Energy Simulation-Driven Life-Cycle Costing of Gobi Solar Greenhouses: Stakeholder-Focused Analysis for Tomato Production

Abstract

1. Introduction

2. Materials and Methods

2.1. Description of Target Systems

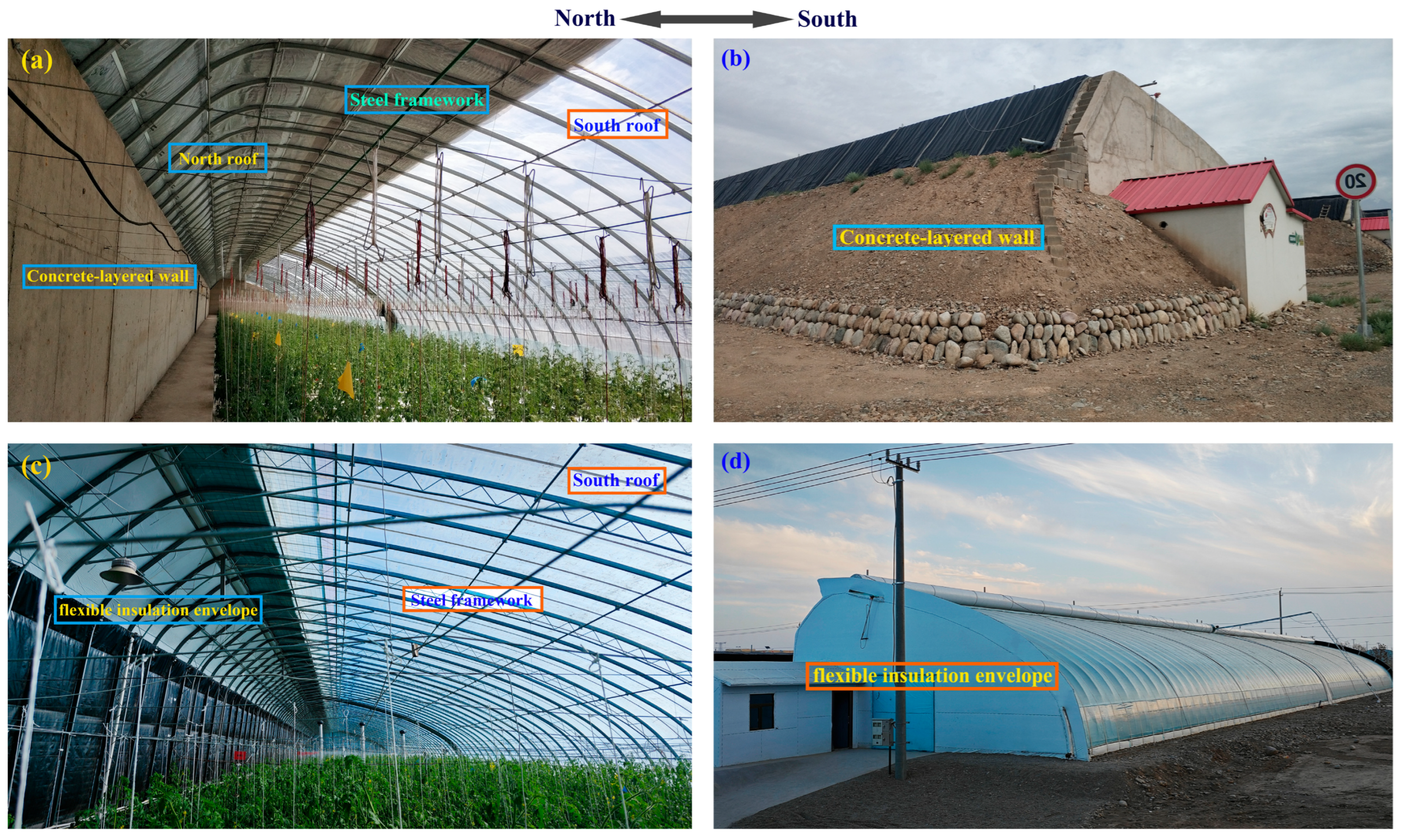

2.1.1. Structures of Gobi Solar Greenhouses

- (1)

- A solar water heating system featured 80 wall-mounted collectors installed on the internal surface of the north wall and a 28.8-m3 insulated storage tank embedded beneath the walkway running parallel to this wall (Figure 2). This system used flexible film-based solar liquid collectors, each (3.0 m length and 0.95 m width), consisting of two layers of black polyethylene film separated by a 3 mm water flow gap and reinforced with a non-woven fabric interlayer. This system absorbed solar heat during the daytime and released it at through continuous water circulation, driven by two water pumps operating in parallel with a combined flow rate of 26 m3·h−1.

- (2)

- A subsurface solar air heating system comprised two PVC heat exchanger arrays. Each array serviced 400 m2 and consisted of eight 40 m-long pipes (Ø160 mm), buried 0.6 m below the greenhouse ground surface at uniform intervals. Arrays converged at central manifolds connecting four Ø200 mm intake ducts, each terminating with an axial fan (1150 m3·h−1 capacity) (Figure 2). On the eastern and western ends, each array was connected to eight Ø160 mm exhaust ducts, forming a closed-loop circulation system for the indoor air that enhanced the ground thermal storage capacity. Driven by the axial fans, air circulated continuously between the greenhouse interior and the underground pipes, transferring excess heat to the soil for storage during daytime and retrieving stored heat to warm the greenhouse at nighttime.

2.1.2. Tomato Production

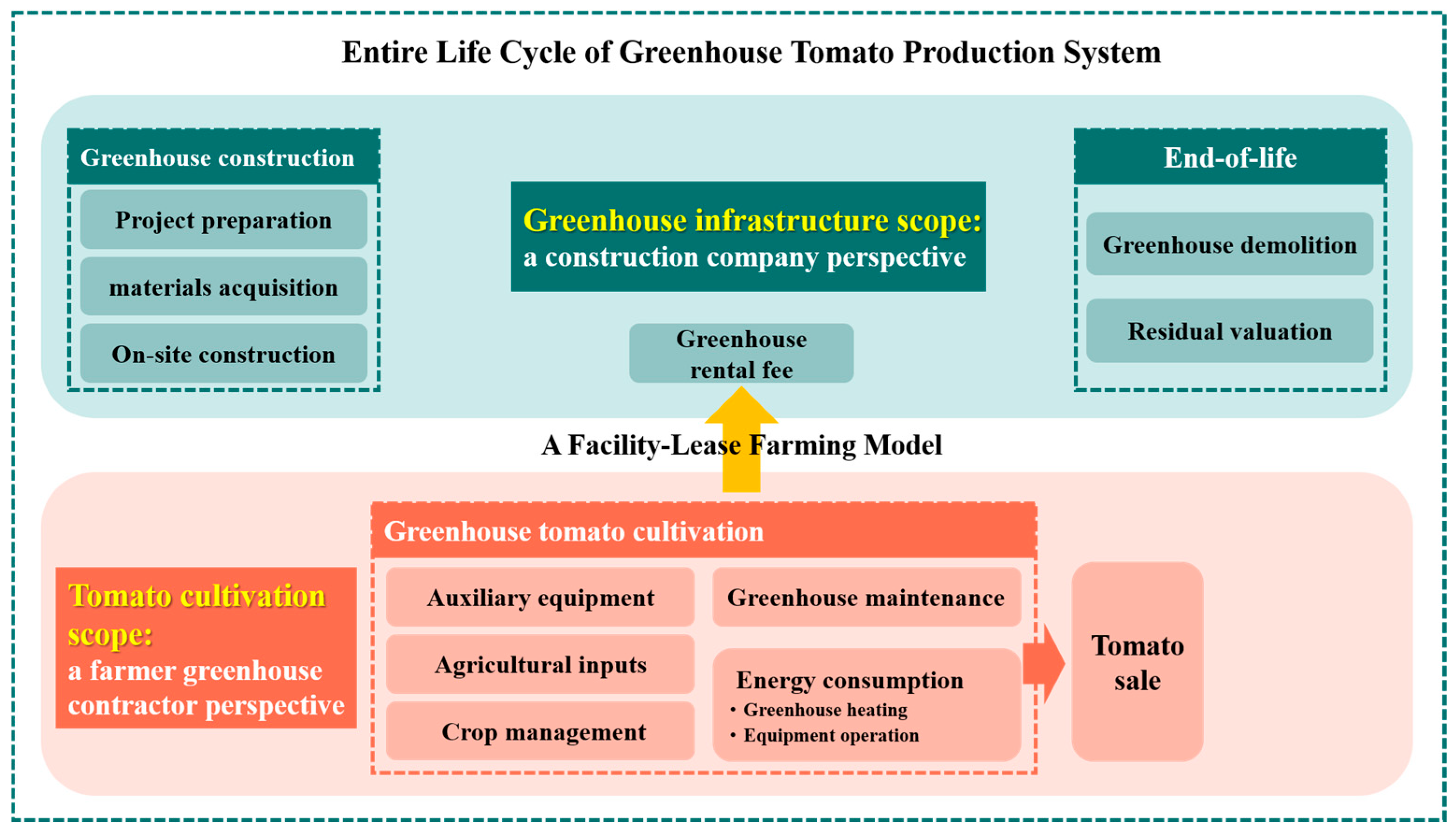

2.1.3. GSG Operational Model

2.2. Heating Demand Simulation

2.3. Life-Cycle Costing

2.3.1. Goal and Scope Definition

2.3.2. Life-Cycle Inventory

- A.

- The greenhouse infrastructure scope

- B.

- The tomato cultivation scope

2.3.3. Life-Cycle Cost Calculation

- A.

- The greenhouse infrastructure scope

- B.

- The tomato cultivation scope

2.3.4. Cost Performance Assessment

2.4. Statistical and Sensitivity Analysis

3. Results

3.1. GSG Heating Demand for Overwintering Cultivation

3.2. LCC of Greenhouse Infrastructure

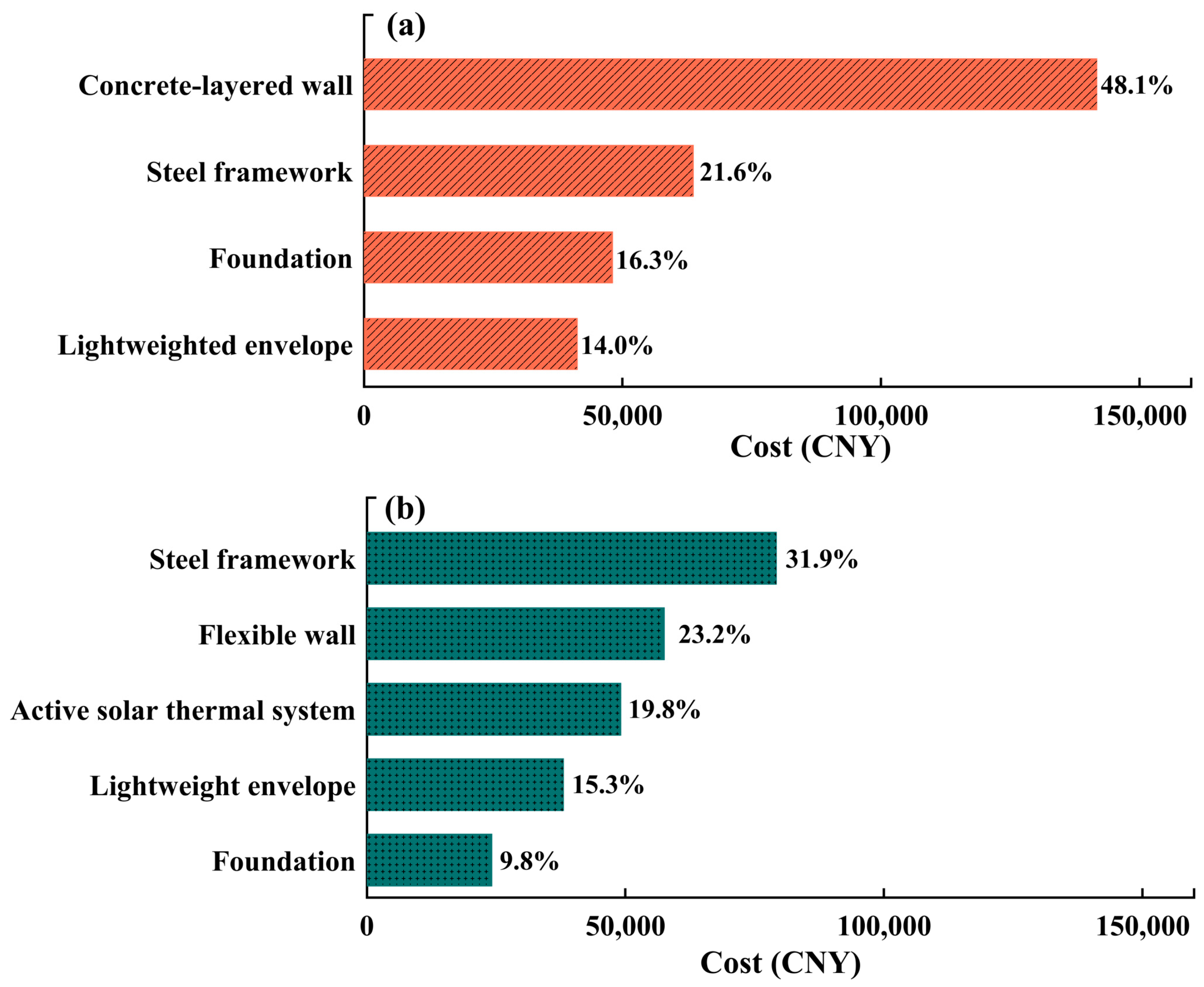

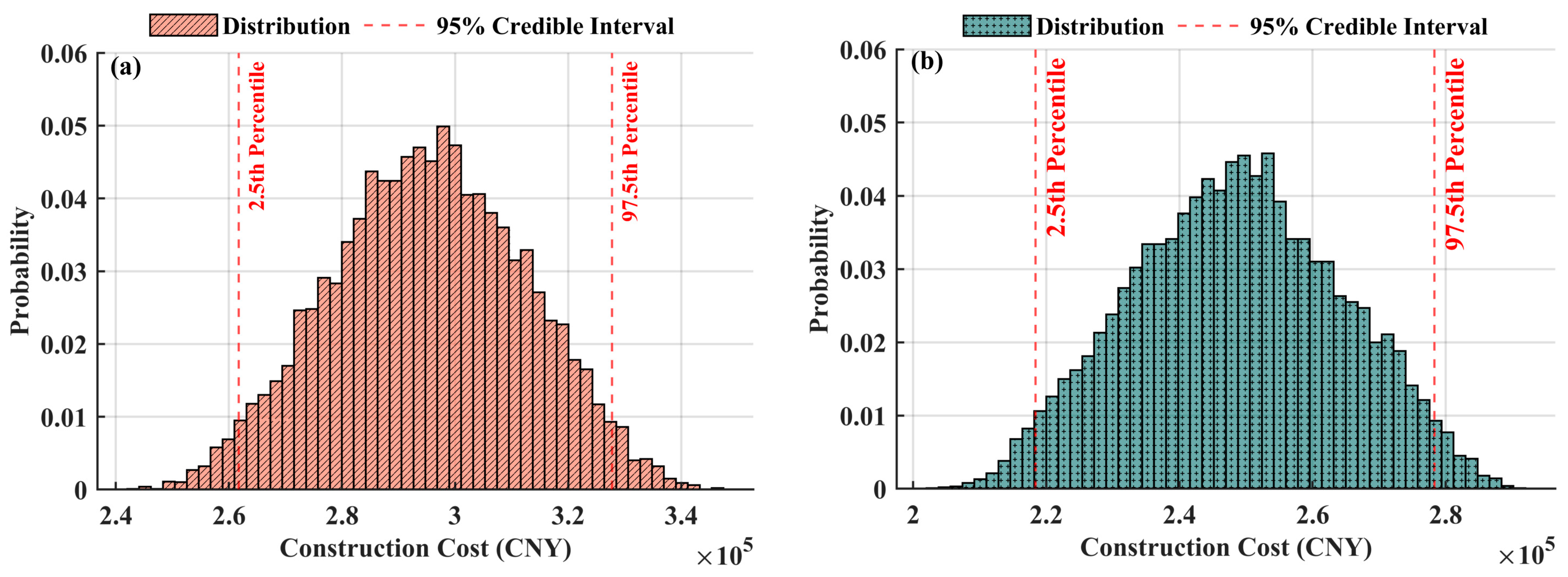

3.2.1. Construction Costs and Initial Investment of the GSGs

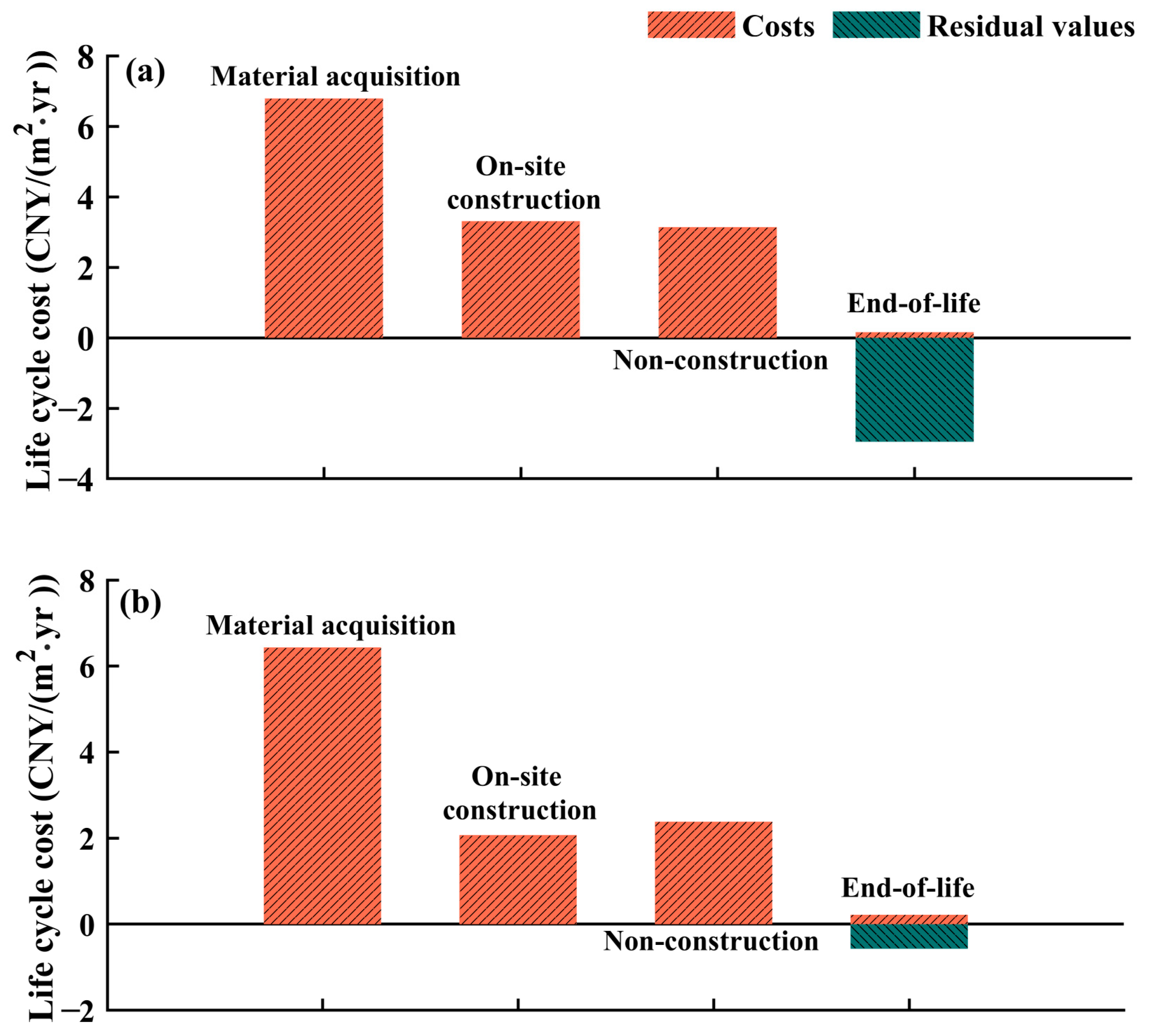

3.2.2. Life-Cycle Cost of the GSGs

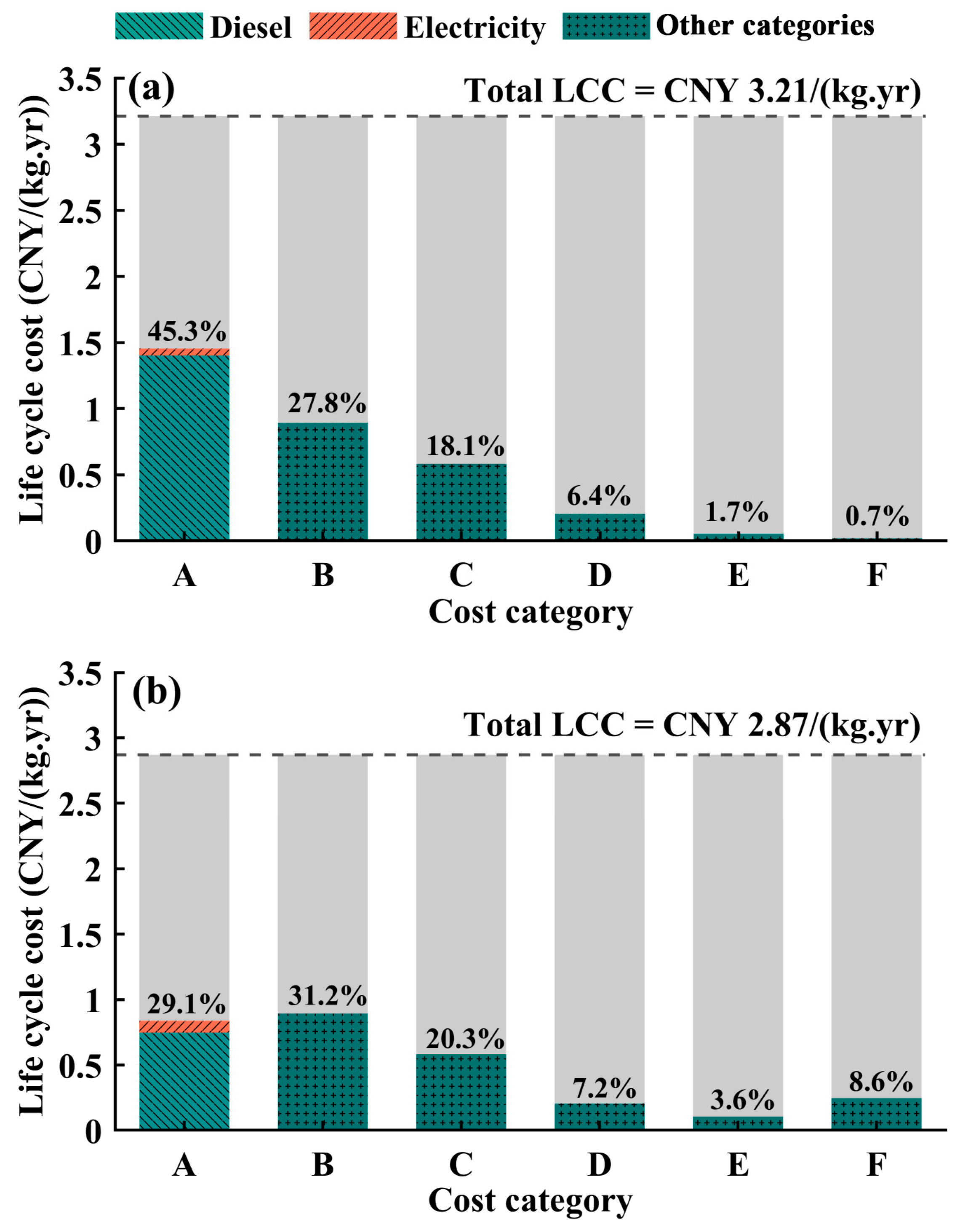

3.3. LCC of Greenhouse Tomato Cultivation

3.4. Cost Performance Assessment Results

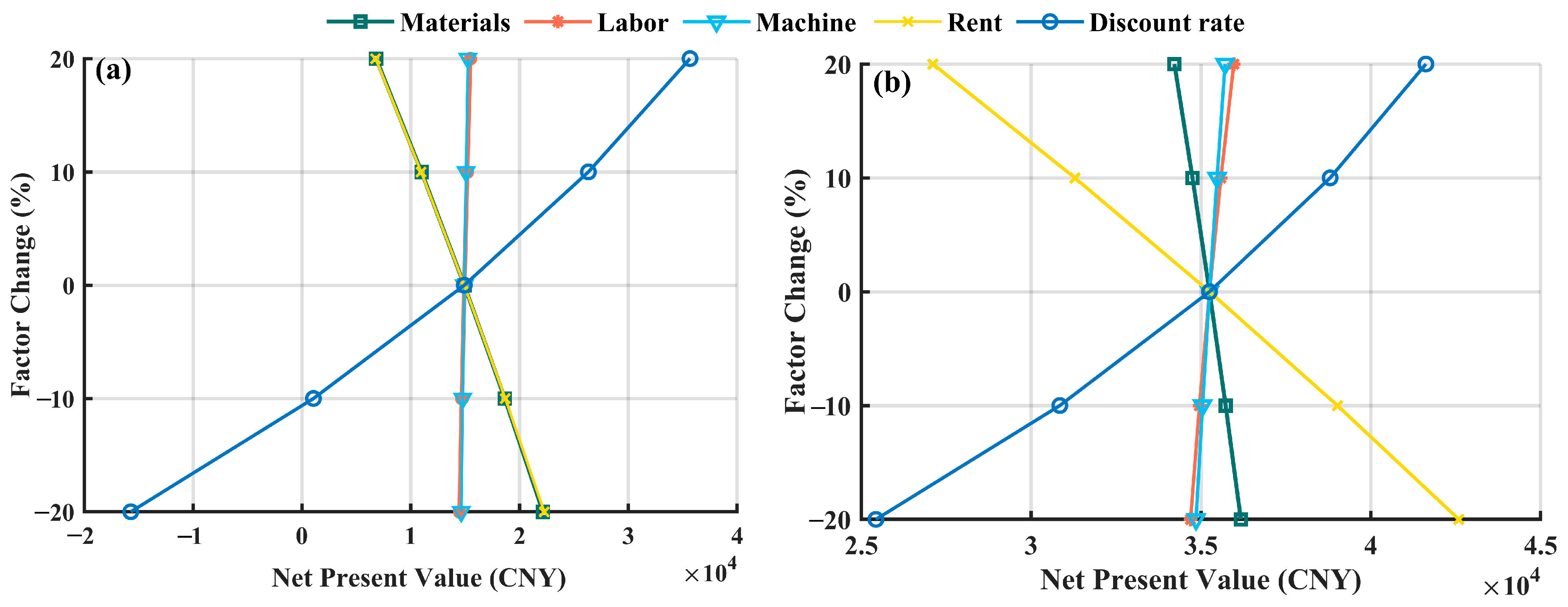

3.4.1. Assessment from a Construction Company Perspective

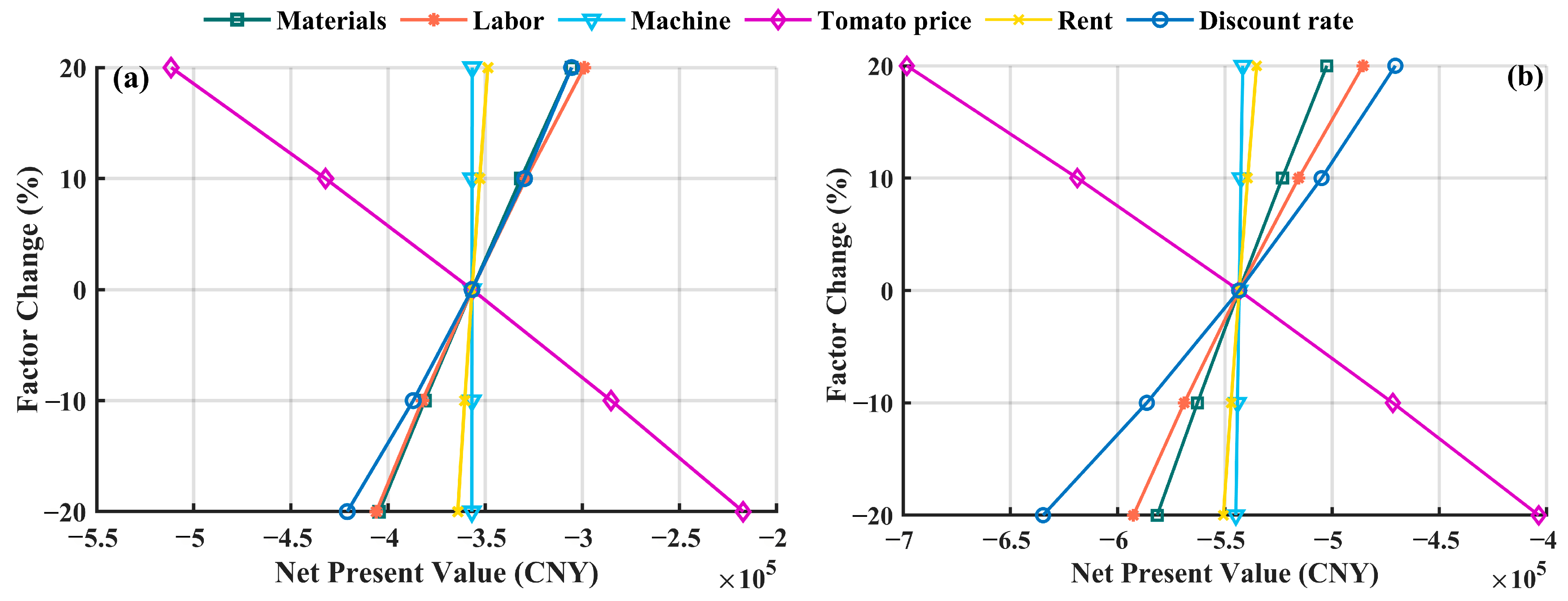

3.4.2. Assessment from a Farmer Greenhouse Contractor Perspective

3.4.3. Comprehensive Assessment

3.5. Sensitivity Analysis

4. Discussion

4.1. Comparison of Greenhouse Heating Demands

4.2. Main Cost Drivers

4.3. Suggestions Related to the GSG Operational Model

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| A | Total solar energy collector area (m2) |

| ca | Specific heat capacity of air (kJ·kg−1·K−1) |

| cw | Specific heat capacity of water (kJ·kg−1·K−1) |

| cs | Specific heat capacity of soil (kJ·kg−1·K−1) |

| C | Cost in the base year (CNY) |

| D | External diameter of pipe (m) |

| d | Date sequence |

| FC | Costs occurred in the future (CNY) |

| fe | Escalation rate |

| fd | Annual discount rate |

| hin | Convective heat transfer coefficient internal the solar energy collector (W·m−2·K−1) |

| hout | Convective heat transfer coefficient external the solar energy collector (W·m−2·K−1) |

| i | Number of years |

| I | Incomes (CNY) |

| Lc | Collector length (m) |

| Lp | Pipe length (m) |

| Water mass flow rate (kg·s−1) | |

| Mc | Total water mass per collector (kg) |

| MD | Diesel consumption (kg) |

| MT | Total water mass in insulated storage tank (kg) |

| nc | Number of collectors |

| np | Pipe quantity |

| NPV | Net present value (CNY) |

| Nu | Nusselt number of airflows |

| P | Period of analysis (year) |

| Pr | Prandtl number of waters |

| Qa | Space heat gain from air exchange between indoor and outdoor (kJ·h−1) |

| Qg | Heat transfer via ground (kJ·h−1) |

| Qnr | Heat transfer via north roof (kJ·h−1) |

| Qsr | Heat transfer via south roof (kJ·h−1) |

| Qw | Heat transfer via wall (kJ·h−1) |

| Qsys_air | Heat contribution from subsurface solar air heating system (kJ·h−1) |

| Qsys_water | Heat contribution from solar water heating system (kJ·h−1) |

| Ra | Thermal resistance of airflow (K·m−2·W −1) |

| Rp | Thermal resistance of pipe wall (K·m−2·W −1) |

| Rs | Thermal resistance of soil media (K·m−2·W −1) |

| Re | Reynolds number of water flow |

| Sc_sur | Solar radiation flux incident (W·m−2) |

| t | Time |

| TH | Thermal load of Gobi solar greenhouse (kJ·h−1) |

| THd | Daily heating load (kJ·day−1) |

| Indoor air temperature (°C) | |

| Collector inlet water temperature (°C) | |

| Collector outlet water temperature (°C) | |

| Collector surface temperature (°C) | |

| TE | Average surface temperature of the greenhouse envelope (°C) |

| Tp_out | Inlet air temperature of subsurface heat-exchange pipe (°C) |

| Tp_in | Outlet air temperature of subsurface heat-exchange pipe (°C) |

| Ts | Soil temperature (°C) |

| U | Overall heat transfer coefficient (K·m−2·W −1) |

| δ | Wall thickness of pipe (m) |

| ε | Emissivity of the collector surface |

| ηc | Solar radiation collection efficiency |

| ηh | Work efficiency of a diesel-fired air heater |

| λa | Heat conductivity of air (W·m−2·K−1) |

| λp | Heat conductivity of pipe wall (W·m−2·K−1) |

| λs | Heat conductivity of soil media (W·m−2·K−1) |

| λw | Heat conductivity of water (W·m−2·K−1) |

| ρs | Volume weight of soil (kg·m−3) |

| CW-GSG | Concrete-walled Gobi solar greenhouse |

| FIW-GSG | Flexible insulation-walled Gobi solar greenhouse |

| LCC | Life-cycle cost |

Appendix A

| Life-Cycle Stages | Cost Items | Unit | Quantity | Cost (CNY) |

|---|---|---|---|---|

| Material procurement | Concrete C25 | m3 | 229.9 | 78,057.1 |

| Steel | t | 11.1 | 56,714.0 | |

| Rock wool-core steel sandwich | m2 | 273.0 | 24,608.2 | |

| Aluminum alloy | kg | 441.8 | 11,044.2 | |

| Bamboo plywood | m2 | 145.5 | 6426.7 | |

| PVC | kg | 294.0 | 2890.0 | |

| Wood | m3 | 1.1 | 2119.8 | |

| Cement mortar | m3 | 5.3 | 1129.3 | |

| Minor Materials | - | - | 2822.0 | |

| Total | 185,811.3 | |||

| Transportation | Concrete transit-mixer truck 12 m3 | hour | 27.1 | 5241.5 |

| Truck 2 t | 4.0 | 193.8 | ||

| Truck 6 t | 36.1 | 4270.0 | ||

| Truck 8 t | 15.9 | 2950.0 | ||

| Total | - | - | 12,654.4 | |

| On-site construction works | Labor | hour | 5545.6 | 73,719.4 |

| Electric winch | 485.3 | 12,037.4 | ||

| Crawler-mounted excavator | 31.8 | 5194.5 | ||

| AC welder | 138.0 | 1903.0 | ||

| Concrete pump | 12.1 | 1124.7 | ||

| Truck 6 t | 18.3 | 1123.0 | ||

| Truck crane | 9.2 | 898.4 | ||

| Crawler-mounted dozer | 4.0 | 472.8 | ||

| Minor cost | - | - | 151.2 | |

| Total | - | - | 96,624.4 | |

| End-of-life | Labor | hour | 191.0 | 2756.2 |

| Plasma cutter | 47.6 | 1493.6 | ||

| Truck crane | 21.4 | 2049.8 | ||

| Truck 8 t | 9.6 | 1785.6 | ||

| Recycled steel | t | 5.7 | −10,731.42 | |

| Recycled aluminum alloy | kg | 419.7 | −7134.6 | |

| In situ retained concrete components | - | - | −189,967.0 | |

| Total | - | - | −199,747.8 |

| Life-Cycle Stages | Cost Items | Unit | Quantity | Cost (CNY) |

|---|---|---|---|---|

| Material procurement | Flexible coiled composite | m2 | 664 | 67,728.0 |

| Steel | t | 9.08 | 50,581.2 | |

| Aluminum alloy | kg | 146.3 | 3658.2 | |

| Concrete C25 | m3 | 7.68 | 2998.2 | |

| Concrete C30 | m3 | 3.72 | 1339.1 | |

| Extruded polystyrene board | m3 | 4.0 | 1339.7 | |

| Waterproof geotextile | m2 | 264.0 | 924.0 | |

| Wood | m3 | 0.43 | 825.4 | |

| Solar water heating system | - | 1 | 20,841.0 | |

| Subsurface solar air heating system | - | 1 | 11,413.9 | |

| Minor Materials | - | - | 1689.7 | |

| Total | 163,338.4 | |||

| Transportation | Concrete transit-mixer truck 4 m3 | hour | 4.0 | 471.7 |

| Truck 2 t | 8.0 | 387.5 | ||

| Truck 10 t | 22.8 | 3916.3 | ||

| Box truck 9.6 m | 72.0 | 17,000.0 | ||

| Flatbed semi-trailer 9.6 m | 13.0 | 2766.0 | ||

| Total | - | - | 24,541.5 | |

| On-site construction works | Labor | hour | 3152.8 | 41,911.6 |

| Electric winch | 485.3 | 12,037.4 | ||

| Crawler-mounted excavator | 20.6 | 3376.3 | ||

| AC welder | 170.2 | 2300.3 | ||

| Pile driver | 3.9 | 454.0 | ||

| Crawler-mounted dozer | 2.6 | 307.7 | ||

| Truck 6 t | 2.9 | 180.6 | ||

| Total | - | - | 60,567.9 | |

| End-of-life | Labor | hour | 251.8 | 3634.7 |

| Plasma cutter | 62.7 | 1969.6 | ||

| Truck crane | 28.2 | 2703.1 | ||

| Truck 8 t | 15.0 | 2794.7 | ||

| Recycled steel | t | 7.49 | −14,151.66 | |

| Recycled aluminum alloy | kg | 139.0 | −2363.2 | |

| In situ retained concrete components | - | - | −24,253.8 | |

| Total | - | - | −27,303.4 |

| Cost Categories | Cost Items | Unit | Service Life (Years) | Total Quantity | Unit Price in 2024 (CNY) | Net Present Value of Total Cost (CNY) |

|---|---|---|---|---|---|---|

| Auxiliary equipment | Blanket-rolling machinery | |||||

| Motor | - | 10 | 3 | 1500.0 | 2789.8 | |

| Steel component | - | 30 | 1 | 3563.7 | 3563.7 | |

| Truck 6 t | times | - | - | 330.0 | 330.0 | |

| film-rolling device | ||||||

| Electric-drive device | - | 5 | 6 | 735.0 | 2903.7 | |

| Hand-drive device | - | 5 | 6 | 59.5 | 235.1 | |

| Integrated fertigation system | ||||||

| Water storage tank (Steel) | - | 30 | 1 | 1400.0 | 1400.0 | |

| Centrifugal filter | - | 10 | 3 | 540.0 | 1004.3 | |

| Water pump | - | 10 | 3 | 756.0 | 1406.1 | |

| Fertilizer canister | - | 5 | 18 | 150.0 | 1642.8 | |

| Drip pile | m | 5 | 762.0 | 11.45 | 5308.0 | |

| Drip tape | m | 5 | 6072.0 | 0.15 | 554.9 | |

| Tee-junction | - | 5 | 690.0 | 1.50 | 629.7 | |

| Solenoid valve | - | 5 | 12.0 | 160.00 | 1168.2 | |

| Heating device | ||||||

| Diesel-fired air heater | - | 30 | 2 | 2240.0 | 4480.0 | |

| Total | - | - | - | - | 27,416.3 | |

| Agricultural inputs | Insulating blanket | m2 | 10 | 2880.8 | 20.0 | 41,480.0 |

| Cladding film | kg | 2 | 1380.0 | 21.4 | 18,397.0 | |

| Mulching film | kg | 1 | 432.0 | 12.0 | 1585.6 | |

| Growth substrate | m3 | 1 | 2400.0 | 30.0 | 44,045.0 | |

| Seedling | - | 0.5 | 144,000.0 | 0.50 | 44,045.0 | |

| Fertilizer | kg | - | 13,200.0 | 7.50 | 60,929.0 | |

| Pesticide | times | - | 300 | 90.0 | 16,517.0 | |

| Irrigation water | m3 | - | 37,500.0 | 1.50 | 34,410.0 | |

| Clamping rail | m | 2 | 8730.0 | 3.50 | 19,042.0 | |

| Wire mesh | m2 | 5 | 960.0 | 8.50 | 5372.8 | |

| Inset net | m2 | 2 | 3285.0 | 2.00 | 4094.4 | |

| Tension rope | m | 5 | 6000.0 | 0.20 | 592.6 | |

| Box truck 6.4 m | times | - | - | 900 | 2012.3 | |

| Total | 292,522.7 | |||||

| Crop management | Labor | day | - | 1800.0 | 150.0 | 449,430.0 |

| Total | - | - | - | - | 449,430.0 | |

| Greenhouse structure maintenance | Antirust paint | kg | 10 | 165.1 | 18.5 | 1767.7 |

| White spirit | kg | - | 17.3 | 8.0 | 79.6 | |

| Fire-proof paint | kg | 10 | 96.54 | 26.7 | 1494.6 | |

| Boiled oil | kg | - | 8.9 | 15.9 | 81.8 | |

| Abrasive paper | sheet | - | 327.6 | 0.7 | 132.8 | |

| Labor | hour | - | 563.5 | 14.4 | 6680.5 | |

| Total | - | - | - | 10,237.0 | ||

| Energy consumption | Electricity | kWh | - | 99,196.8 | 0.44 | 26,633.0 |

| Diesel | kg | - | 167,564.4 | 6.88 | 705,230.0 | |

| Total | - | - | - | 731,863.0 | ||

| Cost Categories | Cost Items | Unit | Service Life (Years) | Total Quantity | Unit Price in 2024 (CNY) | Net Present Value of Total Cost (CNY) |

|---|---|---|---|---|---|---|

| Auxiliary equipment | Blanket-rolling machinery | |||||

| Motor | - | 10 | 3 | 1500.0 | 2789.8 | |

| Steel component | - | 30 | 1 | 3563.7 | 3563.7 | |

| Truck 6 t | times | - | - | 330.0 | 330.0 | |

| film-rolling device | ||||||

| Electric-drive device | - | 5 | 6 | 735.0 | 2903.7 | |

| Hand-drive device | - | 5 | 6 | 59.5 | 235.1 | |

| Integrated fertigation system | ||||||

| Water storage tank (Steel) | - | 30 | 1 | 1400.0 | 1400.0 | |

| Centrifugal filter | - | 10 | 3 | 540.0 | 1004.3 | |

| Water pump | - | 10 | 3 | 756.0 | 1406.1 | |

| Fertilizer canister | - | 5 | 18 | 150.0 | 1642.8 | |

| Drip pile | m | 5 | 762.0 | 11.45 | 5308.0 | |

| Drip tape | m | 5 | 6072.0 | 0.15 | 554.9 | |

| Tee-junction | - | 5 | 690 | 1.50 | 629.7 | |

| Solenoid valve | - | 5 | 12 | 160.00 | 1168.2 | |

| Heating device | ||||||

| Diesel-fired air heater | - | 30 | 2 | 2240.0 | 4480.0 | |

| Solar water heating system | ||||||

| Controller | - | 10 | 2 | 3000.0 | 3479.6 | |

| Water pump | - | 10 | 4 | 1512.0 | 1753.7 | |

| Collector | - | 10 | 160 | 8000.0 | 9279.0 | |

| Rubber insulation board | m3 | 10 | 27.6 | 4134.0 | 4794.9 | |

| High-density polyethylene | m2 | 10 | 240.0 | 336.0 | 389.7 | |

| High-Tenacity PVC Tarpaulin | m2 | 10 | 328 | 2296.0 | 2663.1 | |

| Clamping rail | - | 10 | 320.0 | 560.0 | 649.5 | |

| PPR pipe Ø50 mm | m | 10 | 14.0 | 144.1 | 167.1 | |

| PPR pipe Ø32 mm | m | 10 | 160.0 | 709.8 | 823.3 | |

| PE pipe Ø20 mm | m | 10 | 80.0 | 149.1 | 173.0 | |

| Labor | hour | - | 17.8 | 14.4 | 1689.8 | |

| Total | - | - | - | - | 53,279.0 | |

| Agricultural inputs | Insulating blanket | m2 | 10 | 2880.8 | 20.0 | 41,480.0 |

| Cladding film | kg | 2 | 1380.0 | 21.4 | 18,397.0 | |

| Mulching film | kg | 1 | 432.0 | 12.0 | 1585.6 | |

| Growth substrate | m3 | 1 | 2400.0 | 30.0 | 44,045.0 | |

| Seedling | - | 0.5 | 144,000.0 | 0.50 | 44,045.0 | |

| Fertilizer | kg | - | 13,200.0 | 7.50 | 60,929.0 | |

| Pesticide | times | - | 300 | 90.0 | 16,517.0 | |

| Irrigation water | m3 | - | 37,500.0 | 1.50 | 34,410.0 | |

| Clamping rail system | m | 2 | 8730.0 | 3.50 | 19,042.0 | |

| Wire mesh | m2 | 5 | 960.0 | 8.50 | 5372.8 | |

| Inset net | m2 | 2 | 3285.0 | 2.00 | 4094.4 | |

| Tension rope | m | 5 | 6000.0 | 0.20 | 592.6 | |

| Box truck 6.4 m | times | - | - | 900 | 2012.3 | |

| Total | 292,522.7 | |||||

| Crop management | Labor | day | - | 1800.0 | 150.0 | 449,430.0 |

| Total | - | - | - | - | 449,430.0 | |

| Greenhouse structure maintenance | Antirust paint | kg | 10 | 204.5 | 18.5 | 2190.0 |

| White spirit | kg | - | 21.4 | 8.0 | 98.6 | |

| Fire-proof paint | kg | 10 | 119.6 | 26.7 | 1851.6 | |

| Boiled oil | kg | - | 11.0 | 15.9 | 101.3 | |

| Abrasive paper | sheet | - | 406.3 | 0.7 | 164.7 | |

| Flexible coiled composite | m2 | 10 | 1328.0 | 102.0 | 78,556.0 | |

| Extruded polystyrene board | m2 | 10 | 240.0 | 2.8 | 389.7 | |

| Waterproof geotextile | m2 | 10 | 528.0 | 3.5 | 1071.7 | |

| Axial fan | - | 10 | 8 | 518.0 | 2403.3 | |

| Labor | hour | - | 699.7 | 14.4 | 16,590.3 | |

| Box truck 9.6 m | hour | - | 144.0 | 17,000.0 | 21,011.0 | |

| Total | - | - | - | 124,428.3 | ||

| Energy consumption | Electricity | kWh | - | 145,471.7 | 0.44 | 43,945.0 |

| Diesel | kg | - | 79,386.0 | 6.88 | 375,920.0 | |

| Total | - | - | - | 419,865.0 | ||

References

- Katzin, D.; Marcelis, L.F.M.; van Henten, E.J.; van Mourik, S. Heating greenhouses by light: A novel concept for intensive greenhouse production. Biosyst. Eng. 2023, 230, 242–276. [Google Scholar] [CrossRef]

- Trépanier, M.-P.; Gosselin, L.; Jørgensen, B.N. Best combinations of energy-efficiency measures in greenhouses considering energy consumption, yield, and costs: Comparison between two cold climate cities. Appl. Energy 2025, 382, 125163. [Google Scholar] [CrossRef]

- Paksoy, M.; Türkmen, Ö.; Direk, M. Importance of geothermal water using for greenhouse heating in Turkey. Selcuk J. Agric. Food Sci. 2010, 24, 50–53. [Google Scholar]

- Rezaei, F.; Burg, V.; Solgi, H.; Hellweg, S.; Roshandel, R. Spatiotemporal assessment of the cumulative exergy demand of agricultural greenhouse production with industrial symbiosis. Ecol. Indic. 2024, 169, 112904. [Google Scholar] [CrossRef]

- Ahamed, M.S.; Guo, H.; Tanino, K. Modeling heating demands in a Chinese-style solar greenhouse using the transient building energy simulation model TRNSYS. J. Build. Eng. 2020, 29, 101114. [Google Scholar] [CrossRef]

- Tian, J.; Li, K.; Lin, T.; Li, Y.; He, M.; Li, T.; Liu, X. Wall structural optimization and thermal performance analysis of sunken solar greenhouse. Appl. Therm. Eng. 2025, 279, 127528. [Google Scholar] [CrossRef]

- Boost Facility-Based Crop Cultivation to Ensure Stable and Diverse Food Supply. Available online: https://jhs.moa.gov.cn/gzdt/202412/t20241212_6467889.htm (accessed on 1 March 2025).

- Xie, J.; Yu, J.; Chen, B.; Feng, Z.; Lyu, J.; Hu, L.; Gan, Y.; Siddique, K.H.M. Gobi agriculture: An innovative farming system that increases energy and water use efficiencies. A review. Agron. Sustain. Dev. 2018, 38, 62. [Google Scholar] [CrossRef]

- Xie, J.; Yu, J.; Chen, B.; Feng, Z.; Li, J.; Zhao, C.; Lyu, J.; Hu, L.; Gan, Y.; Siddique, K.H.M. Chapter One—Facility Cultivation Systems “设施农业”: A Chinese Model for the Planet. Adv. Agron. 2017, 145, 1–42. [Google Scholar] [CrossRef]

- Zhang, Z.; Dong, Z.; Li, J.; Qian, G.; Jiang, C. Implications of surface properties for dust emission from gravel deserts (gobis) in the Hexi Corridor. Geoderma 2016, 268, 69–77. [Google Scholar] [CrossRef]

- Yin, X.; Zhang, G.; Zhao, W.; Cui, H.; Yang, M.; Jiang, H. Construction technology of stone-built wall-digging type solar greenhouses under non-cultivated land in Northwest China. China Veg. 2013, 11, 50–52. [Google Scholar]

- Chai, Z.; Cui, H.; Zhang, G. Construction technology of solar greenhouses with flange walls in the Gobi Desert of the Hexi Corridor. Shanghai Veg. 2019, 3, 70–71. [Google Scholar]

- Guo, Z.; Wang, L.; Wang, J. Research on rural revitalization planning based on the integrated development of “production, life, and ecology”: A case of dongdong town in Suzhou District, Jiuquan. Urban. Archit. 2022, 19, 04–07. [Google Scholar] [CrossRef]

- Zhang, X.; Lv, J.; Dawuda, M.M.; Xie, J.; Yu, J.; Gan, Y.; Zhang, J.; Tang, Z.; Li, J. Innovative passive heat-storage walls improve thermal performance and energy efficiency in Chinese solar greenhouses for non-arable lands. Sol. Energy 2019, 190, 561–575. [Google Scholar] [CrossRef]

- Li, H.; Mi, X.; Shi, J.; Zhang, Y.; Zhang, G. The model and effects of renovating old greenhouses for facility vegetables in the Jiuquan Gobi Desert. China Veg. 2024, 9, 142–146. [Google Scholar] [CrossRef]

- Wang, C.; Fang, H.; Zhang, Y.; Sang, S.; Cao, K. Energy consumption analysis of simply soft insulated wall-assembled Chinese solar greenhouse. Trans. CSAE 2023, 39, 190–197. [Google Scholar] [CrossRef]

- Zhou, C.; Gao, H.; Li, Y.; Zhang, B.; Li, X. An assembled solar greenhouse with active thermal storage/release system and samless self-waterproofing rubber-plastic insulation enclosure. Appl. Eng. Technol. 2022, 42, 36–45. [Google Scholar] [CrossRef]

- Avezova, N.R.; Samiev, K.A.; Khaetov, A.R.; Nazarov, I.M.; Ergashev, Z.Z.; Samiev, M.O.; Suleimanov, S.I. Modeling of the unsteady temperature conditions of solar greenhouses with a short-term water heat accumulator and its experimental testing. Appl. Sol. Energy 2010, 46, 4–7. [Google Scholar] [CrossRef]

- Kumar Agrawal, K.; Yadav, T.; Misra, R.; Das Agrawal, G. Effect of soil moisture contents on thermal performance of earth-air-pipe heat exchanger for winter heating in arid climate: In situ measurement. Geothermics 2019, 77, 12–23. [Google Scholar] [CrossRef]

- Attar, I.; Farhat, A. Efficiency evaluation of a solar water heating system applied to the greenhouse climate. Sol. Energy 2015, 119, 212–224. [Google Scholar] [CrossRef]

- Lu, W.; Zhang, Y.; Fang, H.; Ke, X.; Yang, Q. Modelling and experimental verification of the thermal performance of an active solar heat storage-release system in a Chinese solar greenhouse. Biosyst. Eng. 2017, 160, 12–24. [Google Scholar] [CrossRef]

- Zhao, J.; Chen, F.; Wang, Y.; Wang, K.; Zhai, X.; Zhang, D. Experimental study on effect of an active solar heating soil heat storage system on the thermal environment in Gobi solar greenhouses. Energy Build. 2024, 325, 115055. [Google Scholar] [CrossRef]

- Poderytė, I.; Banaitienė, N.; Banaitis, A. Life Cycle Sustainability Assessment of Buildings: A Scientometric Analysis. Buildings 2025, 15, 381. [Google Scholar] [CrossRef]

- Shadram, F.; Bhattacharjee, S.; Lidelöw, S.; Mukkavaara, J.; Olofsson, T. Exploring the trade-off in life cycle energy of building retrofit through optimization. Appl. Energy 2020, 269, 115083. [Google Scholar] [CrossRef]

- Moschetti, R.; Brattebø, H. Combining Life Cycle Environmental and Economic Assessments in Building Energy Renovation Projects. Energies 2017, 10, 1851. [Google Scholar] [CrossRef]

- Carvalho, J.P.; Villaschi, F.S.; Bragança, L. Assessing Life Cycle Environmental and Economic Impacts of Building Construction Solutions with BIM. Sustainability 2021, 13, 8914. [Google Scholar] [CrossRef]

- Ökmen, Ö. Comparison of Design Alternatives Based on Lifecycle Costing: Case of an Irrigation Project in Turkey. J. Manag. Eng. 2015, 31, 05014028. [Google Scholar] [CrossRef]

- McKenney, D.W.; Yemshanov, D.; Fraleigh, S.; Allen, D.; Preto, F. An economic assessment of the use of short-rotation coppice woody biomass to heat greenhouses in southern Canada. Biomass Bioenergy 2011, 35, 374–384. [Google Scholar] [CrossRef]

- Sanyé-Mengual, E.; Oliver-Solà, J.; Montero, J.I.; Rieradevall, J. An environmental and economic life cycle assessment of rooftop greenhouse (RTG) implementation in Barcelona, Spain. Assessing new forms of urban agriculture from the greenhouse structure to the final product level. Int. J. Life Cycle Assess. 2015, 20, 350–366. [Google Scholar] [CrossRef]

- Peña, A.; Rovira-Val, M.R.; Mendoza, J.M.F. Life cycle cost analysis of tomato production in innovative urban agriculture systems. J. Clean. Prod. 2022, 367, 133037. [Google Scholar] [CrossRef]

- Decano-Valentin, C.; Lee, I.-B.; Yeo, U.-H.; Lee, S.-Y.; Kim, J.-G.; Park, S.-J.; Choi, Y.-B.; Cho, J.-H.; Jeong, H.-H. Integrated Building Energy Simulation–Life Cycle Assessment (BES–LCA) Approach for Environmental Assessment of Agricultural Building: A Review and Application to Greenhouse Heating Systems. Agronomy 2021, 11, 1230. [Google Scholar] [CrossRef]

- Ahamed, M.S.; Guo, H.; Taylor, L.; Tanino, K. Heating demand and economic feasibility analysis for year-round vegetable production in Canadian Prairies greenhouses. Inf. Process. Agric. 2019, 6, 81–90. [Google Scholar] [CrossRef]

- Jiuquan City Has Intensified Policy Support to Promote the High-Quality Development of the Tomato Industry. Available online: https://nync.jiuquan.gov.cn/nyncj/c107001/202410/e76f0426b1bb458c98da39910fced3d3.shtml (accessed on 12 December 2024).

- Suzhou: “Greenhouse Economy” Turns the Vegetable Basket into a Money Bag. Available online: https://baijiahao.baidu.com/s?id=1839629586413571812&wfr=spider&for=pc (accessed on 1 June 2025).

- National Agricultural Products Wholesale Market Price Information System. Available online: https://pfsc.agri.cn/#/marketQuotation (accessed on 1 May 2025).

- Qin, J.; Wang, W. Research on the interest linkage model between agricultural leading enterprises and famers in Jiuquan Gobi. Manag. Agric. Sci. Technol. 2025, 44, 85–88. [Google Scholar] [CrossRef]

- Zhang, X.; Xie, J.; Zhang, J.; Li, J.; Ma, N.; Mao, E. Simplified heat-transfer calculation for the trapezoidal cross-section wall in Gobi solar greenhouses and greenhouse thermal-load prediction. Biosyst. Eng. 2023, 234, 46–65. [Google Scholar] [CrossRef]

- Huang, L.; Deng, L.; Li, A.; Gao, R.; Zhang, L.; Lei, W. A novel approach for solar greenhouse air temperature and heating load prediction based on Laplace transform. J. Build. Eng. 2021, 44, 102682. [Google Scholar] [CrossRef]

- Zhang, X.; Lv, J.; Xie, J.; Yu, J.; Zhang, J.; Tang, C.; Li, J.; He, Z.; Wang, C. Solar Radiation Allocation and Spatial Distribution in Chinese Solar Greenhouses: Model Development and Application. Energies 2020, 13, 1108. [Google Scholar] [CrossRef]

- Mao, E.; Zhang, X.; Xie, J.; Ma, N.; Chang, Y.; Hu, S. Simulation of thermal processes and optimization of parameters for active heat storage and discharge system in solar greenhouse. Acta Agric. Zhejiangensis 2024, 36, 671–680. [Google Scholar]

- Fine, J.P.; Nguyen, H.V.; Friedman, J.; Leong, W.H.; Dworkin, S.B. A simplified ground thermal response model for analyzing solar-assisted ground source heat pump systems. Energy Convers. Manag. 2018, 165, 276–290. [Google Scholar] [CrossRef]

- Incropera, F.P. Fundamentals of Heat and Mass Transfer; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2006. [Google Scholar]

- Khiraiya, K.; Ramana, P.V.; Panchal, H.; Sadasivuni, K.K.; Doranehgard, M.H.; Khalid, M. Diesel-fired boiler performance and emissions measurements using a combination of diesel and palm biodiesel. Case Stud. Therm. Eng. 2021, 27, 101324. [Google Scholar] [CrossRef]

- ISO 15686-5; Buildings and CONSTRUCTED Assets—Service Life Planning Part 5: Life-Cycle Costing. International Organization for Standardization: Geneva, Switzerland, 2017. Available online: https://www.iso.org/standard/61148.html (accessed on 12 August 2024).

- DBJD25-67-2019; Gansu Province Construction and Decoration Engineering Budget Quota & Regional Base Price. Deparment of Housing and Urban-Rural Development of Gansu Province: Lanzhou, China, 2020. Available online: https://zjt.gansu.gov.cn/zjt/c108348/202105/b60ac9af9a2a42a698e3d151818fc0ec.shtml (accessed on 1 August 2023).

- Xu, D.; Fei, S.; Wang, Z.; Zhu, J.; Ma, Y. Optimum design of Chinese solar greenhouses for maximum energy availability. Energy 2024, 304, 131980. [Google Scholar] [CrossRef]

- DB61/T 1422-2021; Technical Regulations for Overwintering Tomato Cultivation in Solar Greenhouses. Shaanxi Administration for Market Regulation: Xi’an, China, 2021. Available online: https://std.samr.gov.cn/db/search/stdDBDetailed?id=D7B6451FCF28919DE05397BE0A0A6273 (accessed on 23 January 2023).

- Pricing Rules for Construction Projects in Gansu Province. Department of Housing and Urban-Rural Development of Gansu Province: Lanzhou, China. 2022. Available online: https://zjt.gansu.gov.cn/zjt/c108286/202209/2116822.shtml (accessed on 2 August 2023).

- National Bureau of Statistics of China. China Statistical Yearbook 2024; China Statistics Press: Beijing, China, 2024. Available online: https://www.stats.gov.cn/sj/ndsj/2024/indexch.htm (accessed on 12 May 2025).

- National Development and Reform Commission. Economic Evaluation Methods and Parameters for Construction Projects; China Planning Press: Beijing, China, 2006.

- Interim Measures for Investment Promotion and Industrial Development Support and Reward in Su Zhuo District. Available online: https://mp.weixin.qq.com/s?__biz=MzA4NTUzNjU3NA==&mid=2651307008&idx=3&sn=cef757dd576c2fdf06b090339b16ce0a&chksm=84256651b352ef479697f9013a99c4c078f012075194694cd22beab78c808d0462843365efc6&scene=27 (accessed on 12 July 2024).

- The Implementation Plan for the 2023 Modern Facility Agriculture Construction Subsidy Project and Loan Interest Subsidy in Jiuquan City. Available online: https://www.jiuquan.gov.cn/jiuquan/c111547/202310/1d85a03131b246b0ac9b5eff2843a5c6.shtml (accessed on 12 July 2024).

- Baglivo, C.; Mazzeo, D.; Panico, S.; Bonuso, S.; Matera, N.; Congedo, P.M.; Oliveti, G. Complete greenhouse dynamic simulation tool to assess the crop thermal well-being and energy needs. Appl. Therm. Eng. 2020, 179, 115698. [Google Scholar] [CrossRef]

- Madhusudanan, S.; Amirtham, L.R. Optimization of Construction Cost Using Industrial Wastes in Alternative Building Material for Walls. Key Eng. Mater. 2016, 692, 1–8. [Google Scholar] [CrossRef]

| Parameters | Value | Parameters | Value | |

|---|---|---|---|---|

| A solar water heating system | cw | 4.184 kJ·kg−1·K−1 | Pr | 4.62 |

| Hc | 0.95 m | Re | 204,480 | |

| Lc | 3.0 m | ε | 0.90 | |

| 0.09 kg·s−1 | ηc | 0.65 | ||

| Mc | 5.68 kg | λw | 0.628 W·m−2·K−1 | |

| MT | 28,714 kg | σ | 5.67 × 10−8 W·m−2·K−4 | |

| nc | 80 | |||

| A subsurface solar air heating system | ca | 1.007 kJ·kg−1·K−1 | δ | 0.003 m |

| cs | 1.544 kJ·kg−1·K−1 | λa | 0.026 W·m−2·K−1 | |

| D | 0.16 m | λp | 0.20 W·m−2·K−1 | |

| Lp | 40.0 m | λs | 0.48 W·m−2·K−1 | |

| np | 8 | ρs | 2095 kg·m−3 | |

| Nu | 99.07 |

| Site Safety and Environmental Management Cost | Statutory Fee | |||

|---|---|---|---|---|

| Site Safety Cost | Site Civilization Cost | Environmental Protection Measures Cost | ||

| Charging base | Labor cost + Machinery cost | Labor cost | ||

| Rate | 7.5% | 1.05% | 0.65% | 22% |

| Greenhouse Type | Stage Cost (CNY) | |||||

|---|---|---|---|---|---|---|

| Material Procurement | Transportation | On-Site Construction Work | Construction Cost | Non-Construction Cost | Initial Investment | |

| 1 | 2 | 3 | 4 = 1 + 2 + 3 | 5 | 6 = 4 + 5 | |

| CW-GSG | 185,811.3 | 12,654.4 | 96,624.4 | 295,090 | 91,862.7 | 386,953 |

| FIW-GSG | 163,338.4 | 24,541.5 | 60,567.9 | 248,448 | 69,673.8 | 318,122 |

| Greenhouse Types | Years (i) | Annual Costs | Annual Incomes | Annual Cash Flow | Net Present Value (NPV) |

|---|---|---|---|---|---|

| 1 | 2 | 4 = 2 + 3 | 5 = 4/(1 + 0.06)i | ||

| Concrete-walled Gobi solar greenhouse | 0 | 38,695.0 | −132,542.5 | −93,847.5 | −93,847.5 |

| 1 | 38,695.0 | −5000.0 | 33,695.0 | 33,695.0 | |

| 2 | 38,695.0 | −5155.0 | 33,540.0 | 31,641.5 | |

| 3 | 38,695.0 | −5314.8 | 33,380.2 | 29,708.3 | |

| 4 | 38,695.0 | −5479.6 | 33,215.4 | 27,888.3 | |

| 5 | 38,695.0 | −5649.4 | 33,045.6 | 26,175.2 | |

| 6 | 38,695.0 | −5824.6 | 32,870.4 | 24,562.7 | |

| 7 | 38,695.0 | −6005.1 | 32,689.9 | 23,045.1 | |

| 8 | 38,695.0 | −6191.3 | 32,503.7 | 21,616.8 | |

| 9 | 38,695.0 | −6383.2 | 32,311.8 | 20,272.8 | |

| 10 | - | −6581.1 | −6581.1 | −3895.3 | |

| … | … | … | … | … | |

| … | … | … | … | … | |

| 29 | - | −11,754.7 | −11,754.7 | −2299.6 | |

| 30 | 21,304.6 | −396,381.8 | −375,077.3 | −69,223.0 | |

| Total | 408,254.6 | −758,573.6 | −350,319.0 | 14,907.8 | |

| Flexible insulation-walled Gobi solar greenhouse | 0 | 31,812.0 | −114,302.2 | −82,490.2 | −82,490.2 |

| 1 | 31,812.0 | −5000.0 | 26,812.0 | 26,812.0 | |

| 2 | 31,812.0 | −5155.0 | 26,657.0 | 25,148.1 | |

| 3 | 31,812.0 | −5314.8 | 26,497.2 | 23,582.4 | |

| 4 | 31,812.0 | −5479.6 | 26,332.4 | 22,109.2 | |

| 5 | 31,812.0 | −5649.4 | 26,162.6 | 20,723.2 | |

| 6 | 31,812.0 | −5824.6 | 25,987.4 | 19,419.3 | |

| 7 | 31,812.0 | −6005.1 | 25,806.9 | 18,192.8 | |

| 8 | 31,812.0 | −6191.3 | 25,620.7 | 17,039.2 | |

| 9 | 31,812.0 | −6383.2 | 25,428.8 | 15,954.3 | |

| 10 | - | −6581.1 | −6581.1 | −3895.3 | |

| … | … | … | … | … | |

| … | … | … | … | … | |

| 29 | - | −11,754.7 | −11,754.7 | −2299.6 | |

| 30 | 29,010.6 | −86,604.9 | −57,594.3 | −10,629.4 | |

| Total | 347,130.7 | −430,556.3 | −83,425.7 | 35,233.7 |

| Greenhouse Types | Years (i) | Annual Costs | Annual Incomes | Annual Cash Flow | Net Present Value (NPV) |

|---|---|---|---|---|---|

| 1 | 2 | 4 = 2 + 3 | 5 = 4/(1 + 0.06)i−1 | ||

| Concrete-walled Gobi solar greenhouse | 1 | 114,228.2 | −95,100.0 | 19,128.2 | 19,128.2 |

| 2 | 75,915.7 | −98,048.1 | −22,132.4 | −20,879.6 | |

| 3 | 82,667.4 | −101,087.6 | −18,420.2 | −16,393.9 | |

| 4 | 80,224.4 | −104,221.3 | −23,996.9 | −20,148.3 | |

| 5 | 87,311.3 | −107,452.2 | −20,140.9 | −15,953.5 | |

| … | … | … | … | … | |

| … | … | … | … | … | |

| 29 | 174,469.0 | −223,575.0 | −49,105.9 | −9606.6 | |

| 30 | 171,739.8 | −230,505.8 | −58,766.0 | −10,845.7 | |

| Total | 3,689,959.2 | −4,598,434.0 | −908,474.8 | −355,615.3 | |

| Flexible insulation-walled Gobi solar greenhouse | 1 | 118,688.8 | −95,100.0 | 23,588.8 | 23,588.8 |

| 2 | 55,959.7 | −98,048.1 | −42,088.4 | −39,706.0 | |

| 3 | 62,292.5 | −101,087.6 | −38,795.1 | −34,527.5 | |

| 4 | 59,421.5 | −104,221.3 | −44,799.8 | −37,614.8 | |

| 5 | 66,071.7 | −107,452.2 | −41,380.5 | −32,777.2 | |

| … | … | … | … | … | |

| … | … | … | … | … | |

| 29 | 139,493.6 | −223,575.0 | −84,081.4 | −16,448.9 | |

| 30 | 136,029.5 | −230,505.8 | −94,476.3 | −17,436.2 | |

| Total | 3,259,306.0 | −4,598,434.0 | −1,339,128.0 | −542,289.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Xie, J.; Ma, N.; Chang, Y.; Zhang, J.; Li, J. Energy Simulation-Driven Life-Cycle Costing of Gobi Solar Greenhouses: Stakeholder-Focused Analysis for Tomato Production. Agriculture 2025, 15, 2053. https://doi.org/10.3390/agriculture15192053

Zhang X, Xie J, Ma N, Chang Y, Zhang J, Li J. Energy Simulation-Driven Life-Cycle Costing of Gobi Solar Greenhouses: Stakeholder-Focused Analysis for Tomato Production. Agriculture. 2025; 15(19):2053. https://doi.org/10.3390/agriculture15192053

Chicago/Turabian StyleZhang, Xiaodan, Jianming Xie, Ning Ma, Youlin Chang, Jing Zhang, and Jing Li. 2025. "Energy Simulation-Driven Life-Cycle Costing of Gobi Solar Greenhouses: Stakeholder-Focused Analysis for Tomato Production" Agriculture 15, no. 19: 2053. https://doi.org/10.3390/agriculture15192053

APA StyleZhang, X., Xie, J., Ma, N., Chang, Y., Zhang, J., & Li, J. (2025). Energy Simulation-Driven Life-Cycle Costing of Gobi Solar Greenhouses: Stakeholder-Focused Analysis for Tomato Production. Agriculture, 15(19), 2053. https://doi.org/10.3390/agriculture15192053