Design and Test of Straw Crushing and Spreading Device Based on Straw Mulching No-Tillage Planter

Abstract

1. Introduction

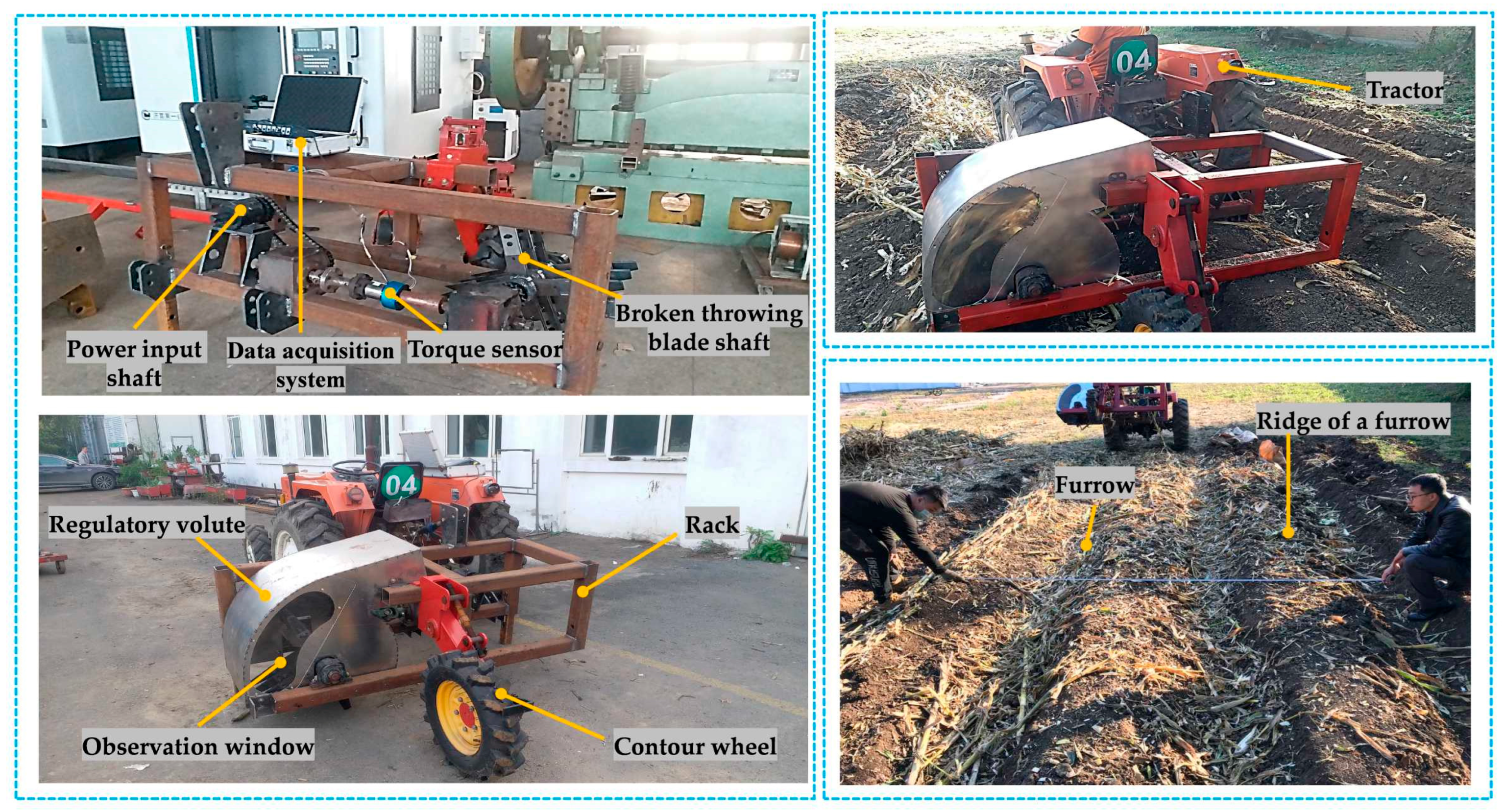

2. Materials and Methods

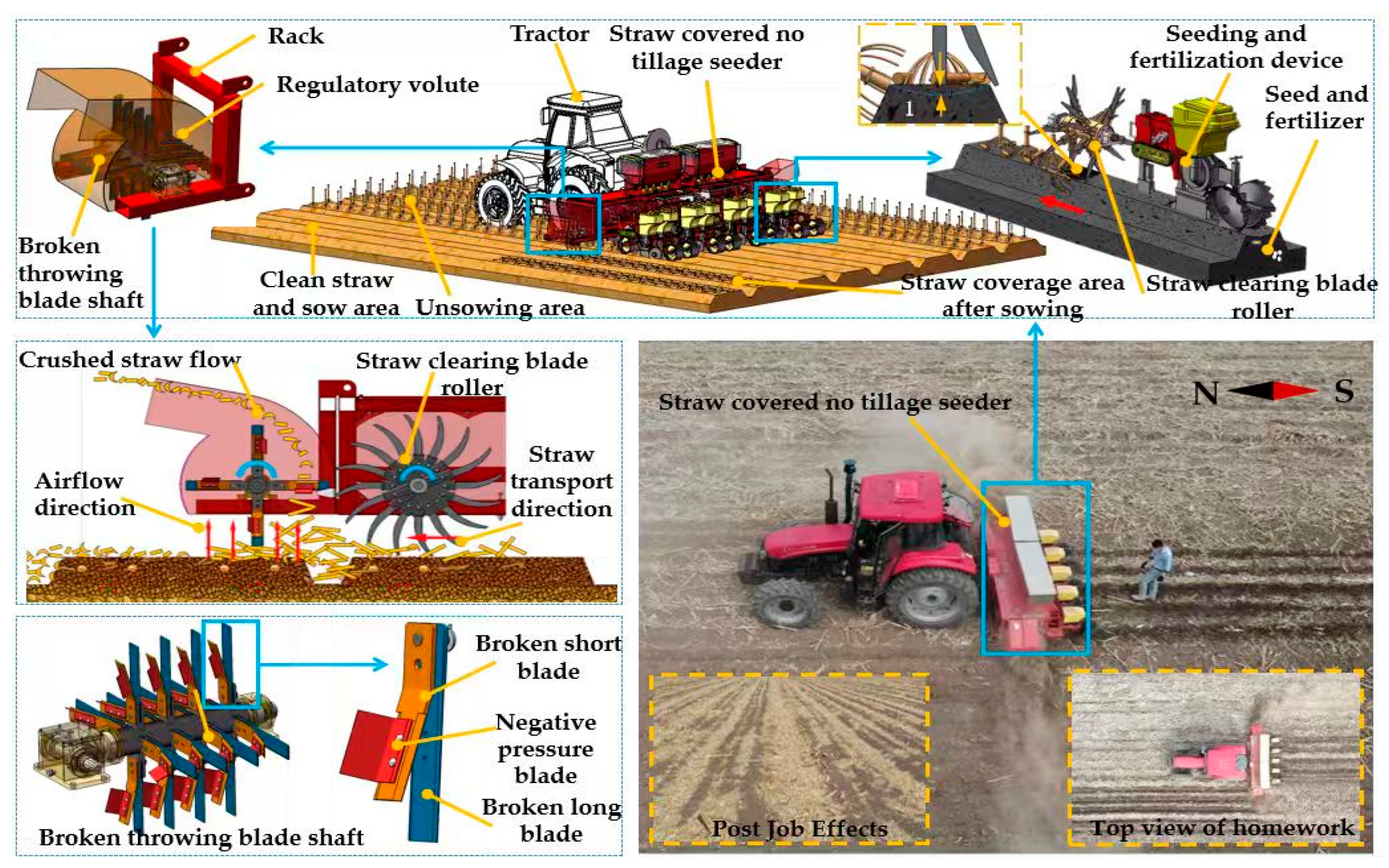

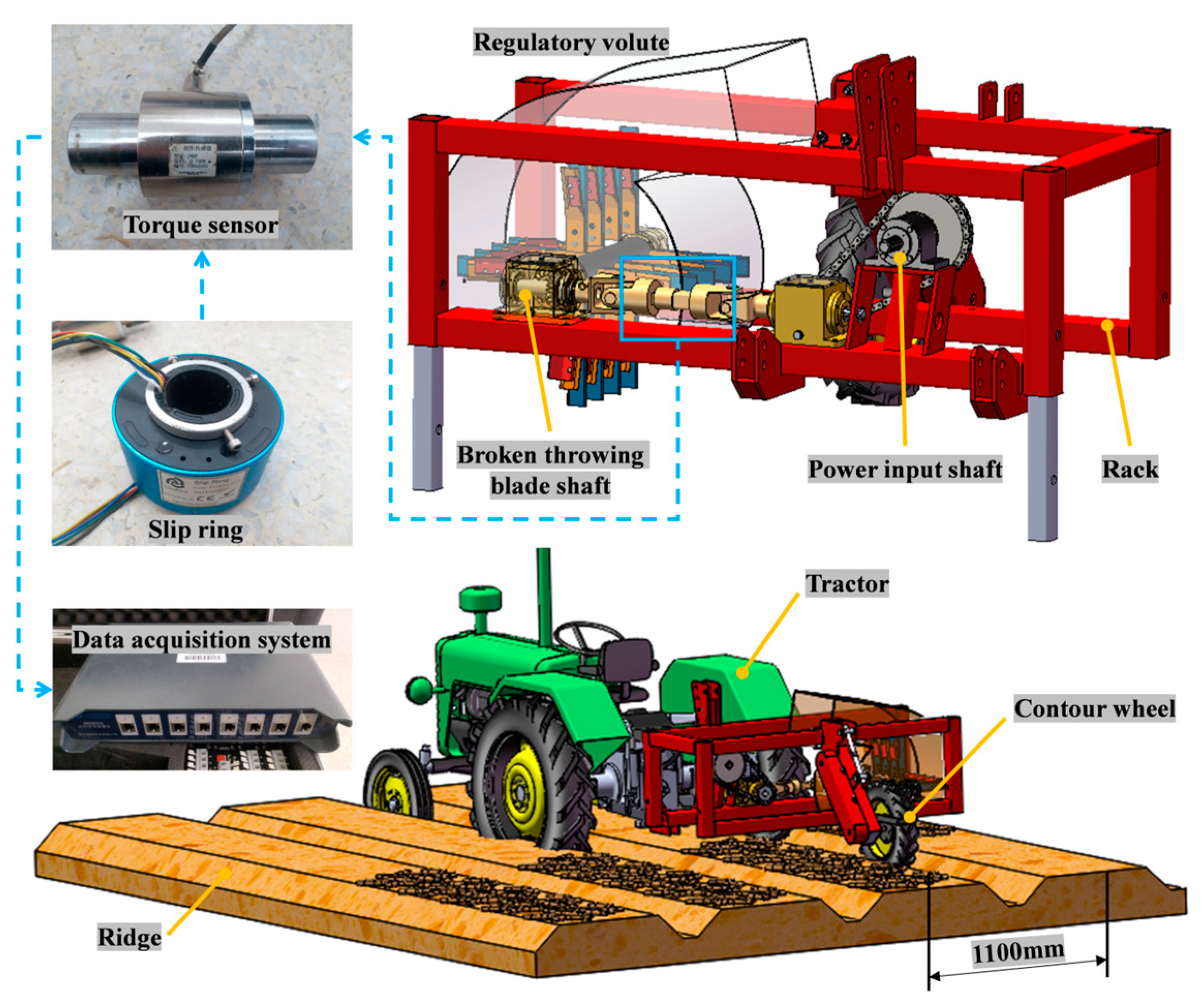

2.1. Structure and Working Principle

2.2. Crushing and Spreading Blade Shaft Design

2.3. Work Process Analysis

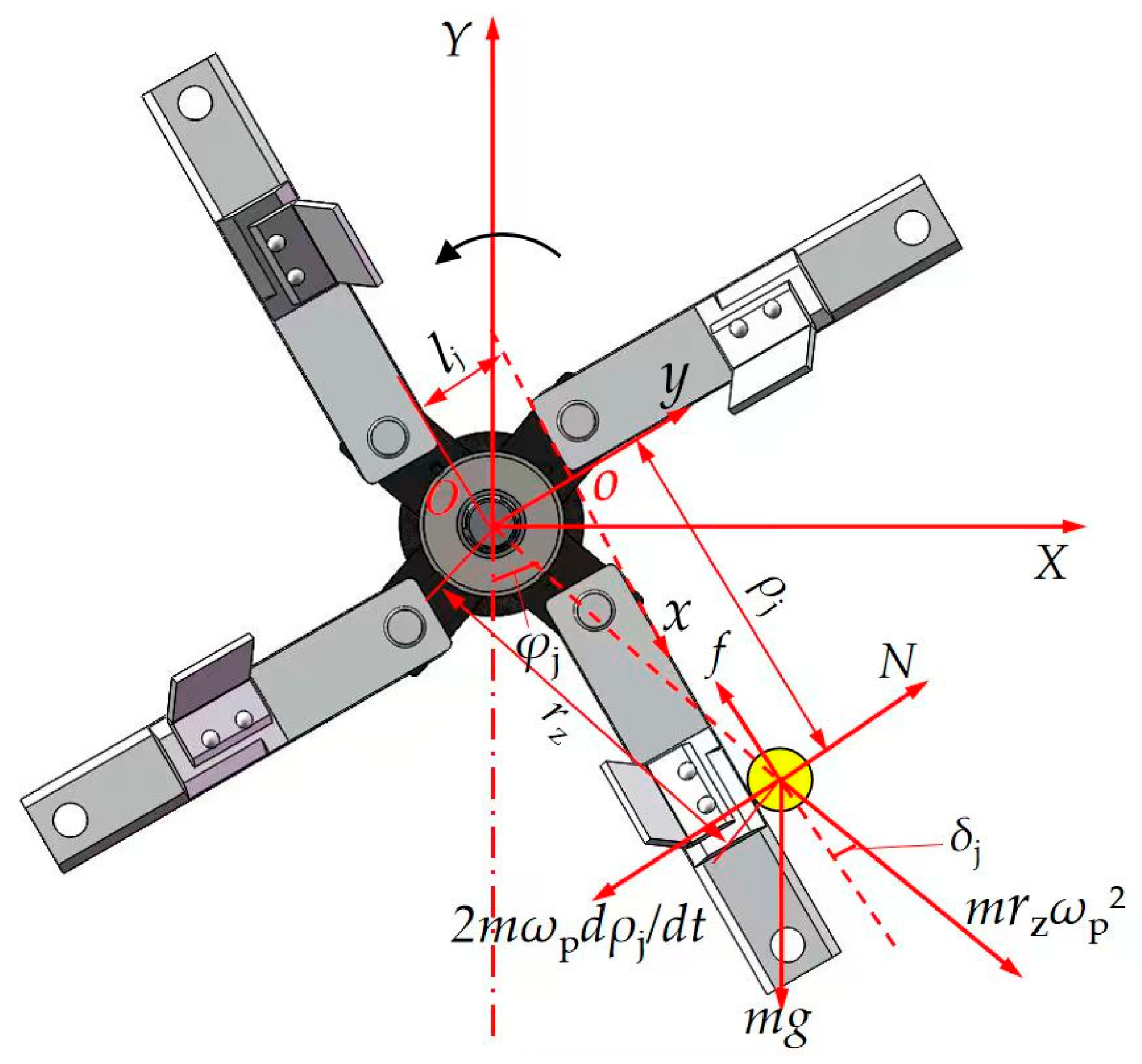

2.3.1. Analysis of the Pick-Up Process

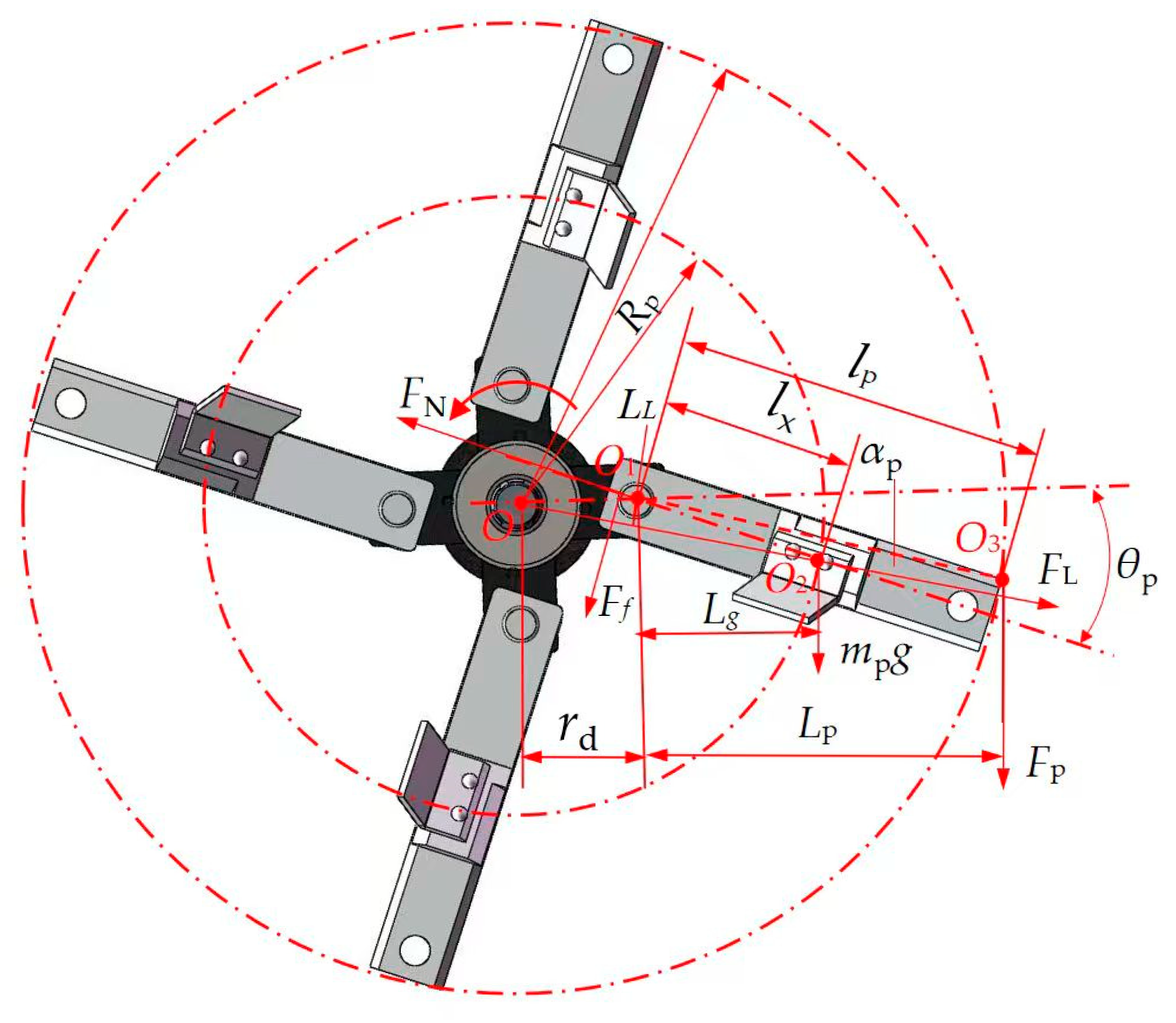

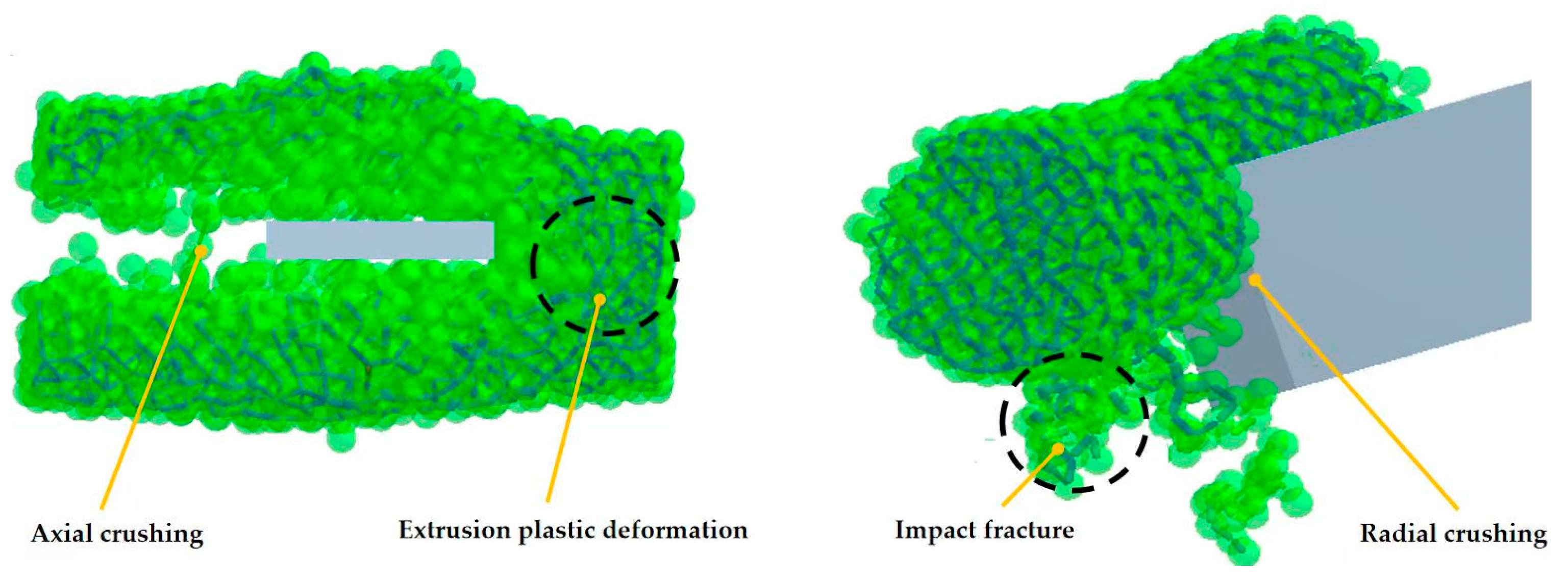

2.3.2. Analysis of the Crushing Process

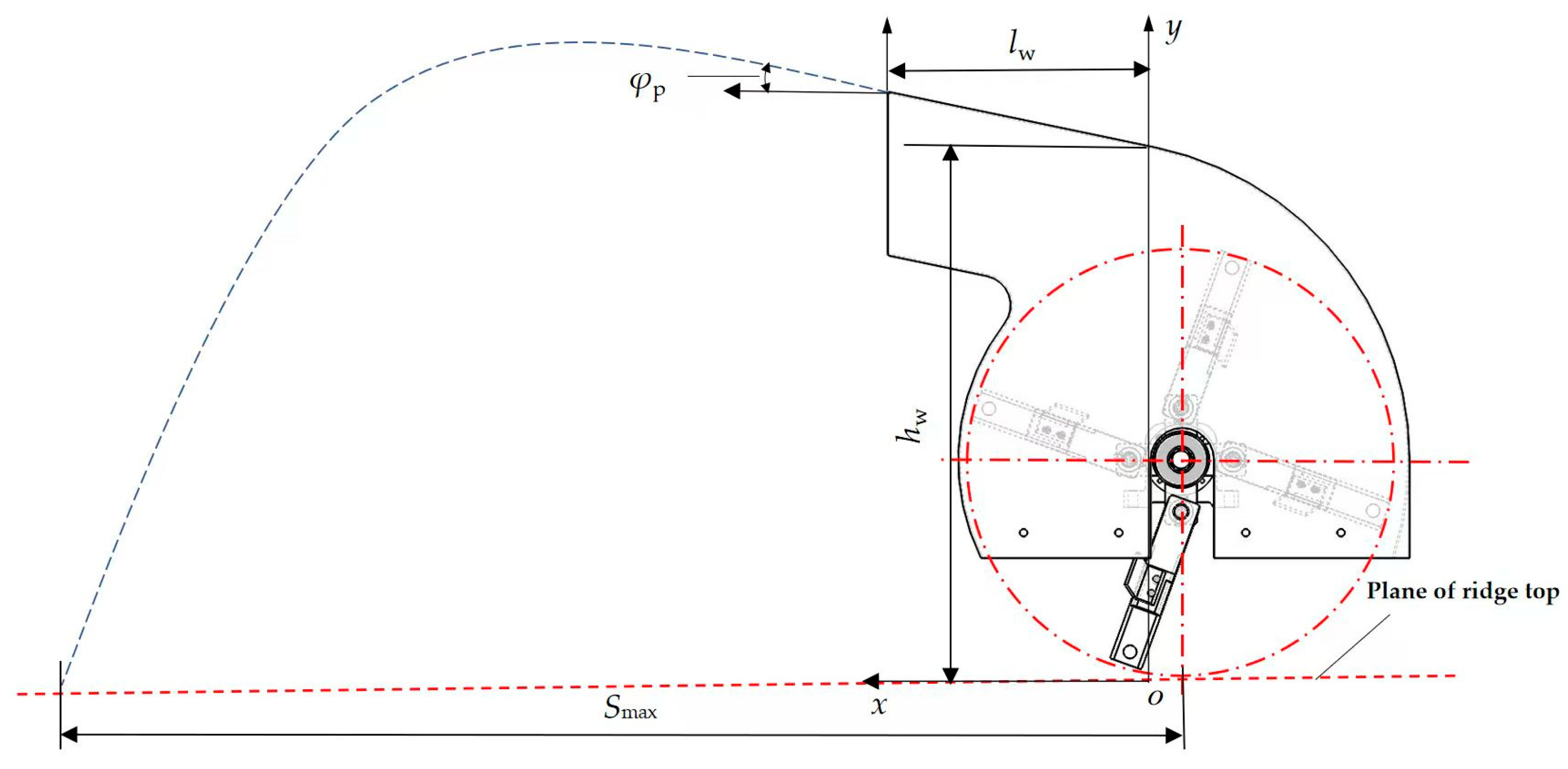

2.3.3. Analysis of the Scattering Process

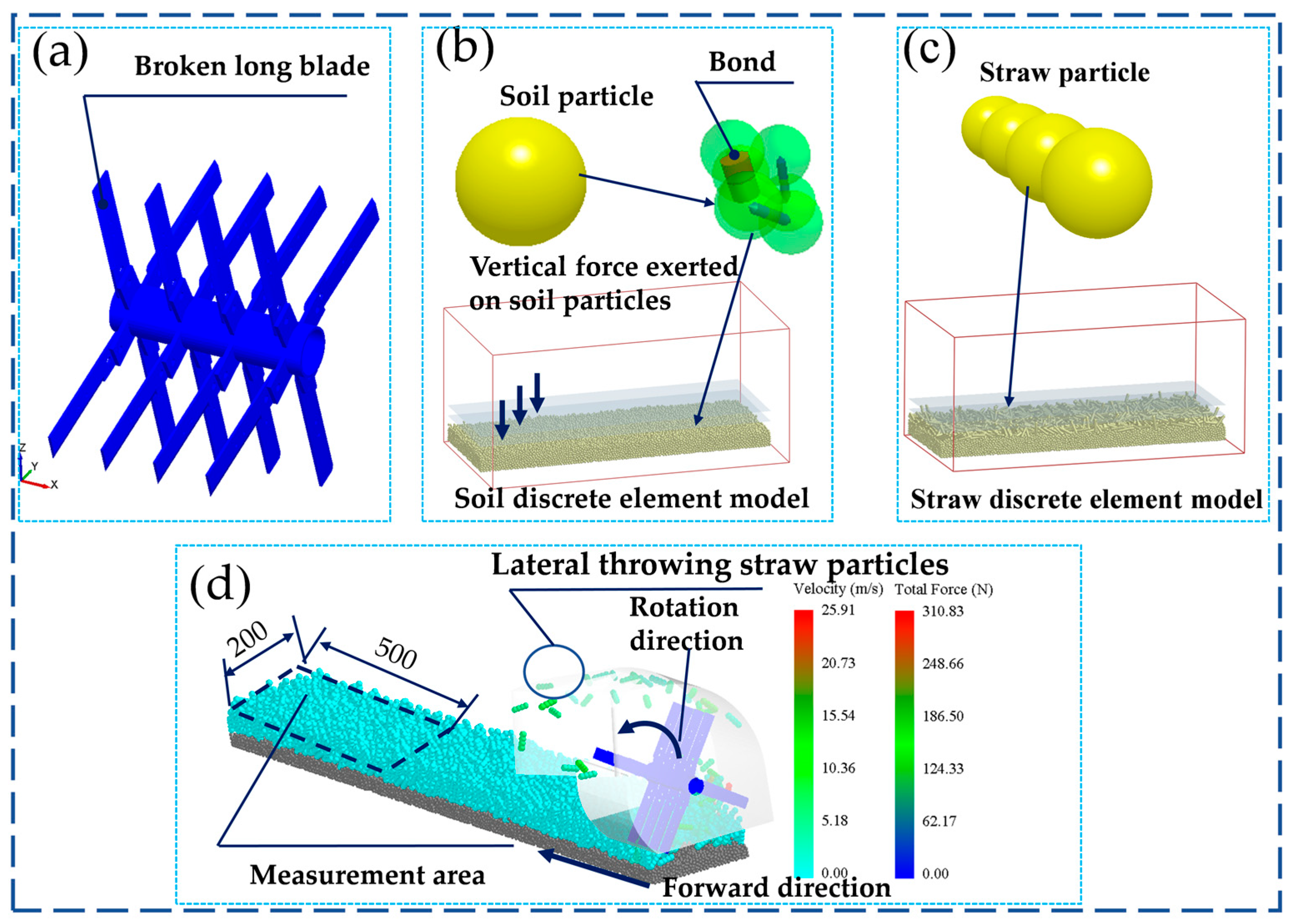

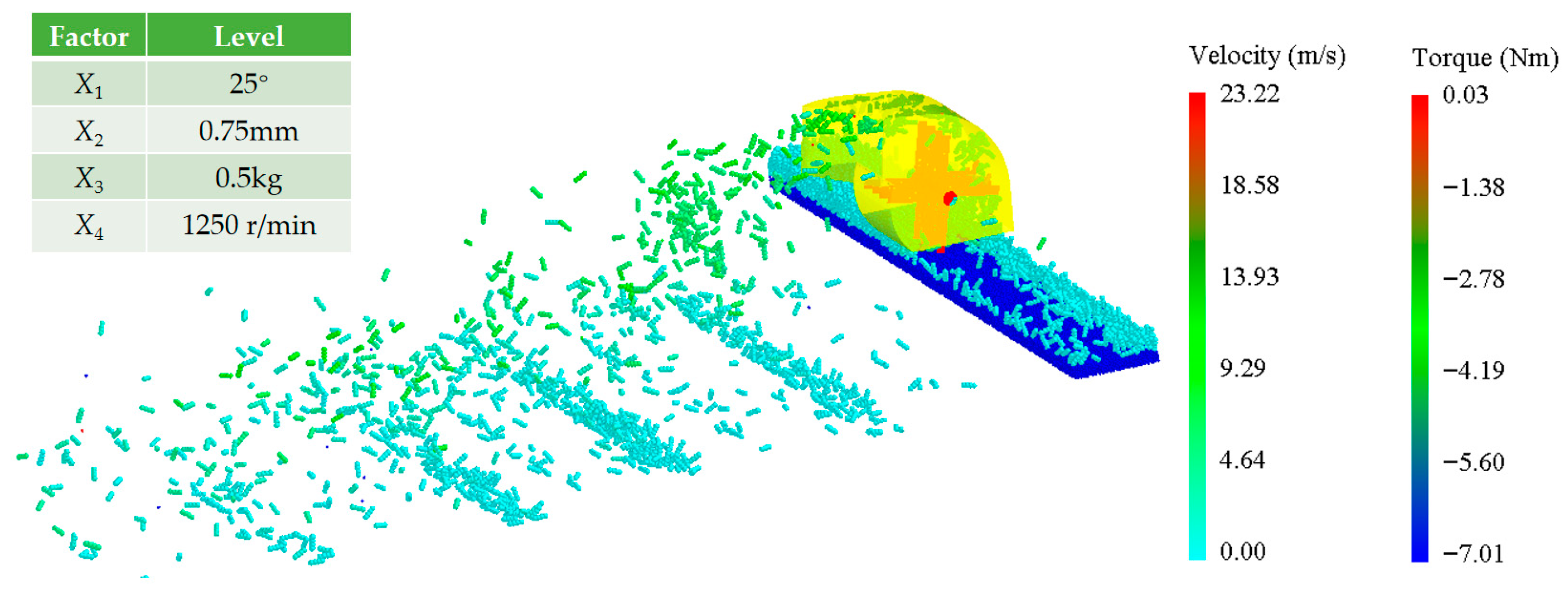

2.4. Optimization of Parameter Combinations Based on EDEM Software

2.4.1. System Modeling

2.4.2. Contact Modeling and Eigenparameters

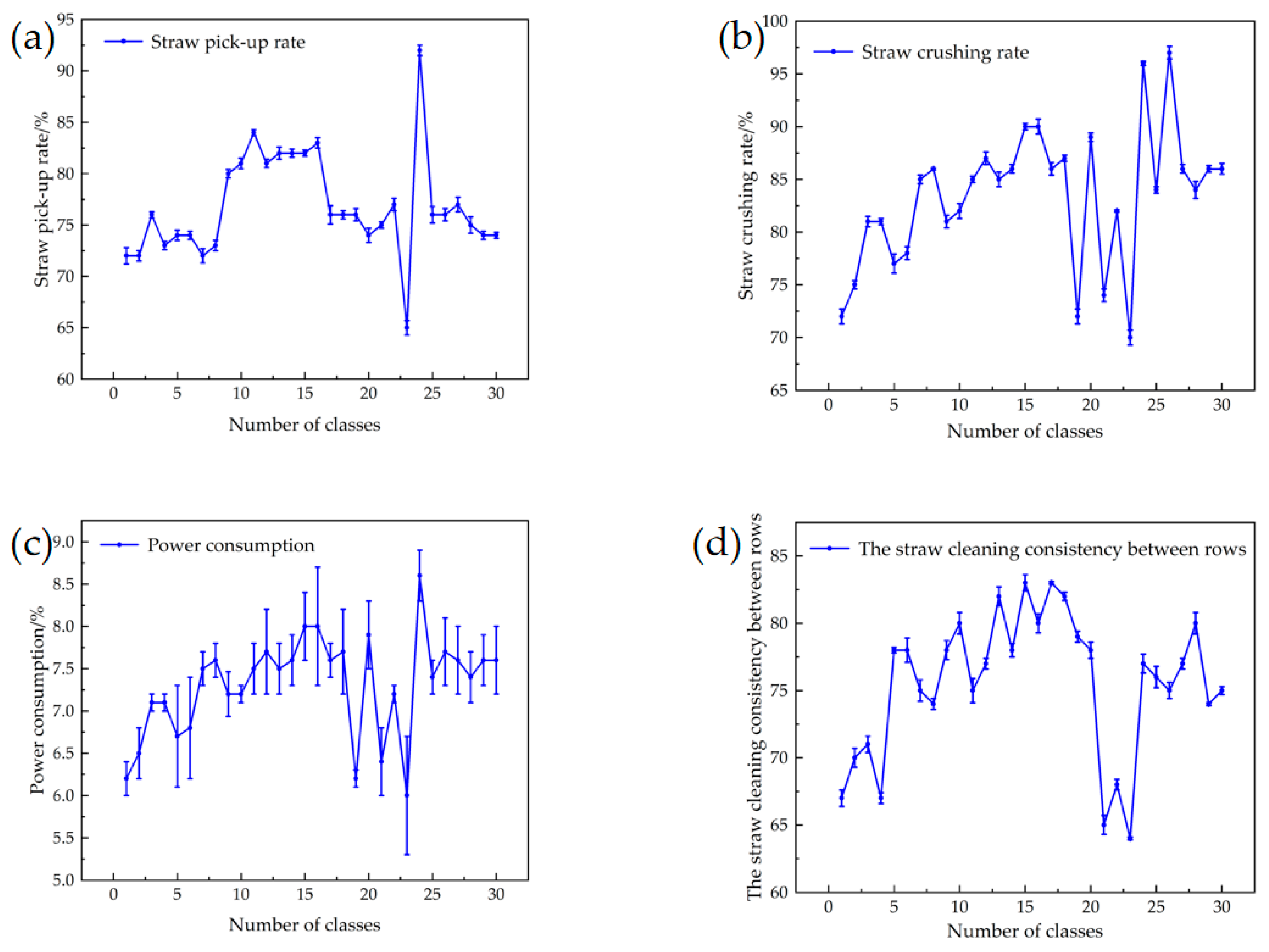

2.4.3. Simulation Test Program

- Crushing long blade edge angle: The blade angle is a critical parameter that influences cutting resistance and straw crushing patterns. A smaller blade angle facilitates penetration but may compromise blade strength, whereas a larger angle significantly increases cutting resistance, adversely affecting crushing efficiency and power consumption. Based on preliminary theoretical analyses and existing blade design experiences, the optimal blade angle range is selected to be between 15° and 35°.

- Crushing long blade edge thickness: The edge thickness has a direct impact on cutting resistance and straw crushing morphology. A thinner edge reduces cutting resistance but is more susceptible to wear, while a thicker edge provides better wear resistance but increases resistance and power consumption.

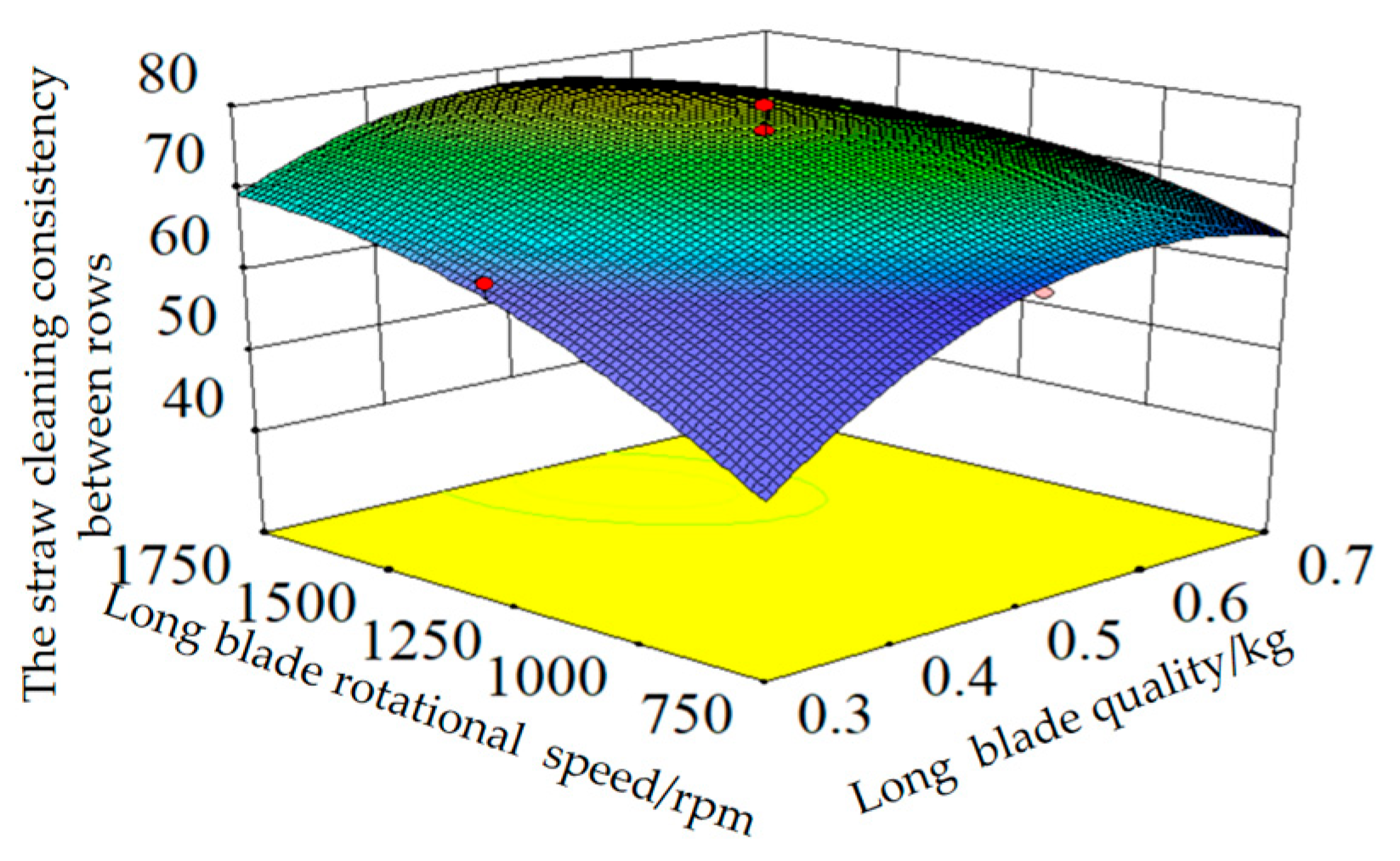

- Crushing long blade weight: The weight of the blade affects its rotational inertia and impact kinetic energy, thereby influencing pick-up capacity, crushing efficiency, and overall machine vibration. Insufficient weight results in inadequate impact force, while excessive weight leads to a significant increase in power consumption. Considering the actual blade material (65Mn) and structural strength requirements, the weight range is established at 0.3 to 0.7 kg.

- Crushing long blade rotational speed: Rotational speed is the primary factor determining straw pick-up, crushing, and scattering performance. A speed that is too low results in incomplete straw processing, while a speed that is too high leads to a dramatic increase in power consumption and vibration. Based on the existing design and material properties of straw crushing blades, the edge thickness is set between 0.25 and 1.25 mm to evaluate its comprehensive impact on crushing quality and energy consumption. Furthermore, based on preliminary linear velocity calculations and the existing rotational speed range of the straw returning machine, the rotational speed is established at 750 to 1750 r/min, corresponding to a blade tip linear velocity of approximately 30 to 48 m/s.

2.4.4. Methods for Determining Performance Indicators

2.5. Field Trials

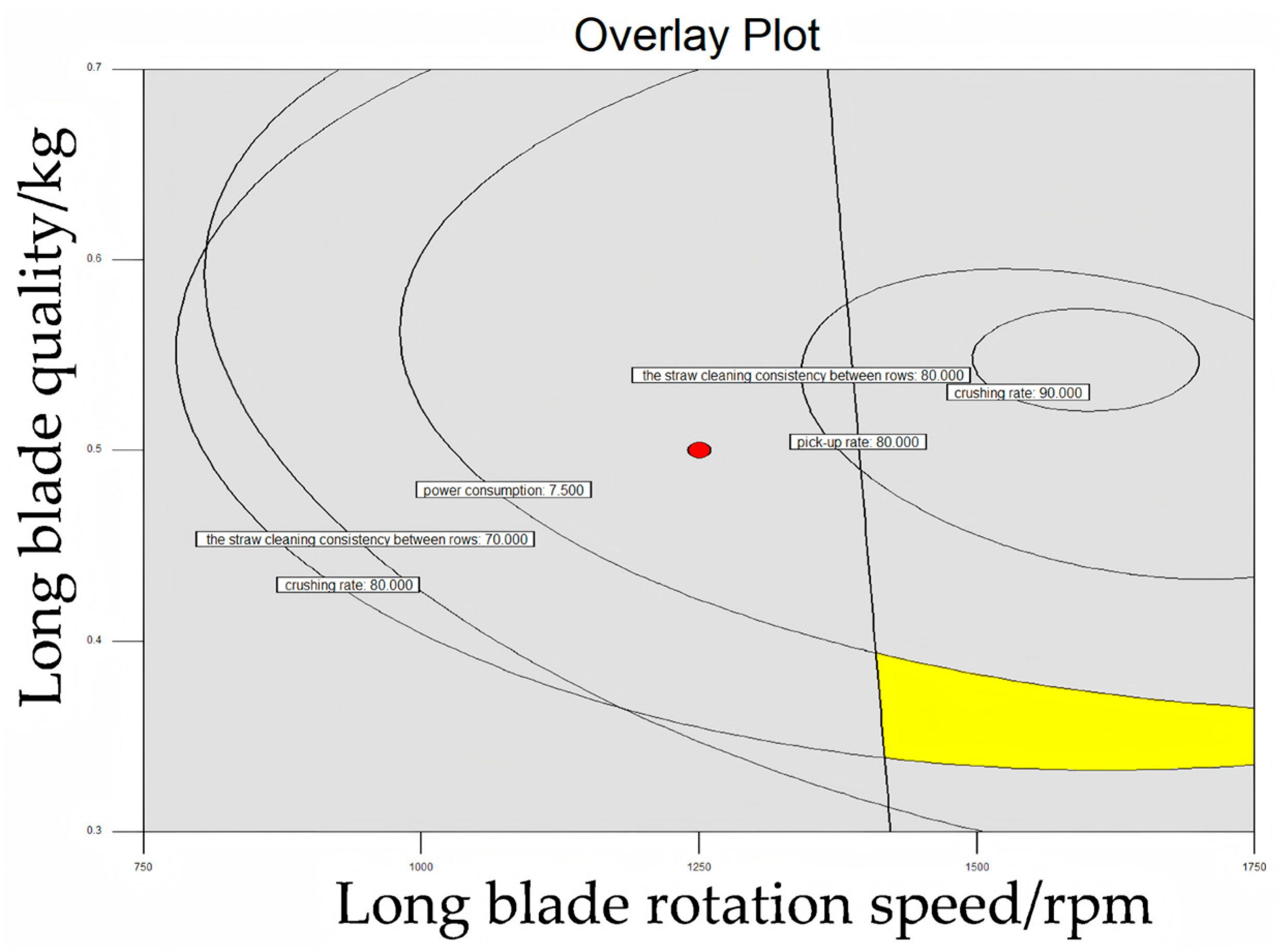

3. Results and Discussion

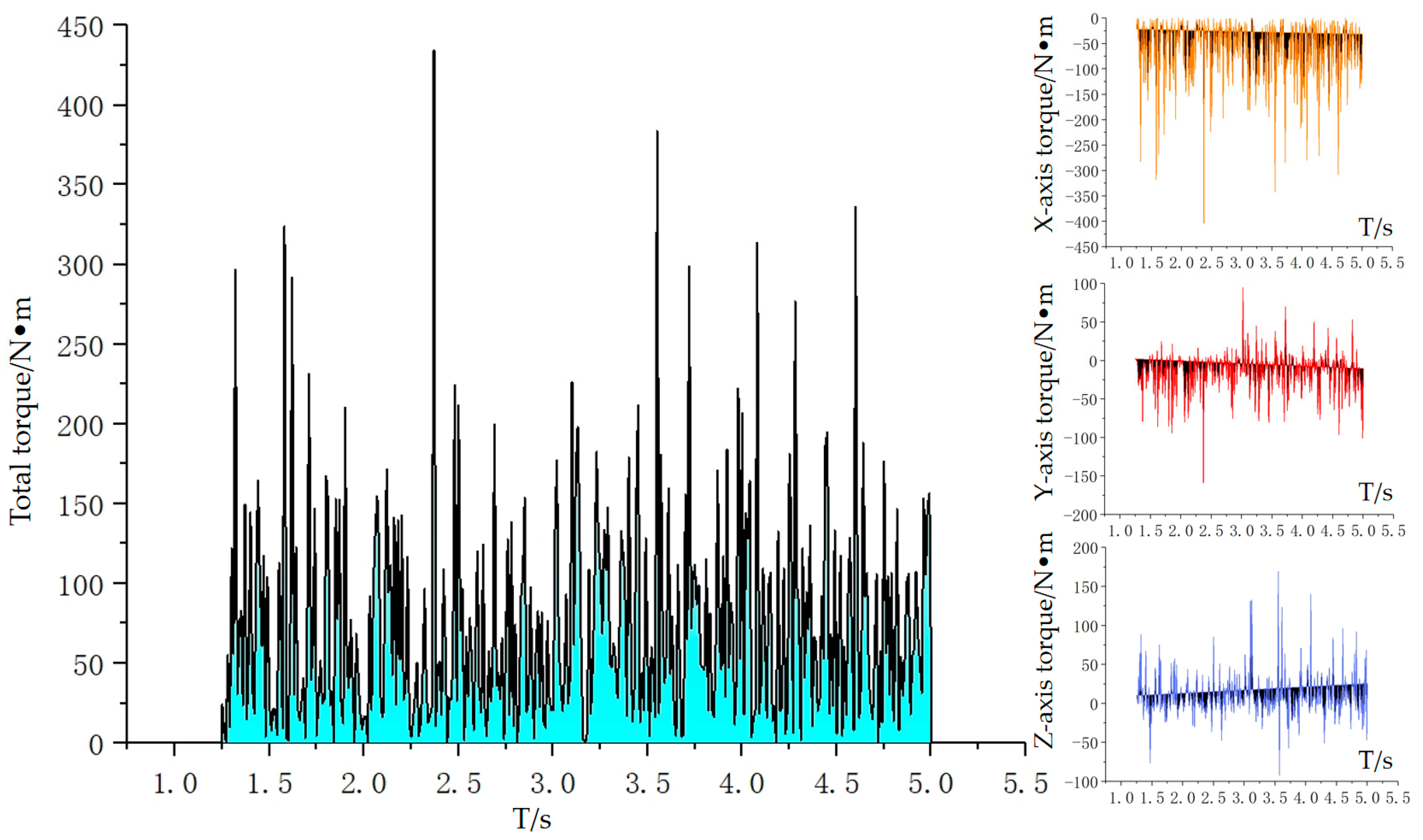

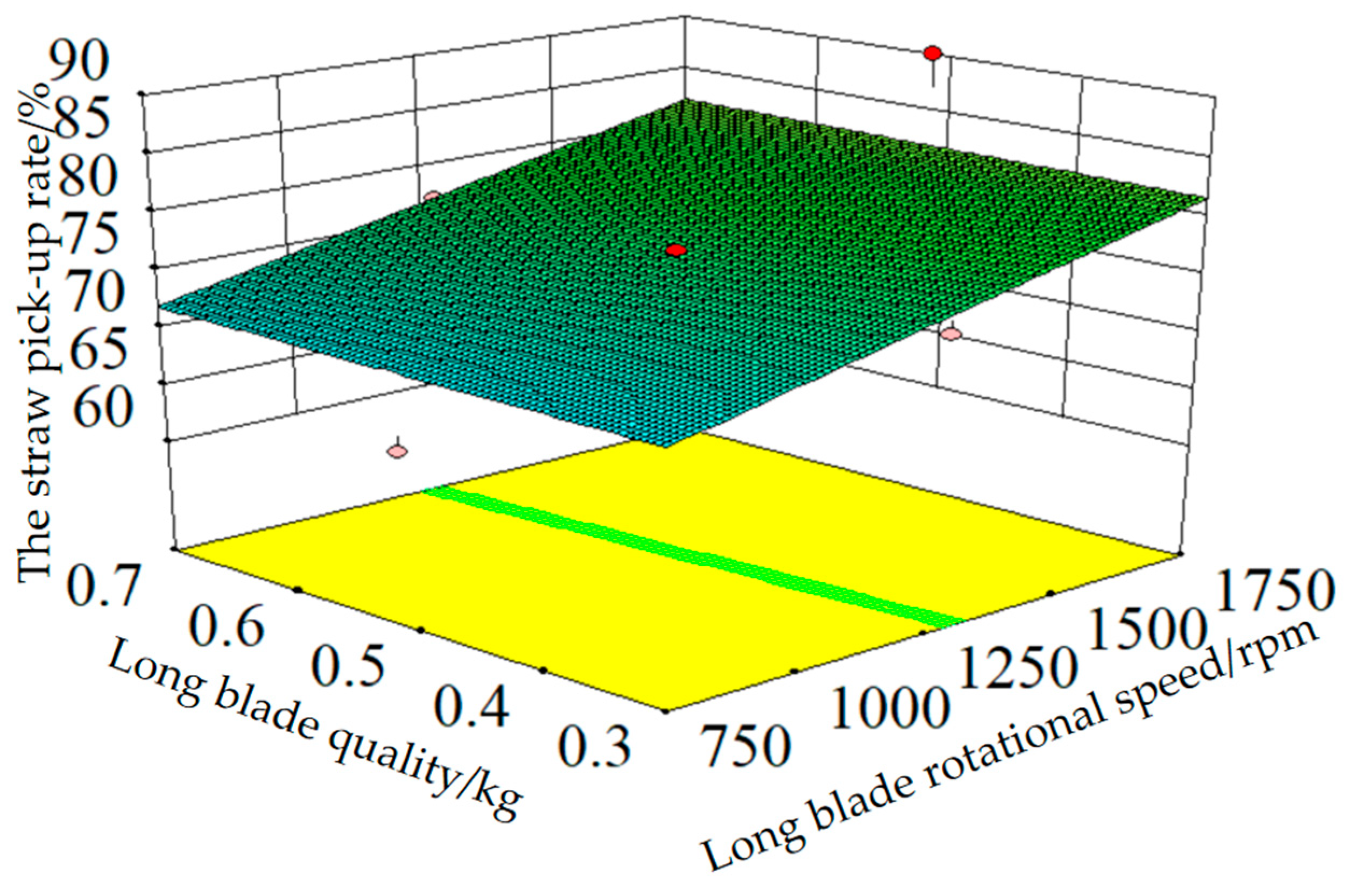

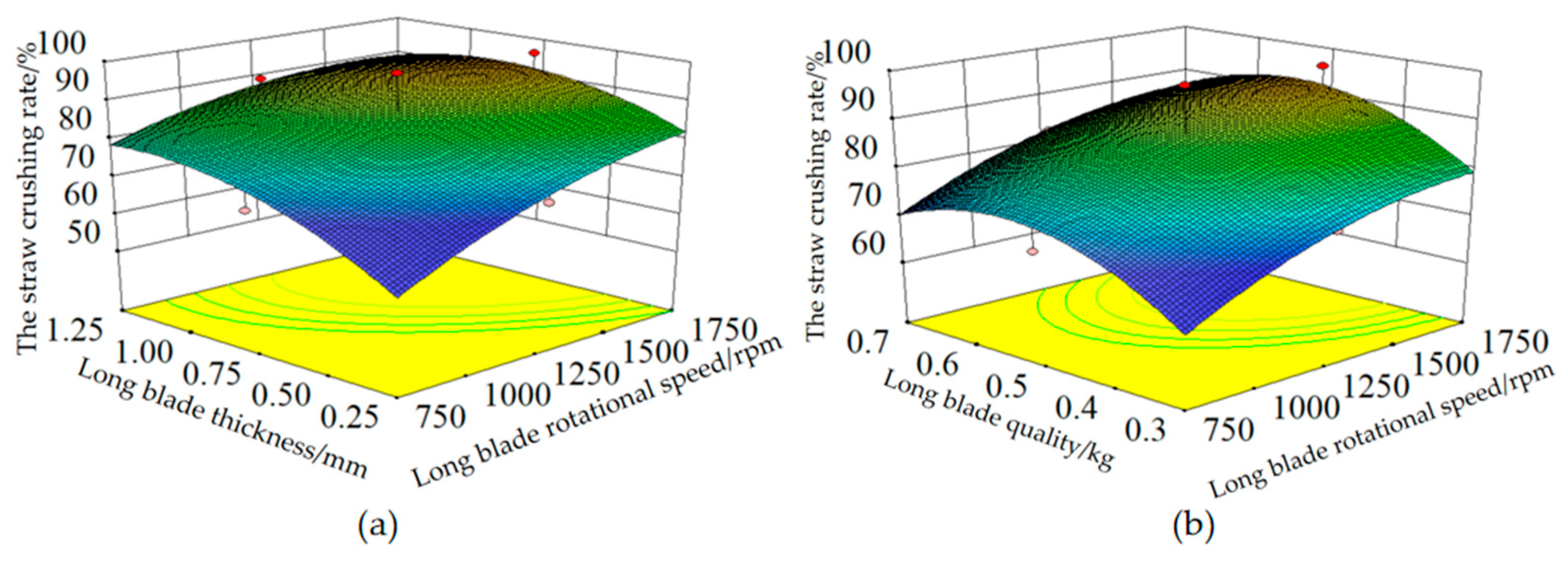

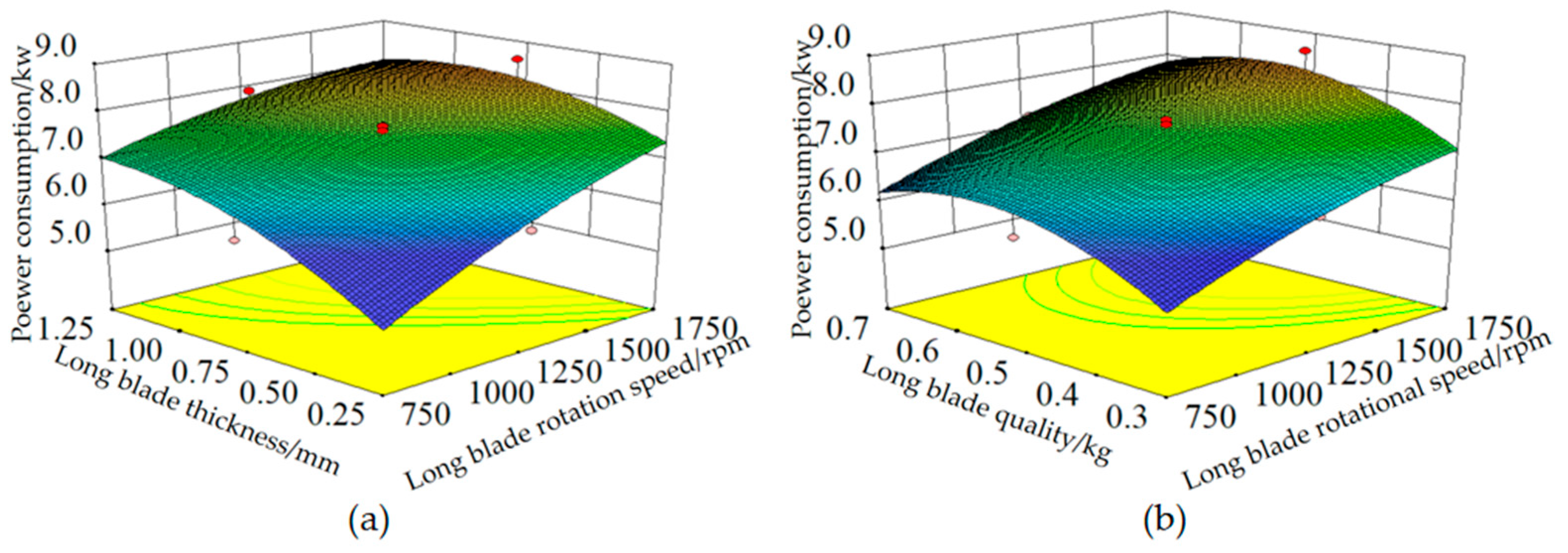

3.1. Characteristic Analysis of Straw Pellet Crushing

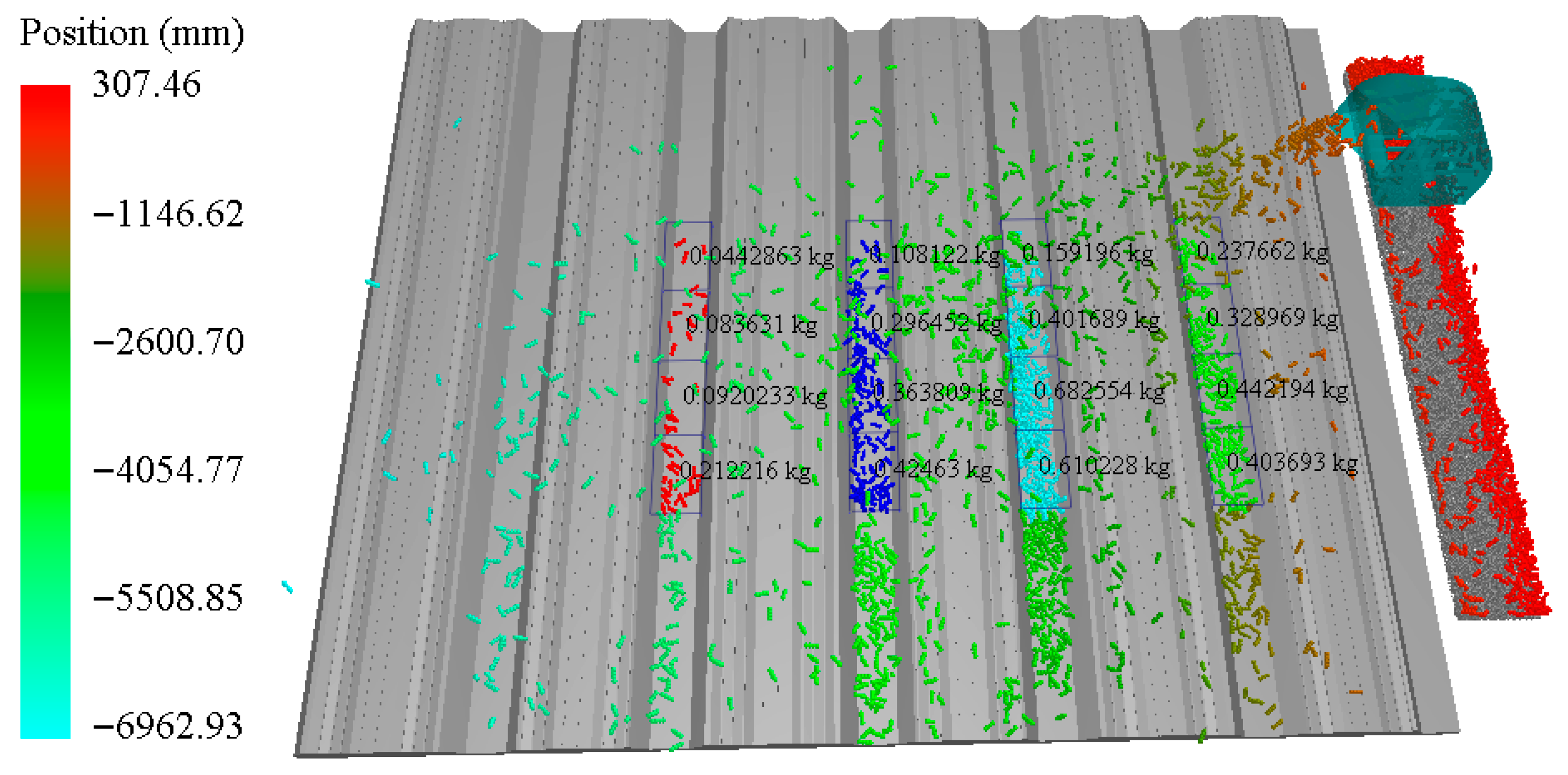

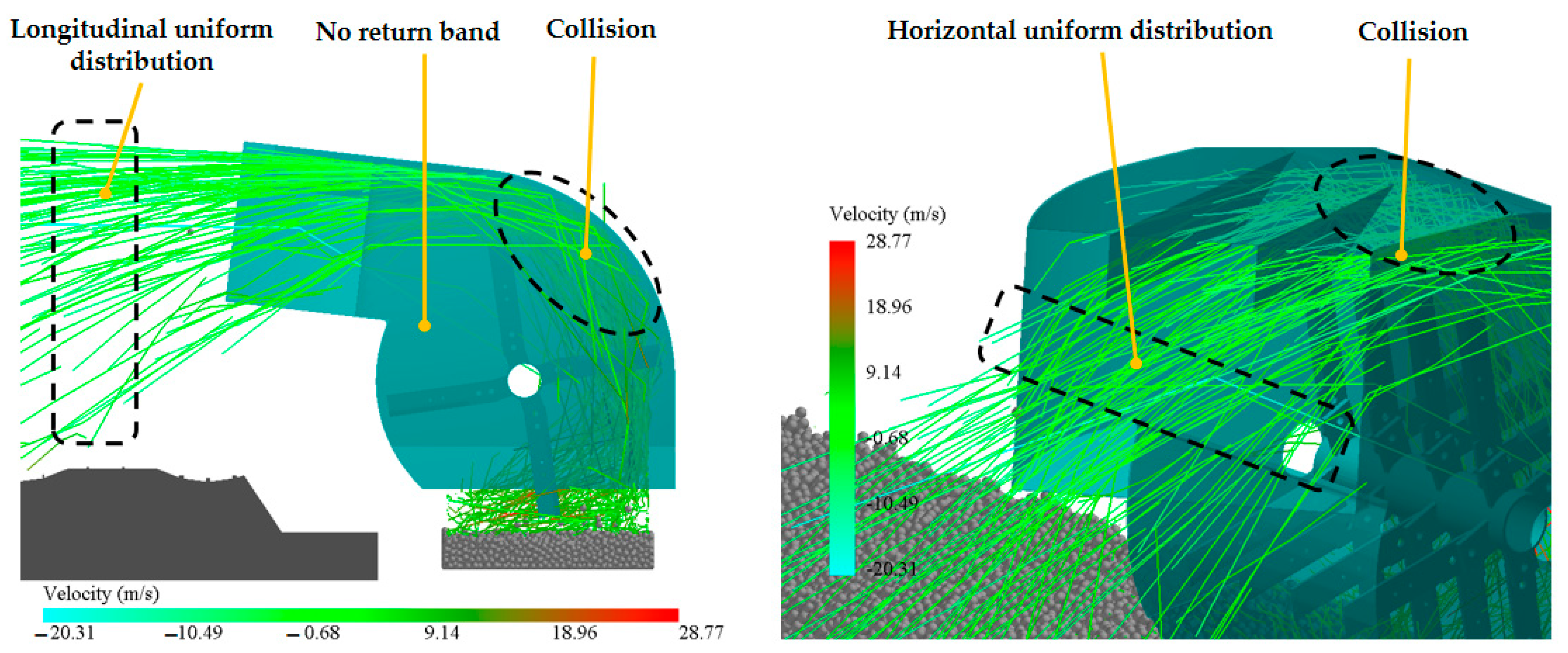

3.2. Characterization of the Motion of the Straw Particle Population

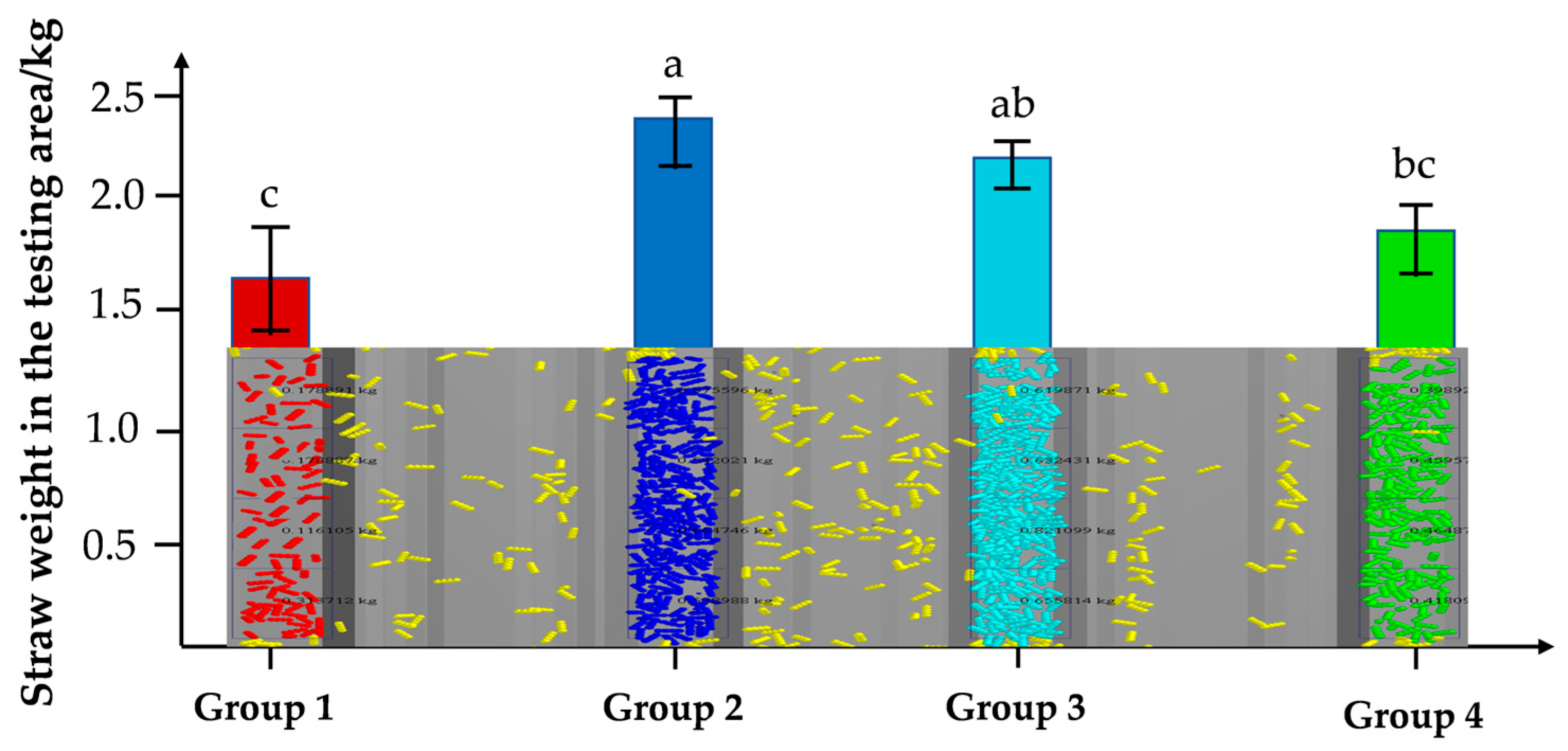

3.3. Field Validation Trial

4. Conclusions

- (1)

- The core working components of the straw crushing and scattering device were designed, with the rotary diameter of the crushing blades established at 700 mm. Through theoretical analysis and mechanical modeling of the straw pick-up, crushing, and scattering processes, key parameters affecting the device’s performance were identified, including blade angle, edge thickness, weight, and rotational speed of the crushing blades.

- (2)

- A straw–soil–machine simulation model was established using the Discrete Element Method (DEM), and virtual simulation experiments, and optimization of key parameters were conducted by employing the Response Surface Methodology (RSM). Performance evaluation indicators, such as straw pick-up rate, crushing rate, power consumption, and inter-row straw coverage consistency, were utilized to derive the optimal parameter combination: a crushing long blade edge angle of 25°, a crushing long blade edge thickness of 1.25 mm, a crushing long blade weight of 0.35–0.41 kg, and a crushing long blade rotational speed of 1400–1750 r/min.

- (3)

- A prototype was manufactured based on the optimization results, followed by field validation tests. The results demonstrate that under the optimal parameter combination, the straw pick-up rate exceeds 87%, the straw crushing rate surpasses 81%, power consumption remains below 7.7 kW, the straw cleaning consistency approaches 80%, and the maximum lateral throwing distance reaches 6300 mm. These outcomes not only satisfy practical operational requirements but also validate the reliability of the simulation optimization results.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kassam, A.; Friedrich, T.; Derpsch, R. Global spread of conservation agriculture. Int. J. Environ. Stud. 2019, 76, 29–51. [Google Scholar] [CrossRef]

- Wang, C.L.; Liu, C.; Lin, D.H.; Liu, Z.J.; Liu, L.J.; Tang, H. Research progress of protective utilization and maintenance technology and machine in northeast black land of China. J. Agric. Mach. 2025, 56, 1–21. [Google Scholar]

- Huang, B.; Gao, J.; Zhang, W.; Gan, C.; Bao, X.; Xu, M.; Wu, L. Impacts of conservation tillage on soil organic carbon and crop yield in black soil region of Northeast China: Integrated regulation by climate, management and soil properties. J. Agric. Food Res. 2025, 24, 102388. [Google Scholar] [CrossRef]

- Li, Y.; Guo, L.; Feng, Y.; Li, C. Long-term conservation tillage enhances soil organic carbon accumulation in rice-wheat rotation systems by improving aggregate stability and reducing carbon flow from macroaggregates to microaggregates. J. Environ. Manag. 2025, 395, 127838. [Google Scholar] [CrossRef]

- Guo, M.; Li, J.; Li, J.; Qi, J.; Zhang, X. Changes of soil structure and function after 16-year conservation tillage in black soil. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2021, 37, 108–118. [Google Scholar]

- Hou, S.; Wang, X.; Ji, Z.; Chen, H.; Zhou, C. Experiments on the Influence of Corn Straw Morphological Combinations on Timely No-Tillage Sowing Soil Temperature and Moisture in Cold Regions. Agriculture 2022, 12, 1425. [Google Scholar] [CrossRef]

- Zhu, Y.; LI, J.; Zhang, C.; Zhang, X. Effects of long-term conservation tillage on black soil organic carbon components in sloping farmland. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2023, 39, 103–111. [Google Scholar]

- Wang, K.; Fu, Q.; Zhang, Z.; Jiang, X.; Hao, Z. Effects of straw mulching mode and tillage methods on soil environment of root zone in northeast black soil. Trans. Chin. Soc. Agric. Mach. 2016, 47, 131–137. [Google Scholar]

- Domokos, Z.; Șimon, A.; Chețan, F.; Ceclan, O.A.; Filip, E.; Călugăr, R.E.; Vâtcă, S.D.; Duda, M.M. The influence of sowing date on the primary yield components of maize. Agronomy 2024, 14, 2120. [Google Scholar] [CrossRef]

- Dutta, R.; Panda, D.J. Influence of dates of sowing and planting geometry on yield, nutrient uptake and economics of baby corn. Int. J. Environ. Clim. Change 2022, 12, 25–33. [Google Scholar] [CrossRef]

- Shi, J.; Wang, S.; Li, S.; Tian, X. Increasing soil organic carbon sequestration and yield stability by no-tillage and straw-returning in wheat–maize rotation. Agron. J. 2022, 114, 1534–1545. [Google Scholar] [CrossRef]

- Sun, J.; Yang, L.; Zhang, D.; Hu, J.; Cui, T.; He, X.; Zhao, H. Development of a prediction model to determine optimal sowing depth to improve maize seedling performance. Biosyst. Eng. 2023, 234, 206–222. [Google Scholar] [CrossRef]

- Kang, Y.; Liao, Q.; Lin, J.; Han, J.; Wan, X.; Zhang, Q. Development of the rapeseed direct seeding machine with stubble covering based on combined harvesting machine platform. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2024, 40, 15–25. [Google Scholar]

- Zhang, X.R.; Ni, S.L.; Liu, J.X.; Hu, X.H.; Zhang, Z.F.; Fu, S.H. Design and test of bionic blade for banana straw crushing and throwing returning machine. J. Agric. Mach. 2024, 55, 128–140. [Google Scholar]

- Qin, K.; Cao, C.; Liao, Y.; Wang, C.; Fang, L.; Ge, J. Design and optimization of crushing and throwing device for straw returning to field and fertilizing hill-seeding machine. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2020, 36, 1–10. [Google Scholar]

- Wang, Q.; Liu, Z.; He, J.; Li, H.; Li, W.; He, J.; Yan, X. Design and experiment of chopping-type maize straw returning machine. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2018, 34, 10–17. [Google Scholar]

- Liu, P.; He, J.; Li, Y.; Li, H.; Wang, Q.; Lu, C.; Zhang, Z.; Li, S. Design and experiment of double rollers maize stalk chopping device with different rotation speeds. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2020, 36, 69–79. [Google Scholar]

- Jia, H.; Jiang, X.; Yuan, H.; Zhuang, J.; Zhao, J.; Guo, M. Stalk cutting mechanism of no-tillage planter for wide/narrow row farming mode. Int. J. Agric. Biol. Eng. 2017, 10, 26–35. [Google Scholar]

- Zheng, Z.; He, J.; Li, H.; Diao, P.; Wang, Q.; Zhang, X. Design and experiment of straw-chopping device with chopping and fixed knife supported slide cutting. Trans. Chin. Soc. Agric. Mach. 2016, 47, 108–116. [Google Scholar]

- Liu, P.; He, J.; Zhang, Z.Q.; Lu, C.Y.; Zhang, Z.G.; Lin, H. Kinematic characteristic analysis and field test of chopped stalk in straw retention machine based on cfd-dem coupling simulation method. Trans. Chin. Soc. Agric. Mach. 2020, 51, 244–253. [Google Scholar]

- Chen, H.; Zou, Z.; Wang, X.; Shi, N.; Han, G.; Hou, S. Design and experiment of straw proportional recovery device for clearing and covering straw of no-tillage planter. Trans. Chin. Soc. Agric. Mach. 2022, 53, 120–129. [Google Scholar]

- Galili, N.; Shteingauz, G. Wide-swath vertical spreader for granular material. Trans. ASAE 1982, 25, 1195–1203. [Google Scholar] [CrossRef]

- Cool, S.; Pieters, J.; Mertens, K.C.; Hijazi, B.; Vangeyte, J. A simulation of the influence of spinning on the ballistic flight of spherical fertiliser grains. Comput. Electron. Agric. 2014, 105, 121–131. [Google Scholar] [CrossRef]

- Olieslagers, R.; Ramon, H.; De Baerdemaeker, J. Calculation of fertilizer distribution patterns from a spinning disc spreader by means of a simulation model. J. Agric. Eng. Res. 1996, 63, 137–152. [Google Scholar] [CrossRef]

- Yi, W.; Zhou, Q.; Lu, Z.Y.; Ma, Z.J.; Zhou, H.X. Research on the influence of fluid resistance and ejection height on the motion law of projectiles. Chin. Phys. Bull. 2024, 39, 27–30, 34. (In Chinese) [Google Scholar]

- Zhang, X.M.; Chen, G.H. Analysis methods of projection velocity and flight trajectory of explosion fragments. Huanan Ligong Daxue Xuebao J. South China Univ. Technol. (Nat. Sci.) 2009, 37, 106–110. [Google Scholar]

- Bi, J.S.; Lu, C.Y.; Li, H.W.; Zhai, C.K. Design and experiment of anti-blocking device passive sawtooth disc based on optimal dynamic sliding cutting. Trans. Chin. Soc. Agric. Mach. 2025, 56, 118–128. (In Chinese) [Google Scholar]

- Zhao, S.; Gao, L.; Yuan, Y.; Hou, L.; Zhang, X.; Yang, Y. Maize straw motion law in subsoiling operation using discrete element method. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2021, 37, 53–62. [Google Scholar]

- Mudarisov, S.; Gabitov, I.; Lobachevsky, Y.; Farkhutdinov, I.; Kravchenko, L. Systematic Evaluation and Experimental Validation of Discrete Element Method Contact Models for Soil Tillage Simulation. AgriEngineering 2025, 7, 256. [Google Scholar] [CrossRef]

- Yuan, Q.; Xu, L.; Ma, S.; Niu, C.; Wang, S.; Yuan, X. Design and test of sawtooth fertilizer block crushing blade of organic fertilizer deep applicator. Trans. Chin. Soc. Agric. Eng. 2020, 36, 44–51. [Google Scholar]

- Wang, D.; Wang, M.; Li, L. Mechanism analysis and parameter optimization of hammer mill for corn stalk. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2017, 48, 165–171. [Google Scholar] [CrossRef]

- Liao, Y.; Wang, Z.; Liao, Q.; Liang, F.; Liu, J. Calibration of discrete element parameters of fodder rape crop stem at flowering stage. In Proceedings of the 2020 ASABE Annual International Virtual Meeting, St. Joseph, MI, USA, 13–15 July 2020; p. 1. [Google Scholar]

- Chen, Z.; Liu, Z.; Guan, W.; Guo, J.; Xue, D. Maize grain modelling for the dem simulation of sowing process. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2024, 40, 14–22. [Google Scholar]

- NY/T 1004-2006; Technical Specification for Quality Evaluation of Straw Returning Machine. Ministry of Agriculture of China: Beijing, China, 2006.

- JB/T 6678-2001; Straw Crushing and Returning Machine. Ministry of Industry and Information Technology of China: Beijing, China, 2001.

- GB/T 14290-1993; Test Methods for Round Balers. Hohhot Animal Husbandry Machinery Research Institute, Ministry of Machinery and Electronics Industry: Beijing, China, 1993.

- Chen, G.; Lu, C.; He, J.; Wang, C.; Wang, X.; Wang, Q. Design and experiment of straw pickup-crushed and deep buried device under strip-tillage. Trans. Chin. Soc. Agric. Mach. 2021, 52, 16–27. [Google Scholar]

- Yuan, X.M.; Li, X.H.; Jiao, H.T.; Zhou, S.L.; Zhang, J.J.; Wu, H.Y. Design and experiment of straw chopping centralized full depthand returning machine. Trans. Chin. Soc. Agric. Mach. 2023, 54, 27–35. (In Chinese) [Google Scholar]

- Matin, M.A.; Desbiolles, J.M.A.; Fielke, J.M. Strip-tillage using rotating straight blades: Effect of cutting edge geometry on furrow parameters. Soil Tillage Res. 2016, 155, 271–279. [Google Scholar] [CrossRef]

- Zhang, C.; Xia, J.; Zhang, J.; Zhou, H.; Zhu, Y.; Wang, J. Design and experiment of knife roller for six-head spiral straw returning cultivator. Trans. Chin. Soc. Agric. Mach. 2019, 50, 25–34. [Google Scholar]

| Platform/Mechanism | Key Contribution | Adaptability Issues in Cold Regions | Implications for This Study. |

|---|---|---|---|

| Combine harvester platform with side-throwing shredding device | Enhance comprehensive utilization rate and operational continuity | Multi-functional deep integration with high requirements for manufacturing and maintenance | Reduce complexity with integrated transformation of the seeding process |

| Bionic serrated knife (Blue Shark Tooth Profile). | Improve Breakage Rate and Spreading Uniformity | Wear resistance lifespan and stability under harsh operating conditions remain to be verified | Balance efficiency with tool material and parameter optimization |

| Straw returning fertilizer seeder with crushing and spreading device | Balance straw incorporation with machinery passability. | Large amounts of straw thrown backward can easily increase the risk of clogging | Controllable and directional blockage-reducing dispersal |

| Chopping-type straw returning machine. | A New Approach for High Surface Straw Coverage. | Principles constrain efficiency, and operational efficiency needs improvement | Increase working width and operational efficiency |

| Allometric roller pair and dynamic dual support | Increase the qualified crushing rate. | Single-stage cutting requires high rotational speed and consumes more power | Reduce dependence on high rotation speed and lower energy consumption |

| Wide-narrow row no-till seeding cutting blade | Optimize from the aspect of tool curve. | Limited promotion for specialized agricultural techniques | Form a more adaptable parameter domain and operating conditions for cold regions |

| Item | 65Mn | Q235A | Straw | Soil |

|---|---|---|---|---|

| Density/(kg/m3) | 7800 | 7850 | 241 | 2650 |

| Shear Modulus/Pa | 7.96 × 1010 | 7.9 × 1010 | 1.0 × 106 | 1.0 × 106 |

| Poisson’s Ratio | 0.3 | 0.3 | 0.4 | 0.34 |

| Dynamic Friction Coefficient (with Straw) | 0.01 | 0.01 | 0.01 | 0.05 |

| Static Friction Coefficient (with Straw) | 0.3 | 0.3 | 0.3 | 0.5 |

| Coefficient of Restitution (with Straw) | 0.3 | 0.3 | 0.3 | 0.5 |

| Factors | ||||

|---|---|---|---|---|

| Encodings | Crushing Long Blade Edge Angle X1/(°) | Crushing Long Blade Edge Thickness X2/mm | Crushing Long Blade Weight X3/kg | Crushing Long Blade Rotational Speed X4/(r·min−1) |

| 2 | 35 | 1.25 | 0.7 | 1750 |

| 1 | 30 | 1.00 | 0.6 | 1500 |

| 0 | 25 | 0.75 | 0.5 | 1250 |

| −1 | 20 | 0.50 | 0.4 | 1000 |

| −2 | 15 | 0.25 | 0.3 | 750 |

| Serial Number | Experimental Factors | Evaluation Indicators | ||||||

|---|---|---|---|---|---|---|---|---|

| X1 | X2 | X3 | X3 | Straw Pick-Up Rate Y1/% | Straw Crushing Rate Y2/% | Power Consumption Y3/kW | The Straw Cleaning Consistency Between Rows Y4 | |

| 1 | 20 | 0.50 | 0.4 | 1000 | 72 | 72 | 6.2 | 67 |

| 2 | 30 | 0.50 | 0.4 | 1000 | 72 | 75 | 6.5 | 70 |

| 3 | 20 | 1.00 | 0.4 | 1000 | 76 | 81 | 7.1 | 71 |

| 4 | 30 | 1.00 | 0.4 | 1000 | 73 | 81 | 7.1 | 67 |

| 5 | 20 | 0.50 | 0.6 | 1000 | 74 | 77 | 6.7 | 78 |

| 6 | 30 | 0.50 | 0.6 | 1000 | 74 | 78 | 6.8 | 78 |

| 7 | 20 | 1.00 | 0.6 | 1000 | 72 | 85 | 7.5 | 75 |

| 8 | 30 | 1.00 | 0.6 | 1000 | 73 | 86 | 7.6 | 74 |

| 9 | 20 | 0.50 | 0.4 | 1500 | 80 | 81 | 7.1 | 78 |

| 10 | 30 | 0.50 | 0.4 | 1500 | 81 | 82 | 7.2 | 80 |

| 11 | 20 | 1.00 | 0.4 | 1500 | 84 | 85 | 7.5 | 75 |

| 12 | 30 | 1.00 | 0.4 | 1500 | 81 | 87 | 7.7 | 77 |

| 13 | 20 | 0.50 | 0.6 | 1500 | 82 | 85 | 7.5 | 82 |

| 14 | 30 | 0.50 | 0.6 | 1500 | 82 | 86 | 7.6 | 78 |

| 15 | 20 | 1.00 | 0.6 | 1500 | 82 | 90 | 8 | 83 |

| 16 | 30 | 1.00 | 0.6 | 1500 | 83 | 90 | 8 | 80 |

| 17 | 15 | 0.75 | 0.5 | 1250 | 76 | 86 | 7.6 | 83 |

| 18 | 35 | 0.75 | 0.5 | 1250 | 76 | 87 | 7.7 | 82 |

| 19 | 25 | 0.25 | 0.5 | 1250 | 76 | 72 | 6.2 | 79 |

| 20 | 25 | 1.25 | 0.5 | 1250 | 74 | 89 | 7.9 | 78 |

| 21 | 25 | 0.75 | 0.3 | 1250 | 75 | 74 | 6.4 | 65 |

| 22 | 25 | 0.75 | 0.7 | 1250 | 77 | 82 | 7.2 | 68 |

| 23 | 25 | 0.75 | 0.5 | 750 | 65 | 70 | 6 | 64 |

| 24 | 25 | 0.75 | 0.5 | 1750 | 92 | 96 | 8.6 | 77 |

| 25 | 25 | 0.75 | 0.5 | 1250 | 76 | 84 | 7.4 | 76 |

| 26 | 25 | 0.75 | 0.5 | 1250 | 76 | 97 | 7.7 | 75 |

| 27 | 25 | 0.75 | 0.5 | 1250 | 77 | 86 | 7.6 | 77 |

| 28 | 25 | 0.75 | 0.5 | 1250 | 75 | 84 | 7.4 | 80 |

| 29 | 25 | 0.75 | 0.5 | 1250 | 74 | 86 | 7.6 | 74 |

| 30 | 25 | 0.75 | 0.5 | 1250 | 74 | 86 | 7.6 | 75 |

| Evaluation Indicators | Source of Variation | Square Sum | Degrees of Freedom | Mean Square | F | p | Significance |

|---|---|---|---|---|---|---|---|

| Straw pick-up rate | model | 633.17 | 4 | 158.29 | 38.94 | <0.0001 | ** |

| X1 | 0.38 | 1 | 0.38 | 0.092 | 0.7639 | ||

| X2 | 0.37 | 1 | 0.37 | 0.092 | 0.7639 | ||

| X3 | 2.04 | 1 | 2.04 | 0.5 | 0.4851 | ||

| X4 | 630.37 | 1 | 630.37 | 155.06 | <0.0001 | ** | |

| residual | 101.63 | 25 | 4.07 | * | |||

| incoherent | 94.3 | 20 | 4.72 | 3.21 | 0.0995 | ||

| errors | 7.33 | 5 | 1.47 | ||||

| sum | 734.8 | 29 | |||||

| Straw crushing rate | model | 1035.25 | 14 | 73.95 | 5.79 | 0.0008 | ** |

| X1 | 5.04 | 1 | 5.04 | 0.40 | 0.5391 | ||

| X2 | 287.04 | 1 | 287.04 | 22.49 | 0.0003 | ** | |

| X3 | 100.04 | 1 | 100.04 | 7.84 | 0.0135 | * | |

| X4 | 442.04 | 1 | 442.04 | 34.64 | <0.0001 | ** | |

| X22 | 67.86 | 1 | 67.86 | 5.32 | 0.0358 | * | |

| X32 | 132.50 | 1 | 132.50 | 10.38 | 0.0057 | ** | |

| residual | 191.42 | 15 | 12.76 | ||||

| incoherent | 70.58 | 10 | 7.06 | 0.29 | 0.9538 | ||

| errors | 120.83 | 5 | 24.17 | ||||

| sum | 1226.67 | 29 | |||||

| Power consumption | model | 9.72 | 14 | 0.69 | 13.34 | <0.0001 | ** |

| X1 | 0.05 | 1 | 0.05 | 0.97 | 0.3407 | ||

| X2 | 2.87 | 1 | 2.87 | 55.14 | <0.0001 | ** | |

| X3 | 1 | 1 | 1 | 19.22 | 0.0005 | ** | |

| X4 | 4.42 | 1 | 4.42 | 84.92 | <0.0001 | ** | |

| X22 | 0.37 | 1 | 0.37 | 7.04 | 0.018 | * | |

| X32 | 0.87 | 1 | 0.87 | 16.72 | 0.001 | ** | |

| residual | 0.78 | 15 | 0.052 | ||||

| incoherent | 0.71 | 10 | 0.071 | 4.71 | 0.0506 | ||

| errors | 0.075 | 5 | 0.015 | ||||

| sum | 10.5 | 29 | |||||

| The straw cleaning consistency between rows | model | 719.55 | 14 | 51.4 | 8.77 | <0.0001 | ** |

| X1 | 2.04 | 1 | 2.04 | 0.35 | 0.5638 | ||

| X2 | 5.04 | 1 | 5.04 | 0.86 | 0.3684 | ||

| X3 | 100.04 | 1 | 100.04 | 17.07 | 0.0009 | ** | |

| X4 | 260.04 | 1 | 260.04 | 44.37 | <0.0001 | ** | |

| X12 | 89.07 | 1 | 89.07 | 15.2 | 0.0014 | ** | |

| X32 | 132.5 | 1 | 132.5 | 22.61 | 0.0003 | ** | |

| X42 | 39.36 | 1 | 39.36 | 6.72 | 0.0204 | * | |

| residual | 87.92 | 15 | 5.86 | ||||

| incoherent | 65.08 | 10 | 6.51 | 1.43 | 0.3651 | ||

| errors | 22.83 | 5 | 4.57 | ||||

| sum | 807.47 | 29 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, S.; Zhang, H.; Shi, Y.; Jin, B.; Huang, H.; Shi, N.; Ji, W.; Zhou, C. Design and Test of Straw Crushing and Spreading Device Based on Straw Mulching No-Tillage Planter. Agriculture 2025, 15, 2404. https://doi.org/10.3390/agriculture15232404

Hou S, Zhang H, Shi Y, Jin B, Huang H, Shi N, Ji W, Zhou C. Design and Test of Straw Crushing and Spreading Device Based on Straw Mulching No-Tillage Planter. Agriculture. 2025; 15(23):2404. https://doi.org/10.3390/agriculture15232404

Chicago/Turabian StyleHou, Shouyin, Hanfei Zhang, Yunze Shi, Bo Jin, Hao Huang, Naiyu Shi, Wenyi Ji, and Cheng Zhou. 2025. "Design and Test of Straw Crushing and Spreading Device Based on Straw Mulching No-Tillage Planter" Agriculture 15, no. 23: 2404. https://doi.org/10.3390/agriculture15232404

APA StyleHou, S., Zhang, H., Shi, Y., Jin, B., Huang, H., Shi, N., Ji, W., & Zhou, C. (2025). Design and Test of Straw Crushing and Spreading Device Based on Straw Mulching No-Tillage Planter. Agriculture, 15(23), 2404. https://doi.org/10.3390/agriculture15232404