Electrification and Smartification for Modern Tractors: A Review of Algorithms and Techniques

Abstract

1. Introduction

2. Classification of Modern Tractor

2.1. Battery Electric Tractor

2.2. Hybrid Tractor

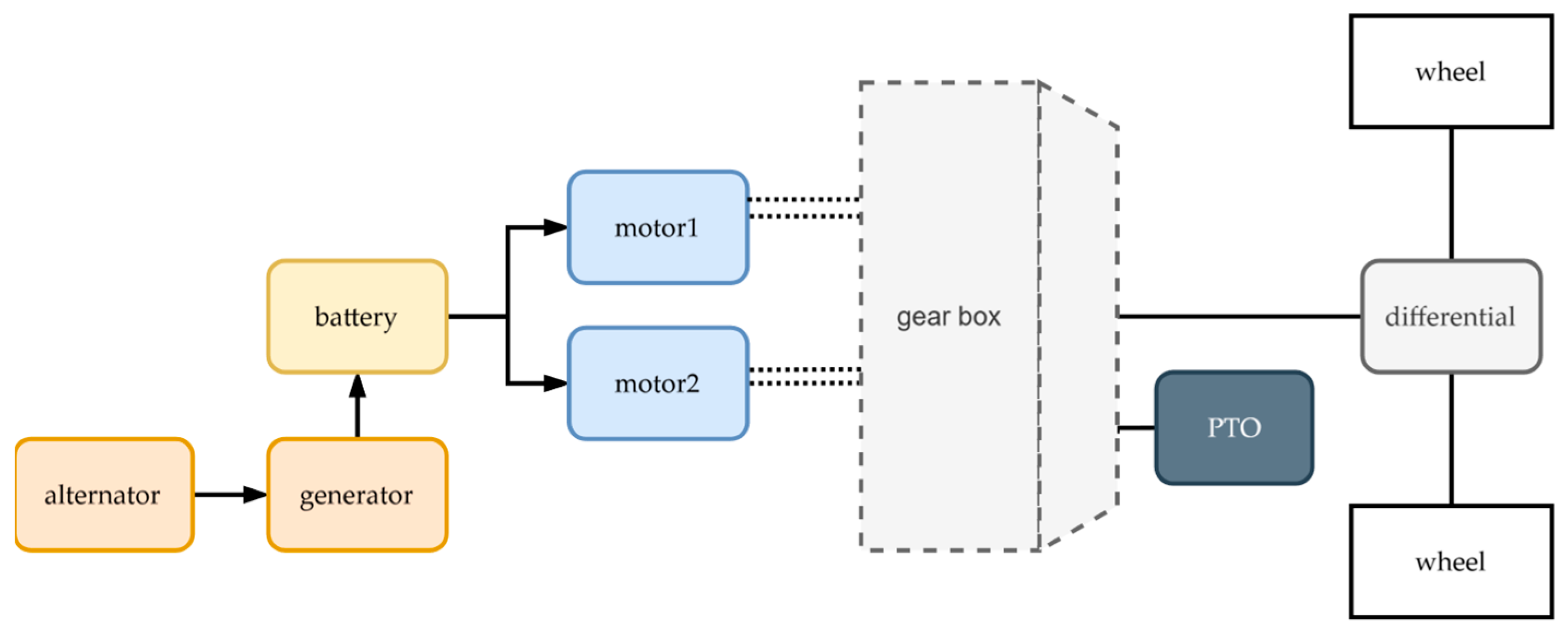

2.2.1. Series Hybrid Tractor

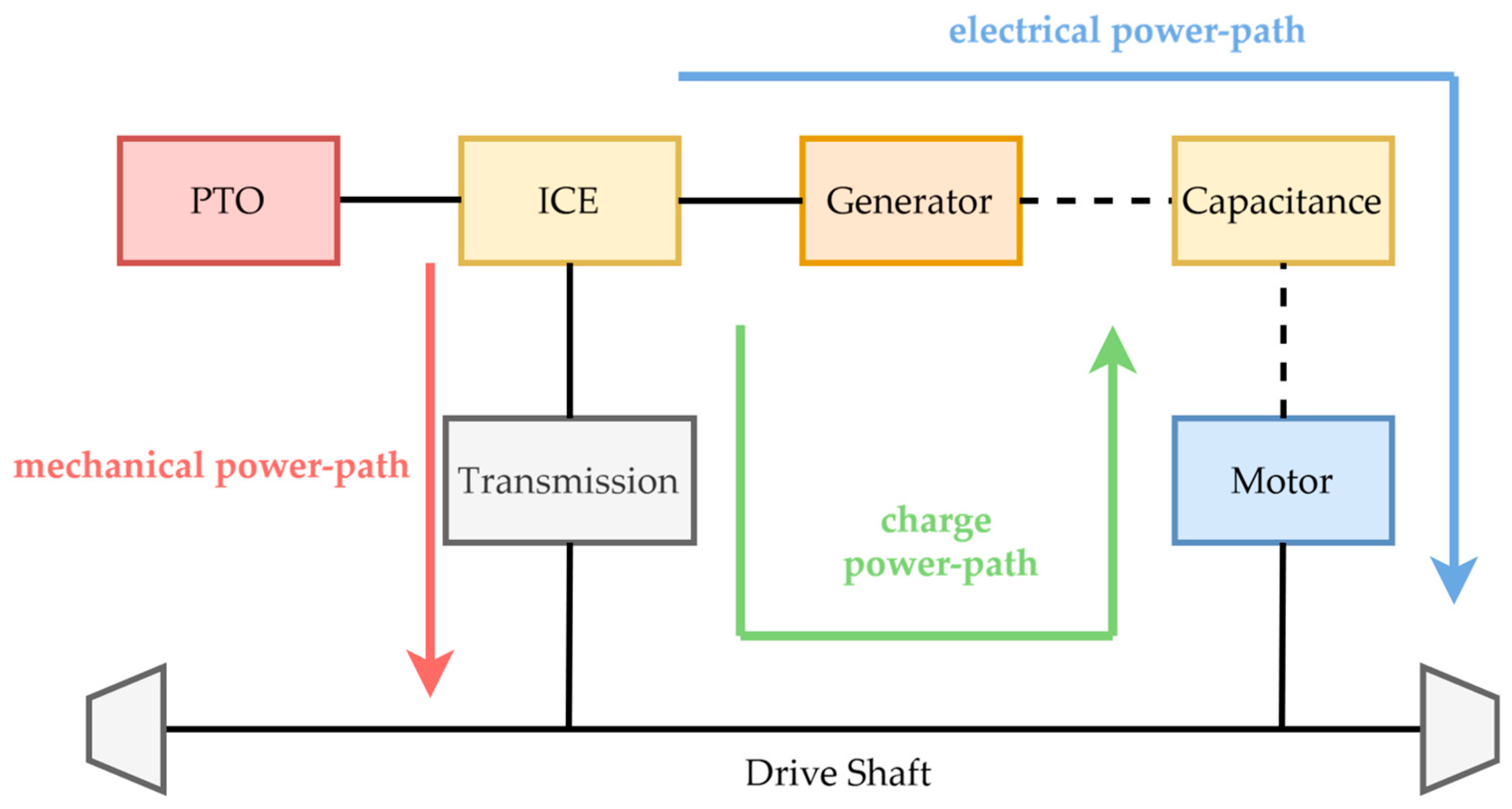

2.2.2. Parallel Hybrid Tractor

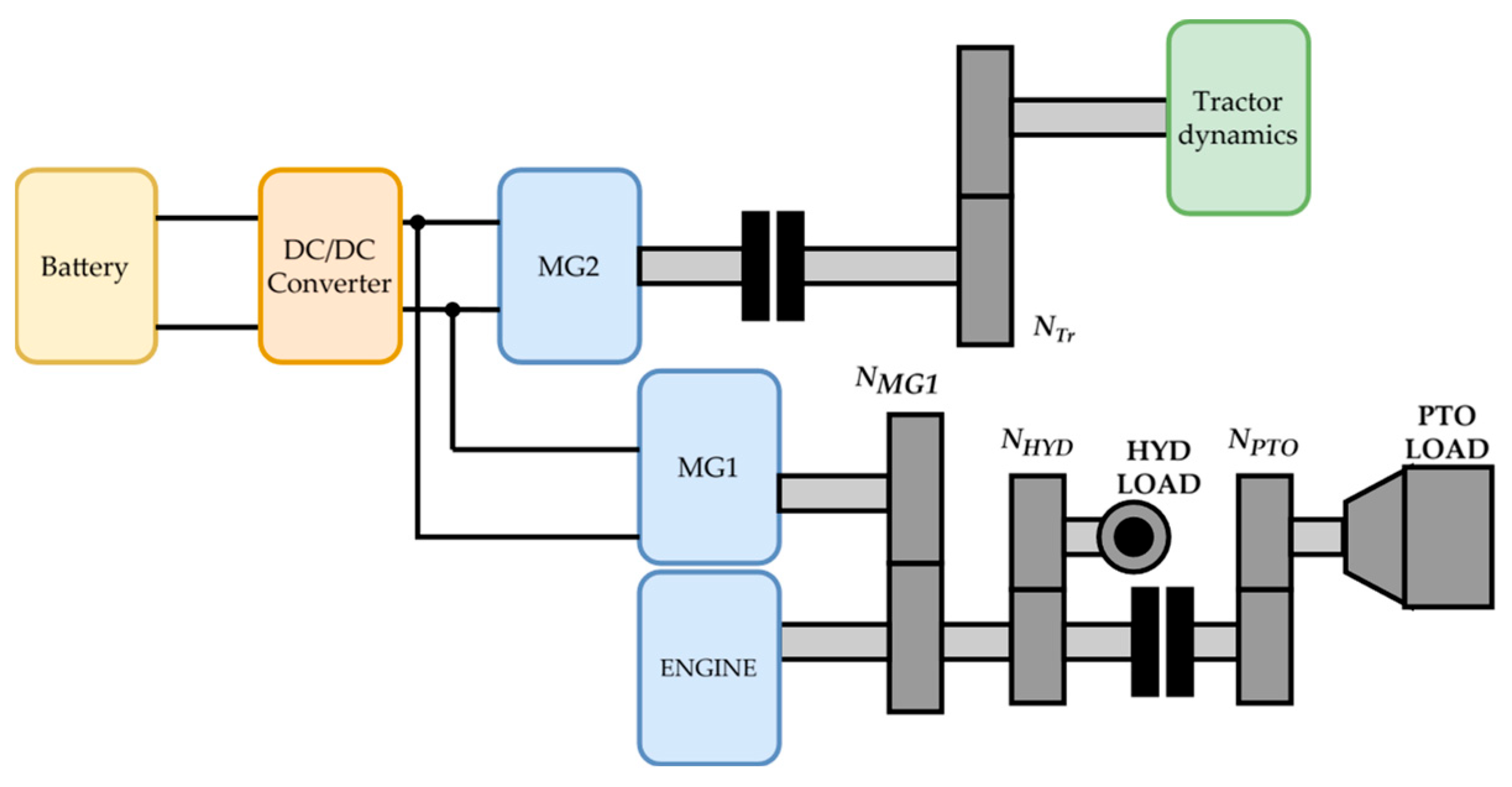

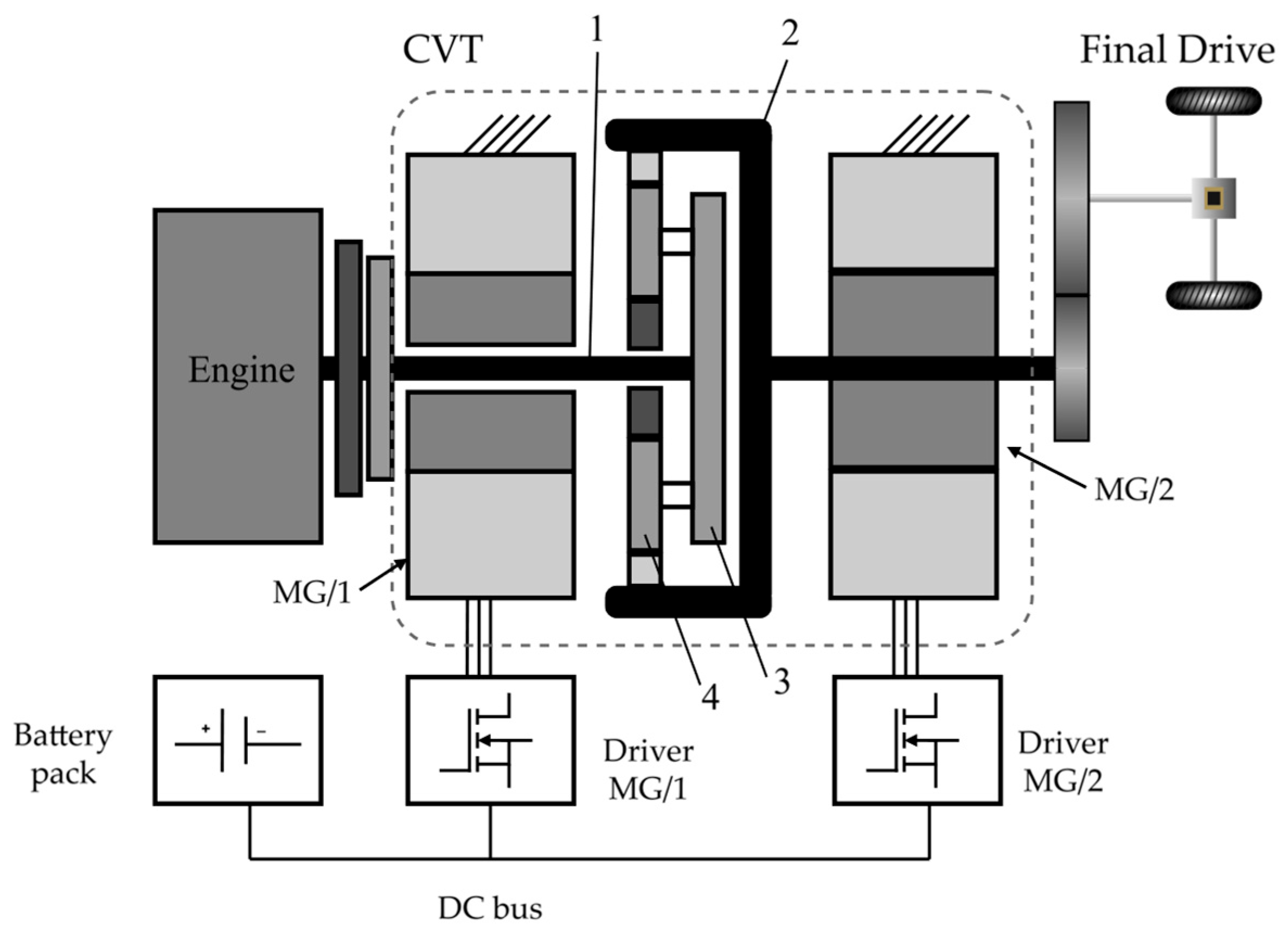

2.2.3. Series-Parallel Hybrid Tractor

3. Algorithms and Control System

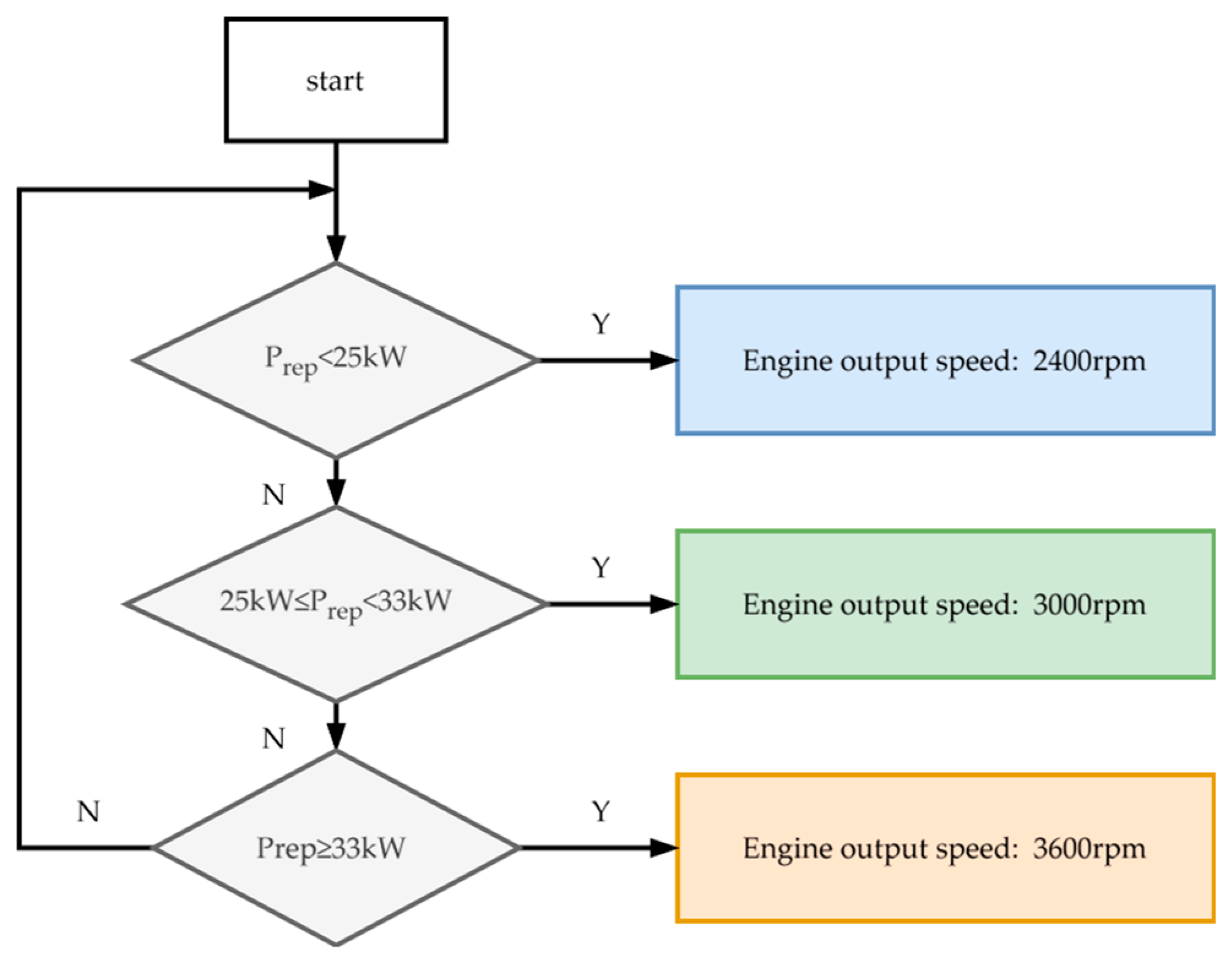

3.1. Rule-Based Algorithm

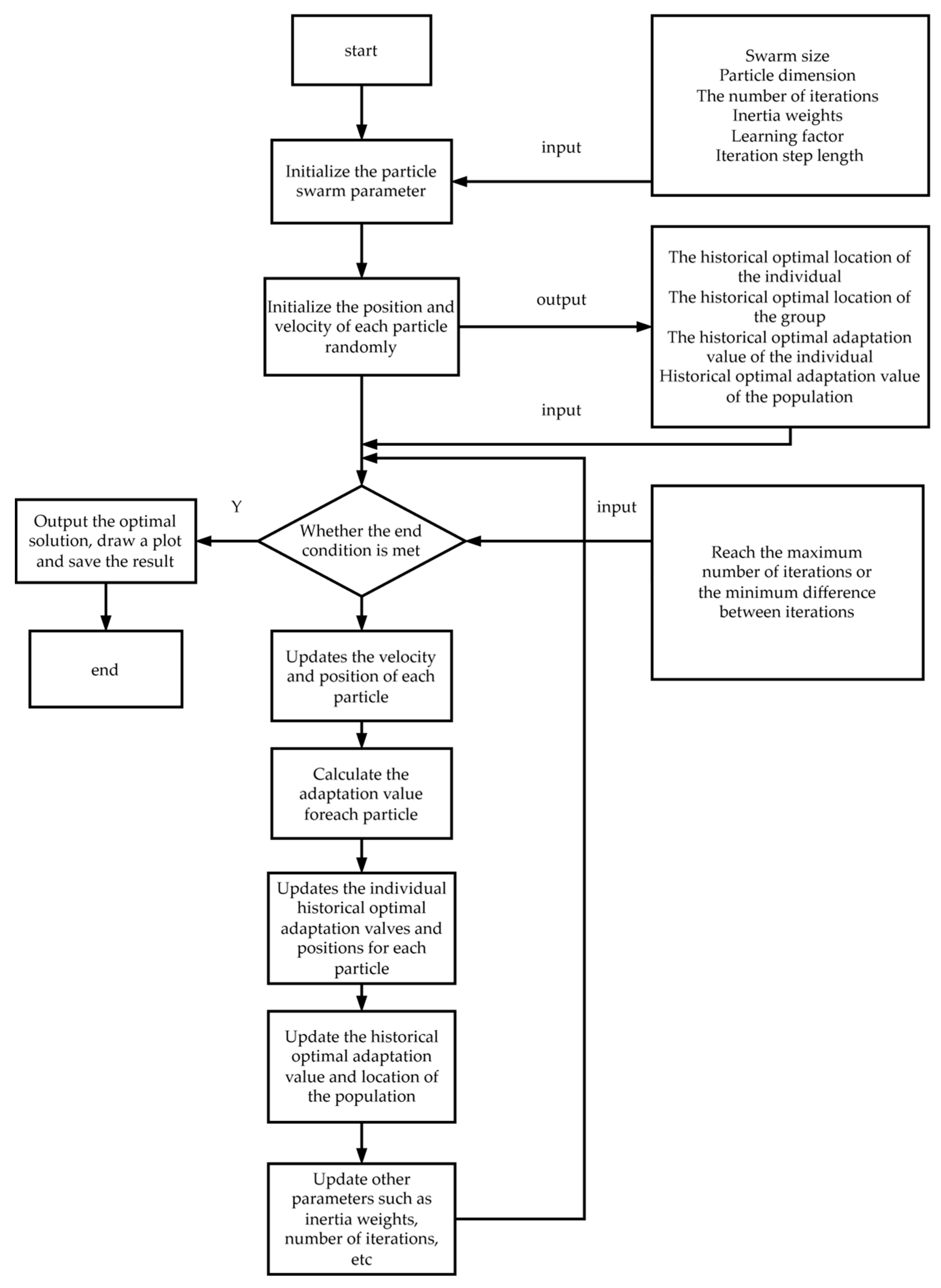

3.2. Optimization-Based Algorithm

3.2.1. DP (Dynamic Programming) Algorithm

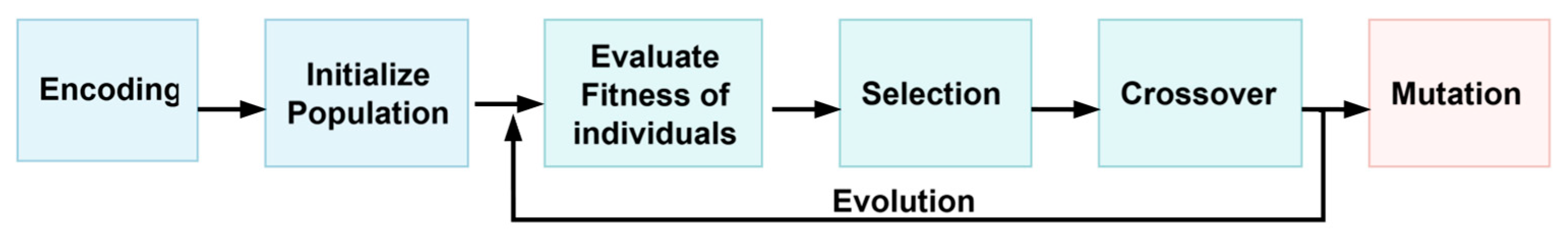

3.2.2. Genetic Algorithm

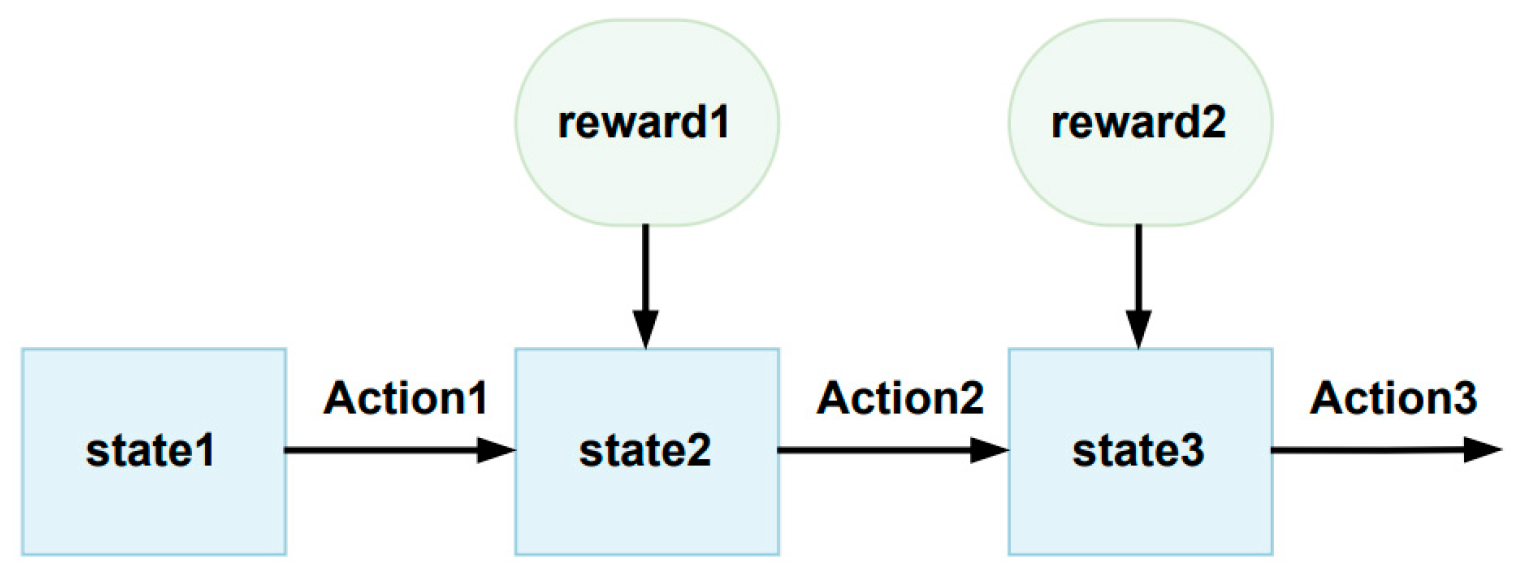

3.2.3. Reinforcement Learning Algorithm

- Value Function-based

- 2.

- Policy-based

4. The Intelligence of Unmanned Farms

4.1. System Architecture

4.2. Multi-Machine Collaboration

4.3. Path Tracking Control Technology

4.4. Automatic Navigation System

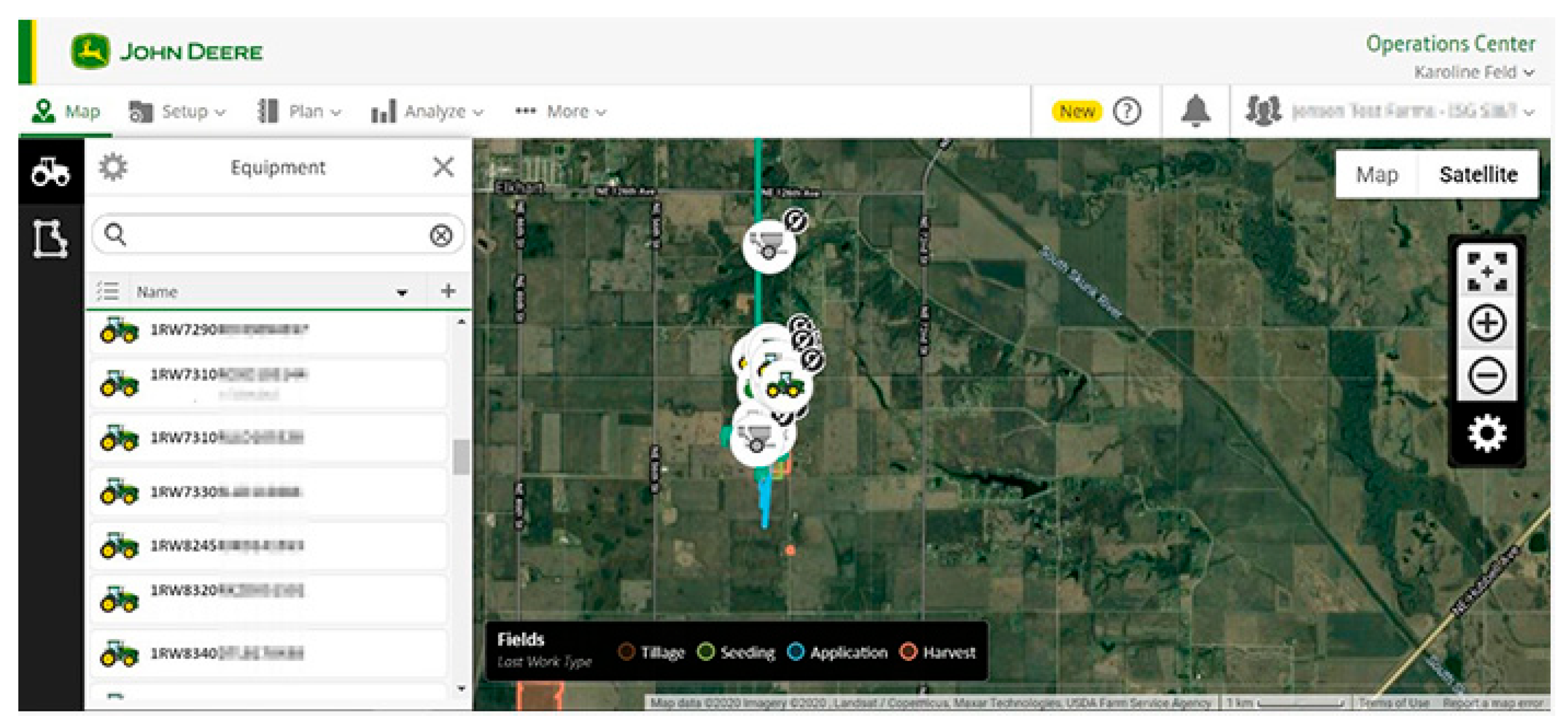

4.5. Commercial Applications (JD Link System)

4.6. Edge Intelligence and Future Directions

5. A Case Analysis of an Electric Smart Tractor

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Goswami, D. Addressing the Challenge of Overexploitation of Natural Resources in Pursuit of Development. Sprin J. Arts Humanit. Soc. Sci. 2024, 3, 65–67. [Google Scholar] [CrossRef]

- IEA. Oil 2024; IEA: Paris, France, 2024. Available online: https://www.iea.org/reports/oil-2024 (accessed on 11 July 2025).

- Mocera, F.; Somà, A.; Martelli, S.; Martini, V. Trends and future perspective of electrification in agricultural tractor-implement applications. Energies 2023, 16, 6601. [Google Scholar] [CrossRef]

- Majeed, Y.; Khan, M.U.; Waseem, M.; Zahid, U.; Mahmood, F.; Majeed, F.; Sultan, M.; Raza, A. Renewable energy as an alternative source for energy management in agriculture. Energy Rep. 2023, 10, 344–359. [Google Scholar] [CrossRef]

- Del Valle, T.M.; Yang, X.; Zhu, J.A.; Jiang, P. Evaluation of straw and agricultural policy impacts on the sustainability of the straw-based bioeconomy with an agent-based model. Biomass Bioenergy 2024, 184, 107177. [Google Scholar] [CrossRef]

- Murphy, D.J.; Myers, J.; McKenzie, E., Jr.; Cavaletto, R.; May, J.; Sorensen, J. Tractors and rollover protection in the United States. J. Agromedicine 2010, 15, 249–263. [Google Scholar] [CrossRef] [PubMed]

- Lovarelli, D.; Bacenetti, J. Exhaust gases emissions from agricultural tractors: State of the art and future perspectives for machinery operators. Biosyst. Eng. 2019, 186, 204–213. [Google Scholar] [CrossRef]

- Pradhan, N.C.; Sahoo, P.K.; Kushwaha, D.K.; Makwana, Y.; Mani, I.; Kumar, M.; Aruna, T.N.; Soumya Krishnan, V. A finite element modeling-based approach to predict vibrations transmitted through different body segments of the operator within the workspace of a small tractor. J. Field Robot. 2023, 40, 1543–1561. [Google Scholar] [CrossRef]

- Pradhan, N.C.; Sahoo, P.K.; Kushwaha, D.K.; Mani, I.; Kumar, M. Actuating force for transmission controls in small farm tractor considering driver’s comfort. Indian J. Agric. Sci. 2022, 92, 876–881. [Google Scholar] [CrossRef]

- Carabin, G.; Karaca, M.; Mazzetto, F. Preliminary results of extensive tractor rollover stability tests using a tilting-rotating rig. Biosyst. Eng. 2025, 254, 104146. [Google Scholar] [CrossRef]

- Pradhan, N.C.; Sahoo, P.K.; Kushwaha, D.K.; Bhalekar, D.G.; Mani, I.; Kumar, K.; Singh, A.K.; Kumar, M.; Makwana, Y.; Soumya Krishnan, V. ANN-PID based automatic braking control system for small agricultural tractors. J. Field Robot. 2024, 41, 2805–2831. [Google Scholar] [CrossRef]

- Ma, Y.; Li, Z.; Xu, Y.; Li, C.; Ding, H.; Li, C.; Tang, Q.; Liu, M.; Hou, J. The Development of No-Tillage Seeding Technology for Conservation Tillage—A Review. Sustainability 2025, 17, 1808. [Google Scholar] [CrossRef]

- Lombardi, G.V.; Berni, R. Renewable energy in agriculture: Farmers willingness-to-pay for a photovoltaic electric farm tractor. J. Clean. Prod. 2021, 313, 127520. [Google Scholar] [CrossRef]

- Vogt, H.H. Electric Tractor System Propelled by Solar Energy for Small-Scale Family Farming in Semiarid Regions of the Northeast of Brazil. Ph.D. Thesis, Universidade Federal do Ceará, Fortaleza, Brazil, 2018. [Google Scholar]

- Zhu, R.; Wang, Y.; Xiang, Y.; Sun, C.; Chang, R.; Hu, G.; Gao, Z. Study on Climate Characteristics and Development Potential of Wind Energy Resources in China. Acta Energiae Solaris Sin. 2021, 42, 409–418. [Google Scholar]

- Bungartz.nl. Siemens Tiller Tractors [EB/OL]. Available online: http://www.bungartz.nl/Siem4mod.html (accessed on 23 June 2022).

- Electric Tractor, Inc. OX2 Indisputable Advantages [EB/OL]. Available online: http://www.electrictractor.com/all-electric (accessed on 23 June 2022).

- Florentsev, S.; Izosimov, D.; Makarov, L.; Baida, S.; Belousov, A. Complete traction electric equipment sets of electro-mechanical drive trains for tractors. In Proceedings of the 2010 IEEE Region 8 International Conference on Computational Technologies in Electrical and Electronics Engineering (SIBIRCON), Irkutsk, Russia, 11–15 July 2010; pp. 611–616. [Google Scholar]

- Karthik, S. John Deere GridCON Autonomous Electric Tractor. 2021. Available online: https://electricvehicles.in/john-deere-gridcon-autonomous-electric-tractor/ (accessed on 12 December 2022).

- Kozhushko, A. Development of Power Plants Wheel Tractors Based on Electrical Sources. 2023. Available online: https://repository.kpi.kharkov.ua/items/560ba389-5188-4728-a793-70419e0acc7d (accessed on 1 July 2025).

- D’Agata, G. Research and Characterization of Battery Technologies for Railway Applications. Ph.D. Thesis, Politecnico di Torino, Torino, Italy, 2018. [Google Scholar]

- Available online: https://www.aiforcetech.com/productinfo/2671886.html?templateId=1745424 (accessed on 1 July 2025).

- Gao, H.S.; Zhu, S.H. Study on design theory and method for driving line of electric tractor. J. Nanjing Agric. Univ. 2009, 32, 140–145. [Google Scholar]

- Xu, L. Design and Selection of Power Coupling Device for Electric Tractor. J. Mech. Transm. 2021. [Google Scholar] [CrossRef]

- Zhang, J.; Zhao, B.; Yan, X.; Liu, M.; Xu, L.; Shang, C. Design and optimization of dual-motor electric tractor drive system based on driving cycles. PLoS one 2023, 18, e0286378. [Google Scholar] [CrossRef]

- Tong, Y.; Zhang, J.; Xu, L.; Yan, X. Driving System Design and Power Source Parameter Optimization of Tractor with Dual-Motor Coupling Drive. World Electr. Veh. J. 2023, 14, 63. [Google Scholar] [CrossRef]

- Lagnelöv, O.; Larsson, G.; Nilsson, D.; Larsolle, A.; Hansson, P.-A. Performance comparison of charging systems for autonomous electric field tractors using dynamic simulation. Biosyst. Eng. 2020, 194, 121–137. [Google Scholar] [CrossRef]

- Xiao-lei, C.A.I.; Xiao-yong, Z.H.U.; Zhi-ling, L.; Hong-ping, J.I.A.; Lei, X.U. Design and Test of Electric Tractor Drive System Used in Greenhouse. J. Agric. Mech. Res. 2023, 45, 222–228. [Google Scholar] [CrossRef]

- Troncon, D.; Alberti, L. Case of study of the electrification of a tractor: Electric motor performance requirements and design. Energies 2020, 13, 2197. [Google Scholar] [CrossRef]

- Jiangyi, H.; Fan, W. Design and testing of a small orchard tractor driven by a power battery. Eng. Agrícola 2023, 43, e20220195. [Google Scholar] [CrossRef]

- Bessette, D.L.; Brainard, D.C.; Srivastava, A.K.; Lee, W.; Geurkink, S. Battery Electric Tractors: Small-Scale Organic Growers’ Preferences, Perceptions, and Concerns. Energies 2022, 15, 8648. [Google Scholar] [CrossRef]

- Huang, S.J. A Brief Discussion on the Development and Research of Electric Tractors. Agric. Equip. Technol. 2021, 47, 43–44. [Google Scholar]

- Wang, X.; Wang, Z.Z.; Zhou, J. Study on Control Strategy of Tandem Hybrid Tractor Considering Battery Life Decay. J. Yunnan Agric. Univ. (Nat. Sci.) 2023, 38, 529–536. [Google Scholar] [CrossRef]

- Curiel-Olivares, G.; Escobar, G.; Johnson, S.; Schacht-Rodríguez, R. MPC-Based EMS for a Series Hybrid Electric Tractor. IEEE Access 2024, 12, 135999–136010. [Google Scholar] [CrossRef]

- Liu, Y.N.; Deng, X.T.; Zhang, W.H.; Zhu, Y.X.; He, R.Y. Design Theory and Method Research on Tandem Hybrid Tractor Drive System. Agric. Equip. Veh. Eng. 2018, 56, 49–54. [Google Scholar]

- Wang, Z.; Zhou, J.; Wang, X. Research on Energy Management Model for Extended-range Electric Rotary-tilling Tractor. Trans. Chin. Soc. Agric. Mach. 2023, 54, 428–438. [Google Scholar]

- Yan, X.; Zhao, Y.; Liu, X.; Liu, M.; Wu, Y.; Zhang, J. Research on Energy Management Strategy for Series Hybrid Tractor under Typical Operating Conditions Based on Dynamic Programming. World Electr. Veh. J. 2024, 15, 156. [Google Scholar] [CrossRef]

- Yang, Y.; Wen, Y.; Sun, X.; Wang, R.; Dong, Z. A Review of Green Agriculture and Energy Management Strategies for Hybrid Tractors. Energies 2025, 18, 3224. [Google Scholar] [CrossRef]

- Zhao, D.; Stobart, R.; Dong, G.; Winward, E. Real-time energy management for diesel heavy duty hybrid electric vehicles. IEEE Trans. Control. Syst. Technol. 2014, 23, 829–841. [Google Scholar] [CrossRef]

- Beligoj, M.; Scolaro, E.; Alberti, L.; Renzi, M.; Mattetti, M. Feasibility Evaluation of Hybrid Electric Agricultural Tractors Based on Life Cycle Cost Analysis. IEEE Access 2022, 10, 28853–28867. [Google Scholar] [CrossRef]

- Kim, Y.J.; Song, B.; Kim, J. Load torque estimation for a parallel hybrid agricultural tractor in field operations. Int. J. Precis. Eng. Manuf. 2013, 14, 1865–1868. [Google Scholar] [CrossRef]

- Lee, D.-H.; Kim, Y.-J.; Choi, C.-H.; Chung, S.-O.; Inoue, E.; Okayasu, T. Development of a Parallel Hybrid System for Agricultural Tractors. J. Fac. Agric. Kyushu Univ. 2017, 62, 137–144. [Google Scholar] [CrossRef]

- Zhu, Z.; Zeng, L.X.; Chen, L.; Zou, R.; Cai, Y.F. Fuzzy Adaptive Energy Management Strategy for a Hybrid Agricultural Tractor Equipped with HMCVT. Agriculture 2022, 12, 1986. [Google Scholar] [CrossRef]

- Deng, X.; Zhu, S.; Gao, H.; Zhang, Y. Design Theory and Method for Drive Train of Hybrid Electric Tractor. Trans. Chin. Soc. Agric. Mach. 2012, 43, 24–31+36. [Google Scholar]

- Mocera, F.; Somà, A. Analysis of a Parallel Hybrid Electric Tractor for Agricultural Applications. Energies 2020, 13, 3055. [Google Scholar] [CrossRef]

- Pascuzzi, S.; Łyp-Wrońska, K.; Gdowska, K.; Paciolla, F. Sustainability Evaluation of Hybrid Agriculture-Tractor Powertrains. Sustainability 2024, 16, 1184. [Google Scholar] [CrossRef]

- Rossi, C.; Pontara, D.; Falcomer, C.; Bertoldi, M.; Mandrioli, R. A Hybrid–Electric Driveline for Agricultural Tractors Based on an e-CVT Power-Split Transmission. Energies 2021, 14, 6912. [Google Scholar] [CrossRef]

- Grammatico, S.; Balluchi, A.; Cosoli, E. A series-parallel hybrid electric powertrain for industrial vehicles. In Proceedings of the 2010 IEEE Vehicle Power and Propulsion Conference, Lille, France, 1–3 September 2010; pp. 1–6. [Google Scholar]

- Diba, F.; Esmailzadeh, E. A new parallel-series configuration for hybridization of a line-haul truck. In Proceedings of the 2013 IEEE Transportation Electrification Conference and Expo (ITEC), Detroit, MI, USA, 16–19 June 2013; pp. 1–6. [Google Scholar]

- Wang, J.; Yang, Z.; Liu, S.; Zhang, Q.; Han, Y. A comprehensive overview of hybrid construction machinery. Adv. Mech. Eng. 2016, 8, 1687814016636809. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Z.W.; Wang, C.; Xie, J. Design and simulation of driving system for eleetrie tractor based on SRM. J. Shanxi Agric. Univ. (Nat. Sci. Ed.) 2018, 38, 69–76. [Google Scholar]

- Xu, L.Y. Research status of the tractor transmission performance. J. Agric. Mech-Anization Res. 2017, 39, 224–230. [Google Scholar]

- Chen, Y.; Xie, B.; Du, Y.; Mao, E. Powertrain parameter matching and optimal design of dual-motor driven electric tractor. Int. J. Agric. Biol. Eng. 2019, 12, 33–41. [Google Scholar] [CrossRef]

- Renken, F.; Wolf, J. Power electronics for hybrid-drive systems. In Proceedings of the 2007 European Conference on Power Electronics and Applications, Aalborg, Denmark, 2–5 September 2007; pp. 1–10. [Google Scholar]

- Goswami, G.; Tupitsina, A.; Jaiswal, S.; Nutakor, C.; Lindh, T.; Sopanen, J. Comparison of various hybrid electric powertrains for non-road mobile machinery using real-time multibody simulation. IEEE Access 2022, 10, 107631–107648. [Google Scholar] [CrossRef]

- Chen, Z.; Xie, B.; Luo, Z.; Liu, K.; Zhang, S.; Wen, C. Fuzzy Control Strategy for Path Tracking-Tillage Depth of Unmanned Electric Tractor Ploughing Unit. Trans. Chin. Soc. Agric. Mach. 2024, 55, 491–504. [Google Scholar]

- Tian, Y.P.; Chen, J.; Wang, L.; Liu, M.C.; Zhao, C. Research on Real-time Monitoring System of Wheeled Tractor Slip Rate. J. Agric. Mech. Res. 2019, 41, 236–240. [Google Scholar]

- Cao, Y.F.; Yao, M.; Sun, X.D. An Overview of Modelling and Energy Management Strategies for Hybrid Electric Vehicles. Appl. Sci. 2023, 13, 5947. [Google Scholar] [CrossRef]

- Lee, H.-S.; Kim, J.-S.; Park, Y.-I.; Cha, S.-W. Rule-based power distribution in the power train of a parallel hybrid tractor for fuel savings. Int. J. Precis. Eng. Manuf.-Green Technol. 2016, 3, 231–237. [Google Scholar] [CrossRef]

- Schouten, N.J.; Salman, M.A.; Kheir, N.A. Fuzzy logic control for parallel hybrid vehicles. IEEE Trans. Control. Syst. Technol. 2002, 10, 460–468. [Google Scholar] [CrossRef]

- Wang, C.G.; Li, H. Research on Energy Management Control Strategy of the Parallel Hybrid Electric Tractor. J. Kaifeng Univ. 2020, 34, 91–96. [Google Scholar]

- Xu, L.Y.; Zhang, J.J.; Liu, M.N.; Zhou, Z.L.; Liu, C.Q. Control algorithm and energy management strategy for extended range electric tractors. Int. J. Agric. Biol. Eng. 2017, 10, 35–44. [Google Scholar] [CrossRef]

- Jia, C.; Qiao, W.; Qu, L. Numerical methods for optimal control of hybrid electric agricultural tractors. In Proceedings of the 2019 IEEE Transportation Electrification Conference and Expo (ITEC), Detroit, MI, USA, 19–21 June 2019; pp. 1–6. [Google Scholar]

- Huang, T.L.; Chen, S.R.; Shi, A.P.; Li, F.Q.; Pan, C.F. Dual Motor Power Split Flow Pure Electric Tractor Energy Management Strategy. J. Agric. Mech. Res. 2020, 6, 246–250. [Google Scholar]

- Ghobadpour, A.; Mousazadeh, H.; Kelouwani, S.; Zioui, N.; Kandidayeni, M.; Boulon, L. An intelligent energy management strategy for an off-road plug-in hybrid electric tractor based on farm operation recognition. IET Electr. Syst. Transp. 2021, 11, 333–347. [Google Scholar] [CrossRef]

- Xu, W.X.; Xu, L.Y.; Liu, M.N.; Ma, K. Research on energy management system strategy of multi-power hybrid electric tractor. J. Chin. Agric. Mech. 2023, 44, 135–142. [Google Scholar]

- Xu, L.Y.; Wang, Y.T.; Li, Y.Y.; Zhao, J.H.; Liu, M.N. Research on Control Strategy of APSO-Optimized Fuzzy PID for Series Hybrid Tractors. World Electr. Veh. J. 2023, 14, 258. [Google Scholar] [CrossRef]

- Li, R.C.; Ding, X.K.; Sun, Q.Y.; Cheng, Y.; Liu, Q.; Liu, J.L.; Sun, Q. Study on Tractor Multiple Fuzzy PID Variable UniverseTillage Depth Regulation. J. Agric. Mech. Res. 2024, 46, 260–264. [Google Scholar]

- Jia, C.; Qiao, W.; Qu, L. Modeling and control of hybrid electric vehicles: A case study for agricultural tractors. In Proceedings of the 2018 IEEE Vehicle Power and Propulsion Conference (VPPC), Chicago, IL, USA, 27–30 August 2018; pp. 1–6. [Google Scholar]

- Dou, H.S.; Wei, H.Q.; Ai, Q.; Zhang, Y.T. Optimal energy management strategy for dual-power coupling tractor based on the adaptive control technology. PLoS ONE 2023, 18, e0292510. [Google Scholar] [CrossRef] [PubMed]

- Dou, H.S.; Wei, H.Q.; Zhang, Y.T.; Ai, Q. Configuration Design and Optimal Energy Management for Coupled-Split Powertrain Tractor. Machines 2022, 10, 1175. [Google Scholar] [CrossRef]

- Zhu, Z.; Zeng, L.X.; Lin, Y.G.; Chen, L.; Zou, R.; Cai, Y.F. Adaptive Energy Management Strategy for Hybrid Tractor Based on Condition Prediction. J. Xi’an Jiaotong Univ. 2023, 57, 201–210. [Google Scholar]

- Zhang, J.J.; Feng, G.H.; Xu, L.Y.; Yan, X.H.; Wang, W.; Liu, M.N. Energy-Saving Control of Hybrid Tractors Based on Instantaneous Optimization. World Electr. Veh. J. 2023, 14, 27. [Google Scholar] [CrossRef]

- Radrizzani, S.; Panzani, G.; Savaresi, S.M. Simultaneous energy management and speed control in a hybrid tractor with experimental validation. IEEE Trans. Control. Syst. Technol. 2024, 32, 1285–1297. [Google Scholar] [CrossRef]

- Xie, G.; Ding, R.; Xie, H.; Qin, H.; Bian, Y. Model Predictive Control-Assisted Energy Management Strategy for Hybrid Mining Dump Trucks Based on Speed and Slope Prediction. Electronics 2025, 14, 1999. [Google Scholar] [CrossRef]

- Curiel-Olivares, G.; Johnson, S.; Escobar, G.; Schacht-Rodríguez, R. Model Predictive Control-Based Energy Management System for a Hybrid Electric Agricultural Tractor. IEEE Access 2023, 11, 118801–118811. [Google Scholar] [CrossRef]

- Xu, W.X.; Xu, L.Y.; Liu, M.N.; Zhang, Y.G.; Song, L.T. Research on energy management strategy of hybrid tractor based on layered decoupling. J. Phys. Conf. Ser. 2022, 2343, 012018. [Google Scholar] [CrossRef]

- Dou, H.S.; Wei, H.Q.; Ai, Q.; Zhang, Y.T. Control Strategy for Rotary Tillage Condition of Hybrid Electric Tractor with Coupled-split Dynamic Configuration. Trans. Chin. Soc. Agric. Mach. 2024, 55, 393–400+414. [Google Scholar]

- Wang, H.C.; Wu, H.R.; Zhu, H.J.; Miao, Y.S.; Yang, B.Z. Path optimization of unmanned agricultural machinery in vegetable field based onimproved ant colony algorithm. J. Chin. Agric. Mech. 2023, 44, 187–194. [Google Scholar]

- Zhang, J.J.; Feng, G.H.; Xu, L.Y.; Wang, W.; Yan, X.H. Energy-saving Control of Hybrid Tractor Based on Pontryagin’s Minimum Principle. Trans. Chin. Soc. Agric. Mach. 2023, 54, 396–406. [Google Scholar]

- Yang, Y.J.; Li, Z.L.; Jia, F.; Han, J.G. Control Strategy for Multi-Mode Hybrid Electrie Vehicle. Veh. Engine 2022, 1, 64–70. [Google Scholar]

- Cheng, Z.; Lu, Z.X.; Tang, D.; Jiang, C.X.; Zhou, J. PID control strategy of tractor driving anti slip control based on improved PSO algorithm. Appl. Res. Comput. 2017, 34, 83–86. [Google Scholar]

- Li, X.; Xu, L.; Liu, M.; Yan, X.; Zhang, M. Research on torque cooperative control of distributed drive system for fuel cell electric tractor. Comput. Electron. Agric. 2024, 219, 108811. [Google Scholar] [CrossRef]

- Zheng, B.; Song, Z.; Mao, E.; Zhou, Q.; Luo, Z.; Deng, Z.; Shao, X.; Liu, Y. An ANN-PSO-Based Method for Optimizing Agricultural Tractors in Field Operation for Emission Reduction. Agriculture 2022, 12, 1332. [Google Scholar] [CrossRef]

- Sun, L.; Liu, M.; Wang, Z.; Wang, C.; Luo, F. Research on Load Spectrum Reconstruction Method of Exhaust System Mounting Bracket of a Hybrid Tractor Based on MOPSO-Wavelet Decomposition Technique. Agriculture 2023, 13, 1919. [Google Scholar] [CrossRef]

- Pan, W.; Li, J.; Zhang, G.; Zhou, L.; Tu, M. Multi-Objective Optimization of Organic Rankine Cycle (ORC) for Tractor Waste Heat Recovery Based on Particle Swarm Optimization. Energies 2022, 15, 6720. [Google Scholar] [CrossRef]

- Li, T.; Xie, B.; Wang, D.; Zhang, S.; Wu, L. Real-time adaptive energy management strategy for dual-motor-driven electric tractors. Trans. Chin. Soc. Agric. Mach. 2020, 51, 530–543. [Google Scholar]

- Sheng, Z.P.; Xia, C.G.; Sun, Y.; Han, J.Y. Energy Management Strategy of Electric Tractor Based on Power Demand Prediction. J. Agric. Mech. Res. 2024, 46, 216–221. [Google Scholar]

- Zhao, Y.; Xu, L.; Zhao, C.; Xu, H.; Yan, X. Research on Energy Management Strategy for Hybrid Tractors Based on DP-MPC. Energies 2024, 17, 3924. [Google Scholar] [CrossRef]

- Zhang, K.; Deng, X.T.; Lu, Z.X.; Wang, T. Research on the Energy Management Strategy of a Hybrid Tractor OS-ECVT Based on a Dynamic Programming Algorithm. Agriculture 2024, 14, 1658. [Google Scholar] [CrossRef]

- Plerou, A.; Vlamou, E.; Papadopoulos, V. Fuzzy genetic algorithms: Fuzzy logic controllers and genetics algorithms. Glob. J. Res. Anal. 2016, 5, 497–500. [Google Scholar]

- Li, Y.Y.; Liu, M.N.; Xu, L.Y.; Lei, S.H. Control strategy of series hybrid tractor based on nonlinear program genetic algorithm. J. Jiangsu Univ. (Nat. Sci. Ed.) 2023, 44, 166–172+185. [Google Scholar]

- Xie, Z.H.; Wang, P.; Gu, B.X.; Ji, C.Y.; Tian, G.Z. Application of genetic algorithm based on group and elite strategy for robot navigation. J. South China Agric. Univ. 2017, 38, 110–116. [Google Scholar]

- Lü, X.; Wu, Y.; Lian, J.; Zhang, Y.; Chen, C.; Wang, P.; Meng, L. Energy management of hybrid electric vehicles: A review of energy optimization of fuel cell hybrid power system based on genetic algorithm. Energy Convers. Manag. 2020, 205, 112474. [Google Scholar] [CrossRef]

- Zhou, B.; Su, X.; Yu, H.; Guo, W.; Zhang, Q. Research on Path Tracking of Articulated Steering Tractor Based on Modified Model Predictive Control. Agriculture 2023, 13, 871. [Google Scholar] [CrossRef]

- Wang, L.; Zhai, Z.; Zhu, Z.; Mao, E. Path Tracking Control of an Autonomous Tractor Using Improved Stanley Controller Optimized with Multiple-Population Genetic Algorithm. Actuators 2022, 11, 22. [Google Scholar] [CrossRef]

- Chen, H.; Xie, H.; Sun, L.; Shang, T. Research on Tractor Optimal Obstacle Avoidance Path Planning for Improving Navigation Accuracy and Avoiding Land Waste. Agriculture 2023, 13, 934. [Google Scholar] [CrossRef]

- Yang, M.; Sun, X.; Deng, X.; Lu, Z.; Wang, T. Extrapolation of Tractor Traction Resistance Load Spectrum and Compilation of Loading Spectrum Based on Optimal Threshold Selection Using a Genetic Algorithm. Agriculture 2023, 13, 1133. [Google Scholar] [CrossRef]

- Fan, X.; Wang, J.; Wang, H.; Yang, L.; Xia, C. LQR Trajectory Tracking Control of Unmanned Wheeled Tractor Based on Improved Quantum Genetic Algorithm. Machines 2023, 11, 62. [Google Scholar] [CrossRef]

- Li, B.; Pan, J.; Li, Y.; Ni, K.; Huang, W.; Jiang, H.; Liu, F. Optimization Method of Speed Ratio for Power-Shift Transmission of Agricultural Tractor. Machines 2023, 11, 438. [Google Scholar] [CrossRef]

- Yang, Y.Q.; Zhang, J.L.; Wang, D.Y.; Zheng, D.C. Gear train optimization of404p traetor hased on multi-abjective genetie algorithm. Agric. Eng. 2022, 12, 91–96. [Google Scholar]

- Wu, Y.; Zhao, Y.; Wen, C.; Zhang, J.; Yan, X. Research on energy management strategies for high-power diesel-electric hybrid tractors based on double deep Q-network. Sci. Rep. 2025, 15, 17130. [Google Scholar] [CrossRef]

- Dou, H.S.; Zhang, Y.T.; Ai, Q.; Zhao, X.Q. Control strategy for hybrid tractor plow conditions oriented to coupled-split dynamic configuration. Trans. Chin. Soc. Agric. Eng. 2022, 38, 41–49. [Google Scholar]

- Chen, B.; Ma, R.; Zhou, Y.; Ma, R.; Jiang, W.; Yang, F. Co-optimization of speed planning and cost-optimal energy management for fuel cell trucks under vehicle-following scenarios. Energy Convers. Manag. 2024, 300, 117914. [Google Scholar] [CrossRef]

- Watkins, C.J.C.H. Learning from Delayed Rewards. Ph.D. Thesis, King’s College London, London, UK, 1989. [Google Scholar]

- Liu, T.; Wang, B.; Yang, C. Online Markov Chain-based energy management for a hybrid tracked vehicle with speedy Q-learning. Energy 2018, 160, 544–555. [Google Scholar] [CrossRef]

- Wu, J.; He, H.; Peng, J.; Li, Y.; Li, Z. Continuous reinforcement learning of energy management with deep Q network for a power split hybrid electric bus. Appl. Energy 2018, 222, 799–811. [Google Scholar] [CrossRef]

- Han, X.; He, H.; Wu, J.; Peng, J.; Li, Y. Energy management based on reinforcement learning with double deep Q-learning for a hybrid electric tracked vehicle. Appl. Energy 2019, 254, 113708. [Google Scholar] [CrossRef]

- Xu, B.; Rathod, D.; Zhang, D.; Yebi, A.; Zhang, X.; Li, X.; Filipi, Z. Parametric study on reinforcement learning optimized energy management strategy for a hybrid electric vehicle. Appl. Energy 2020, 259, 114200. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, X.; Ren, Z.; Yao, Z.; Tan, X. Synchronized path planning and tracking for front and rear axles in articulated wheel loaders. Autom. Constr. 2024, 165, 105538. [Google Scholar] [CrossRef]

- Olcay, E.; Rui, X.; Wang, R. Headland Turn Automation Concept for Tractor-Trailer System with Deep Reinforcement Learning. In Proceedings of the 2023 IEEE 19th International Conference on Automation Science and Engineering (CASE), Auckland, New Zealand, 30 August 2023; pp. 1–7. [Google Scholar]

- Elhaki, O.; Shojaei, K. Output-feedback robust saturated actor–critic multi-layer neural network controller for multi-body electrically driven tractors with n-trailer guaranteeing prescribed output constraints. Robot. Auton. Syst. 2022, 154, 104106. [Google Scholar] [CrossRef]

- Xiao, B.; Yang, W.; Wu, J.; Walker, P.D.; Zhang, N. Energy management strategy via maximum entropy reinforcement learning for an extended range logistics vehicle. Energy 2022, 253, 124105. [Google Scholar] [CrossRef]

- Drungilas, D.; Kurmis, M.; Senulis, A.; Lukosius, Z.; Andziulis, A.; Januteniene, J.; Bogdevicius, M.; Jankunas, V.; Voznak, M. Deep reinforcement learning based optimization of automated guided vehicle time and energy consumption in a container terminal. Alex. Eng. J. 2023, 67, 397–407. [Google Scholar] [CrossRef]

- Qi, C.; Zhu, Y.; Song, C.; Yan, G.; Xiao, F.; Zhang, X.; Cao, J.; Song, S. Hierarchical reinforcement learning based energy management strategy for hybrid electric vehicle. Energy 2022, 238, 121703. [Google Scholar] [CrossRef]

- Lian, R.; Peng, J.; Wu, Y.; Tan, H.; Zhang, H. Rule-interposing deep reinforcement learning based energy management strategy for power-split hybrid electric vehicle. Energy 2020, 197, 117297. [Google Scholar] [CrossRef]

- Zhang, Y.G.; Liu, M.N.; Xu, W.X.; Xu, L.Y. Parameter optimization of electric tractor dual motor coupling drive based on DDPG algorithm. J. Chin. Agric. Mech. 2023, 44, 129–136. [Google Scholar]

- Tang, X.; Chen, J.; Pu, H.; Liu, T.; Khajepour, A. Double deep reinforcement learning-based energy management for a parallel hybrid electric vehicle with engine start–stop strategy. IEEE Trans. Transp. Electrif. 2021, 8, 1376–1388. [Google Scholar] [CrossRef]

- Tang, X.; Chen, J.; Liu, T.; Qin, Y.; Cao, D. Distributed deep reinforcement learning-based energy and emission management strategy for hybrid electric vehicles. IEEE Trans. Veh. Technol. 2021, 70, 9922–9934. [Google Scholar] [CrossRef]

- Lin, J.Q.; Wang, H.J.; Zou, X.J.; Zhang, P.; Li, C.E. Obstacle Avoidance Path Planning and Simulation of Mobile Picking Robot Based on DPPO. J. Syst. Simul. 2023, 35, 1692–1704. [Google Scholar]

- Yang, N.; Ruan, S.; Han, L.; Liu, H.; Guo, L.; Xiang, C. Reinforcement learning-based real-time intelligent energy management for hybrid electric vehicles in a model predictive control framework. Energy 2023, 270, 126791. [Google Scholar] [CrossRef]

- Zhou, Q.; Li, J.; Shuai, B.; Williams, H.; He, Y.; Li, Z.; Xu, H.; Yan, F. Multi-step reinforcement learning for model-free predictive energy management of an electrified off-highway vehicle. Appl. Energy 2019, 255, 113755. [Google Scholar] [CrossRef]

- Zhang, W.; Gai, J.; Zhang, Z.; Tang, L.; Liao, Q.; Ding, Y. Double-DQN based path smoothing and tracking control method for robotic vehicle navigation. Comput. Electron. Agric. 2019, 166, 104985. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, X.; Yuan, P.; Tian, H.; Shu, G. Optimizing hybrid electric vehicle coupling organic Rankine cycle energy management strategy via deep reinforcement learning. Energy AI 2024, 17, 100392. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, W.; Wang, J.; Yuan, Y. Recent progress, challenges and future prospects of applied deep reinforcement learning: A practical perspective in path planning. Neurocomputing 2024, 608, 128423. [Google Scholar] [CrossRef]

- Hafner, D.; Pasukonis, J.; Ba, J.; Lillicrap, T. Mastering diverse control tasks through world models. Nature 2025, 640, 647–653. [Google Scholar] [CrossRef]

- Song, H.; Jiang, J.; Min, Y.; Chen, J.; Chen, Z.; Zhao, W.X.; Fang, L.; Wen, J.-R. R1-searcher: Incentivizing the search capability in llms via reinforcement learning. arXiv 2025, arXiv:2503.05592. [Google Scholar] [CrossRef]

- Shao, Z.; Wang, P.; Zhu, Q.; Xu, R.; Song, J.; Bi, X.; Zhang, H.; Zhang, M.; Li, Y.; Wu, Y. Deepseekmath: Pushing the limits of mathematical reasoning in open language models. arXiv 2024, arXiv:2402.03300. [Google Scholar]

- Hoang, T.; Le, H.; Becker, P.; Ngo, V.A.; Neumann, G. Geometry-aware RL for Manipulation of Varying Shapes and Deformable Objects. arXiv 2025, arXiv:2502.07005. [Google Scholar]

- Li, X.; Wang, X.; Bai, C.; Zhang, J. Exponential Topology-enabled Scalable Communication in Multi-agent Reinforcement Learning. arXiv 2025, arXiv:2502.19717. [Google Scholar]

- Wang, T.; Xu, X.; Wang, C.; Li, Z.; Li, D. From Smart Farming towards Unmanned Farms: A New Mode of Agricultural Production. Agriculture 2021, 11, 145. [Google Scholar] [CrossRef]

- Wang, N.; Li, S.; Xiao, J.; Wang, T.; Han, Y.; Wang, H.; Zhang, M.; Li, H. A collaborative scheduling and planning method for multiple machines in harvesting and transportation operations-Part I: Harvester task allocation and sequence optimization. Comput. Electron. Agric. 2025, 232, 110060. [Google Scholar] [CrossRef]

- Wang, N.; Yang, X.; Wang, T.; Xiao, J.; Zhang, M.; Wang, H.; Li, H. Collaborative path planning and task allocation for multiple agricultural machines. Comput. Electron. Agric. 2023, 213, 108218. [Google Scholar] [CrossRef]

- Man, Z.X.; He, J.; Liu, S.Q.; Yue, M.D.; Hu, L. Method and test for operating multi-machine cooperative harvesting in intelligent agricultural machinery. Trans. Chin. Soc. Agric. Eng. 2024, 40, 17–26. [Google Scholar]

- Zhang, W.Y.; Zhang, Z.G.; Zhang, F.; Ding, F.; Hu, L. Cooperative autonomous operation strategy and experiment of the rice harvester together with a rice-transporting vehicle. Trans. Chin. Soc. Agric. Eng. 2022, 38, 1–9. [Google Scholar]

- Zhang, W.; Hu, L.; Ding, F.; Luo, X.; Zhang, Z.; Hu, L.; Huang, P.; Peng, M. Parking precise alignment control and cotransporter system for rice harvester and transporter. Comput. Electron. Agric. 2023, 215, 108443. [Google Scholar] [CrossRef]

- Hu, L.; Guan, J.J.; He, J.; Man, Z.X.; Tian, L. Design and Experiment of Automatic Driving Operation System of Peanut Harvester Based on BDS. Trans. Chin. Soc. Agric. Mach. 2022, 53, 21–27. [Google Scholar]

- He, J.; Man, Z.X.; Hu, L.; Luo, X.W.; Wang, P. Path tracking control method and experiments for the crawler-mounted peanut combine harvester. Trans. Chin. Soc. Agric. Eng. 2023, 39, 9–17. [Google Scholar]

- Ding, F.; Zhang, W.Y.; Luo, X.W.; Hu, L.; Zhang, Z.G.; Wang, M.C.; Li, H.K.; Peng, M.D.; Wu, X.L.; Hu, L.W.; et al. Gain self-adjusting single neuron PID control method and experiments for longitudinal relative position of harvester and transport vehicle. Comput. Electron. Agric. 2023, 213, 108215. [Google Scholar] [CrossRef]

- Zhang, W.Y.; Hu, L.W.; Wang, H.; Zhang, G.C.; Luo, X.W. Improved Pure Pursuit Agricultural Machinery Navigation Curve Path Tracking Method Based on B-spline Optimization. Trans. Chin. Soc. Agric. Mach. 2024, 55, 42–51+115. [Google Scholar]

- He, J.; Liu, S.Q.; Man, Z.X.; Yue, M.D.; Wang, J.T. Curve Path Tracking Control of Agricultural Machinery Automatic Driving Based on Full State Feedback Control. Trans. Chin. Soc. Agric. Mach. 2025, 56, 145–154. [Google Scholar]

- He, J.; Zeng, H.X.; Li, M.J.; He, J.; Mo, J.J.; Wang, P.; Zhao, R.M. Improved Pure Pursuit Path Tracking Control Method for Automatic Navigation Tractor Based on Drive Wheel Lateral Deviation Compensation. Trans. Chin. Soc. Agric. Mach. 2025, 56, 28–37. [Google Scholar]

- He, J.; Luo, X.; Zhang, Z.; Wang, P.; He, J.; Yue, B.; Ding, F.; Zhu, Q. Positioning correction method for rice transplanters based on the attitude of the implement. Comput. Electron. Agric. 2020, 176, 105598. [Google Scholar] [CrossRef]

- He, J.; Hu, L.; Wang, P.; Liu, Y.; Man, Z.; Tu, T.; Yang, L.; Li, Y.; Yi, Y.; Li, W.; et al. Path tracking control method and performance test based on agricultural machinery pose correction. Comput. Electron. Agric. 2022, 200, 107185. [Google Scholar] [CrossRef]

- Hu, L.; Zhang, H.; He, J.; Man, Z.X.; Yue, M.D.; Qu, G.K.; Tang, Q.Y.; Huang, P.K.; Luo, X.W. Path Planning Technical Research of Low-rolling Compaction Harvesting Operation for the First Season of Ratoon Rice. Trans. Chin. Soc. Agric. Mach. 2025, 56, 19–27. [Google Scholar]

- Zhang, Z.G.; Wang, G.M.; Luo, X.W.; He, J.; Wang, J. Detection Method of Steering Wheel Angle for Tractor Automatic Driving. Trans. Chin. Soc. Agric. Mach. 2019, 50, 352–357. [Google Scholar]

- He, J.; Zhu, J.G.; Luo, X.W.; Zhang, Z.G.; Hu, L. Design of steering control system for rice transplanter equipped with steering wheel-like motor. Trans. Chin. Soc. Agric. Eng. 2019, 35, 10–17. [Google Scholar]

- Available online: https://www.deere.com/en/technology-products/precision-ag-technology/data-management/jdlink/ (accessed on 13 July 2025).

- Jiang, D.; Shen, Z.; Zheng, Q.; Zhang, T.; Xiang, W.; Jin, J. Farm-LightSeek: An Edge-centric Multimodal Agricultural IoT Data Analytics Framework with Lightweight LLMs. IEEE Internet of Things Magazine, 6 June 2025; pp. 1–6. [Google Scholar]

- Fendt e100 V Vario. Available online: https://www.fendt.com/int/agricultural-machinery/e-tractors/fendt-e100-v-vario (accessed on 10 July 2025).

- Luo, X.W.; Liao, J.; Hu, L.; Zhou, Z.Y.; Zhang, Z.G.; Zang, Y.; Wang, P.; He, J. Research progress of intelligent agricultural machinery and practice of unmanned farm in China. J. South China Agric. Univ. 2021, 42, 8–17. [Google Scholar] [CrossRef]

- News. Sciencenet. Available online: https://news.sciencenet.cn/sbhtmlnews/2020/5/355053.shtm?id=355053 (accessed on 19 July 2025).

- GB/T 16877-2008; Prohibition and Scrapping for Tractors. Standardization Administration of China: Beijing, China, 2008. (In Chinese)

- GB/T15370.1-2012; General Requirement of Agricultural Tractors—Part 1: Under 50 kW Wheeled Tractors. Standardization Administration of China: Beijing, China, 2012. (In Chinese)

- GB/T 15370.2-2009; General Requirement of Agricultural Tractors—Part 2: 50 kW~130 kW Wheeled Tractors. Standardization Administration of China: Beijing, China, 2009. (In Chinese)

- Usage Price: Electricity for industry: 35 kV & Above:Guangzhou. Available online: https://www.ceicdata.com/en/china/electricity-price-36-city/cn-usage-price-electricity-for-industry-35-kv--above-guangzhou (accessed on 19 July 2025).

- Gao, H.; Xue, J. Modeling and economic assessment of electric transformation of agricultural tractors fueled with diesel. Sustain. Energy Technol. Assess. 2020, 39, 100697. [Google Scholar] [CrossRef]

- Proctor, K. Total Cost of Ownership of a Compact Battery Electric Agricultural Tractor. 2022. Available online: https://static1.squarespace.com/static/656a0f83560384720ffc2a8c/t/6626c0cfff2241134020a818/1713815760384/TCO_report_May%2B2022.pdf (accessed on 19 July 2025).

| Year | Name | Key Functions and Technical Features | Energy Type | Picture |

|---|---|---|---|---|

| 1912 | Siemens First Electric Tractor | Rail-powered, wheeled structure, driving rotary tiller operations, power 36.8 kW | Pure Electric (External Power) |  |

| 1973 | GE Elec-Trak (General Electric Company, Schenectady, NY, USA) [21] | Lead-acid battery driven, permanent magnet DC motor, power 5.9–11 kW, for home lawn mowing | Pure Electric (External Power) |  |

| 1995 | Electric Ox | Lead-acid battery powered, dual-motor independent drive (travel + PTO), supported regenerative braking | Pure Electric |  |

| 2017 | John Deere SESAM (Deere & Company, Moline, IL, USA) | Lithium-ion battery (130 kWh × 2), pure electric drive, CVT, 2 h heavy-load operation | Pure Electric |  |

| 2022 | Dongfanghong HB2204 (First Tractor Company Limited, Luoyang, Henan, China) [22] | Series-parallel hybrid, E-CVT, 85% localization rate | Hybrid (Strong Hybrid) |  |

| 2024 | Wantu 2604ET (Wantu Group, Wuhu, Anhui, China) [22] | World’s first 260 hp pure electric model, LFP battery (7000 cycles), supports battery swap/supercharging | Pure Electric |  |

| Power Source | Key Advantages | Main Challenges | Typical Applications | |

|---|---|---|---|---|

| Electric Tractor | Battery + Single/Dual Motors | - Zero emissions, simple structure [51] - Dual-motor design decouples traction and PTO systems [25] | - Limited range [52] - Poor adaptability under heavy loads [53] | Short-haul/fixed-site operations [26] |

| Series Hybrid | ICE + Generator + Battery + Motor [34] | - Extended range (generator support) [54] - PTO speed independent of vehicle speed due to decoupling [54] - Optimized ICE efficiency [54] | - Large battery size/cost - Low braking energy recovery efficiency [55] | Medium/large-scale continuous fieldwork [48,55] |

| Parallel Hybrid | ICE + Motor (parallel coupling) | - Engine-motor torque assist [39] - Fuel mode backup [41] - Up to 24% energy savings (Deng [44]) | - Complex control algorithms [41] - Higher fuel consumption in heavy tasks [45] | Variable-load scenarios (transport/plowing) [48] |

| Series-Parallel Hybrid | ICE + Dual Motors (planetary gear) [47] | - Optimal power split for efficiency [48] - Multi-mode operation [49] (electric/mechanical) | - High system complexity [47] | Complex operations (e.g., heavy loaders) [48] |

| Algorithm | Core Advantage | Typical Application | Tractor Adaptability |

|---|---|---|---|

| DreamerV3 [126] | Cross-task zero-shot adaptation | Game AI, Robotics Simulation | Adaptive terrain navigation |

| R1-Searcher [127] | Dynamic retrieval-reasoning loop | Real-time QA, Customer Service | Fault diagnosis knowledge base |

| GRPO (Group Relative Policy Optimization) [128] | Value-function-free optimization | Math Reasoning, Code Generation | Low-power edge deployment |

| HEPi (Heterogeneous Equivariant Policy) [129] | SE(3)-equivariant action space | Rigid/Deformable Object Manipulation | Precision implement control |

| ExpoComm [127,130] | Linear-communication-overhead topology | Large-scale Multi-Agent Systems | Swarm farming coordination |

| Operation Type | Speed (km/h) | Time (min) | Average Annual Frequency (Time) | Annual Energy Consumption (kW·h) |

|---|---|---|---|---|

| Land Preparation | 6 | 45 | 4 | 24.10 |

| Sowing | 3.5 | 85 | 2 | 40.80 |

| Crop Protection | 15 | 22 | 5 | 9.68 |

| Harvesting | 4 | 63 | 2 | 34.24 |

| Cost Category | The Range of 44.1 kw and 58.8 kw Electric Tractor (in Unmanned Farms) | 44.1 kw Diesel Tractor |

|---|---|---|

| Energy Consumption | 60,000–105,000 | 304,691.7 |

| Maintenance cost | 19,314.4–25,953.0 | 7518.4 |

| Replacing cost | 50,446.1–67,261.5 | 0 |

| Cost of tractors (including tax) | 35,767.4–48,061.0 | 12,045.7 |

| Insurance | 13,144.5–17,662.4 | 3070.0 |

| residual value | 15,018.5–20,180.6 | 3507.7 |

| Total | 163,653.9–243,757.3 | 323,818.1 |

| Phase | Timeframe | Technical Focus | Application Scenarios | Policy/Industry Recommendations |

|---|---|---|---|---|

| Short-term | 2025–2030 | High-energy LFP batteries; hybrid EMS (rule + optimization) | Protected horticulture, orchards; light-load operations | Purchase subsidies; energy/range standards; |

| Mid-term | 2030–2035 | Solid-state and hydrogen fuel cells; tractor–implement–soil coordination; edge–cloud decision-making | Hybrid tractors mainstream; wider use of pure electric; regional unmanned farm pilots | Agricultural big data platforms; interdisciplinary R&D; green supply chains |

| Long-term | Beyond 2035 | AI-driven autonomous operation; closed-loop energy ecosystem | Tractors as Ag-IoT nodes; integrated energy–information flows | Build an integrated Agricultural IoT ecosystem; renewable energy–microgrid integration |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Li, J.; Li, C.; Lin, P.; Shi, L.; Xiao, B. Electrification and Smartification for Modern Tractors: A Review of Algorithms and Techniques. Agriculture 2025, 15, 1943. https://doi.org/10.3390/agriculture15181943

Zhang C, Li J, Li C, Lin P, Shi L, Xiao B. Electrification and Smartification for Modern Tractors: A Review of Algorithms and Techniques. Agriculture. 2025; 15(18):1943. https://doi.org/10.3390/agriculture15181943

Chicago/Turabian StyleZhang, Chaoxian, Jun Li, Chuxi Li, Peihan Lin, Linlin Shi, and Boyi Xiao. 2025. "Electrification and Smartification for Modern Tractors: A Review of Algorithms and Techniques" Agriculture 15, no. 18: 1943. https://doi.org/10.3390/agriculture15181943

APA StyleZhang, C., Li, J., Li, C., Lin, P., Shi, L., & Xiao, B. (2025). Electrification and Smartification for Modern Tractors: A Review of Algorithms and Techniques. Agriculture, 15(18), 1943. https://doi.org/10.3390/agriculture15181943