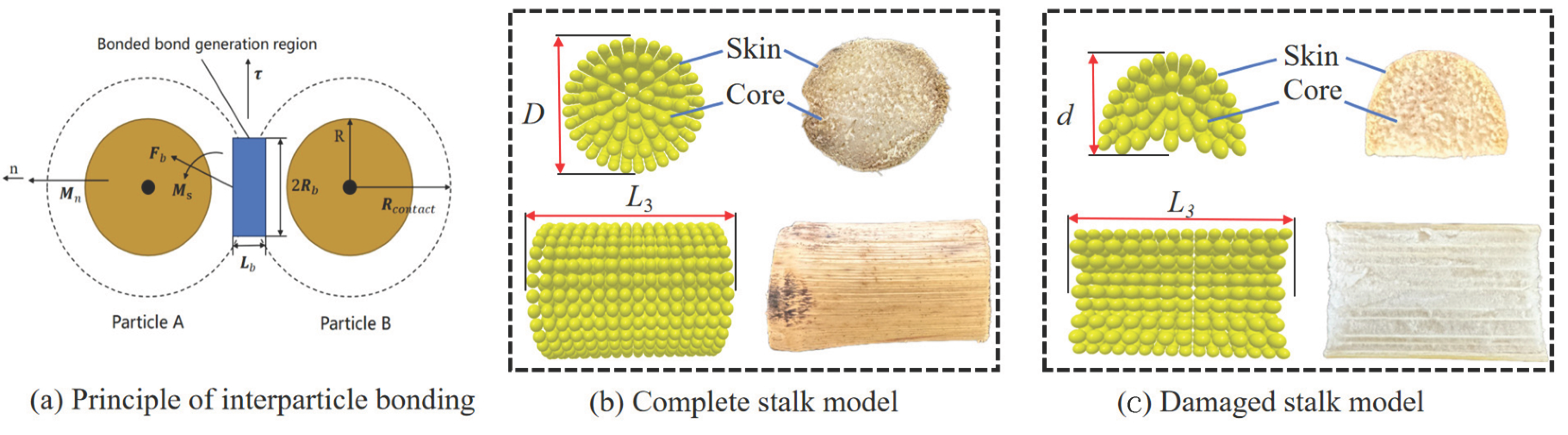

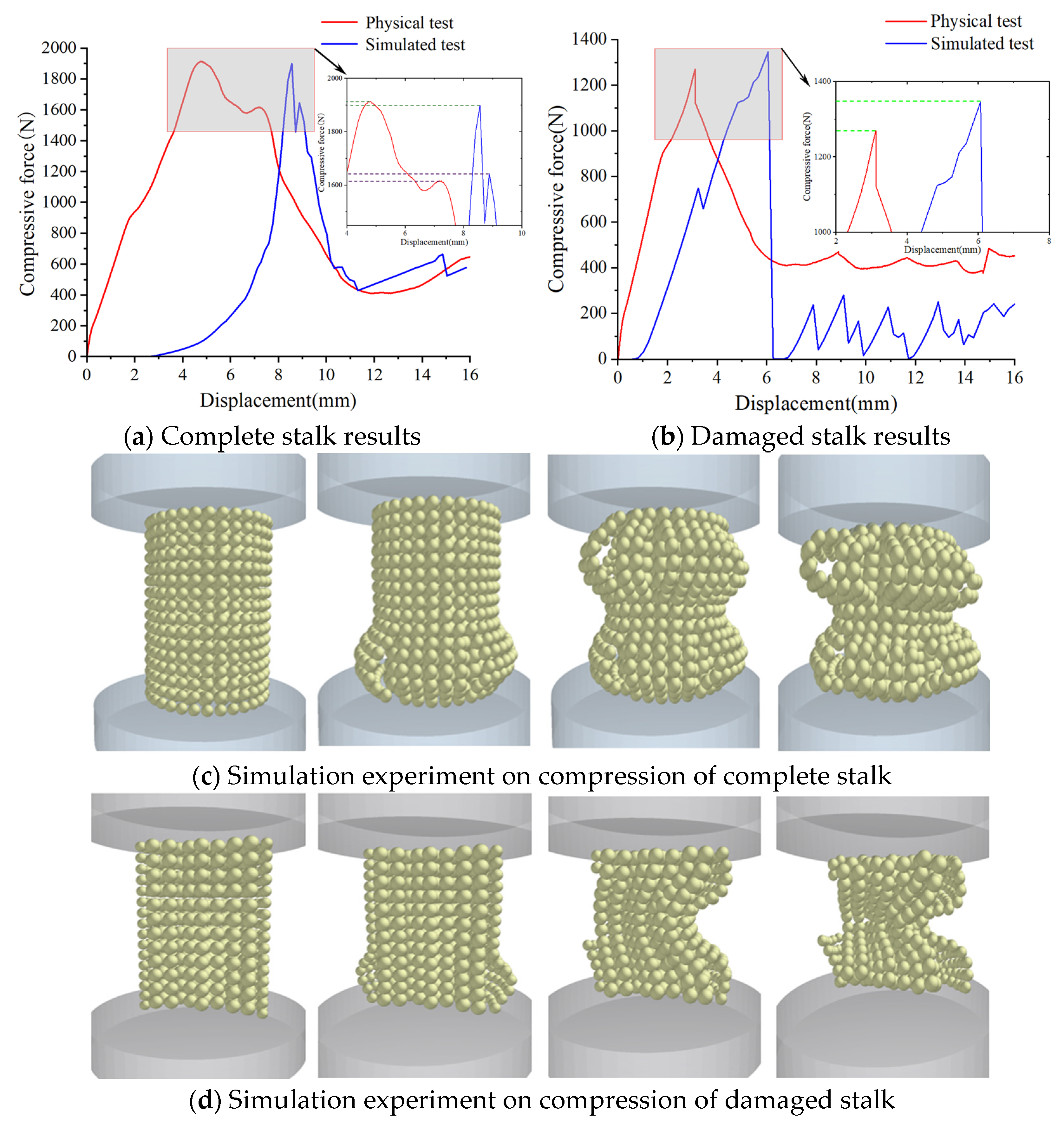

3.7.1. Radial Compression Simulation of Complete Corn Stalks

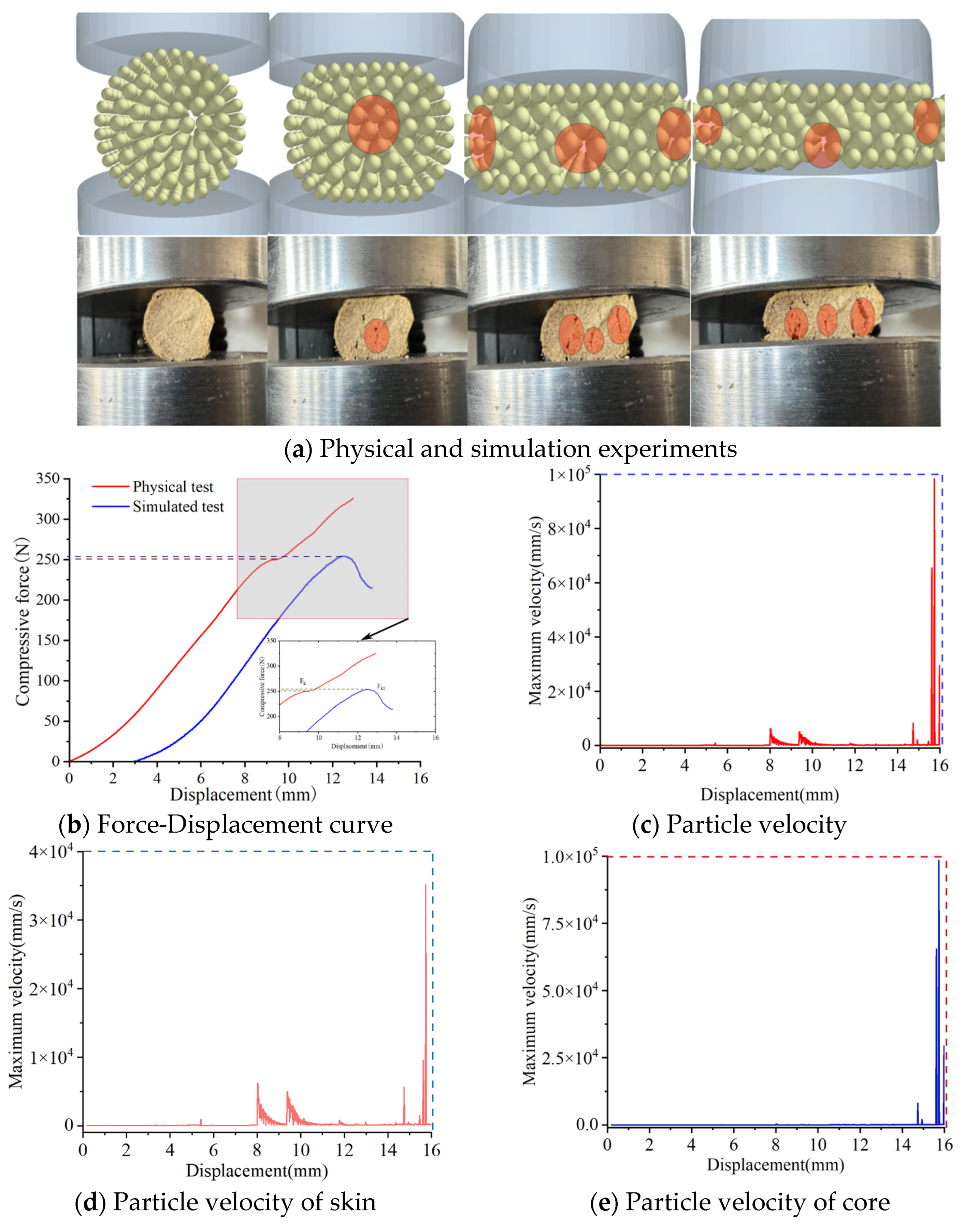

Figure 13a depicts the compression processes in both the physical experiments and simulations. The results indicate that as the compression displacement increases, longitudinal cracks first emerge, with the cracked areas located on the middle sides of the core part. Eventually, the complete corn stalks fractured.

Figure 13b presents the radial compression force–displacement curves from both the simulations and physical tests for the complete corn stalks. The average maximum compressive force in the experiment is 250.36 N, while the maximum compressive force obtained from the simulation is 254.11 N, with a relative error of 1.5% compared to the experimental average, as shown in

Table 10. These results demonstrate that the changing trends of the two curves are essentially consistent, and the complete corn stalk model can accurately reflect the relationship between compressive force and displacement.

Analysis of the model fitting effect shows that the root mean square error (RMSE) is 9.21 N, as shown in

Table 10, indicating a small average deviation between the simulated values and measured values with high overall agreement. The coefficient of determination,

R2 = 0.97, is close to 1, suggesting that the model has an excellent ability to capture the mechanical response of complete stalks. The average error percentage is 1.55%, verifying the reliability of the error description. The calculated 95% confidence interval is from −1.23% to 4.33%; this interval contains 0 and has a narrow range, indicating no systematic bias and good stability of errors.

Figure 13c shows the maximum velocity of particles.

Figure 13d shows the maximum velocity of skin particles.

Figure 13e shows the maximum velocity of core particles. When the compression displacement is 15.84 mm, the maximum velocity of the skin of complete corn stalks is 3.51 × 10

4 mm/s. The maximum velocity of the core of complete corn stalks is 9.83 × 10

4 mm/s.

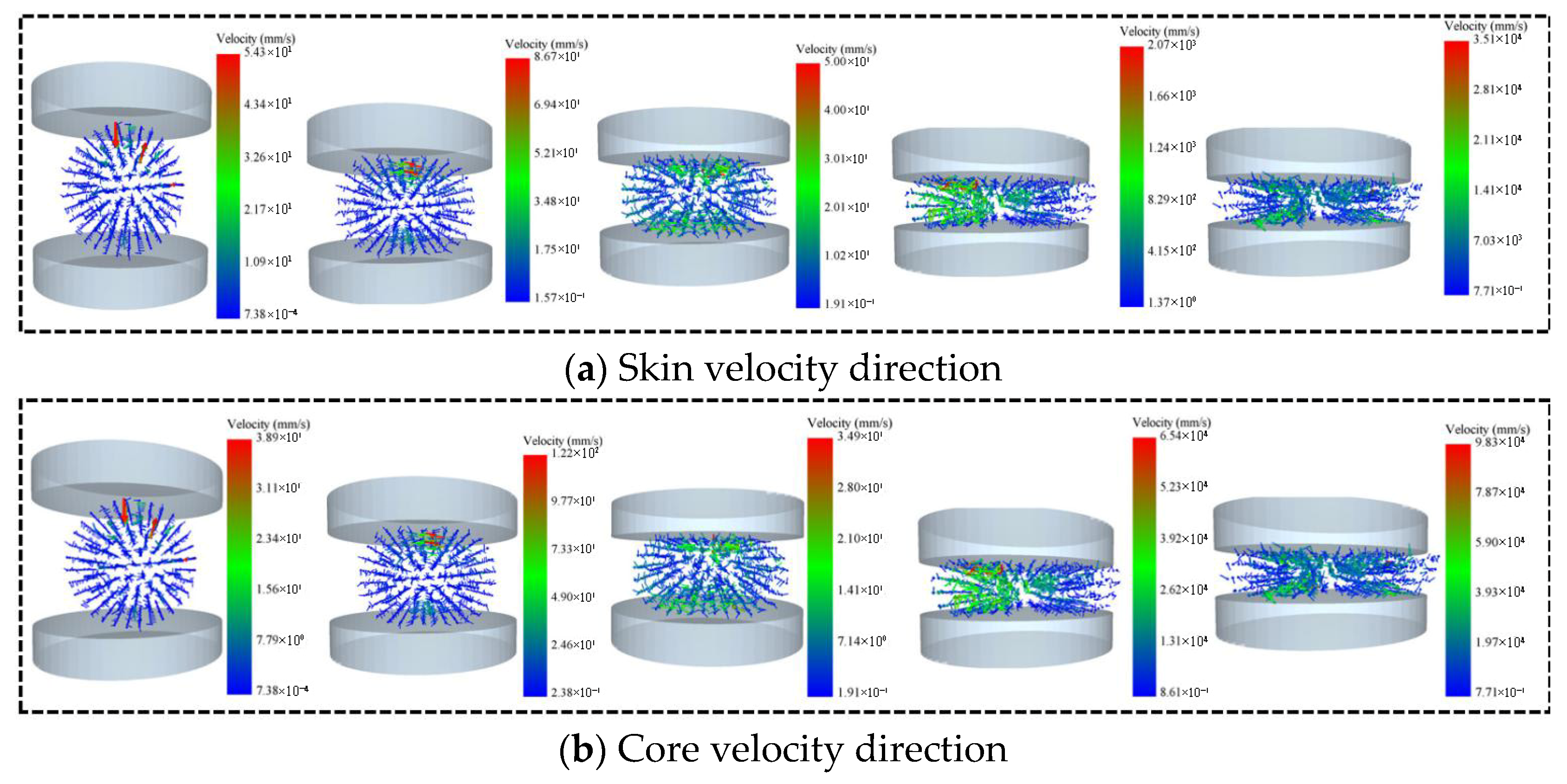

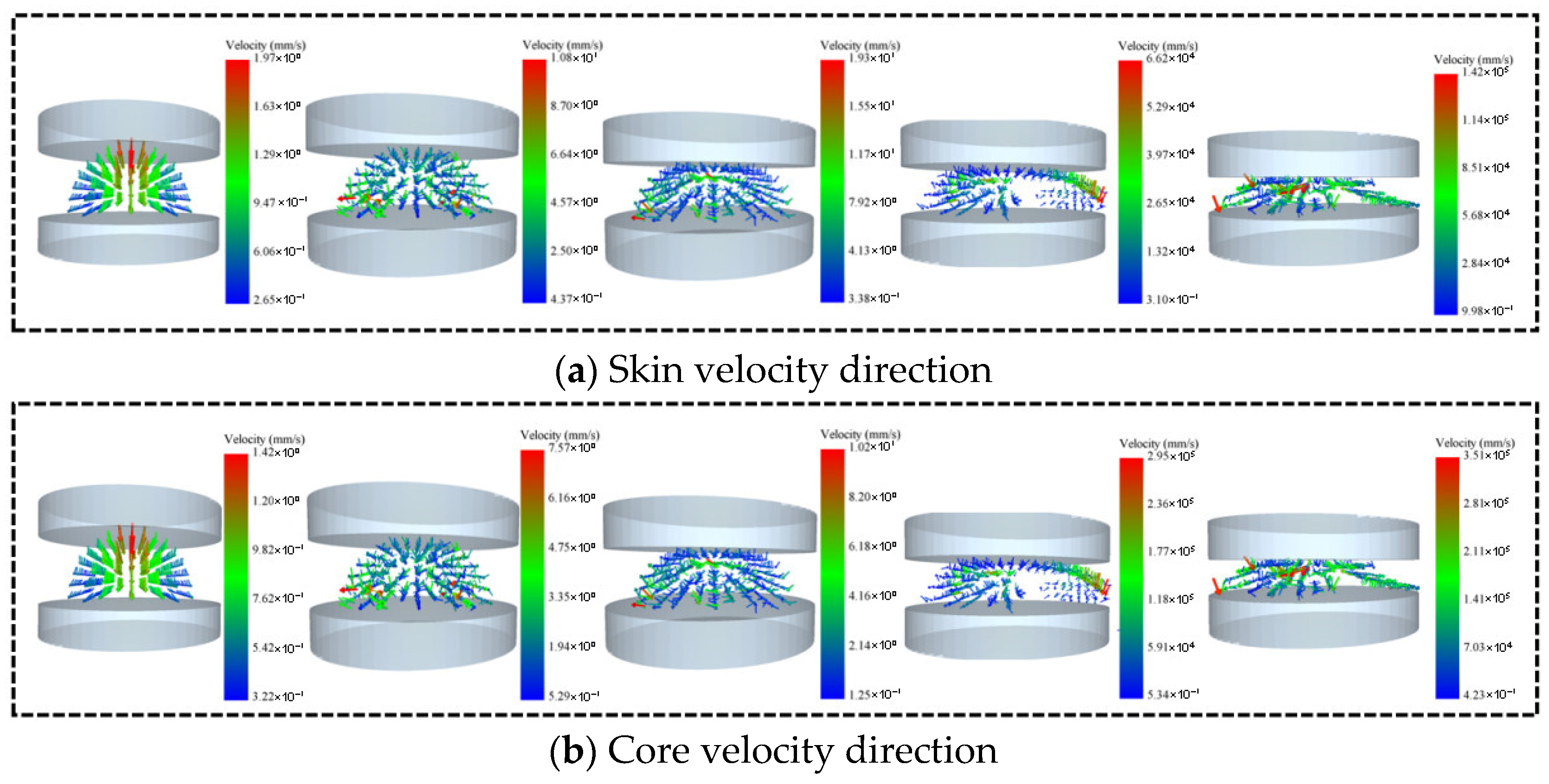

The direction of the radial compression velocity of the skin is shown in

Figure 14a.

Figure 14b shows the direction of the radial compression velocity of the core. It can be seen that during the initial stage of compression, the velocity direction of the complete corn stalks is directed toward the central region. As the loading displacement increases, the velocity direction at the loaded position of the stalk shifts. The maximum velocity of the outer skin is 3.51 × 10

4 mm/s when the speed of the core is 9.83 × 10

4 mm/s. When compression starts, the velocity of stressed stalk particles increases. When the complete stalks develop cracks, the particle velocity decreases, accompanied by a phenomenon of local velocity concentration that diverges to both sides. When the complete stalks are compressed into a clump, the particle concentration causes a sharp increase in particle velocity.

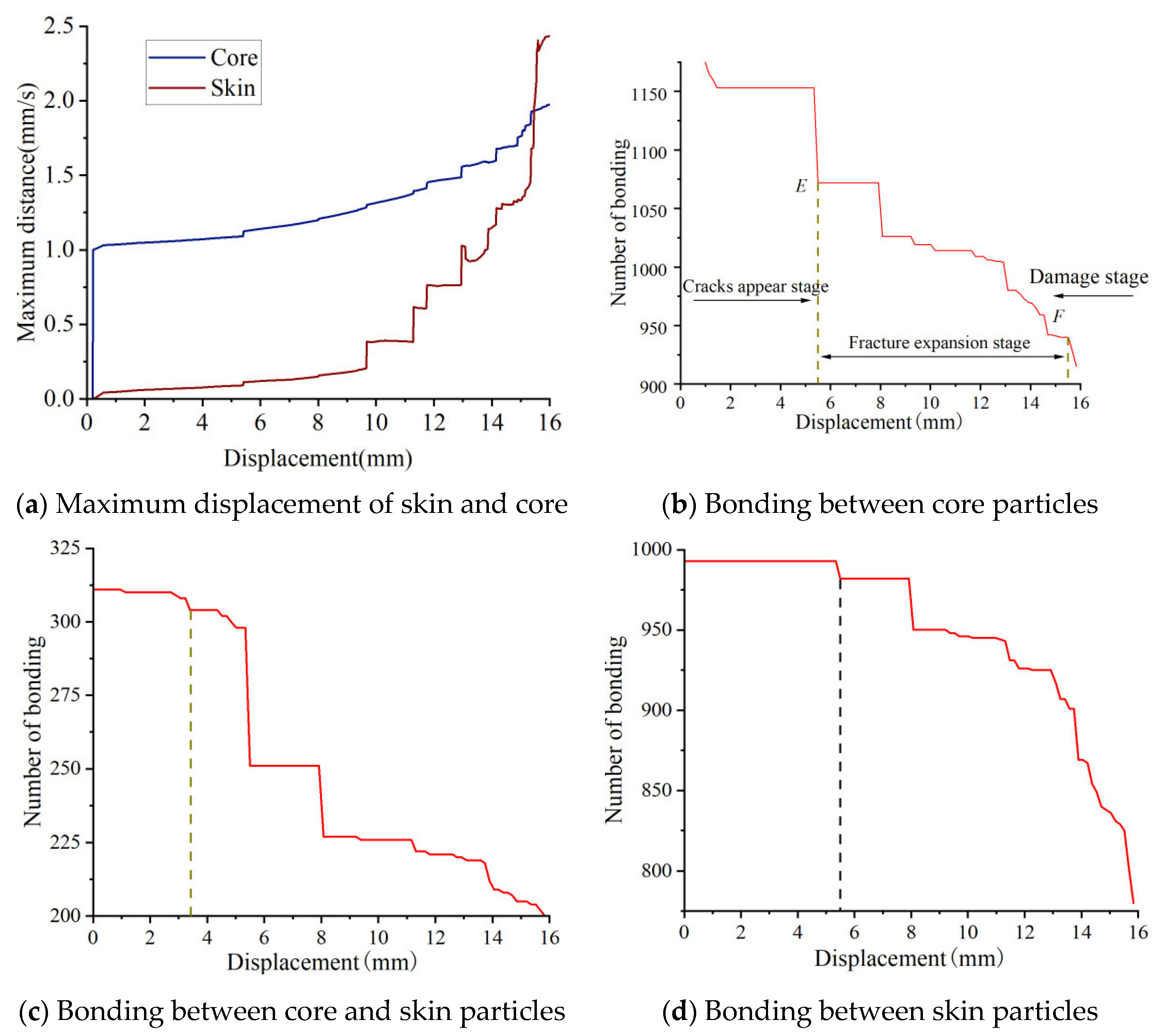

The maximum displacement curve of skin particles during the compression of the complete corn stalks is shown in

Figure 15a. It can be seen that at a compression displacement of 15.85 mm, the maximum displacement of the skin particles is 1.96 mm. It can be seen that the maximum displacement of the core particles is 2.43 mm with a compression displacement of 15.94 mm.

Figure 15b illustrates the changes in the number of bonds among the core particles during the radial compression of the complete corn stalks. For the behavior of crack occurrence, key time points were selected to measure crack lengths and calculate areas, which were synchronously verified with the diagrams of particle number changes. It can be observed that as the compression displacement increases, the number of bonds decreases slightly before point E. Crack initiation occurs at point E, where the number of bonds is 1072. The crack propagation stage spans from point E to point F, during which the number of bonds drops from 1072 to 940. After point F, the stalk is fully crushed, and the number of bonds reaches a minimum of 928.

Figure 15c shows the variation in bonds between core and skin particles. When the compression displacement is 5.5 mm, the number of bonds among the core particles decreases by 105, while the number of bonds among the core and skin particles decreases by 60. At this point, cracks form in the core, and partial separation occurs among the core and skin tissues. When the compression displacement reaches 8.28 mm, cracks in the skin are observed, as shown in

Figure 15d.

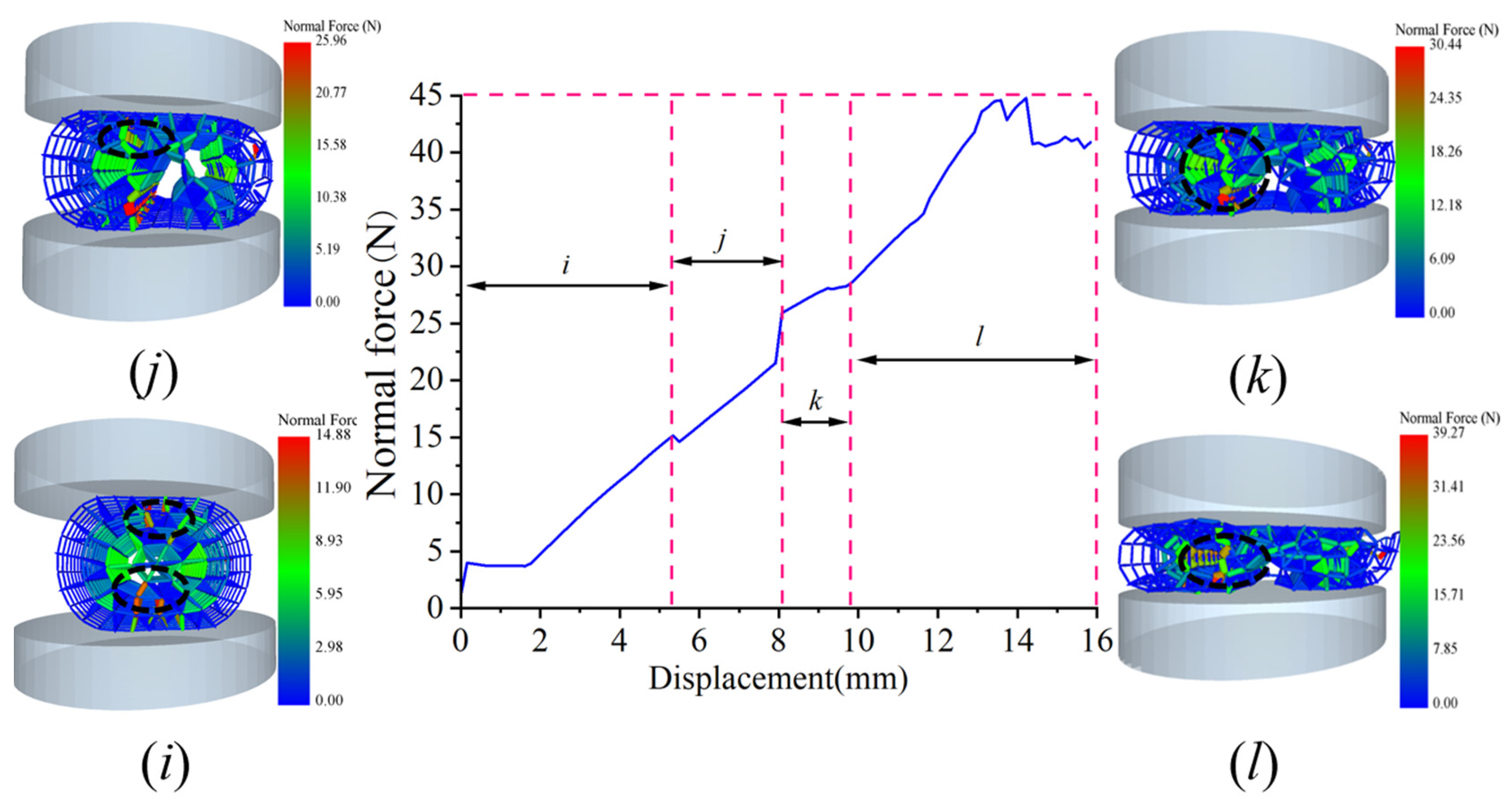

Figure 16 shows the normal force distribution of the skin and core during the radial compression of the complete corn stalks. The stalk fracturing process is divided into four stages: i, j, k, and l. The interval from 0 to 5.24 mm is defined as the vertical fracturing stage (stage i), where the normal force ranges from 0 to 14.88 N, with the maximum normal force in this stage found in the third-layer area of the core. The interval from 5.24 to 8.12 mm is classified as the upper- and lower-part fracturing stage (stage j), with normal forces ranging from 14.88 to 25.96 N; here, the maximum normal force is situated in the area connecting the two transverse fracturing regions. The interval from 8.12 to 9.86 mm is referred to as the skin–core separation stage (stage k), where normal forces range from 25.96 to 30.44 N, and the maximum normal force is located in the area connecting the core and skin. The interval from 9.86 to 16 mm is identified as the complete fracturing stage (stage l), with normal forces ranging from 30.44 to 39.27 N, and the maximum normal force in this stage is found at the center of the stalk. When the compression displacement reaches 14.54 mm, the maximum normal force in stage i is 44.8 N.

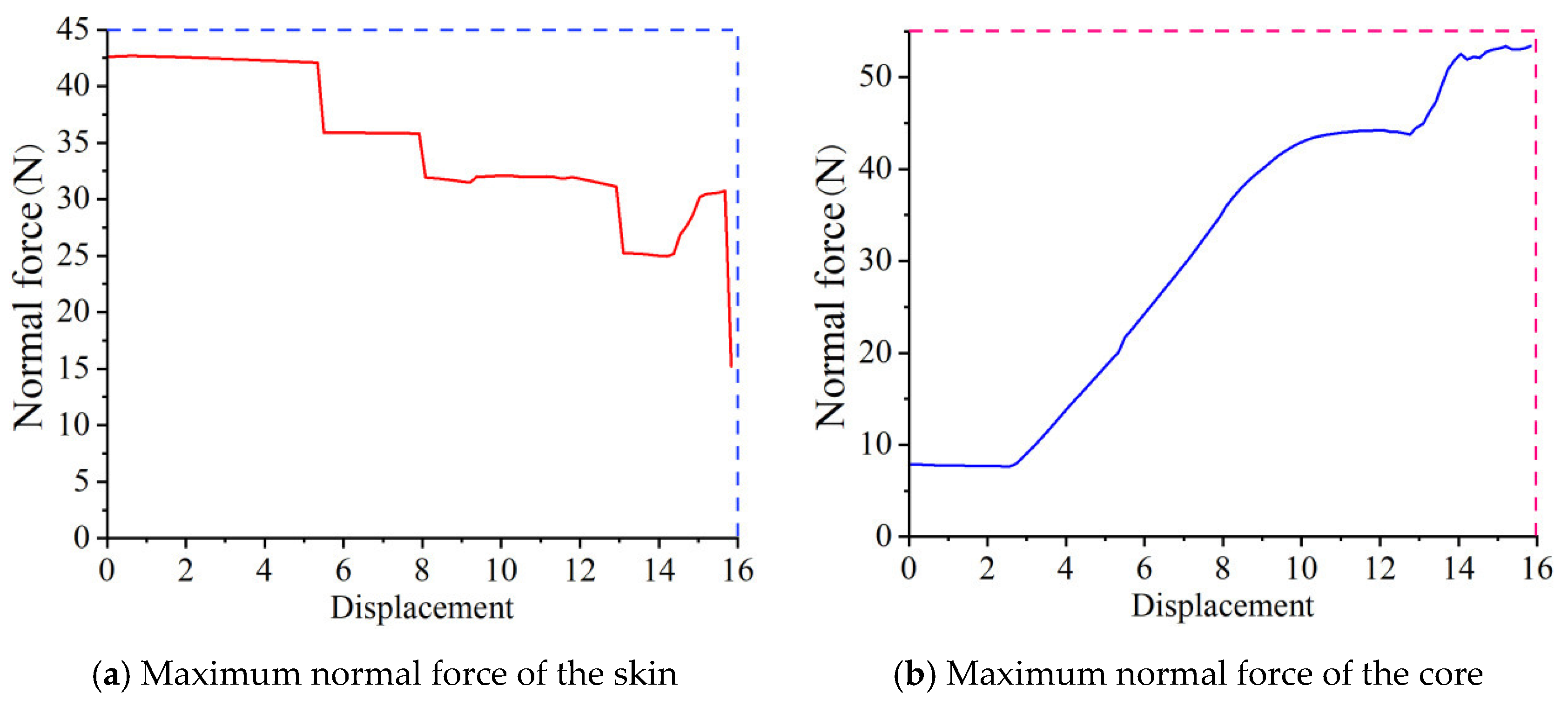

When the compression displacement of the skin is 0.64 mm, the normal force among the skins peaks at 42.69 N, as illustrated in

Figure 17a. The normal force among the cores reaches a maximum of 53.39 N at a compression displacement of 15.96 mm, which is shown in

Figure 17b.

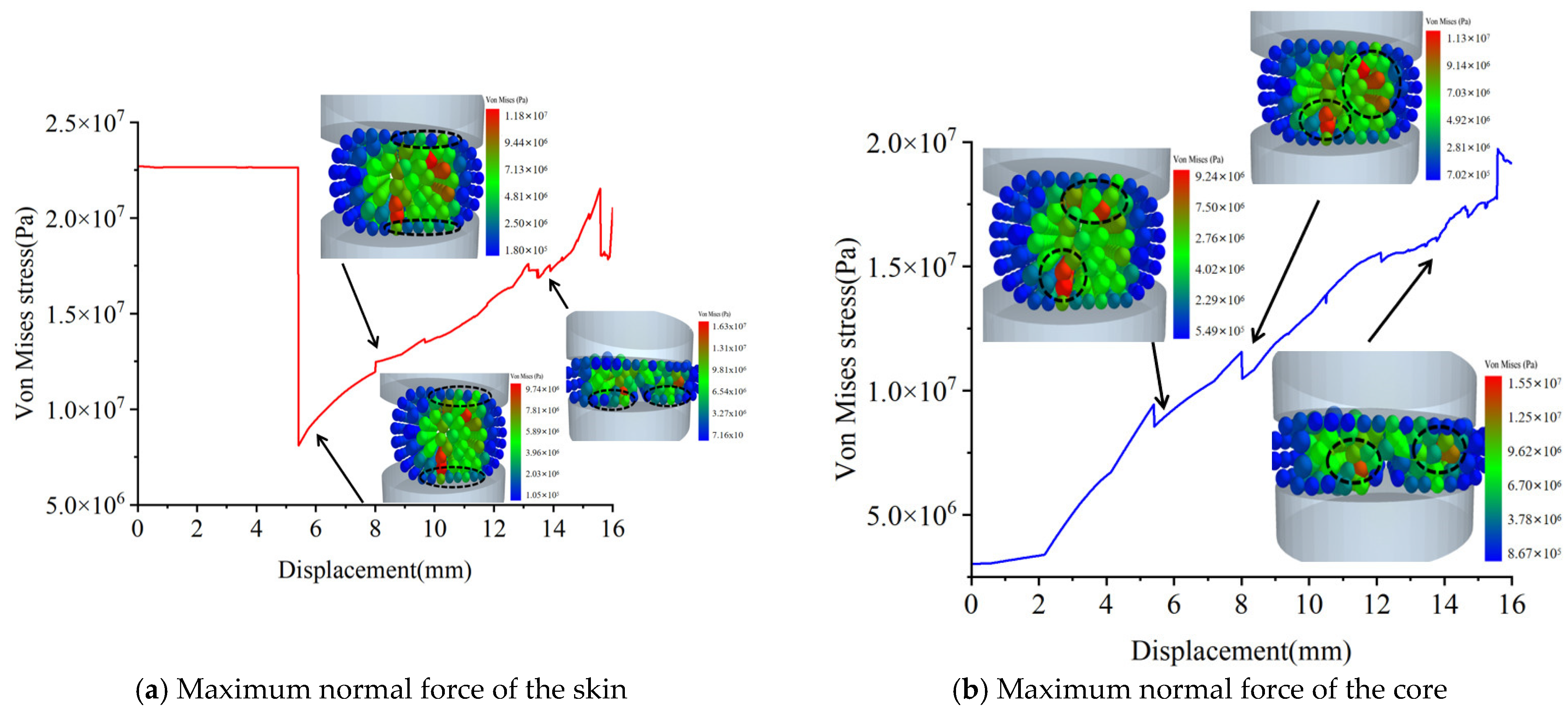

Figure 18a illustrates the equivalent stress of skin particles in the complete corn stalks. It can be observed that when a crack forms at the middle position, the maximum equivalent stress of the skin is 9.74 × 10

6 pa, with this maximum stress located in the contact area between the corn stalks and the compression plate. When cracks form on the left and right sides of the stalk, the maximum equivalent stress of the skin reaches 1.18 × 10

7 pa, and the maximum stress in the skin is situated in the region where it connects to the crack core particles. When cracks form at the edges on both sides, the maximum equivalent stress of the skin is 1.63 × 10

7 pa.

Figure 18b shows the equivalent stress of core particles in the complete corn stalks. It can be observed that when a crack forms at the middle position, the maximum equivalent stress of the core is 9.24 × 10

6 pa, with this maximum stress located in the connection region among the skin and the core (the parts of the stalk between the skin and the core). When cracks appear on the left and right sides of the stalk, the maximum equivalent stress of the core reaches 1.13 × 10

7 pa. When cracks form at the edges on both sides, the maximum equivalent stress of the core is 1.55 × 10

7 pa, with the maximum stress concentrated in the middle area around the cracks.

3.7.2. Radial Compression Simulation of Damaged Corn Stalks

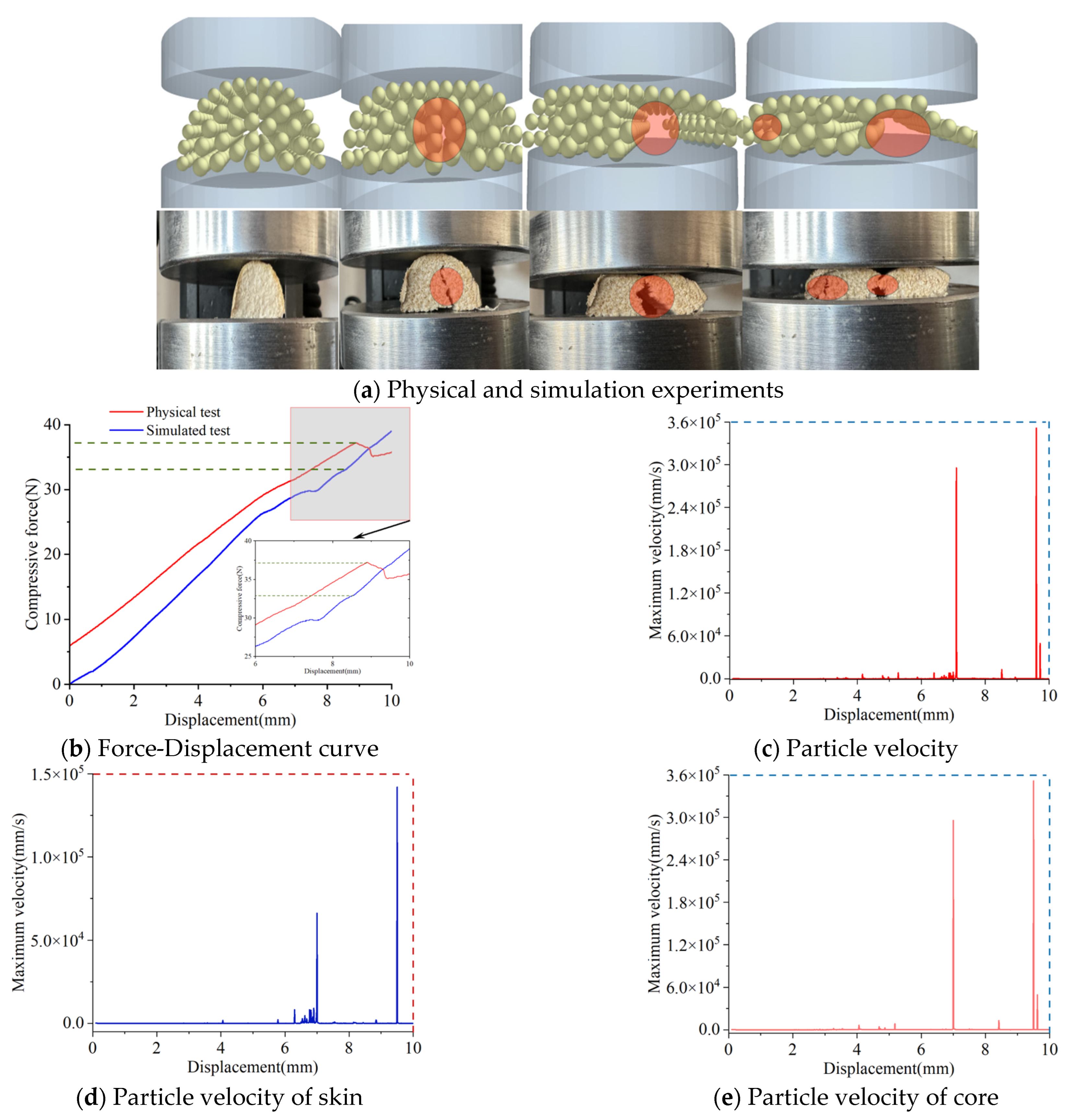

Figure 19a depicts the compression processes in both the physical experiments and simulations. The results indicate that as the compression displacement increases, longitudinal cracks first emerge, with the cracked areas located on the middle sides of the core part. Eventually, separation among the core and skin occurs. Additionally, a crack forms on the left side of the stalk, which is then compressed into a flattened shape.

Figure 19b presents the radial compression force–displacement curves from both the simulations and physical tests for the damaged corn stalks. The average maximum compressive force in the experiment is 37.18 N, while the maximum compressive force obtained from the simulation is 33.1 N, with a relative error of 12.3% compared to the experimental average. These results show that the changing trends of the two curves are essentially consistent, and the damaged corn stalk model can accurately reflect the relationship between compressive force and displacement.

The RMSE is 4.92 N with small absolute deviation, indicating good overall agreement between the simulated values and measured values in

Table 11. The coefficient of determination (

R2 = 0.84) shows that the model can explain 84% of the variation in measured force, and despite individual errors, it still maintains a relatively high coefficient of determination. The average error percentage is −10.36%. The 95% confidence interval is from −16.23% to −4.49%. Since its force bearing differs from that of the complete stalks, it exhibits higher strain variability under mechanical response.

Figure 19c shows the maximum velocity of the particles. The maximum velocity of the skin particles is as in

Figure 19d, and the maximum velocity of the core particles is as in

Figure 19e. At a compression displacement of 9.76 mm, the maximum velocity of the skin of the damaged corn stalks is 1.42 × 10

5 mm/s. The maximum velocity of the core of the damaged corn stalks is 3.51 × 10

5 mm/s.

Figure 20a shows the direction of radial compression velocity of the skin.

Figure 20b shows the direction of the radial compression velocity of the core. It can be seen that during the initial stage of compression, the velocity direction of the damaged corn stalks is directed toward the central region. As the loading displacement increases, the velocity direction at the loaded position of the stalk shifts. The maximum velocity of the skin is 1.42 × 10

5 mm/s when the speed of the core is 3.51 × 10

5 mm/s. The particle velocity of the damaged stalks increases as compression proceeds, with a relatively uniform velocity distribution. When separation of the rind and core occurs in the damaged stalks, the particle velocity rises sharply, and velocity concentration zones emerge. When the damaged stalks are compressed into a flat shape, the velocity of the stressed particles reaches its maximum.

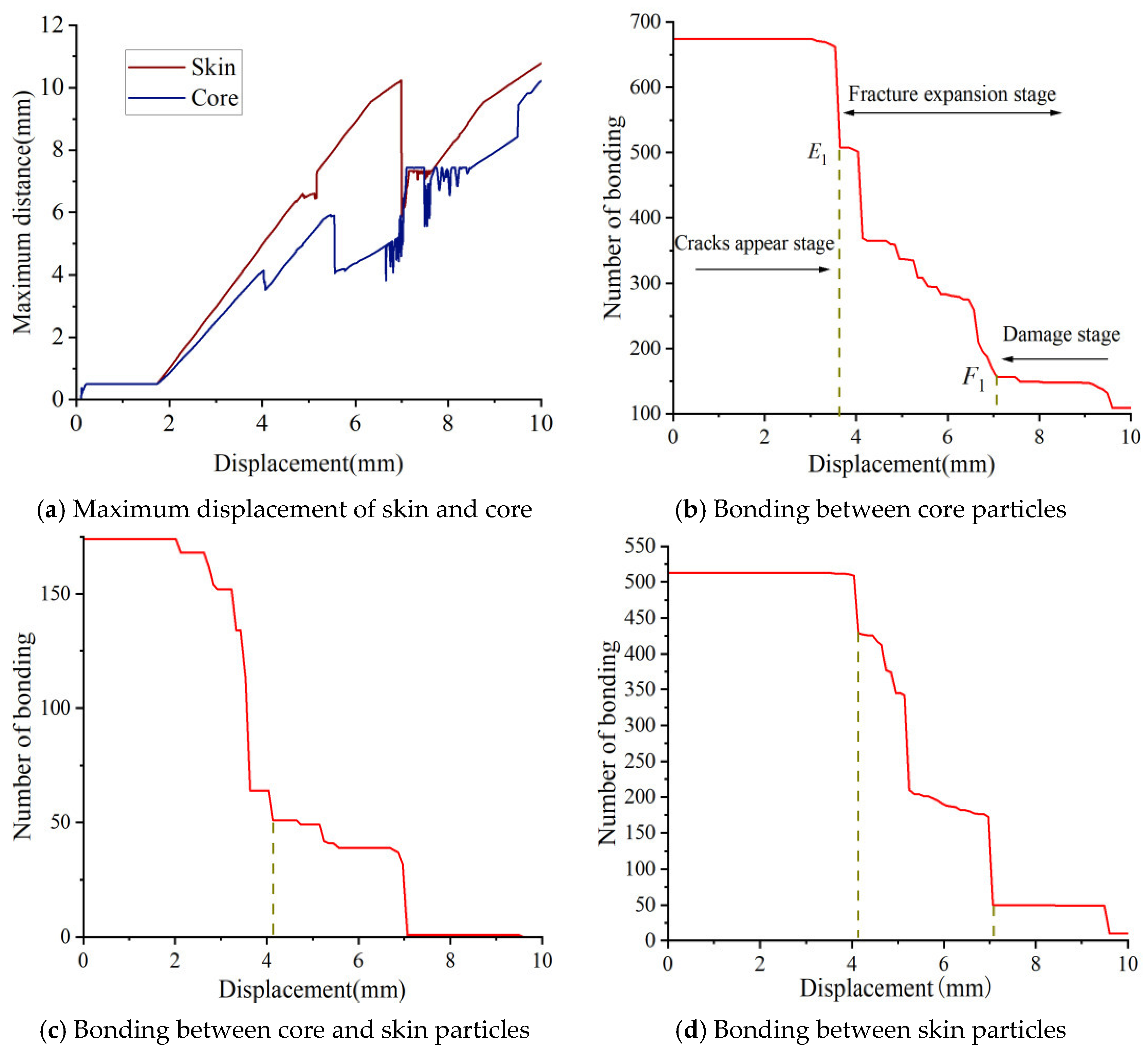

The maximum displacement curve of the skin particles during the compression of the damaged corn stalks is shown in

Figure 21a. It can be seen that at a compression displacement of 9.98 mm, the maximum displacement of the skin particles is 10.2 mm. The maximum displacement of core particles is 10.76 mm.

Figure 21b shows the variation in the number of bonds among core particles during the radial compression of damaged corn stalks. As the compression displacement increases, the number of bonds decreases slightly before point E

1. Cracks initiate at point E

1, where the number of bonds is 512. The crack propagation stage spans from point E

1 to F

1, during which the number of bonds decreases from 512 to 178. A greater reduction in the number of bonds corresponds to a higher degree of corn stalk fracturing. After point F

1, the stalk is completely fractured, with the number of bonds reduced to 162.

Figure 21c illustrates the variation in bonds among the core and skin particles in the damaged corn stalks. When the compression displacement is 4.19 mm, the number of bonds among the core particles decreases by 166, the number of bonds among the core and skin particles decreases by 110, and the number of bonds among the skin particles decreases by 86. This indicates that not only do cracks form in the core, but partial separation also occurs among the core and skin tissues, as shown in

Figure 21d.

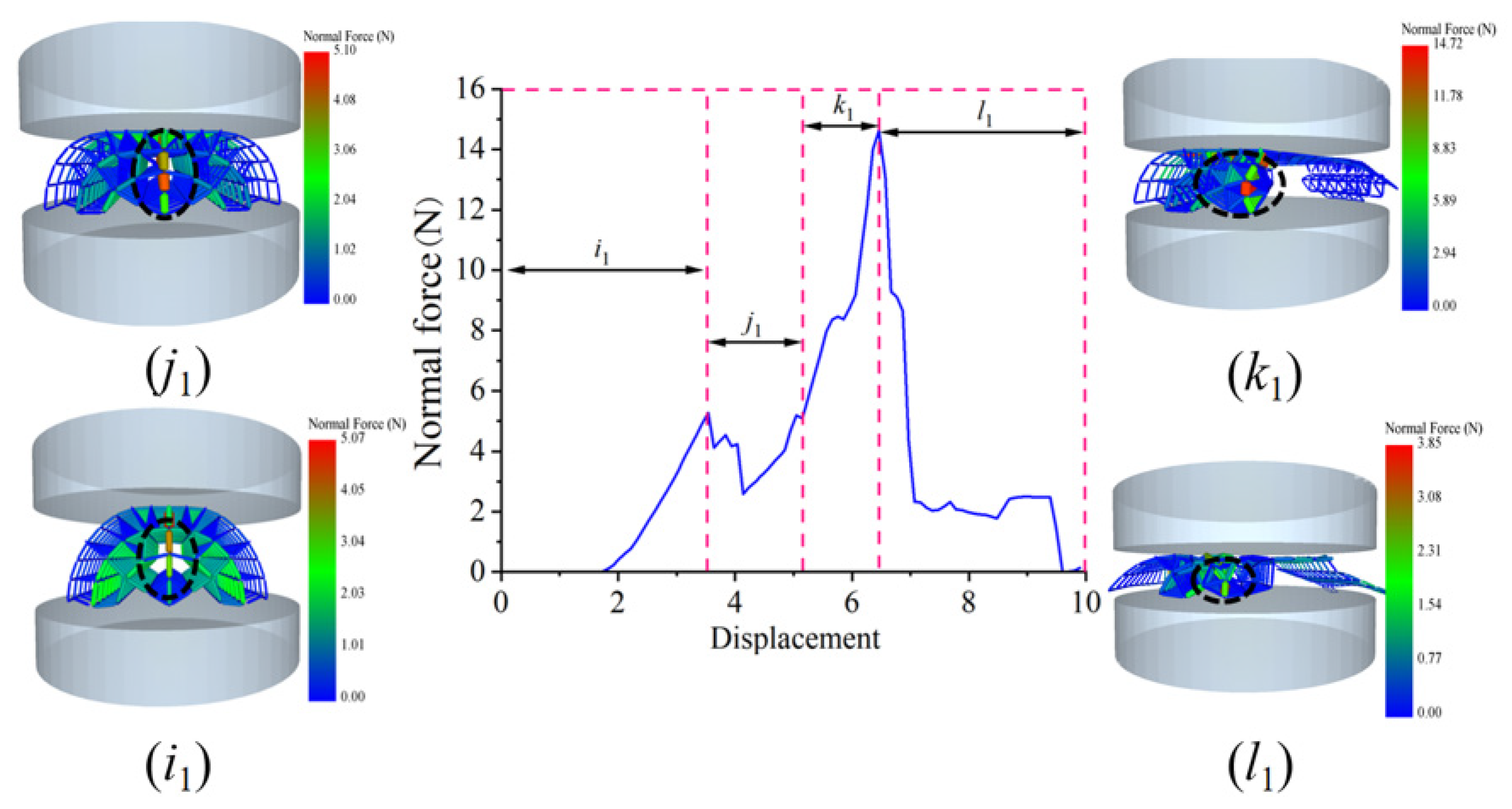

Figure 22 shows the normal force distribution of the skin and core during the radial compression of the damaged corn stalks. The stalk fracturing process is divided into four stages: i

1, j

1, k

1, and l

1. The interval from 0 to 3.64 mm is defined as the force-bearing stage (stage i

1), where the normal force ranges from 0 to 5.07 N, with the maximum normal force in this stage located in the middle part of the skin. The interval from 3.64 to 5.05 mm is classified as the lateral fracturing stage (stage j

1), with normal forces ranging from 5.07 to 5.1 N; here, the maximum normal force is situated in the middle area of the core. The interval from 5.05 to 7.34 mm is referred to as the core detachment stage (stage k

1), where normal forces range from 5.1 to 14.72 N, and the maximum normal force is located in the area of the middle-bent core. The interval from 7.34 to 10 mm is identified as the complete fracturing stage (stage l

1), with normal forces ranging from 14.72 to 3.85 N, and the maximum normal force in this stage is found in the remaining area of the core. When the compression displacement reaches 6.46 mm, the maximum normal force in this stage

k1 is 14.72 N.

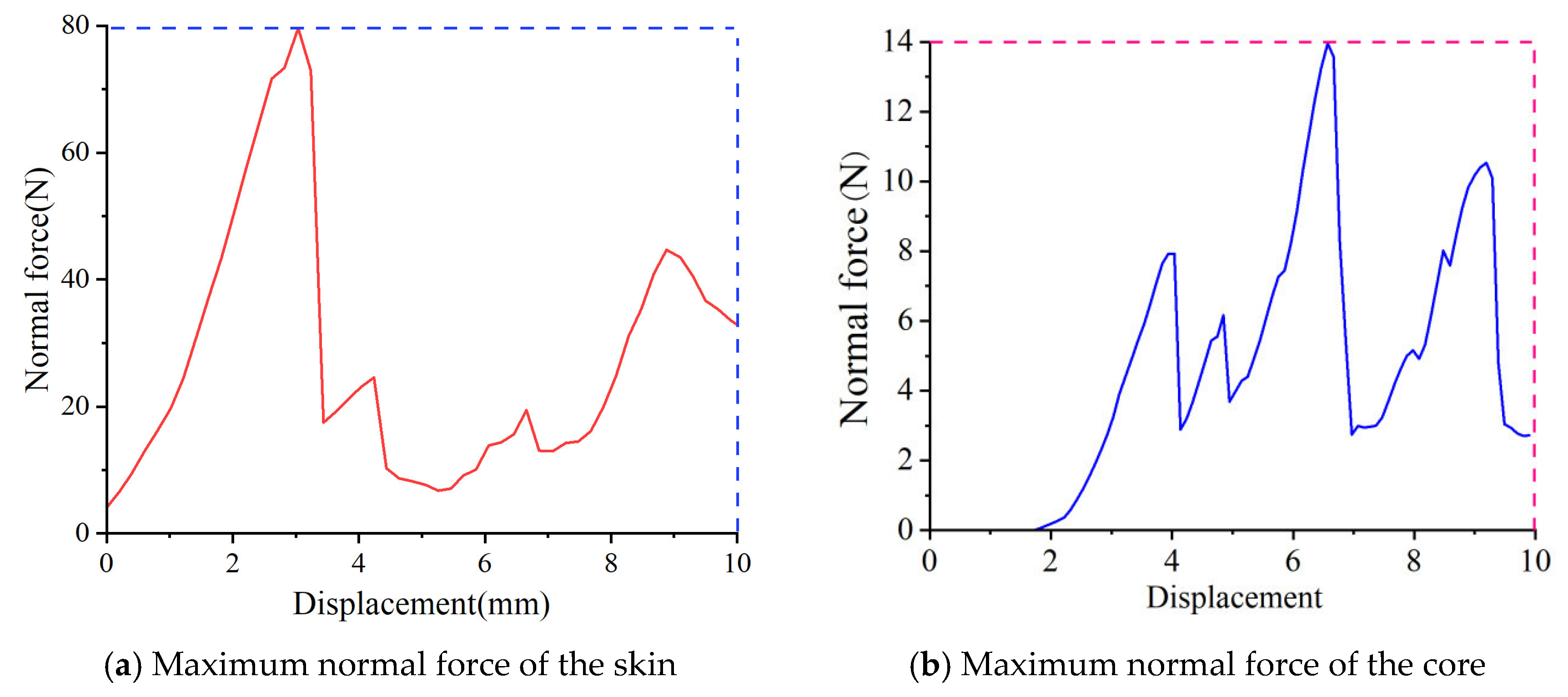

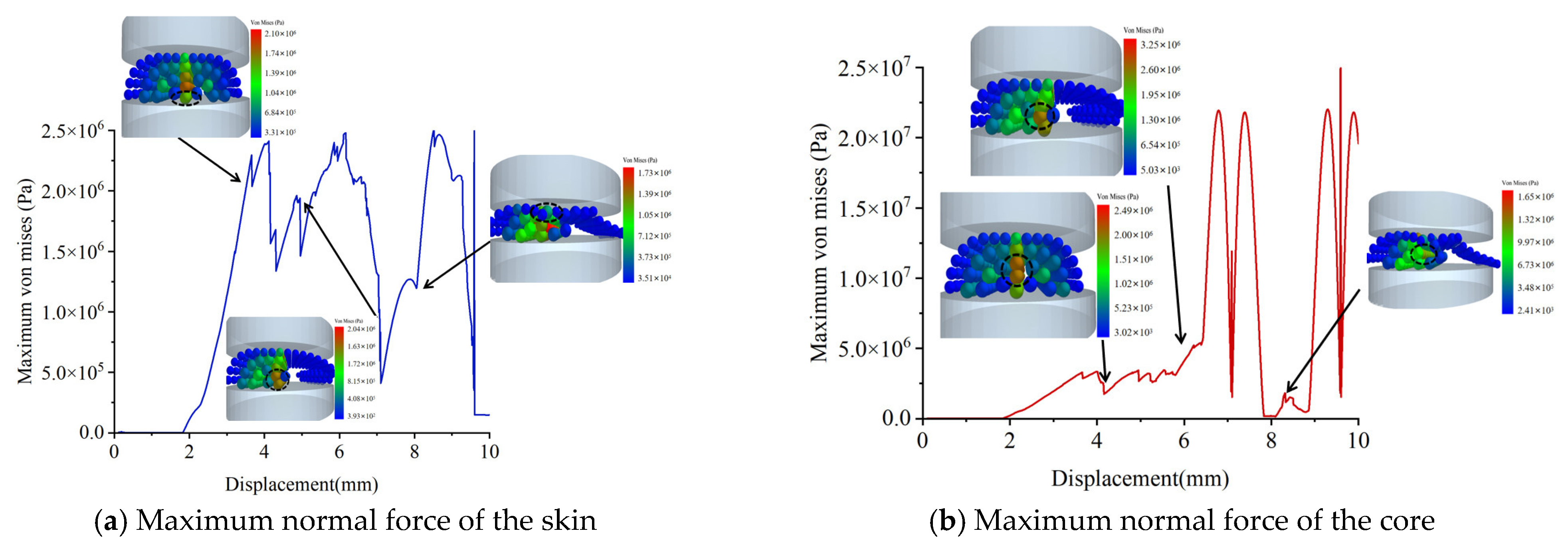

Figure 23a shows the maximum normal force of the skin in the damaged corn stalks. It can be seen that when the compression displacement of the skin is 2.89 mm., the maximum normal force between the skins reaches a value of 79.65 N. When the compression displacement is 6.67 mm, the maximum normal force between the cores reaches a value of 13.57 N. This is shown in

Figure 23b.

Figure 24a shows the maximum equivalent stress of the core particles in the damaged corn stalks. When a crack forms at the center of the stalk, the maximum equivalent stress of the core is 2.1 × 10

6 pa, with the maximum stress located at the middle position. When a crack appears on the right side of the stalk, the maximum equivalent stress is 2.04 × 10

6 pa, and the maximum stress is still located at the middle position of the stalk. When a crack forms at the left edge, the maximum equivalent stress of the core is 1.73 × 10

6 pa, with the maximum stress located at the middle position.

Figure 24b shows the equivalent stress of the core particles of the damaged corn stalks. It can be seen that when a crack is generated at the middle position, the maximum equivalent stress of the core is 2.49 × 10

6 pa. The maximum stress is located at the lower parts of the stalk in between the skin and the core. When cracks appear on the right side of the stalk, the maximum equivalent stress of the core is 3.25 × 10

6 pa. The maximum stress is in the middle area around the cracks. When cracks are generated at the edges on the left side, the maximum equivalent stress of the core is 1.65 × 10

6 pa. The maximum stress is in the middle area around the cracks. The region of maximum equivalent stress in the skin is located around the crack areas, which is attributed to particle compression caused by stress concentration.

There are significant differences in the stress values and stress concentration patterns between the complete and damaged maize stalks. The stress in the epidermis and core of complete stalks is 3 to 5 times that of the damaged ones. This is because complete stalks have a compact internal structure, enabling them to effectively transmit loads. In contrast, damaged stalks have an incomplete structure and fail to form effective support under high stress conditions. This is due to the fact that the incompleteness of damaged stalks leads to the formation of cracks, which disrupts the connection between the epidermis and the core. Consequently, the stress concentration at the core particles is dispersed, with their stress values dropping abruptly, while the epidermal particles are confined to the area around the cracks and passively bear the load.