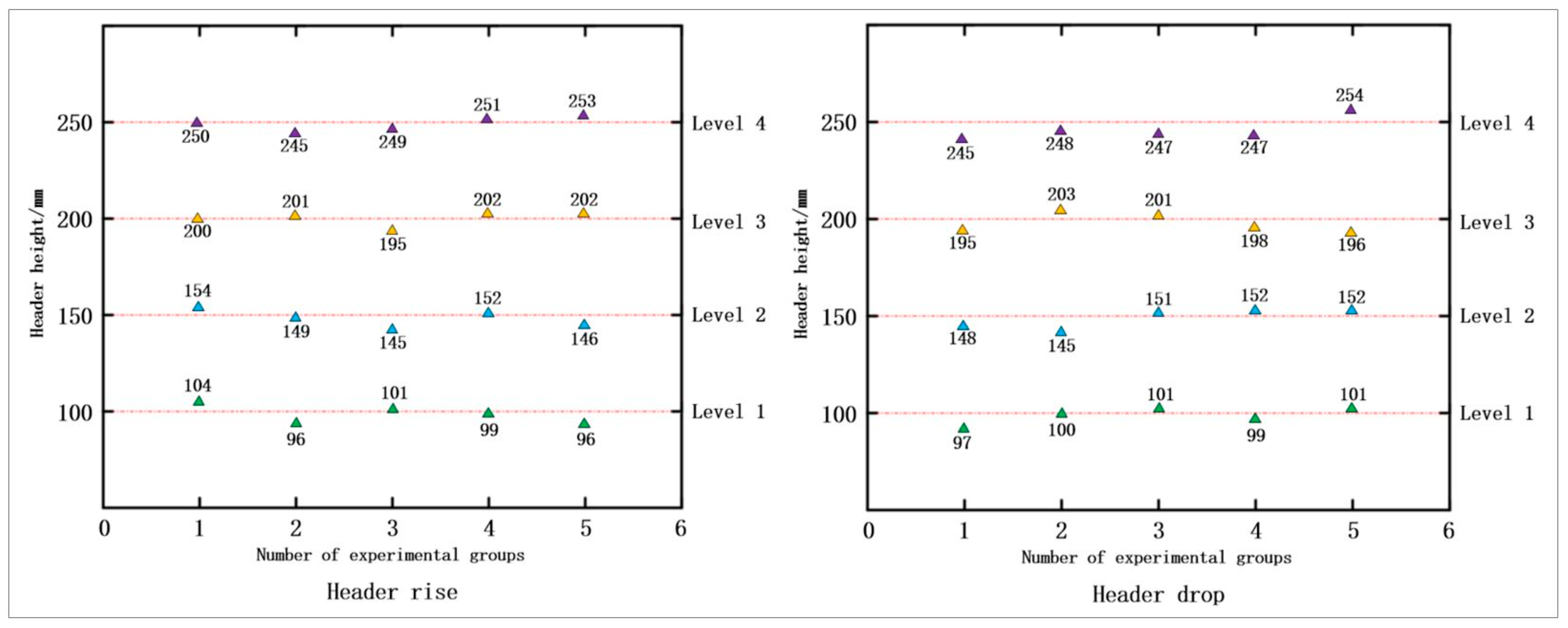

3.1.1. Header Rise and Fall Test

3.1.2. Header Slope Test

3.2. Field Trial

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Deng, L.; Li, Y. Current situation and development trend of rice combine harvester in China. Res. Agric. Mech. 2001, 02, 4–6. [Google Scholar]

- Zhao, C.; Ma, C.; Li, J. Research status and prospects of mechanization technology for rice in hill and mountainous areas. J. Agric. Eng. 2005, 1, 1–11. [Google Scholar]

- Shen, Y.; Zhang, Y.; Liu, H. Research Review of Agricultural Equipment Automatic Control Technology. J. Agric. Mach. 2023, 8, 1–18. [Google Scholar]

- Lian, X.; Wang, J.; Zhu, Y. Research status analysis of key technology and loss of soybean harvester header. Chin. J. Agric. Mach. Chem. 2024, 45, 8–13. [Google Scholar]

- Wang, Q.; Meng, J.; Wen, K. Grain combine harveser header profiling control system development and testing. Comput. Electron. Agric. 2024, 183, 105907. [Google Scholar]

- Ni, Y.; Jin, C.; Chen, M.; Yuan, W.; Qian, Z.; Yang, T.; Cai, Z. A model for calculating the head height of a soybean harvester based on an earth-machine system with an adjustment system. Comput. Electron. Agric. 2021, 183, 105907. [Google Scholar] [CrossRef]

- Geng, A.; Zhang, M.; Zhang, J. Design and Experiment of Automatic Control System for Corn Header Height. J. Agric. Mach. 2020, 51, 118–125. [Google Scholar]

- Liu, W.; Luo, X.; Zeng, S. Performance test and analysis of the self-adaptive profiling header for ratooning rice based on fuzzy PID control. J. Agric. Eng. 2022, 38, 1–9. [Google Scholar]

- Wang, J.; Wang, Y.; Yu, W. Motion analysis and experimental study of automatic copying system and key components of residual film recovery machine. Xinjiang Agric. Sci. 2023, 60, 2842–2852. [Google Scholar]

- Jing, C.; Liu, G.; Ni, Y. Design and experiment of heauder profiling mechanism for combine harvester based on MBD-DEM coupling. J. Agric. Eng. 2022, 38, 1–10. [Google Scholar]

- Zhuang, X.; Li, Y. Header Height Control Strategy of Harvester Based on Robust Feedback Linearization. J. Agric. Eng. 2020, 51, 123–130. [Google Scholar]

- Lopes, T.; Magalhaaes, P.S.G.; Nobrega, E.G.O. Optimal header height control system for combines. BioSystems 2002, 81, 261–272. [Google Scholar] [CrossRef]

- Zhang, T.; Zhai, X.; Gao, J. Development of Adaptive Profiling System for Header of Fresh Corn Harvester which Reaping Both Corn Stalk and Spike. Agric. Eng. 2023, 13, 15–20. [Google Scholar]

- Wang, Z.; Yang, R.; Chen, D. Design of Header Profiling Height Control System Based on PID Regulation. Agric. Mech. Res. 2024, 46, 97–102. [Google Scholar]

- Li, R.; Xu, L.; Xu, X. Design and Simulation of Mechanical–hydraulic Combined Soybean Header Profiling Device. Agric. Mech. Res. 2024, 46, 60–65. [Google Scholar]

- Yang, R.; Wang, Z.; Shang, S. The Design and Experimentation of EVPIVS-PID Harvesters’ Header Height Control System Based on Sensor Ground Profiling Monitoring. Agriculture 2022, 12, 282. [Google Scholar] [CrossRef]

- Qian, J.; Ma, S.; Xu, Y. Experimental study on sugarcane stubble base-cutting mechanism. Biosyst. Eng. 2024, 245, 122–134. [Google Scholar] [CrossRef]

- Wei, L.; Che, Y.; Wang, F. Design and Experiment of the Ground Profiling Control System of Combine Header. Agric. Mech. Res. 2017, 39, 150–154. [Google Scholar]

- Luo, Y.; Liao, Z.; Shi, S. Design and Testing of a 2-DOF Adaptive Profiling Header for Forage Harvesters. Agronomy 2024, 14, 1909. [Google Scholar] [CrossRef]

- Ji, K.; Li, Y.; Li, G. Design and Test of Film Mulch Precision Planter for Turnips. Agric. Mech. Res. 2023, 45, 85–89+94. [Google Scholar]

- Zhao, L. Study on the Adaptive Control System of Sugarcane Harvester Based on Cutting Height Detection. Master’s Thesis, Changan University, Xian, China, 2022. [Google Scholar]

- Zhang, Z. Design and analysis of hydraulic lifting system of combine harvester cutting platform. Master’s Thesis, Shandong University of Science and Technology, Shandong, China, 2019. [Google Scholar]

- Yi, S.; Li, Y.; Li, Y. Design and test of hydraulic active profiling mechanism for high-speed no-till corn planter. J. Agric. Mach. 2024, 55, 110–120+130. [Google Scholar]

- Zhao, S.; Zhou, J.; Zhang, S. Simulation on position Overshoot of Hydraulic Cylinder Piston Based on AMESim. Chin. Hyd. Pneum. 2023, 47, 138–145. [Google Scholar]

- Liu, G.; Ni, Y.; Yang, T. Design and experiment of header height automatic control system for soybean harvester. Chin. J. Agric. Mach. Chem. 2023, 44, 155–160+2. [Google Scholar]

- Zhou, Y.; Luo, Y.; Liu, D. Designandexperimentofrapecutterin4LZ-4.0graincombineharvester. Chin. J. Agric. Mach. Chem. 2023, 44, 22–29+35. [Google Scholar]

- Yao, Y.; Song, Z.; Du, Y. Analysis of vibration characteristics and its major influenced factors of header for corn combine harvesting machine. Agric. Eng. 2017, 33, 40–49. [Google Scholar]

- Qi, M. Research on the Application of Intelligent Control Technology in the Header Height Control of Corn Harvesters. Agric. Dev. Equip. 2024, 09, 59–61. [Google Scholar]

| State | Header Height (mm) | Max. AEV (mm) | Min. AEV (mm) | MAEV (mm) | MRE (%) | ART (%) |

|---|---|---|---|---|---|---|

| Up | 100 | 4 | 1 | 2.5 | 2.83 | 0.52 |

| 150 | 5 | 1 | 3 | 2.15 | 0.45 | |

| 200 | 5 | 0 | 2.5 | 1.00 | 0.77 | |

| 250 | 5 | 0 | 2.5 | 0.80 | 0.60 | |

| Down | 100 | 3 | 0 | 1.5 | 1.22 | 0.70 |

| 150 | 4 | 1 | 2.5 | 1.62 | 0.84 | |

| 200 | 5 | 1 | 3 | 1.51 | 0.65 | |

| 250 | 5 | 2 | 3.5 | 1.37 | 0.72 |

| State | Header Height (mm) | Max AEV (mm) | Min AEV (mm) | MAEV (mm) | MRE (%) | ART (%) |

|---|---|---|---|---|---|---|

| Left deflection | 100 | 4 | 2 | 2.6 | 2.58 | 0.62 |

| 150 | 5 | 0 | 2.4 | 1.65 | 0.55 | |

| 200 | 4 | 2 | 2.8 | 1.39 | 0.87 | |

| 250 | 5 | 0 | 2 | 0.81 | 0.56 | |

| Right deflection | 100 | 4 | 0 | 2 | 2.04 | 0.63 |

| 150 | 4 | 1 | 2.6 | 1.76 | 0.78 | |

| 200 | 4 | 1 | 3 | 1.51 | 0.71 | |

| 250 | 5 | 1 | 2.6 | 1.03 | 0.82 |

| No. | Vehicle Travel Speed (km/h) | Stubble Height L (mm) | C.V (%) | Τ (%) | SSR (%) |

|---|---|---|---|---|---|

| 1 | 5 | 198.22 | 3.2 | 94 | 0 |

| 2 | 7 | 199.68 | 3.0 | 96 | 0 |

| 3 | 9 | 199.14 | 6.1 | 94 | 0 |

| 4 | 11 | 199.40 | 5.8 | 92 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Niu, Y.; Li, R.; Liu, W.; Rong, K.; Hong, H.; Zhang, G. Development and Testing of the Adaptive Control System for Profiling Grain Header. Agriculture 2025, 15, 473. https://doi.org/10.3390/agriculture15050473

Niu Y, Li R, Liu W, Rong K, Hong H, Zhang G. Development and Testing of the Adaptive Control System for Profiling Grain Header. Agriculture. 2025; 15(5):473. https://doi.org/10.3390/agriculture15050473

Chicago/Turabian StyleNiu, Yi, Ruixue Li, Wei Liu, Kai Rong, Haoxuan Hong, and Guohai Zhang. 2025. "Development and Testing of the Adaptive Control System for Profiling Grain Header" Agriculture 15, no. 5: 473. https://doi.org/10.3390/agriculture15050473

APA StyleNiu, Y., Li, R., Liu, W., Rong, K., Hong, H., & Zhang, G. (2025). Development and Testing of the Adaptive Control System for Profiling Grain Header. Agriculture, 15(5), 473. https://doi.org/10.3390/agriculture15050473