Abstract

This study examines the impact of noise inside the cabin of an agricultural tractor on the operator, focusing on operational parameters: agrotechnical surfaces, speed of movement, and tire pressure. Noise measurements were conducted on a LANDINI POWERFARM 100 tractor on agricultural fields and access roads. The tests followed HRN ISO 5008:2015 standards for smooth and rough tracks, and the noise was measured with a Metrel Multinorm device using an “A” filter, positioned according to HRN ISO 6396:2018 and ISO 5131:2018 standards. A two-factor analysis of variance was performed, considering tractor speed (“B”) and tire pressure (“C”). The Analytical Hierarchy Process (AHP) was applied to group the agronomic surfaces (“A”) into smooth and rough categories. By conducting a one-way ANOVA on the mean values of the dependent variables grouped by AHP, significant differences in noise were found. On the right side of the operator, significant noise differences were found between speeds B2, B3, and B4 (from 73.60 dB(A) to 73.99 dB(A)), with a decrease in noise as speed increased at C2. The coefficient of determination decreased from 78.99% to 44.93% with increasing speed. On the left side, significant differences in noise were found at tire pressure C1 at lower speeds, with increasing R2 values up to 50.89%, and similarly for C3 at higher speeds, reaching 72.61%.

1. Introduction

Noise is defined as any unwanted and unpleasant sound, or a mixture of sounds with varying properties, which may be continuous, intermittent, or impact-like, with fluctuating levels, durations, and temporal distributions [1]. Noise has become a serious issue that threatens both the mental and physical health of individuals, reduces their work efficiency, and increases the energy expenditure required for tasks. By adequately organizing work conditions and adapting the environment, the negative impact of excessive noise can be mitigated [2]. The issue of noise has become more prominent in developed countries due to technological advancements (agricultural machinery, tools, and devices, which are becoming more and more numerous every day), negatively impacting quality of life. According to data from the Croatian Health Insurance Institute, the most commonly diagnosed occupational diseases in Croatia are hearing impairments caused by noise exposure [3]. Noise at the workplace of an agricultural tractor operator is the result of the operation of the tractor engine, transmission parts, exhaust pipe, air cleaner, and attached machines or tools. The negative effects of noise on the operator are manifested in reduced concentration, increased irritability, disturbances in breathing, more frequent errors during work, and the quicker onset of fatigue, which directly impact the efficiency or productivity of the machine–operator system [4].

The authors in [5] focused on the study of noise’s impact on drivers and concluded that increased noise levels negatively impact the physical and psychological characteristics of drivers.

The authors in [6] emphasize that prolonged exposure to high noise levels leads to hearing loss among farmers. Agricultural production can generate high noise levels. Severe hearing injuries are not as sudden as incidents like tractor rollovers but are persistent and hazardous. The authors in [7], investigating the level of vibration and noise on an agricultural tractor, note that the type of terrain and the number of operating hours should be taken into account as key factors when assessing the noise level of a tractor.

The authors in [8], investigating the tendency of noise levels in the cabin of an agricultural tractor, concluded that noise level trends are inversely related to the year of tractor production, with newer models producing lower noise levels. An average noise reduction of 1 dB(A) per year of tractor production was observed. Their study analyzed 50 agricultural tractors, from models manufactured in 1981 to the most recent. The measurement results revealed a large variation in noise levels inside the tractor cabins. This variation ranged from 67.7 dB(A) to 94.7 dB(A), with the highest recorded value being 119 dB(A). The analysis showed that low-frequency noise in the range of 16 to 125 Hz dominated the tractors. Tractors manufactured after 2000 showed an average noise reduction of 13.4 dB(A) compared to older tractors, reflecting significant improvements in noise reduction. However, in older cabs and tractors without cabs, noise levels ranged between 95 and 100 dB(A).

The authors in [9] investigated noise and vibration levels in tractors produced between 1980 and 2013. Detailed noise measurements were conducted on five-wheeled tractors, three of which were manufactured between 2006 and 2012 and two between 1988 and 1999. The results indicated that during plowing and transportation, the cabin noise levels ranged from 71.5 dB(A) to 92.3 dB(A). Furthermore, the data demonstrated that technical advancements in tractor cabin design (advanced cab noise insulation and vibro-isolation) significantly reduced noise levels, from 90 dB(A) in tractors manufactured between 1980 and 1990 to 73 dB(A) in tractors produced after 2000. The authors in [10,11] highlighted differences in noise levels based on tractor design, particularly between tractors with and without cabins. Their research showed that tractors without cabins often produced noise levels exceeding the permissible limit, whereas noise levels in tractors with cabins were lower. This study focused on a MASSEY FERGUSON 285 tractor at different speeds during various agrotechnical operations. Measurements taken at the operator’s right ear level revealed that noise levels at 1000 engine revolutions per minute (RPM) were within permissible limits at 78.8 dB(A). However, noise levels exceeded the permissible limit of 90 dB(A) at 2000 RPM. This study also found that operators were exposed to hazardous conditions in such environments, with the primary causes of increased noise levels attributed to the tractor’s age, the intensity of the work performed, and insufficient maintenance [11]. The authors in [12] noted that noise in single-axle tractors results from engine operation. As a solution, they proposed modifications to the design of single-axle tractors, including the installation of exhaust mufflers. These mufflers would reduce pressure drops, friction, and fluid flow direction changes while redistributing the total energy of the fluid to a lower noise intensity. Given the extensive use of such equipment, they emphasized the importance of implementing preventive and regular maintenance for single-axle tractors.

Determining the noise level of the threshing machine, the authors in [13] state that the maximum equivalent noise level was 81.2 dB(A), and the minimum was 70.0 dB(A). In [14], noise levels were measured on a Massey Ferguson 399 tractor with and without a cabin at 1500, 1750, and 2000 engine revolutions per minute (rpm). For the tractor without a cabin, the highest recorded noise level at 2000 rpm was 88 dB(A), while for the tractor with a cabin, the highest noise level at 2000 rpm was 72 dB(A), which represents a significantly lower noise level compared to the tractor without a cabin. On the same manufacturer’s tractor, noise levels were measured during sugar loading operations, with and without a cabin. The measured noise levels varied by up to 1% depending on whether the bucket was full or empty. It was evident that tractors with cabins achieved lower noise levels, providing better conditions for the operator. The authors in [15] conducted a study between 1991 and 2012 in Italy. Noise level measurements were made on tracked tractors, as well as on wheeled tractors with and without cabs. The noise levels were measured on 123 tracked tractors, of which 96% exceeded 90 dB(A), while only 4% were in the range of 76.4 to 90 dB(A). The lowest recorded noise level was 76.4 dB(A), and the highest was 106.4 dB(A). For wheeled tractors, 432 vehicles were tested, including 77 with cabs. Of the tractors with cabs, 49.35% (38 tractors) had a noise level below 80 dB(A), 31% had a noise level above 90 dB(A), and the rest were within the permitted limits. Most of the tractors without a cab were older models, and among the 355 tested, 152 (43%) had noise levels above 90 dB(A), 107 had noise levels below 80 dB(A), and 96 were in the range of 80 to 90 dB(A).

The author in [16] reported measured noise levels ranging from 62.1 to 87.4 dB(A) during various agricultural operations on tractors with power outputs ranging from 96 to 227 kW. It was determined that the average noise level did not adversely affect the machine operator. Measurements of external and internal noise levels on a YTO 454 tractor showed that external noise on the exhaust pipe side was 85.3 dB(A), while on the opposite side, it was 84.2 dB(A). The internal noise levels were 88.1 dB(A) with the doors and windows closed and 89.2 dB(A) with the doors and windows open [17].

The measured noise level at the operator’s position of a tractor without an attachment was 3.4 dB(A) lower when driving on a gravel road compared to the noise level during sowing operations [18]. The authors in [19], investigating noise levels at the operator’s position on tractors with and without cabins during movement on agricultural surfaces, found that tractors without cabins produced higher noise levels (94 dB(A)) compared to those with cabins (88 dB(A)). The authors in [20] conducted noise measurements on Fendt 410 tractors, both inside and outside the cabin at the operator’s position. It was determined that none of the measured values exceeded the permissible limit of 90 dB(A). The authors in [7] measured the noise level on six different tractors at three locations and determined the lowest measured noise level to be 89.69 dB(A), while the highest measured noise level was 99.68 dB(A). The study in [21] included five agricultural tractor operators and five office workers to determine noise levels on the left and right sides. The measured values indicate that the noise levels on both sides were higher for agricultural tractor operators compared to office workers. Comparing frequencies and noise levels, it was observed that in the frequency range of 1250 Hz to 8000 Hz, noise did not exceed 40 dB(A).

In order to reduce the negative impact of noise on workers, limited values for worker exposure have been prescribed for an eight-hour working time. The Regulation on the Protection of Workers from Exposure to Noise at Work [22] establishes exposure limit values and warning thresholds for an eight-hour workday, including the following peak sound pressure levels:

- Exposure limit value: L (EX, 8 h) = 87 dB(A);

- Upper warning threshold: L (EX, 8 h) = 85 dB(A);

- Lower warning threshold: L (EX, 8 h) = 80 dB(A).

The authors in [7] highlight that overcoming excessive noise levels requires the mandatory use of personal protective equipment, such as earplugs, to mitigate noise on tractors without cabins. The authors in [23] state that when operating tractors without cabins, the use of protective devices capable of reducing the equivalent sound pressure level by 10 to 45 dB(A) is recommended. Today, the protection of tractor operators and workers using attached machinery against the adverse effects of noise is achieved through personal protective equipment, such as earplugs, cotton pads for noise protection, and lightweight, comfortable earmuffs. Although earmuffs fit snugly around the ears, prolonged use often creates an unpleasant sensation of pressure, making workers reluctant to use them [3]. The design of the tractor cabin prototype and its testing currently offer the best means for providing a relatively quiet working environment for the operator. Such a tractor cabin should be a fully integrated chamber with insulation from the chassis. Panel resonances must be controlled, and there should be no significant sound sources inside the cabin. These cabins should have an absorptive lining to reduce the noise of reflected sound [24]. The impact of tractor operating conditions on internal noise in the cabin, with a frequency range up to 2000 Hz, is influenced by some operational factors (engine speed, motion speed, agrotechnical surface, gear shifting, and cabin installation). Han et al. [25] investigated the transmission of airborne and structure-borne noise at the operator’s seat of an agricultural tractor. The results of the study indicate that structure-borne noise is dominant, while airborne noise increases with increasing engine speed. Installing an acoustic silencer and sound absorber on the fender, which is the transmission path of the rear wheel noise, can effectively reduce airborne noise. For the quality assessment of agricultural machinery, Ranji et al. [26] indicate the importance of an analytical hierarchical process, which is characterized by the correct selection of the importance of independent variables (agronomic, technical, economic, and environmental). Abhijeet and Nandkumar [27], investigating the application of AHP to assess the importance of parameters for the selection of agricultural machinery, indicate that it is a complex process where it is important to choose the right factors. They conclude that the most influential factor in choosing a tractor is the type of operation it will perform, as well as the service, type of business, brand, and price. Mousavi and Naeini [28], through a case study of a petrochemical company implementing the Analytic Hierarchy Process (AHP) for noise control and worker noise exposure reduction, thoroughly explored the AHP and its application within occupational health and safety. Occupational health, a critical component of healthcare, focuses on safeguarding employee safety, health, and well-being across diverse occupations. This field utilizes scientific methodologies to anticipate, quantify, assess, and manage potential workplace hazards, enabling the development of tailored solutions. The Analytic Hierarchy Process (AHP) offers a valuable mechanism for selecting optimal control strategies in occupational health and safety. AHP facilitates decision-making by decomposing intricate issues into smaller, more easily addressed components. This framework empowers decision-makers to weigh various options based on factors such as cost, efficacy, and practicality, ultimately leading to the identification of the most suitable action plan.

Durczak and Rybacki [29] list the following technological solutions for tractors of different brands with the aim of reducing noise in the tractor cabin: 1. Fendt—transmission sleeve, front axle suspension with level control, mechanical or pneumatic cabin suspension and driver’s seat, and active rear link for damping vibrations (structural noise). 2. Lamborghini—new shock-absorbing elements in the cabin (hydraulic silent blocks) significantly reduce vibrations (up to 40% more than standard silent blocks) and structural noise. Ahistrom et al. [30,31] state in their research that factors that significantly influence the reduction in noise levels in the operator’s cab are the design—cab structure and exhaust systems emission 4 (EURO4). Somashekarappa [32], investigating noise reduction in internal combustion engines, cite traditional and innovative technological solutions. The traditional approach included acoustic enclosures and insulation; muffler design and optimization; engine mount improvements; balancing and vibration damping; advanced noise reduction materials; and sound-absorbing materials in engine compartments, while the innovative approach included fluid flow optimization; structural vibration reduction; and the inclusion of noise control measures early in the design process.

Compared to the abovementioned modern technological solutions, the researched tractor, with its design, ensures significantly less noise generation in the cabin, since it has a front axle suspension, cabin and pneumatic seat suspension, and power steering. The application of these modern technological solutions on agricultural tractors will certainly further reduce the noise level of agricultural tractors.

The objective of this study was to determine the dependency of the investigated variable (internal noise within the tractor cabin) on operational parameters (surface type, travel speed, and tire air pressure of the agricultural tractor). The research hypothesis posits that variations in operational parameters will result in significant differences in the investigated variables and that the measured values of these variables will significantly deviate from the values observed under controlled conditions during testing on experimental tracks. It is expected that with higher tire pressure, their stiffness will increase, which will make them less able to dampen vibrations during driving, which will result in increased structural noise in the tractor cabin. Furthermore, we expect that there will be the same effect of increasing structural noise due to increased speed. It is expected that increasing the roughness of the agricultural surface (increasing the number of bumps and increasing the hardness of the surface) will increase the generation of structural noise.

2. Materials and Methods

This study was conducted on agricultural production areas and access roads of the Agricultural and Veterinary School Osijek. The aim was to measure the generated noise level at the operator’s position of an agricultural tractor. During the measurements, movement occurred on four different agrotechnical surfaces (asphalt, gravel, grass-covered surface, and field road) and two standardized test tracks (smooth and rough) in accordance with the HRN ISO 5008:2015 standard [33].

The research was performed using a LANDINI POWERFARM 100 tractor (Table 1) with a nominal power of 68 kW. Before the start of the research, the tractor had completed 7000 operating hours and had undergone a full technical inspection, which determined that it was completely operational and that during its previous exploitation, the service and preventive maintenance measures prescribed by the manufacturer had been regularly carried out. This tractor features front suspension, including a suspended front axle and a suspended cabin. The seat suspension is pneumatic. During this study, the air pressure in the tires was set to the recommended value (2.4 bar), below the recommended value (1.9 bar), and above the recommended value (2.9 bar). The tires the tractor was equipped with were new. The tractor’s travel speeds on the selected surfaces were determined according to the HRN ISO 5008:2015 standard [33] and were set to 6, 5, 4, 3, 2, and 1 kmh−1. The recommended travel speeds on the smooth track were up to 12 kmh−1, while on the rough track, they were up to 5 kmh−1 [33].

Table 1.

Technical specifications of the LANDINI POWERFARM 100 tractor.

All meteorological conditions during the measurements were within the permissible limits, as prescribed for the measuring equipment and as shown in Table 2 and Table 3.

Table 2.

Technical specifications of the METREL device type MI 6201 MULTINORM.

Table 3.

Technical specifications of sound probe A 1146.

According to HRN ISO 5008:2015, two test tracks were constructed: a smooth track (100 m long) and a rough track (35 m long). The tracks were specifically designed for each wheel row, using rubber as the base material and wooden slats to simulate irregularities. The slats were crafted and positioned in compliance with the specified standard.

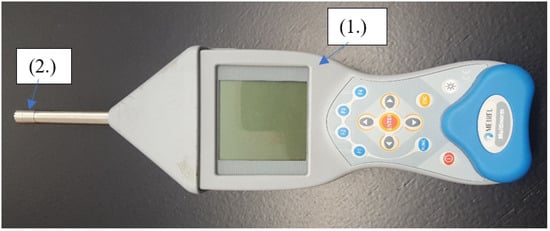

Noise was measured using a METREL sound level meter, model MI 6201 MULTINORM (Table 2), equipped with an A-weighted filter microphone (Table 3) (Figure 1).

Figure 1.

Noise measurement device (1.) with associated sensor (2.).

Measuring sound pressure level does not directly provide a value that corresponds to the subjective perception of noise. To address this, the sound level meter incorporates electronic circuits whose sensitivity varies with frequency in the same way as the human ear. This simulates equal-loudness contours. As a result, four standardized correction filters—”A”, “B”, “C”, and “D”—are available. The “A” filter measures signals inversely proportional to the loudness curve at low sound pressure levels. The “B” filter corresponds to the loudness curve at medium sound pressure levels, while the “C” filter is linear from 30 to 8000 Hz. The “D” filter is designed for aircraft noise measurements. In this study, as previously mentioned, the “A” filter was used because the purposes of the “B” and “C” filters do not align with the subjective perception of noise, as they are designed for pure tones. Noise almost always consists of complex tones. Most of the measured noise levels were variable. Therefore, two standardized response speeds, labeled as “F” (fast = 125 ms) and “S” (slow = 1000 ms), were used. In this study, the “F” response speed was applied, as it performs more measurements within a given time frame (approximately seven measurements per second) compared to “S” (one measurement per second). Additionally, this approach is recommended in the Metrel user manual. Data transmission and processing were carried out using the SoundLink PRO by METREL v1 software (Horjul, Slovenia).

The specified sound level meter is required to be sent for calibration twice a year to an authorized laboratory that performs the calibration according to the HRN EN IEC 61672-3:2014 standard [34]. The standard requires periodic verification of the microphone’s compliance with the applicable specifications specified in the HRN EN IEC 61672-1:2014 standard [34]. Additionally, in the field, and before each new set of measurements that must be performed, a field calibration of the microphone was performed using a digital sound level calibrator manufactured by GAIN EXPRESS type ND98, which is manufactured in accordance with the HRN EN IEC 60942:2018 standard [35] for class 1 microphones. The method of performing each individual field calibration was carried out through the following procedures. Before calibration, the microphone calibrator itself is prepared for operation according to the recommendations for the same (related to checking the calibrator power supply/battery). After that, the calibration procedure begins. The microphone tip is placed in the calibrator cavity. The sound level calibrator is placed above the microphone of the sound measurement instrument being calibrated (tested). On the instrument under test, the level range control is set to a range with 100 dB as the upper limit (if 94 dB is selected on the sound level calibrator). If 114 dB is selected on the sound level calibrator, a range with an upper limit of 120 dB is selected on the device being calibrated. The instrument can be set to FAST or SLOW (FAST selected) response and C or A weighting (A filter selected). Then, the measured sound level is read on the instrument under test and, if necessary, the sensitivity control is adjusted so that it accurately shows the sound level previously selected on the calibrator (94 dB or 114 dB). This completes the field calibration procedure, and the device is ready for use.

The sound level meter was positioned according to the HRN ISO 6396:2018 standard [36], which mandates that measurements are conducted inside the operator’s cabin of the moving tractor. During the measurements, all doors, windows, and other openings in the tractor cabin were closed. The ventilation system did not generate airflow that could influence the microphone. The tractor operator wore no clothing that could produce additional noise or dampen noise levels, nor did they wear a helmet. The operator’s sitting height ranged from 800 mm to 960 mm, measured from the seat surface to the top of the head.

The HRN ISO 5131:2018 standard [37] specifies that the sound level meter must be positioned 250 mm ± 20 mm from the center of the operator’s head, at a height of 700 mm ± 20 mm above the seat reference point, and 100 mm ± 20 mm forward from the seat reference point, on both the left and right sides (Figure 2). The standard also requires that no buildings or similar structures be located within a 20 m radius of the tested tractor. Furthermore, wind speed must not exceed 5 m/s. The temperature during the measurements must be within the range of −5 °C to 30 °C, and only the tractor operator may be present in the cabin during the measurements.

Figure 2.

Sound level meter installed on the left (1.) and right (2.) sides when measuring on tracks and agrotechnical surfaces.

The following abbreviation was used in this study:

- Leq—time-averaged or equivalent continuous sound level, measured in both measurement channels. It is the most important and widely used parameter, representing the average sound level over the entire measurement period.

The experiment was designed as a three-factorial study, with the main factors being the following:

- A—Surface type (smooth and rough test tracks, along with other selected agrotechnical surfaces (6));

- B—Vehicle speed (6 levels);

- C—Tire pressure (3 levels).

This study measured noise levels inside the tractor cabin with the operator. Statistical analysis of the data was conducted using SAS/STAT Software 9.4. In addition to descriptive statistics, the analysis included a two-factorial analysis of variance (ANOVA—BxC) with six repetitions (measurements). A multiple correlation test and regression analysis were also performed to examine significant relationships between the factors as independent variables and noise as dependent variables.

Due to the high variability of the results obtained using the aforementioned statistical methods, a form of grouping for the dependent variables was necessary. Since the dependent variable agrotechnical surface is nonparametric (ordinal), hierarchical analysis was chosen and performed using the Analytical Hierarchy Process (AHP). The result of the hierarchical analysis is a dendrogram, essentially a summarized visualized matrix of differences.

3. Results

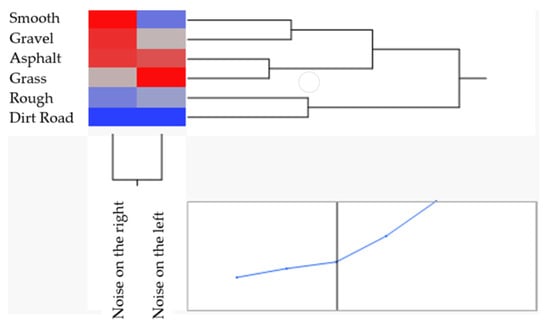

Since the dependent variable agrotechnical surface is nonparametric (ordinal), hierarchical analysis was chosen and performed using the Analytical Hierarchy Process (AHP). The result of the hierarchical analysis is a dendrogram, which is essentially a summarized, visualized matrix of differences.

The AHP analysis considered agrotechnical surfaces as the independent variable and noise levels on the right and left sides as dependent variables. Using the method of two-way clustering, the results are presented in Figure 3. The first level of clustering revealed three groups of agrotechnical surfaces: Smooth–Gravel, Asphalt–Grass, Rough–Dirt Road. At the second clustering level, two of the three groups (Smooth–Gravel and Asphalt–Grass) were close to each other and merged into one combined group (Smooth–Gravel–Asphalt–Grass).

Figure 3.

Display of data clustering by AHP for noise. The colors represent differences in noise levels for various agrotechnical surfaces: red—higher noise levels, gray—intermediate noise levels, blue—lower noise levels. The blue line represents the similarity of noise levels across different agrotechnical surfaces.

In subsequent analysis, this combined group was labeled as the Smooth Group (GL). In contrast, the Rough Group (GR) was formed, which, according to the AHP, only included the “Dirt Road” category.

A one-way analysis of variance (ANOVA) of the mean values of dependent variables was performed based on the independent variable groups identified through the hierarchical analysis (AHP). The results are presented in Table 4 and Table 5. The air pressure levels in the tires are represented by color coding, ranging from the lowest to the highest pressure as follows: green indicates the lowest pressure (C1), red represents the prescribed pressure (C2), and blue represents the highest pressure (C3).

Table 4.

Analysis of variance of noise on the right side.

Table 5.

Analysis of variance of noise on the left side.

A one-way ANOVA of the mean noise levels on the right side between the previously determined AHP groups (Rough Group—GR and Smooth Group—GL) revealed significant differences at tractor speeds of 2, 3, and 4 kmh−1, with the prescribed tire pressure of 2.4 bar.

The mean noise level on the right side decreases as speed increases, while at the same time the coefficient of variation increases. As speed rises, the coefficient of determination (R2) also decreases (from 78.99% to 44.93%) for the variants where significance was found. Additionally, a significant difference between the GR and GL groups was observed at the tractor speed of 2 kmh−1, but in this case, with air pressure higher than the prescribed value (Table 4).

An analysis of variance of the mean noise levels on the left side of the operator between the agrotechnical surface groups identified by the AHP revealed significant differences in air pressure in the tires lower than the prescribed value. This applies to tractor speeds of 1, 2, and 3 kmh−1, with increasing coefficients of determination from 38.98% to 50.89%. The same was found for air pressure in the tires higher than the prescribed value, but at slightly higher speeds (2, 3, and 4 kmh−1), with R2 increasing from 38.37% to 72.61%. Furthermore, Table 5 shows statistically significant differences between GR and GL at the prescribed tire pressure at speeds of 3 and 4 kmh−1.

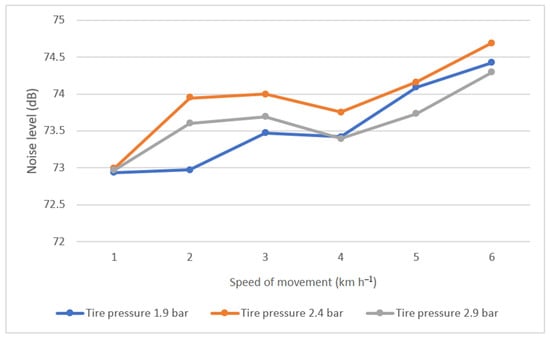

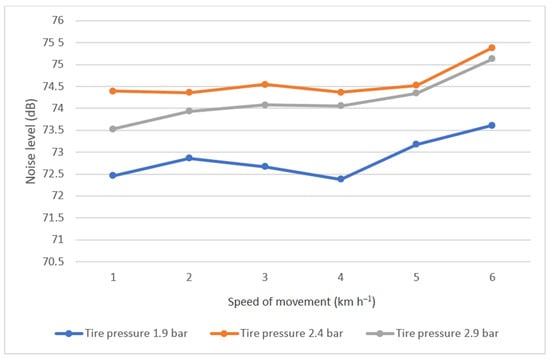

Figure 4 and Figure 5 visually show the noise level data at the workplace of an agricultural tractor operator in relation to independent factors (speed and tire pressure). Furthermore, it is visible that the highest noise level was determined at standard pressure and that the noise level increases with increasing speed.

Figure 4.

Mean values of noise level on the right side.

Figure 5.

Mean values of noise level on left side.

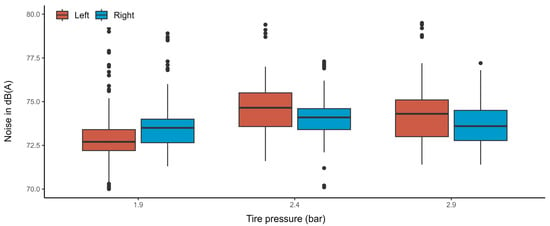

Boxplots of tire pressure input noise datasets according to left and right sides are visible in Figure 6. The median is higher on the left side for all tire pressures, except for the lower tire pressure, where it is higher on the right side. Similarly, the data dispersion is greatest precisely for the highest pressure, both for the left and right sides.

Figure 6.

Boxplots of tire pressure input noise datasets according to left and right sides.

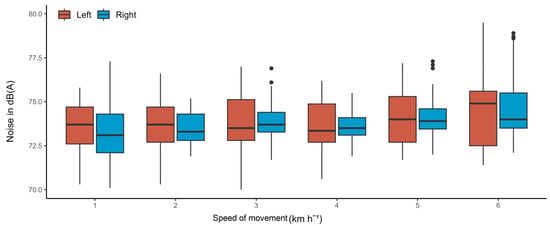

Boxplots of speed of movement input noise datasets according to the left and right sides are visible in Figure 7. The median is higher on the left side for all of the measured speeds of movement, except for the speed of movement 3 kmh−1 and 4 kmh−1, where it is higher on the right sides. Similarly, the data dispersion is lowest precisely for the all the speed of movement on the right side, except 1 kmh−1.

Figure 7.

Boxplots of speed of movement input noise datasets according to left and right sides.

4. Discussion

Modern agricultural wheeled tractors are equipped with tires that must provide good traction properties and at the same time serve as a damping element to reduce external vibrations, which affects the reduction in structural noise at the operator’s workplace. Tire manufacturers prescribe their pressure during operation on hard and soft surfaces. Despite this, in operation, this pressure is often different from the recommended one due to failure to check the air pressure in the tire. Higher tire pressure than prescribed will cause greater tire stiffness, which will not be able to dampen external vibrations and noise well. The choice of tires for the tractor alters the frequency of the generated noise up to about 500 Hz, thereby giving a different subjective impression of the vehicle or tractor. For example, the use of radial ply tires can significantly reduce the sound pressure level at low frequencies, but unfortunately, this only indicates the impact of certain engine components [38].

Another important factor that affects the noise level in the tractor cabin is the speed of the tractor. Increasing the speed of the tractor also increases the noise level. In this study, an increase in noise at the operator’s workplace was determined at all tractor speeds, ranging from 72.38 dB to 75.38 dB. The results of this study align with those in [19], which found that as the speed increases from 10 to 21 kmh−1, the noise level in the cabin rises (from 85 to 92 dB). Yamin et al. [39], investigating the noise level at the workplace of an agricultural tractor operator at operating speeds of 5.3 kmh−1 and 10.6 kmh−1 while working with four implements, measured the lowest noise level when working with a seed drill (81.9 dB(A)) and the highest when working with a disk harrow (86.9 dB(A)). The above research results are significantly higher compared to the results obtained in this study.

In this research, most of the obtained values have a stochastic character. The relatively low significance of the impact of independent variables on the noise on the right side of the operator is also a result of the placement of the exhaust pipe on the right side of the cabin. The increase in the variability of noise (0.42 to 0.93) reflects a reduction in the coefficient of determination (0.78 to 0.44) as the speed of movement increases, caused by the uneven change in noise emitted from the exhaust pipe.

The authors in [40] and [28], when measuring noise levels in a tractor of an unnamed brand, determined high significance between the measured mean noise values at the operator’s position while moving, similar to the findings in this study. Furthermore, the obtained coefficient of determination was 0.675, while in this study, it ranged from 0.380 to 0.789. The authors in [41] state that one of the key factors influencing the generated noise level is the surface on which the agricultural tractor moves, and by comparing the coefficients of determination, it was determined that the values were higher than those in this study, both on the left and right sides (0.555–0.955). Significantly higher coefficients of determination (0.88–0.97) are reported by the authors in [42] investigating the noise level in the cabin of agricultural tractor operators with respect to changes in engine speed. Favaretto [43] investigated the perception of sound, i.e., noise, at the workplace of agricultural tractor operators. Applying two tests, the Immersive Test and the Binaural, to predict sound quality, the obtained coefficients of determination were in the range of 0.88–0.97, which is significantly higher than the values obtained in this study.

5. Conclusions

This research reached the following conclusions:

- −

- Noise levels on the right side of the operator showed significant differences among groups during tractor movement at speeds of 2 kmh−1, 3 kmh−1, 4 kmh−1, and 2.4 bar. Noise decreased with increased speed, while the coefficient of variation rose. The coefficient of determination dropped from 78.99% to 44.93% as speed increased.

- −

- Variance analysis indicated significant noise differences on the left side at tire pressures of 1.9 bar and 2.9 bar across various speeds (1–4 kmh−1), with R2 values rising from 38.98% to 50.89% (1.9 bar) and 38.37% to 72.61% (2.9 bar), respectively.

- −

- All noise levels were below the safety thresholds (80–87 dB(A)), indicating no health risk for the operator. Noise levels rose from 72.38 to 75.38 dB(A) with increased speed, while tire pressure impacted noise levels; higher pressure resulted in lower noise than standard pressure.

- −

- The highest noise was recorded with prescribed tire pressure. Future research should explore noise levels concerning varying tire pressures under different conditions. The authors acknowledge the complexity of agricultural production and emphasize the need for the systematic study of noise factors, including different tractor suspensions and agrotechnical surface classifications for better repeatability in research.

- −

- The measurement results have a certain degree of error, since it is possible to measure separately from each side of the operator. In future research, the use of a high-performance system with multiple probes positioned in fixed locations will be considered to enhance the spatial resolution of noise measurements within the tractor cabin. This approach could provide a more detailed analysis of noise distribution and its interaction with operational parameters. Such an extension of the methodology would further contribute to refining noise assessment and mitigation strategies in agricultural machinery.

Author Contributions

Conceptualization, Ž.B. and I.P.; methodology, Ž.B. and I.P.; software, Ž.B. and I.P.; validation, Ž.B., I.P., D.R. and M.J.; formal analysis, Ž.B.; investigation, Ž.B.; resources, Ž.B.; data curation, Ž.B.; writing—original draft preparation, Ž.B. and I.P.; writing—review and editing, Ž.B., I.P., D.R. and M.J.; visualization, Ž.B.; supervision, M.J.; project administration, D.R.; funding acquisition, Ž.B., I.P., D.R. and M.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- van Kamp, I.; Woudenberg, F. (Eds.) A Sound Approach to Noise and Health; Springer Nature: Berlin/Heidelberg, Germany, 2025. [Google Scholar]

- Bačić, T. Razina Buke u Logopedskim Kabinetima. Master’s Thesis, Faculty of Education and Rehabilitation Sciences, University of Zagreb, Zagreb, Croatia, 2017. [Google Scholar]

- Fabijanić, K. Occupational Safety And Health Of The Farming Population. Sigur. Časopis Za Sigur. U Radn. I Zivotn. Okolini 2010, 52, 367–379. [Google Scholar]

- Melemez, K.; Tunay, M. The Investigation of the Ergonomic Aspects of the Noise Caused by Agricultural Tractors Used in Turkish Forestry. Afr. J. Agric. Res. 2010, 5, 243–249. [Google Scholar] [CrossRef]

- Ozer, S.; Yilmaz, H. Evaluation of Noise Pollution Caused by Vehicles in the City of Tokat, Turkey. Sci. Res. Essay 2009, 4, 1205–1212. [Google Scholar]

- Noise Induced Hearing Loss in Agriculture. Available online: https://extension.psu.edu/noise-induced-hearing-loss-in-agriculture (accessed on 20 December 2024).

- Vallone, M.; Bono, F.; Quendler, E.; Febo, P.; Catania, P. Risk Exposure to Vibration and Noise in the Use of Agricultural Track-Laying Tractors. Ann. Agric. Environ. Med. 2016, 23, 591–597. [Google Scholar] [CrossRef] [PubMed]

- Butkus, R.; Liegus, M.; Vasiliauskas, G. Tendencies of Noise Levels in Cabs of Agricultural Tractors. In Proceedings of the Rural Development 2015: Towards the Transfer of Knowledge, Innovations and Social Progress, Kaunas, Lithuania, 19–20 November 2015; pp. 1–5. [Google Scholar]

- Butkus, R.; Vasiliauskas, G. Harmful Factors In The Workplaces of Tractor Drivers. Res. Rural Dev. 2016, 1, 242–247. [Google Scholar]

- Lar, M.B.; Payandeh, M.; Bagheri, J.; Pour, Z.K. Comparison of Noise Level of Tractors with Cab and without in Different Gears on Driver Ear and Bystander. Afr. J. Agric. Res. 2012, 7, 1150–1155. [Google Scholar] [CrossRef]

- Ghotbi, M.R.; Monazzam, M.R.; Khanjani, N.; Nadri, F.; Fard, S.M.B. Driver Exposure and Environmental Noise Emission of Massey Ferguson 285 Tractor during Operations with Different Engine Speeds and Gears. Afr. J. Agric. Res. 2013, 8, 652–659. [Google Scholar]

- Beheshti, M.H.; Ghandhari, P. Assessment of Noise Exposure in Operator Cultivator Tiller. Int. J. Occup. Hyg. 2015, 7, 197–201. [Google Scholar]

- Kuznetsov, Y.; Rodimtsev, S.; Goncharenko, V.; Patrin, E.; Kalashnikova, V. Invastigation of Noise Parameters at Head Thresher Operation and Noise Map Development in Free Sound Field. Poljopr. Teh. 2016, 41, 21–24. [Google Scholar]

- Mofrad, F.E.; Lar, M.B.; Kohan, A. Reduce Noise in the Cab of the Tractor MF 399 Sugar Transport Operation. Aensi J.-Adv. Environ. Biol. 2014, 8, 3035–3038. [Google Scholar]

- Riccioni, S.; Cecchini, M.; Monarca, D.; Colantoni, A.; Longo, L.; Cavalletti, P.; Bedini, R. Overview of the Noise Measurements Process in Recent Years. Contemp. Eng. Sci. 2015, 26, 1179–1191. [Google Scholar] [CrossRef]

- Bilski, B. Audible and Infrasonic Noise Levels in the Cabins of Modern Agricultural Tractors—Does the Risk of Adverse, Exposure-Dependent Effects Still Exist? IJOMEH 2013, 26, 488–493. [Google Scholar] [CrossRef]

- Savin, L.; Tomić, M.; Simikić, M.; Mago, L. Ispitivanje Mogućnosti Homologacije Traktora YTO 454. Časopis Trakt. I Pogon. Mašine 2011, 16, 37–42. [Google Scholar]

- Pobedin, A.V.; Dolotov, A.A.; Iskaliev, A.I.; Potapov, P.V. Research of Noise in Tractor K700 Cabin. J. KONES 2015, 22, 261–264. [Google Scholar] [CrossRef]

- Abd-El-Tawwab, A.M.; Abouel-Seoud, S.A.; El-Sayed, F.M.; Abd-El-Hakim, T.A. Characteristics of Agriculture Tractor Interior Noise. J. Low Freq. Noise Vib. Act. Control 2000, 19, 73–81. [Google Scholar] [CrossRef]

- Barač, Ž.; Plaščak, I.; Jurić, T.; Jurišić, M. The influence of tractor exploitation time on the generated noise level. Teh. Vjesn. 2016, 23, 1505–1510. [Google Scholar] [CrossRef][Green Version]

- Khadatkar, A.; Mehta, C.R.; Gite, L.P.; Narwariya, B.S.; Kumar, A. Hearing Impairment of Indian Agricultural Tractor Drivers. Curr. Sci. 2017, 113, 969–974. [Google Scholar] [CrossRef]

- Pravilnik o Zaštiti Radnika Od Izloženosti Buci Na Radu. Available online: https://narodne-novine.nn.hr/clanci/sluzbeni/2023_12_148_2096.html (accessed on 20 December 2024).

- Aybek, A.; Kamer, H.A.; Arslan, S. Personal Noise Exposures of Operators of Agricultural Tractors. Appl. Ergon. 2010, 41, 274–281. [Google Scholar] [CrossRef]

- Ling, M.K. Measurement of Sound Insulation of Automotive Body Components Using Sound Intensity. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 1992, 206, 137–141. [Google Scholar] [CrossRef]

- Han, H.-W.; Kang, M.-W.; Lee, S.-H.; Seo, Y.-H.; Cho, S.-J.; Kim, J.-G.; Kim, Y.-J.; Park, Y.-J. Root Cause Analysis of Noise Transfer in an Entire Tractor System Using Multi-Layer Operational Transfer Path Analysis. Smart Agric. Technol. 2025, 10, 100754. [Google Scholar] [CrossRef]

- Ranji, A.; Parashkoohi, M.G.; Zamani, D.M.; Ghahderijani, M. Evaluation of Agronomic, Technical, Economic, and Environmental Issues by Analytic Hierarchy Process for Rice Weeding Machine. Energy Rep. 2022, 8, 774–783. [Google Scholar] [CrossRef]

- Karmarkar, A.U.; Gilke, N.R. An Application of AHP for Parameter Importance Evaluation for Farm Machinery Selection. IOP Conf. Ser. Mater. Sci. Eng. 2020, 810, 012022. [Google Scholar] [CrossRef]

- Mousavi, S.M.; Naeini, M.J.; Mousavi, S.M.; Naeini, M.J. Application of the Analytical Hierarchy Process (AHP) in Occupational Health and Safety. In The Art of Decision Making—Applying AHP in Practice; IntechOpen: London, UK, 2025; ISBN 978-1-83769-767-0. [Google Scholar]

- Durczak, K.; Rybacki, P. Noise Emission in the Cabs of Modern Farm Tractors. Teh. Vjesn. 2023, 30, 669–675. [Google Scholar] [CrossRef]

- Ahlstrom, B.J.; Zilles, J.; Pate, M.L. Innovations in Engine Design and Cab Structures of Agricultural Equipment Considerations for Noise Exposure. In Proceedings of the 2022 ASABE Annual International Meeting, Houston, TX, USA, 17–20 July 2022. [Google Scholar]

- Kumar, A. Human Engineering in Tractor Design—A Review. Int. J. Sci. Res. Eng. Trends 2019, 5, 1586–1589. [Google Scholar]

- M, S. A Noise Reduction Technique in Internal Combustion Engines: A Multidisciplinary Approach. World J. Adv. Res. Rev. 2020, 5, 170–179. [Google Scholar] [CrossRef]

- HRN ISO 5008:2015; Agricultural wheeled tractors and field machinery—Measurement of whole-body vibration of the operator. Croatian Standards Institute: Zagreb, Croatia, 2015.

- HRN EN IEC 61672-3:2014; Electroacoustics—Sound Level Meters—Part 3: Periodic Tests. Croatian Standards Institute: Zagreb, Croatia, 2014.

- HRN EN IEC 60942:2018; Electroacoustics—Sound Calibrators. Croatian Standards Institute: Zagreb, Croatia, 2018.

- HRN ISO 6396:2018; Earth-Moving Machinery—Determination of Emission Sound Pressure Level at Operator’s Position—Dynamic Test Conditions. Croatian Standards Institute: Zagreb, Croatia, 2018.

- HRN ISO 5131:2018; Tractors for Agriculture and Forestry—Measurement of Noise at the Operator’s Position—Survey Method. Croatian Standards Institute: Zagreb, Croatia, 2018.

- Li, W.L.; Somayajula, G.; Li, W.L.; Somayajula, G. Off-Highway Vehicle Ride Comfort Analysis; SAE International: Warrendale, PA, USA, 1 September 1994. [Google Scholar]

- Yamin, M.; Yousaf, Z.; Bhatti, K.M.; Ibrahim, M.; Akbar, F.N.; Shamshiri, R.R.; Mahmood, A.; Tauni, R.A. Noise Exposure and Its Impact on Psychological Health of Agricultural Tractor Operators. Noise Control Eng. J. 2021, 69, 500–506. [Google Scholar] [CrossRef]

- Barač, Ž.; Plaščak, I.; Jurišić, M.; Tadić, V.; Zimmer, D.; Duvnjak, V. Noise in the Cabin of Agricultural Tractors. Teh. Vjesn. 2018, 25, 1611–1615. [Google Scholar] [CrossRef]

- Barač, Ž.; Radočaj, D.; Plaščak, I.; Jurišić, M.; Marković, M. Prediction of Noise Levels According to Some Exploitation Parameters of an Agricultural Tractor: A Machine Learning Approach. AgriEngineering 2024, 6, 995–1007. [Google Scholar] [CrossRef]

- de Souza, C.M.A.; Junior, G.M.; da Silva, R.R.; Rafull, L.Z.L.; Orlando, R.C.; Ale, L.P. Occupational Noise Level Exposures Outside and inside Agricultural Tractor Cabs. Obs. Econ. Latinoam. 2023, 21, 4968–4987. [Google Scholar] [CrossRef]

- Favaretto, M. Sound Quality Evaluation of the Interior Noise of a Tractor HVAC System Based on Prediction Model. Ph.D. Thesis, Politecnico di Torino, Turin, Italy, 2024. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).