Soilless Growing Media for Cannabis Cultivation

Abstract

1. Introduction

2. Soilless Cultivation and Growing Media

2.1. Historical Development of Soilless Cultivation

2.2. Properties and Classification

3. Characterization of Soilless Inert and Semi-Inert Media

3.1. Rockwool

3.1.1. Production, Composition, and Physical Properties

3.1.2. Agricultural Use and Management Practices

3.1.3. Environmental Impact and Sustainability

3.2. Coconut Coir

3.2.1. Production, Composition, and Physical Properties

3.2.2. Agricultural Use and Management Practices

3.2.3. Environmental Impact and Sustainability

3.3. Perlite

3.3.1. Production, Composition, and Physical Properties

3.3.2. Agricultural Use and Management Practices

3.3.3. Environmental Impact and Sustainability

3.4. Vermiculite

3.4.1. Production, Composition, and Physical Properties

3.4.2. Agricultural Use and Management Practices

3.4.3. Environmental Impact and Sustainability

3.5. Expanded Clay

3.5.1. Production, Composition, and Physical Properties

3.5.2. Agricultural Use and Management Practices

3.5.3. Environmental Impact and Sustainability

3.6. Foamed Glass

3.6.1. Production, Composition, and Physical Properties

3.6.2. Agricultural Use and Management Practices

3.6.3. Environmental Impact and Sustainability

3.7. Biochar

3.7.1. Production, Composition, and Physical Properties

3.7.2. Agricultural Use and Management Practices

3.7.3. Environmental Impact and Sustainability

3.8. Peat

3.8.1. Production, Composition, and Physical Properties

3.8.2. Agricultural Use and Management Practices

3.8.3. Environmental Impact and Sustainability

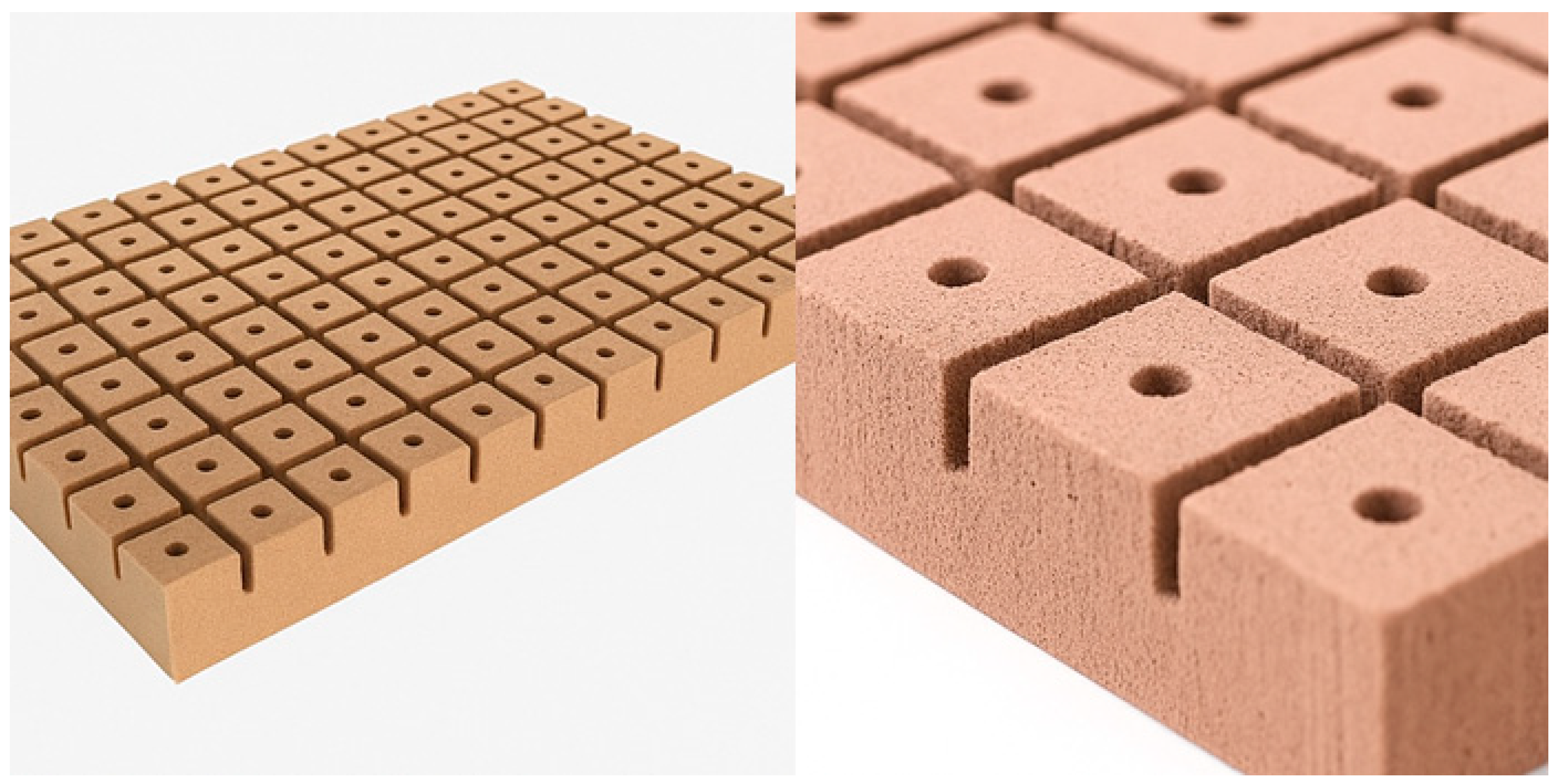

3.9. Phenolic Foam

3.9.1. Production, Composition, and Physical Properties

3.9.2. Agricultural Use and Management Practices

3.9.3. Environmental Impact and Sustainability

4. Effects of Medium on Cannabis Growth, Yield, and Cannabinoid Content

4.1. Vegetative Growth in Different Growing Media

4.2. Root Development and Nutrient Uptake

4.3. Generative Phase—Inflorescence Yield and Cannabinoid Content

5. Conclusions and Future Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CBD | Cannabidiol |

| CEC | Cation exchange capacity |

| DWC | Deep water culture |

| EAW | Easily available water |

| EC | Electrical conductivity |

| EPD | Environmental product declaration |

| FOCUS | Foundation of Cannabis Unified Standards |

| GACP | Good agricultural and collection practice |

| GMP | Good manufacturing practice |

| GPP | Good production practice |

| IMC-GAP | Israeli Medical Cannabis Good Agricultural Practice |

| LECA | Lightweight expanded clay aggregate |

| LCA | Life cycle assessment |

| RLD | Root length density |

| RO | Reverse osmosis |

| SOP | Standard operating procedure |

| TGO 93 | Therapeutic Goods Order No. 93 |

| THC | Tetrahydrocannabinol |

| THCA | Tetrahydrocannabinolic acid |

References

- Steinmetz, F.P.; Kohek, M. Farmability and pharmability: Transforming the drug market to a health-and human rights-centred approach from self-cultivation to safe supply of controlled substances. Drug Sci. Policy Law 2022, 8, 20503245221097797. [Google Scholar] [CrossRef]

- Nemati, R.; Fortin, J.-P.; Craig, J.; Donald, S. Growing Mediums for Medical Cannabis Production in North America. Agronomy 2021, 11, 1366. [Google Scholar] [CrossRef]

- Zheng, Y. Soilless production of drug-type Cannabis sativa. Acta Hortic. 2019, 1305, 375–382. [Google Scholar] [CrossRef]

- Thawonkit, T.; Insalud, N.; Dangtungee, R.; Bhuyar, P. Integrating Sustainable Cultivation Practices and Advanced Extraction Methods for Improved Cannabis Yield and Cannabinoid Production. Int. J. Plant Biol. 2025, 16, 38. [Google Scholar] [CrossRef]

- Malabadi, R.B.; Mammadova, S.S.; Kolkar, K.P.; MR, S.; Chalannavar, R.K.; Coronado, K.V.C. Cannabis sativa: A therapeutic medicinal plant-global marketing updates. World J. Biol. Pharm. Health Sci. 2024, 17, 170–183. [Google Scholar] [CrossRef]

- Søgaard, T.F.; Brummer, J.E.; Wilkins, C.; Sznitman, S.R.; Sevigny, E.L.; Frank, V.A.; Potter, G.; Hakkarainen, P.; Barratt, M.J.; Werse, B.; et al. Global patterns in small-scale cannabis growers’ distribution practices: Exploring the grower-distributor nexus. Int. J. Drug Policy 2025, 144, 104463. [Google Scholar] [CrossRef]

- Chandra, S.; Lata, H.; ElSohly, M.A.; Walker, L.A.; Potter, D. Cannabis cultivation: Methodological issues for obtaining medical-grade product. Epilepsy Behav. 2017, 70, 302–312. [Google Scholar] [CrossRef]

- Jin, D.; Jin, S.; Chen, J. Cannabis Indoor Growing Conditions, Management Practices, and Post-Harvest Treatment: A Review. Am. J. Plant Sci. 2019, 10, 925–946. [Google Scholar] [CrossRef]

- Malík, M.; Velechovský, J.; Tlustoš, P. The overview of existing knowledge on medical cannabis plants growing. Plant Soil Environ. 2021, 67, 425–442. [Google Scholar] [CrossRef]

- Trancoso, I.; de Souza, G.A.R.; dos Santos, P.R.; dos Santos, K.D.; de Miranda, R.M.d.S.N.; da Silva, A.L.P.M.; Santos, D.Z.; García-Tejero, I.F.; Campostrini, E. Cannabis sativa L.: Crop Management and Abiotic Factors That Affect Phytocannabinoid Production. Agronomy 2022, 12, 1492. [Google Scholar] [CrossRef]

- Fussy, A.; Papenbrock, J. An Overview of Soil and Soilless Cultivation Techniques—Chances, Challenges and the Neglected Question of Sustainability. Plants 2022, 11, 1153. [Google Scholar] [CrossRef] [PubMed]

- Kumar, T.V.; Verma, R. A Comprehensive Review on Soilless Cultivation for Sustainable Agriculture. J. Exp. Agric. Int. 2024, 46, 193–207. [Google Scholar] [CrossRef]

- Lakhiar, I.A.; Yan, H.; Syed, T.N.; Zhang, C.; Shaikh, S.A.; Rakibuzzaman, M.; Vistro, R.B. Soilless Agricultural Systems: Opportunities, Challenges, and Applications for Enhancing Horticultural Resilience to Climate Change and Urbanization. Horticulturae 2025, 11, 568. [Google Scholar] [CrossRef]

- Balliu, A.; Zheng, Y.; Sallaku, G.; Fernández, J.A.; Gruda, N.S.; Tuzel, Y. Environmental and Cultivation Factors Affect the Morphology, Architecture and Performance of Root Systems in Soilless Grown Plants. Horticulturae 2021, 7, 243. [Google Scholar] [CrossRef]

- Stoa, R. Craft Weed, with a New Preface by the Author: Family Farming and the Future of the Marijuana Industry, 1st ed.; The MIT Press: Cambridge, MA, USA; London, UK, 2024; pp. 1–256. [Google Scholar]

- Caputo, S. History, Techniques and Technologies of Soil-Less Cultivation. In Small Scale Soil-Less Urban Agriculture in Europe, 1st ed.; Springer International Publishing: Cham, Switzerland, 2022; pp. 45–86. [Google Scholar] [CrossRef]

- Nemali, K. History of Controlled Environment Horticulture: Greenhouses. HortScience 2022, 57, 239–246. [Google Scholar] [CrossRef]

- De Rijck, G.; Schrevens, E. Comparison of the mineral composition of twelve standard nutrient solutions. J. Plant Nutr. 1998, 21, 2115–2125. [Google Scholar] [CrossRef]

- Gericke, W.F. Crop Production without Soil. Nature 1938, 141, 536–540. [Google Scholar] [CrossRef]

- Gericke, W.F. Hydroponics—Crop Production in Liquid Culture Media. Science 1937, 85, 177–178. [Google Scholar] [CrossRef]

- Jensen, M.H. Hydroponics. HortScience 1997, 32, 1018–1021. [Google Scholar] [CrossRef]

- Yoshida, S.; Forno, D.A.; Cock, J.H.; Gomez, K.A. Laboratory Manual for Physiological Studies of Rice, 3rd ed.; International Rice Research Institute: Los Baños, Philippines, 1971; p. 61. [Google Scholar]

- Yamasaki, K. Studies on water culture of several vegetables with special reference to the control of nutrient solution and ratio of nutrients asborption per water consumption. Mem. Fac. Agric. Tokyo Univ. Edue. 1976, 22, 53–100. [Google Scholar]

- Gruda, N.S.; Bragg, N. Developments in Alternative Organic Materials for Growing Media in Soilless Culture Systems. In Advances in Horticultural Soilless Culture, 1st ed.; Gruda, N.S., Ed.; Burleigh Dodds Science Publishing: London, UK, 2021; pp. 73–106. [Google Scholar] [CrossRef]

- Abad, M.; Fornes, F.; Carrión, C.; Noguera, V.; Noguera, P.; Maquieira, A.n.; Puchades, R. Physical Properties of Various Coconut Coir Dusts Compared to Peat. HortScience 2005, 40, 2138–2144. [Google Scholar] [CrossRef]

- Tong, X.; Zhang, X.; Fensholt, R.; Jensen, P.R.D.; Li, S.; Larsen, M.N.; Reiner, F.; Tian, F.; Brandt, M. Global area boom for greenhouse cultivation revealed by satellite mapping. Nat. Food 2024, 5, 513–523. [Google Scholar] [CrossRef] [PubMed]

- Sonneveld, C. Rockwool as a Substrate for Greenhouse Crops. In High-Tech and Micropropagation I, 1st ed.; Bajaj, Y.P.S., Ed.; Springer Berlin Heidelberg: Berlin/Heidelberg, Germany, 1991; pp. 285–312. [Google Scholar] [CrossRef]

- Wittwer, S.H. World-wide Use of Plastics in Horticultural Production. HortTechnology 1993, 3, 6–19. [Google Scholar] [CrossRef]

- Criscione, K.S.; Fields, J.S. Root growth and development in soilless culture—A review. Acta Hortic. 2023, 1389, 1–16. [Google Scholar] [CrossRef]

- Carlile, W.R.; Raviv, M.; Prasad, M. Organic Soilless Media Components. In Soilless Culture Theory and Practice, 2nd ed.; Raviv, M., Lieth, J.H., Bar-Tal, A., Eds.; Academic Press: London, UK; San Diego, CA, USA; Cambridge, MA, USA; Oxford, UK, 2019; pp. 303–378. [Google Scholar] [CrossRef]

- Islam, S.; Khan, S.; Ito, T.; Maruo, T.; Shinohara, Y. Characterization of the physico-chemical properties of environmentally friendly organic substrates in relation to rockwool. J. Hortic. Sci. Biotechnol. 2002, 77, 143–148. [Google Scholar] [CrossRef]

- Ombódi, A.; Valkai, M.B. Effect of reused rockwool slabs on the performance of ‘Daras F1’hot pepper under glasshouse conditions. Hung. Agric. Eng. 2020, 37, 48–52. [Google Scholar] [CrossRef]

- Lee, J.S.; Shin, J.H. Comparison of basal physicochemical changes of reused rockwool substrate in hydroponic tomato cultivation. J. Bio-Env. Con. 2024, 33, 114–119. [Google Scholar] [CrossRef]

- Flury, K.; Frischknecht, R.; Flumroc, A.G. Life Cycle Assessment of Rock Wool Insulation; ESU-Services: Uster, Switzerland, 2012. [Google Scholar]

- Koyama, S.; Urayama, H.; Karunaratne, K.M.P.D.; Yamashita, T. Effects of Coir Application on Soil Properties and Cucumber Production as a Reuse Model of Organic Medium Used in Soilless Culture. Trop. Agric. Dev. 2009, 53, 7–13. [Google Scholar] [CrossRef]

- Vieira, F.; Santana, H.E.P.; Jesus, M.; Santos, J.; Pires, P.; Vaz-Velho, M.; Silva, D.P.; Ruzene, D.S. Coconut Waste: Discovering Sustainable Approaches to Advance a Circular Economy. Sustainability 2024, 16, 3066. [Google Scholar] [CrossRef]

- Dzięcioł, J.; Szlachetka, O.; Rodrigues Tavares, J.M. From Volcanic Popcorn to the Material of the Future: A Critical Review of Expanded Perlite Applications and Environmental Impacts. Sustainability 2025, 17, 1454. [Google Scholar] [CrossRef]

- Khanday, S.A.; Hussain, M.; Das, A.K. A Review on Chemical Stabilization of Peat. Geotech. Geol. Eng. 2021, 39, 5429–5443. [Google Scholar] [CrossRef]

- Gruda, N.S.; Hirschler, O.; Stuart, J. Peat reduction in horticulture—An overview of Europe. Acta Hortic. 2023, 1391, 545–560. [Google Scholar] [CrossRef]

- Stichnothe, H. Life cycle assessment of peat for growing media and evaluation of the suitability of using the Product Environmental Footprint methodology for peat. Int. J. Life Cycle Assess. 2022, 27, 1270–1282. [Google Scholar] [CrossRef]

- Dsouza, G.C.; Dodangeh, F.; Venkata, G.B.; Ray, M.B.; Prakash, A.; Xu, C. A comprehensive review of biobased polyurethane and phenol formaldehyde hydrophilic foams for environmental remediation, floral, and hydroponics applications. Biomass Bioenergy 2025, 192, 107493. [Google Scholar] [CrossRef]

- Gohardoust, M.R.; Bar-Tal, A.; Effati, M.; Tuller, M. Characterization of Physicochemical and Hydraulic Properties of Organic and Mineral Soilless Culture Substrates and Mixtures. Agronomy 2020, 10, 1403. [Google Scholar] [CrossRef]

- Carvalho, J.; Nascimento, L.; Soares, M.; Valério, N.; Ribeiro, A.; Faria, L.; Silva, A.; Pacheco, N.; Araújo, J.; Vilarinho, C. Life Cycle Assessment (LCA) of Biochar Production from a Circular Economy Perspective. Processes 2022, 10, 2684. [Google Scholar] [CrossRef]

- Eksi, M.; Rowe, D.B. Green roof substrates: Effect of recycled crushed porcelain and foamed glass on plant growth and water retention. Urban For. Urban Green. 2016, 20, 81–88. [Google Scholar] [CrossRef]

- Ingrao, C.; Selvaggi, R.; Valenti, F.; Matarazzo, A.; Pecorino, B.; Arcidiacono, C. Life cycle assessment of expanded clay granulate production using different fuels. Resour. Conserv. Recycl. 2019, 141, 398–409. [Google Scholar] [CrossRef]

- Kalaskar, M.; Ayyanar, M.; Gurav, N.; Surana, S.J. Cultivation, Collection, and Preparation of Plant Drugs. In Pharmacognosy and Phytochemistry; Odoh, U.E., Gurav, S.S., Chukwuma, M.O., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 2025; pp. 83–102. [Google Scholar] [CrossRef]

- European Medicines Agency. Guideline on Good Agricultural and Collection Practice (GACP) for Starting Materials of Herbal Origin; EMA: Amsterdam, The Netherlands, 2025. [Google Scholar]

- European Commission. EudraLex Volume 4—EU Guidelines for Good Manufacturing Practice, Annex 7: Manufacture of Herbal Medicinal Products; Publications Office of the European Union: Brussels, Belgium, 2008. [Google Scholar]

- Government of Canada. Good Production Practices Guide for Cannabis; Health Canada: Ottawa, ON, Canada, 2025.

- Government of Canada. Cannabis Regulations (SOR/2018-144), Part 5: Good Production Practices; Government of Canada: Ottawa, ON, Canada, 2019.

- Gruda, N.S. Increasing Sustainability of Growing Media Constituents and Stand-Alone Substrates in Soilless Culture Systems. Agronomy 2019, 9, 298. [Google Scholar] [CrossRef]

- FS-1001-1:2016; © 2014–2021 Foundation of Cannabis Unified Standards; Cannabis Cultivation. FOCUS: Phoenix, AZ, USA, 2016.

- Steinberg, J.N. Cannabis Legalization: An Ethnography of the Global Movement and Market Forces. PhD Dissertation, University of Oxford, Oxford, UK, 2022. [Google Scholar]

- Therapeutic Goods Administration. Therapeutic Goods Order No. 93 (Standard for Medicinal Cannabis); TGA: Canberra, Australia, 2017. [Google Scholar]

- Veit, M. Quality requirements for medicinal cannabis and respective products in the European Union–Status Quo. Planta Med. 2023, 89, 808–823. [Google Scholar] [CrossRef]

- Singh, J.; Nigam, R.; Tiwari, A.; Rathi, M. Effect of different soilless media on the growth and development of Horticultural Crops. Int. J. Agric. Inven. 2024, 9, 68–77. [Google Scholar] [CrossRef]

- Olympios, C. Soilless media under protected cultivation rockwool, peat, perlite and other substrates. Acta Hortic. 1993, 323, 215–234. [Google Scholar] [CrossRef]

- De Rijck, G.; Schrevens, E. Distribution of nutrients and water in rockwool slabs. Sci. Hortic. 1998, 72, 277–285. [Google Scholar] [CrossRef]

- Silber, A. Chapter 4—Chemical Characteristics of Soilless Media. In Soilless Culture, 2nd ed.; Raviv, M., Lieth, J.H., Bar-Tal, A., Eds.; Elsevier: Boston, MA, USA, 2019; pp. 113–148. [Google Scholar] [CrossRef]

- An, C.B.; Shin, J.H. Comparion of rockwool, reused rockwool and coir medium on tomato (Solanum lycopersicum) growth, fruit quality and productivity in greenhouse soilless culture. J. Bio-Environ. Control 2021, 30, 175–182. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, T. Development and Application Status of Glass Wool, Rock Wool, and Ceramic Wool. In Thermal Insulation and Radiation Control Technologies for Buildings, 1st ed.; Kośny, J., Yarbrough, D.W., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 129–161. [Google Scholar] [CrossRef]

- Da Silva, F.; Wallach, R.; Chen, Y. Hydraulic properties of rockwool slabs used as substrates in horticulture. Acta Hortic. 1994, 401, 71–76. [Google Scholar] [CrossRef]

- Thomas, P.; Knox, O.G.G.; Powell, J.R.; Sindel, B.; Winter, G. The Hydroponic Rockwool Root Microbiome: Under Control or Underutilised? Microorganisms 2023, 11, 835. [Google Scholar] [CrossRef]

- Rajaseger, G.; Chan, K.L.; Tan, K.Y.; Ramasamy, S.; Khin, M.C.; Amaladoss, A.; Haribhai, P.K. Hydroponics: Current trends in sustainable crop production. Bioinformation 2023, 19, 925–938. [Google Scholar] [CrossRef]

- Weingarten, M.; Mattson, N.; Grab, H. Evaluating Propagation Techniques for Cannabis sativa L. Cultivation: A Comparative Analysis of Soilless Methods and Aeroponic Parameters. Plants 2024, 13, 1256. [Google Scholar] [CrossRef]

- McGehee, C.S.; Raudales, R.E. Pathogenicity and Mefenoxam Sensitivity of Pythium, Globisporangium, and Fusarium Isolates From Coconut Coir and Rockwool in Marijuana (Cannabis sativa L.) Production. Front. Agron. 2021, 3, 706138. [Google Scholar] [CrossRef]

- Nakano, Y.; Sasaki, H.; Nakano, A.; Suzuki, K.; Takaichi, M. Growth and yield of tomato plants as influenced by nutrient application rates with quantitative control in closed rockwool cultivation. J. Jpn. Soc. Hortic. Sci. 2010, 79, 47–55. [Google Scholar] [CrossRef]

- Baas, R.; Wijnen, D. Salinity effects on yield and nutrient uptake in Cannabis sativa L. Acta Hortic. 2022, 1377, 785–792. [Google Scholar] [CrossRef]

- Berthold, D.E.; Elazar, A.; Lefler, F.; Marble, C.; Laughinghouse IV, H.D. Control of algal growth on greenhouse surfaces using commercial algaecides. Sci. Agric. 2021, 78, e20180292. [Google Scholar] [CrossRef]

- Zheng, Y. Rootzone Management in Cannabis Production. In Handbook of Cannabis Production in Controlled Environments, 1st ed.; Zheng, Y., Ed.; CRC Press: Boca Raton, FL, USA, 2022; pp. 123–162. [Google Scholar] [CrossRef]

- Seaman, C. Cultivation Stress Techniques and the Production of Secondary Metabolites in Cannabis Sativa. In Recent Advances in the Science of Cannabis, 1st ed.; Strongin, R.M., Meehan-Atrash, J., Vialpando, M., Eds.; CRC Press: Boca Raton, FL, USA, 2021; pp. 1–30. [Google Scholar] [CrossRef]

- Adekomaya, O.; Majozi, T. Mitigating environmental impact of waste glass materials: Review of the existing reclamation options and future outlook. Environ. Sci. Pollut. Res. 2021, 28, 10488–10502. [Google Scholar] [CrossRef] [PubMed]

- Pandey, S.; Tripathi, G.K.; Dixit, P. Potentiality of the Wastes as Thermal Insulating Materials for Globular Economy and Sustainability. In Development of Sustainable Thermal Insulators from Waste Materials: A Circular Economy Approach, 1st ed.; Verma, S., Akram Khan, M., Srivastava, A.K., Eds.; Springer: Singapore, 2024; pp. 1–24. [Google Scholar] [CrossRef]

- Olasehinde, A.A. Biodegradable Growth Media Alternatives for Sustainable Hydroponic Farming. Curr. J. Appl. Sci. Technol. 2025, 44, 147–152. [Google Scholar] [CrossRef]

- Atzori, G.; Pane, C.; Zaccardelli, M.; Cacini, S.; Massa, D. The Role of Peat-Free Organic Substrates in the Sustainable Management of Soilless Cultivations. Agronomy 2021, 11, 1236. [Google Scholar] [CrossRef]

- Atapattu, A.J.; Udumann, S.S.; Nuwarapaksha, T.D.; Dissanayaka, N.S. Upcycling Coconut Husk By-Products: Transitioning from Traditional Applications to Emerging High-Value Usages. In Agricultural Waste to Value-Added Products: Bioproducts and Its Applications, 1st ed.; Neelancherry, R., Gao, B., Wisniewski, A., Jr., Eds.; Springer: Singapore, 2024; pp. 249–273. [Google Scholar] [CrossRef]

- Baş, S.; Hasan, K.M.F.; Csiha, C.; Dénes, L. Chapter 1—Coir fiber: Geographic distribution and cultivation. In Coir Fiber and Its Composites, 1st ed.; Jawaid, M., Ed.; Woodhead Publishing: Cambridge, UK, 2022; pp. 1–19. [Google Scholar] [CrossRef]

- Ma, Y.B.; Nichols, D.G. Phytotoxicity and Detoxification of Fresh Coir Dust and Coconut Shell. Commun. Soil Sci. Plant Anal. 2004, 35, 205–218. [Google Scholar] [CrossRef]

- Cui, W.; Bai, Q.; Liu, J.; Chen, J.; Qi, Z.; Zhou, W. Phytotoxicity Removal Technologies for Agricultural Waste as a Growing Media Component: A Review. Agronomy 2024, 14, 40. [Google Scholar] [CrossRef]

- Pandiselvam, R.; Khanashyam, A.C.; Dakshayani, R.; Beveridge, F.C.; Karouw, S.; Manikantan, M.R. Harvest and Postharvest Management of Coconut. In The Coconut Botany, Production and Uses, 1st ed.; Adkins, S.W., Biddle, J.M., Bazrafshan, A., Kalaipandian, S., Eds.; CABI: Wallingford, UK, 2024; pp. 99–110. [Google Scholar] [CrossRef]

- Jayasekara, C.; Amarasinghe, N. Coir–Coconut Cultivation, Extraction and Processing of Coir. In Industrial Applications of Natural Fibres: Structure, Properties and Technical Applications, 1st ed.; Müssig, J., Ed.; Wiley: Chichester, UK, 2010; pp. 197–217. [Google Scholar] [CrossRef]

- Gbollie, S.N.; Mwonga, S.M.; Kibe, A.M. Effects of calcium nitrate levels and soaking durations on cocopeat nutrient content. J. Agric. Chem. Environ. 2021, 10, 372–388. [Google Scholar] [CrossRef]

- Hettiarachchi, E.; Perera, R.; Chandani Perera, A.D.L.; Kottegoda, N. Activated coconut coir for removal of sodium and magnesium ions from saline water. Desalination Water Treat. 2016, 57, 22341–22352. [Google Scholar] [CrossRef]

- Evans, M.R.; Taylor, M.; Kuehny, J. Physical Properties of Biocontainers for Greenhouse Crops Production. HortTechnology 2010, 20, 549–555. [Google Scholar] [CrossRef]

- Kumar, S.; Singh, R.P.; Vipin; Singh, N.K. Chapter—15 Modern Techniques for Soilless Cultivation. In Modern Concept in Horticulture; Hanni, S.S., Gouthami, Y., Mangroliya, R., Sharma, S., Manjusha, D., Eds.; Integrated Publications: New Delhi, India, 2023; pp. 357–374. [Google Scholar]

- Israel, A.U.; Ogali, R.E.; Akaranta, O.; Obot, I.B. Extraction and characterization of coconut (Cocos nucifera L.) coir dust. Songklanakarin J. Sci. Technol. 2011, 33, 717–724. [Google Scholar]

- Masquelier, S.; Sozzi, T.; Bouvet, J.C.; Bésiers, J.; Deogratias, J.-M. Conception and Development of Recycled Raw Materials (Coconut Fiber and Bagasse)-Based Substrates Enriched with Soil Microorganisms (Arbuscular Mycorrhizal Fungi, Trichoderma spp. and Pseudomonas spp.) for the Soilless Cultivation of Tomato (S. lycopersicum). Agronomy 2022, 12, 767. [Google Scholar] [CrossRef]

- Caplan, D.; Dixon, M.; Zheng, Y. Coir-based growing substrates for indoor cannabis production. Acta Hortic. 2017, 1266, 55–62. [Google Scholar] [CrossRef]

- Reddy, N. Agricultural Applications of Coir. In Sustainable Applications of Coir and Other Coconut By-products, 1st ed.; Springer: Cham, Switzerland, 2019; pp. 31–54. [Google Scholar] [CrossRef]

- Caplan, D.; Dixon, M.; Zheng, Y. Optimal Rate of Organic Fertilizer during the Vegetative-stage for Cannabis Grown in Two Coir-based Substrates. HortScience 2017, 52, 1307–1312. [Google Scholar] [CrossRef]

- Saloner, A.; Bernstein, N. Nitrogen Source Matters: High NH4/NO3 Ratio Reduces Cannabinoids, Terpenoids, and Yield in Medical Cannabis. Front. Plant Sci. 2022, 13, 830224. [Google Scholar] [CrossRef] [PubMed]

- Caplan, D.; Dixon, M.; Zheng, Y. Optimal Rate of Organic Fertilizer during the Flowering Stage for Cannabis Grown in Two Coir-based Substrates. HortScience 2017, 52, 1796–1803. [Google Scholar] [CrossRef]

- Lapjit, C.; Nounbunma, P. The effects of different growing media on the growth and cannabinoid contents of Cannabis in an indoor pot cultivation system. Acta Hortic. 2024, 1423, 317–324. [Google Scholar] [CrossRef]

- Yin, D.; Montazerian, M.; Hunziker, P.; Cornejo, I.A.; Mauro, J.C. Perspective on glass properties influencing perlite expansion and strength. J. Am. Ceram. Soc. 2025, 108, e70055. [Google Scholar] [CrossRef]

- Maxineasa, S.G.; Isopescu, D.N.; Lupu, M.L.; Baciu, I.R.; Pruna, L.; Somacescu, C. The use of perlite in civil engineering applications. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1242, 012022. [Google Scholar] [CrossRef]

- Ahmadi, F.; Samadi, A.; Sepehr, E.; Rahimi, A.; Shabala, S. Increasing medicinal and phytochemical compounds of coneflower (Echinacea purpurea L.) as affected by NO3−/NH4+ ratio and perlite particle size in hydroponics. Sci. Rep. 2021, 11, 15202. [Google Scholar] [CrossRef]

- Fields, J.S.; Gruda, N.S. Developments in inorganic materials, synthetic organic materials and peat in soilless culture systems. In Advances in Horticultural Soilless Culture, 1st ed.; Burleigh Dodds Science Publishing: London, UK, 2021; pp. 45–72. [Google Scholar] [CrossRef]

- Sahoo, U.; Gaikwad, D.J.; Banerjee, M.; Malik, G.C.; Maitra, S. Artificial media for soilless cultivation. In Advances in Agricultural Technology; Maitra, S., Gaikwad, D.J., Santosh, D.T., Eds.; Griffon: Québec, QC, Canada, 2023; pp. 29–45. [Google Scholar]

- Hasama, Y.; Saito, Y.; Ohkubo, J. Water storage and drainage in perlite in container cultivation. SICE J. Control Meas. Syst. Integr. 2021, 14, 104–110. [Google Scholar] [CrossRef]

- Veazie, P.; Balance, M.S.; Whipker, B.E.; Jeong, K.Y. Comparison of Peat–Perlite-based and Peat–Biochar-based Substrates with Varying Rates of Calcium Silicate on Growth and Cannabinoid Production of Cannabis sativa ‘BaOx’. HortScience 2023, 58, 1250–1256. [Google Scholar] [CrossRef]

- Yang, T.; Altland, J.E.; Samarakoon, U.C. Evaluation of substrates for cucumber production in the Dutch bucket hydroponic system. Sci. Hortic. 2023, 308, 111578. [Google Scholar] [CrossRef]

- Liu, Q.; Wang, S.; Zhang, J.; He, T.; Chen, W.; Zhao, X.; Li, B.; Zhang, N. Research on preparing seedling substrates using edible mushroom waste and application. Folia Hort. 2023, 35, 275–285. [Google Scholar] [CrossRef]

- Erdal, İ.; Aktaş, H. Comparison of the Perlite, Leonardite, Vermicompost and Peat Moss and Their Combinations with Cocopeat as Tomato Growing Media. J. Soil Sci. Plant Nutr. 2025, 25, 2726–2741. [Google Scholar] [CrossRef]

- Abed, A.-T.; Éva, L. A comprehensive study of perlite in building materials: Balancing sustainability and performance. J. Therm. Anal. Calorim. 2025, 150, 10627–10643. [Google Scholar] [CrossRef]

- Önen, U.; Boyraz, T. Correlation between bending strength and porosity in vermiculite added ceramic bodies. J. Ceram. Process. Res. 2024, 25, 624–632. [Google Scholar] [CrossRef]

- Kara, A.; Yüksek, S. Determination of The Properties of Noise and Temperature Reducing Lightweight Building Material Produced From Expanded Vermiculite With Simple İnstruments. J. Eng. Fac. 2025, 3, 1–10. [Google Scholar]

- Lahchich, A.; Álvarez-Lloret, P.; Reynes, J.F.; Marcos, C. Relationships Between Physicochemical and Structural Properties of Commercial Vermiculites. Materials 2025, 18, 831. [Google Scholar] [CrossRef]

- Ortiz-Delvasto, N.; Garcia-Gomez, P.; Carvajal, M.; Bárzana, G. Aquaporins-mediated water availability in substrates for cannabis cultivation in relation to CBD yield. Plant Soil 2024, 495, 469–485. [Google Scholar] [CrossRef]

- Malla, P.B. Vermiculites. In Soil Mineralogy with Environmental Applications, 2nd ed.; Dixon, J.B., Schulze, D.G., Eds.; Soil Science Society of America: Madison, WI, USA, 2002; pp. 501–529. [Google Scholar] [CrossRef]

- Reis, V.U.V.; Carvalho, E.R.; Maciel, D.C.; Tavares, G.I.S.; Medeiros, J.C.; de Brito, R.B.; Pereira, J.E.J. Benefits of using vermiculite in the soybean seed germination testing. Discov. Plants 2025, 2, 165. [Google Scholar] [CrossRef]

- Kremenetskaya, I.; Ivanova, L.; Chislov, M.; Zvereva, I.; Vasilieva, T.; Marchevskaya, V.; Semushin, V.; Slukovskaya, M. Physicochemical transformation of expanded vermiculite after long-term use in hydroponics. Appl. Clay Sci. 2020, 198, 105839. [Google Scholar] [CrossRef]

- Sharma, M.R. Effect of plant growth regulators and different growing media on propagation of fruit crops. Pharm. Innov. J. 2022, 11, 4638–4642. [Google Scholar]

- Assis Neto, P.C.d.; Sales, L.P.B.; Oliveira, P.K.S.; Silva, I.C.d.; Barros, I.M.d.S.; Nóbrega, A.F.d.; Carneiro, A.M.P. Expanded Vermiculite: A Short Review about Its Production, Characteristics, and Effects on the Properties of Lightweight Mortars. Buildings 2023, 13, 823. [Google Scholar] [CrossRef]

- Álvarez-Ayuso, E.; García-Sánchez, A. Removal of heavy metals from waste waters by vermiculites. Env. Tech. 2003, 24, 615–625. [Google Scholar] [CrossRef] [PubMed]

- Raviv, M. Substrate’s end-of-life: Environmental and horticultural considerations. Acta Hortic. 2014, 1112, 281–290. [Google Scholar] [CrossRef]

- Narasimha, K.N.P. Vermiculite: Nature’s Versatile Mineral. GeoChron. Pan. 2024, 4, 1–7. [Google Scholar]

- Nemes, R.; Abed, M.A.; Seyam, A.M.; Lublóy, É. Behavior of structural lightweight concrete produced with expanded clay aggregate and after exposure to high temperatures. J. Therm. Anal. Calorim. 2022, 147, 8111–8118. [Google Scholar] [CrossRef]

- Subari; Hernawan; Wahyudi, K.; Rosmayanti, I.; Nurhidayati. The development of indonesian local clay as a lightweight expanded clay aggregate (LECA) for organic growing medium. IOP Conf. Ser. Mater. Sci. Eng. 2020, 980, 012010. [Google Scholar] [CrossRef]

- Zukri, A.; Nazir, R.; Said, K.N.M.; Moayedi, H. Physical and Mechanical Properties of Lightweight Expanded Clay Aggregate (LECA). MATEC Web Conf. 2018, 250, 01016. [Google Scholar] [CrossRef]

- Zukri, A.; Nazir, R.; Hasbollah, D.Z.A.; Mustapha, A.H. Lightweight Expanded Clay Aggregate (LECA) as replacement materials for geotechnical application. Phys. Chem. Earth Parts ABC 2023, 130, 103366. [Google Scholar] [CrossRef]

- Malík, M.; Praus, L.; Tlustoš, P. Comparison of recirculation and drain-to-waste hydroponic systems in relation to medical cannabis (Cannabis sativa L.) plants. Ind. Crops Prod. 2023, 202, 117059. [Google Scholar] [CrossRef]

- Butcher, J.D.; Laubscher, C.P.; Coetzee, J.C. A Study of Oxygenation Techniques and the Chlorophyll Responses of Pelargonium tomentosum Grown in Deep Water Culture Hydroponics. HortScience 2017, 52, 952–957. [Google Scholar] [CrossRef]

- Malík, M.; Praus, L.; Kuklina, A.; Velechovský, J.; Janatová, A.K.; Klouček, P.; Mládek, V.; Tlustoš, P. Cannabis yield and cannabinoid profile affected by plant nutrition and planting density. Ind. Crops Prod. 2025, 223, 120293. [Google Scholar] [CrossRef]

- Suryawanshi, Y.C. Hydroponic Cultivation Approaches to Enhance the Contents of the Secondary Metabolites in Plants. In Biotechnological Approaches to Enhance Plant Secondary Metabolites, 1st ed.; CRC Press: Boca Raton, FL, USA, 2021; pp. 71–88. [Google Scholar] [CrossRef]

- Burgel, L.; Hartung, J.; Graeff-Hönninger, S. Impact of Different Growing Substrates on Growth, Yield and Cannabinoid Content of Two Cannabis sativa L. Genotypes in a Pot Culture. Horticulturae 2020, 6, 62, Erratum in Horticulturae 2022, 8, 298. [Google Scholar] [CrossRef]

- George, P.; George, N. Hydroponics-(soilless cultivation of plants) for biodiversity conservation. Int. J. Mod. Trends Eng. Sci. 2016, 3, 97–104. [Google Scholar]

- Singh, N.; Raza, J.; Colangelo, F.; Farina, I. Advancements in Lightweight Artificial Aggregates: Typologies, Compositions, Applications, and Prospects for the Future. Sustainability 2024, 16, 9329. [Google Scholar] [CrossRef]

- Mendes, A.M.; Monteiro, C.M.; Santos, C. Green Roofs Hydrological Performance and Contribution to Urban Stormwater Management. Water Resour. Manag. 2025, 39, 1015–1031. [Google Scholar] [CrossRef]

- Fernandes, H.R.; Gaddam, A.; Tulyaganov, D.U.; Ferreira, J.M.F. Design and synthesis of foam glasses from recycled materials. Int. J. Appl. Ceram. Technol. 2020, 17, 64–74. [Google Scholar] [CrossRef]

- Gol’tsman, B.M.; Yatsenko, E.A. Modern Methods for Foaming of Glass and Silicate Raw Materials: Review and Analysis. Theor. Found. Chem. Eng. 2022, 56, 678–686. [Google Scholar] [CrossRef]

- Østergaard, M.B. Preparation and Characteristics of Glass Foam. Ph.D. Dissertation, Aalborg University, Aalborg, Denmark, 2019. [Google Scholar] [CrossRef]

- Owoeye, S.S.; Matthew, G.O.; Ovienmhanda, F.O.; Tunmilayo, S.O. Preparation and characterization of foam glass from waste container glasses and water glass for application in thermal insulations. Ceram. Int. 2020, 46, 11770–11775. [Google Scholar] [CrossRef]

- Pilon, L. Foams in Glass Manufacturing, 1st ed.; John Wiley & Sons, Ltd.: Chichester, UK, 2012; pp. 355–409. [Google Scholar] [CrossRef]

- Chen Lopez, J.C. Characterization, Simulation, Analysis and Management of Hydraulic Properties of Greenhouse Plant Growth Substrates. Ph.D. Dissertation, The University of Arizona, Tucson, AZ, USA, 2011. [Google Scholar]

- Thach, B.K.; Tan, L.N.; Minh, D.Q.; Hung, L.C.; Tuan, P.D. Production of Porous Glass-Foam Materials from Photovoltaic Panel Waste Glass. In Proceedings of the Green Materials and Electronic Packaging Interconnect Technology Symposium. EPITS 2022 14-15 September, Langkawi, Malaysia; Springer Proceedings in Physics: Singapore; pp. 317–327. [CrossRef]

- Khac, T.B.; Truong, V.; Do Quang, M.; Cam, H.L.; Phan, T.Đ. Production of porous material from solar panels waste glass. Vietnam J. Sci. Technol. 2025, 63, 327–337. [Google Scholar] [CrossRef]

- Tramontin Souza, M.; Onghero, L.; Batista Passos, A.; Simão, L.; Honorato Piva, R.; Longuini Repette, W.; Novaes de Oliveira, A.P. Sustainable glass foams produced with stone waste as a pore-forming agent: Assessing the role of heating rate in foamability and glass foams recyclability. J. Clean. Prod. 2022, 338, 130596. [Google Scholar] [CrossRef]

- Banitalebi, G.; Mosaddeghi, M.R.; Shariatmadari, H. Evaluation of physico-chemical properties of biochar-based mixtures for soilless growth media. J. Mater. Cycles Waste Manag. 2021, 23, 950–964. [Google Scholar] [CrossRef]

- Chrysargyris, A.; Prasad, M.; Kavanagh, A.; Tzortzakis, N. Biochar Type, Ratio, and Nutrient Levels in Growing Media Affects Seedling Production and Plant Performance. Agronomy 2020, 10, 1421. [Google Scholar] [CrossRef]

- Naeem, M.A.; Khalid, M.; Arshad, M.; Ahmad, R. Yield and nutrient composition of biochar produced from different feedstocks at varying pyrolytic temperatures. Pak. J. Agri. Sci. 2014, 51, 75–82. [Google Scholar]

- Machado, R.M.A.; Alves-Pereira, I.; Morais, C.; Alemão, A.; Ferreira, R. Effects of Coir-Based Growing Medium with Municipal Solid Waste Compost or Biochar on Plant Growth, Mineral Nutrition, and Accumulation of Phytochemicals in Spinach. Plants 2022, 11, 1893. [Google Scholar] [CrossRef] [PubMed]

- Jabborova, D.; Kadirova, D.; Narimanov, A.; Wirth, S. Beneficial effects of biochar application on lettuce (Lactuca sativa L.) growth, root morphological traits and physiological properties. Ann. Phytomed. 2021, 10, 93–100. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, J.; Wang, Q.; Chang, T.; Shaghaleh, H.; Hamoud, Y.A. Improvement of Photosynthesis by Biochar and Vermicompost to Enhance Tomato (Solanum lycopersicum L.) Yield under Greenhouse Conditions. Plants 2022, 11, 3214. [Google Scholar] [CrossRef]

- Lin, C.-C.; Chuang, Y.-H.; Shen, F.-T.; Chung, W.-H.; Chen, C.-Y.; Liu, Y.-T.; Hsieh, Y.-C.; Tzou, Y.-M.; Jien, S.-H. Alleviating Continuous Cropping Obstacles in Celery Using Engineered Biochar: Insights into Chemical and Microbiological Aspects. Agronomy 2024, 14, 2685. [Google Scholar] [CrossRef]

- Messiga, A.J.; Hao, X.; Dorais, M.; Bineng, C.S.; Ziadi, N. Supplement of biochar and vermicompost amendments in coir and peat growing media improves N management and yields of leafy vegetables. Can. J. Soil Sci. 2022, 102, 39–52. [Google Scholar] [CrossRef]

- Luigi, M.; Manglli, A.; Dragone, I.; Antonelli, M.G.; Contarini, M.; Speranza, S.; Bertin, S.; Tiberini, A.; Gentili, A.; Varvaro, L.; et al. Effects of Biochar on the Growth and Development of Tomato Seedlings and on the Response of Tomato Plants to the Infection of Systemic Viral Agents. Front. Microbiol. 2022, 13, 862075. [Google Scholar] [CrossRef] [PubMed]

- Sani, M.N.H.; Hasan, M.; Uddain, J.; Subramaniam, S. Impact of application of Trichoderma and biochar on growth, productivity and nutritional quality of tomato under reduced N-P-K fertilization. Ann. Agric. Sci. 2020, 65, 107–115. [Google Scholar] [CrossRef]

- Ahmad, C.A.; Akhter, A.; Haider, M.S.; Abbas, M.T.; Hashem, A.; Avila-Quezada, G.D.; Abd_Allah, E.F. Demonstration of the synergistic effect of biochar and Trichoderma harzianum on the development of Ralstonia solanacearum in eggplant. Front. Microbiol. 2024, 15, 1360703. [Google Scholar] [CrossRef] [PubMed]

- Kumari, R.; Kumar, V.; Koul, B.; Abul Farah, M.; Mishra, A.K. Synergistic effects of Trichoderma and biochar on the biocontrol of two soil-borne phytopathogens in chickpeas. Front. Microbiol. 2025, 16, 1583114. [Google Scholar] [CrossRef] [PubMed]

- Iacomino, G.; Idbella, M.; Laudonia, S.; Vinale, F.; Bonanomi, G. The Suppressive Effects of Biochar on Above- and Belowground Plant Pathogens and Pests: A Review. Plants 2022, 11, 3144. [Google Scholar] [CrossRef] [PubMed]

- Kuryntseva, P.; Karamova, K.; Galitskaya, P.; Selivanovskaya, S.; Evtugyn, G. Biochar Functions in Soil Depending on Feedstock and Pyrolyzation Properties with Particular Emphasis on Biological Properties. Agriculture 2023, 13, 2003. [Google Scholar] [CrossRef]

- Kaudal, B.B.; Chen, D.; Madhavan, D.B.; Downie, A.; Weatherley, A. An examination of physical and chemical properties of urban biochar for use as growing media substrate. Biomass Bioenergy 2016, 84, 49–58. [Google Scholar] [CrossRef]

- Sri Shalini, S.; Palanivelu, K.; Ramachandran, A.; Raghavan, V. Biochar from biomass waste as a renewable carbon material for climate change mitigation in reducing greenhouse gas emissions—A review. Biomass Conv. Bioref. 2021, 11, 2247–2267. [Google Scholar] [CrossRef]

- Ayaz, M.; Feizienė, D.; Tilvikienė, V.; Akhtar, K.; Stulpinaitė, U.; Iqbal, R. Biochar Role in the Sustainability of Agriculture and Environment. Sustainability 2021, 13, 1330. [Google Scholar] [CrossRef]

- Tolunay, D.; Kowalchuk, G.A.; Erkens, G.; Hefting, M.M. Aerobic and anaerobic decomposition rates in drained peatlands: Impact of botanical composition. Sci. Total Environ. 2024, 930, 172639. [Google Scholar] [CrossRef] [PubMed]

- Paul, A.; Hussain, M.; Ramu, B. The physicochemical properties and microstructural characteristics of peat and their correlations: Reappraisal. Int. J. Geotech. Eng. 2021, 15, 692–703. [Google Scholar] [CrossRef]

- Caron, J.; Rivière, L.-M. Quality of Peat Substrates for Plants Grown\in Containers. In Organic Soils and Peat Materials for Sustainable Agriculture, 1st ed.; Parent, L.E., Ilnicki, P., Eds.; CRC Press: Boca Raton, FL, USA, 2002; pp. 67–92. [Google Scholar] [CrossRef]

- Goulding, K.W.T. Soil acidification and the importance of liming agricultural soils with particular reference to the United Kingdom. Soil Use Manag. 2016, 32, 390–399. [Google Scholar] [CrossRef] [PubMed]

- Reeza, A.A.; Hussin, A.; Ahmed, O.H. Comparison of the effectiveness of three extractants in extracting potassium, calcium and magnesium from tropical peat soils. Mires Peat 2021, 27, 06. [Google Scholar] [CrossRef]

- Kim, H.-S.; Kim, K.-H. Physical properties of the horticultural substrate according to mixing ratio of peatmoss, perlite and vermiculite. Korean J. Soil Sci. Fert. 2011, 44, 321–330. [Google Scholar] [CrossRef]

- Sonneveld, C.; Voogt, W. Fertigation Management of Potted Plants. In Plant Nutrition of Greenhouse Crops, 1st ed.; Springer: Dordrecht, The Netherlands, 2009; pp. 313–344. [Google Scholar] [CrossRef]

- Maplestone, P.A.; Whipps, J.M.; Lynch, J.M. Effect of peat-bran inoculum of Trichoderma species on biological control of Rhizoctonia solani in lettuce. Plant Soil 1991, 136, 257–263. [Google Scholar] [CrossRef]

- Hidayat, I. Characteristics of the peat soil Bacilllus sp. J. Biol. Res. 2004, 10, 31–35. [Google Scholar] [CrossRef]

- Moore, T.R.; Knorr, K.-H.; Thompson, L.; Roy, C.; Bubier, J.L. The effect of long-term fertilization on peat in an ombrotrophic bog. Geoderma 2019, 343, 176–186. [Google Scholar] [CrossRef]

- Airaksinen, J.; Albrecht, E. Arguments and their effects—A case study on drafting the legislation on the environmental impacts of peat extraction in Finland. J. Clean. Prod. 2019, 226, 1004–1012. [Google Scholar] [CrossRef]

- Urák, I.; Hartel, T.; Gallé, R.; Balog, A. Worldwide peatland degradations and the related carbon dioxide emissions: The importance of policy regulations. Environ. Sci. Policy 2017, 69, 57–64. [Google Scholar] [CrossRef]

- Li, H.; Li, B.; Yuan, Z.; Zhang, Y.; Xu, C.C. Synthesis of Bio-/lignin-Based Phenolic Foams for Insulation and Floral Applications. In Phenolic Based Foams: Preparation, Characterization, and Applications, 1st ed.; Sandhya, P.K., Sreekala, M.S., Thomas, S., Eds.; Springer: Singapore, 2022; pp. 253–274. [Google Scholar] [CrossRef]

- Erzen, B.; Karataş, M.; Deniz, Ş.; Aydoğmuş, E. Advances in Synthesis, Characterization, and Industrial Applications of Phenol Formaldehyde Resins. Int. J. Adv. Nat. Sci. Eng. Res. 2024, 8, 26–34. [Google Scholar]

- Briou, B. Phenol and formaldehyde alternatives for novel synthetic phenolic resins: State of the art. Green Mater. 2025, 13, 37–54. [Google Scholar] [CrossRef]

- Tseng, C.J.; Kuo, K.T. Thermal properties of phenolic foam insulation. J. Chin. Inst. Eng. 2002, 25, 753–758. [Google Scholar] [CrossRef]

- Adelberg, J.; Naylor-Adelberg, J.; Rapaka, V. Phenolic foam rooting matrices allows faster transfer and more rapid growth of Echinacea plants in greenhouse. In Vitro Cell. Dev. Biol.-Plant 2017, 53, 546–552. [Google Scholar] [CrossRef]

- Shen, H.; Nutt, S. Mechanical characterization of short fiber reinforced phenolic foam. Compos. Part A Appl. Sci. Manufact. 2003, 34, 899–906. [Google Scholar] [CrossRef]

- Kim, H.M.; No, K.O.; Hwang, S.J. Use of Pellet or Cube-type Phenolic Foam as an Artificial Medium for Production of Tomato Plug Seedlings. Hortic. Sci. Technol. 2016, 34, 414–423. [Google Scholar] [CrossRef]

- Park, J.-E.; An, C.-G.; Jeong, B.-R.; Hwang, S.-J. Use of phenolic foam as a medium for production of plug seedlings of paprika. Hortic. Sci. Technol. 2012, 30, 34–41. [Google Scholar] [CrossRef]

- Lakhiar, I.A.; Yan, H.; Zhang, J.; Wang, G.; Deng, S.; Bao, R.; Zhang, C.; Syed, T.N.; Wang, B.; Zhou, R.; et al. Plastic Pollution in Agriculture as a Threat to Food Security, the Ecosystem, and the Environment: An Overview. Agronomy 2024, 14, 548. [Google Scholar] [CrossRef]

- Trestrail, C.; Walpitagama, M.; Hedges, C.; Truskewycz, A.; Miranda, A.; Wlodkowic, D.; Shimeta, J.; Nugegoda, D. Foaming at the mouth: Ingestion of floral foam microplastics by aquatic animals. Sci. Total Environ. 2020, 705, 135826. [Google Scholar] [CrossRef]

- de Sousa, B.S.; de Brito, L.M.; Ramsdorf, W.A.; de Freitas, A.M.; Kloss, J.R. Evaluation of Phenolic Foam’s Toxicity Used in Floral Arrangements. Macromol. Symp. 2024, 413, 2400054. [Google Scholar] [CrossRef]

- Sarika, P.R.; Nancarrow, P.; Khansaheb, A.; Ibrahim, T. Bio-Based Alternatives to Phenol and Formaldehyde for the Production of Resins. Polymers 2020, 12, 2237. [Google Scholar] [CrossRef]

- Gao, Z.; Karthäuser, J.; Frauendorf, H.; Wang, Y.; Xie, Y.; Militz, H. Synthesis of phenolic resin using furfural as a sustainable partial alternative to formaldehyde and its impact on wood dimensional stability. Eur. J. Wood Prod. 2025, 83, 124. [Google Scholar] [CrossRef]

- Li, W.; Sun, H.; Wang, G.; Sui, W.; Dai, L.; Si, C. Lignin as a green and multifunctional alternative to phenol for resin synthesis. Green Chem. 2023, 25, 2241–2261. [Google Scholar] [CrossRef]

- Cardona, F.; Sultan, M.T.H. Characterization of environmentally sustainable resole phenolic resins synthesized with plant-based bioresources. BioResources 2016, 11, 965–983. [Google Scholar] [CrossRef]

- Thébault, M.; Pizzi, A.; Policardi, F. Naturally Occurring Phenolic Sources for Industrial Applications. In Industrial Arene Chemistry; Mortier, J., Ed.; Wiley-VCH: Weinheim, Germany, 2023; pp. 2059–2100. [Google Scholar] [CrossRef]

- Fan, P.; Yu, H.; Xi, B.; Tan, W. A review on the occurrence and influence of biodegradable microplastics in soil ecosystems: Are biodegradable plastics substitute or threat? Environ. Int. 2022, 163, 107244. [Google Scholar] [CrossRef] [PubMed]

- Stuenkel, J.; Anderson, N.O.; Goodman, E. The Effect of Oasis® Floral Foam on the Postharvest Performance of Perennial Flax Cut Flowers. HortTechnology 2025, 35, 223–232. [Google Scholar] [CrossRef]

- Hesami, M.; Pepe, M.; Jones, A.M.P. Morphological Characterization of Cannabis sativa L. Throughout Its Complete Life Cycle. Plants 2023, 12, 3646. [Google Scholar] [CrossRef] [PubMed]

- Spitzer-Rimon, B.; Duchin, S.; Bernstein, N.; Kamenetsky, R. Architecture and Florogenesis in Female Cannabis sativa Plants. Front. Plant Sci. 2019, 10, 350. [Google Scholar] [CrossRef]

- Schober, T.; Präger, A.; Hartung, J.; Hensmann, F.; Graeff-Hönninger, S. Growth dynamics and yield formation of Cannabis (Cannabis sativa) cultivated in differing growing media under semi-controlled greenhouse conditions. Ind. Crops Prod. 2023, 203, 117172. [Google Scholar] [CrossRef]

- Ferrini, F.; Fraternale, D.; Donati Zeppa, S.; Verardo, G.; Gorassini, A.; Carrabs, V.; Albertini, M.C.; Sestili, P. Yield, Characterization, and Possible Exploitation of Cannabis sativa L. Roots Grown under Aeroponics Cultivation. Molecules 2021, 26, 4889. [Google Scholar] [CrossRef]

- Robertson, K.J.; Brar, R.; Randhawa, P.; Stark, C.; Baroutian, S. Opportunities and challenges in waste management within the medicinal cannabis sector. Ind. Crops Prod. 2023, 197, 116639. [Google Scholar] [CrossRef]

- Xiong, J.; Tian, Y.; Wang, J.; Liu, W.; Chen, Q. Comparison of Coconut Coir, Rockwool, and Peat Cultivations for Tomato Production: Nutrient Balance, Plant Growth and Fruit Quality. Front. Plant Sci. 2017, 8, 1327. [Google Scholar] [CrossRef]

- He, L.; Ding, X.; Jin, H.; Zhang, H.; Cui, J.; Chu, J.; Li, R.; Zhou, Q.; Yu, J. Comparison of rockwool and coir for greenhouse cucumber production: Chemical element, plant growth, and fruit quality. Heliyon 2022, 8, e10930. [Google Scholar] [CrossRef]

- Caplan, D.; Dixon, M.; Zheng, Y. Increasing Inflorescence Dry Weight and Cannabinoid Content in Medical Cannabis Using Controlled Drought Stress. HortScience 2019, 54, 964–969. [Google Scholar] [CrossRef]

- Massuela, D.C.; Munz, S.; Hartung, J.; Nkebiwe, P.M.; Graeff-Hönninger, S. Cannabis Hunger Games: Nutrient stress induction in flowering stage—Impact of organic and mineral fertilizer levels on biomass, cannabidiol (CBD) yield and nutrient use efficiency. Front. Plant Sci. 2023, 14, 1233232. [Google Scholar] [CrossRef]

| Substrate | Origin | Key Properties | Limitations | Cost–Benefit/Sustainability |

|---|---|---|---|---|

| Rockwool | Mineral | High porosity, inert, consistent structure | Algae risk | Uniform, low setup labor; typically single-use → recurring cost; high energy in manufacture; non-biodegradable, limited recycling |

| Coconut Coir | Organic | High water retention, partial buffering | Variability, salt content, risk of pathogens and insect pests (e.g., fungus gnats) | Moderate price; possible reuse after sanitation; higher setup labor (hydration/drainage); renewable byproduct, biodegradable; transport adds emissions |

| Perlite | Mineral | Lightweight, excellent aeration, inert | Floats, limited mechanical support | Low cost; limited reuse; moderate embodied energy (thermal expansion); inert non-biodegradable end-of-life |

| Vermiculite | Mineral | High water retention, moderate CEC * | Waterlogging when used alone | Moderate cost; energy-intensive exfoliation; finite mineral resource; typically single-use in mixes |

| Expanded Clay (LECA) | Mineral | Durable, free-draining | Low water retention, floats when dry | Higher upfront cost offset by multi-cycle reuse (good cost per crop); kiln-fired (high energy) but inert and long-lived → reduced waste |

| Foamed Glass | Recycled Glass | Porous, inert | Needs frequent irrigation, friable | Recycled feedstock (sustainability plus); may be pricier; reusable to a point; inert end-of-life |

| Biochar | Carbon-based | Water/nutrient retention, microbial habitat | Variable quality, high pH risk | Potentially low cost if local; can improve nutrient/water efficiency; may offer favorable carbon balance depending on feedstock/pyrolysis |

| Peat (Peat Moss) | Organic | High water holding, acidic pH, natural | Hydrophobic when dry | Low upfront cost but strong sustainability downside: non-renewable, releases long-stored carbon, ecosystem loss; facing restrictions/phase-outs |

| Phenolic Foam | Synthetic Foam | Sterile, lightweight, consistent porosity | Mostly for propagation | Labor-saving in propagation; high unit cost; non-biodegradable synthetic waste → disposal burden |

| Substance | Content [%] |

|---|---|

| Silicon dioxide (SiO2) | 73.06 |

| Aluminum oxide (Al2O3) | 15.30 |

| Potassium oxide (K2O) | 4.50 |

| Sodium oxide (Na2O) | 3.65 |

| Ferric oxide (Fe2O3) | 1.05 |

| Calcium oxide (CaO) | 0.80 |

| Magnesium oxide (MgO) | 0.05 |

| Substrate | pH | CEC * | Water Holding Capacity | Aeration | Standalone Use | Mixes/Notes |

|---|---|---|---|---|---|---|

| Rockwool | ~7.5 | Very low (~0) | High | Excellent | Yes | Used alone or with coir |

| Coconut Coir | 5.2–6.8 | High | High | Moderate | Yes | Mixed with perlite or clay (70:30) |

| Perlite | 7.0–7.5 | None (~0) | Low–moderate | Excellent | No | Mixed with coir or vermiculite (10–50%) |

| Vermiculite | 7.0–7.5 | Moderate–high | High | Low–moderate | No | Mixed with perlite, coir, or peat |

| Expanded Clay (LECA) | 6.0–7.0 | None (~0) | Low | Excellent | Yes | Sometimes mixed for weight or retention |

| Foamed Glass | 6.5–7.5 | None (~0) | Low–moderate | Excellent | Yes | May be mixed for better retention |

| Biochar | 6.5–9.5 | Variable (low to high) | Moderate | Moderate | No | Mixed into coir or peat (5–20%) |

| Peat | 3.0–4.5 (raw), 5.5–6.5 (adjusted) | Moderate–high (100–200 cmol(+)/kg) | Very high (600–1200%) | Low–moderate | No | Mixed with perlite or coir |

| Phenolic Foam | 5.8–6.8 | Very low | High | Moderate | No | Used in propagation, not final stage |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malík, M.; Tlustoš, P. Soilless Growing Media for Cannabis Cultivation. Agriculture 2025, 15, 1955. https://doi.org/10.3390/agriculture15181955

Malík M, Tlustoš P. Soilless Growing Media for Cannabis Cultivation. Agriculture. 2025; 15(18):1955. https://doi.org/10.3390/agriculture15181955

Chicago/Turabian StyleMalík, Matěj, and Pavel Tlustoš. 2025. "Soilless Growing Media for Cannabis Cultivation" Agriculture 15, no. 18: 1955. https://doi.org/10.3390/agriculture15181955

APA StyleMalík, M., & Tlustoš, P. (2025). Soilless Growing Media for Cannabis Cultivation. Agriculture, 15(18), 1955. https://doi.org/10.3390/agriculture15181955