Design and Experiment of a Multi-Duct Air-Delivered Sprayer for Closed Apple Orchards

Abstract

1. Introduction

2. Materials and Methods

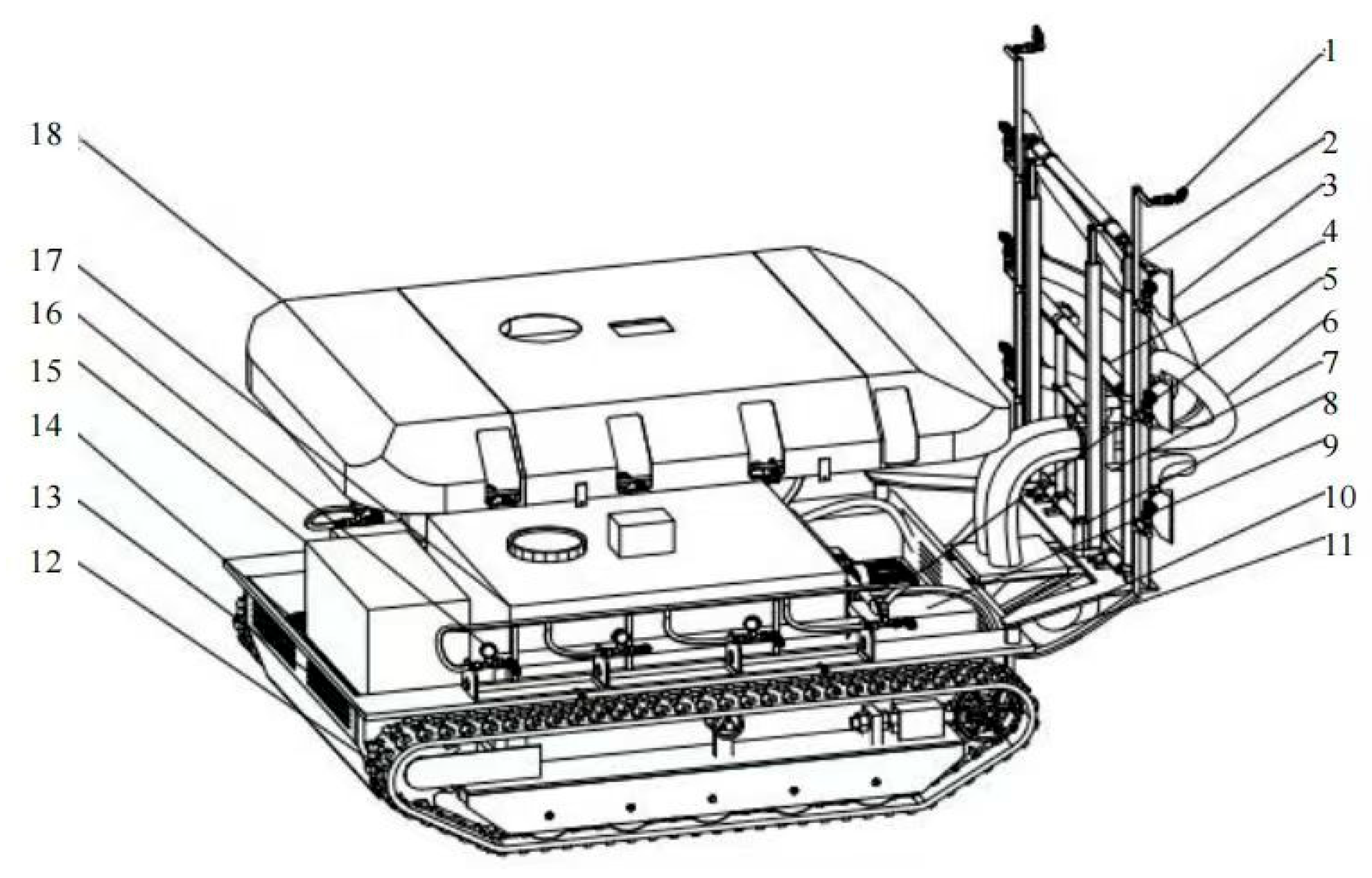

2.1. Overall DesignComplete Machine Structure and Working Principles

2.1.1. Design Requirements

- (1)

- Passability and spatial adaptability. For orchards with the cropping pattern of dense planting with standard rootstocks, the management is predominantly handled by small-scale farmers, with canopy maintenance relying mainly on conventional pruning; after the trees enter the full fruiting stage, trees develop relatively short trunks and have numerous main branches, resulting in overlapping canopies and narrow rows in closed orchards; the orchard canopy density ranges from 0.49 to 0.93 [34]. A compact structure was adopted for the sprayer, and the height of the complete machine was less than 1.2 m, ensuring passability in low spaces. The unilateral spraying width was greater than 2 m to cover the canopy crossing areas; the longitudinal spraying height was greater than 3 m, and the penetration of droplets in dense canopies was enhanced by combining multi-duct directional air delivery technology, meeting the pesticide application needs of different fruit tree shapes.

- (2)

- Spraying operation quality and parameter control. To ensure operation quality, the driving speed of the sprayer should be less than 1.5 m/s to reduce missed spraying and re-spraying; the spray volume was greater than 4 L/min to ensure effective, comprehensive coverage of liquid chemical; meanwhile, the powerful airflow produced by the air delivery system could enhance the penetration of droplets and improve the droplet deposition effect inside canopies and on the back surfaces of leaves.

- (3)

- Dynamic adjustable structure and adaptability optimization. The sprayer should be designed with a height- and width-adjustable spray bar to adapt to the growth stages of different fruit trees in closed orchards and to the tree shape changes after intermediate pruning and transformation. The dynamic agronomic needs of orchards can be satisfied by flexibly adjusting spraying parameters, thereby improving the sprayer’s working efficiency.

- (4)

- Terrain adaptability and power abundance. Given the large slope and scattered plots in mountain orchards, the travel system was improved, and the sprayer had the climbing ability of ≥25° due to its range-extended engine and a crawler-type chassis structure; the weight of the complete machine was reduced by using lightweight materials; an extended-range power system was adopted to guarantee endurance; and the suspension system provided shock absorption and stability, mitigating the influence of bumpiness on spraying uniformity and ensuring continuous operational capability under complex terrains.

2.1.2. Complete Machine Structure and Working Principles

2.2. Key Components and Main Parameters

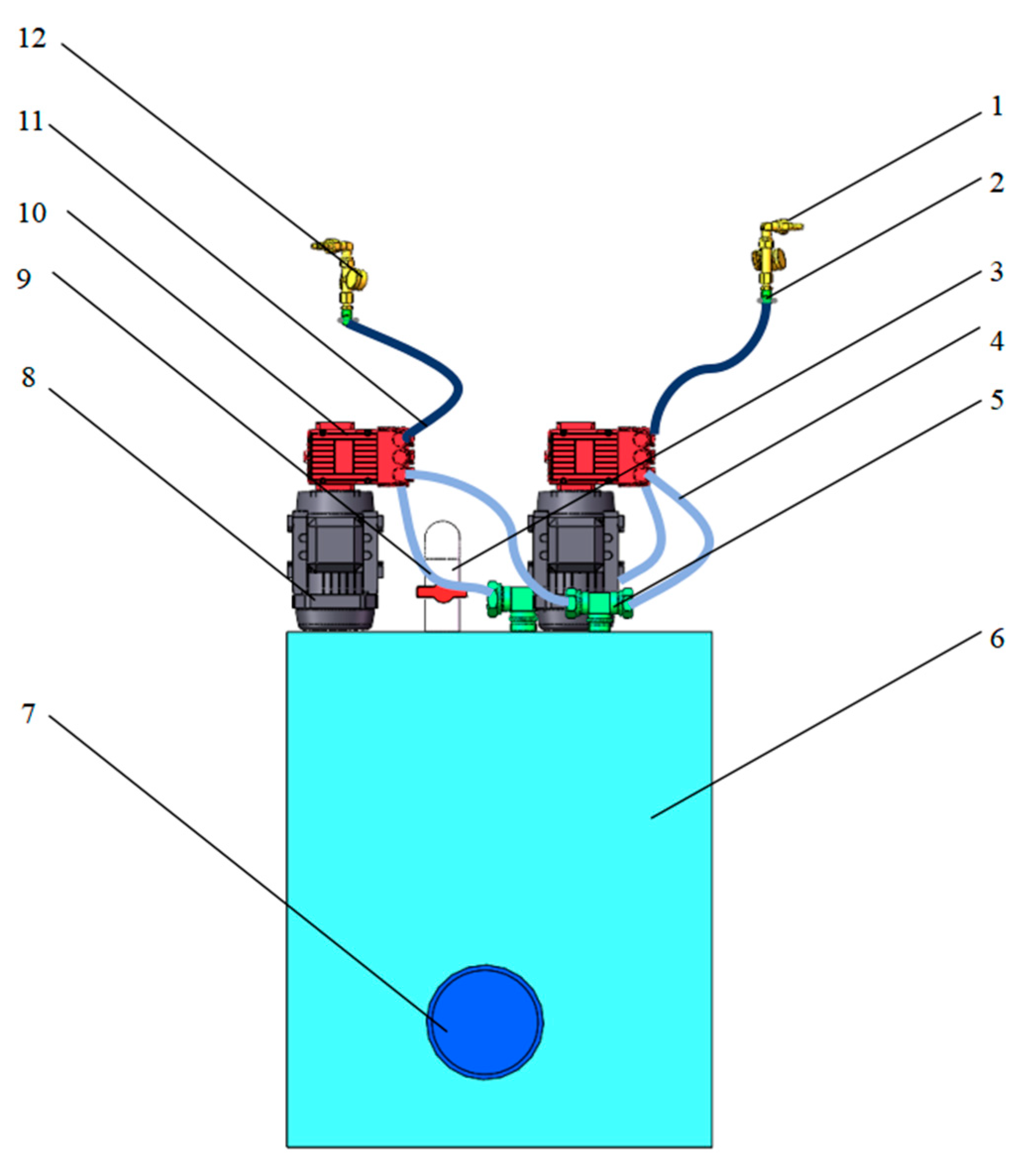

2.2.1. Waterway Design for the High-Pressure Atomization System

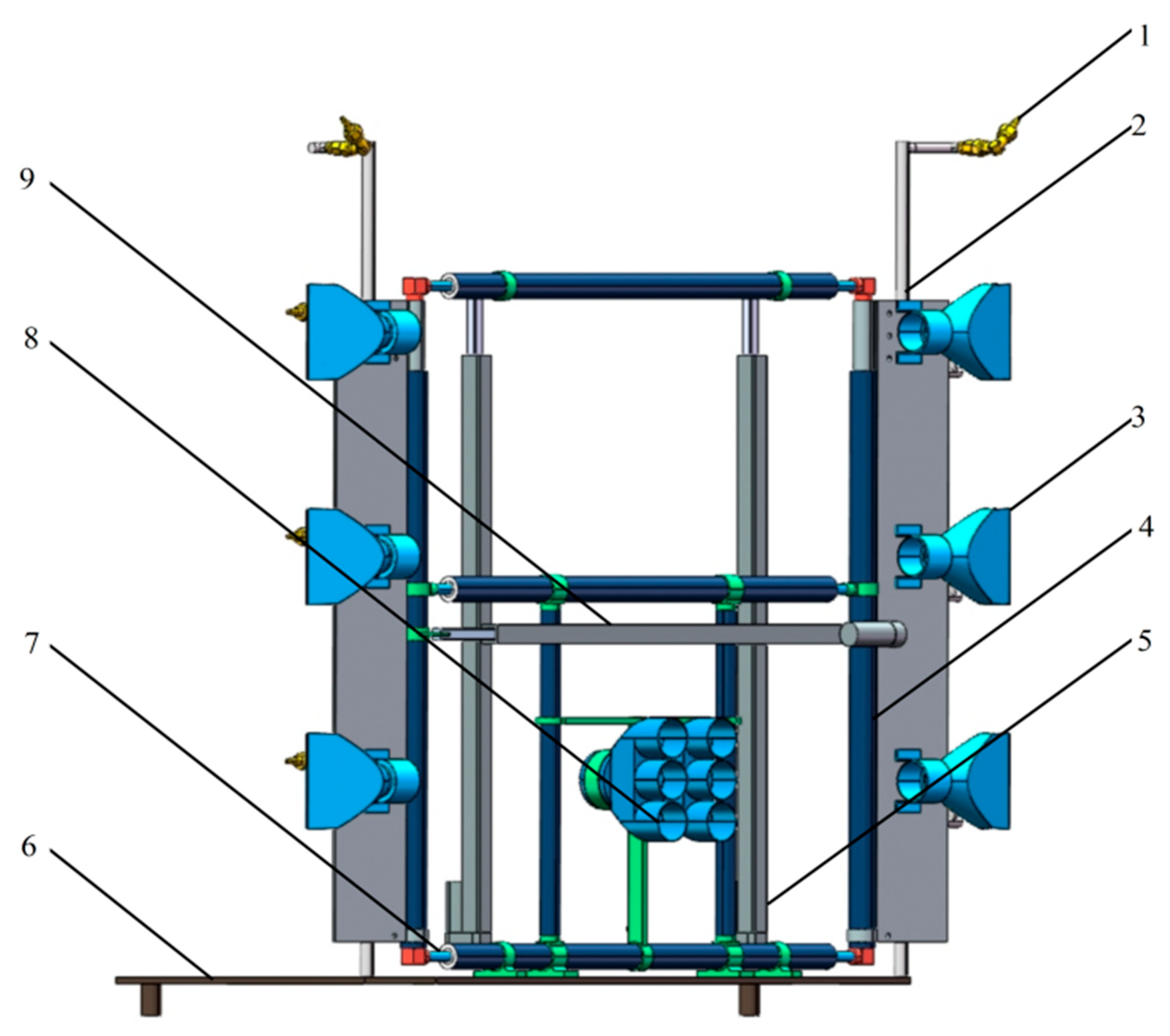

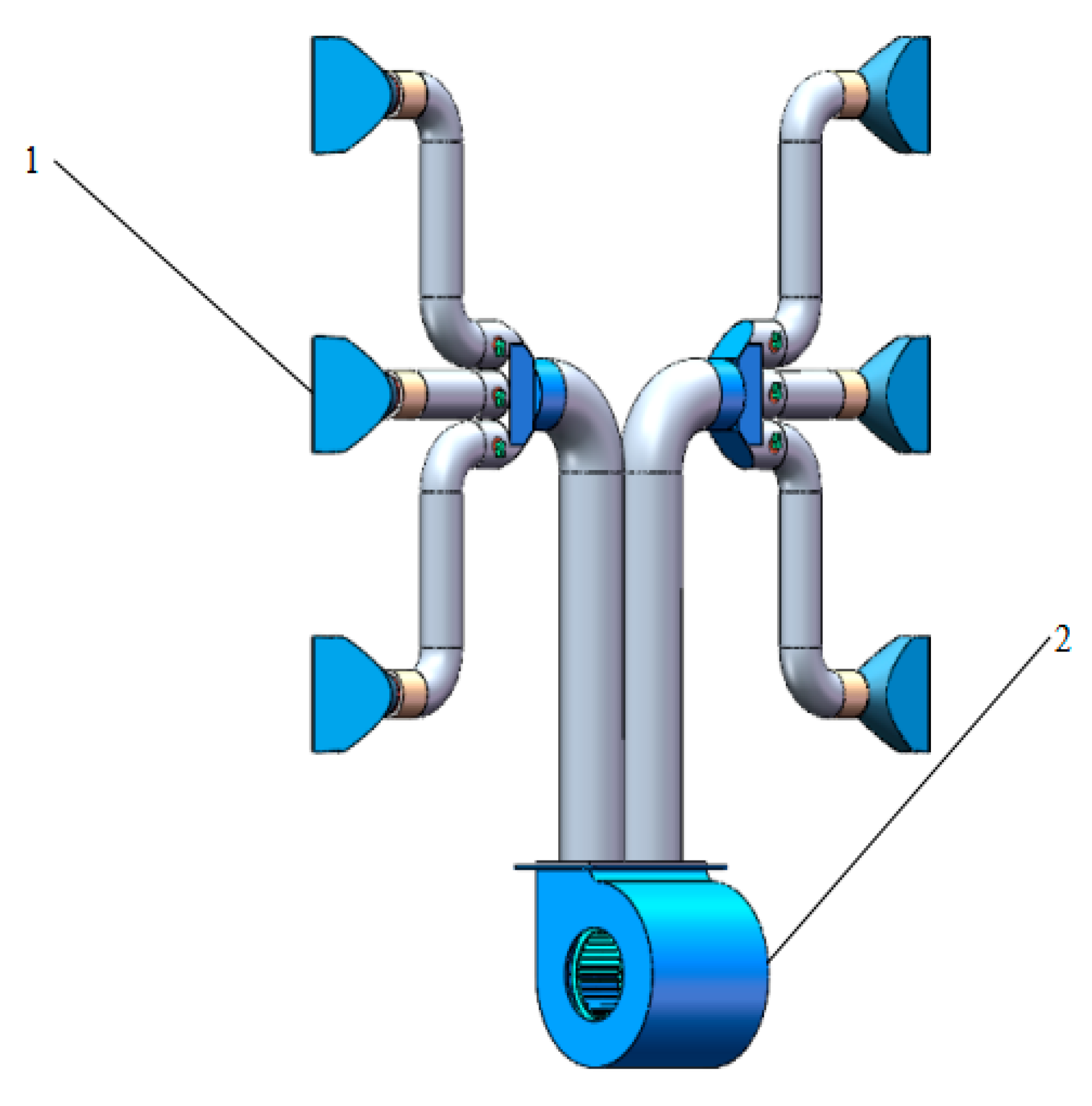

2.2.2. Multi-Duct Air-Delivered System Design

- (1)

- Air volume of the fan

- (2)

- Adjustable vertical lifting device

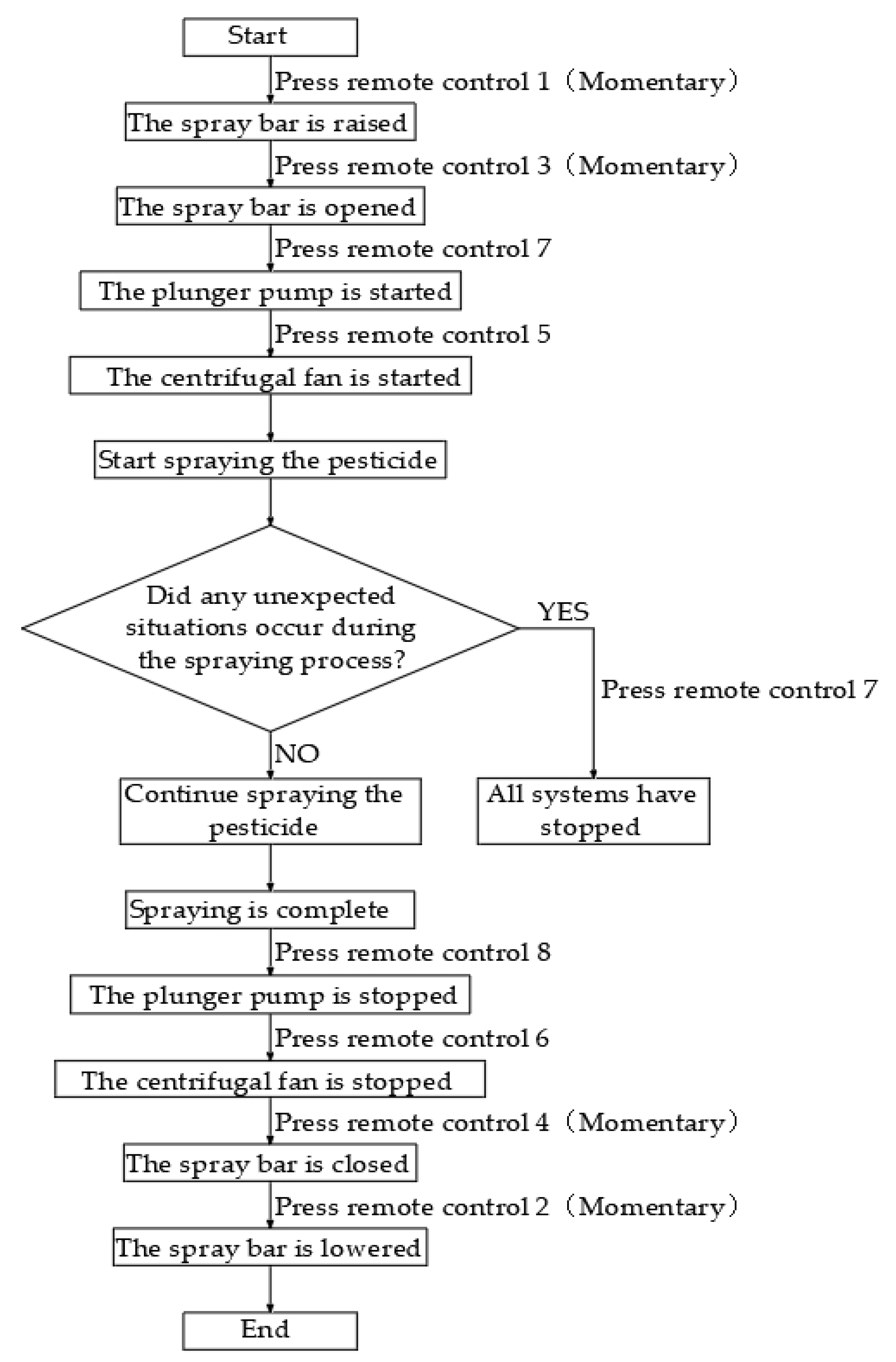

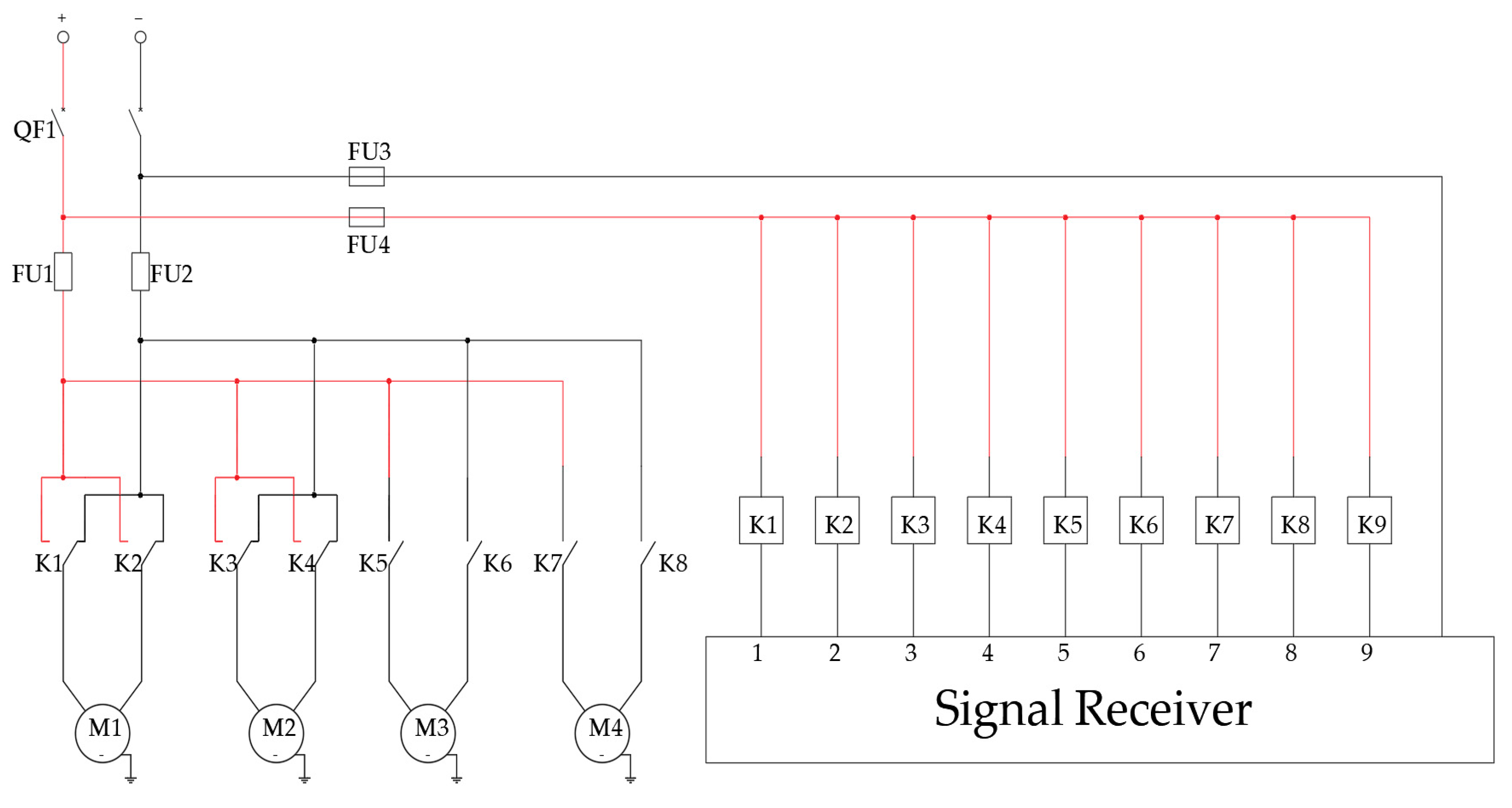

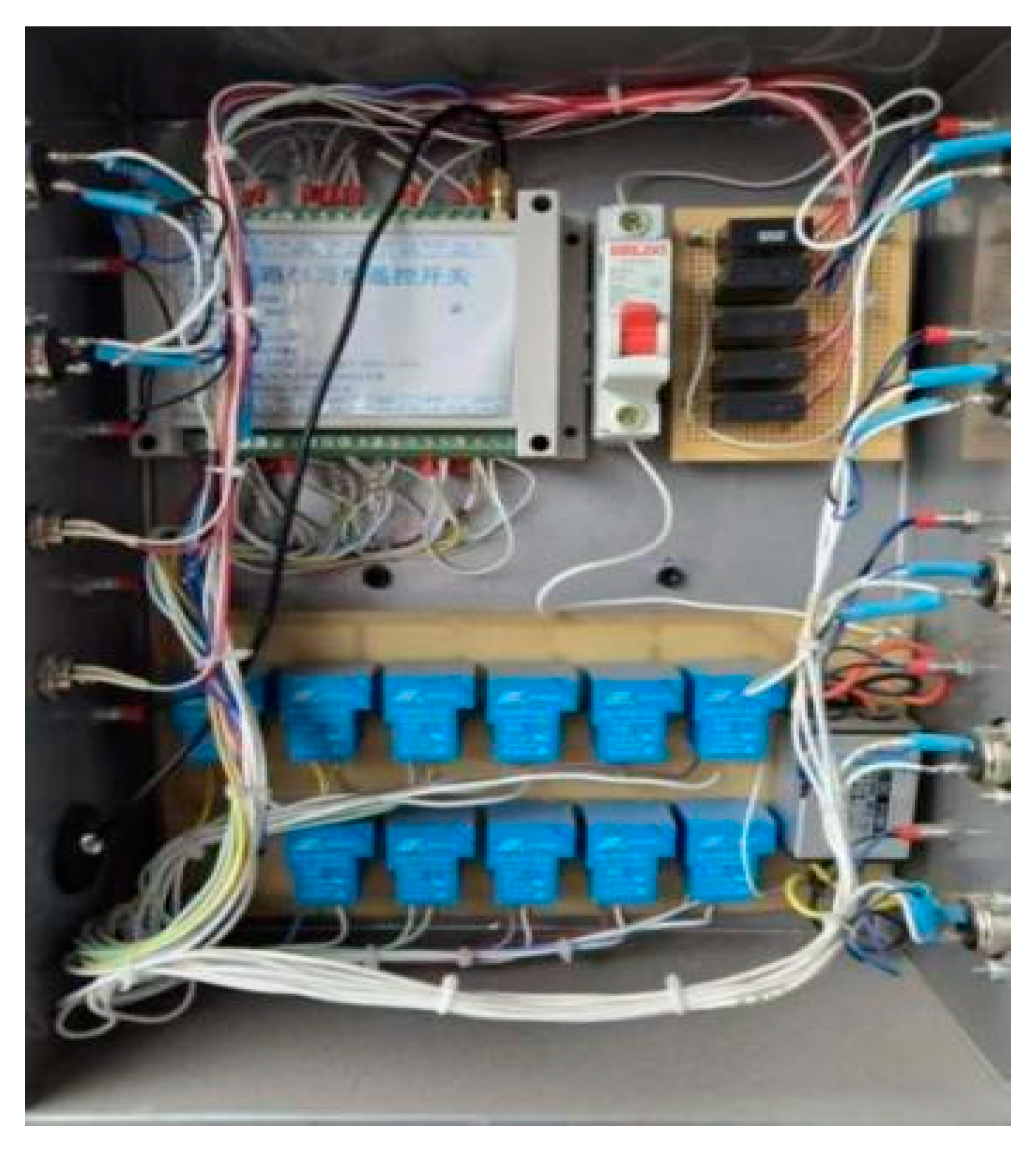

2.3. Design of the Spray Control System

2.4. The Flow Field Simulation and Wind Speed Test

2.4.1. Simulation of Flow Field Inside the Fan Air Duct

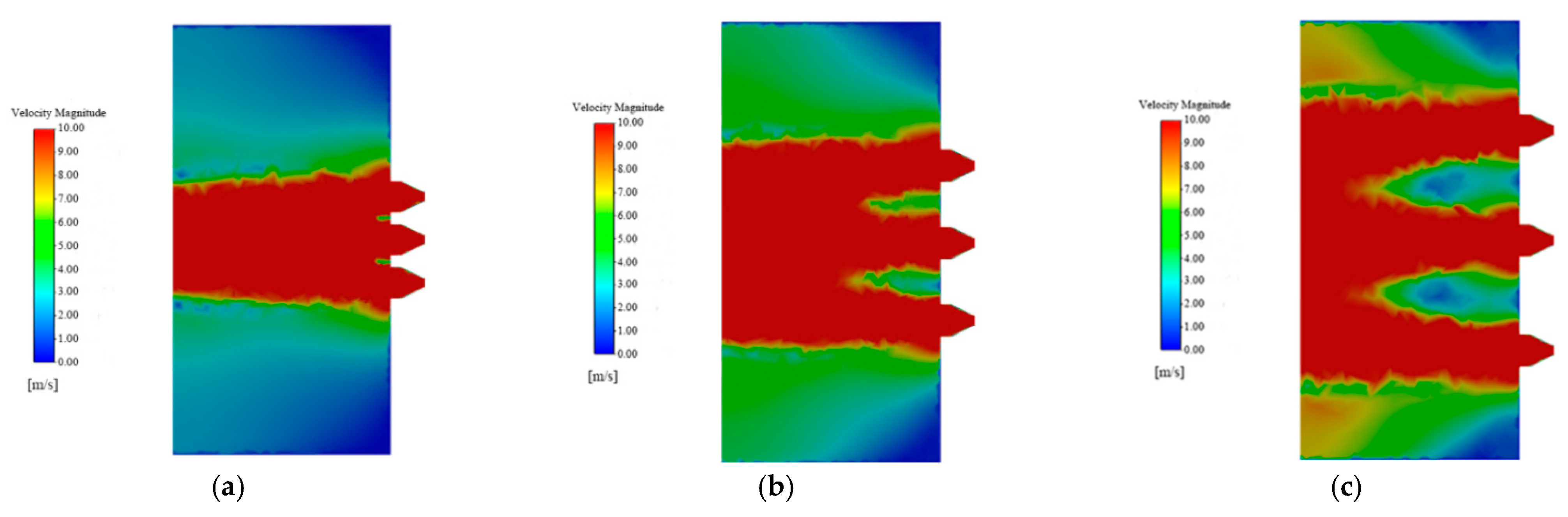

2.4.2. Simulation of Flow Field Outside the Air Delivery System

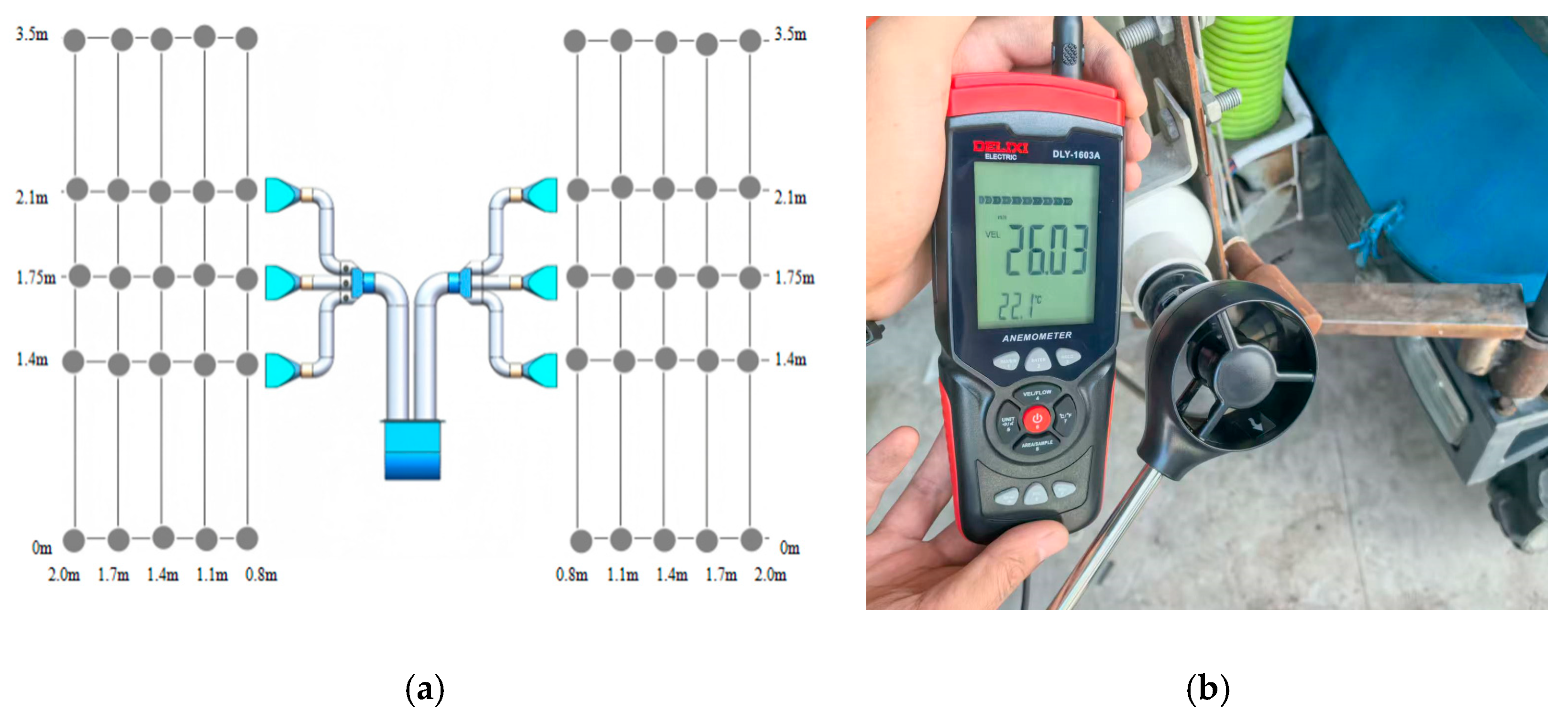

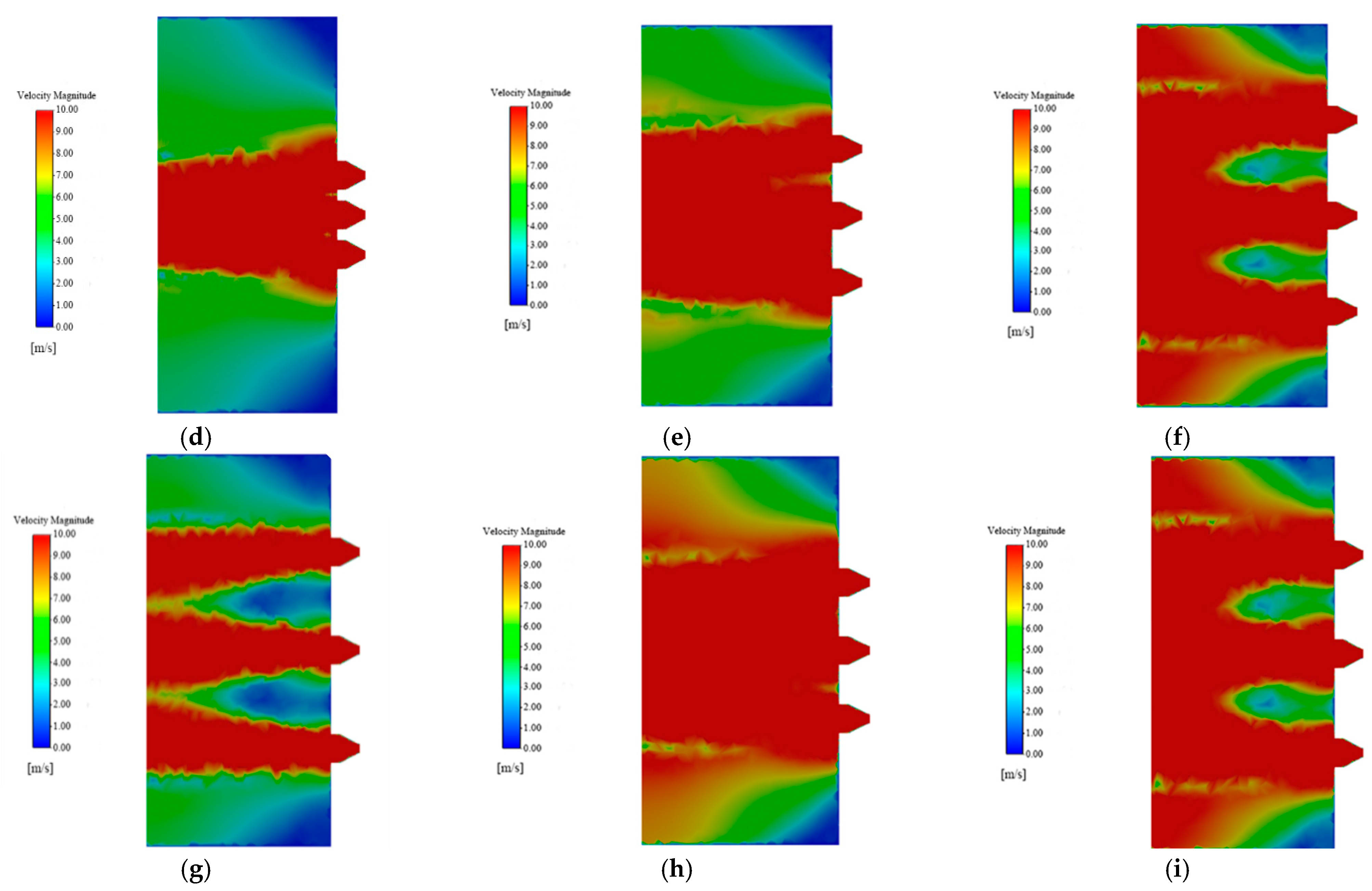

2.4.3. Wind Speed Test

2.5. Field Operation Performance Test

2.5.1. Test Conditions

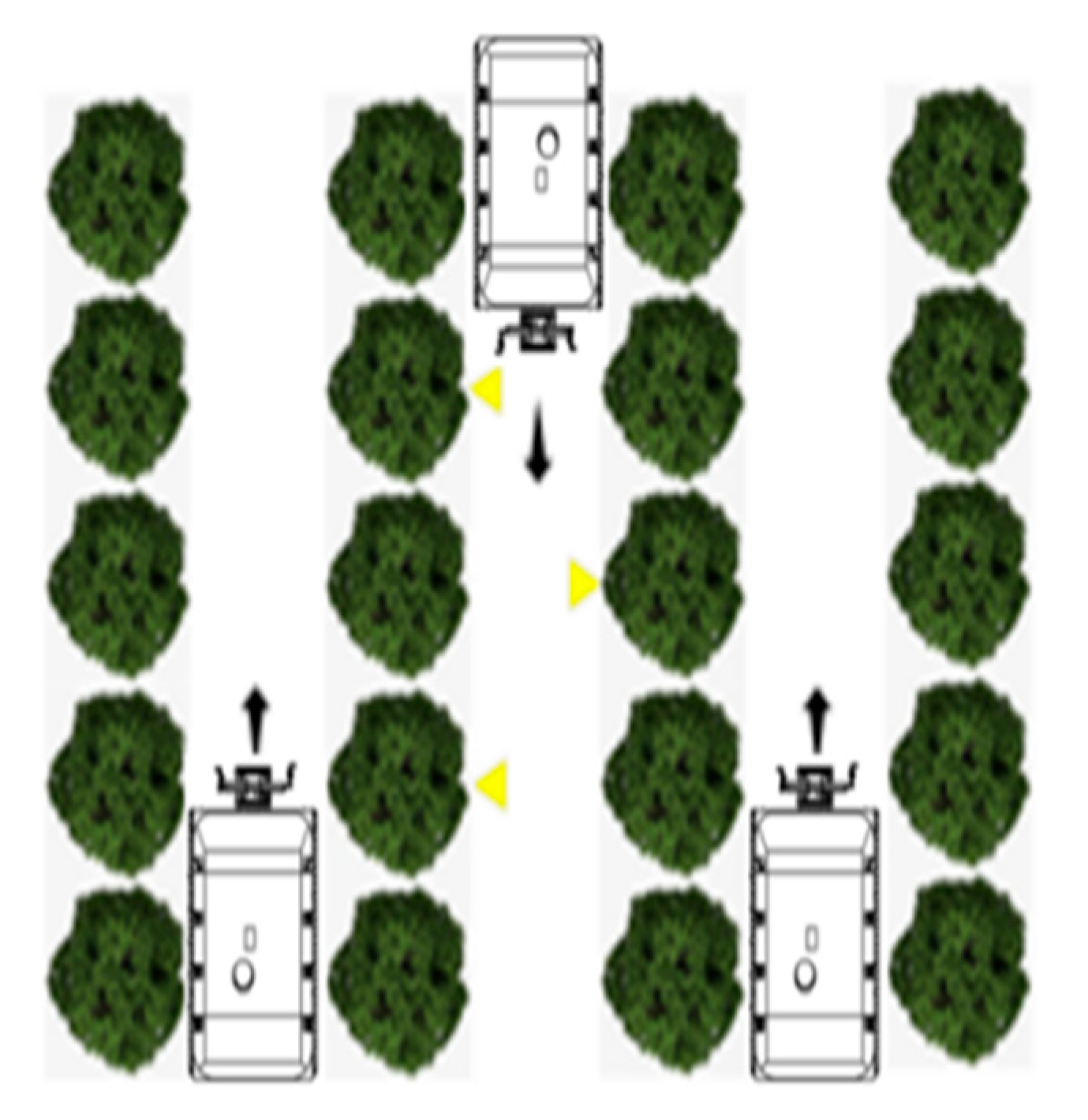

2.5.2. Test Method

- (1)

- Orthogonal test design

- (2)

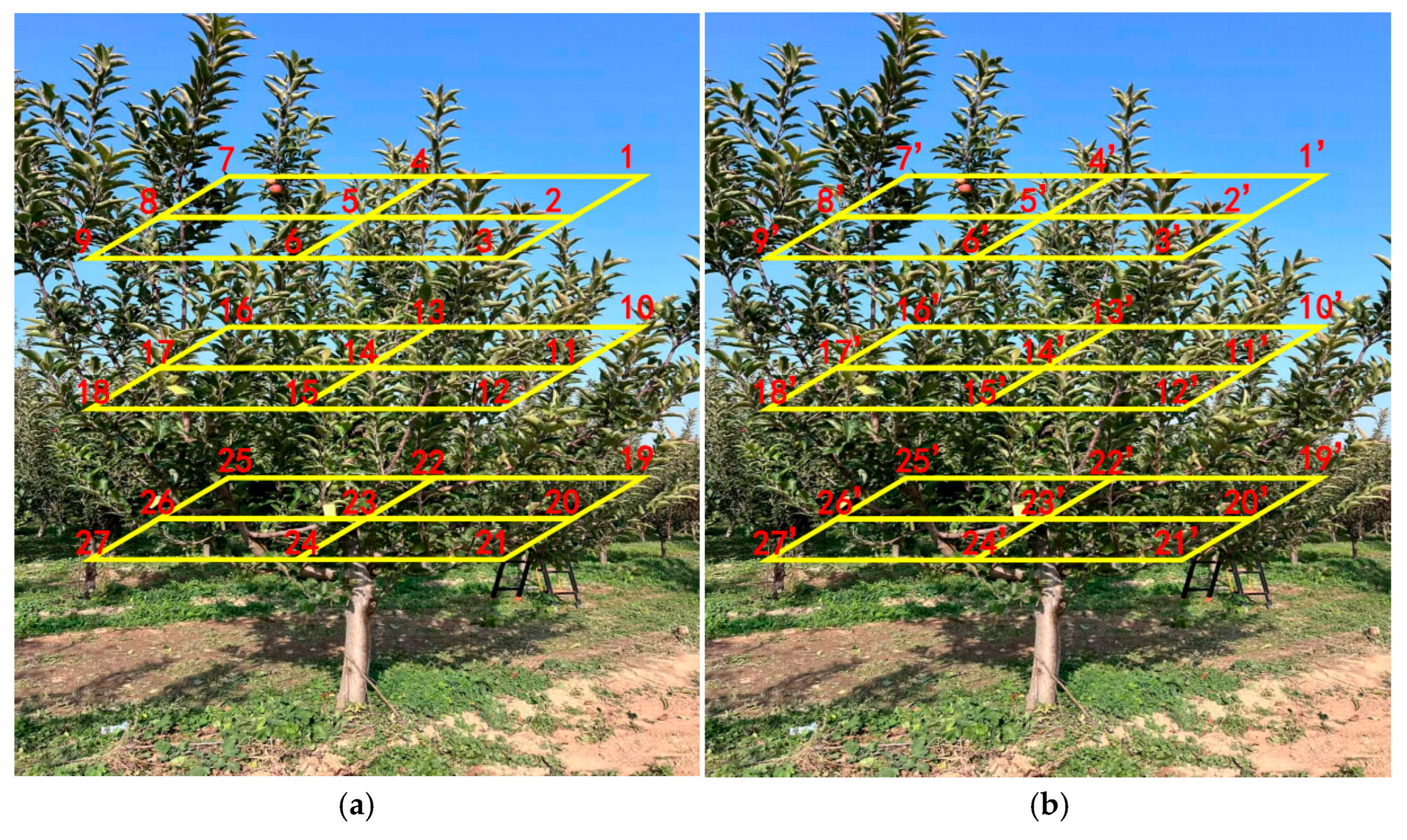

- Field sampling layout

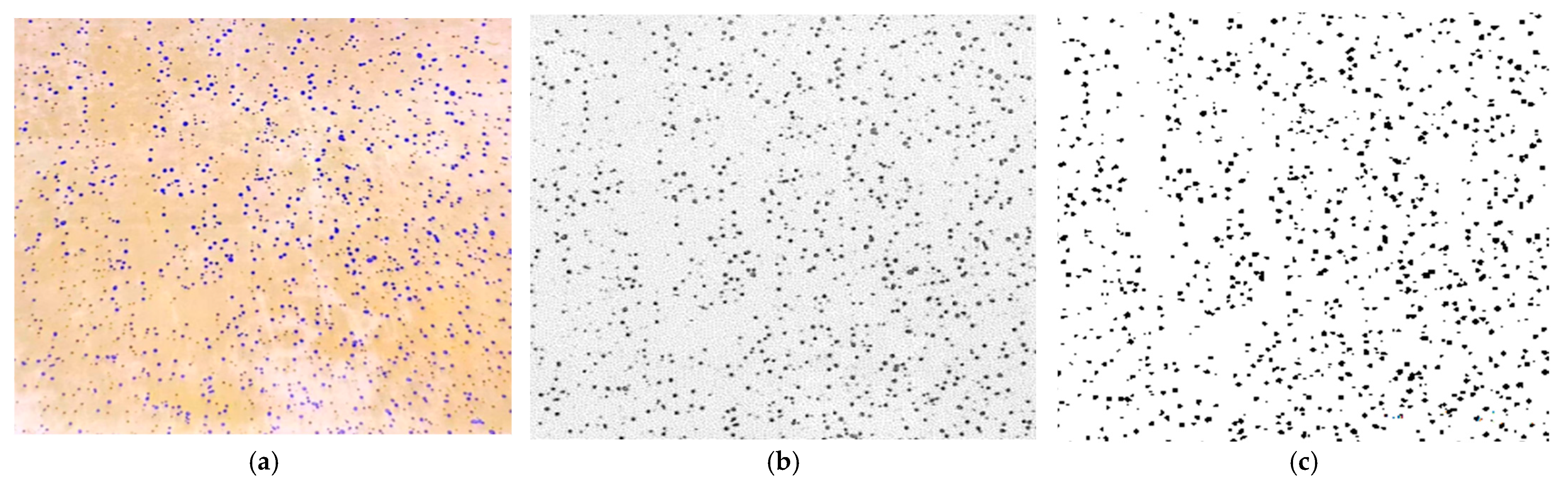

2.5.3. Treatment of Test Samples

2.6. Data Processing

3. Results and Discussion

3.1. Simulation Analysis of the Flow Field Inside the Air Duct and Outside the Air Delivery System

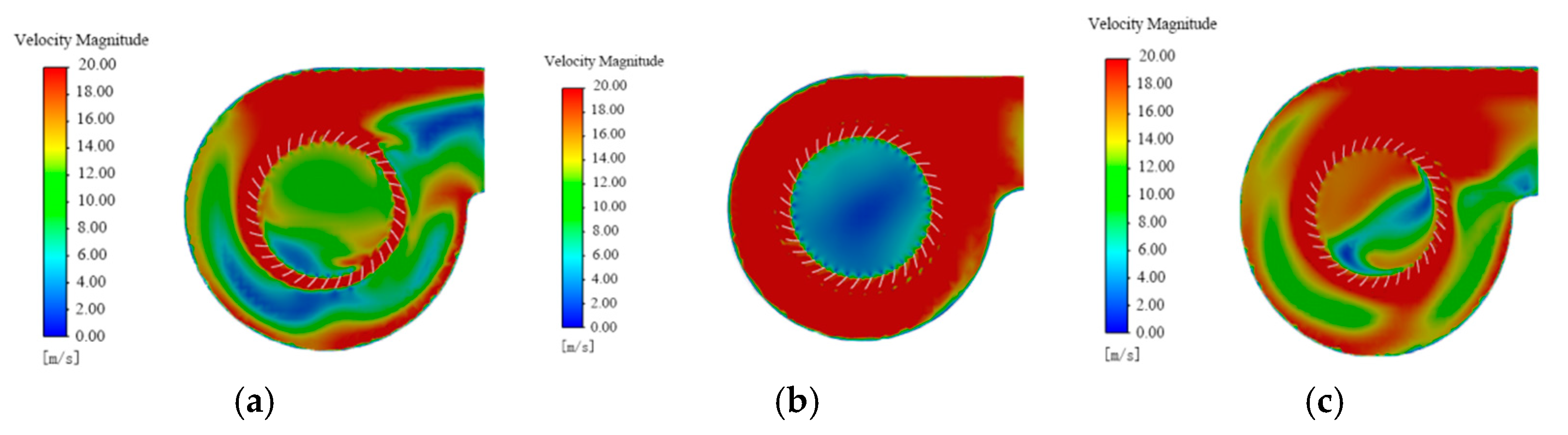

3.1.1. Simulation Analysis of the Flow Field Inside the Fan Air Duct

3.1.2. Simulation Analysis of Flow Field Outside the Air Delivery System

3.1.3. Wind Speed Test Analysis

3.2. Performance Test Results of the Multi-Duct Sprayer and Result Analysis

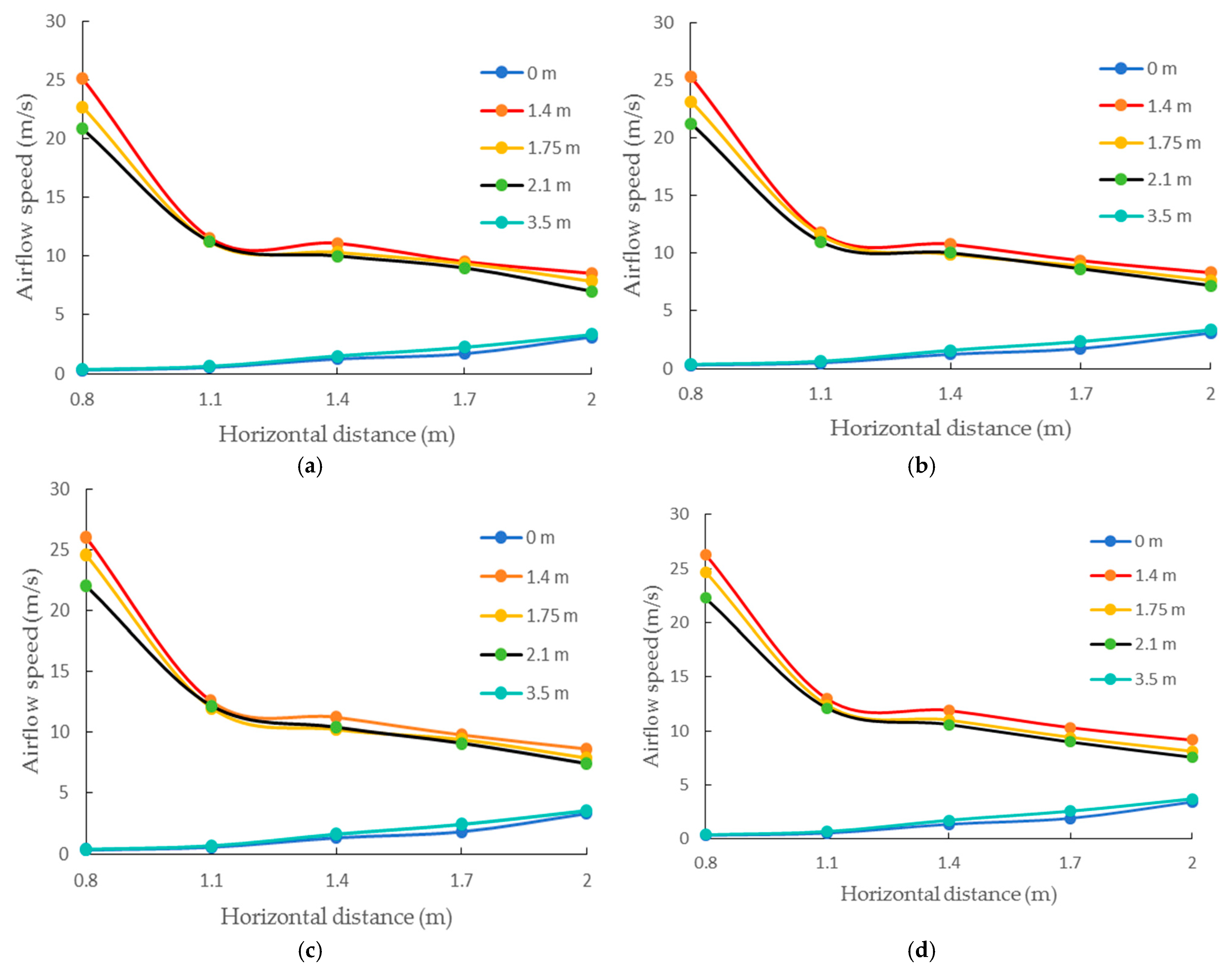

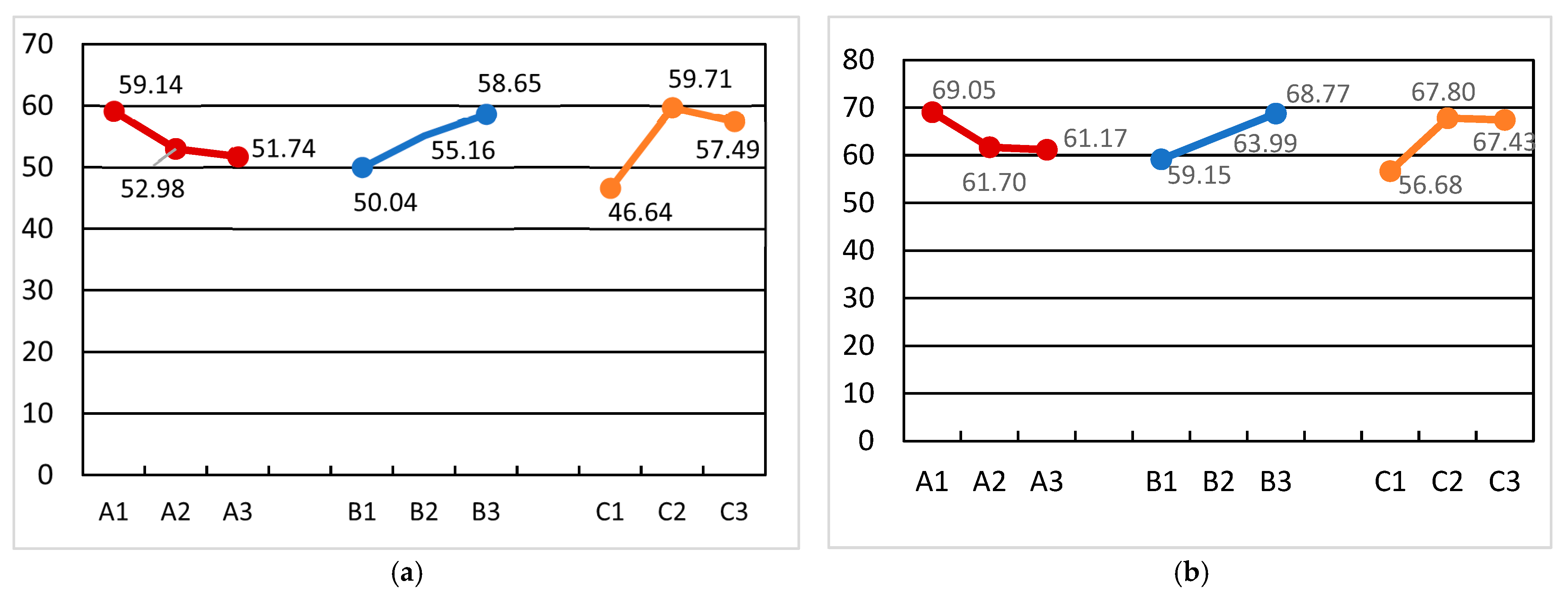

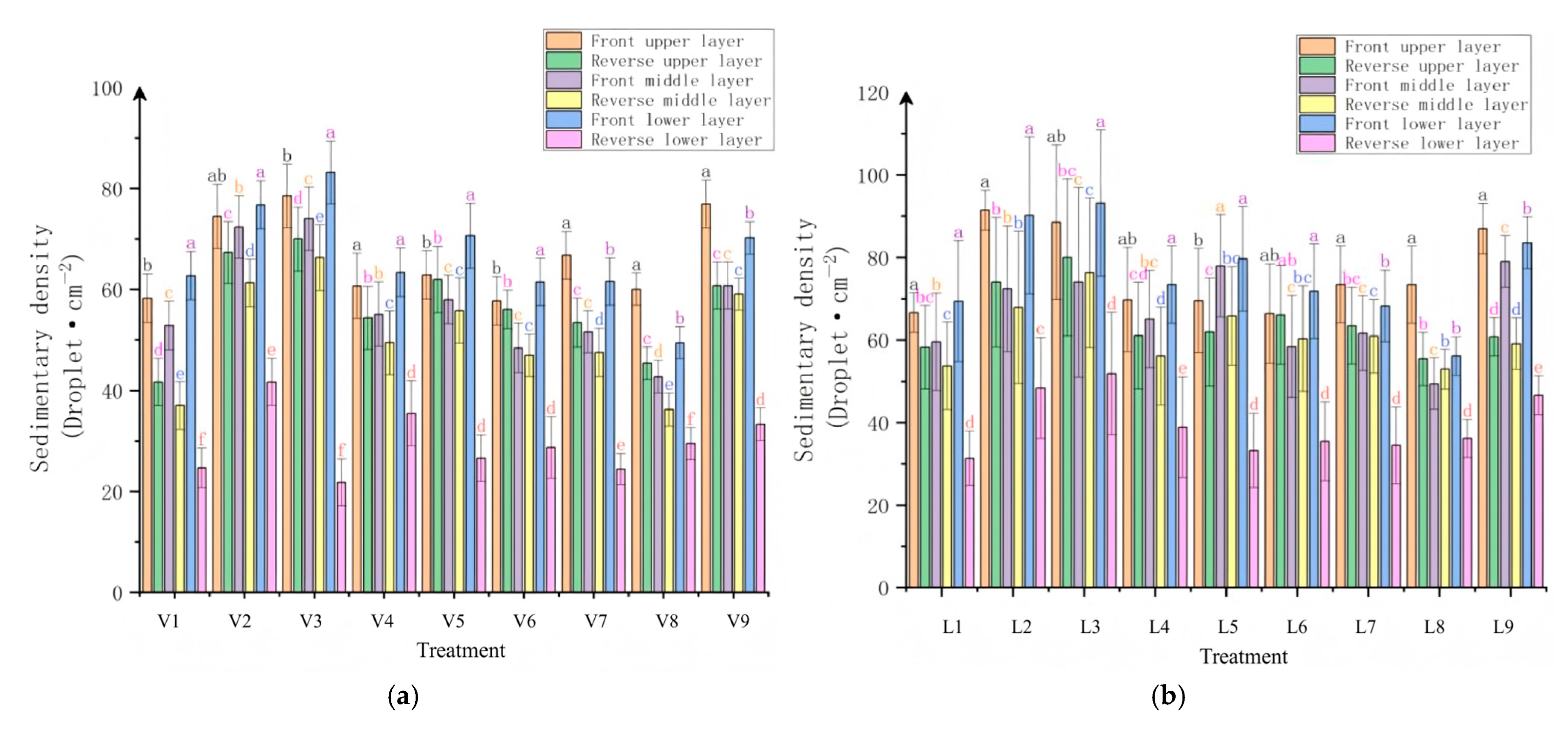

3.2.1. Droplet Deposition Characteristic Analysis Under Different Spraying Modes

3.2.2. Droplet Deposition Density Analysis Under Different Canopy Heights

3.3. Results and Analysis of Field Verification Test

4. Conclusions

- (1)

- According to the complex topographic characteristics of the closed orchard and the agronomic requirements of the plant protection operation, a centrifugal fan was selected for the air volume generation device in the air delivery system and was matched with an adjustable splitter and duckbill air outlets to ensure the air delivery effect. Based on the principles of air replacement and final velocity, the air volume of the centrifugal fan in the air-delivered spray system was designed as 10,000/m3·h, enabling the airflow to overcome the canopy resistance and carry droplets to enter the inner chamber of the fruit tree. The vertical and horizontal adjustment ranges of the integral intelligent lifting device driven by the electric push rod in the multi-duct system were 1.0–1.5 m and 0.9–1.3 m, respectively, meeting the plant protection requirement of orchards under different planting patterns in different periods.

- (2)

- CFD-based simulation of the flow field inside the centrifugal fan and outside the air delivery system showed that an air duct size of 230 × 110 mm, an air outlet distance of 350 mm, and a fan speed of 2160 r/min can simultaneously meet the requirements for both width and final velocity.

- (3)

- The field L9(34) orthogonal test results indicate that under the same operating parameters, the droplet deposition density under liquid pump–fan cooperative operation is significantly higher than that under liquid pump independent operation (p < 0.05). Under the liquid pump–fan cooperative spraying mode, liquid pesticide achieves better adhesion on fruit tree leaves, with a reduced dispersion degree of droplet deposition; under different operating modes, the factors with the greatest influences are, in order, C, B, and A, and the optimal spraying performance is achieved at a driving speed of 0.3 m/s, a nozzle pressure of 3 MPa, and a nozzle type of 6502.

- (4)

- The field spraying experimental verification was conducted under the optimal operating parameters. The results show that the average droplet coverage and deposition density on fruit tree canopy leaves under liquid pump independent operation mode are 48.30% and 60.54 droplets/cm2, respectively, and those under liquid pump–fan cooperative operation mode are 56.54% and 71.34 droplets/cm2, respectively; the coefficients of variation for the average droplet coverage on the front and back sides of fruit tree canopy leaves under liquid pump independent operation mode range from 9.70% to 11.85% and from 11.33% to 22.67%, respectively, and those under liquid pump–fan cooperative operation mode range from 13.37% to 16.82% and from 4.19% to 19.07%, respectively. Both sets of results meet the evaluation criterion for the coefficient of variation in plant protection machinery in orchards. Furthermore, the average droplet coverage and deposition density on fruit tree canopy leaves under liquid pump–fan cooperative mode are significantly higher than those under liquid pump independent operation mode (p < 0.05). Under cooperative operation mode, the droplets, assisted by the fan airflow, can penetrate the canopy, improving the uniformity of droplet coverage on leaves and elevating the adhesion rate of droplets at different canopy heights.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Argenta, C.; Amarante, D.; Betinelli, S.; Brancher, L.; Nesi, N.; Vieira, J. Comparison of fruit attributes of ‘Fuji’ apple strains at harvest and after storage. Sci. Hortic. 2020, 272, 109585. [Google Scholar] [CrossRef]

- Abasi, S.; Minaei, S.; Jamshidi, B.; Fathi, D. Development of an optical smart portable instrument for fruit quality detection. IEEE Trans. Instrum. Meas. 2021, 70, 7000109. [Google Scholar] [CrossRef]

- Wang, Y.; Han, L.; Qi, K.; Hou, J. Transaction Costs and Farm-to-Market Linkages in China: Empirical Evidence from Apple Producers. J. Agric. Sci. 2024, 12, 82. [Google Scholar] [CrossRef]

- Zhou, J.; Zhao, D.; Chen, Y.; Kang, G.; Cheng, C. Analysis of apple producing area changes in China. J. Fruit Sci. 2021, 38, 372–384. [Google Scholar]

- Wang, H. Study on the Restrictions and Countermeasures of Developing Shanxi Apple Industry. Master’s Thesis, Northwest A&F University, Yanling, China, 2012. [Google Scholar]

- Yu, L.; Zhao, Q.; Li, L.; Zhang, J.; Du, J.; Niu, Z. Major cultivation techniques suitable for fruit high quantityand efficiency production Shanxi Province in 2020. J. Fruit Res. 2020, 1, 52–56. [Google Scholar]

- Zhang, J.; Wang, C.; He, J.; Zhang, D. Causes and Reformation Strategies of Apple Closed-in Orchards. Xiandai Nongcun Keji 2019, 12, 43+99. [Google Scholar]

- Shang, G. Causes of Canopy Closure and Improvement Measures in Standard Apple Orchards. Northwest Hortic. 2022, 12, 15–16. [Google Scholar]

- Wang, S.; Song, J.; He, X.; Li, Y.; Ling, Y. Design of air-assisted electric knapsack sprayer and experiment of its operation performance. Tran. Chin. Soc. Agric. Eng. 2016, 32, 67–73. [Google Scholar]

- Wu, J.; Wang, X.; Zhang, W.; Xie, X.; Li, C.; Rao, X. Study on precise variable operation control method of orchard plant protection unmanned aerial vehicles. China Plant Prot. 2024, 44, 11–16. [Google Scholar]

- Chen, H. Portable Efficient Application Techniques in Hilly Orchards Chen Hongju. Beijing Nongye 2012, 15, 45–46. [Google Scholar]

- Gao, Y.; Zhao, J.; Zhang, P.; Liu, Z.; Shi, G.; Fan, R. Risk Assessment of Human Exposure to Beta-Cypermethrin During Application in Apple Orchard. Agr. Ochem. 2021, 60, 38–41+65. [Google Scholar]

- Li, C.; Zhang, X.; Jiang, J.; Hu, Y. Development and experiment of riser air-blowing sprayer in vineyard. Tran. Chin. Soc. Agric. Eng. 2013, 29, 71–78. [Google Scholar]

- Dong, X.; Zhang, T.; Yan, M.; Yang, X.; Yan, H.; Sun, X. Design and Experiment of 3WPZ-4 Type Air-assisted Grape Sprayer. J. Agric. Mach. 2018, 49, 205–213. [Google Scholar]

- Chen, J.Z.; Song, S.R.; Sun, D.Z.; Hong, T.S.; Zhang, L. Test on airflow field and spray characteristics for long-range air-blast sprayer. J. Agric. Mach. 2017, 33, 72–79. [Google Scholar]

- Li, H.; Chen, Z.; Li, Q.; Tang, Y.; Wang, P. Structural Designal and Experimental Test for Airflow Field Optimization of An Air-Assisted Radial Targeting Sprayer. J. Southwest Univ. (Nat. Sci. Ed.) 2024, 46, 195–206. [Google Scholar]

- Zhu, H.; Brazee, R.; Derksen, R.; Ozkan, H.; Fox, R. A specially designed air-assisted sprayer to improve spray penetration and air jet velocity distribution inside dense nursery crops. Trans. Asabe 2006, 49, 1285–1294. [Google Scholar] [CrossRef]

- Gil, E.; Llorens, J.; Llop, J.; Gallart, R.; Arnó, J.; Escolà, A. Variable rate sprayer. Part 2-Vineyard prototype: Design, implementation, and validation. Comput. Electron. Agric. 2013, 95, 136–150. [Google Scholar] [CrossRef]

- Ru, Y.; Chen, X.; Liu, B.; Wang, S.; Lin, M. Optimized Design and Performance Test of Axial Flow Orchard Sprayer Air Delivery System. J. Agric. Mach. 2022, 53, 147–157. [Google Scholar]

- Jiang, H.; Bai, P.; Liu, L.; Dong, X.; Song, J.; Zhang, X. Caterpillar Self-propelled and Air-assisted Orchard Sprayer with Automatic Target Spray System. J. Agric. Mach. 2016, 47, 189–195. [Google Scholar]

- Song, L.; Li, J.; Yang, X.; Wang, P. Optimization Design of Wind Field Parameters of Tower Type Wind-driven Orchard Sprayer. J. Agric. Mech. Res. 2020, 42, 12–17. [Google Scholar]

- Zhang, Z.; Wang, D.; Li, J.; Wang, P.; Guo, Y.; Tian, S. Design and Experiment of Dual Flexible Air Duct Spraying Device for Orchards. Agriculture 2021, 15, 1031. [Google Scholar] [CrossRef]

- Duga, A.; Delele, M.; Ruysen, K.; Nuyttens, D.; Verboven, P.; Nicolai, B. Development and validation of a 3D CFD model of drift and its application to air-assisted orchard sprayers. Biosyst. Eng. 2017, 154, 62–75. [Google Scholar] [CrossRef]

- Duga, A.; Dekeyser, D.; Ruysen, K.; Nuyttens, D.; Verboven, P.; Nicolai, B. Numerical analysis of the effects of wind and sprayer type on spray distribution in different orchard training systems. BLM 2015, 157, 517–535. [Google Scholar] [CrossRef]

- Delele, M.; Jaeken, P.; Baer, C.; Schampheleire, J.; Verboven, P.; Nicolai, B.; Velde, H.; Nuyttens, D. CFD prototyping of an air-assisted orchard sprayer aimed at drift reduction. Comput. Electron. Agric. 2007, 55, 16–27. [Google Scholar] [CrossRef]

- Endalew, A.; Baer, C.; Rutten, N.; Vercammen, J. A new integrated CFD modelling approach towards air-assisted orchard spraying. Part I. Model development and effect of wind speed and direction on sprayer airflow. Comput. Electron. Agric. 2010, 71, 128–136. [Google Scholar] [CrossRef]

- Yang, F.; Li, Z.; Li, Y.; Huang, Z.; Ru, Y.; Zhou, H. Wind force test and simulation analysis for air delivery system of orchard sprayer. Acta Agric. Univ. Jiangxiensis 2024, 46, 1610–1622. [Google Scholar] [CrossRef]

- Niu, Y. Design and Experiment of Three-Port Air-Assisted Variable Sprayer for Citrus Orchards. Master’s Thesis, Huazhong Agricultural University, Wuhan, China, 2012. [Google Scholar]

- Huang, X.; Li, Y.; Chen, L.; Wang, K. CFD-Based Flow Field Characteristics of Air-Assisted Sprayer in Citrus Orchards. Agriculture 2021, 15, 1103. [Google Scholar] [CrossRef]

- Yang, F.; Sun, J.; Li, Y.; Zhang, Y.; Liu, Z. Design and performance test of image transmission remote control mower in closed orchard. J. Jilin Univ. Eng. Technol. Ed. 2024, 54, 281–293. [Google Scholar]

- GB/T 17997-2008; Evaluating Regulations for the Operation and Spraying Quality of Sprayers in the Field. China Standards Press: Beijing, China, 2008.

- NY/T 650-2013; Operating Quality for Sprayers. China Agriculture Press: Beijing, China, 2013.

- GB/T 32250.1-2022; National Technical Committee of Agricultural Machinery on Standardization (SAC/TC 201). Agricultural and Forestry Machinery—Inspection of Sprayers in Use—Part 1: General. China Standards Press: Beijing, China, 2022.

- Zhang, J.N.; Wang, C.; Zhang, D.; Yang, C. Effect of smallholder farmers’ management behavior on the canopy density of apple orchard. Jiangsu J. Agric. Sci. 2021, 37, 163–168. [Google Scholar]

- Dai, F.F. Selection and calculation of the blowing rate of air-assisted sprayers. Plan Prot. 2008, 6, 124–127. [Google Scholar]

- JB/T 9782-2014; Equipment for Crop Protection-General Test Methods. China Machine Press: Beijing, China, 2014.

- Fritz, B.K.; Hoffmann, W.C.; Bagley, W.E.; Kruger, G.R.; Czaczyk, Z.; Henry, R.S. Measuring droplet size of agricultural spray nozzles–Measurement distance and airspeed effects. At. Sprays 2014, 24, 747–760. [Google Scholar] [CrossRef]

- He, G.X.; Zeng, A.J.; He, J. Effect of Wind velocity from orchard sprayer on droplet deposit and Distribution. Tran. Chin. Soc. Agric. Eng. 2002, 04, 75–77. [Google Scholar]

- Li, X.; Lu, D.P.; Wang, S.L.; Fan, D.Q.; Zhou, H.; Lü, X.L. Simulation and Test on Droplet Distribution and Deposition of Fixed-pipe Cold Fogging System in Greenhouse. J. Agric. Mach. 2020, 51, 261–267. [Google Scholar]

- Xu, L.Y.; Wu, Y.Z.; Zhou, H.P.; Zhang, J.; Zhang, C. Analysis of spatial motion attitude and droplet deposition effect of tree leaves in response to wind vibration. Tran. Chin. Soc. Agric. Eng. 2024, 40, 71–81. [Google Scholar]

- Yan, Y.; Lan, Y.; Wang, G.; Xu, T.; Deng, J.; Chen, P.; Wang, L. Evaluation of the deposition and distribution of spray droplets in citrus orchards by plant protection drones. Fron. Plant Sci. 2023, 14, 1303669. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Xiao, Q.; Han, X.; Lan, Y.; Chen, S.; Wang, J.; Zhang, H.; Wang, X.; Li, J. Effect of aerial application of adjuvants on pepper defoliant droplet deposition and efficacy of defoliation sprayed by unmanned aerial vehicles. Fron. Plant Sci. 2022, 13, 917462. [Google Scholar] [CrossRef]

| Item | Value |

|---|---|

| Unmanned vehicle power (kW) | 17.4 |

| Unmanned vehicle overall size (L × W × H mm) | 2000 × 1260 × 750 |

| Overall weight (kg) | 665 |

| Walking mode | Self-propelled crawler-type |

| Operation mode | Remote mode |

| Operation speed (m/s) | 0–1.5 |

| Climbing slope (°) | ≤45 |

| Oil tank capacity (L) | 7.5 |

| Battery capacity (A·h) | 100 |

| Spraying power (kW) | 2 × 1.5 |

| Number of nozzles | 6 |

| Liquid chemical tank capacity (L) | 300 |

| Spraying width (m) | 8 |

| Rated spray volume of single pump (L/min) | ≥8 |

| Item | Value |

|---|---|

| Vertical spray bar height (mm) | 1100 |

| The adjustment range of vertical spray bar height (mm) | 500 |

| The adjustment range of vertical spray bar width (mm) | 400 |

| Treats | Factor Coding Variables | Factor Actual Variables | ||||

|---|---|---|---|---|---|---|

| Driving Speed (m/s) | Nozzle Pressure (MPa) | Nozzle Type | Driving Speed (m/s) | Nozzle Pressure (MPa) | Nozzle Type | |

| 1 | A1 | B1 | C1 | 0.3 | 2 | 6501 |

| 2 | A1 | B2 | C2 | 0.3 | 2.5 | 6502 |

| 3 | A1 | B3 | C3 | 0.3 | 3 | 6503 |

| 4 | A2 | B1 | C2 | 0.8 | 2 | 6502 |

| 5 | A2 | B2 | C3 | 0.8 | 2.5 | 6503 |

| 6 | A2 | B3 | C1 | 0.8 | 3 | 6501 |

| 7 | A3 | B1 | C3 | 1.3 | 2 | 6503 |

| 8 | A3 | B2 | C1 | 1.3 | 2.5 | 6501 |

| 9 | A3 | B3 | C2 | 1.3 | 3 | 6502 |

| Experiment Number | Droplet Deposition Density | Experiment Number | Droplet Deposition Density | ||

|---|---|---|---|---|---|

| Mean ± Standard Deviation (Droplets/cm2) | Coefficient Variation | Mean ± Standard Deviation (Droplets/cm2) | Coefficient Variation | ||

| V1 | 46.17 ± 12.93 A | 28.01% | L1 | 56.45 ± 13.59 B | 24.07% |

| V2 | 65.64 ± 12.99 A | 19.79% | L2 | 73.42 ± 15.14 B | 20.63% |

| V3 | 65.62 ± 18.27 A | 27.85% | L3 | 77.28 ± 14.47 B | 18.73% |

| V4 | 53.07 ± 9.93 A | 18.72% | L4 | 60.68 ± 12.34 B | 20.34% |

| V5 | 55.97 ± 15.27 A | 27.29% | L5 | 64.69 ± 16.86 B | 26.06% |

| V6 | 49.89 ± 11.77 A | 23.59% | L6 | 59.72 ± 12.84 B | 21.51% |

| V7 | 50.88 ± 14.72 A | 28.94% | L7 | 60.32 ± 13.54 B | 22.44% |

| V8 | 43.87 ± 10.61 A | 24.18% | L8 | 53.87 ± 12.03 B | 22.33% |

| V9 | 60.43 ± 14.9 A | 24.66% | L9 | 69.31 ± 16.12 B | 23.26% |

| Source | Sum of Squares | DF | Mean Square | F Value | p Value | |

|---|---|---|---|---|---|---|

| Liquid pump independent operation | A | 153.156 | 2 | 76.578 | 77.234 | 0.013 |

| B | 339.825 | 2 | 169.9125 | 171.3697 | 0.006 | |

| C | 730.569 | 2 | 365.2845 | 368.416 | 0.003 | |

| Error | 1.983 | 4347 | 0.9915 | |||

| Cor Total | 1225.533 | 4353 | ||||

| Liquid pump–fan cooperative operation | A | 349.497 | 2 | 174.7485 | 76.999 | 0.013 |

| B | 416.457 | 2 | 208.2285 | 91.751 | 0.011 | |

| C | 718.29 | 2 | 359.145 | 158.249 | 0.006 | |

| Error | 4.539 | 4347 | 2.2695 | |||

| Cor Total | 1488.783 | 4353 | ||||

| Canopy Positions | Droplet Coverage Rate (%) | Droplet Deposition Density (Droplets/cm2) | ||||

|---|---|---|---|---|---|---|

| Liquid Pump Independent | Liquid Pump–Fan Cooperative | p Value | Liquid Pump Independent | Liquid Pump–Fan Cooperative | p Value | |

| Front side in upper layer | 59.92 ± 5.81 B (9.70%) | 64.19 ± 8.58 A (13.37%) | 0.0368 | 70.97 ± 4.50 B (6.34%) | 86.25 ± 2.43 A (2.81%) | <0.0001 |

| Front side in middle layer | 48.61 ± 6.09 B (12.53%) | 61.02 ± 8.82 A (14.45%) | <0.0001 | 73.98 ± 5.44 B (7.35%) | 78.63 ± 1.33 A (1.69%) | <0.0001 |

| Front side in lower layer | 46.85 ± 5.55 B (11.85%) | 55.46 ± 9.33 A (16.82%) | 0.0001 | 42.77 ± 3.34 B (7.81%) | 63.92 ± 0.33 A (0.52%) | <0.0001 |

| Back side in upper layer | 51.46 ± 5.83 B (11.33%) | 58.11 ± 8.99 A (15.47%) | 0.0022 | 70.11 ± 4.03 B (5.75%) | 74.60 ± 0.50 A (0.67%) | <0.0001 |

| Back side in middle layer | 47.81 ± 5.84 B (12.21%) | 57.24 ± 8.12 A (14.19%) | <0.0001 | 66.28 ± 5.05 B (7.62%) | 72.26 ± 0.29 A (0.40%) | <0.0001 |

| Back side in lower layer | 35.12 ± 7.96 B (22.67%) | 43.22 ± 8.24 A (19.07%) | 0.0006 | 39.14 ± 1.37 B (3.50%) | 51.79 ± 0.23 A (0.44%) | <0.0001 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Zhang, F.; Wang, Y.; Li, H.; Jin, Y.; Zhang, Y.; Zhang, Z.; Cui, Q. Design and Experiment of a Multi-Duct Air-Delivered Sprayer for Closed Apple Orchards. Agriculture 2025, 15, 1958. https://doi.org/10.3390/agriculture15181958

Wang J, Zhang F, Wang Y, Li H, Jin Y, Zhang Y, Zhang Z, Cui Q. Design and Experiment of a Multi-Duct Air-Delivered Sprayer for Closed Apple Orchards. Agriculture. 2025; 15(18):1958. https://doi.org/10.3390/agriculture15181958

Chicago/Turabian StyleWang, Juxia, Fengzi Zhang, Yuanmeng Wang, Haoran Li, Yusheng Jin, Yanqing Zhang, Zhiyong Zhang, and Qingliang Cui. 2025. "Design and Experiment of a Multi-Duct Air-Delivered Sprayer for Closed Apple Orchards" Agriculture 15, no. 18: 1958. https://doi.org/10.3390/agriculture15181958

APA StyleWang, J., Zhang, F., Wang, Y., Li, H., Jin, Y., Zhang, Y., Zhang, Z., & Cui, Q. (2025). Design and Experiment of a Multi-Duct Air-Delivered Sprayer for Closed Apple Orchards. Agriculture, 15(18), 1958. https://doi.org/10.3390/agriculture15181958