Design and Fatigue Life Analysis of the Rope-Clamping Drive Mechanism in a Knotter

Abstract

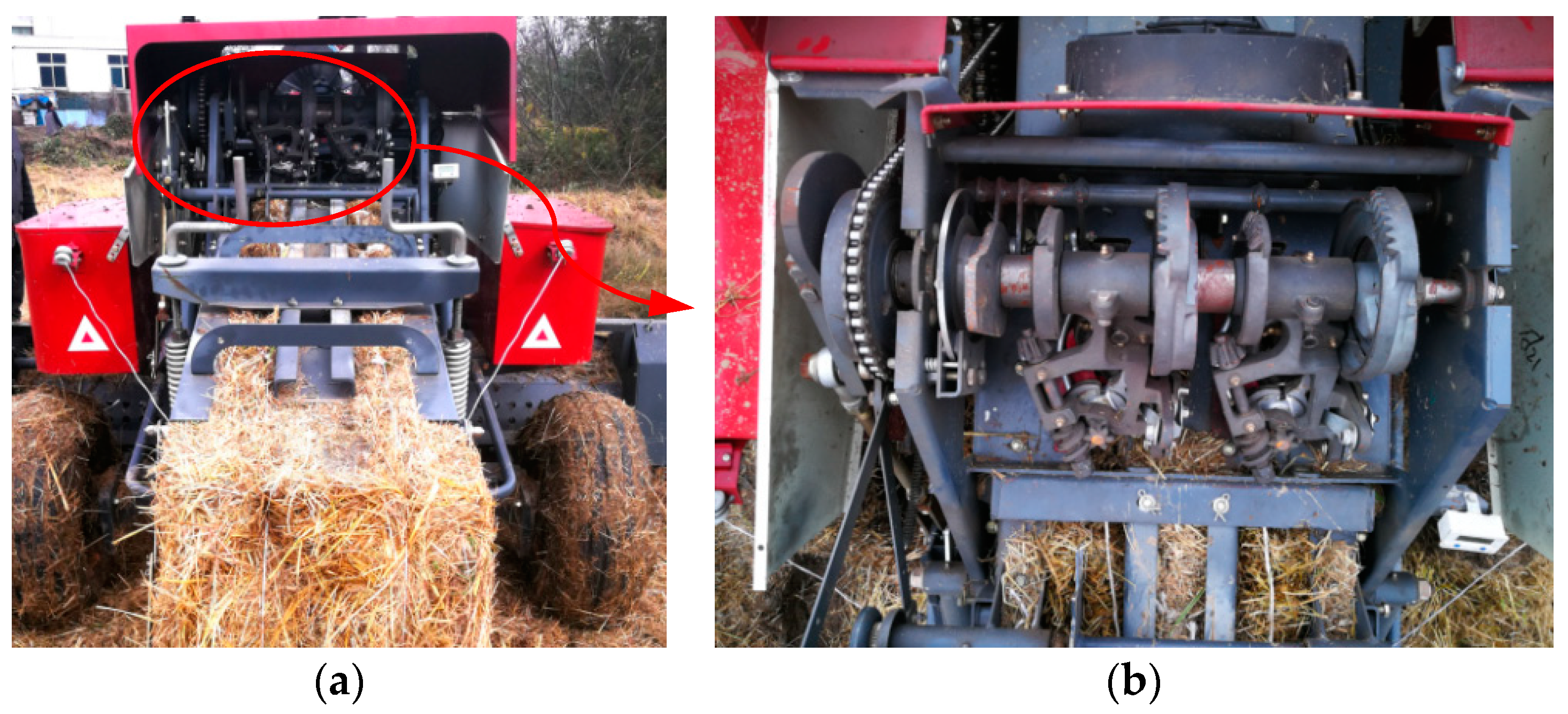

1. Introduction

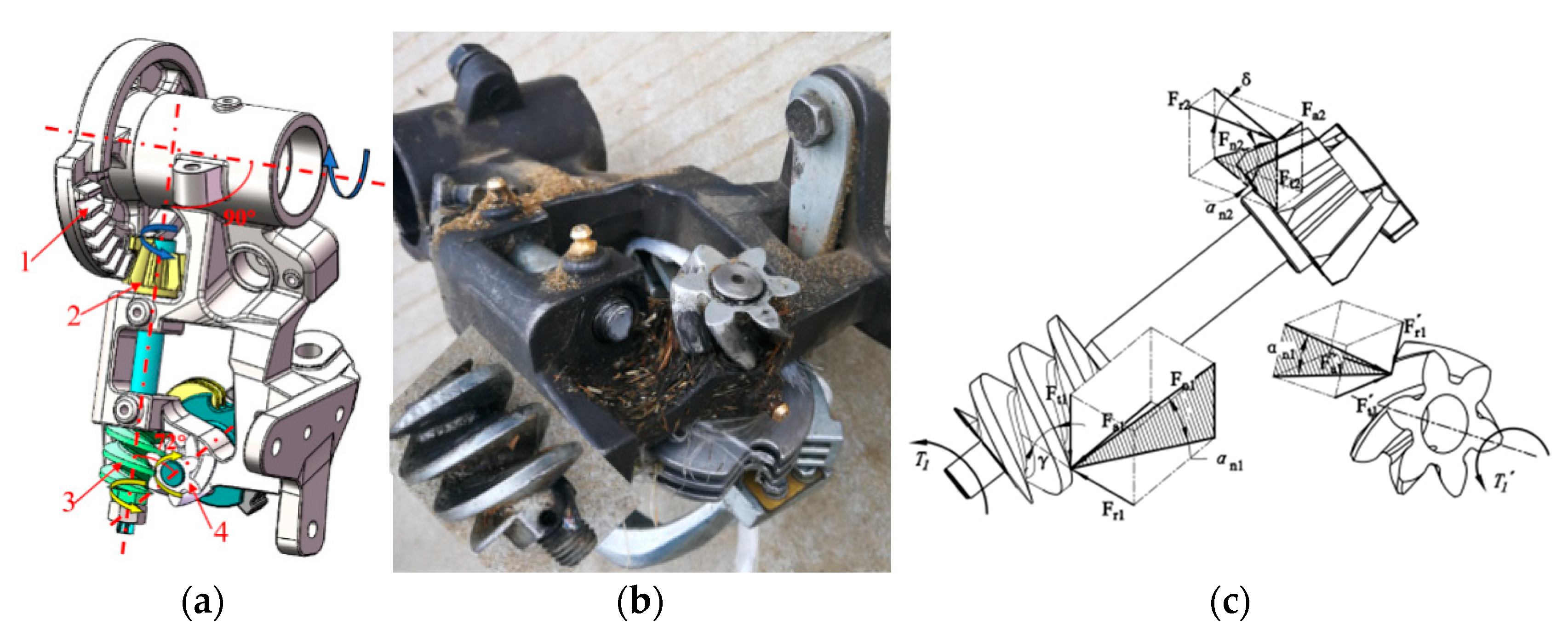

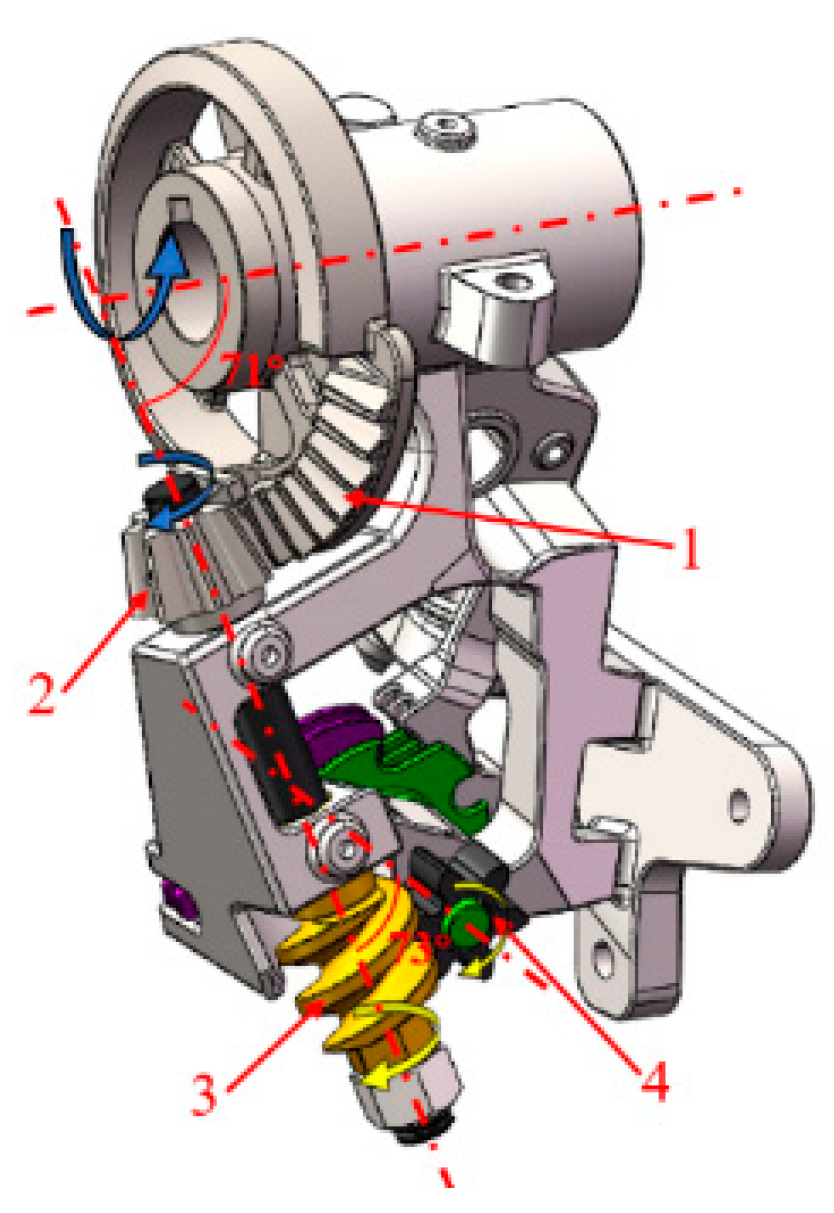

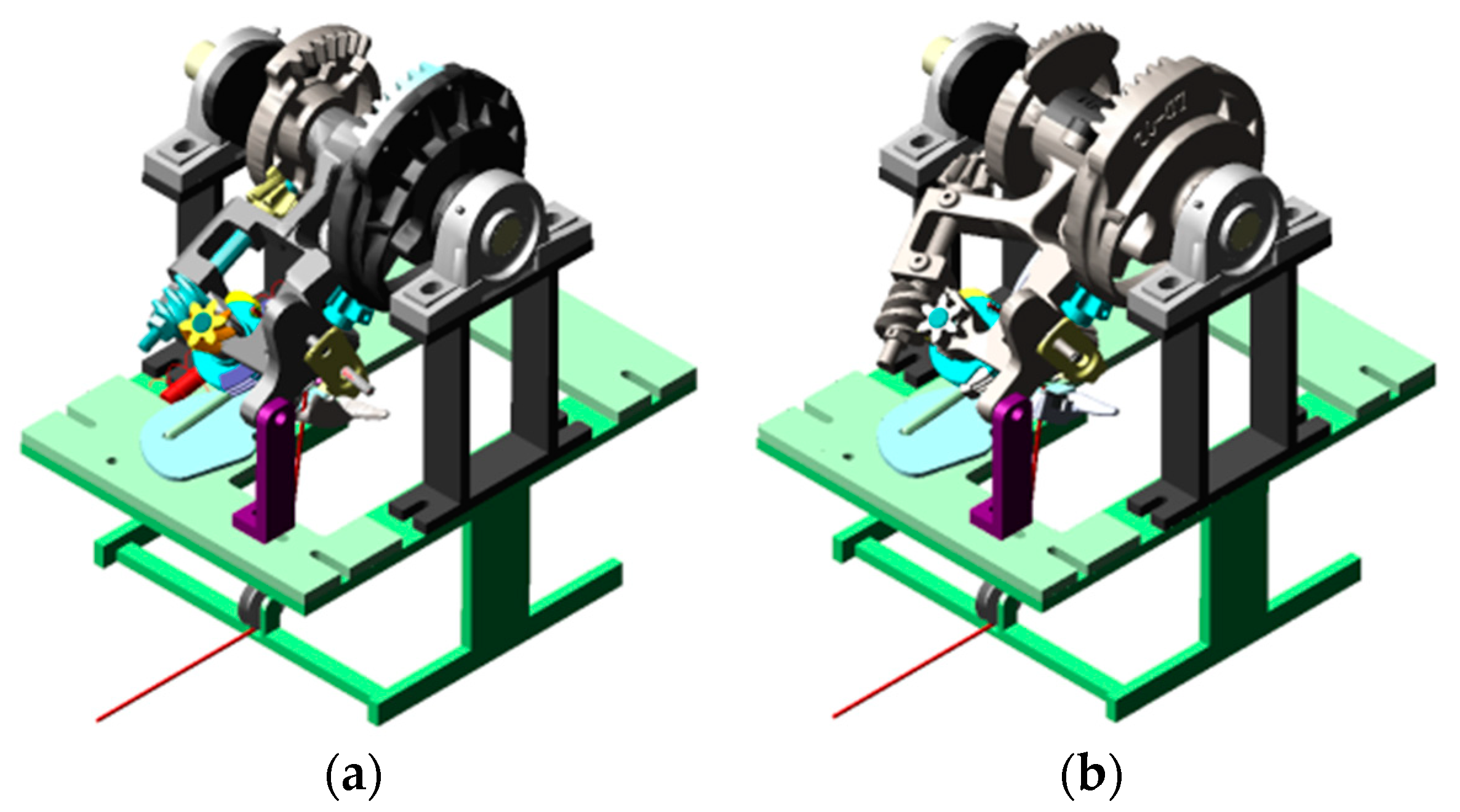

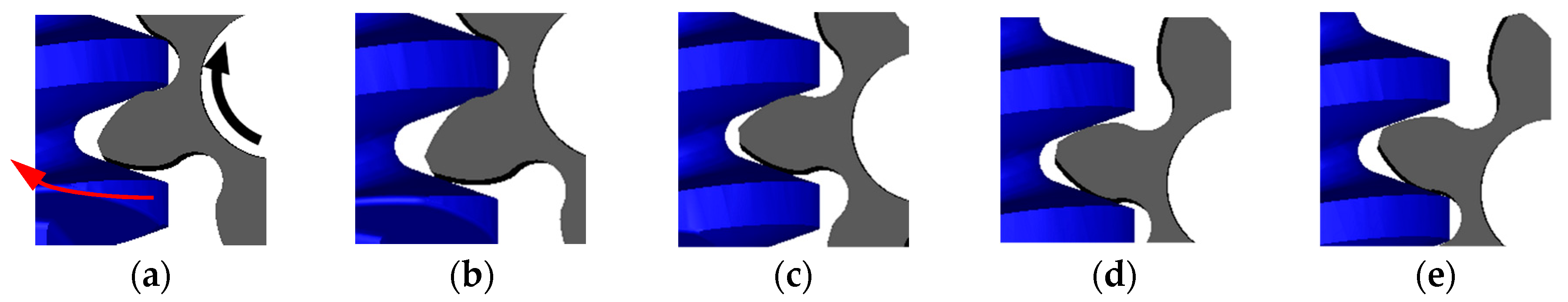

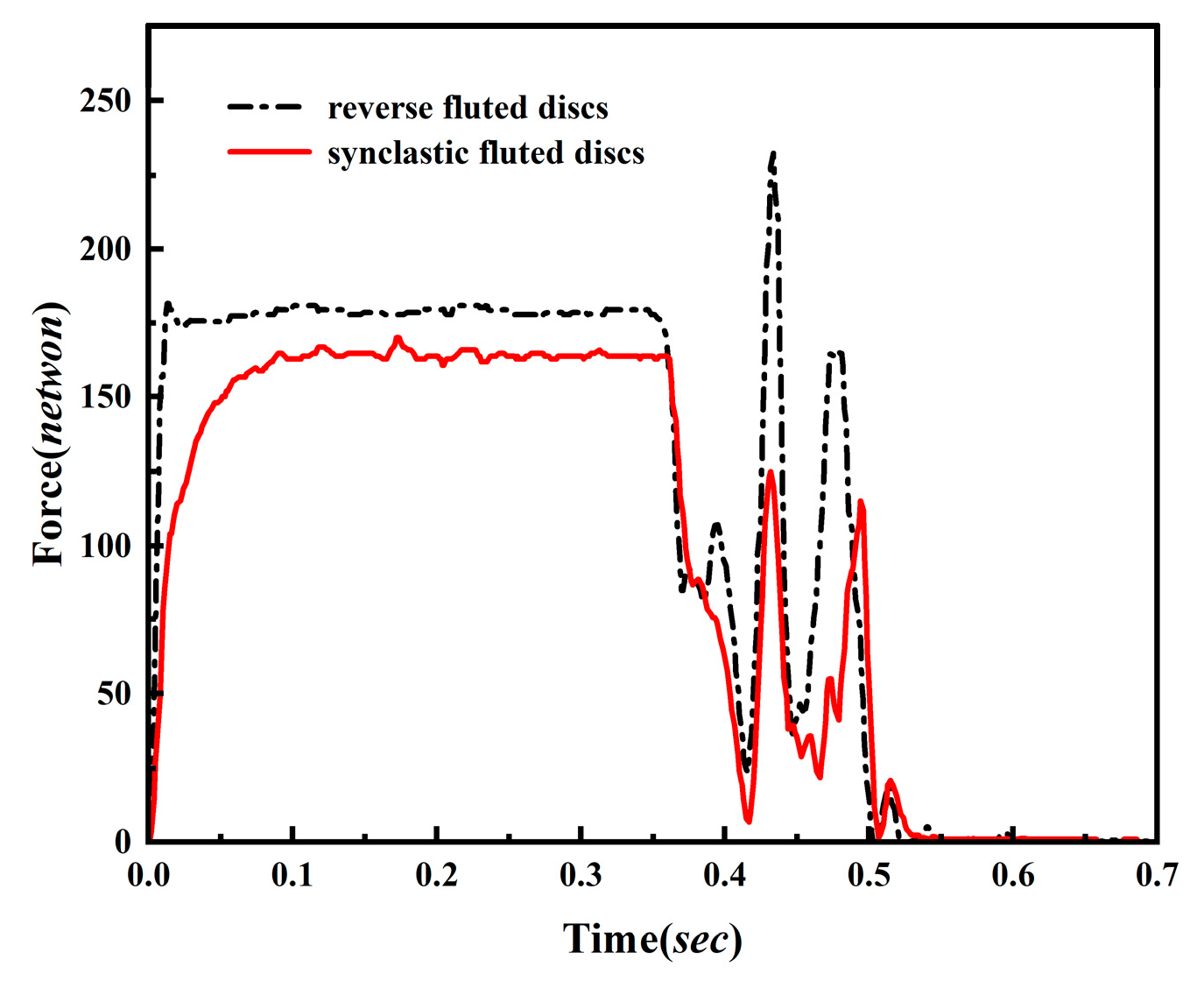

2. Analysis of the Failure Causes of Rope Clamping and the Transmission Redesign of the Rope-Clamping Drive Mechanism in a Knotter with Double-Fluted Discs

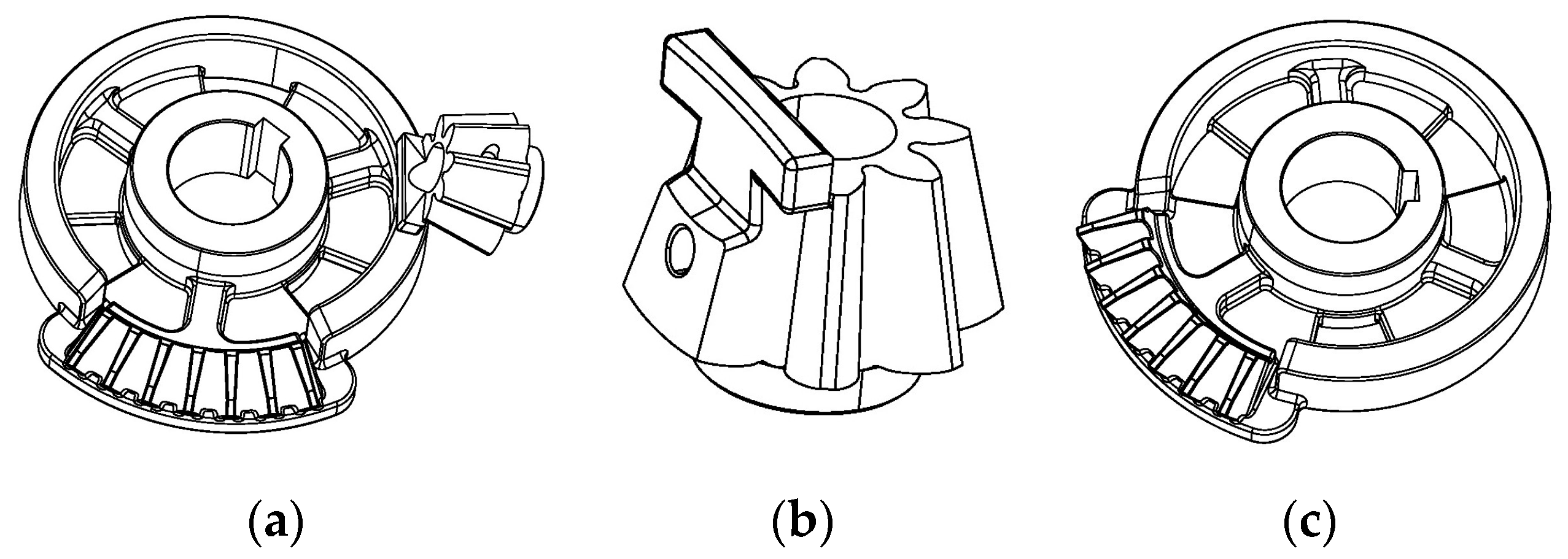

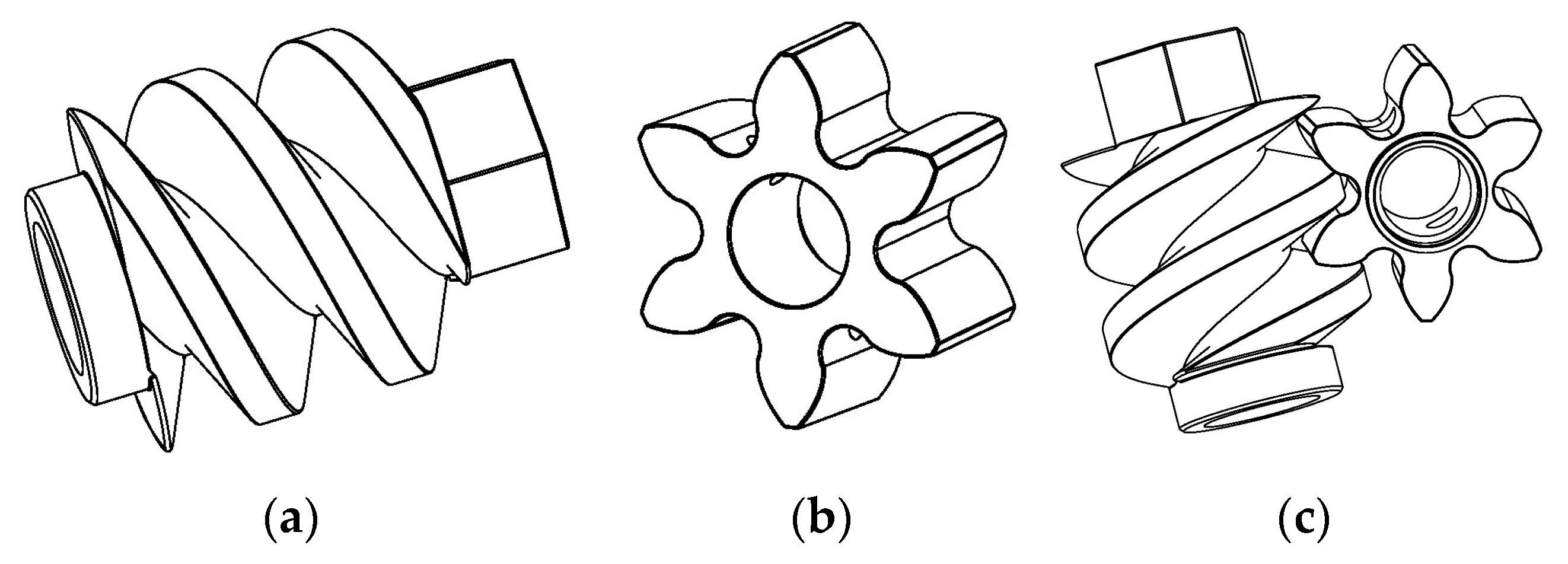

3. Design of the Transmission Structure of the Rope-Clamping Drive Mechanism in a Knotter with Double Synclastic Fluted Discs

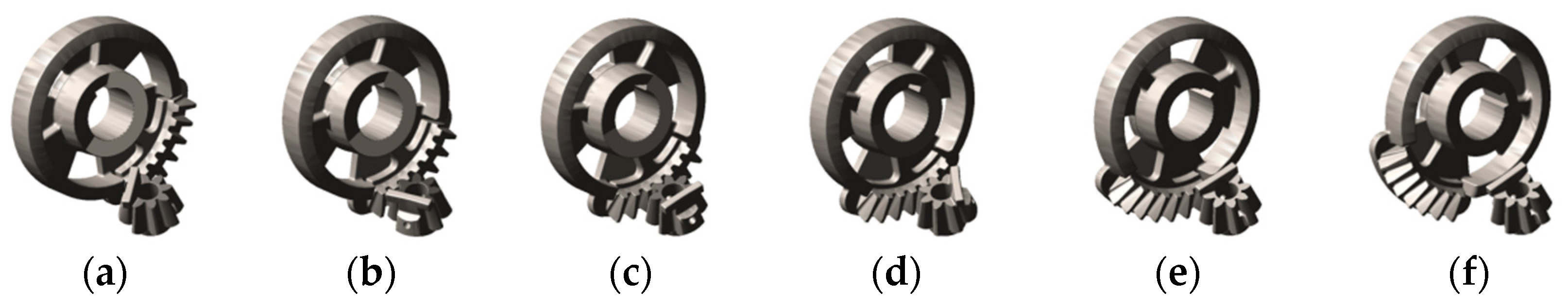

3.1. Design of Bevel Gear Transmission with Intersecting Axis Angle of 71°

3.2. Design of Worm Drive with Spatial Staggered Shaft Angle of 73°

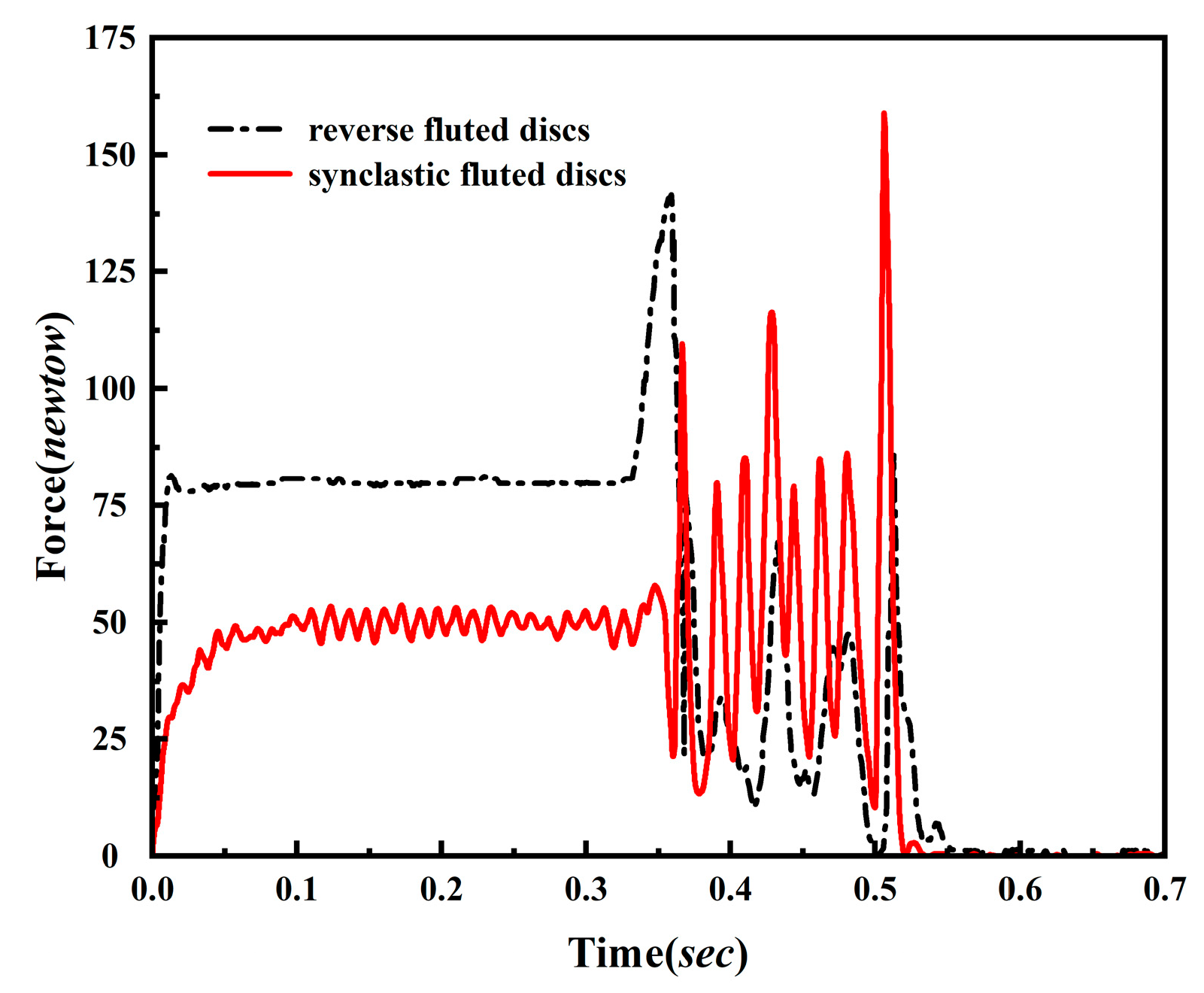

4. Dynamic Simulation of the Rope-Clamping Drive Mechanism

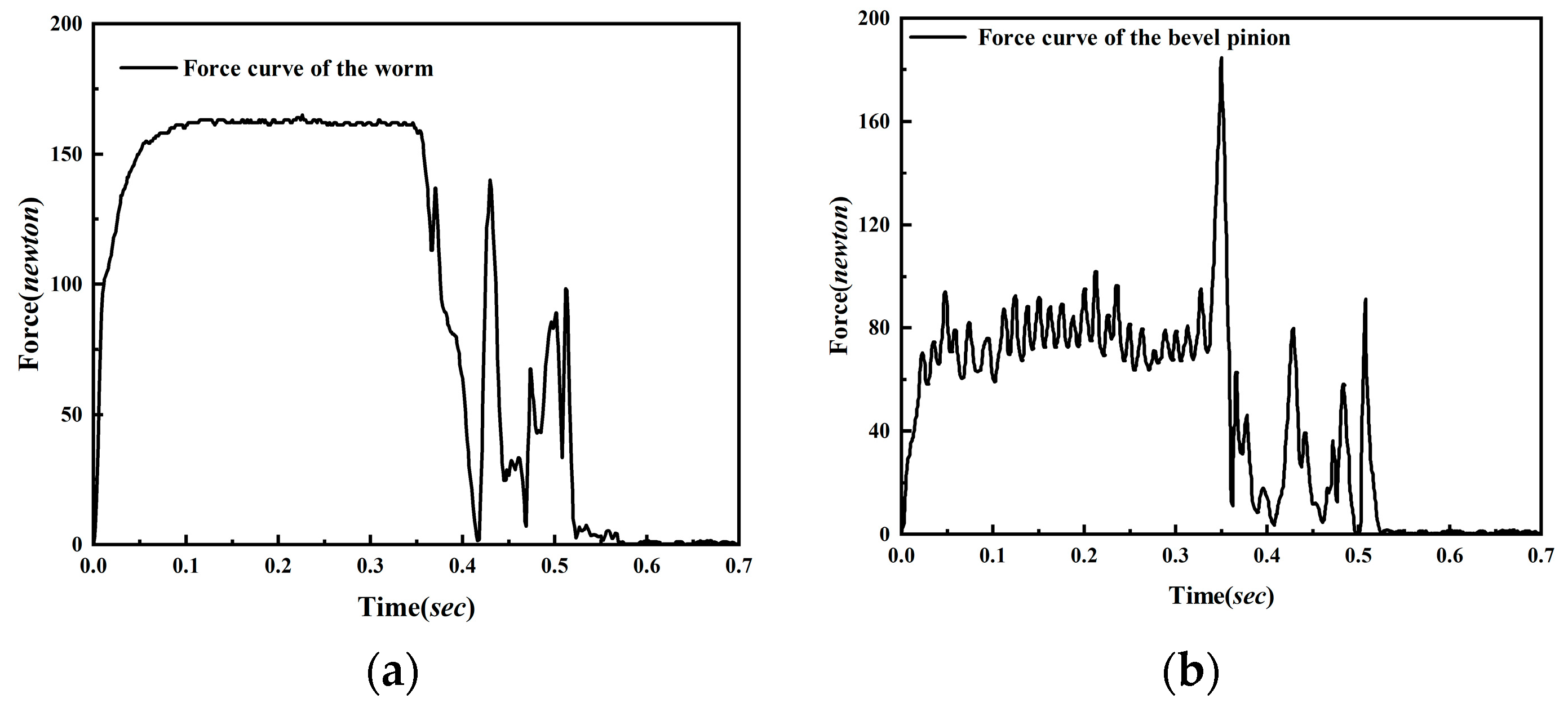

4.1. Simulation and Analysis of Incomplete Bevel Gear Transmission with Intersecting Axis Angle of 71°

4.2. Simulation and Analysis of Involute Worm Drive with Spatial Staggered Shaft Angle of 73°

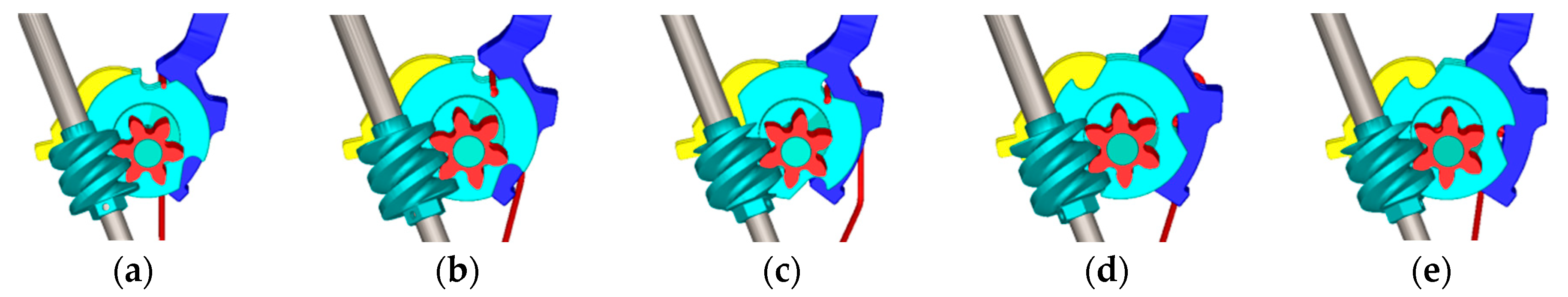

4.3. Virtual Simulation of the Rope-Clamping Drive Mechanism

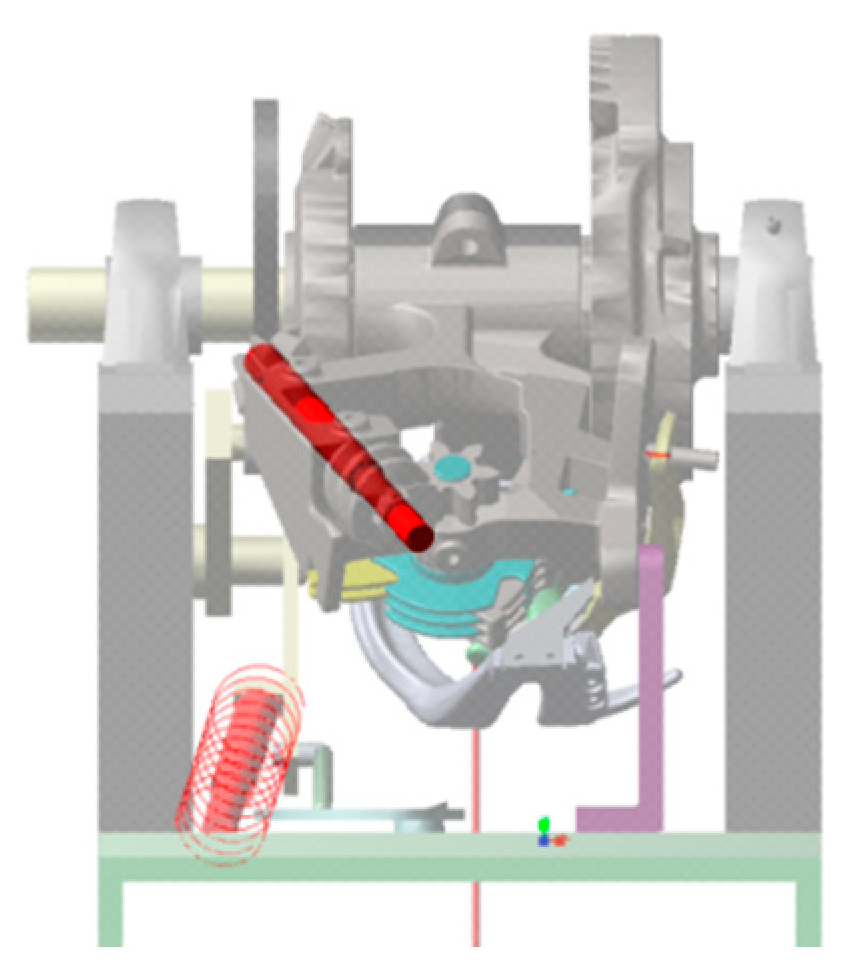

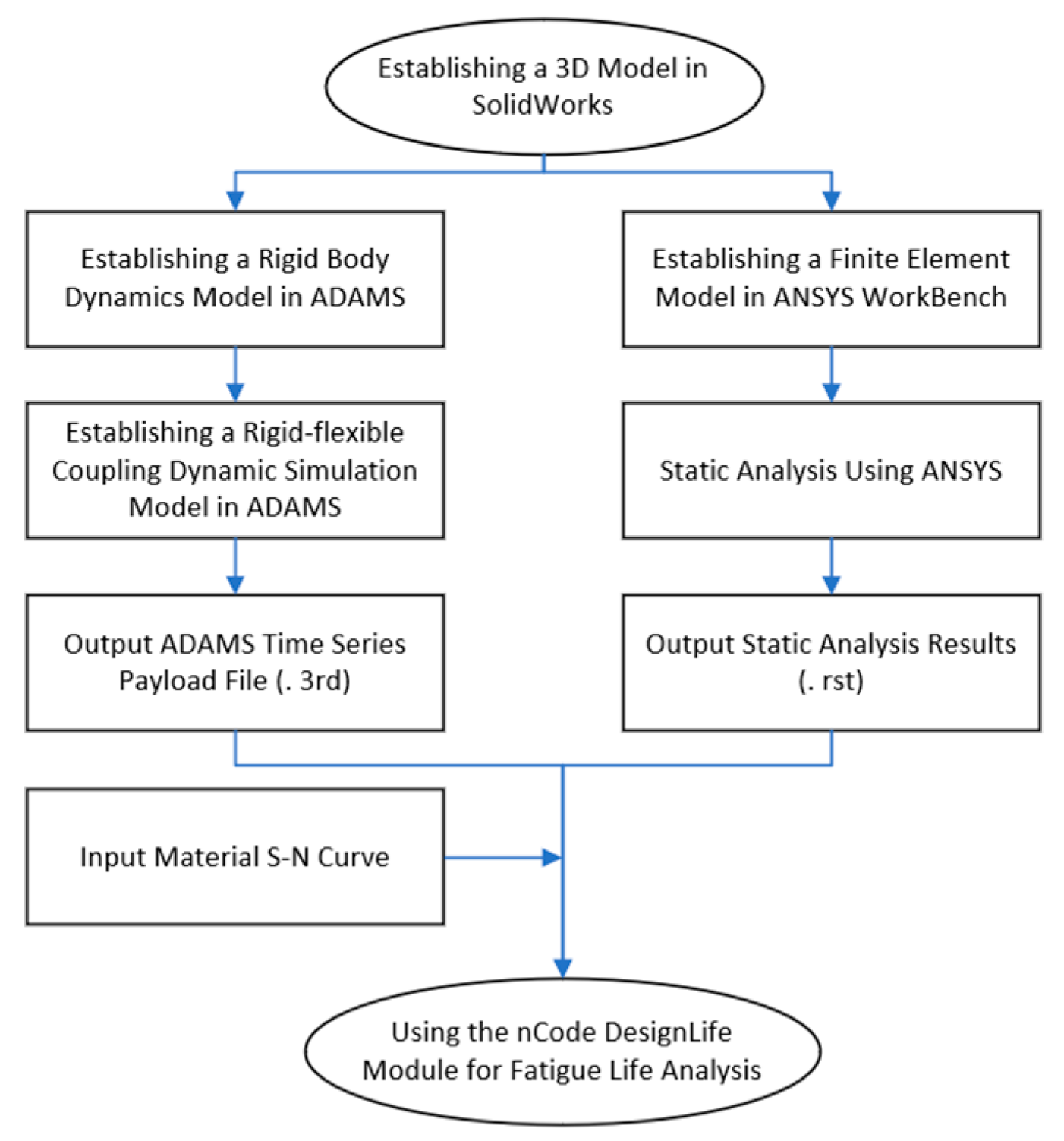

5. Simulation of Rigid–Flexible Coupling Dynamics and Fatigue Life of the Rope-Clamp Drive Mechanism Based on the Collaborative Simulation of ADAMS and ANSYS

5.1. Simulation of Rigid–Flexible Coupling Dynamics of the Rope-Clamping Drive Mechanism

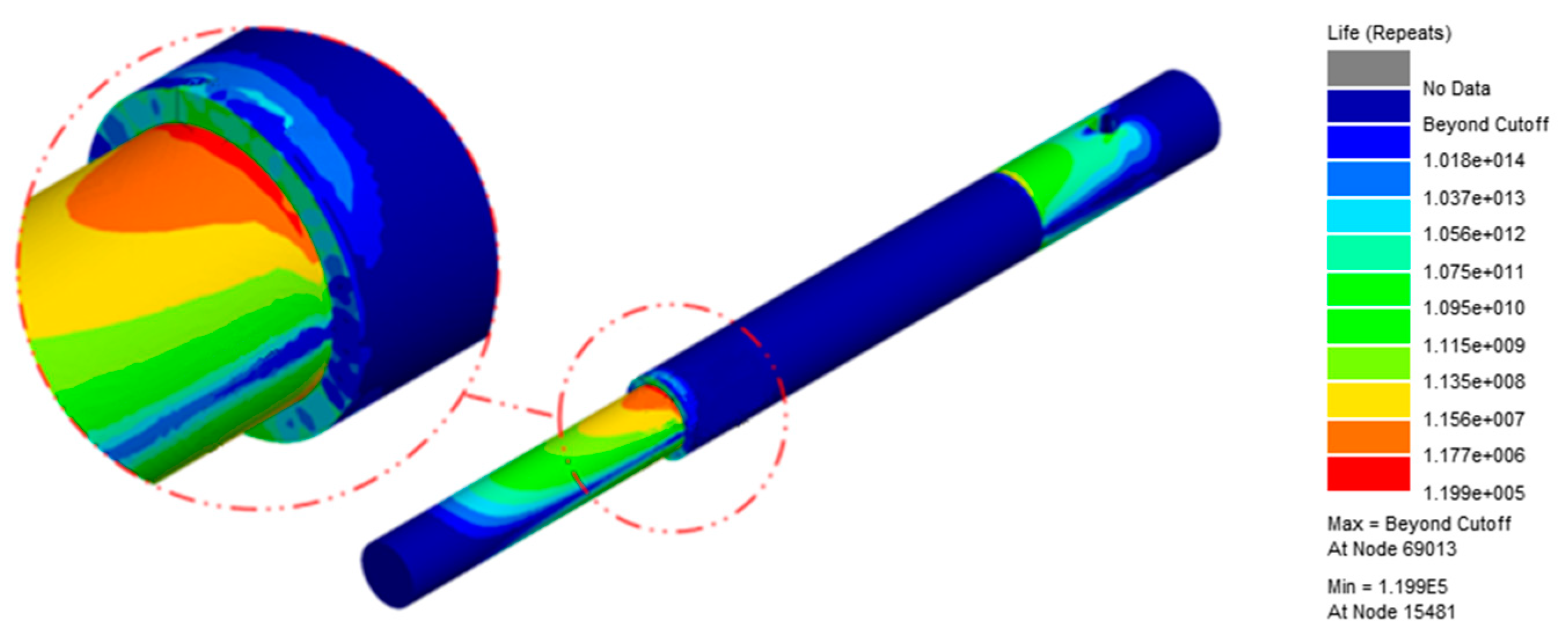

5.2. Simulation of the Fatigue Life of the Rope-Clamping Drive Mechanism

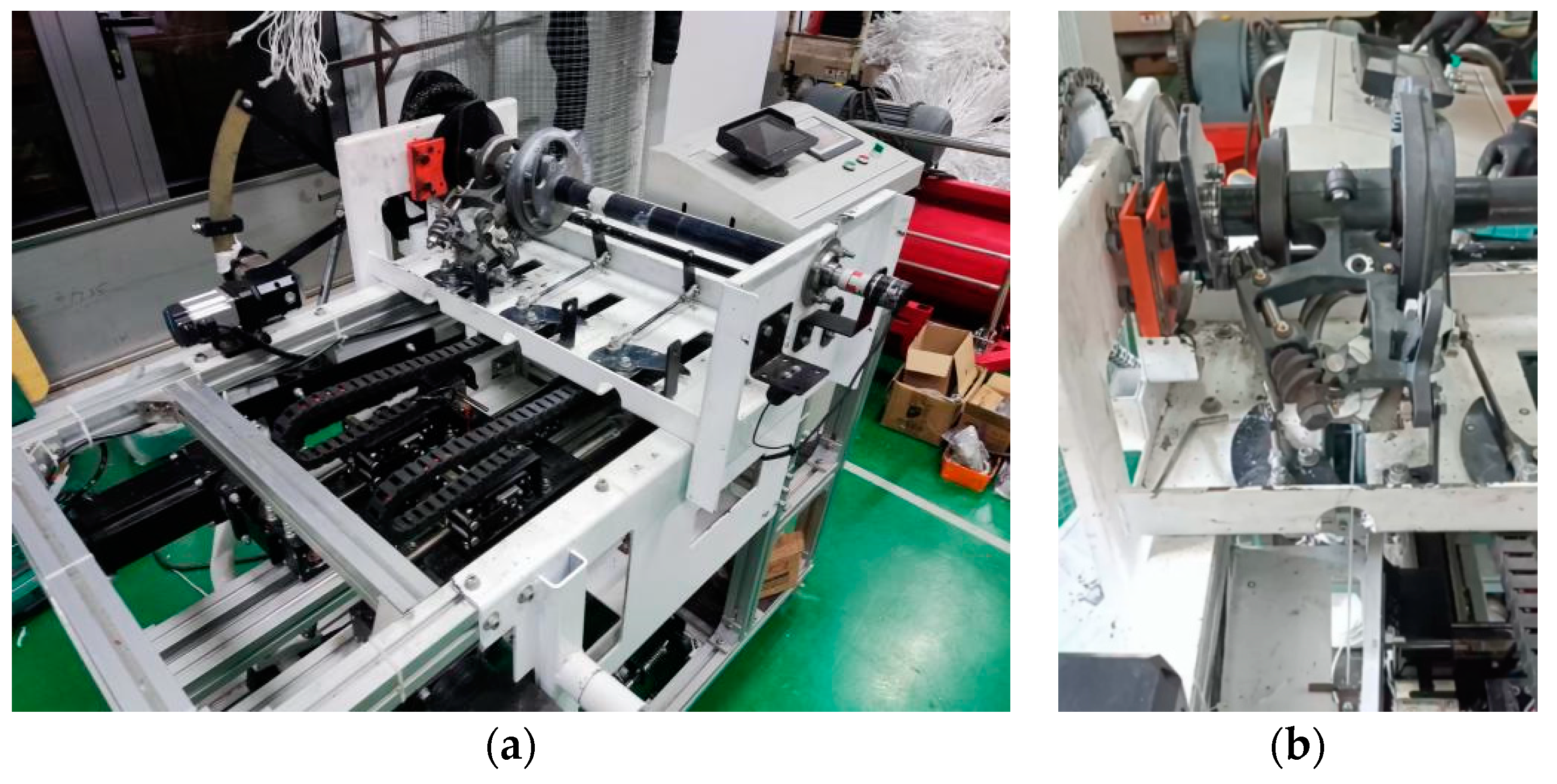

6. Reliability Test of the Rope-Clamping Drive Mechanism

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yin, J.J.; Zheng, J.; Wang, X.X.; Zhu, H. Analysis of Rope-twining Failure of Knotter Hook and Its Improved Design of Curved Surface Shape. Trans. Chin. Soc. Agric. Mach. 2018, 49, 82–89. [Google Scholar] [CrossRef]

- Huang, S.T.; Hu, C.; Lv, J.J.; Ma, L.; Ying, F. Key parameters of knotting process of new knot tying device. J. Mech. Electr. Eng. 2018, 3, 261–265. [Google Scholar]

- Yin, J.; Zhang, W.; Chen, Y.; Gao, Q. Design and Knotting Test Analysis of Knotter Driven by Double Gear-discs. Trans. Chin. Soc. Agric. Mach. 2016, 47, 98–105. [Google Scholar]

- Yu, X.; Chen, L.; Wu, M.; Zhang, J. Simulation and Experiment of D-bale Based on Multi-body Dynamics. Master’s Thesis, Anhui Agricultural University, Hefei, China, 2017. [Google Scholar]

- Zhang, A.; Chen, L.; Dong, H.; Zhang, S.; Li, H.; Han, L. Spatial Structure Parameter Analysis of Rope Cutting and Releasing Mechanism of D-knotter. Trans. Chin. Soc. Agric. Mach. 2017, 48, 73–80. [Google Scholar]

- Li, H.; Xiong, Y.; Chen, L.; Zhang, S.; Li, X.; Han, L. Wear Research and Improved Design of D-knotter Wiper Mechanism. Trans. Chin. Soc. Agric. Mach. 2015, 46, 118–124. [Google Scholar]

- Ma, W. Reliability Research on Knotter of Square Baler. Master’s Thesis, Inner Mongolia Agricultural University, Hohhot, China, 2021. [Google Scholar]

- Na, R.; Liu, Y. Random Vibration Analysis and Structural Optimization of the D-Knotter Frame. Comput. Simul. 2021, 38, 235–241. [Google Scholar]

- The Newfoundland circular knotter won the gold medal at the Edison Invention Award in 2021. Agric. Mach. 2021, 8, 36.

- Feuerborn, B. Krone Ballenpressen neuer Knoter ohne Schnipsel [EBOL]. 25 February 2022. Available online: https://www.agrarheute.com/technik/krone-ballenpressen-neuer-knoter-ohne-schnipsel-590703 (accessed on 20 October 2023). (In German).

- Shuang, Z.; Cen, H.T.; Si, X.K. Frame body structural design and modal analysis of D-type double knotter. J. Mach. Des. 2021, 38 (Suppl. S2), 118–122. [Google Scholar]

- Zhang, Y.; Zhu, L.Y.; Gou, X.F. Calculation methods of load distribution ratio for spiral bevel gear. Int. J. Mech. Sci. 2023, 257, 108531. [Google Scholar] [CrossRef]

- Song, C.S.; Zhu, C.C.; Lim, T.C.; Luo, J.Y.; Xu, X.Y. Time-varying mesh characteristics of beveloid gears with crossed axes and small shaft angle. J. Vib. Shock. 2012, 31, 153–157. [Google Scholar]

- Chen, Z.; Zhou, J.; Liu, B.; Fu, H.; Meng, X.; Ji, J.; Zhang, Y.; Hua, X.; Xu, X.; Fu, Y. Meshing frictional characteristics of spur gears under dry friction and heavy loads: Effects of the preset pitting-like micro-textures array. Tribol. Int. 2023, 180, 108296. [Google Scholar] [CrossRef]

- Ma, L.Z.; Xie, J.; Yin, X.Q. Principle and Design of Mechanism, 2nd ed.; China Machine Press: Beijing, China, 2015. [Google Scholar]

- Xu, X.Y.; Li, L.; Ren, B.; Zhu, C. Study on the Dynamic Characteristics of Herringbone Planetary Gear System with Space Shafts Angle. J. Mech. Eng. 2023, 59, 141–150. [Google Scholar] [CrossRef]

- Zhou, M.L.; Yang, J.J.; Xu, T.B.; Ying, J.; Wang, X. Optimal design of transplanting mechanism with differential internal engagement non-circular gear trains. J. Agric. Eng. 2022, 53, 1–10. [Google Scholar] [CrossRef]

- Guo, E.K.; Hu, L.L.; Zhang, E.Z.; Liu, C.; Xu, J.; He, W. A Cylindrical Skiving Tool Design Method Based on a Conjugate Surface for Internal Gear Manufacture. J. Manuf. Process. 2023, 101, 1538–1550. [Google Scholar] [CrossRef]

- Qiao, G.; Liao, R.; Guo, S.J.; Shi, Z.; Ma, S. Design and Dynamic Analysis of the Recirculating Planetary Roller Screw Mechanism. Chin. J. Mech. Eng. 2022, 35, 87. [Google Scholar] [CrossRef]

- Huang, J.C.; Tan, L.; Tian, K.P.; Zhang, B.; Ji, A.; Liu, H.; Shen, C. Formation mechanism for the laying angle of hemp harvester based on ANSYS-ADAMS. Int. J. Agric. Biol. Eng. 2023, 16, 109–115. [Google Scholar] [CrossRef]

- Li, X.F.; Wang, Y.B. Analysis of mixed model in gear transmission based on ADAMS. Chin. J. Mech. Eng. 2012, 25, 968–973. [Google Scholar] [CrossRef]

- Huang, T.; Zhao, J.X.; Song, K.X.; Zhang, X.; Jiang, Y.; Hao, L. Fatigue Life Research of Bellows under Coupled Loading of Velocity and External Pressure Based on S-N Curve of Components. J. Mech. Eng. 2022, 58, 269–282. [Google Scholar] [CrossRef]

- Fu, Q.; Wang, D.D.; Zhang, R.Y.; Lu, Y.; Wang, R.; Zhu, R. Stress Analysis and Stress Fatigue Life Prediction of Rcp Impeller Based on Fluid-thermal-solid Coupling. Nucl. Eng. Des. 2023, 414, 112596. [Google Scholar] [CrossRef]

- Li, F.Z.; Tong, S.G.; Wang, X.B.; Cheng, X.M. Rigid-flexible coupling dynamics and characteristics of marine excavator’s mechanical arm. J. Vib. Shock. 2014, 33, 157–163. [Google Scholar]

- Zheng, T.; Zhang, D.G. Limitations of MSC.ADAMS for High speed and Large Deformation Problems of Rigid flexible Coupling Systems. J. Nanjing Univ. Ence Technol. 2012, 36, 993–998. [Google Scholar]

- Wu, D.; Ding, D.; Cui, B.; Jiang, S.; Zhao, E.; Liu, Y.; Cao, C. Design and experiment of vibration plate type camellia fruit picking machine. Trans. Chin. Soc. Agric. Eng. 2022, 15, 130–138. [Google Scholar] [CrossRef]

| Theoretical Gear Teeth | Module (mm) | Pressure Angle α (°) | Pitch Angle δ (°) | Modification Coefficient x1 (mm) | |

|---|---|---|---|---|---|

| Bevel Pinion | 8 | 4 | 20 | 10.55 | 0.4396 |

| Bevel Gear | 38 | 60.45 | −0.4396 |

| Gear Teeth | Module (mm) | Normal Pressure Angle α (°) | Helix Angle β (°) | Lead Angle γ (°) | Modification Coefficient x2 (mm) | |

|---|---|---|---|---|---|---|

| Worm | 2 | 4.5 | 20 | 76.78 | 13.22 | −0.20 |

| Helical Gear | 6 | −3.78 | −86.22 | 0.20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, J.; Chen, Z.; Lv, S.; Wu, H.; Gao, Y.; Wu, L. Design and Fatigue Life Analysis of the Rope-Clamping Drive Mechanism in a Knotter. Agriculture 2024, 14, 1254. https://doi.org/10.3390/agriculture14081254

Yin J, Chen Z, Lv S, Wu H, Gao Y, Wu L. Design and Fatigue Life Analysis of the Rope-Clamping Drive Mechanism in a Knotter. Agriculture. 2024; 14(8):1254. https://doi.org/10.3390/agriculture14081254

Chicago/Turabian StyleYin, Jianjun, Zefu Chen, Shiyu Lv, Han Wu, Yansu Gao, and Luning Wu. 2024. "Design and Fatigue Life Analysis of the Rope-Clamping Drive Mechanism in a Knotter" Agriculture 14, no. 8: 1254. https://doi.org/10.3390/agriculture14081254

APA StyleYin, J., Chen, Z., Lv, S., Wu, H., Gao, Y., & Wu, L. (2024). Design and Fatigue Life Analysis of the Rope-Clamping Drive Mechanism in a Knotter. Agriculture, 14(8), 1254. https://doi.org/10.3390/agriculture14081254