Evaluation of Energy and Water Use Efficiencies and Economic Feasibility for a Solar-Powered FCTB Cooling System in Greenhouse Farming

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Setup

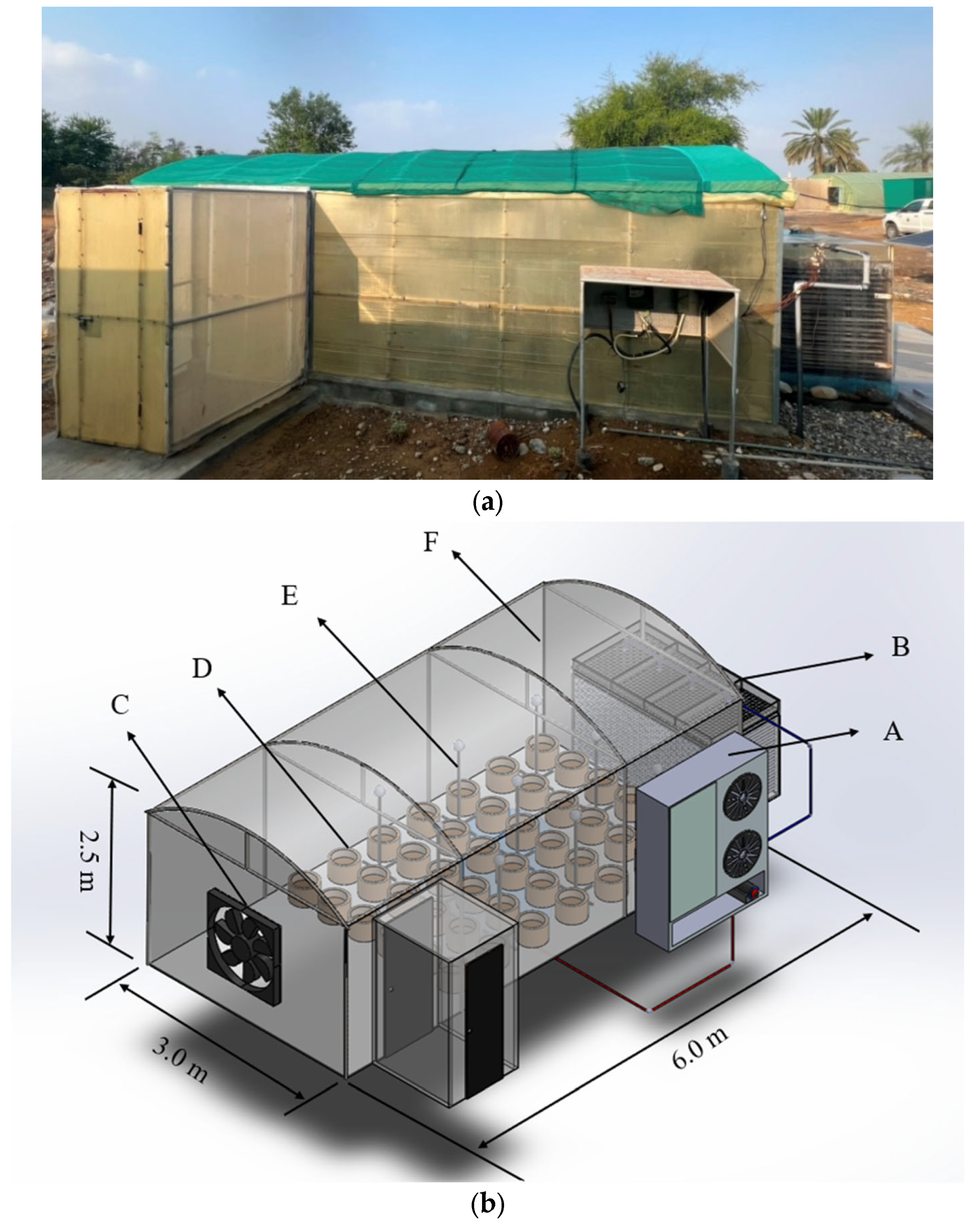

2.1.1. Greenhouse Location and Specifications

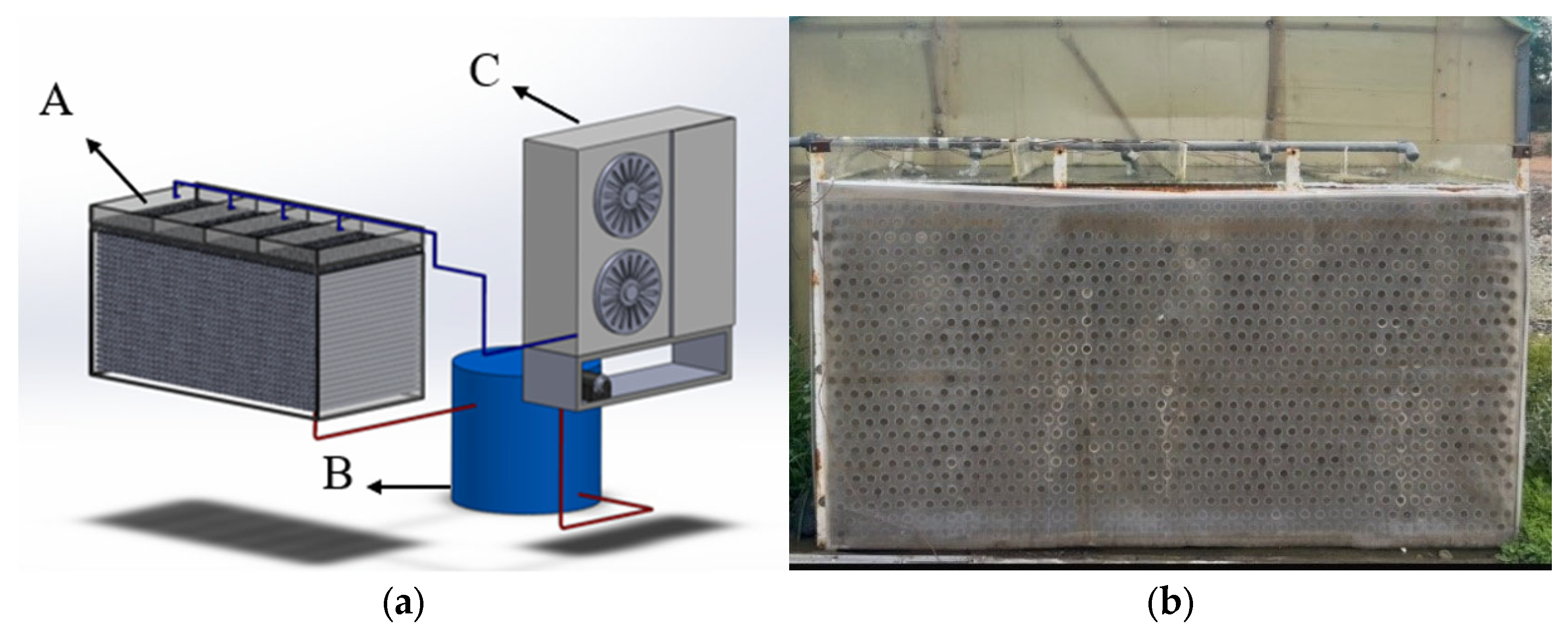

2.1.2. Greenhouse Cooling System

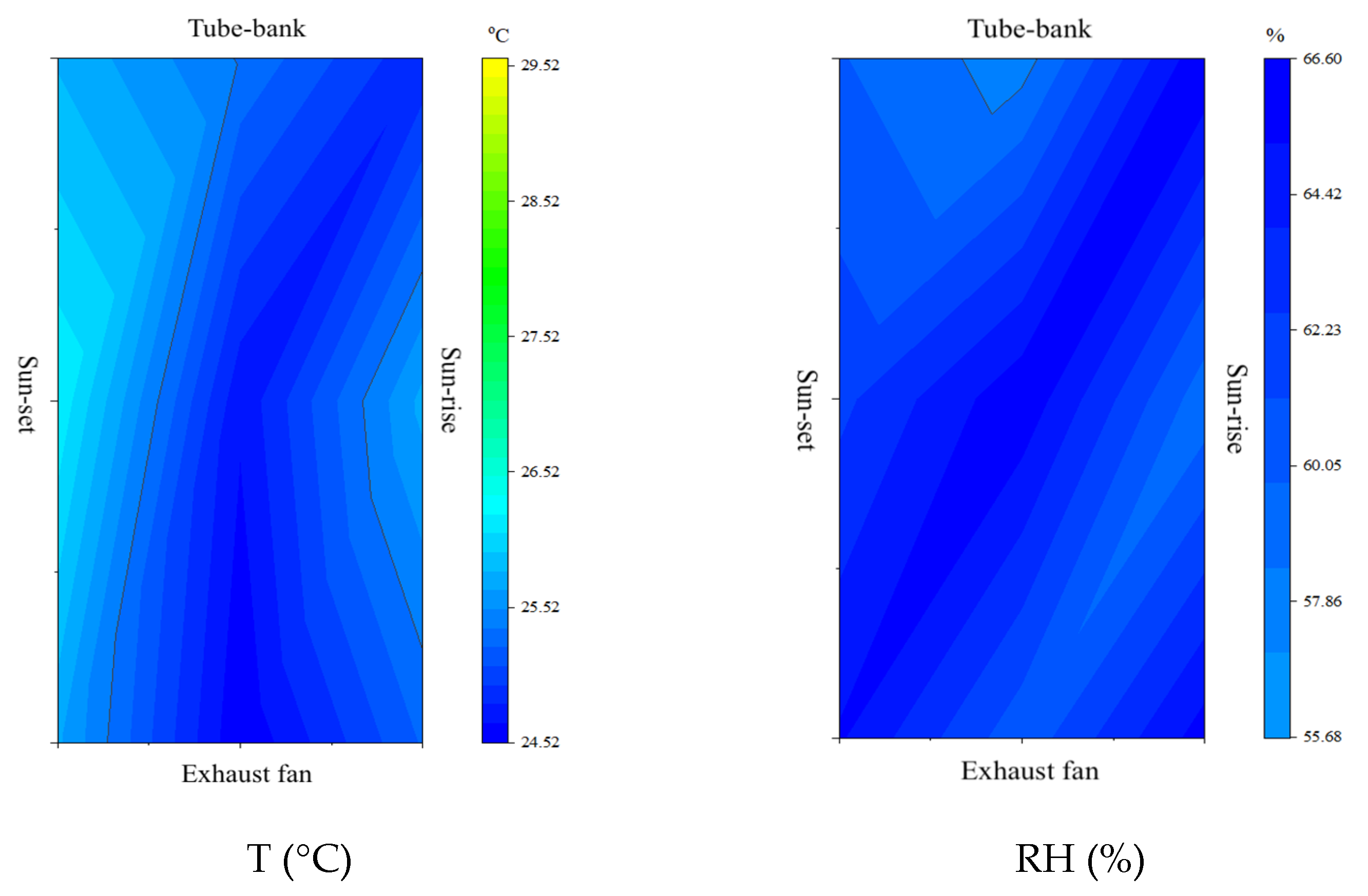

2.1.3. Sensors Arrangement and Distribution

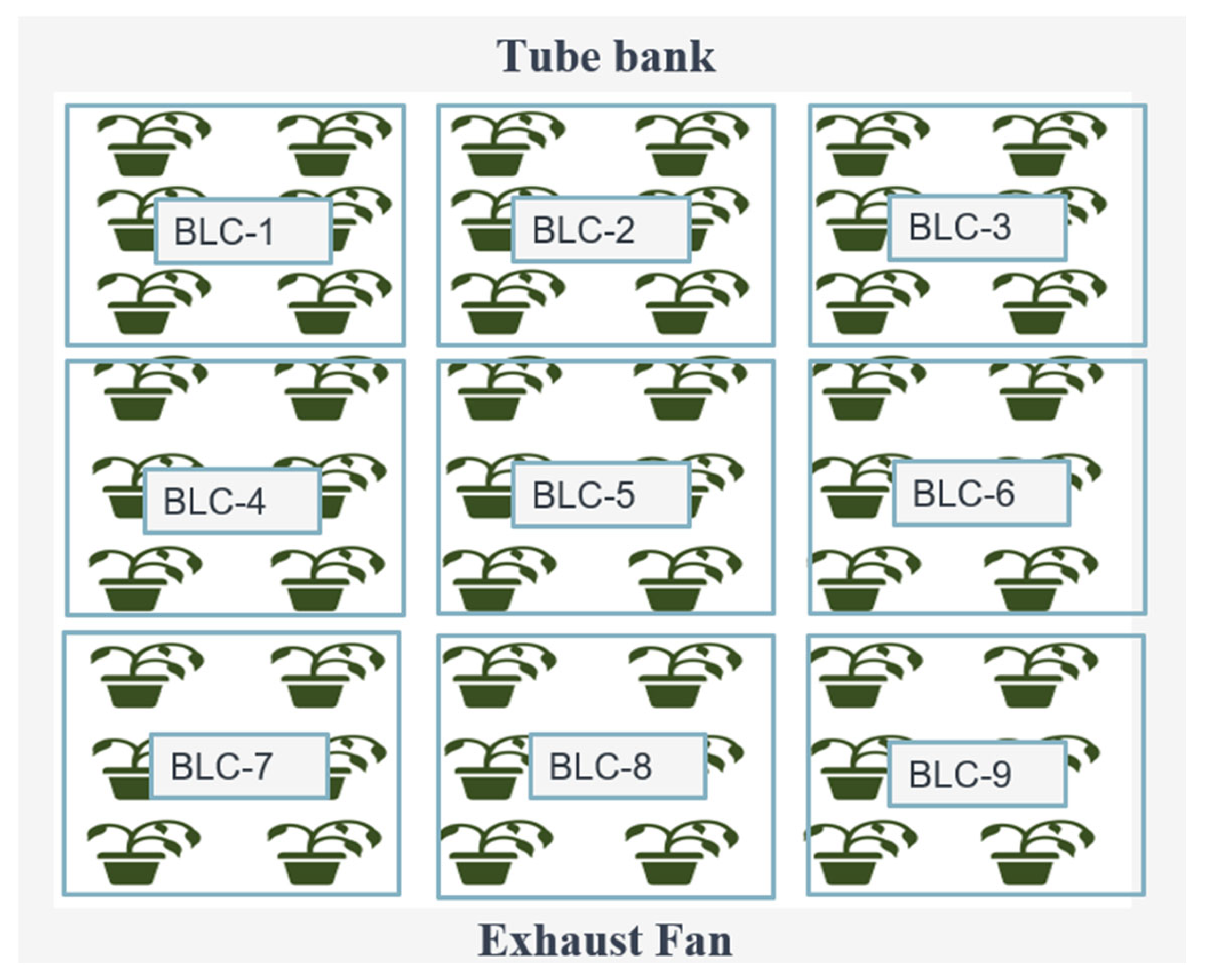

2.1.4. Greenhouse Plant Cultivation

2.2. Estimation of Energy Use Efficiency (EUE)

2.3. Estimation of Water Use Efficiency (WUE)

2.4. Greenhouse Gas (GHG) Emissions Estimation

2.5. Financial Analysis

2.6. Data Collection and Analysis

3. Results and Discussion

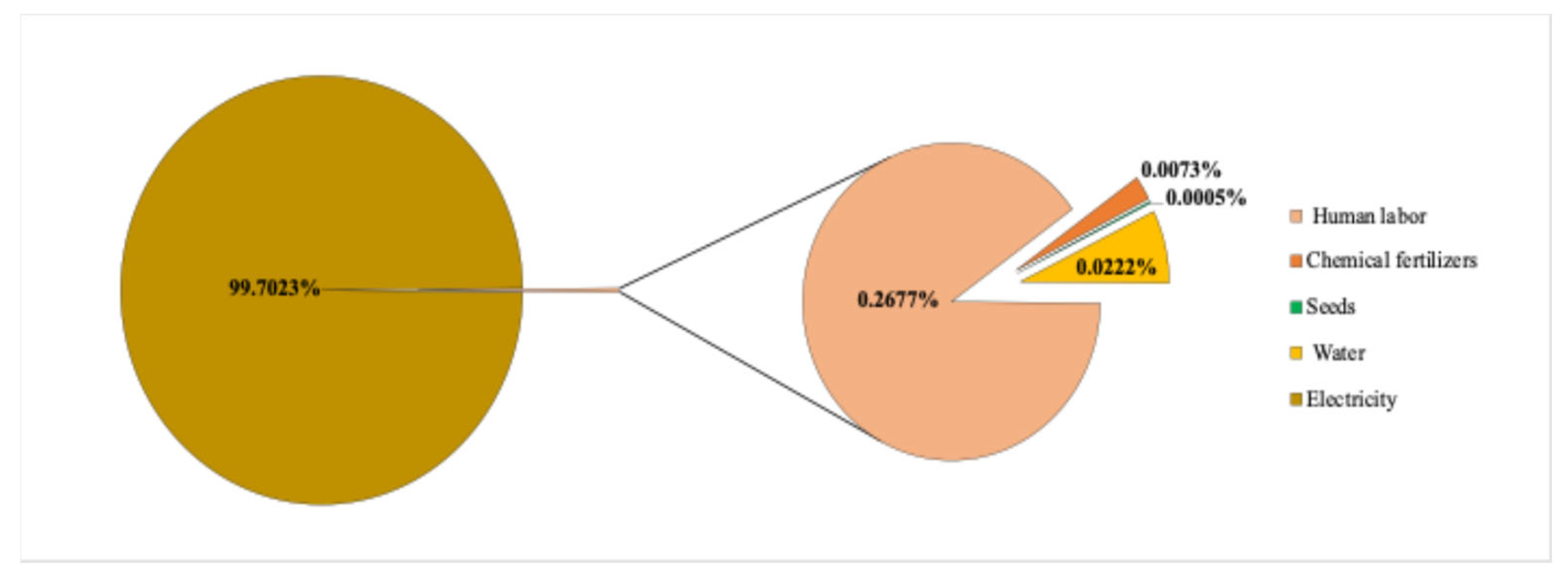

3.1. Energy Input and Output Distribution

3.1.1. Energy Inputs

3.1.2. Energy Output

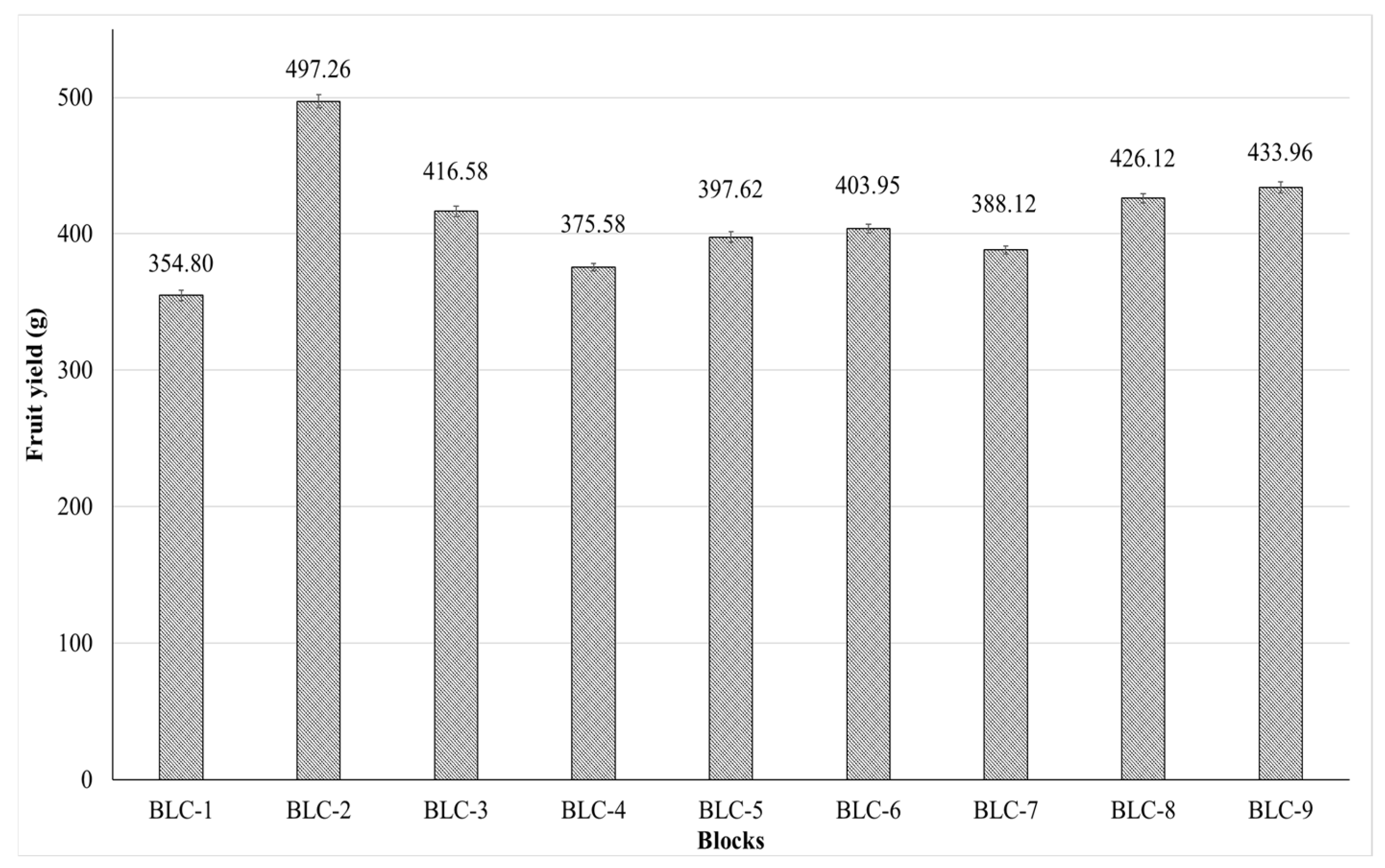

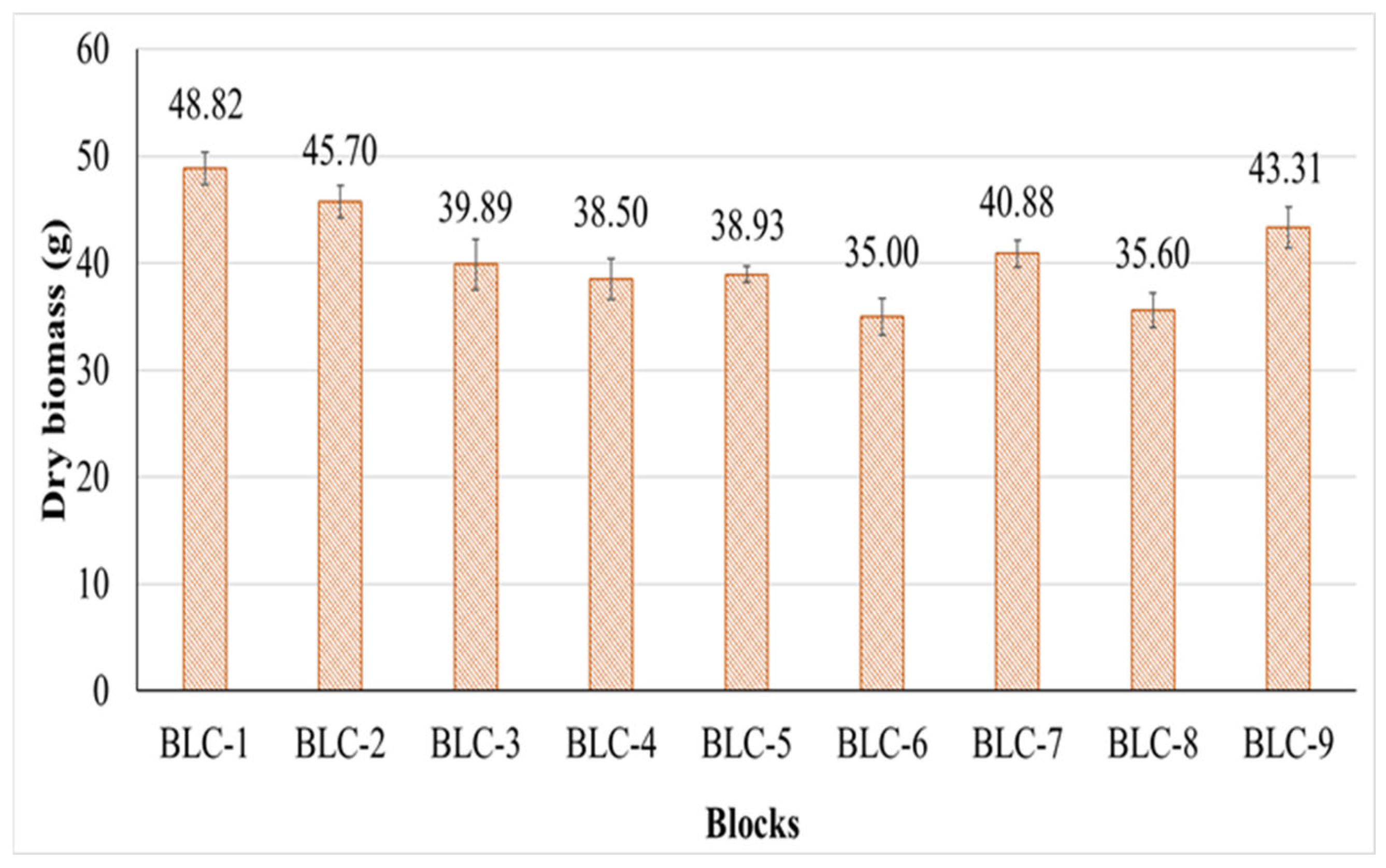

- Okra yield and biomass

- b.

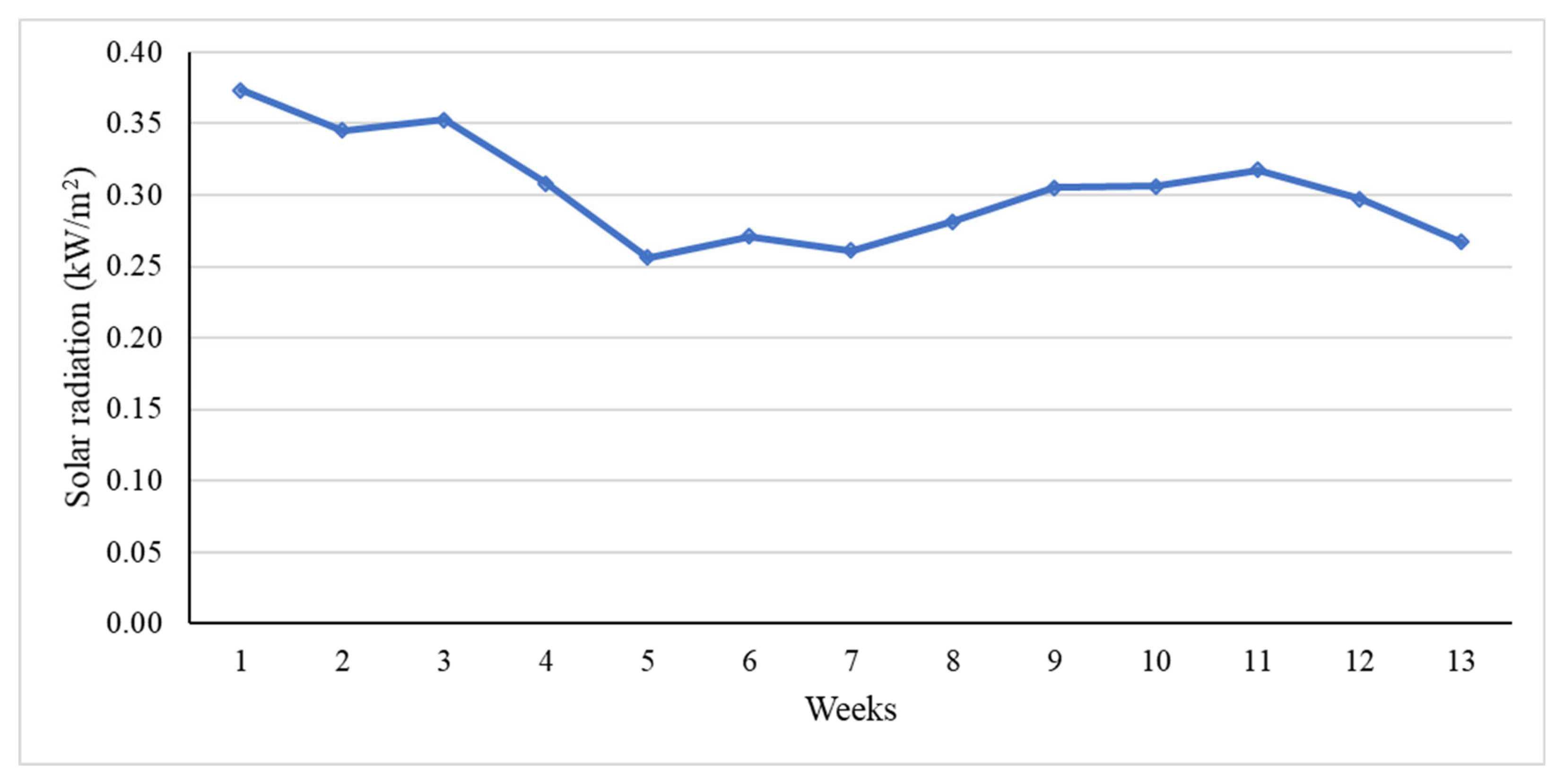

- Solar energy received

3.2. Energy Use Efficiency (EUE)

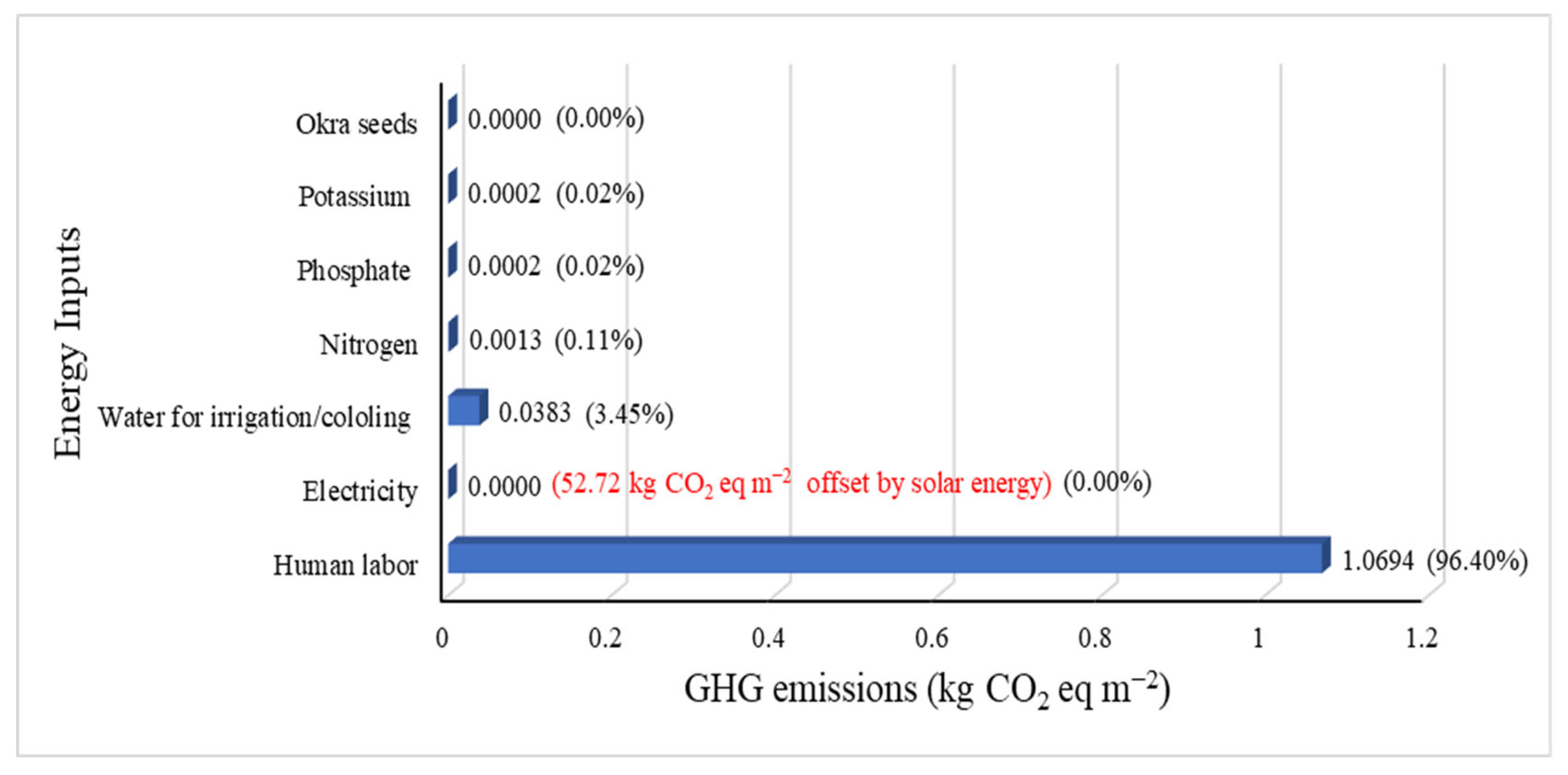

3.3. Greenhouse Gas Estimation

3.4. Water Use Efficiency (WUE)

3.5. Financial Feasibility Analysis

3.5.1. Cost–Benefit and Investment Analysis

3.5.2. Cash Flow Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| T | Temperature |

| RH | Relative humidity |

| EV | Evaporative cooling system |

| AC | Air conditioner cooling system |

| EUE | Energy use efficiency |

| WUE | Water use efficiency |

| FCTB | Fan-chiller tube bank |

| GHG | Greenhouse gas |

| GVP | Gross value of production |

| IRR | Internal rate of return |

| NPV | Net present value |

| IWUE | Irrigation water use efficiency |

| CWUE | Cooling water use efficiency |

References

- Dalai, S.; Tripathy, B.; Mohanta, S.; Sahu, B. Green-houses: Types and Structural Components. In Protected Cultivation and Smart Agriculture; New Delhi Publishers: New Delhi, India, 2020. [Google Scholar]

- Shamshiri, R.R.; Jones, J.W.; Thorp, K.R.; Ahmad, D.; Man, H.C.; Taheri, S. Review of optimum temperature, humidity, and vapour pressure deficit for microclimate evaluation and control in greenhouse cultivation of tomato: A review. Int. Agrophys. 2018, 32, 287–302. [Google Scholar]

- Iddio, E.; Wang, L.; Thomas, Y.; McMorrow, G.; Denzer, A. Energy efficient operation and modeling for greenhouses: A literature review. Renew. Sustain. Energy Rev. 2020, 117, 109480. [Google Scholar] [CrossRef]

- Soussi, M.; Chaibi, M.T.; Buchholz, M.; Saghrouni, Z. Comprehensive Review on Climate Control and Cooling Systems in Greenhouses under Hot and Arid Conditions. Agronomy 2022, 12, 626. [Google Scholar] [CrossRef]

- Singh, M.C.; Singh, J.P.; Pandey, S.K.; Mahay, D.; Shrivastva, V. Factors Affecting the Performance of Greenhouse Cucumber Cultivation-A Review. Int. J. Curr. Microbiol. Appl. Sci. 2017, 6, 2304–2323. [Google Scholar] [CrossRef]

- Ghoulem, M.; El Moueddeb, K.; Nehdi, E.; Boukhanouf, R.; Kaiser Calautit, J. Greenhouse design and cooling technologies for sustainable food cultivation in hot climates: Review of current practice and future status. Biosyst. Eng. 2019, 183, 121–150. [Google Scholar] [CrossRef]

- Al-Manthria, I.; Al-Ismailia, A.M.; Kotagamab, H.; Khanc, M.; Jeewanthad, L.H.J. Water, land, and energy use efficiencies and financial evaluation of air conditioner cooled greenhouses based on field experiments. J. Arid Land 2021, 13, 375–387. [Google Scholar] [CrossRef]

- Tabook, S.M. Evaluating the Performance of Greenhouse Cucumber Production in Barka. Master’s Thesis, Sultan Qaboos University, Muscat, Oman, 2017. [Google Scholar]

- Fadel, M.A.; Almekhmary, M.; Mousa, M. Water and Energy Use Efficiencies of Organic Tomatoes Production in a Typical Greenhouse under UAE Weather Conditions. Acta Hortic. 2014, 1054, 81–88. [Google Scholar] [CrossRef]

- Tabook, S.M.; Al-Ismaili, A.M. Evaluation of greenhouse cropping systems in Oman. Natl. Acad. Agric. Sci. 2016, 34, 715–720. [Google Scholar]

- Fan, Y.; Wang, C.; Nan, Z. Comparative evaluation of crop water use efficiency, economic analysis and net household profit simulation in arid Northwest China. Agric. Water Manag. 2014, 146, 335–345. [Google Scholar] [CrossRef]

- Al-Mezeini, N.K.; Al-Ismaili, A.M.; Tabook, S.M. Evaluation of energy use efficiency for greenhouse cucumber production in Barka, Oman. J. Agric. Mar. Sci. (JAMS) 2019, 24, 24–29. [Google Scholar]

- Sabeh, N.C.; Giacomelli, G.A.; Kubota, C. Water use in a greenhouse in a semi-arid climate. Am. Soc. Agric. Biol. Eng. 2011, 54, 1069–1077. [Google Scholar]

- Çakir, R.; Kanburoglu-Çebi, U.; Altintas, S.; Ozdemir, A. Irrigation scheduling and water use efficiency of cucumber grown as a spring-summer cycle crop in solar greenhouse. Agric. Water Manag. 2017, 180, 78–87. [Google Scholar] [CrossRef]

- Pishgar-Komleh, S.H.; Omid, M.; Heidari, M.D. On the study of energy use and GHG (greenhouse gas) emissions in greenhouse cucumber production in Yazd province. Energy 2013, 59, 63–71. [Google Scholar] [CrossRef]

- Sarkar, B.; Das, B.; Sundaram, P.K.; Mali, S.S.; Anurag, A.P.; Upadhyaya, A.; Chandra, N.; Bhatt, B.P.; Kumar, A. Energy input–output analysis and greenhouse gas emission in okra and tomato production in Chotanagpur plateau region of India. Environ. Dev. Sustain. 2023, 11, 12945–12964. [Google Scholar] [CrossRef]

- Taki, M.; Abdi, R.; Akbarpour, M.; Mobtaker, H.G. Energy inputs–yield relationship and sensitivity analysis for tomato greenhouse production in Iran. Agric. Eng. Int. CIGR J. 2013, 15, 59–67. [Google Scholar]

- Baptista, F.J.; Silva, L.L.; Murcho, D. Energy consumption and greenhouse gas emissions of zucchini (Cucurbita pepo L.) cultivated in hydroponic greenhouses in the western region of Portugal. In ISHS Acta Horticulturae 1227, Proceedings of the International Symposium on New Technologies for Environment Control, Energy-Saving and Crop Production in Greenhouse and Plant Factory—GreenSys 2017, Beijing, China, 20–24 August 2017; ISHS: Leuven, Belgium, 2018; pp. 181–188. [Google Scholar]

- Jayasuriya, H.; Al-Ismaili, A.; Al-Shukaili, T. Farming Systems in Oman and Mechanization Potentials. Agric. Mech. Asia Afr. Lat. Am. 2017, 48, 66–74. [Google Scholar]

- Benchasri, S. Okra (Abelmoschus esculentus (L.) Moench) as a valuable vegetable of the world. Ratar. Povrt. 2012, 49, 105–112. [Google Scholar]

- Morwal, B.R.; Patel, M.C. Growth and Yield of Okra (Abelmoschus esculentus L) as Affected by Date of Sowing and Spacing under north Gujarat Condition. J. Krishi Vigyan 2017, 6, 93. [Google Scholar] [CrossRef]

- Mohammadi, A.; Rafiee, S.; Jafari, A.; Keyhani, A.; Mousavi-Avval, S.H.; Nonhebel, S. Energy use efficiency and greenhouse gas emissions of farming systems in north Iran. Renew. Sustain. Energy Rev. 2014, 30, 724–733. [Google Scholar] [CrossRef]

- Hedau, N.K.; Tuti, M.D.; Stanley, J.; Mina, B.L.; Agrawal, P.K.; Bisht, J.K.; Bhatt, J.C. Energy-use efficiency and economic analysis of vegetable cropping sequences under greenhouse condition. Energy Effic. 2014, 7, 507–515. [Google Scholar]

- Houshyar, E.; Dalgaard, T.; Tarazkar, M.H.; Jørgensen, U. Energy input for tomato production what economy says, and what is good for the environment. J. Clean. Prod. 2015, 89, 99–109. [Google Scholar] [CrossRef]

- Baran, M.F.; Eren, O.; Gökdoğan, O.; Oğuz, H.I. Determination of Energy Efficiency and Greenhouse Gas (GHG) Emissions in Organic Almond Production in Turkey. Erwerbs-Obstbau 2020, 62, 341–346. [Google Scholar] [CrossRef]

- Nabavi-Pelesaraei, A.; Abdi, R.; Rafiee, S.; Mobtaker, H.G. Optimization of energy required and greenhouse gas emissions analysis for orange producers using data envelopment analysis approach. J. Clean. Prod. 2014, 65, 311–317. [Google Scholar] [CrossRef]

- Sepat, N.K.; Sepat, S.R.; Sepat, S.; Kumar, A. IPA-Under Creative Commons license 3.0 Energy use efficiency and cost analysis of tomato under greenhouse and open field production system at Nubra valley of Jammu and Kashmir. Int. J. Environ. Sci. 2013, 3, 1233–1241. [Google Scholar]

- Gaspars-Wieloch, H. Project net present value estimation under uncertainty. Cent. Eur. J. Oper. Res. 2019, 27, 179–197. [Google Scholar] [CrossRef]

- Bwire, D.; Watanabe, F.; Suzuki, S.; Suzuki, K. Improving Irrigation Water Use Efficiency and Maximizing Vegetable Yields with Drip Irrigation and Poly-Mulching: A Climate-Smart Approach. Water 2024, 16, 3458. [Google Scholar] [CrossRef]

- Harun -Or-Rashid, M.; Rahman, K.M.; Sultana, F.; Hossain, M.M.; Gazi, A.R. Greenhouse climate on production potentialities of Okra. J. Agrofor. Environ. 2018, 79–82. [Google Scholar]

- Kakade, S.R.V.; Gupta, S.N.; Patil, B.C.; Karne, S. Study of Biometric Parameters of Okra in Different Shade Net House. Int. J. Curr. Microbiol. Appl. Sci. 2018, 7, 43–53. [Google Scholar] [CrossRef]

- Chacha, J.M.; Thirumalai, M.; Mathias, N.M.; Idawa, O.K.; Chilwea, J.P.; Kilamba, C.J.; Hussy, B.D.; Rajendran, K.; Ishaq, H. Greenhouse and open-field Tomato farming. A comparison through yield and growth parameters investigated in Dar es Salaam. Innov. Agric. 2023, 6, e32876. [Google Scholar] [CrossRef]

- Prasad, R.P.; Gill, R.; Gupta, V.; Rao, R.K.; Bordoloi, P.; Ahmed, M. Recent Advances in Agricultural Science and Technology for Sustainable India. 2022. Available online: https://www.researchgate.net/publication/358021517 (accessed on 25 September 2025).

- Alhamrani, K.S.L.; Abdullah, A.A.; Taain, D.A. Effect of planting dates, soil mulching and foliar spraying calcium on the quantitative yield characteristics of okra plant grown in plastic greenhouse. Basrah J. Agric. Sci. 2019, 32, 171–182. [Google Scholar] [CrossRef]

- Poorter, H.; Bühler, J.; Van Dusschoten, D.; Climent, J.; Postma, J.A. Pot size matters: A meta-analysis of the effects of rooting volume on plant growth. Funct. Plant Biol. 2012, 39, 839–850. [Google Scholar] [CrossRef]

- Oagile, O.; Gabolemogwe, P.; Matsuane, C.; Mathowa, T. Effect of container size on the growth and development of tomato seedlings. Int. J. Curr. Microbiol. Appl. Sci. 2016, 5, 890–896. [Google Scholar] [CrossRef]

- Sansa, I.; Mrabet Bellaaj, N. Forecasting and Modelling of Solar Radiation for Photovoltaic (PV) Systems. In Solar Radiation—Measurement, Modeling and Forecasting Techniques for Photovoltaic Solar Energy Applications; IntechOpen: London, UK; Vienna, Austria, 2021. [Google Scholar]

- Elhag, M.; Boteva, S. Conceptual assessment of energy input-output analysis and data envelopment analysis of greenhouse crops in Crete Island, Greece. Environ. Sci. Pollut. Res. 2019, 26, 35377–35386. [Google Scholar] [CrossRef] [PubMed]

- Kuswardhani, N.; Soni, P.; Shivakoti, G.P. Comparative energy input-output and financial analyses of greenhouse and open field vegetables production in West Java, Indonesia. Energy 2013, 53, 83–92. [Google Scholar] [CrossRef]

- Ntinas, G.K.; Neumair, M.; Tsadilas, C.D.; Meyer, J. Carbon footprint and cumulative energy demand of greenhouse and open-field tomato cultivation systems under Southern and Central European climatic conditions. J. Clean Prod. 2017, 142, 3617–3626. [Google Scholar] [CrossRef]

- Almasraf, S.A.; Hommadi, A.H. Improving Water Use Efficiency and Water Productivity for Okra Crop by using Subsurface Water Retention Technology. J. Eng. 2018, 24, 64–74. [Google Scholar] [CrossRef]

- Ayas, S. Response of Okra (Abelmoschus Esculentus l. Yalova Akköy-41) to Different Irrigation and Fertigation Levels. Turk. J. Agric. Food Sci. Technol. 2020, 8, 2225–2235. [Google Scholar] [CrossRef]

- Tupkanloo, Z.N. Economic analysis of greenhouse cultivation of tomatoes and cucumber vegetables in Neyshabur, Iran. J. Pure Appl. Microbiol. 2015, 9, 613–616. [Google Scholar]

- Malikk, K. Economic Viability of Cucumber Cultivation in Greenhouses. Int. J. Bus. Manag. Res. 2017, 5, 1–3. [Google Scholar]

- Malik, K.; Kumar, V. Economic viability of cucumber cultivation under polyhouses in Haryana. Ann. Agri Bio Res. 2020, 25, 299–301. [Google Scholar]

- Al-Mfargy, O.K.A.; Al-Juwari, M.S.M. Estimation of Hybrid Vigor for Flowering and Yield Cherry Tomato Hybrids. IOP Conf. Ser. Earth Environ. Sci. 2023, 1158, 042066. [Google Scholar] [CrossRef]

- Badgery-Parker, J.; James, L.; Jarvis, J.; Parks, S. Commercial Greenhouse Cucumber Production; NSW Agriculture: Sydney, Australia, 2019. [Google Scholar]

- Al-Abdulkader, A.M. Financial Analysis of Greenhouse Vegetable Specialized Projects in Saudi Arabia. Acta Hortic. 2006, 710, 527–534. [Google Scholar] [CrossRef]

- Diab, Y.A.A.; Mousa, A.A.; Abbas, H.S. Greenhouse-grown Cucumber as an Alternative to Field Production and its Economic Feasibility in Aswan Governorate, Egypt. Assiut J. Agric. Sci. 2016, 47, 122–135. [Google Scholar]

- Sokar, M.A.M. Economic study Cucumber Crop production in greenhouses in new lands. Egypt. J. Agric. Econ. 2024, 9, 3. [Google Scholar]

| Inputs | Unit | Equivalent Energy (MJ·unit−1) |

|---|---|---|

| 1. Human labor | ||

| (a) Adult men | h | 1.96 |

| (b) Women | h | 1.57 |

| 2. Electricity | kWh | 11.93 |

| 3. Water for irrigation/cooling | m3 | 1.02 |

| 4. Chemical fertilizers | ||

| (a) Nitrogen | kg | 60.6 |

| (b) Phosphate (P2O5) | kg | 11.1 |

| (c) Potassium (K2O) | kg | 6.7 |

| 5. Okra seeds | kg | 25.6 |

| Output | ||

| Crop yield (okra) | kg | 1.9 |

| Leaves, vines, and straw from the vegetables | kg | 10 |

| Inputs | Unit | GHG Coefficient (kg CO2eq·unit−1) | References |

|---|---|---|---|

| 1. Human labor | h | 0.7 | [25] |

| 2. Electricity | kWh | 0.608 | [26] |

| 3. Water for irrigation | m3 | 0.17 | [25] |

| 4. Chemical fertilizers | |||

| (a) Nitrogen | kg | 1.3 | [26] |

| (b) Phosphate (P2O5) | kg | 0.2 | [26] |

| (c) Potassium (K2O) | kg | 0.2 | [26] |

| 5. Okra seeds | kg | 0.17 | [24] |

| Energy Source | Units | Quantity per Unit Area (unit m−2) | Equivalent Energy (MJ·unit−1) | Total Energy Equivalents (MJ·m−2) |

|---|---|---|---|---|

| Inputs | ||||

| 1. Human labor | ||||

| (a) Men | h | 0.97 | 1.96 | 1.91 |

| (b) Women | h | 0.56 | 1.57 | 0.87 |

| 2. Electricity | kWh | 86.71 | 11.93 | 1034.39 |

| 3. Water for irrigation/cooling | m3 | 0.23 | 1.02 | 0.23 |

| 4. Chemical fertilizers | ||||

| (a) Nitrogen | kg | 1.00 × 10−3 | 60.6 | 5.86 × 10−2 |

| (b) Phosphate (P2O5) | kg | 1.00 × 10−3 | 11.1 | 1.07 × 10−2 |

| (c) Potassium (K2O) | kg | 1.00 × 10−3 | 6.7 | 6.50 × 10−3 |

| 5. Okra seeds | kg | 2.00 × 10−4 | 25.6 | 4.70 × 10−3 |

| Total input (MJ/m2) | 1037.48 | |||

| Output | ||||

| Crop yield (okra) | kg | 0.21 | 1.90 | 0.39 |

| Leaves, vines, and straw from vegetables | kg | 0.02 | 10.00 | 0.17 |

| Solar energy received | kWh | 100.65 | 11.93 | 1200.79 |

| Total output (MJ/m2) | 1201.35 | |||

| Performance Index | Solar Powered GH |

|---|---|

| Energy use efficiency | 1.16 |

| Energy productivity (kg·MJ−1) | 2.00 × 10−4 |

| Net energy (MJ·m−2) | 163.87 |

| Units | Quantity per Unit Area (unit·m−2) | GHG Coefficient (kg CO2 eq·unit−1) | GHG Emissions (kg CO2eq·m−2) | |

|---|---|---|---|---|

| Solar energy exported to the grid | kWh | 100.65 | ||

| GHG offset for GH electricity use | kWh | 86.71 | 0.61 | 52.72 |

| Surplus solar energy (offsets emissions elsewhere) | kWh | 13.94 | 0.61 | 8.48 |

| Crop | Irrigation Water (m3) | Cooling Water (m3) | WUE (kg·m−3) | IWUE (kg·m−3) | CWUE (kg·m−3) |

|---|---|---|---|---|---|

| Okra | 1.79 | 2.27 | 0.91 | 2.07 | 1.63 |

| Item | Lifetime | Initial Investment Cost (USD) | Annualized Investment Cost (USD) |

|---|---|---|---|

| Greenhouse frame | 20 | 1664.00 | 24.18 |

| Covering material (polycarbonate) | 10 | 540.46 | 12.24 |

| Cooling system | 10 | 1560.00 | 35.33 |

| Irrigation accessories | 5 | 26.00 | 1.03 |

| Water tank | 20 | 208.00 | 3.02 |

| Irrigation pump | 5 | 39.00 | 1.54 |

| Pots | 1 | 15.60 | 2.76 |

| Solar energy system | 20 | 1212.82 | 17.62 |

| Battery-powered controller | 5 | 15.60 | 0.62 |

| Thermocouples | 5 | 52.00 | 2.06 |

| RH, T, LI sensors | 10 | 1344.56 | 30.45 |

| Total | 5281.48 | 98.33 |

| Crops | Yield (kg/Plant) | Yield (kg) | Reference |

|---|---|---|---|

| Okra * | 0.06841 | 3.694 | - |

| Okra | 0.163 | 8.802 | [30] |

| Cherry tomatoes | 4.66 | 252.64 | [46] |

| Cucumber | 15.00 | 810.00 | [47] |

| Cost and Return Components | Okra ** | Okra | Cucumber | Cherry Tomatoes |

|---|---|---|---|---|

| Total yield (kg) | 24.91 | 26.41 | 2430.00 | 754.92 |

| Price 1 (USD/kg) | 2.26 | 2.26 | 1.09 | 1.08 |

| Revenue 1 (USD) | 56.30 | 59.69 | 2648.70 | 815.31 |

| Solar energy received (kWh) | 5435.29 | 5435.29 | 5435.29 | 5435.29 |

| Price 2 (USD/kWh) | 0.05 | 0.05 | 0.05 | 0.05 |

| Revenue 2 (USD) | 271.76 | 271.76 | 271.76 | 271.76 |

| Total gross value of production (USD) | 328.06 | 331.45 | 2920.46 | 1087.07 |

| Total variable cost (USD) | 273.89 | 273.89 | 296.1 | 272.71 |

| Total fixed cost (USD) | 98.33 | 98.33 | 98.33 | 98.33 |

| Total cost of production (USD) | 372.22 | 372.22 | 394.43 | 371.04 |

| Gross return (USD) | 54.17 | 57.56 | 2624.36 | 814.36 |

| Net return (USD) | −44.16 | −40.77 | 2526.03 | 716.03 |

| Benefit to cost ratio | 0.88 | 0.89 | 7.40 | 2.93 |

| Financial productivity (yield income alone) (USD/kg) | 0.07 | 0.07 | 6.16 | 2.03 |

| Financial productivity (for both income) (USD/kg) | 0.39 | 0.39 | 6.79 | 2.71 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Ghadani, O.; Al-Shukaili, T.; Jayasuriya, H.P.; Pathare, P.B.; Al-Busaidi, A. Evaluation of Energy and Water Use Efficiencies and Economic Feasibility for a Solar-Powered FCTB Cooling System in Greenhouse Farming. Agriculture 2025, 15, 2044. https://doi.org/10.3390/agriculture15192044

Al-Ghadani O, Al-Shukaili T, Jayasuriya HP, Pathare PB, Al-Busaidi A. Evaluation of Energy and Water Use Efficiencies and Economic Feasibility for a Solar-Powered FCTB Cooling System in Greenhouse Farming. Agriculture. 2025; 15(19):2044. https://doi.org/10.3390/agriculture15192044

Chicago/Turabian StyleAl-Ghadani, Ohood, Talal Al-Shukaili, Hemanatha P. Jayasuriya, Pankaj B. Pathare, and Ahmed Al-Busaidi. 2025. "Evaluation of Energy and Water Use Efficiencies and Economic Feasibility for a Solar-Powered FCTB Cooling System in Greenhouse Farming" Agriculture 15, no. 19: 2044. https://doi.org/10.3390/agriculture15192044

APA StyleAl-Ghadani, O., Al-Shukaili, T., Jayasuriya, H. P., Pathare, P. B., & Al-Busaidi, A. (2025). Evaluation of Energy and Water Use Efficiencies and Economic Feasibility for a Solar-Powered FCTB Cooling System in Greenhouse Farming. Agriculture, 15(19), 2044. https://doi.org/10.3390/agriculture15192044