1. Introduction

Sudan, situated in northeastern Africa, receives abundant solar radiation, with average irradiance levels between 5 and 7 kWh/m

2/day. Despite this immense renewable energy potential, solar power accounts for less than 1% of the country’s total electricity generation. Access to reliable electricity remains severely limited, particularly in rural and off-grid communities, where infrastructure development has long been neglected [

1].

These energy challenges have been exacerbated by recent armed conflicts and ongoing civil unrest, which have led to the widespread destruction of national power infrastructure. Many regions have experienced the collapse of the central grid, fuel shortages, and the breakdown of essential public services. The agricultural sector—vital to rural livelihoods—has been particularly affected, with irrigation systems, grain mills, and cold storage facilities rendered inoperable due to lack of electricity.

In this context, solar photovoltaic (PV) technology presents not only a sustainable alternative to diesel generators but also a strategic opportunity for post-conflict reconstruction and rural development. Unlike fossil-fuel-based systems, PV systems are decentralized, require minimal maintenance, and can be rapidly deployed to support critical needs, including water pumping for agriculture, healthcare services, and educational facilities [

2].

However, technical feasibility alone is insufficient to realize the transformative potential of solar energy. Broader considerations—such as policy alignment, institutional support, financial accessibility, and community engagement—are essential to ensure long-term success. Energy systems must be designed with the social and economic realities of rural Sudan in mind, integrating local needs, governance structures, and capacity-building initiatives.

Given these challenges, solar energy emerges as the most viable and sustainable solution for electrification in off-grid and rural areas. Unlike diesel generators, photovoltaic (PV) systems require minimal maintenance, entail lower operational costs, and are not dependent on fuel availability. Solar energy systems can be rapidly deployed in isolated communities, offering a decentralized and resilient energy solution. Moreover, advancements in solar technology, coupled with the declining costs of PV panels and batteries, make solar power more accessible and economically attractive than ever before [

3].

To conduct a comprehensive and accurate analysis, this study utilized several software tools and datasets. MATLAB (v24b) was employed to simulate and analyze the performance of energy systems, enabling precise modeling of generation, storage, and consumption patterns. High-resolution solar radiation and meteorological data for the selected village were obtained from the Global Solar Atlas, a World Bank-developed database, to ensure realistic assessments of solar energy potential. In addition, HOMER, a professional simulation software for renewable energy systems, was used to optimize the PV system design, evaluating parameters such as efficiency, battery storage capacity, and seasonal variations in energy production. Together, these tools enabled a detailed technical and economic comparison between solar energy and diesel-generated electricity [

4,

5].

A key component of this analysis involved assessing energy consumption patterns and peak demand scenarios. MATLAB was used to generate load profiles based on estimated electricity usage for households, irrigation systems, and communal facilities. HOMER simulations provided insights into optimal PV system sizing, battery requirements, and projected energy output under various weather conditions. Meanwhile, seasonal solar data from the Global Solar Atlas was instrumental in evaluating solar energy availability throughout the year [

6].

Beyond the immediate role of solar PV, Sudan’s rapidly growing population will further intensify energy demand in the near future, requiring a diversification of renewable energy options. The country’s vast river systems, particularly the Nile and its tributaries, present a significant untapped hydropower potential. Integrating hydropower with photovoltaic systems could create a more balanced and resilient renewable energy mix that accommodates seasonal variability in solar irradiance. As noted by recent studies (Water, 2022; 14(22):3631) [

7], water resources in Africa can serve as a strategic adjunct to PV installations, allowing rural electrification strategies to evolve from single-technology projects into multi-resource solutions capable of sustaining long-term development under demographic and climatic pressures.

This study builds on these imperatives by combining a detailed techno-economic analysis of PV system deployment with a contextual understanding of the social and political landscape. Focusing on a representative village in the Shariq al-Nil region, the research evaluates solar energy not only as a technical solution but also as a pathway toward inclusive, sustainable, and resilient development in post-crisis Sudan.

The village selected as the case study site was not chosen arbitrarily but because its demographic characteristics (approximately 250 inhabitants distributed among 30 households), socio-economic profile (subsistence farming on an average of three feddans per household), and infrastructural status (complete absence of national grid connection and reliance on costly diesel generators) are broadly representative of rural communities across the Shariq al-Nil region and much of Sudan, thus ensuring that the results of this analysis do not only provide insights for one locality but also address a wider research gap concerning how photovoltaic-based electrification systems can serve as both a technical solution for electricity access and a strategic tool for agricultural recovery and post-conflict community resilience in fragile contexts.

Recent studies on centralized mini-grids in sub-Saharan Africa (e.g., El-Maaroufi et al., 2024) [

8] have shown that village-scale centralized systems can deliver significant cost savings per kWh while ensuring reliable service. By integrating these perspectives, the present study extends the applicability of its findings to both decentralized and centralized models of rural electrification.

Several previous studies have examined the feasibility and advantages of solar energy in Sudan. For instance, Babkir Ali (2018) [

9] reviews the advantages of solar energy for water pumping, emphasizes its potential to improve living conditions, and advocates for investment and implementation of these systems in rural areas. Kazem et al. (2022) [

10] utilized Polysun software to design solar-powered systems for off-grid villages, highlighting their economic viability in areas with abundant sunlight. Osman (2020) [

1] conducted a comparative study using the Global Solar Atlas and MATLAB, concluding that solar PV systems significantly reduce energy costs and dependence on fuel.

Further research by Khan et al. (2021) [

11] confirmed that integrating wind energy in rural areas enhances the reliability of power supply for agricultural applications in Sudan. (Osman, 2023) [

1] emphasized the role of solar energy in strengthening energy security and supporting sustainable development in rural communities, while the subsequent work demonstrated the long-term financial advantages of PV systems despite their higher initial investment costs.

Additional studies, such as those by Omer, A. M. (2007) [

12], highlight the limited electricity access in rural Sudan and emphasize the country’s significant solar and wind potential as a foundation for expanding renewable energy technologies to meet basic energy needs. Abdeen, A., 2019 [

13], assessed the feasibility of supplying a small Sudanese town with an integrated renewable energy system, demonstrating localized solutions using solar PV and anaerobic digestion, and Ahmed et al. (2023) [

14] highlight the importance of implementing de-risking policies to promote the adoption of grid-connected rooftop solar PV systems in Sudan, aiming to provide affordable electricity and enhance energy security. Similar techno-economic assessments of PV-based rural electrification systems have been conducted in Morocco [El-Maaroufi et al., 2024] [

15], Egypt, and Algeria, where studies confirmed the cost-effectiveness and environmental benefits of hybrid PV-diesel systems for off-grid communities. These regional examples reinforce the relevance of our study in Sudan.

Collectively, these studies highlight the pivotal role solar energy can play in overcoming Sudan’s rural electrification challenges and advancing sustainable development. However, the significance of this research lies in its focused comparative analysis of solar PV and diesel generators for a specific rural Sudanese village. By leveraging advanced tools such as MATLAB, HOMER, and the Global Solar Atlas, this study delivers a detailed assessment of technical feasibility, economic efficiency, and environmental impact. Its findings aim to guide stakeholders in adopting more sustainable, affordable, and reliable energy solutions tailored to the needs of Sudan’s off-grid communities [

12].

The Role of Solar Energy in Reviving Agriculture and Ensuring Food Security in Sudan

Sudan is fundamentally an agricultural nation, endowed with vast tracts of arable land and favorable climatic conditions. Historically referred to as the “breadbasket of the Arab world” and the “food basket of Africa,” Sudan possesses the natural potential to contribute significantly to regional and global food security. Numerous studies have affirmed that with the right infrastructure and policy support, Sudan could become a leading exporter of agricultural products. However, decades of political instability and, more recently, the escalation of armed conflict have severely damaged the country’s agricultural backbone [

14].

Sudan’s prolonged internal conflict has severely damaged its national infrastructure, particularly in the energy and agricultural sectors. The destruction of the national electricity grid, widespread fuel shortages, and the collapse of transportation networks have left many rural areas in complete darkness. These conditions have paralyzed agricultural activities, as diesel-powered irrigation systems, cold storage facilities, and agricultural processing units have become inoperable. For a country where over 60% of the population depends on farming for their livelihoods, the inability to sustain agricultural operations presents a critical threat to both food security and economic stability [

15].

- 2.

Solar Energy as a Tool for Agricultural Recovery

In the face of widespread infrastructure destruction, solar energy emerges as a viable and immediate solution for reviving agriculture in rural Sudan. Photovoltaic (PV) systems can be deployed rapidly and independently of the central grid, making them ideal for off-grid communities. Solar-powered water pumps, for example, can restore irrigation to idle farmlands, while PV-driven cold storage can reduce post-harvest losses. Given Sudan’s high solar irradiance, solar energy systems can support continuous agricultural activity year-round. This decentralized and renewable energy source can help restart food production, improve self-sufficiency, and reduce reliance on imported fuel.

- 3.

The Agricultural Significance of Sudan and Global Food Security

Sudan is one of the most agriculturally endowed countries in Africa, often referred to as the “food basket of the Arab world.” Its fertile land and extensive river systems offer immense potential for large-scale food production. However, this potential remains untapped due to energy poverty, policy instability, and conflict-related destruction. By harnessing solar energy to restore agricultural systems, Sudan can not only feed its own population but also contribute to regional and global food security. Reinvesting in agriculture through renewable energy is thus not only a national priority but also a strategic opportunity for the broader region [

16].

- 4.

Policy and Community-Based Frameworks for Scalable Solar Deployment

While technical feasibility is a critical first step, scalable solar energy deployment in rural Sudan requires integrated policy and implementation strategies. This includes designing community-based ownership models, establishing financial support mechanisms for low-income farmers, and building local capacity for system maintenance and management. Government support and international development partnerships must align to ensure affordability, sustainability, and inclusiveness. By embedding solar projects within broader rural development and reconstruction policies, their long-term success and adoption can be significantly enhanced [

1].

- 5.

Solar Energy and Post-Conflict Sustainable Development

In post-conflict contexts, energy access is foundational to rebuilding communities. Solar energy offers a clean, affordable, and resilient alternative that can be tailored to the specific needs of rural populations. By supporting essential services such as healthcare, education, and agriculture, solar solutions can contribute directly to peacebuilding and economic recovery. More importantly, they empower local communities to participate in their own development, fostering a sense of ownership and resilience. For Sudan, solar energy is not just a power solution—it is a pathway toward inclusive and sustainable reconstruction.

4. Determining the Size of the Solar Array and Designing the System

Designing a photovoltaic (PV) system involves careful planning and equipment selection based on factors such as location, solar radiation, and energy storage needs. In off-grid regions of Sudan, all electricity must be produced and stored locally to ensure a stable supply, especially during the night or cloudy periods. Therefore, the system must be sized to handle maximum demand during times of minimal solar generation. Proper system sizing establishes the required voltage and current ratings for each component, accounting for installation and operational costs [

21].

Key Factors Influencing System Sizing

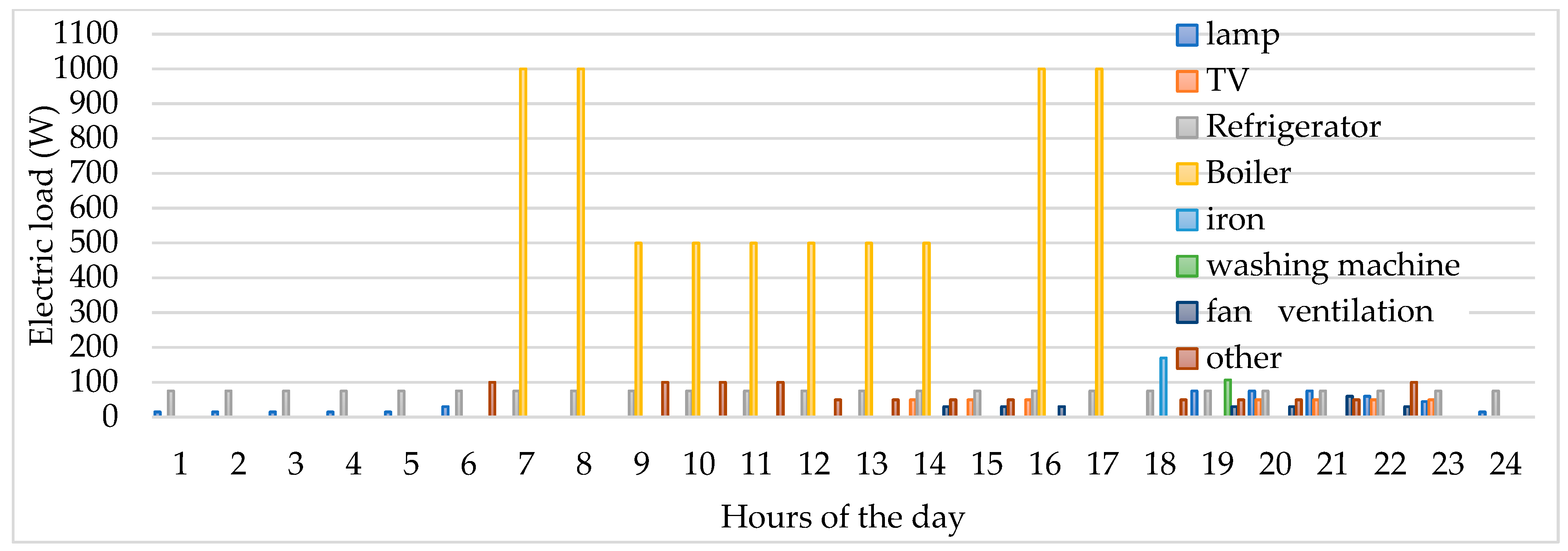

Load Profile: Determined by listing all household appliances and their daily usage in watt-hours.

Panel Positioning: Affects tilt angle, orientation, and daily solar exposure.

Home Design: Optimizing sunlight exposure by clearing the southern side, orienting windows southward, and using good insulation reduces energy loss.

Energy Efficiency: Using low-consumption appliances such as CFLs helps minimize energy needs. Cooking and water heating can be handled separately using gas or thermal systems.

Appliance Type: Choosing low-voltage DC appliances reduces system cost and minimizes the need for high-rated inverters.

Startup Loads: High-surge appliances like refrigerators and pumps require special consideration due to their high initial current draw [

22].

Solar Array Dimensioning

Calculate the average number of hours in the sun each day (Tmin) and the amount of energy used each day in Watt-hours (E) before designing the array. To determine losses and acquire the necessary energy, as well as to avoid under-sizing, divide the total daily power consumption in watt-hours by the product of all individual efficiencies within the system.

Divide the preceding value by the mean number and calculate the maximum available power by multiplying the number of sunlight hours per day for the geographical region by Tmin [

5].

To find the total required current, simply divide the maximum power by the system’s DC voltage.

To get the required voltage and current, units should be linked in series and parallel as needed. Use the following formula: Divide the total DC voltage of the system by the rated voltage (

) of each individual module to calculate the number of series modules.

Ultimately, the sum of the series and parallel modules equals the overall number of modules,

The PV module chosen in this study is a monocrystalline photovoltaic solar panel Longi LNGLR4-72HPH-455M, 144 cells, 455 W455M north sydny. It has 144 monocrystalline cells (6 × 24) and provides a maximum output of 455 watts. The panel has a high power conversion efficiency of approx. 20.9%, with very little energy loss. LNGLR4-72HPH-455M has a very big advantage compared to other photovoltaic panels, and this consists in the fact that it minimizes the impact of microcracks, showing a high tolerance to shading. The innovative technology offers superior performance and low radiation on mornings, evenings, and overcast days [

6,

7]. The snow and wind load values (5400 Pa for snow and 2400 Pa for wind) were obtained from the official technical datasheet of the Longi LNGLR4-72HPH-455M PV panel. These values are based on standardized test conditions and not calculated manually.

The panel is 209.4 cm × 103.8 cm × 3.5 cm, Also, the panel helps to increase energy production, increasing the general effectiveness of the PV system. The load borne for the snow is quite important, namely 5400 Pa (on the front of the panel), and the wind load is up to 2400 Pa (behind the panel). The degree of protection is guaranteed by the IP 68 standard, the panel being resistant to adverse weather conditions, such as water and dust. The frame of the panel is made of anodized aluminum, and the surface of 3.2 mm tempered glass. The dimensions are 209.4 × 103.8 × 3.5 cm.

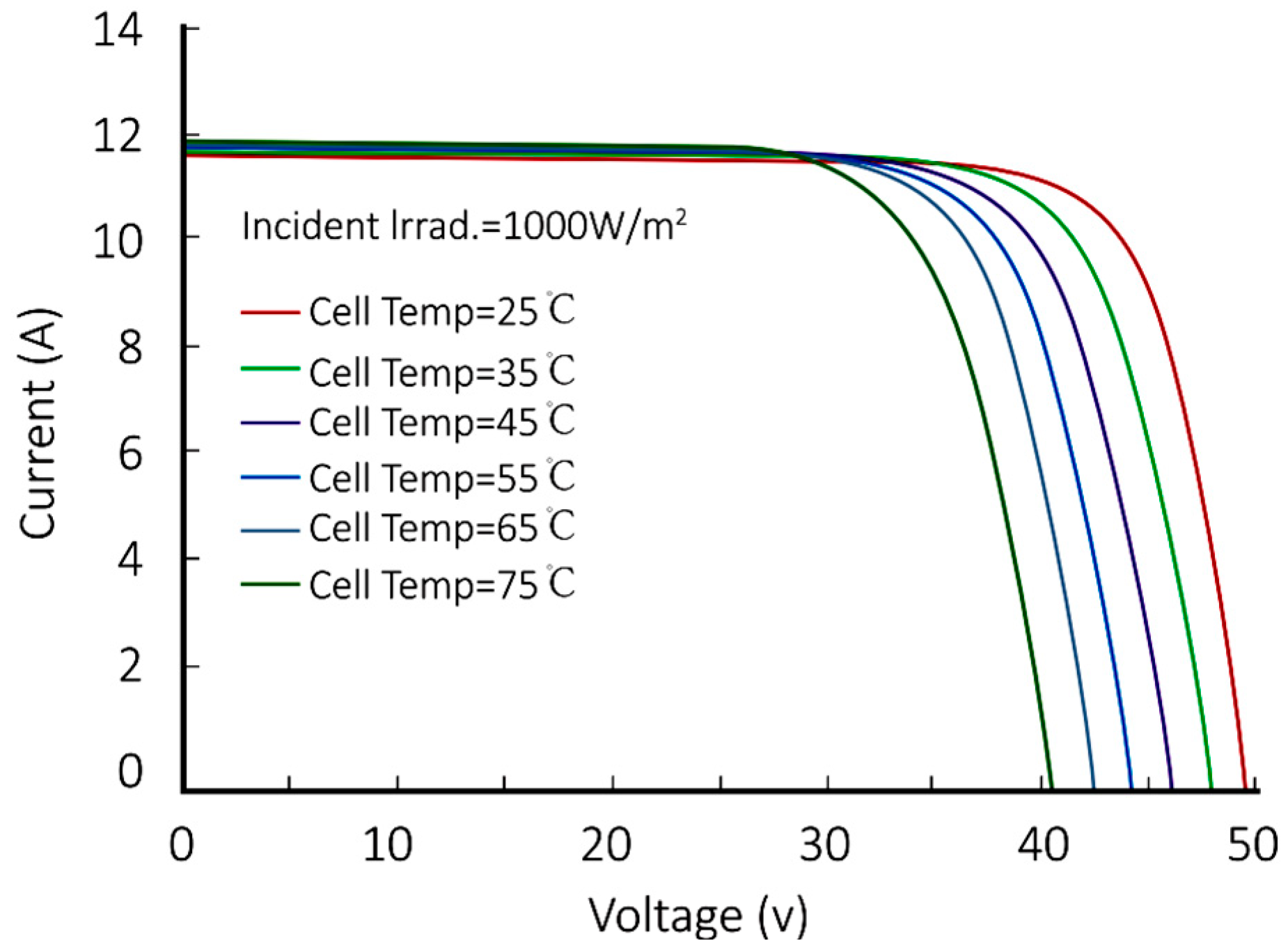

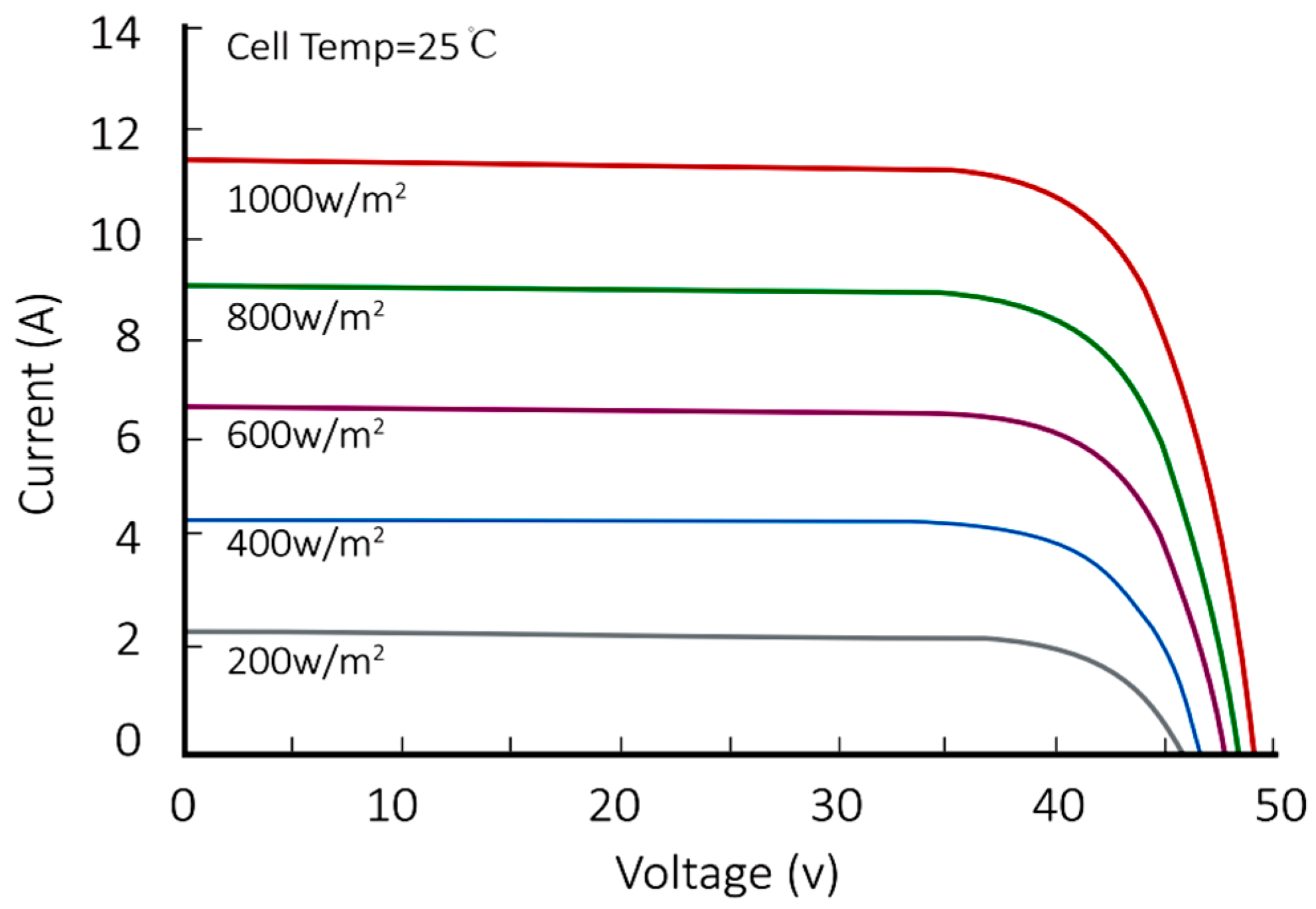

A current–voltage (I-V) curve is a graphical representation of the relationship between the current passing through the panel and the voltage applied across it.

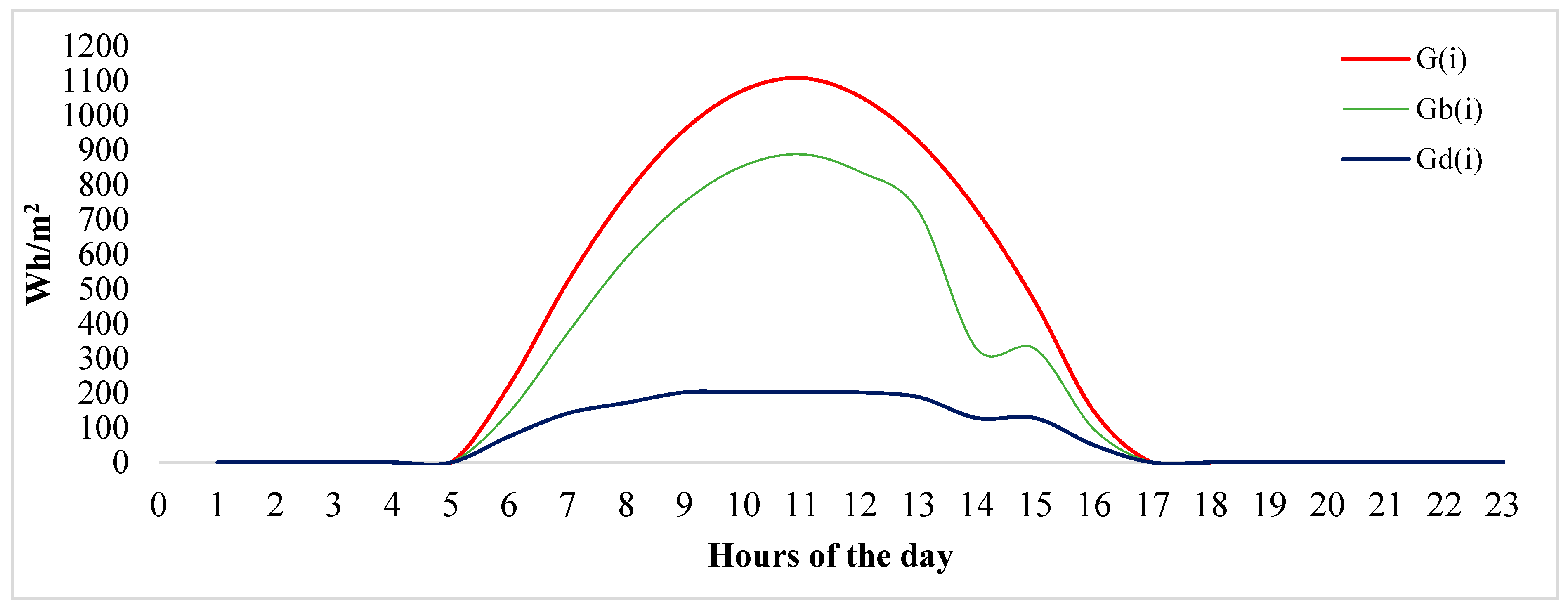

Figure 5 depicts a specific I-V curve relevant to a system under different temperature [

23].

Figure 6 depicts the current–voltage (I-V) curve of a solar cell under different solar radiations. This curve is crucial in understanding the behavior and performance of solar cells under different operating conditions.

Table 6 represent the electrical and mechanical characteristics of the panel.

Standard Test and Operating Conditions:

Under Standard Test Conditions (STCs), the panel operates at an irradiance of 1000 W/m2, with a cell temperature of 25 °C, and solar spectrum measured at AM1.5. Under Normal Operating Cell Temperature (NOCT), irradiance is 800 W/m2, ambient temperature is 20 °C, and the spectrum remains at AM1.5, with a wind speed of 1 m/s.

Panel Construction and Cable Specifications:

The module features a 4 mm2 output cable, 1400 mm in length. Its frame is built from anodized aluminum alloy, while the front surface is made of 3.2 mm tempered glass. The panel operates within a temperature range of −40 °C to +85 °C and weighs 23.5 kg.

Panel Quantity and Cost:

Using the Longi LR4-72HPH-455M model (455 W, 144 cells), each building requires eight panels. For 33 buildings (30 houses, a clinic, a supermarket, and public lighting), the total number of panels is 264. At a cost of USD 100 per panel, the total investment in PV panels is approximately USD 26,000.

Battery Bank Sizing:

The required battery storage capacity is calculated by multiplying the total daily energy consumption by the number of autonomy days (days without solar production). The result is then divided by the maximum allowable depth of discharge to ensure safe and efficient battery operation.

To determine the nominal voltage (

) of each battery to be used in the battery bank, we consider the required safe energy storage. This can be achieved by dividing the necessary safe energy storage by the DC voltage of one of the chosen batteries, resulting in the required capacity of the battery bank in ampere-hours (

) [

9]

Once the capacity of the battery bank has been determined, the capacity (

) of each individual battery within the bank needs to be established. Based on the battery voltage rating and system requirements, the battery bank is constructed by connecting batteries in both series and parallel configurations [

24]. To calculate the total number of batteries required, the capacity of the battery bank (

) in ampere-hours is divided by the capacity of one of the selected batteries (

):

At that point, it is simple to ascertain the battery bank’s arrangement [

10]. The rating of the voltage of one selected battery is subtracted by the system’s DC voltage to obtain the number of batteries

linked in series:

The number of parallel paths

is then calculated by dividing the total number of batteries by the number of batteries connected in sequence [

11].

We will move on to the next system component as soon as the bank’s battery size is known.

According to the system, the battery size is approximately 80,000/12 V = 6600 Ah. In this system we can use 100 Ah. Number of batteries = 66.

Lithium Battery 12 V, 100 Ah Storage Box Case Organizer Apply for Energy Solar, off grid, RV, etc. [

12]. One battery costs USD 75, making the total cost of the purchase USD 5000.

Sizing of the Voltage Regulator

Its job is to control the flow of the current. The highest current of the arrays and the maximum current of the load must both be tolerated by an effective voltage regulator [

13]. A safety factor

can be used to double the short-circuit current of the parallel modules. The rated current I of the voltage controller is the outcome:

where

Np is the number of parallel modules,

is the short-circuit current of an individual module, and

is The safety factor is utilized to guarantee that the regulator can handle the highest current produced by the array, which could surpass the calculated amount. It also allows for the addition of new equipment or a larger load current than originally anticipated. This safety factor essentially permits a little system growth [

25].

Sizing of the Inverter

Figuring out how much power the appliances that will be operating simultaneously actually need is a crucial first step in sizing the inverter [

14]. Secondly, it is necessary to multiply the rated power of large motors by a factor of three to account for their high starting (inrush) current requirements. The two preceding numbers are then added together and multiplied by 1.25 as a safety precaution to allow for system growth [

15].

Based on the load, a solar hybrid inverter with an output power of 800 W in each building is deemed suitable. The cost of each inverter is USD 100, and 33 inverters cost USD 3300 in total. The technical specifications of the inverter are shown in

Table 7.

Table 7 outlines the technical specifications of the solar hybrid inverter (Model No. VG1012), featuring key attributes such as rated power, voltage, frequency, efficiency, input/output protection, and various alarm indicators.

Diesel Generator Group

The same life cycle cost analysis is used to determine the cost of 80 kWh generated considering the following remarks:

- -

It is necessary to use five separate diesel units, one as a backup, which increases the kWh cost of diesel [

16]. At the same time, due to the minimum practical size for small loads, diesel generators are often oversized, as in our case. This oversizing leads to low utilization of the diesel generators, which, combined with the frequent need for spare parts and overhauls, resulting in increased maintenance and repair costs [

26].

The five diesel units consists of 2 × 5 kW + 3 × 20 kW = 70 kW total capacity

5 kW diesel generator

Soundproof single-phase diesel generator 5 kW, 18 A, 3000 rpm, engine YD186FAG, Stager YDE7000TD.

20 kW diesel generator

Table 8 shows the technical specifications of the 20 kW diesel generator, priced at USD 10,000 per unit, detailing its rated power and fuel type as diesel. When considering the total cost for five generators, including the cost of diesel, the sum amounts to USD 34,000 [

27].

System Components Summary

The equipment needed to construct the standalone photovoltaic system for the hypothetical distant home mentioned above is included in

Table 9, together with certain specs and details. This is not the only equipment on the market, and there are many manufacturers who sell them.

The cost of USD 100 per PV panel and per inverter reflects bulk purchase estimated from regional suppliers in Sudan and does not include installation or soft costs such as transport, labor, and maintenance. These costs were intentionally excluded to isolate capital equipment cost for comparative analysis. Price data was obtained from local vendor quotations collected in 2023. This means that equipment ratings and prices will differ. However, to achieve optimal performance, equipment ratings, quality, and prices are used to select this equipment.

Cost estimate of the system

The equipment used in the system costs a total of USD 34,300 for PV and USD 34,000 for diesel. Additional costs must be added for design, labor, wiring, metering, monitoring, disconnect devices, and shipment, this additional expense is estimated to cost 4000 USD on diesel.

5. System Design and Simulation

The proposed system includes solar panels, inverters, and supporting components designed to convert solar energy into usable electricity for the village. The system’s size is based on local energy demand, available solar radiation, and other design considerations.

Panel positioning and orientation represent a decisive factor in the performance of photovoltaic systems. Fixed installations can be oriented along a north–south or east–west axis, each offering different trade-offs in terms of energy yield across the day. East–west layouts, for instance, may better distribute energy production across morning and evening demand peaks, while north–south configurations tend to maximize total annual energy capture. Beyond fixed orientations, solar tracking technologies have emerged as innovative solutions to further enhance efficiency. Single-axis trackers allow panels to follow the sun’s daily trajectory, while dual-axis trackers adjust to both daily and seasonal variations in solar angles. Although trackers increase system cost and require additional maintenance, studies have shown that they can improve energy yields by up to 30% under certain conditions (Energies, 2024, 17(1), 265) [

26]. In the rural Sudanese context, such improvements could play a decisive role in ensuring reliable energy availability for irrigation, refrigeration, and medical services.

5.1. Battery Backup

The battery bank stores excess solar energy, ensuring a steady power supply during the night or cloudy conditions. It also serves as a backup during outages. Its capacity is determined by daily energy needs, surplus solar generation, and the desired level of energy autonomy [

28].

5.2. Auto-Sizing Diesel Generator

An auto-sizing diesel generator is included to meet the demand when solar output is insufficient. It adjusts its output based on the system’s needs, improving efficiency and reducing fuel use. Generator sizing is based on the energy gap not covered by the PV system.

5.3. Hybrid System Optimization Using HOMER

HOMER software, developed by NREL, is used to design and optimize hybrid systems combining solar and diesel power. While solar panels provide clean energy during the day, diesel generators ensure reliability at night or in poor weather. HOMER helps balance performance, cost, and energy availability to create a reliable and sustainable system.

Figure 7 illustrates the overall system design [

29].

Using Homer, we can create a detailed model of our village’s power system and optimize it to provide reliable and cost-effective electricity. With this information, we can make informed decisions about the best way to power our village and ensure that it has access to electricity around the clock.

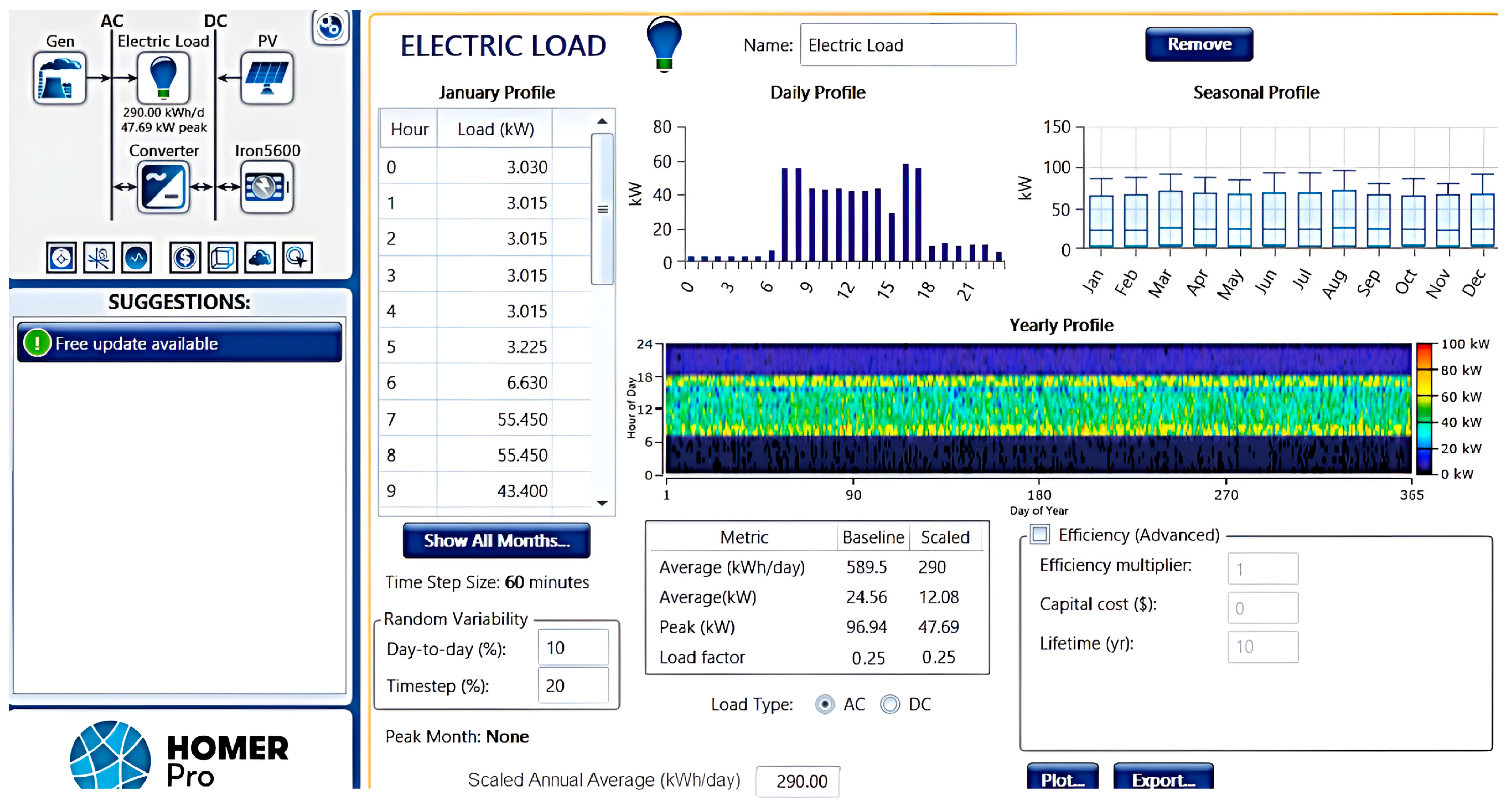

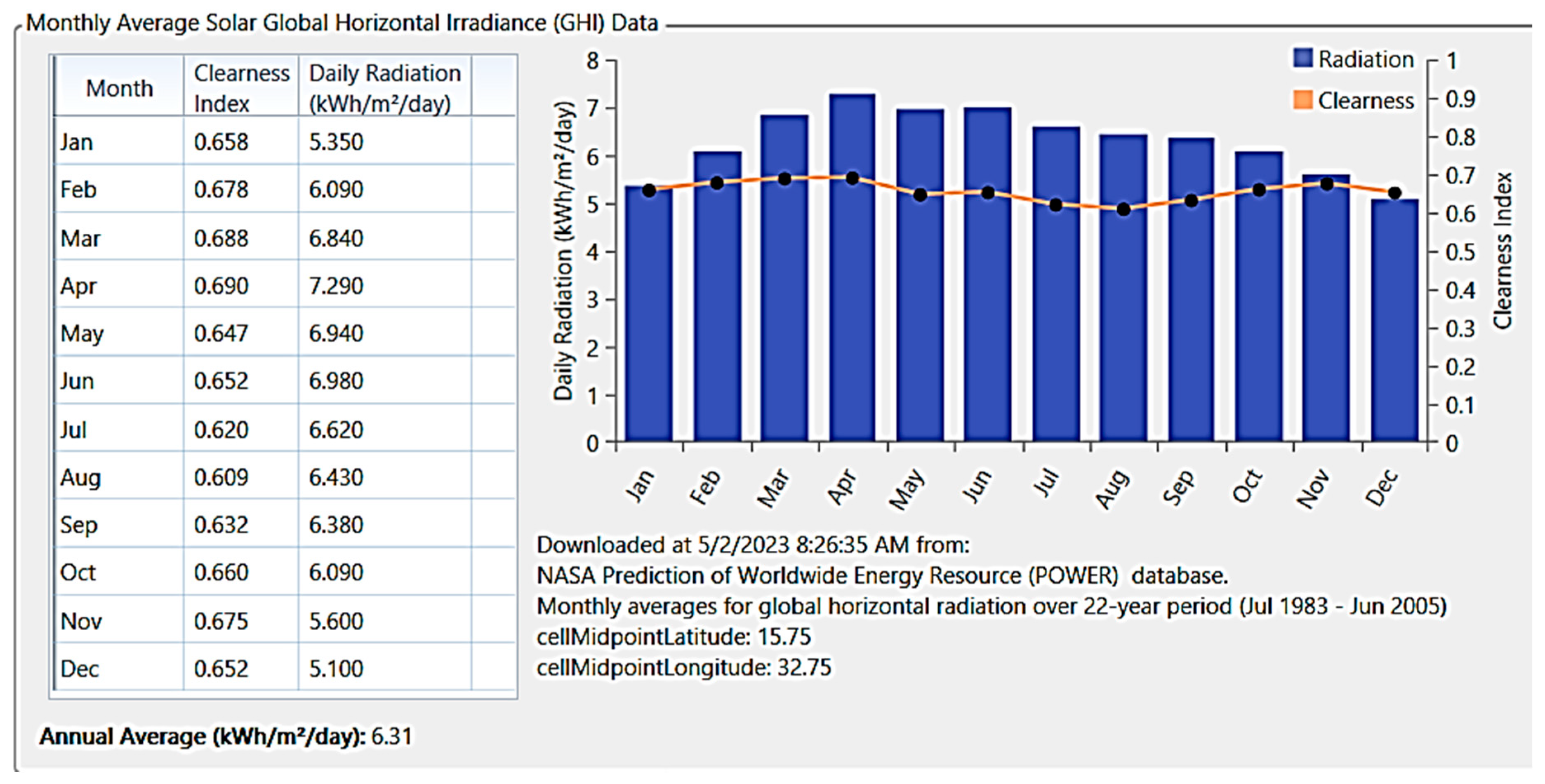

Figure 8 presents the monthly average solar global horizontal irradiation data. This data provides insights into the amount of solar radiation received on a horizontal surface over the course of each month. The values are typically measured in units (kWh/m

2/day).

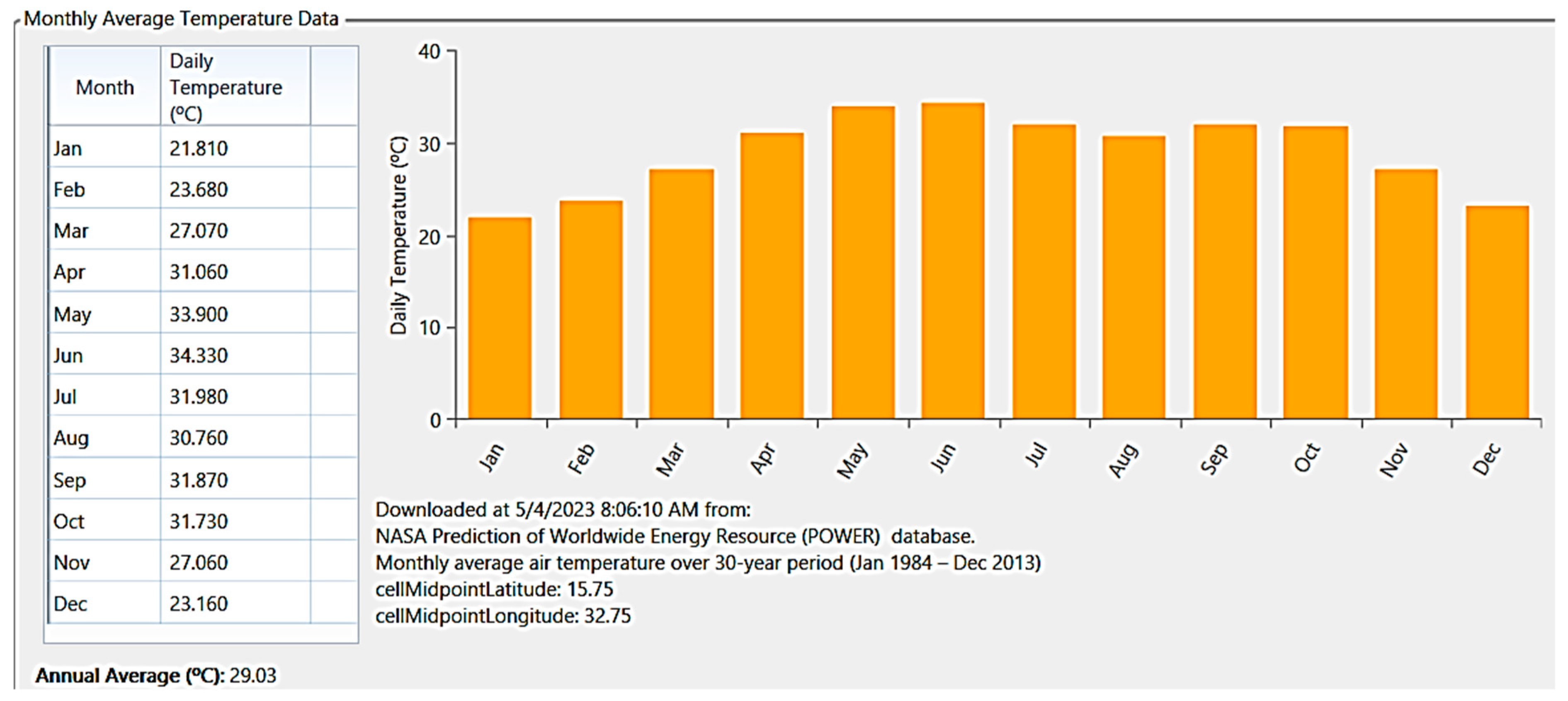

Figure 9 presents the monthly average temperature data. This data provides insights into the average temperature recorded for each month over a certain period, typically measured in degrees Celsius.

The software has simulated and optimized the five different configurations of the hybrid power system that are designed.

5.4. The First Configuration

In this configuration, solar panels generate daytime electricity for the village and charge batteries. At night, batteries power lights and appliances. With a COE of USD 0.673 per kWh and an NPC of USD 1.58 million, the system prioritizes sustainability by emitting no carbon. While the COE is relatively high, the NPC suggests a significant upfront investment, potentially leading to long-term cost-effectiveness. Striking a balance between financial viability and environmental impact is essential for a reliable and cost-effective power solution [

17].

Figure 10 displays the outcomes of a simulation conducted on the converter, likely showcasing various performance metrics, efficiency levels, and other relevant data obtained through the simulation process. Displays the outcomes of a simulation conducted on the converter, showcasing various performance metrics, efficiency levels, and other relevant data obtained through the simulation process [

30].

Based on the results provided in

Table 10 and

Figure 9 we can conclude the following:

Capacity: The capacity of both the inverter and rectifier is 35 kW. This indicates the maximum power they can handle.

Mean output: The mean output of the inverter is 11.8 kW, while the rectifier does not provide any output.

Minimum output: Both the inverter and rectifier show a minimum output of 0 kW.

Maximum output: The inverter’s maximum output is 35.5 kW, while the rectifier still shows 0 kW. The inverter can generate up to its maximum capacity.

Energy in: The energy input is given as 109.172 kWh per year. It indicates the amount of energy consumed by the system, possibly in the form of electricity supplied to the inverter and rectifier.

Energy out: The energy output is mentioned as 103.713 kWh per year; it represents the amount of energy produced or delivered by the system.

Hours of operation: The system appears to operate 8629 h per year. This indicates the total duration of operation for both the inverter and rectifier [

31].

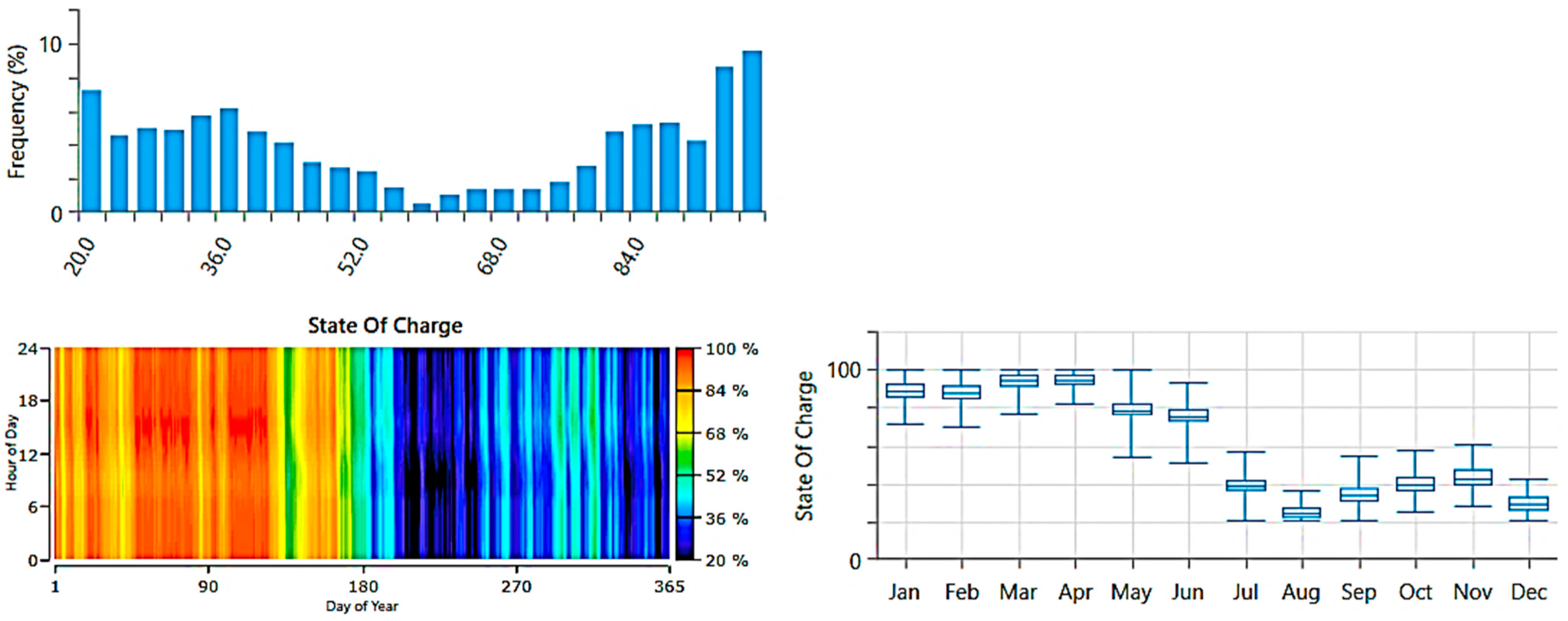

Figure 11 provides a visual representation of the status of battery charging. This figure likely includes information such as battery charge level, charging progress, and other associated indicators [

32].

The bus voltage is indicated to be 24 V.

The nominal capacity is 1613 kW/h, representing the maximum capacity of the system’s energy storage batteries.

The energy input is 37,363 kWh/year, reflecting the total energy consumed throughout the year.

The energy output is 36,706 kWh/year, representing the total energy delivered by the system over the year.

The system has been operational for 8473 h.

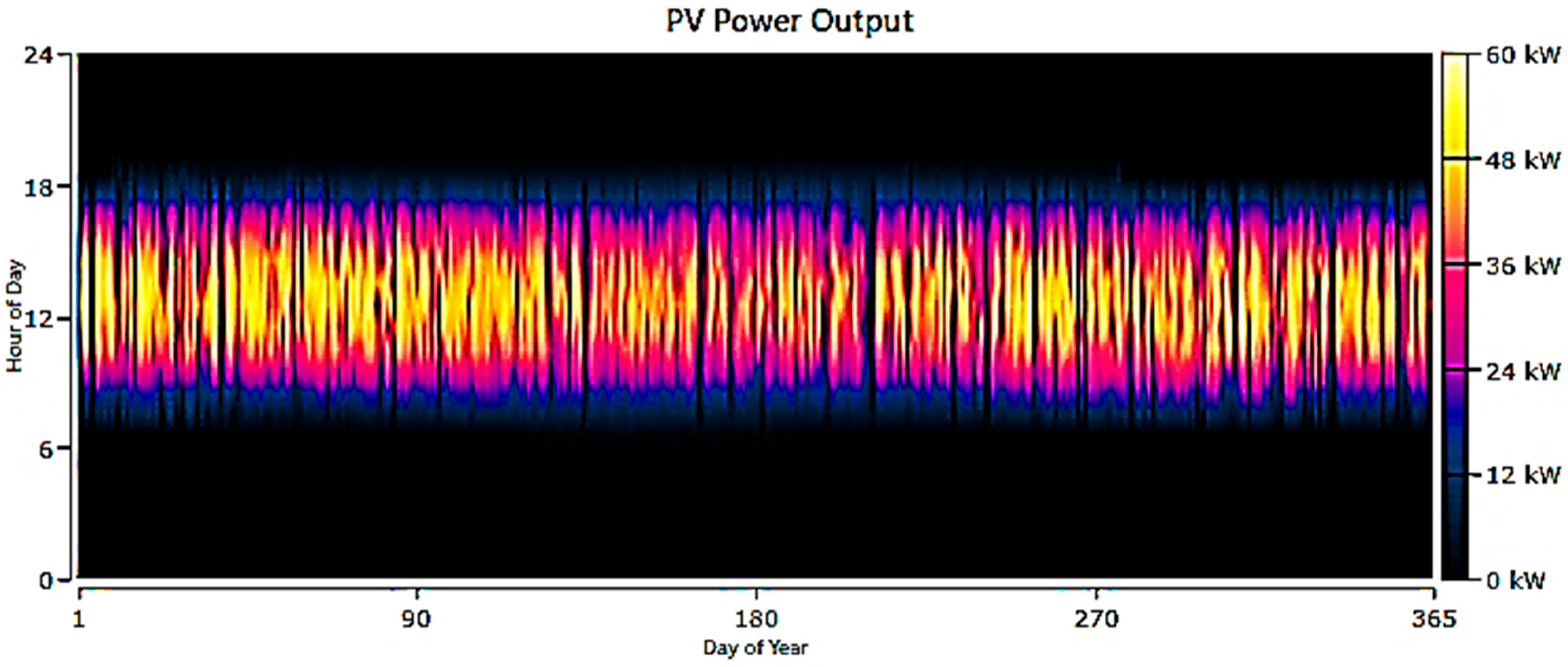

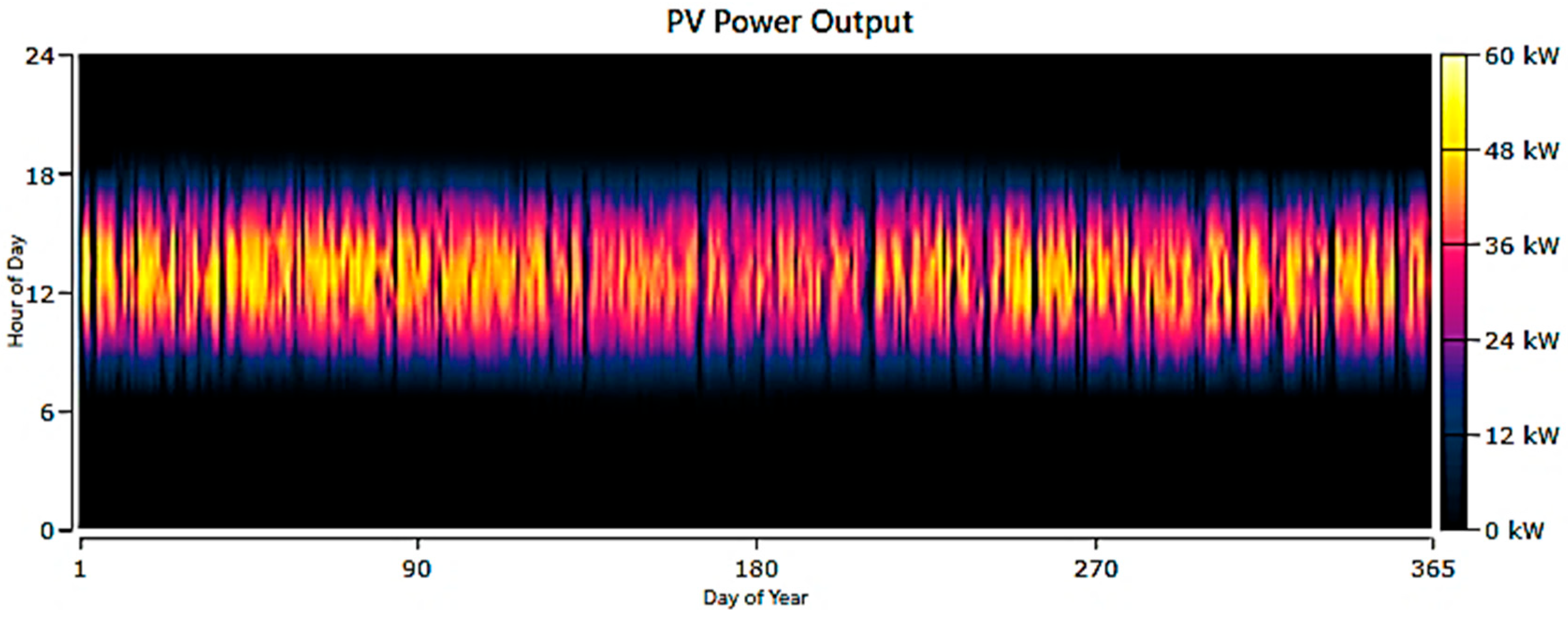

Figure 12 depicts the annual performance of PV panels, showcasing their output or energy production throughout the year.

Figure 12 presents data on the variation in solar energy generation across different seasons and months [

33].

From the results provided in

Table 12 and

Figure 11 we can conclude the following: The rated capacity is specified as 58.8 kW. This indicates the maximum power output or capacity of the system, typically associated with a solar photovoltaic (PV) installation.

The mean output is mentioned as 307 kWh per day. This represents the average energy output of the system over a day. It indicates the amount of energy generated by the PV installation on average.

The total production is calculated to be 112,017 kWh per year. This value represents the overall energy output of the system over the course of a year.

The minimum output is 0 kW.

The maximum output is 57.3 kW. This represents the peak power output that the system can achieve.

The PV penetration is 106%.

The system operated for 4361 h during a year. This indicates the total duration of operation over the given period [

34].

5.5. The Second Configuration

It is a hybrid power system that uses solar panels during the day and a diesel generator at night to provide power to the village. During the day, the solar panels generate electricity from the sun and power the village. At night, when the solar panels are not generating electricity, the diesel generator starts up and provides the energy needed to keep the lights on and run other electrical appliances.

In this scenario, the fact that there are carbon emissions associated with the system would be a disadvantage compared to the first option, which utilizes renewable energy sources and does not produce any carbon emissions. The COE value of USD 0.935 per kWh and NPC of USD 3.51 million would still be relevant for this option, but the carbon emissions should also be taken into consideration when evaluating the overall environmental impact of the system [

35].

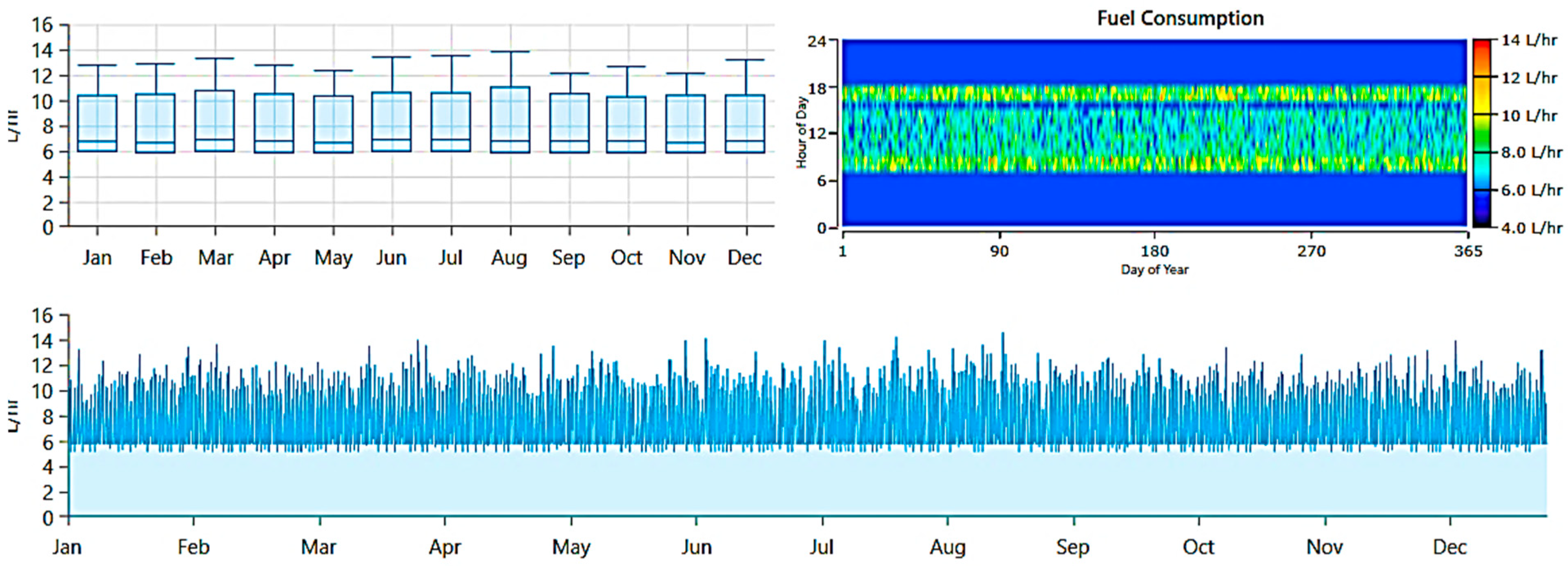

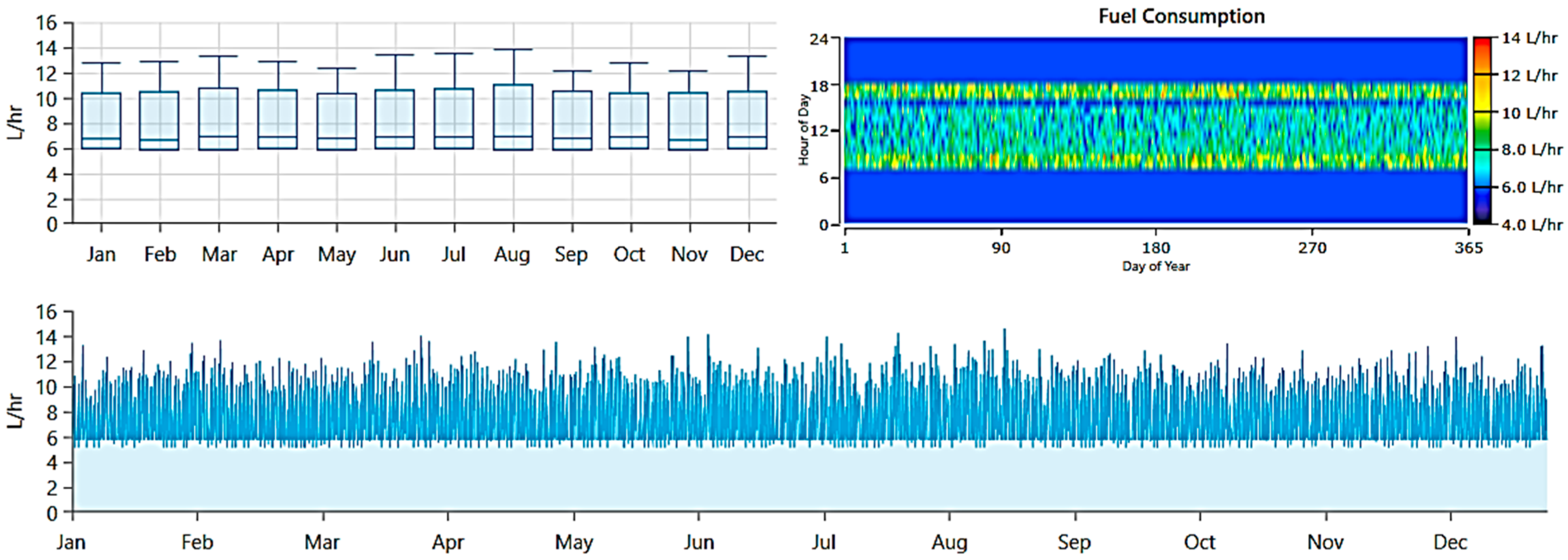

Figure 13 offers a concise overview of fuel consumption, potentially detailing usage patterns, total consumption, and other relevant metrics related to fuel usage.

Based on the data presented in

Table 13 and the information from

Figure 13, we can draw the following conclusions:

The total fuel consumed is 59,780 L. This represents the overall amount of fuel that has been consumed over a given period.

The average fuel consumption per day is 164 L/day. This value indicates the average amount of fuel consumed daily.

The average fuel consumption per hour is 6.82 L/h. This figure represents the average rate at which fuel is consumed within a single hour.

The provided quantities and units describe the fuel consumption of a system. It provides insights into the total fuel consumed, as well as the average fuel consumption per day and per hour. These metrics can be helpful in evaluating fuel efficiency, estimating fuel costs, or analyzing the performance of the system or machinery in terms of fuel utilization [

36].

5.6. The Third Configuration

In this configuration, batteries and a diesel generator provide village power. Batteries charge during the day with diesel, ensuring reliable electricity. While emitting fewer carbon emissions than a primary generator, it relies on diesel, making it less environmentally friendly than solar-based options. The COE is USD 0.952 per kWh, lower than the second option. The NPC is USD 3.83 million, higher than the first but lower than the second option. Factors like fuel cost, generator efficiency, battery capacity, and electricity demand impact the financial and environmental aspects, necessitating careful consideration for the most suitable option [

37].

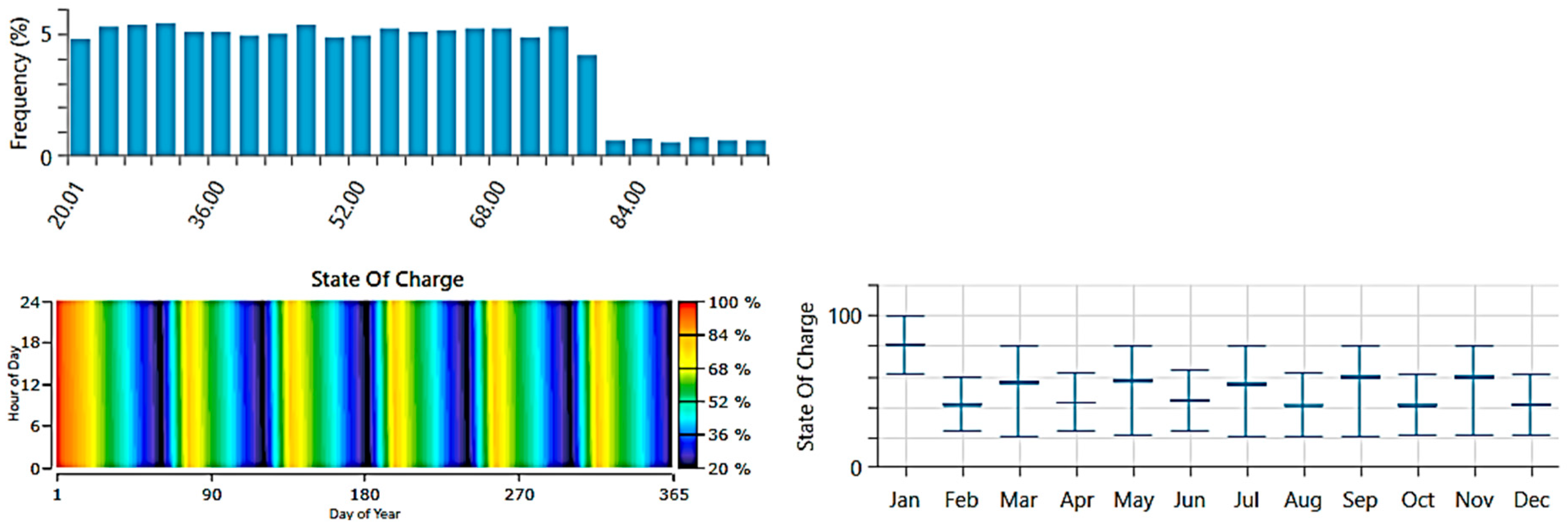

Figure 14 visually represents the ongoing process of battery charging, offering insights into the current state, charging progress, and another associated indicator.

Based on the data presented in

Table 14 and the information from

Figure 14, we can draw the following conclusions:

The system utilizes a total of 88 batteries.

The nominal capacity is 23,654 kW/h, denoting the maximum capacity of the system or the energy storage capacity of the batteries.

The energy input as 72,823 kWh/year, reflecting the total energy consumed or supplied to the system throughout the year.

The energy output is 70,821 kWh/year, representing the total energy generated or delivered by the system during the year.

The system has been in operation for 8760 h, representing the total duration of operation over a given period [

38].

Figure 15 provides a visual representation of the output performance of the converter.

Figure 15 includes specific performance data such as voltage, current, power, and efficiency metrics derived from the simulation of the converter [

39].

We can derive conclusions from the data provided in

Table 15 and the insights from

Figure 15.

The capacity of both the inverter and rectifier is 53 kW. This indicates the maximum power they can handle.

The mean output of the inverter is 9.48 kW, while the mean output of the rectifier is 8.31 kW.

Both the inverter and rectifier show a minimum output of 0 kW.

The inverter’s maximum output is 47.7 kW, while the rectifier’s maximum output is 50 kW. These values represent the peak power outputs that the components can achieve.

The energy input for the inverter is stated as 87,450 kWh/year, while the rectifier’s energy input is 76,656 kWh/year. These values indicate the total amount of energy consumed by each component over the course of a year.

The energy output for the inverter is 83,078 kWh/year, while the rectifier’s energy output is 72,823 kWh/year. These values represent the total amount of energy produced or delivered by each component over the course of a year [

40].

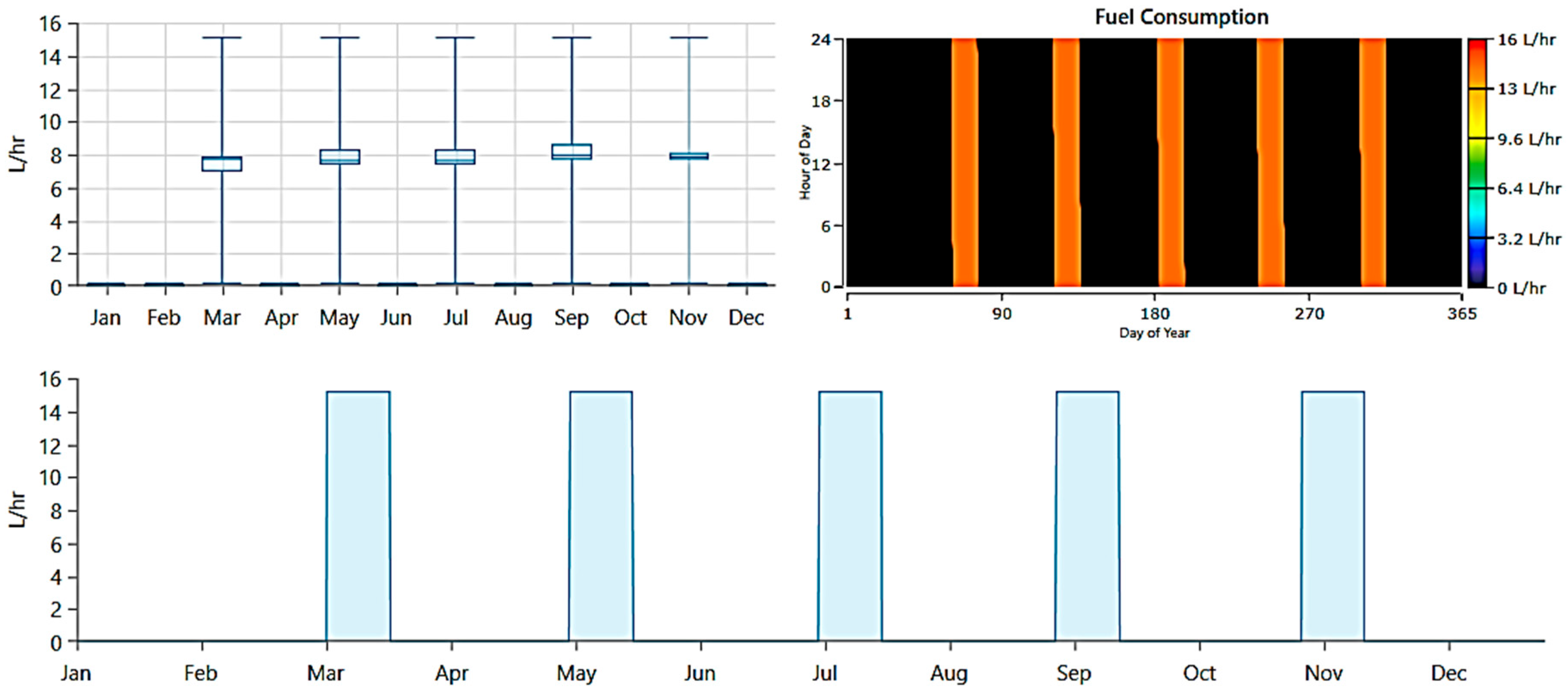

Figure 16 provides an overview of the performance of the fuel, presenting data on parameters such as consumption rate, efficiency, emissions, and other relevant metrics related to the operation or utilization of the fuel source [

41].

Conclusions can be drawn from the data in

Table 16 and the details illustrated in

Figure 16.

The total fuel consumed is 28,470 L. This value represents the overall amount of fuel that has been consumed over a given period.

The average fuel consumption per day is 78 L/day. This value indicates the average amount of fuel consumed daily.

The average fuel consumption per hour is 3.25 L/h.

Figure 16 represents the average rate at which fuel is consumed within a single hour.

The provided quantities and units describe the fuel consumption of a system, vehicle, or machinery. It provides insights into the total fuel consumed, as well as the average fuel consumption per day and per hour. These metrics are helpful in evaluating fuel efficiency, estimating fuel costs, or analyzing the performance of the system or machinery in terms of fuel utilization [

42].

5.7. The Fourth Configuration

This hybrid power system combines solar panels, batteries, and a diesel generator for reliable and sustainable electricity in the village. Solar panels generate daytime electricity and charge batteries for nighttime use. A diesel generator serves as backup, auto-sized based on demand for efficiency. This balance of renewable and backup power minimizes carbon emissions, with a COE of USD 0.912 per kWh and an NPC of USD 3.62 million. Although requiring a larger initial investment, the long-term cost-effectiveness and reduced reliance on diesel make it an environmentally friendly and reliable option [

43].

The specifications of the PV panels listed in

Table 17 include a rated capacity of 58.8 kW, with mean daily output reaching 291 kWh and total yearly production amounting to 106,177 kWh, alongside a minimum output of 0 kW. The maximum output power is 54.3 kW, achieving full PV penetration at 100%, operating for 4361 h per year.

Figure 17 illustrates the output of a photovoltaic (PV) panel over the course of a year, depicting variations in power generation influenced by factors such as solar irradiance, temperature, and daylight hours, which are crucial for understanding the performance and efficiency of solar energy systems.

Beyond household-based systems, a centralized photovoltaic–battery hybrid system was also considered. Centralized systems benefit from economies of scale, improved operational efficiency, and simplified maintenance. However, decentralized household-level systems enhance resilience, allow for flexible scaling, and reduce vulnerability to system-wide failures. A hybrid approach may therefore be optimal: centralized systems powering communal services such as the medical center, water pumping, and street lighting, while decentralized systems cover household-level demand.

5.8. The Fifth Configuration

Using only a diesel generator for power is not recommended due to its environmental impact, high operating costs, and lack of sustainability. Relying solely on non-renewable energy sources contributes to pollution and climate change. Diesel generators are noisy, emit pollutants, and require frequent maintenance. Fluctuating fuel costs make long-term predictions challenging, especially for financially limited villages. This option has a high COE of USD 0.986 and NPC of USD 3.91 million, making it less economical and environmentally friendly compared to options incorporating renewable energy sources as shown in

Table 18.

The diesel-only configuration results in annual carbon dioxide emissions of 156,798 kg, as calculated based on diesel consumption and emission factors.

The amount of carbon monoxide emitted is 988 kg/year. Carbon monoxide is a toxic gas produced by incomplete combustion of carbon-based fuels. It is harmful to human health and can contribute to air pollution.

The quantity of unburned hydrocarbons emitted is 43.1 kg/year. Unburned hydrocarbons are volatile organic compounds (VOCs) that are released during combustion processes. They can contribute to the formation of ground-level ozone and air pollution.

The amount of particulate matter emitted is 5.99 kg/year. Particulate matter consists of solid or liquid particles suspended in the air. It includes fine particles (PM2.5) and coarse particles (PM10), which can have adverse effects on human health and contribute to air pollution [

44].

The quantity of sulfur dioxide emitted is 384 kg/year. Sulfur dioxide is a gas released during the combustion of fossil fuels, particularly those containing sulfur. It can contribute to respiratory issues, acid rain, and air pollution.

The amount of nitrogen oxide emitted is 928 kg/year. Nitrogen oxides are produced during the combustion of fossil fuels and contribute to air pollution. They can react with other compounds in the atmosphere to form smog and contribute to the formation of acid rain.

Table 19 represents the total fuel consumed, estimated to be 59,901 L. This value represents the overall amount of fuel that has been consumed over a given period.

The average fuel consumption per day is 164 L/day. This value indicates the average amount of fuel consumed daily.

Figure 18 illustrates the performance of a fuel system over a certain period, providing insights into factors such as fuel consumption, efficiency, and emissions, which are essential for evaluating the effectiveness and sustainability of the fuel system.

The average fuel consumption per hour is 6.84 L/h.

Figure 18 represents the average fuel consumption rate per hour of generator operation over one year, while

Figure 19 shows the generator’s hourly power output throughout the year, highlighting operation mainly during daylight hours [

4].

To facilitate comparison and enhance clarity,

Table 20 presents a summary of the five system configurations, detailing key metrics such as energy generation, levelized cost of energy (COE), net present cost (NPC), and fuel consumption where applicable.

An additional scenario analysis using HOMER software compared centralized and decentralized configurations. The results demonstrated that centralized systems achieved lower per-kWh costs, while decentralized systems provided greater autonomy and reliability. These findings highlight a trade-off between economic efficiency and resilience, offering valuable insights for policymakers and stakeholders in rural electrification planning.

The evaluation using Homer software explored five options for village power. The most cost-effective and eco-friendly was the first option: a PV system with battery backup. However, the fourth option, the combination of PV panels and battery backup with diesel, also proved viable for emergency power. Other options had high costs or emissions. In our MATLAB code, parameters like energy demand and PV panel area were calculated. Costs for components like PV panels and batteries were factored in. Results showed a daily energy demand of 589.50 kWh, yearly demand of 215,167.50 kWh, and system cost of USD 113,500.00. Solar energy emerged as a sustainable and cost-effective solution.

While the current research focuses on a single village case study, the methodology, load profiling, and system simulation approach are applicable to a wide range of rural settings with similar geographical and socio-economic conditions across Sudan and neighboring countries.

In order to strengthen the scientific contribution of this work, a dedicated Discussion section has been included, where the results are not only presented but also critically analyzed in relation to comparable techno-economic studies from Sudan, Morocco, Egypt, and other sub-Saharan African contexts, with explicit reflection on the methodological limitations associated with relying on synthetic rather than empirically validated demand profiles, as well as consideration of the broader policy and development implications of hybrid PV–battery–diesel systems for rural electrification, agricultural productivity, and post-conflict reconstruction, thereby transforming the manuscript from a report on technical feasibility into a more comprehensive scientific analysis.

6. Conclusions

This study demonstrates that photovoltaic systems are a technically and economically viable solution for powering rural communities in Sudan. The optimized hybrid systems offer significant advantages in cost, environmental impact, and reliability over diesel-based alternatives. However, realizing the full potential of solar energy in Sudan requires more than technical implementation—it demands alignment with broader reconstruction efforts, including rural development planning, agricultural policy, and community engagement. In the aftermath of widespread infrastructure destruction, solar energy presents an opportunity to power irrigation systems, restore agricultural productivity, and support essential services such as clinics and schools. To enable this transition, policy support must prioritize decentralized energy solutions, offer financial incentives, and remove barriers to local participation in renewable energy deployment.

The study commenced with an assessment of the village’s load demand, distinguishing between daytime and nighttime consumption. Daytime peak usage reached 57.86 kWh, and nighttime consumption totaled 80.46 kWh, leading to an overall daily demand of 589.5 kWh. This energy is distributed across critical sectors including households, water pumping, healthcare, street lighting, and a local supermarket.

To address this need, a 60 kW photovoltaic (PV) system was proposed, supported by a solar thermal system for hot water supply. A custom MATLAB model was developed to calculate system parameters such as required PV panel area, battery storage capacity, total system cost, and energy cost per kilowatt-hour. The simulations indicated an annual energy demand of 215,167.5 kWh, requiring 34.6 m2 of PV panels and 72 batteries (6900 kWh storage capacity). The total estimated system cost was USD 113,500, with a levelized cost of energy (LCOE) of USD 0.671/kWh. The system is projected to generate approximately 12,113.29 MWh per year.

The results highlighted the effectiveness of integrating PV and solar thermal technologies. A solar thermal system with an initial investment of USD 15,500 could cover the village’s hot water needs while contributing 7.75 kW of electrical power. By adding 22.5 kW of conventional PV modules at an estimated cost of USD 23,000, the village’s overall energy capacity can be further enhanced, improving system reliability and resilience.

Compared to diesel-based systems, which suffer from high fuel costs, logistical limitations, and significant environmental impacts, the proposed solar-based solution is cleaner, more sustainable, and economically viable for long-term rural electrification—particularly in conflict-affected areas like Sudan.

This study also acknowledges that designing renewable energy systems in rural Sudan requires careful consideration of the trade-off between centralized economies of scale and decentralized resilience. A combined or hybrid model may thus provide the most effective and sustainable pathway for rural electrification. By combining robust techno-economic modeling with a policy and implementation framework tailored to post-conflict realities, solar energy can shift from a feasibility concept to a driver of sustainable development. The approach outlined in this study can inform national strategies and international aid programs focused on recovery, resilience, and rural empowerment in Sudan and similar conflict-affected regions.