Design of the Vibrating Sieving Mechanism for a Quinoa Combine Harvester and Coupled Analysis of DEM-MBD

Abstract

1. Introduction

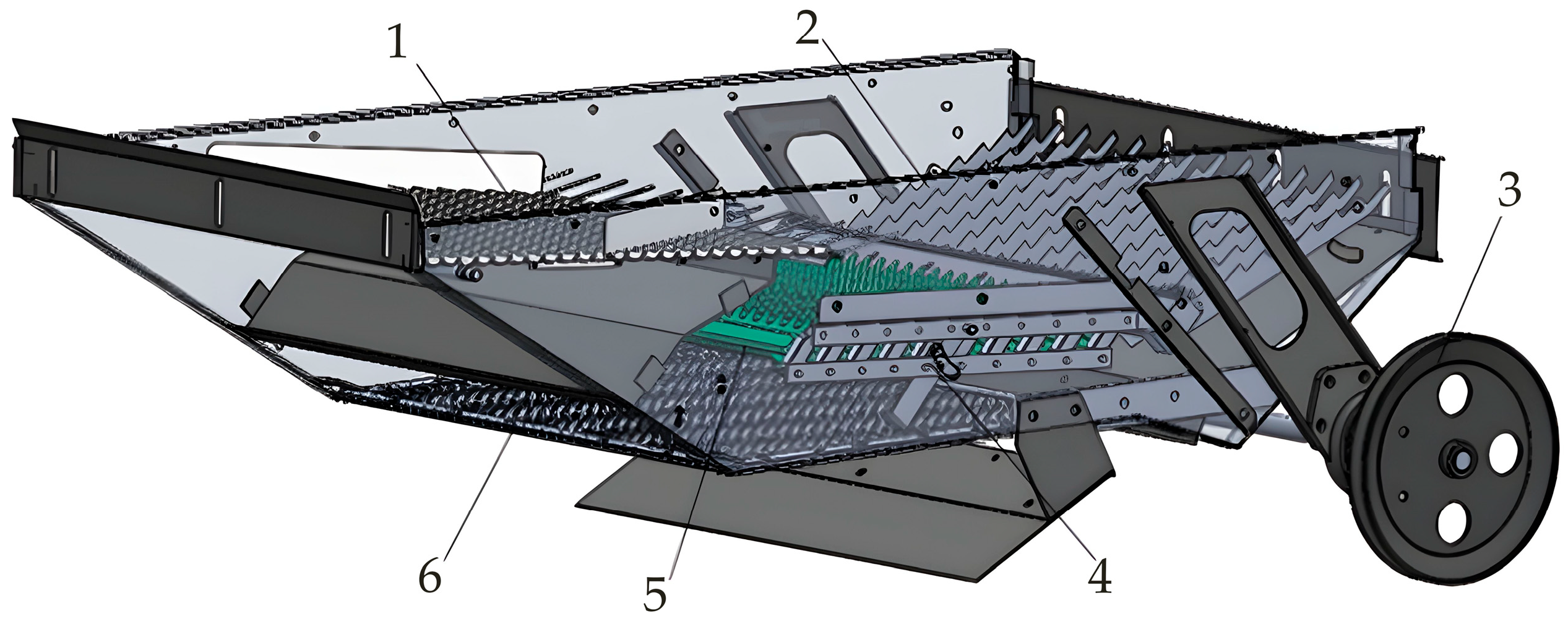

2. Structure and Working Principle of Quinoa Harvester

2.1. Machine Structure and Principle

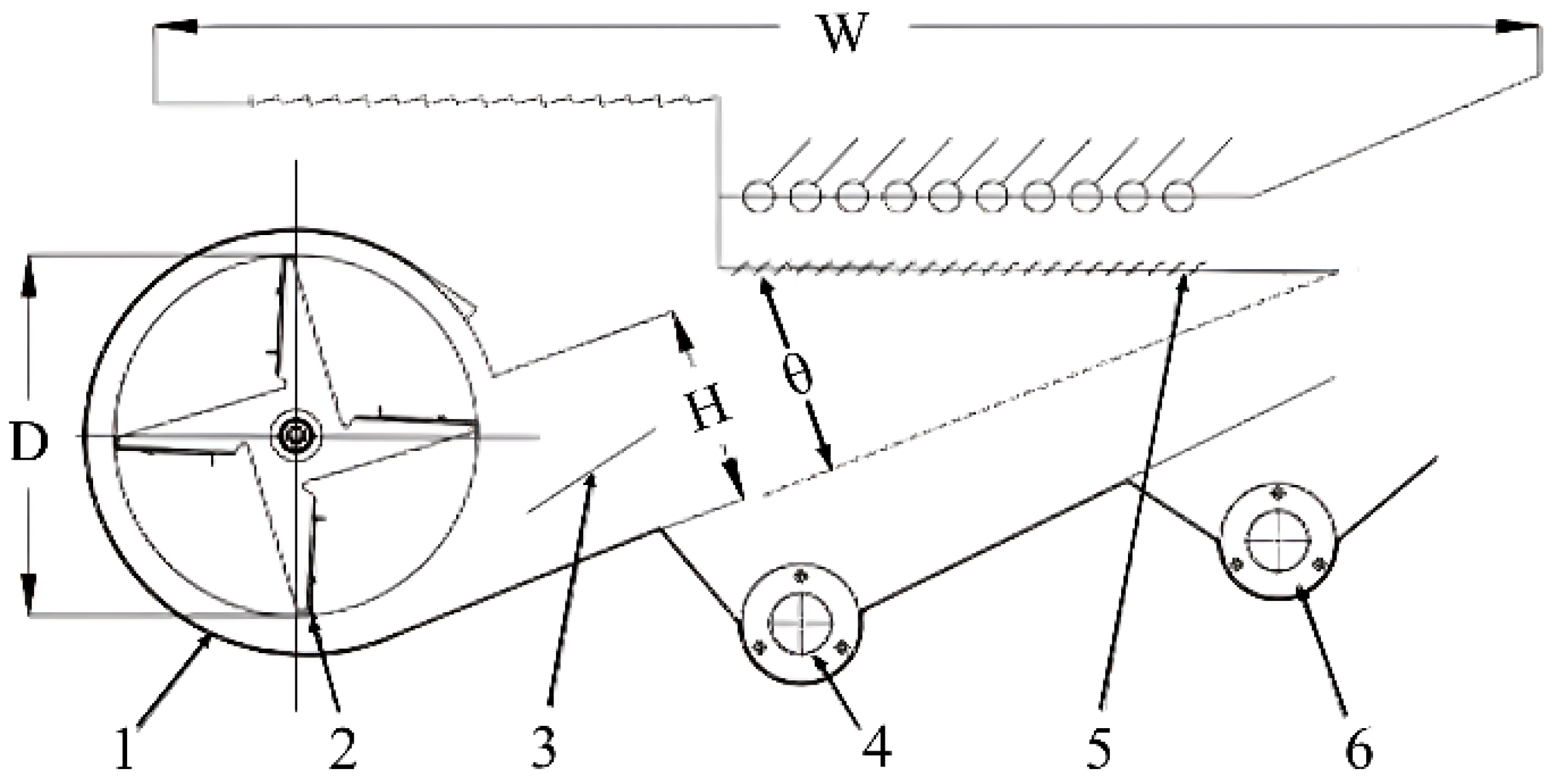

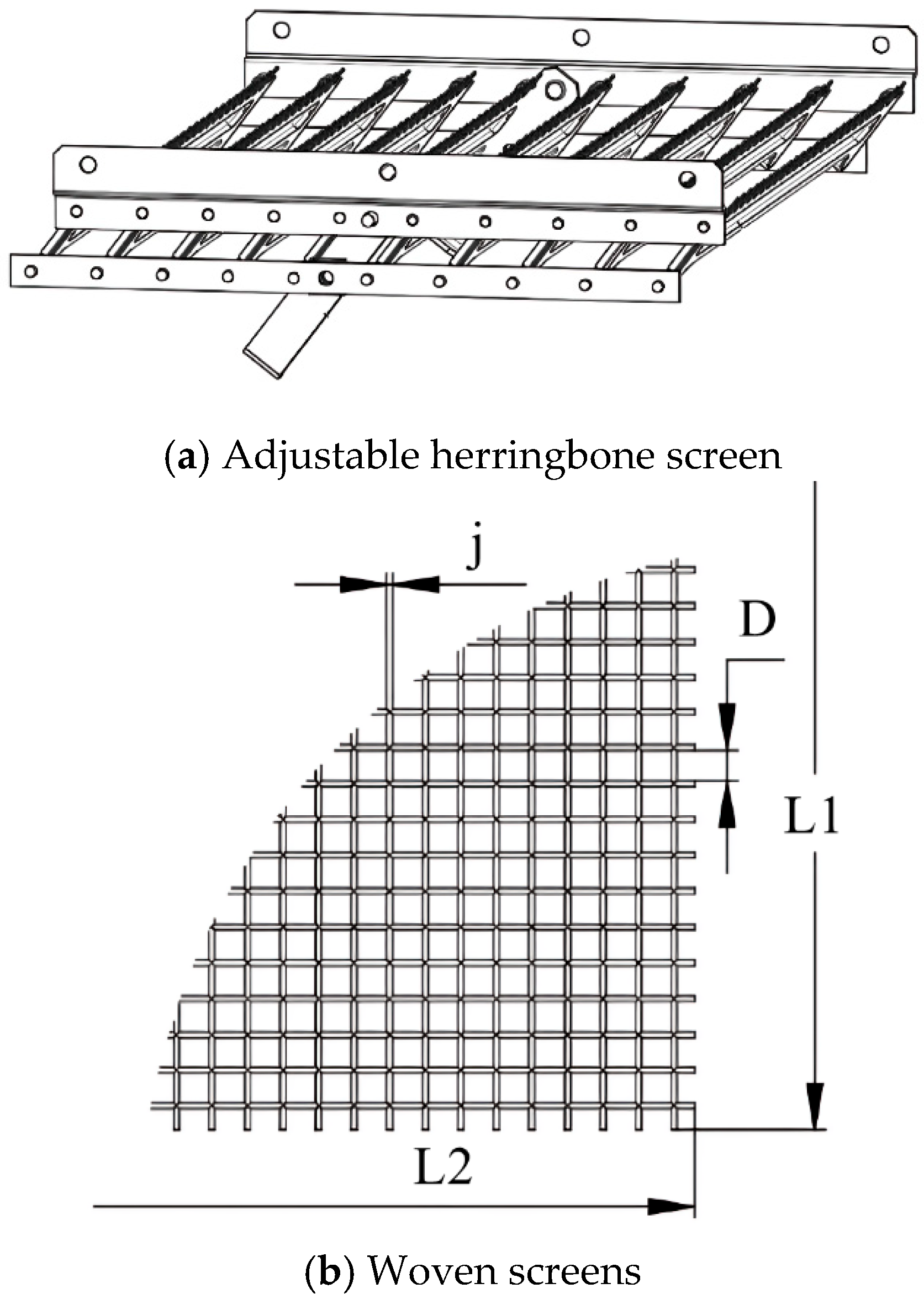

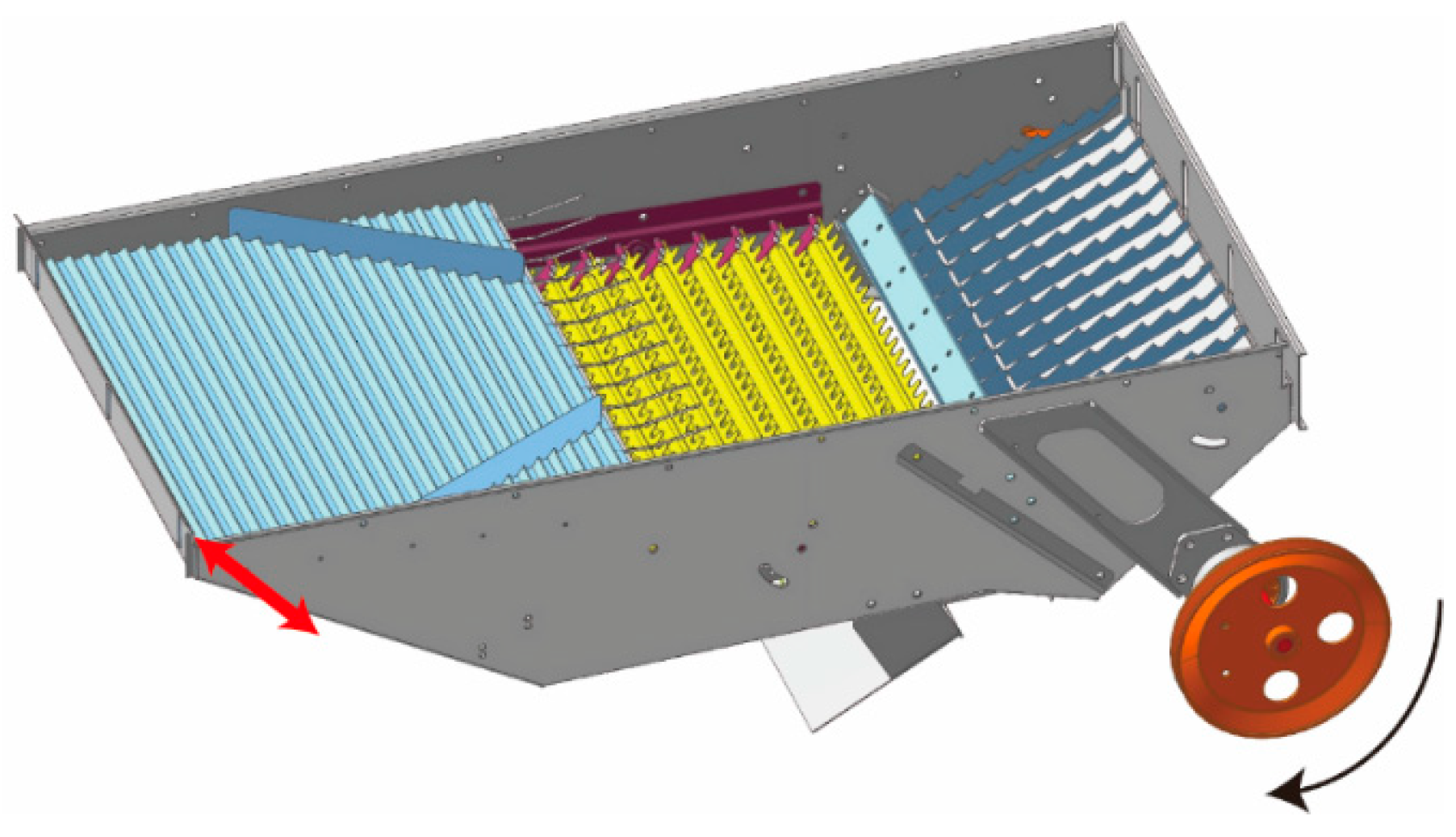

2.2. Structure and Working Principle of Vibrating Screening Mechanism

3. Key Component Design and Kinematic Analysis

3.1. Vibrating Screening Mechanism Design

- L

- —length of the sieve plate, mm;

- Qs

- —feeding rate, kg/s;

- qs

- —feeding rate per unit area of the sieve surface, kg/s;

- φ

- —proportion of stalks and panicles in the total weight of quinoa threshing material;

- K

- —working characteristic coefficient of the threshing and cleaning device;

- Bs

- —width of the sieve plate, Bs = 650 mm.

- H

- —outlet height, mm;

- K1

- —working coefficient, K1 = 0.4;

- θ0

- —angle between airflow and sieve surface, θ0 = 30°.

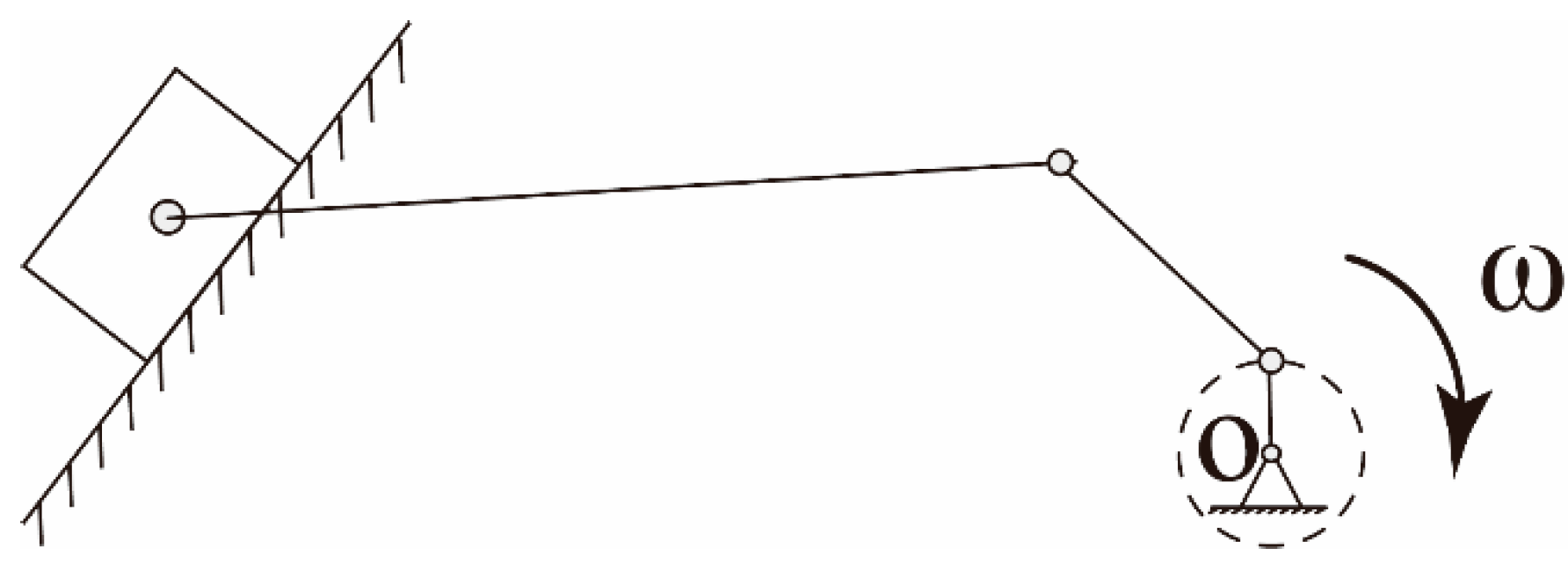

3.2. Kinematic Analysis of Vibrating Screen

- r

- —eccentric radius, mm;

- ω

- —angular velocity of the eccentric wheel, rad/s;

- t

- —rotation time of the eccentric wheel, s.

- α

- —inclination angle of the sieve surface (°);

- n

- —rotational speed of the eccentric wheel, r/min;

- β

- —oscillation direction angle of the sieve surface (°);

- φ

- —Friction angle between threshing material and sieve surface (°).

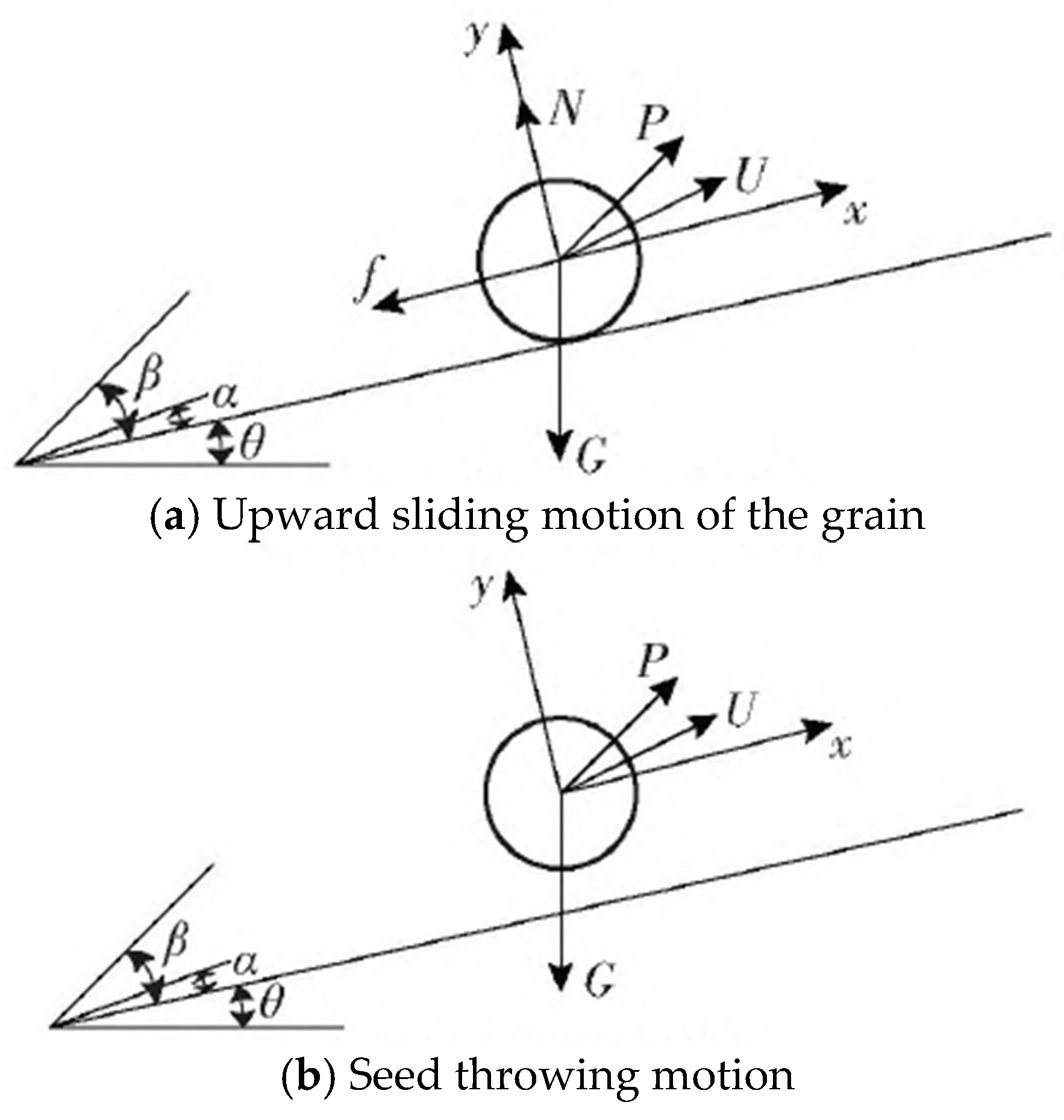

3.3. Analysis of Quinoa Grain Movement Patterns

- Force analysis of quinoa sliding upward on the screen.

- α

- —vibration direction angle (°);

- β

- —angle between grain inertial force and sieve surface (°);

- θ

- —inclination angle of the sieve surface (°);

- φ

- —friction angle (°).

- 2.

- Force analysis of quinoa during its throwing motion on the screen.

4. Modeling and Coupling Analysis

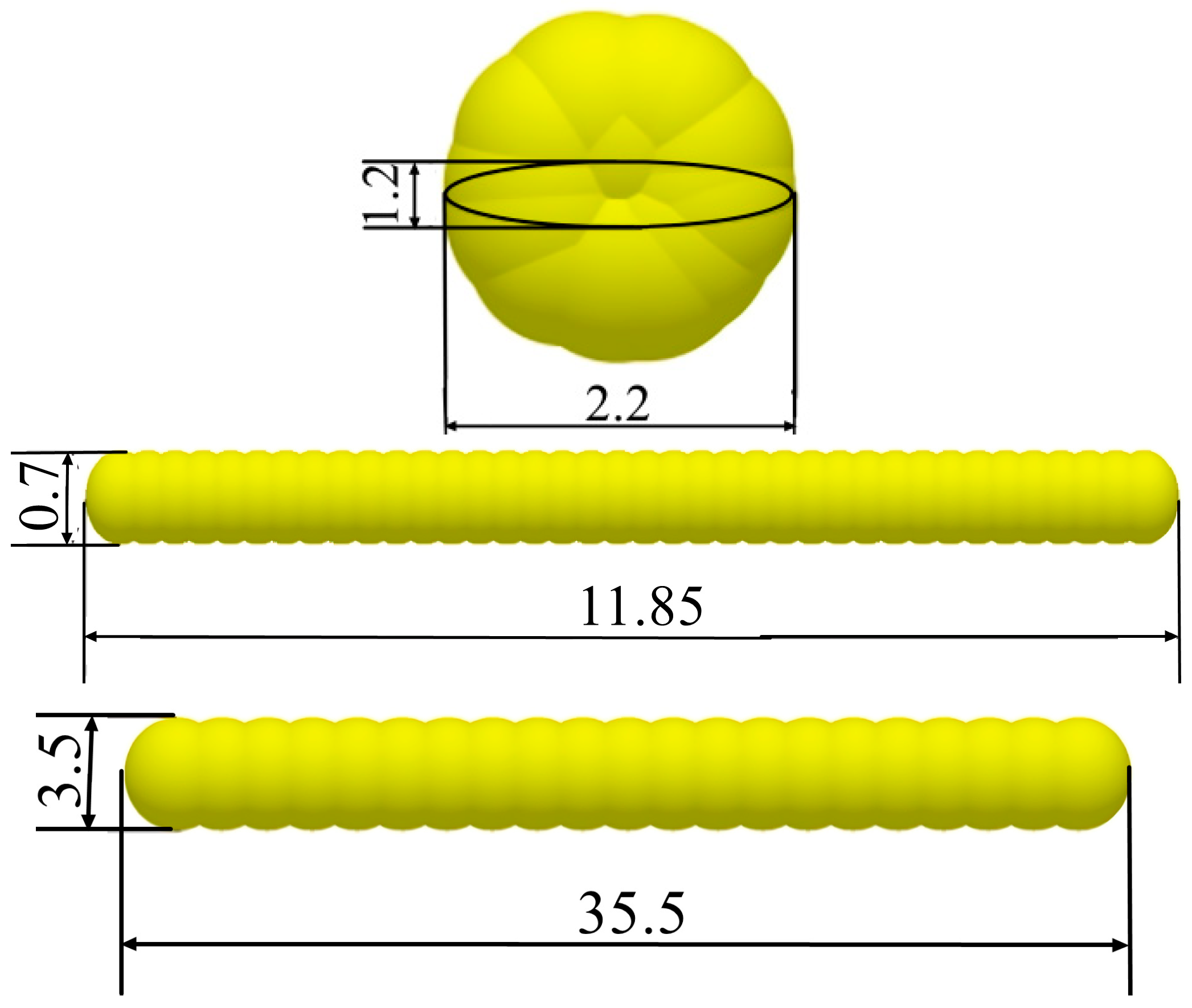

4.1. Numerical Models

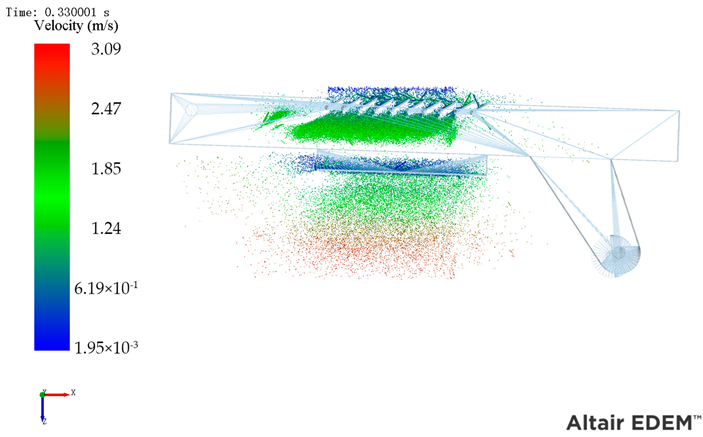

4.2. Coupling Analysis

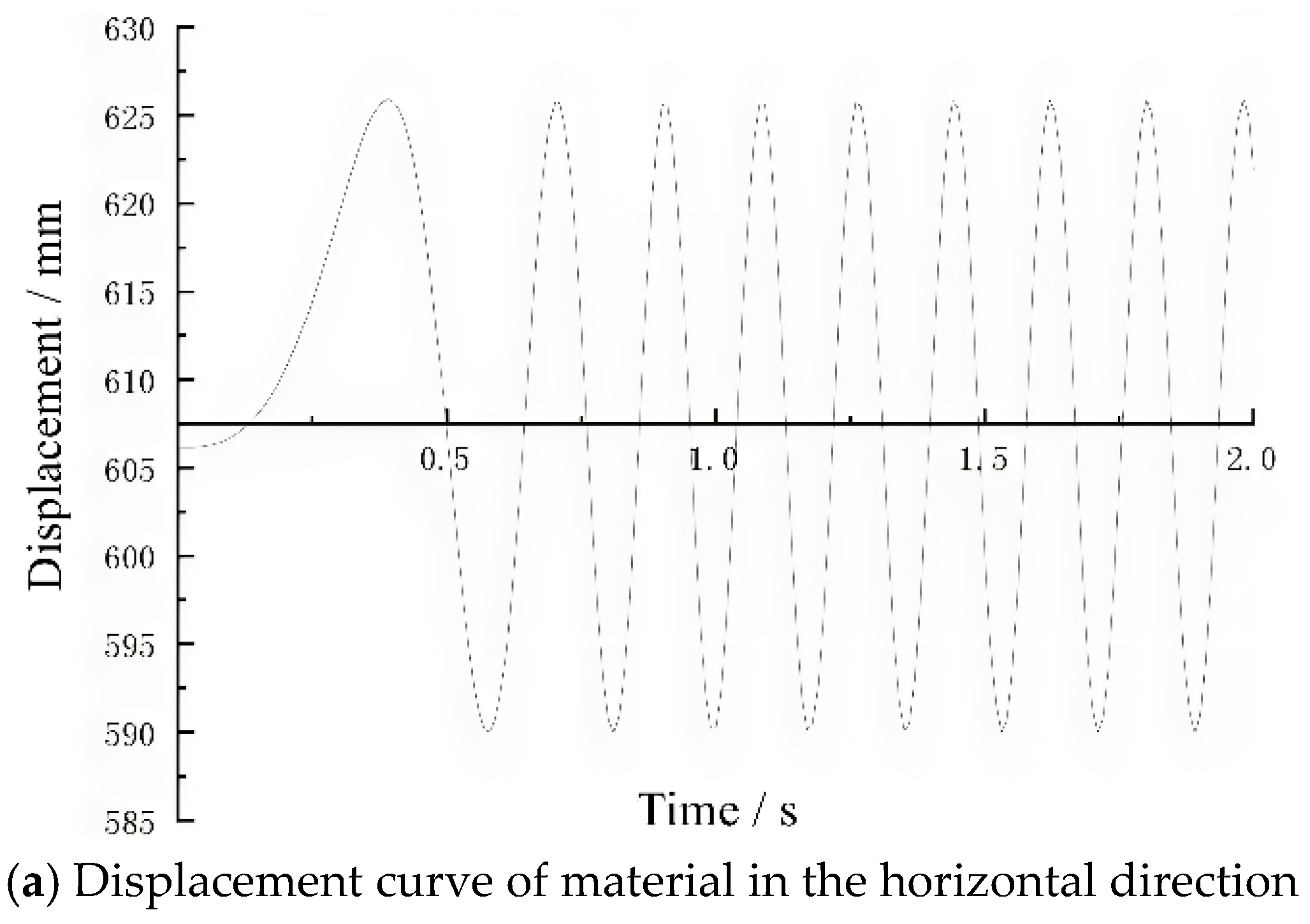

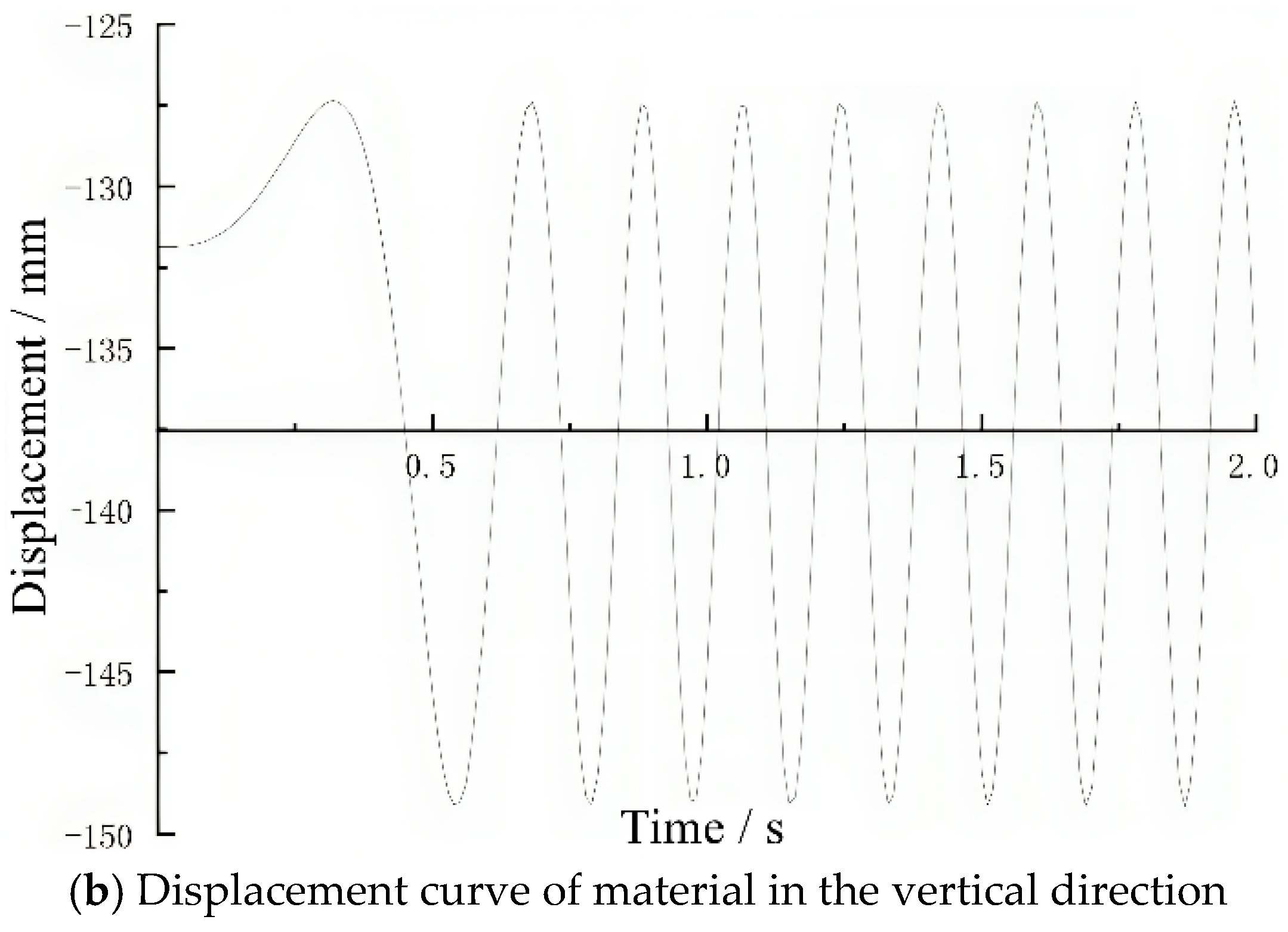

4.2.1. Displacement and Acceleration Analysis at the Center of Mass of the Vibrating Screen

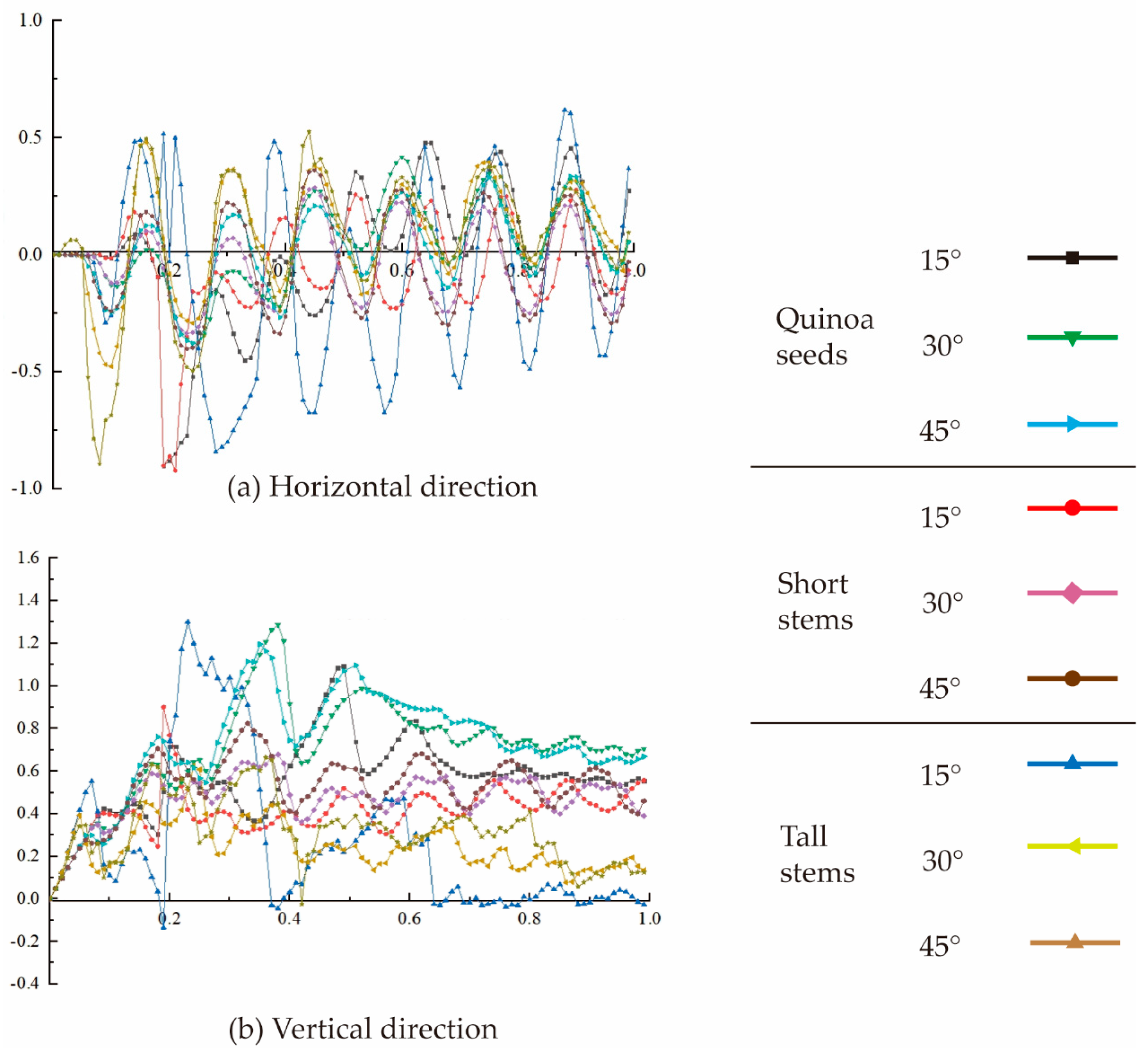

4.2.2. Analysis of Horizontal and Vertical Average Velocities of Threshed Material

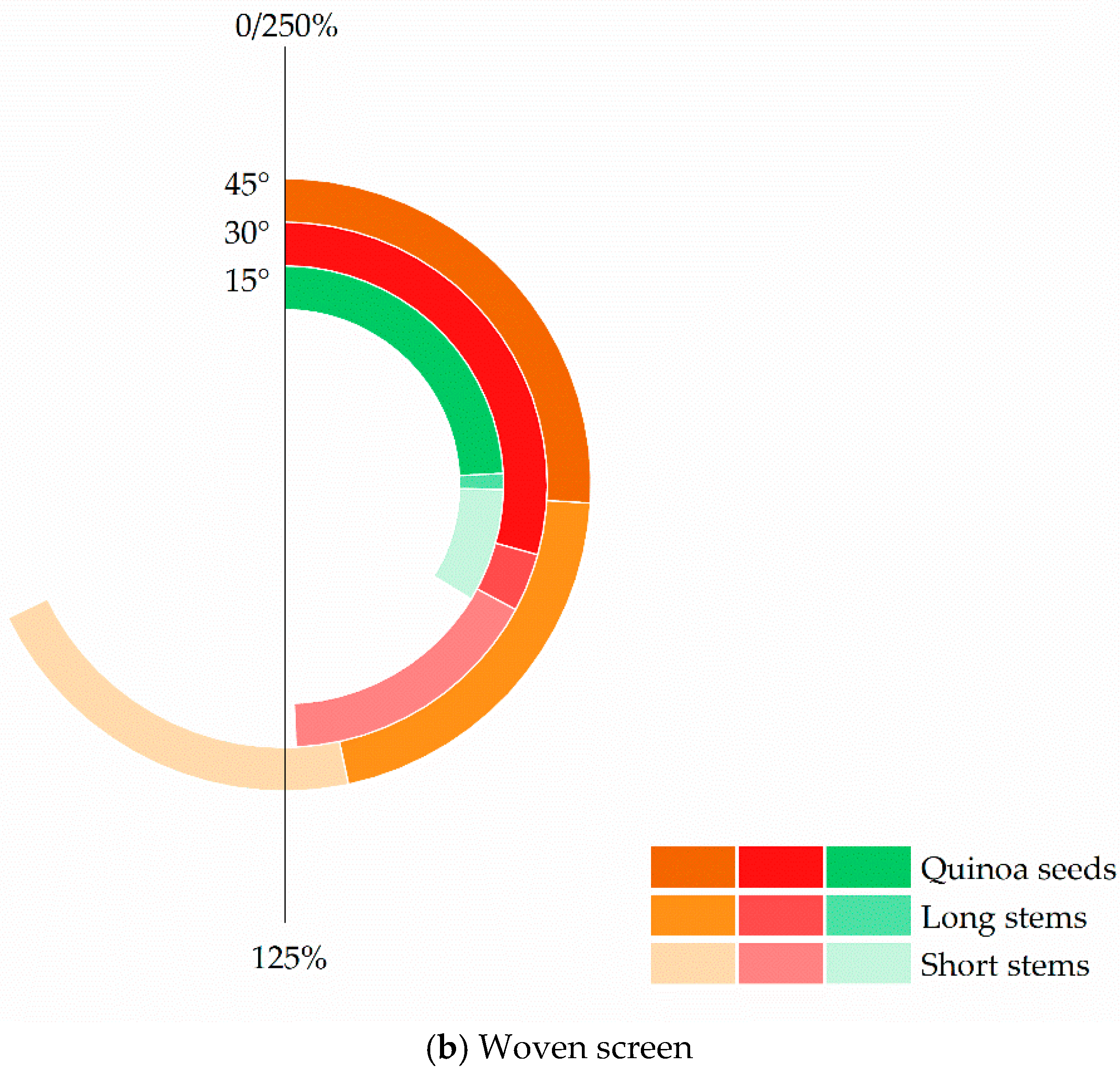

4.2.3. Analysis of Screening Performance of Vibrating Screen

5. Materials and Methods

5.1. Test Subjects and Equipment Description

5.2. Experimental Methodology

6. Results and Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jiang, C. Highlights of the No.1 Central Document in 2025. Rural Finance Research. pp. 1–16. Available online: https://ncjr.cbpt.cnki.net/ (accessed on 16 June 2025).

- State Council. Opinions of the Cpc Central Committee and State Council on Further Deepening Rural Reform and Solidly Promoting Comprehensive Rural Revitalization. People’s Daily, 2025. [Google Scholar]

- Liu, Y.; Li, Z.; Li, X.; Xu, S. Patent Map Analysis of Quinoa Industry at Home and Abroad. J. Hebei Agric. Sci. 2022, 26, 47–52. [Google Scholar]

- Guo, H.; Geng, Y.; Lv, W.; Yang, X. Research Progress on Development and Utilization of Quinoa. Cereals Oils 2021, 34, 9–11. [Google Scholar]

- Hirich, A.; Sifeddine, R.; Mohamed, R.; Amira, F.; Fatima, A.; Kaoutar, F.; Hayatullah, A.; Younes, J.; Aziz, S.; Mariam, M.; et al. Development of Quinoa Value Chain to Improve Food and Nutritional Security in Rural Communities in Rehamna, Morocco: Lessons Learned and Perspectives. Plants 2021, 10, 301. [Google Scholar] [CrossRef]

- Angeli, V.; Miguel Silva, P.; Crispim Massuela, D.; Khan, M.W.; Hamar, A.; Khajehei, F.; Graeff-Hönninger, S.; Piatti, C. Quinoa (Chenopodium Quinoa Willd.): An Overview of the Potentials of the “Golden Grain” and Socio-Economic and Environmental Aspects of Its Cultivation and Marketization. Foods 2020, 9, 216. [Google Scholar] [CrossRef] [PubMed]

- Zgren, E.; Yapar, A. Kinoa (Chenopodium Quinoa Willd) Unu Ile Zenginletirilen Muffin Keklerin Baz Fizikokimyasal Ve Duyusal Zellikleri. Akad. Gida 2022, 20, 244–252. [Google Scholar] [CrossRef]

- Tang, Z.; Li, J.; Zhu, X.; Yang, Y. Extraction and Separation of Protein Fromquinoa (Chenopodium Quinoa Willd). Food Ferment. Ind. 2021, 47, 129–136. [Google Scholar]

- Hongliang, C.; Yao, Q.; Xing, B.; Zhou, B.; Shah, S.S.; Qin, P. The Performance of Agronomic and Quality Traits of Quinoa under Different Altitudes in Northwest of China. Agronomy 2024, 14, 1194. [Google Scholar] [CrossRef]

- Xiao, Z.; Zhang, G. Development and Utilization of Chenopodium Quinoa Willd. Chin. Wild Plant Resour. 2014, 33, 5. [Google Scholar]

- Qi, T.; Li, Z.; Qin, P.; Ren, G.; Zhou, B. Research and Application Prospect of Quinoacultivation Technology. J. Agric. Sci. Technol. 2022, 24, 157–165. [Google Scholar]

- Hou, Y.; Pang, C.; Zhang, Y.; Kang, S.; Wu, Y.; Yan, J.; Wang, J. Effects of Biochar and Nitrogen Fertilizer on the Physiological Growth characteristics of Quinoa Seedlings under Saline Alkali Stress. Crops 2024, 240–246. [Google Scholar] [CrossRef]

- Radmila, S.; Glamoclija, D.; Demin, M.; Vucelic-Radovic, B.; Jovanovic, Z.; Milojkovic-Opsenica, D.; Jacobsen, S.E.; Milovanovic, M. Agronomical and Nutritional Evaluation of Quinoa Seeds (Chenopodium Quinoa Willd) as an Ingredient in Bread Formulations. J. Cereal Sci. 2012, 55, 132–138. [Google Scholar]

- Huang, J.; Yang, F.; Li, M.; Wei, Y.; Gu, X.; Qi, Y. Preliminary Evaluation of Adaptability of 13 Quinoa Varieties in the Linxia Arid Region of Gansu Province, China. Acta Prataculturae Sin. 2016, 25, 191–201. [Google Scholar]

- Ren, G.; Yang, X.; Yao, Y. Current Situation of Quinoa Industry in China. Crops 2015, 5. [Google Scholar] [CrossRef]

- Yang, F.; Huang, J.; Wei, Y.; Li, M.; He, X.; Zheng, J. A Review of Biological Characteristics, Applications, and Culture of Chenopodium Quinoa. Pratacultural Sci. 2017, 34, 607–613. [Google Scholar]

- Yuan, F.; Quan, Y.; Liu, D.; Chen, Z. Primary Observation the Plant Morphology and Floral Structure on Quinoa (Chenopodium Quinoa Willd). J. Gansu Agric. Univ. 2018, 53, 49–53. [Google Scholar]

- Wu, X.; He, C.; Hu, J.; Ma, C. Mechanized Production Mode of Quinoa in Qaidam Basin. Agric. Eng. 2022, 12, 5–10. [Google Scholar]

- Wang, W.; Liu, W.; Yuan, L.; Qu, Z.; He, X.; Lv, Y. Simulation and Experiment of Single Longitudinal Axial Material Movementand Establishment of Wheat Plants Model. Trans. Chin. Soc. Agric. Mach. 2020, 51, 170–180. [Google Scholar]

- Shen, Y.; Wu, M.; Wu, Z.; Li, X.; Zhang, L. Structural Design of Cleaning System for Longitudinal Flow Rice Combine Harvester. J. Hunan Agric. Univ. (Nat. Sci.) 2013, 39, 94–96. [Google Scholar]

- Lu, Q.; Xu, B.; Liu, Y.; Ye, S.; Li, L.; Kong, L.; Zheng, D. Design Optimization and Experimental Evaluation of a Reciprocating Grain Vibrating Screen Based on Adams System. J. Shanxi Agric. Univ. (Nat. Sci. Ed.) 2019, 39, 98–104. [Google Scholar]

- Zhao, Z.; Guo, Z.; Du, W.; Wu, Y.; Hai, M. The Study of the Mechanical Properties of Quinoa. J. Agric. Mech. Res. 2018, 40, 162–165+170. [Google Scholar]

- Hai, M.; Du, W.; Wu, Y.; Zhao, Z. Test and Analysis of Aerodynamics on the Quinoa Threshed Mixture. J. Agric. Mech. Res. 2019, 41, 192–195+215. [Google Scholar]

- Wu, Y.; Guo, Z.; Du, W.; Chen, W.; Wei, P. Study of the Material Properties on the Quinoa Threshed Mixture. J. Agric. Mech. Res. 2017, 39, 184–189. [Google Scholar]

- Gu, H. Tianzhu County Plateau Cold Dry Area Quinoa Industry the Whole Mechanization Promotion Investigation. South China Agric. 2020, 14, 156–157. [Google Scholar]

- Hai, M. Experimental Study on Clearance of Quinoa Combine Harvester. Master’s Thesis, Inner Mongolia Agricultural University, Hohhot, China, 2018. [Google Scholar]

- Liu, P.; Jin, C.; Yang, T.; Chen, M.; Ni, Y.; Yin, X. Design and Experiment of Multi Parameter Adjustable Andmeasurable Cleaning System. Trans. Chin. Soc. Agric. Mach. 2020, 51, 191–201. [Google Scholar]

- Wang, X.; Bian, B.; Tuluhong, T.; Zhang, L. Experiments and Parameter Optimization of Almond Shell and Kernel Airseparation Device. Trans. Chin. Soc. Agric. Eng. 2021, 37, 299–306. [Google Scholar]

- Yu, Z.; Hu, Z.; Cao, M.; Wang, S.; Zhang, P.; Peng, B. Design of Cleaning Device of Tangential Flow and Whole-Feed Peanutcombine Harvester. Trans. Chin. Soc. Agric. Eng. 2019, 35, 29–37. [Google Scholar]

- Ding, Z. Theoretical Research on Motion Law of Aparticle Based on Motioncharacteristics of Screen. Master’s Thesis, Northeast Agricultural University, Harbin, China, 2017. [Google Scholar]

- Dai, F.; Zhao, W.; Shi, R.; Liu, X.; Cui, Y.; Fu, S. Design and Experiment on Self-Propelled Flax Combine Harvester. Chin. J. Oil Crop Sci. 2022, 44, 678–686. [Google Scholar]

- Wang, T.; Dai, F.; Zhao, W.; Shi, R.; Zhao, Y.; Qu, H.; Guo, J. Design and Simulation of Vibrating Screen for Quinoa Combine Harvester in Hills and Mountains. Agric. Equip. Veh. Eng. 2023, 61, 16–20. [Google Scholar]

- Mechanization, China Academy of Agricultural. Agricultural Machinery Design Manual (Upper and Lower); Agricultural Science Press: Beijing, China, 2007. [Google Scholar]

- Wang, F.; Alimu, M.; Zhang, J.; Li, Q.; Xu, L. Design and Experiment of Pre-Screening Cleaning Device for Combined Screen Surface of Corn Grain Harvester. Trans. Chin. Soc. Agric. Mach. 2024, 55, 135–147+166. [Google Scholar]

- Wang, T.; Dai, F.; Zhao, W.; Shi, R.; Zhao, Y.; Yang, F.; Xing, L.; Wang, G. Design and Test of Quinoa Combine Harvester in Hilly and Mountainous Areas. Agric. Res. Arid Areas 2023, 41, 252–262. [Google Scholar]

- Shi, R.; Dai, F.; Zhao, W.; Yang, F.; Zhang, F.; Zhao, Y.; Qu, H.; Wang, T.; Guo, J. Design and Experiments of Self-Propelled Quinoa Combine Harvester. J. Jilin Univ. (Eng. Technol. Ed.) 2023, 53, 2686–2694. [Google Scholar]

- Dai, F.; Fu, Q.; Zhao, W.; Shi, R.; Song, X.; Zhang, S. Design and Test of Double Duct System of Air-Screen Separatingand Cleaning Machine for Flax Threshing Material. Trans. Chin. Soc. Agric. Mach. 2021, 52, 117–125+247. [Google Scholar]

- Zhang, M.; Jin, C.; Liang, S.; Tang, Q.; Wu, C. Parameter Optimization and Experiment on Air-Screen Cleaning Device Ofrapeseed Combine Harvester. Trans. Chin. Soc. Agric. Eng. 2015, 31, 8–15. [Google Scholar]

- Zhou, Y.; Qin, D.; Li, Q.; Nie, J.; Luo, H.; Zhang, L. Optimization Design of Coix Vibrating Screen Cleaning Device Based on Edem. J. Northeast. Agric. Univ. 2022, 53, 68–76. [Google Scholar]

- Zhou, Y.; Huang, B.; Qu, Y.; Yan, X.; Li, J. Analysis of Particle Motion Characteristics on the Screen Surface of Linear Vibrating Screen. Coal Eng. 2023, 55, 173–178. [Google Scholar]

- Chen, Y.Z.; Yao, H.L.; Liu, G. Experimental Study on Influence of Vibration Parameters Onscreening Efficiency. J. Northeast. Univ. (Nat. Sci.) 2019, 40, 1122–1126. [Google Scholar]

- Li, J.; Zeng, Q.; Deng, J.; Shen, H.; Xiong, K. Screening Process Analysis for Multi-Dimensional Parallel Vibratingscreen and Optimization of Screen Surface Movement. Trans. Chin. Soc. Agric. Mach. 2016, 47, 399–407. [Google Scholar]

- Wang, F.; Zhang, F.; Dai, F.; Zhang, L.; Zhao, W.; Yang, X. Design and Experiment of Double Layer Flat Screen Type Pinellia Ternate Harvester. Acta Agric. Zhejiangensis 2021, 33, 1946–1955. [Google Scholar]

- Zhang, L.; Qiu, Q.; Qin, D.; Luo, H.; Yuan, S.; Nie, J. Design and Test of the Dual-Purpose Cleaning Device for Soybean and Corn. Trans. Chin. Soc. Agric. Eng. 2022, 38, 21–30. [Google Scholar]

- He, Z.; Wang, X.; Xing, Z.; Xiao, H. Dynamic Characteristics Analysis of Vibrating Screen Based on Systemand Particle Coupling Dynamics. J. South China Univ. Technol. (Nat. Sci. Ed.) 2023, 51, 41–50. [Google Scholar]

- Zeng, Z.; Ma, X.; Cao, X.; Li, Z.; Wang, X. Critical Review of Applications of Discrete Element Methodin Agricultural Engineering. Trans. Chin. Soc. Agric. Mach. 2021, 52, 1–20. [Google Scholar]

- GB/T 8097-2008; Harvesting Machinery-Combine Harvester-Test Method. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. Standardization Administration of the People’s Republic of China: Beijing, China, 2008.

| Parameter Name | Parameter Value | Unit |

|---|---|---|

| Structural Form | Full-Feed Tracked | - |

| Overall Machine Dimensions (Length × Width × Height) | 4950 × 2150 × 2590 | mm |

| Header Width | 1900 | mm |

| Feeding Capacity | 4 | kg/s |

| Operating Speed | 0.75–1.50 | m/s |

| Productivity | 0–0.5 | hm2/h |

| Rated Rotational Speed | 2400 | r/min |

| Threshing Drum Parameters (Diameter × Length) | 550 × 1350 | mm |

| Track Pitch × Number of Links × Width | 90 × 44 × 400 | mm |

| Track Gauge | 1080 | mm |

| Ground Clearance | 320 | mm |

| Rated Power | 51.5 | kW |

| Material | Diameter (mm) | Length/Thickness (mm) |

|---|---|---|

| Quinoa grains | 2.2 | 1.2 |

| Short stalks | 0.7 | 11.85 |

| Long stalks | 3.5 | 35.5 |

| (a) | |||

| Item | Poisson’s Ratio | Shear Modulus (MPa) | Density (kg/m3) |

| Quinoa grains. | 0.25 | 156 | 870 |

| Long stalks | 0.3 | 160 | 590 |

| Short stalks | 0.3 | 150 | 360 |

| Screen mesh | 0.3 | 79,000 | 7800 |

| (b) | |||

| Item | Coefficient of Restitution | Static Friction Coefficient | Kinetic (Dynamic) Friction Coefficient |

| Quinoa grain–Quinoa grain | 0.22 | 0.26 | 0.08 |

| Quinoa grain–Screen mesh | 0.46 | 0.38 | 0.12 |

| Long stalk–Long stalk | 0.21 | 0.25 | 0.18 |

| Long stalk–Short stalk | 0.21 | 0.25 | 0.18 |

| Short stalk–Short stalk | 0.21 | 0.25 | 0.18 |

| Long stalk–Quinoa grain | 0.21 | 0.25 | 0.18 |

| Long stalk–Screen mesh | 0.42 | 0.34 | 0.12 |

| Short stalk–Screen mesh | 0.42 | 0.34 | 0.12 |

| (a) | |||

| Opening Angle (°) | Amplitude of Average Velocity Changes in the Horizontal Direction (m/s) | ||

| Quinoa Grains | Long Stems | Short Stems | |

| 15 | 1.76 | 1.45 | 1.29 |

| 30 | 0.795 | 0.956 | 0.648 |

| 45 | 0.713 | 1.42 | 0.764 |

| (b) | |||

| Opening Angle (°) | Amplitude of Average Velocity Changes in the Vertical Direction (m/s) | ||

| Quinoa Grains | Long Stems | Short Stems | |

| 15 | 1.53 | 1.437 | 1.04 |

| 30 | 1.287 | 0.626 | 0.678 |

| 45 | 1.163 | 0.688 | 0.424 |

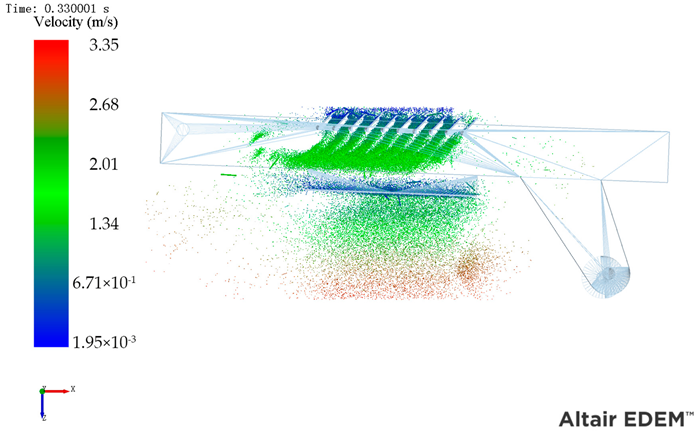

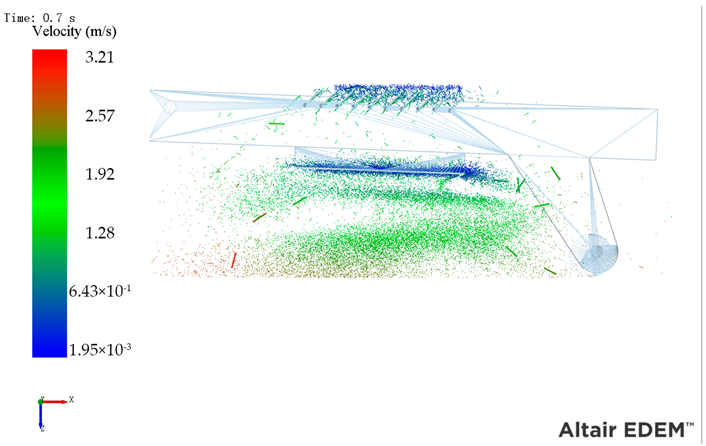

| Angle | Time | Velocity Distribution Map |

|---|---|---|

| 15° | 0.33 s |  |

| 30° | 0.33 s |  |

| 45° | 0.33 s |  |

| 0.7 s |  | |

| 1 s |  |

| Experimental Indicators | Threshing Efficiency (%) | Impurity Content (%) | Seed Damage Rate (%) | Cleaning Loss Rate (%) |

|---|---|---|---|---|

| Indicator requirements | ≥95 | ≤5 | ≤3 | ≤3 |

| Experimental results | 96.83 | 4.3 | 0.15 | 0.52 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, R.; Ren, X.; Dai, F.; Zhao, W.; Wang, T. Design of the Vibrating Sieving Mechanism for a Quinoa Combine Harvester and Coupled Analysis of DEM-MBD. Agriculture 2025, 15, 1317. https://doi.org/10.3390/agriculture15121317

Shi R, Ren X, Dai F, Zhao W, Wang T. Design of the Vibrating Sieving Mechanism for a Quinoa Combine Harvester and Coupled Analysis of DEM-MBD. Agriculture. 2025; 15(12):1317. https://doi.org/10.3390/agriculture15121317

Chicago/Turabian StyleShi, Ruijie, Xiaojing Ren, Fei Dai, Wuyun Zhao, and Tianfu Wang. 2025. "Design of the Vibrating Sieving Mechanism for a Quinoa Combine Harvester and Coupled Analysis of DEM-MBD" Agriculture 15, no. 12: 1317. https://doi.org/10.3390/agriculture15121317

APA StyleShi, R., Ren, X., Dai, F., Zhao, W., & Wang, T. (2025). Design of the Vibrating Sieving Mechanism for a Quinoa Combine Harvester and Coupled Analysis of DEM-MBD. Agriculture, 15(12), 1317. https://doi.org/10.3390/agriculture15121317