Design and Experimentation of a Low-Damage Combined Full-Feeding Peanut Picking Device

Abstract

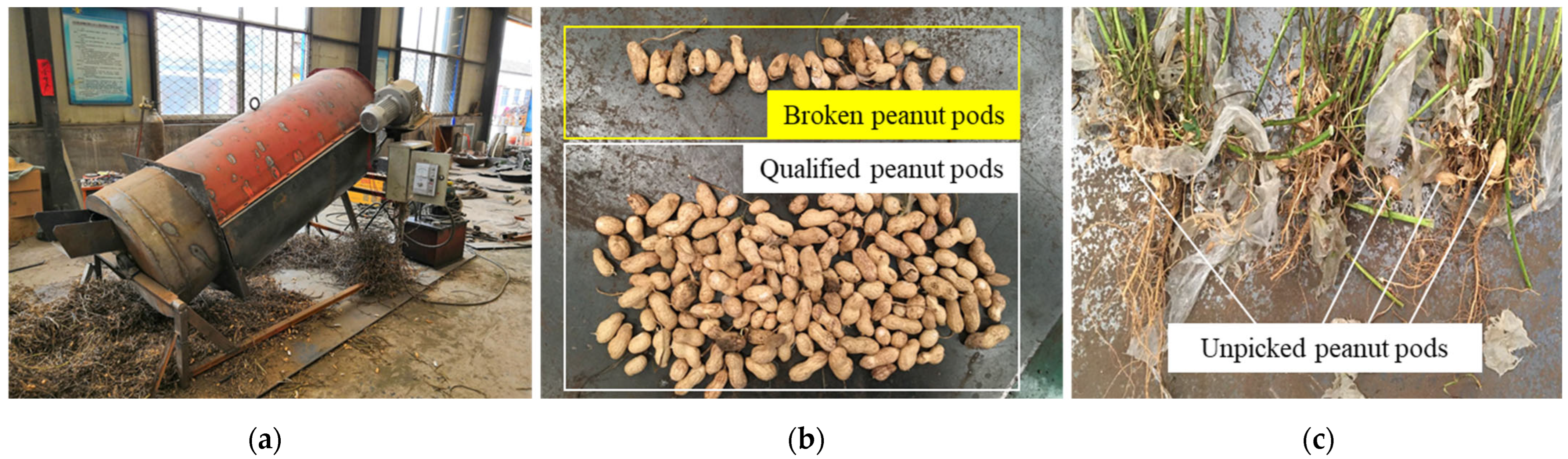

1. Introduction

2. Materials and Methods

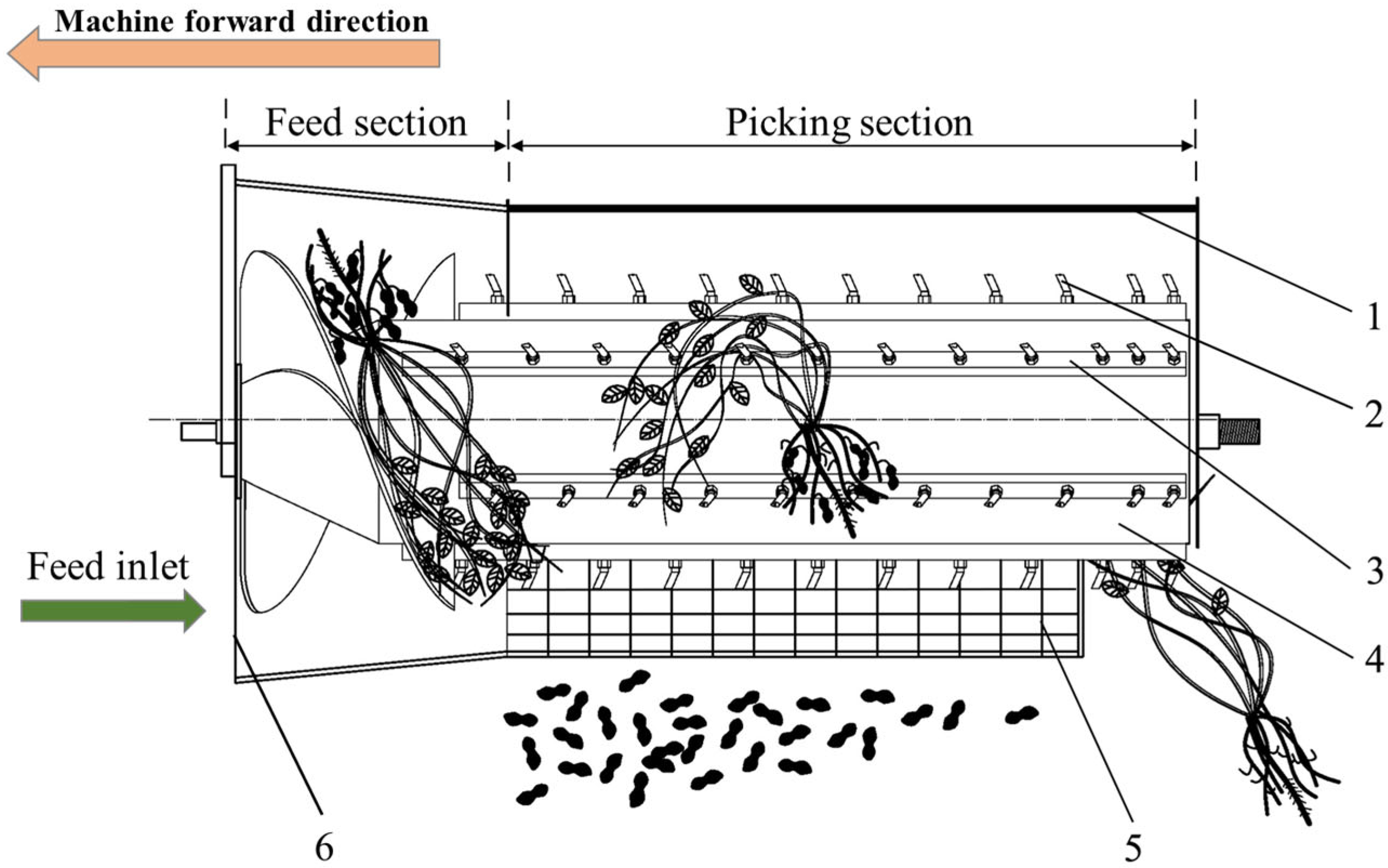

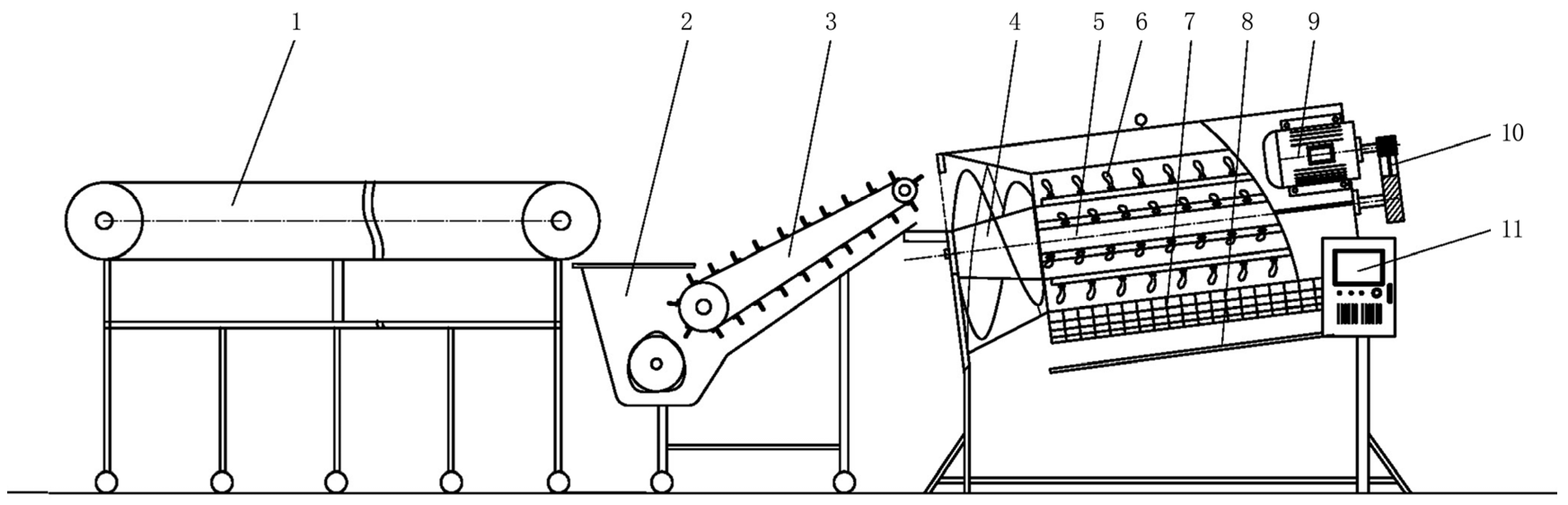

2.1. Structure and Working Principle

2.2. Design of Key Parameters

2.2.1. Structural Design of Longitudinal Flow Picking Drum

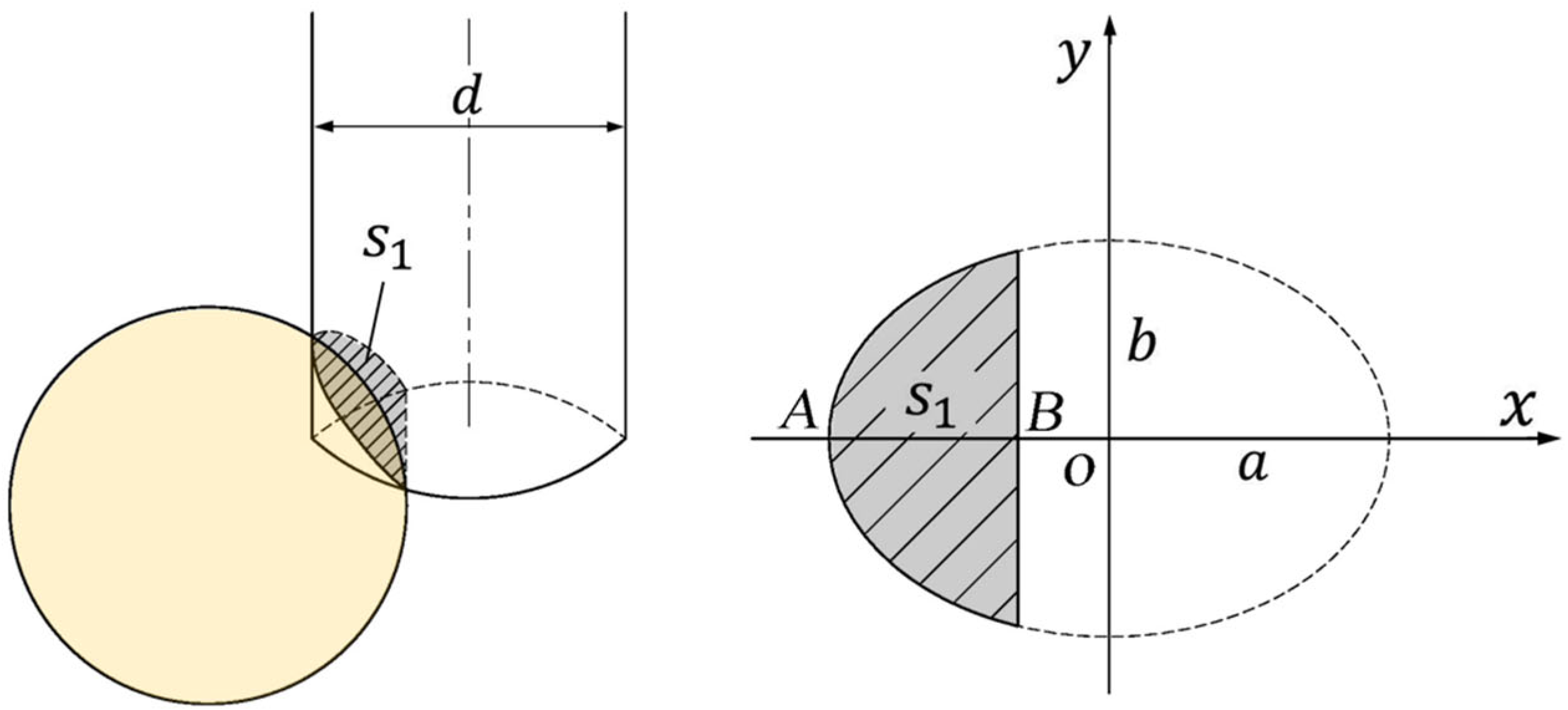

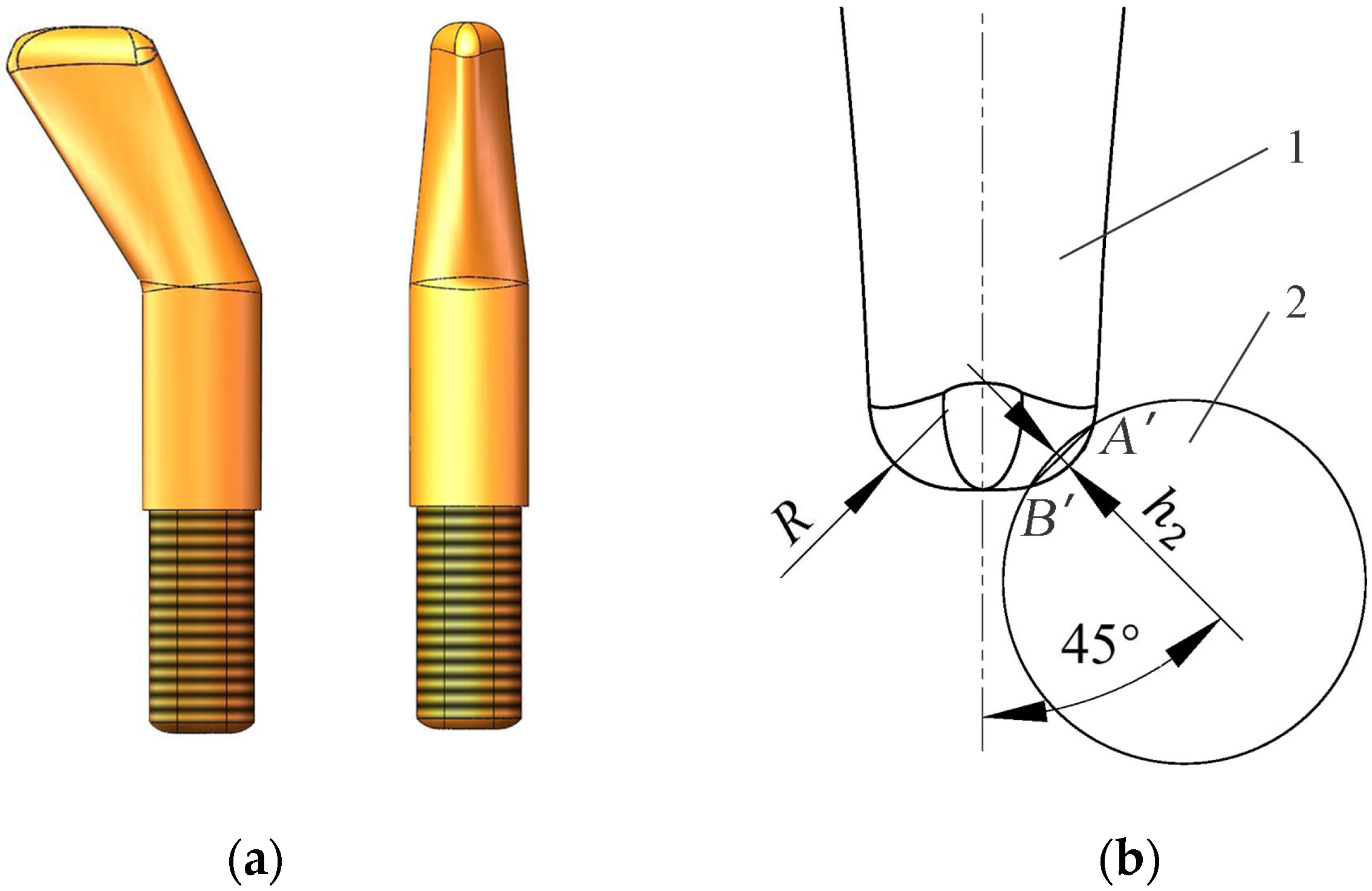

2.2.2. Design of Structural Parameters of Picking Components

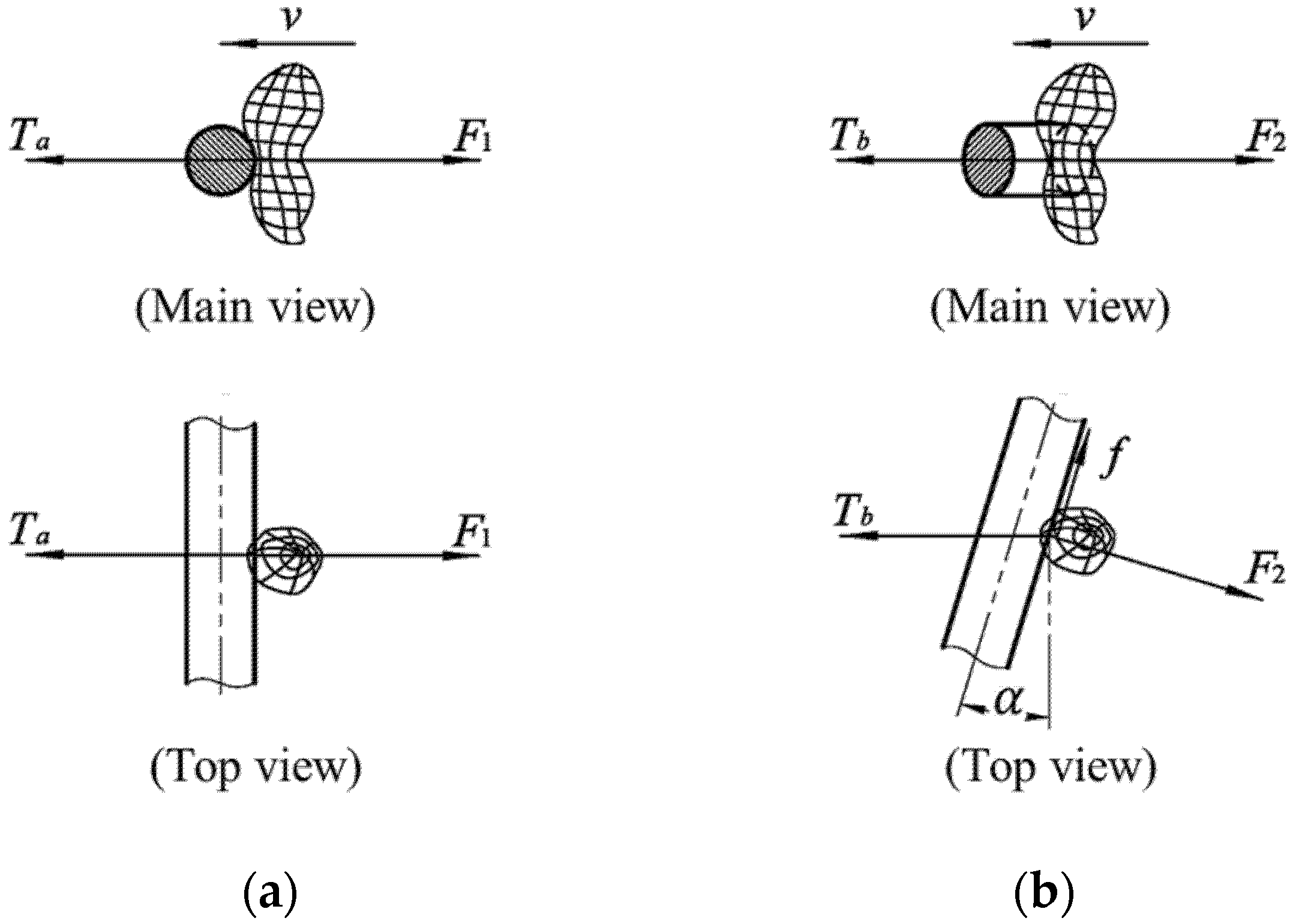

- Analysis of the collision process of conventional bend cylindrical bar teeth

- Analysis of the collision process of flat pin teeth

- Determination of structural parameters of flat pin teeth

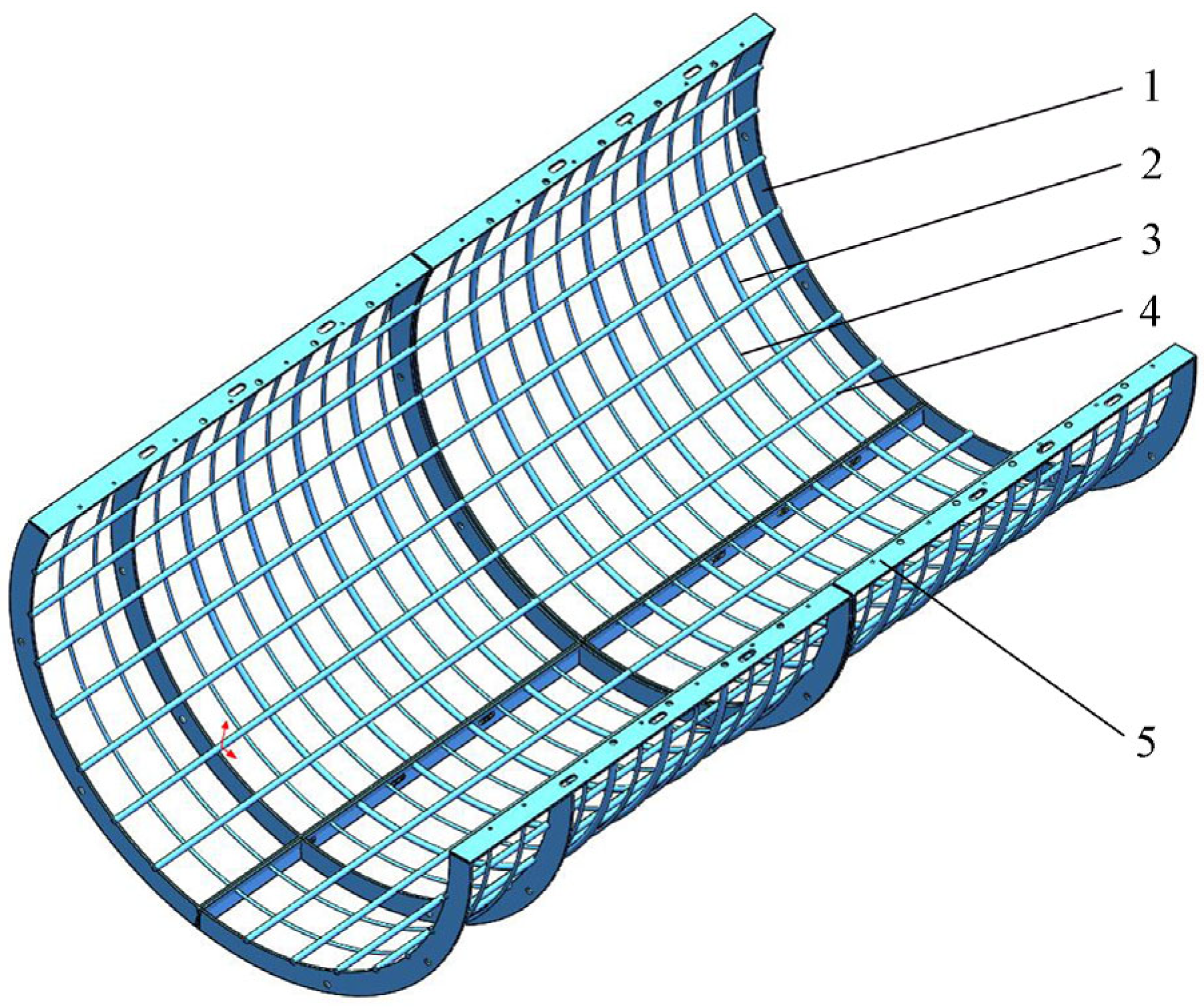

2.2.3. Structural Parameter Design of Segmented Combination Cylindrical Concave Screen

2.3. EDEM-Based Simulation Optimization of Key Parameters

2.3.1. Model Parameter Setting

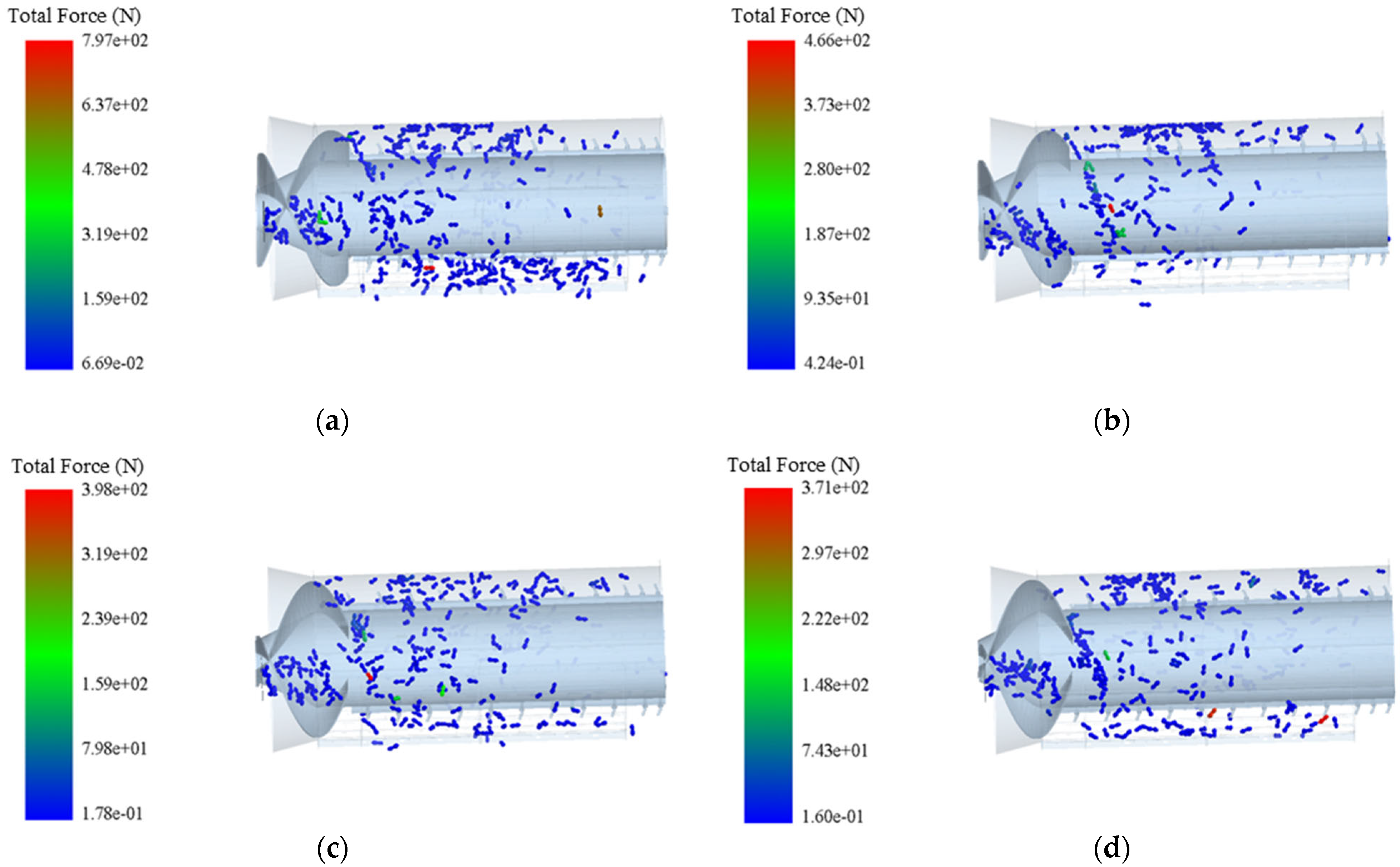

2.3.2. Simulation Optimization of Low-Damage Flat Pin Teeth

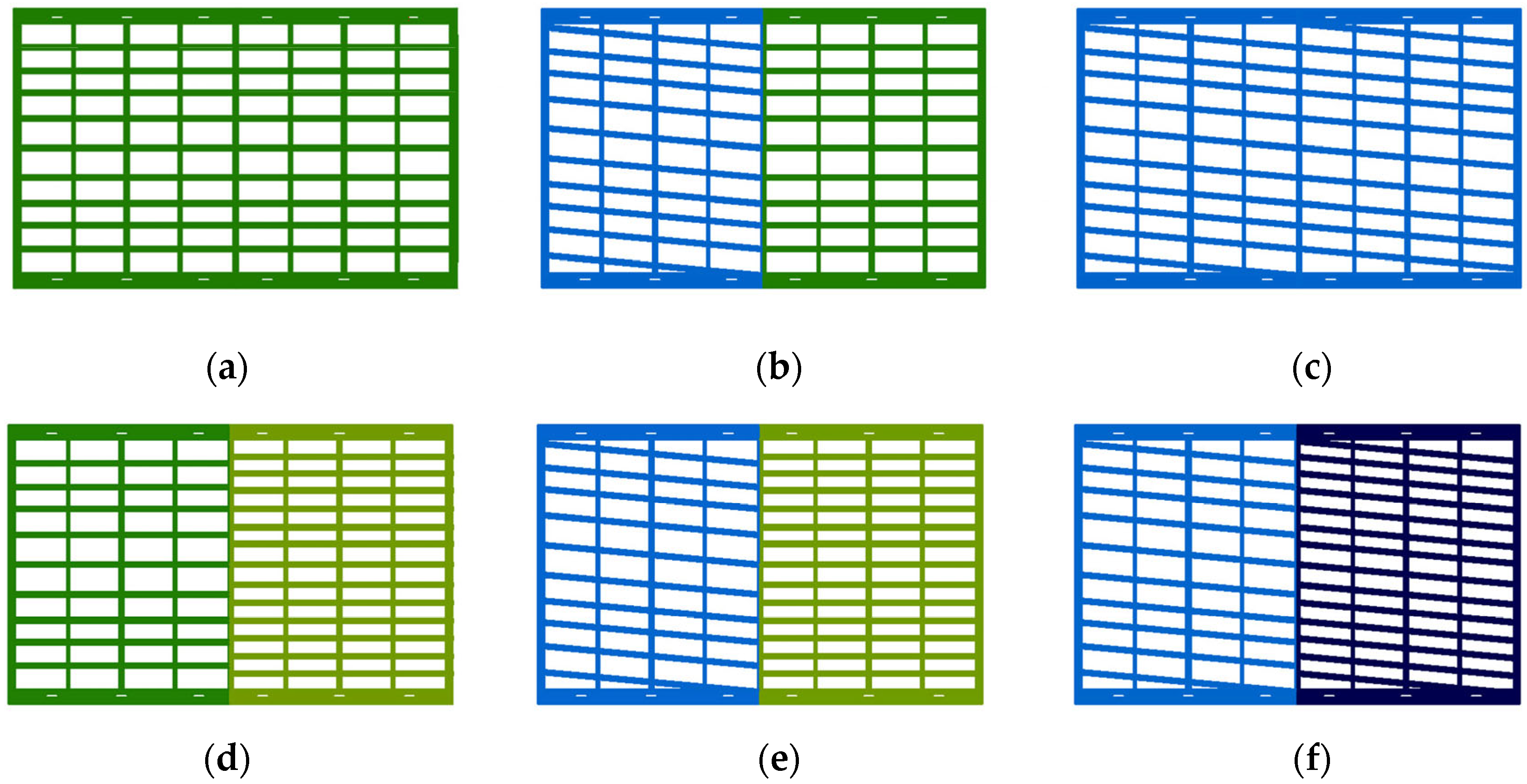

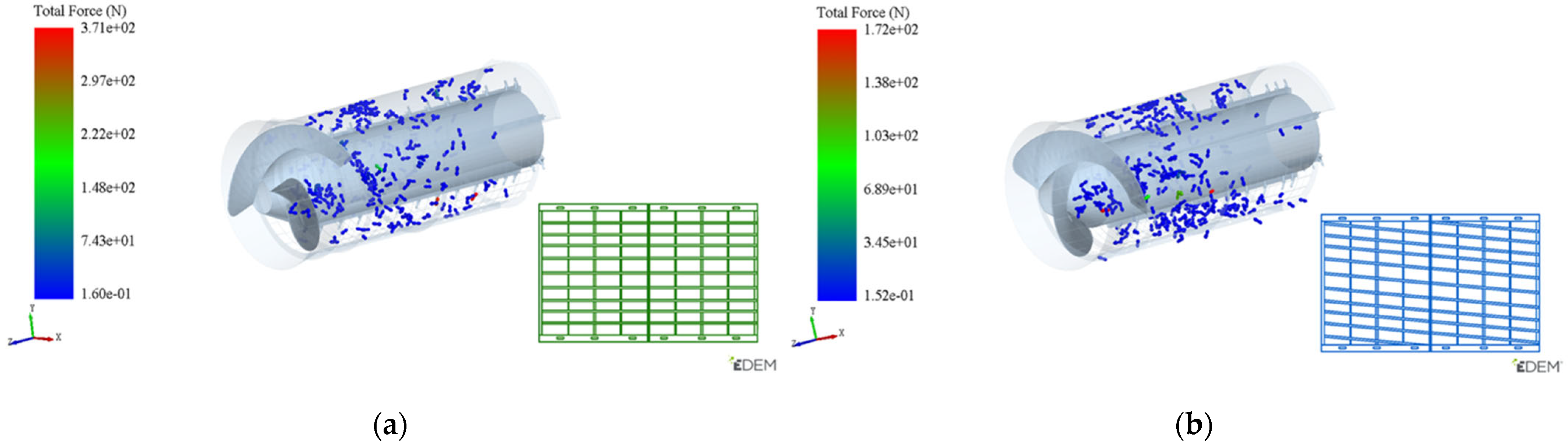

2.3.3. Simulation Optimization of Concave Screen

2.4. Bench Test

2.4.1. Bench Test Materials

2.4.2. Bench Test Methods

2.5. Field Experiment

2.5.1. Experimental Materials

2.5.2. Experimental Method

3. Results and Analysis

3.1. Simulation Results and Analysis

3.1.1. Simulation Results and Analysis of Low-Damage Flat Pin Teeth

3.1.2. Simulation Results and Analysis of the Concave Screen

3.2. Bench Test Results and Analysis

3.2.1. Effects of Different Picking Components and Installation Orientations on Peanut Picking Performance

3.2.2. Two-Section Combined Round Steel Concave Screen Picking Test

3.3. Field Experiment Results and Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, S.; Hu, Z.; Yao, L.; Peng, B.; Wang, B.; Wang, Y. Simulation and parameter optimisation of pickup device for full-feed peanut combine harvester. Comput. Electron. Agric. 2022, 192, 106602. [Google Scholar] [CrossRef]

- Pan, L.; Yang, H.; Yu, Z.; Shen, H.; Gu, M.; Luo, W.; Wu, F.; Gu, F.; Ren, G.; Hu, Z. Development and Test of a Self-Propelled Peanut Combine Harvester for Hilly and Mountainous Regions. Agriculture 2025, 15, 457. [Google Scholar] [CrossRef]

- Shang, S.Q.; Li, G.Y.; Yang, R.B.; Sun, T.Z.; Wang, Y.Y.; Lian, Z.G. Development of 4HQL-2 type whole-feed peanut combine. Trans. Chin. Soc. Agric. Eng. 2009, 25, 125–130. [Google Scholar]

- Wang, Q.; Yu, Z.; Zhang, Y.; Li, J.; Peng, B.; Wang, B.; Hu, Z. Experimental Study of a 4HLB-4 Half-Feed Four-Row Peanut Combine Harvester. Agronomy 2022, 12, 3094. [Google Scholar] [CrossRef]

- Wang, B.; Gu, F.; Cao, M.; Xie, H.; Wu, F.; Peng, B.; Hu, Z. Analysis and Evaluation of the Influence of Different Drum Forms of Peanut Harvester on Pod-Pickup Quality. Agriculture 2022, 12, 769. [Google Scholar] [CrossRef]

- Wang, B.K.; Zhang, P.; Cao, M.Z.; Gu, F.W.; Wu, F.; Hu, Z.C. Design and Experiment of Pneumatic Conveying Device for Seedlings of Peanut Harvester. Trans. Chin. Soc. Agric. Mach. 2022, 53, 126–137. [Google Scholar]

- Wang, S.Y.; Hu, Z.C.; Wu, F.; Yu, Z.Y.; Cao, M.Z.; Gao, X.M. Modeling and experiment of feeding rate for full-feed pea-nut pickup harvester. Trans. Chin. Soc. Agric. Eng. 2019, 35, 29–36. [Google Scholar]

- Chen, M.; Zhai, X.; Zhang, H.; Yang, R.; Wang, D.; Shang, S. Study on control strategy of the vine clamping conveying system in the peanut combine harvester. Comput. Electron. Agric. 2020, 178, 105744. [Google Scholar] [CrossRef]

- Wang, D.W.; Shang, S.Q.; Han, K. Design and test of 4HJL-2 harvester for peanut picking-up and fruit-picking. Trans. Chin. Soc. Agric. Eng. 2013, 29, 27–36. [Google Scholar]

- Yu, Z.Y.; Hu, Z.C.; Cao, M.Z.; Wang, S.Y.; Zhang, P.; Peng, B.L. Design of cleaning device of tangential flow and whole-feed peanut combine harvester. Trans. Chin. Soc. Agric. Eng. 2019, 35, 29–37. [Google Scholar]

- Guo, W.H.; Guo, H.; Yu, X.D.; Wang, M.C.; Xing, S.K.; Peng, B. Design and experimental of peanut digger based on two-stage harvesting process. J. Chin. Agric. Mech. 2020, 41, 34–39. [Google Scholar]

- Xu, T.; Shen, Y.Z.; Gao, L.X.; Zhang, X.D.; Lu, Z.Y.; Liu, Z.X. Spring-finger Peanut Pickup Mechanism Based on Two-stage Harvest. Trans. Chin. Soc. Agric. Mach. 2016, 47, 90–97, 111. [Google Scholar]

- Zhang, J.; Zhao, Z.; Gao, Z.; Tian, Y.; Wang, D.; Xu, N. Peanut Pickup Combine Harvester Seedling Vines Crushing Mechanism Performance Enhancement and Pilot Studies. Agriculture 2024, 14, 1635. [Google Scholar] [CrossRef]

- Xu, T.; Gao, L.; Liu, Z. Spring-Finger Motion Law Analysis and Cam Slide Optimal Design of Spring-Finger Cylinder Peanut Pickup Mechanism. Agriculture 2024, 14, 1459. [Google Scholar] [CrossRef]

- Ling, J.; Shen, H.; Gu, M.; Hu, Z.; Zhao, S.; Wu, F.; Xu, H.; Gu, F.; Zhang, P. The Design and Optimization of a Peanut-Picking System for a Fresh-Peanut-Picking Crawler Combine Harvester. Agriculture 2024, 14, 1332. [Google Scholar] [CrossRef]

- Wang, S.Y.; Hu, Z.C.; Xu, H.B.; Cao, M.Z.; Yu, Z.Y.; Peng, B.L. Design and test of pickup and conveyor device for full-feeding peanut pickup harvester. Trans. Chin. Soc. Agric. Eng. 2019, 35, 20–28. [Google Scholar]

- Gao, L.X.; Chen, Z.Y.; Charles, C.; Butts, C.L. Development course of peanut harvest mechanization technology of the United States and enlightenment to China. Trans. Chin. Soc. Agric. Eng. 2017, 33, 1–9. [Google Scholar]

- Shi, L.; Wang, B.; Hu, Z.; Yang, H. Mechanism and Experiment of Full-Feeding Tangential-Flow Picking for Peanut Harvesting. Agriculture 2022, 12, 1448. [Google Scholar] [CrossRef]

- Liu, L.; Wang, Q.; Liu, H.Z. Application and Its Present on Method for Drying Storage of Peanut. Agric. Prod. Process. 2011, 8, 49–52. [Google Scholar]

- Wu, L.X. Researches on Risk Prediction Model of Aflatoxin Contamination in China. Ph.D. Thesis, Chinese Academy of Agricultural Sciences, Wuhan, China, 2019. [Google Scholar]

- Chen, Z.Y.; Guan, M.; Gao, L.X.; Chen, L.J.; Ma, F.; Dong, H.S. Design and Test on Axial Flow Peanut Picking Device with Screw Bending-tooth. Trans. Chin. Soc. Agric. Mach. 2016, 47, 106–113. [Google Scholar]

- Wang, M.; Yang, R.B.; Shang, S.Q.; Wang, F.J.; Wang, Z.Z. Design Analysis and Test of Key Equipment for Fully Fed Peanut Picking Machine. J. Agric. Mech. Res. 2021, 43, 141–145. [Google Scholar]

- Li, S.X.; Shang, S.Q.; Yu, Y.; Wang, D.W.; Yang, R.B.; Hou, Q.S. Researching Design and Experiments of Spring Tined Type Picking Peanut Mechanism. J. Agric. Mech. Res. 2015, 37, 136–139. [Google Scholar]

- Wang, B.K.; Hu, Z.C.; Cao, M.Z.; Zhang, P.; Yu, Z.Y.; Zhang, C. Design and Test of Axial-flow Peanut Picking and Harvesting Machine. Trans. Chin. Soc. Agric. Mach. 2021, 52, 109–118. [Google Scholar]

- Xu, N.; Shang, S.Q.; Wang, D.W.; He, X.N.; Gao, Z.; Liu, J.Q.; Zhang, Y.D.; Guo, P. Design and Research of Spike Tooth Type Peanut Picking Device with Longitudinal Axial Flow. J. Agric. Mech. Res. 2020, 42, 197–201. [Google Scholar]

- Liu, X.; Lü, Q.; Yang, L.; Li, G. Design and Test of Peanut Root-Disk Full-Feeding Longitudinal Axial Flow Pod-Picking Device. Agronomy 2023, 13, 1103. [Google Scholar] [CrossRef]

- Chen, Y.Q.; Hu, Z.C.; Wang, H.; Peng, B.L. Restrictive Factors and Development Countermeasure for Peanut Mechanized Harvesting in China. Chin. Agric. Mech. 2012, 4, 14–17, 11. [Google Scholar]

- Shen, H.Y.; Luo, W.W.; Wu, F.; Gu, F.W.; Yang, H.G.; Hu, Z.C. Research Progress on Mechanized Harvesting Equipment and Technology for Peanuts. Trans. Chin. Soc. Agric. Mach. 2024, 55, 21–38. [Google Scholar]

- Guan, M. Research on Full-Feeding Peanut Picking Test Device and Key Components of Peanut Picker. Ph.D. Thesis, Shenyang Agricultural University, Shenyang, China, 2016. [Google Scholar]

- Guan, M.; Shen, Y.Z.; Gao, L.X.; Zhao, B.Q.; Liu, W.W. Mechanical properties of peanut peg after digging and drying. Trans. Chin. Soc. Agric. Eng. 2014, 30, 87–93. [Google Scholar]

- Zhang, S.Z.; Li, G.W.; Wang, F.F.; Hu, X.H.; Miao, H.R.; Zhong, W.; Chen, J. Evaluation of Peanut Peg Tensile Force and Screening for Breeding Lines with Low Percentage of Shed Pods. J. Peanut Sci. 2025, 54, 184–189. [Google Scholar]

| Material | Poisson’s Ratio | Shear Modulus/MPa | Density/(kg·m−3) |

|---|---|---|---|

| Pod | 0.32 | 7 | 257 |

| Steel | 0.27 | 8240 | 7830 |

| Contact Form | Collision Recovery Factor | Static Friction Factor | Kinetic Friction Factor |

|---|---|---|---|

| Pod-Pod | 0.50 | 0.30 | 0.20 |

| Pod-Steel | 0.37 | 0.40 | 0.10 |

| Parameters | Value |

|---|---|

| Water content ± SD/% | 13.94 ± 1.20 |

| Length ± SD/mm | 33.42 ± 3.12 |

| Width ± SD/mm | 16.73 ± 2.31 |

| Thicknesses ± SD/mm | 15.61 ± 2.41 |

| Parameters | Value |

|---|---|

| Drying time/d | 3 |

| Combined plant water content ± SD/% | 15.09 ± 1.54 |

| Water content of peanut pods ± SD/% | 14.10 ± 1.23 |

| Ridge spacing/mm | 760–800 |

| Plant spacing/mm | 170–230 |

| Pod length ± SD/mm | 34.54 ± 2.34 |

| Pod width ± SD/mm | 18.94 ± 1.73 |

| Pod thickness ± SD/mm | 20.22 ± 1.80 |

| Drum Speed/ (r·min−1) | Flat Pin Teeth (5 mm) | Flat Pin Teeth (6 mm) | Flat Pin Teeth (7 mm) | Conventional Cylindrical Bar Teeth | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| T1/ N | S1/ mm2 | P1/ MPa | T2/ N | S2/ mm2 | P2/ MPa | T3/ N | S3/ mm2 | P3/ MPa | T4/ N | S4/ mm2 | P4/ MPa | |

| 400 | 72.94 | 30.25 | 2.41 | 63.07 | 37.03 | 1.70 | 52.83 | 43.81 | 1.21 | 126.74 | 15.70 | 8.07 |

| 500 | 129.33 | 30.25 | 4.28 | 94.23 | 37.03 | 2.55 | 86.39 | 43.81 | 1.97 | 146.83 | 15.70 | 9.35 |

| 600 | 185.34 | 30.25 | 6.13 | 146.07 | 37.03 | 3.95 | 131.92 | 43.81 | 3.01 | 210.25 | 15.70 | 13.39 |

| Drum Speed/ (r·min−1) | Collision Force of Different Types of Picking Concave Screens/N | |

|---|---|---|

| Straight Round Steel Type | Right Round Steel Type | |

| 400 | 54.45 | 45.67 |

| 500 | 58.52 | 48.90 |

| 600 | 64.08 | 53.71 |

| Types and Installation Orientations of Picking Components | Pod Breakage Rate/% | Unpicked Pod Rate/% |

|---|---|---|

| Axially Forward Curved Flat Pin Teeth | 1.84 | 1.08 |

| Axially Backward Curved Flat Pin Teeth | 1.67 | 1.21 |

| Conventional Bent Cylindrical Bar Teeth with Axial Forward Bend | 2.79 | 1.14 |

| Concave Screen Types | Pod Breakage Rate/% | Unpicked Pod Rate/% |

|---|---|---|

| Conventional Straight Round Steel, Uniform Density Type | 3.14 | 1.06 |

| Right Round Steel + Straight Round Steel, Uniform Density Type | 1.79 | 0.98 |

| Right Round Steel, Uniform Density Type | 1.84 | 1.08 |

| Straight Round Steel, Front Sparse and Rear Dense Type | 2.83 | 0.73 |

| Right Round Steel + Straight Round Steel, Front Sparse and Rear Dense Type | 1.90 | 0.81 |

| Right Round Steel, Front Sparse and Rear Dense Type | 2.05 | 1.04 |

| Indicators | Conventional Peanut Picking Device | Low-Damage Combined Peanut Picking Device |

|---|---|---|

| Pod Breakage Rate/% | 1.92 | 1.17 |

| Unpicked Pod Rate/% | 1.14 | 0.62 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, J.; Shang, S.; Zhang, N.; Wu, Y.; Wang, X.; Xu, N. Design and Experimentation of a Low-Damage Combined Full-Feeding Peanut Picking Device. Agriculture 2025, 15, 1394. https://doi.org/10.3390/agriculture15131394

Zheng J, Shang S, Zhang N, Wu Y, Wang X, Xu N. Design and Experimentation of a Low-Damage Combined Full-Feeding Peanut Picking Device. Agriculture. 2025; 15(13):1394. https://doi.org/10.3390/agriculture15131394

Chicago/Turabian StyleZheng, Jinming, Shuqi Shang, Ning Zhang, Yao Wu, Xiaochan Wang, and Nan Xu. 2025. "Design and Experimentation of a Low-Damage Combined Full-Feeding Peanut Picking Device" Agriculture 15, no. 13: 1394. https://doi.org/10.3390/agriculture15131394

APA StyleZheng, J., Shang, S., Zhang, N., Wu, Y., Wang, X., & Xu, N. (2025). Design and Experimentation of a Low-Damage Combined Full-Feeding Peanut Picking Device. Agriculture, 15(13), 1394. https://doi.org/10.3390/agriculture15131394