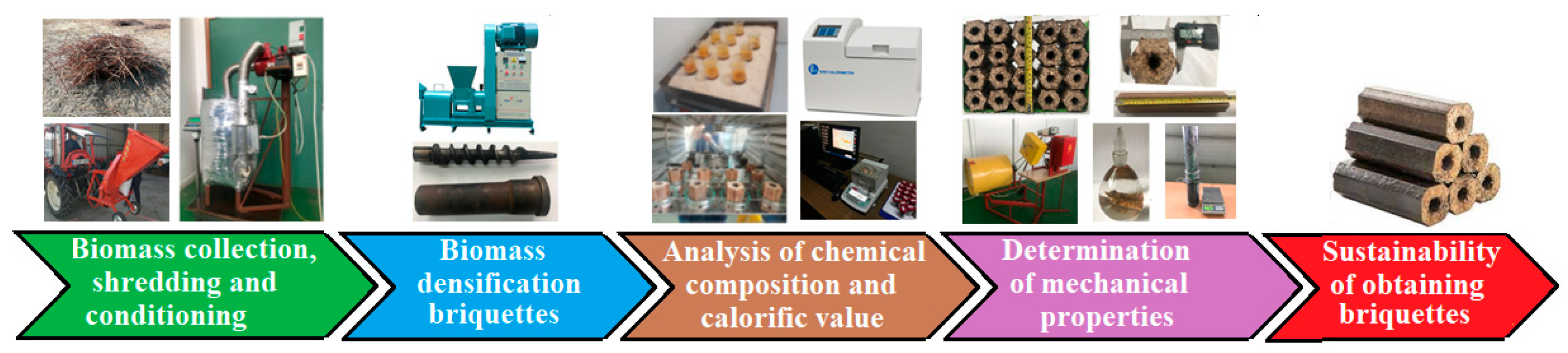

Briquette Production from Vineyard Winter Pruning Using Two Different Approaches

Abstract

1. Introduction

2. Materials and Methods

- Density: 4347 stumps/ha;

- Distance between rows: 2.3 m;

- Distance between the stumps on a row: 1.0 m.

2.1. Collection of the Vine Tendrils

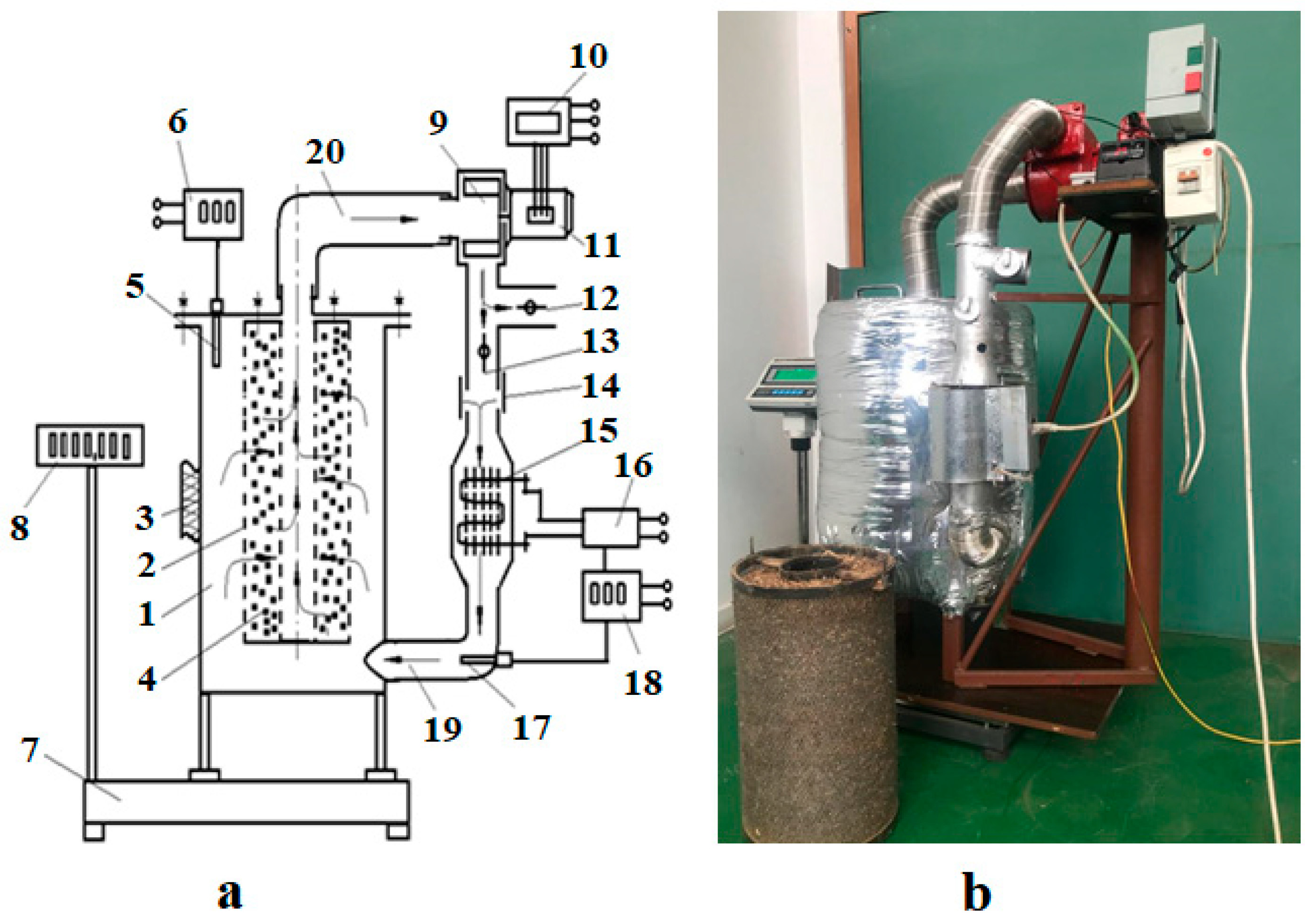

2.2. Drying of Biomass

2.3. Tendrils Shredding–Grinding

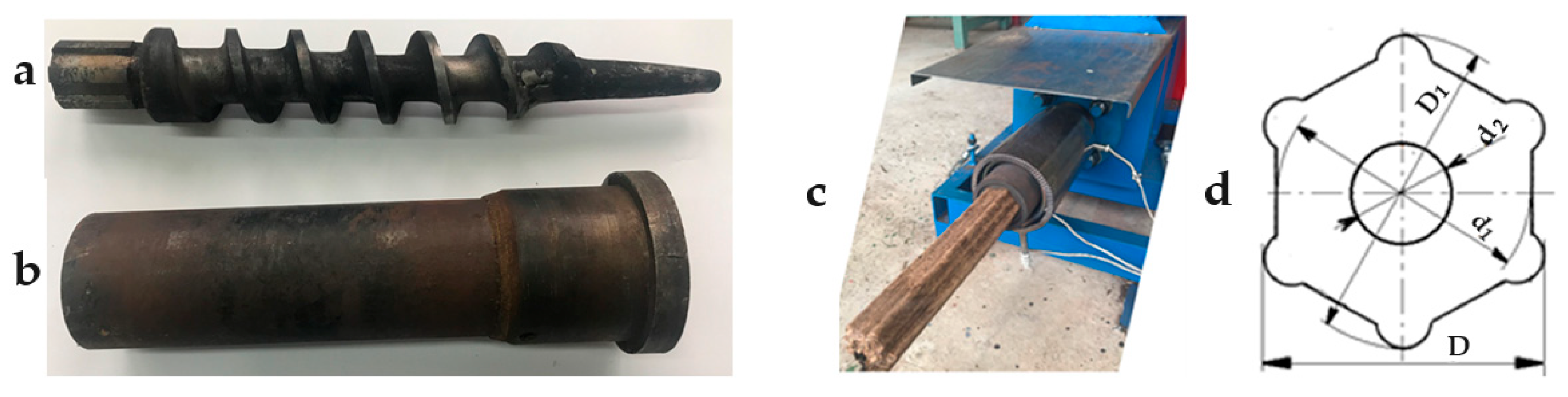

2.4. Densification of Biomass

2.5. Physical and Chemical Characterization of Briquettes

- Dimensions—the width and diameter were measured with a caliper for the smaller dimensions and with the measuring tape, for larger dimensions;

- Moisture ratio of the densified biomass—this was evaluated using the thermal balance method;

- Ash content and chemical composition (N, S, Cl, As, Cd, Cr, Cu, Pb, Hg, Ni, and Zn) for briquettes– measured according to the specifications of the ISO 16948 [39] for nitrogen; ISO 16994 [40] for Sulphur and chlorine; and ISO 16968 [41] for arsenic, cadmium, chrome, copper, mercury, nickel and zinc (analysis performed at ICIA branch in Cluj-Napoca, Romania);

- Unit density—a graduated cylinder (62 mm diameter, 440 mm high) and an electronic scale (precision 0.01 g) were used to measure the unit density; the cylinder, filled with 500 mL of water (ma) was weighted and the briquette was then immersed into the cylinder, measuring the volume of dislocated water (Va), and the overall mass of the cylinder (mb). The unit density was then calculated using the following relation [23]:

- Mechanical durability—this represents the property of densified biofuels to withstand shocks and wear during manipulation and/or transport, and was tested by subjecting the samples to controlled blows between the samples and with the walls of a rotating drum.

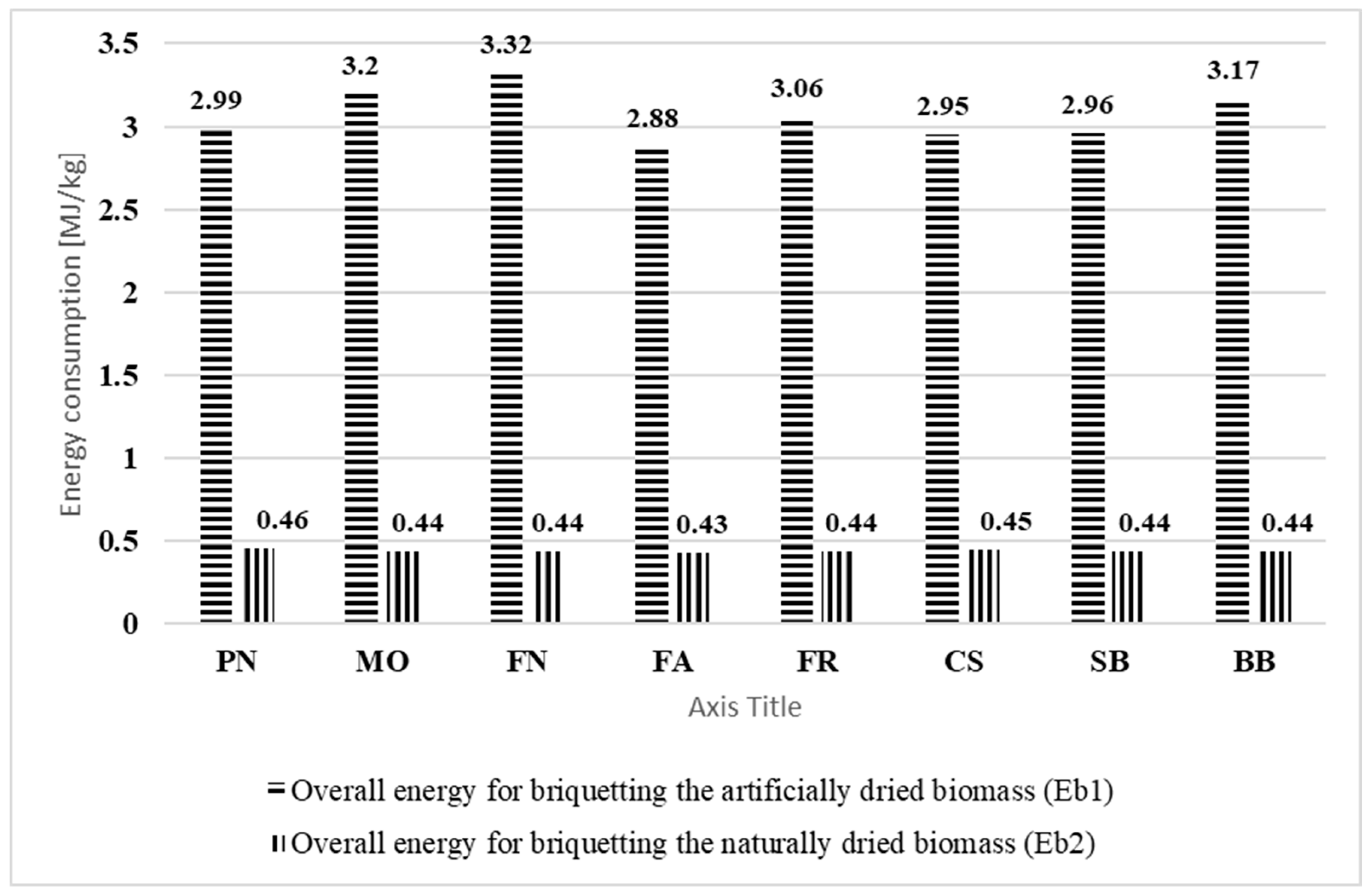

2.6. Evaluation of the Overall Energy Consumption for Producing the Briquettes

- For the artificial dried biomass:

- For the naturally dried biomass:

- Eb1 is the energy consumption for briquetting the artificially dried biomass (MJ/kg);

- Ebcg is the energy input for shredding the tendrils with a moisture ratio of 44–46% (MJ/kg);

- Ebd is the energy consumption for the artificial drying of biomass to a moisture ratio of 10–12% (MJ/kg);

- Ebm is the energy consumption for grinding the fractions bigger than 8 mm (MJ/kg);

- Ebs is the energy input for sieving the shredded biomass (MJ/kg);

- Eb is the energy consumption for briquetting the ground biomass (MJ/kg);

- Eb2 is the overall energy consumption for briquetting the naturally dried biomass (MJ/kg);

- Ebcd is the energy consumption for grinding the naturally dried tendrils (MJ/kg);

- kb1 și kb2 fractions referring to the biomass with particles bigger than 8 mm.

- For the artificial dried biomass:

- For the naturally dried biomass:

2.7. Statistical Analysis

3. Results and Discussion

3.1. Quantity of Biomass Collected from the Winter Pruning

3.2. Preparation of Biomass for Briquetting

3.3. Characteristics of the Briquettes Produced from Vine Tendrils

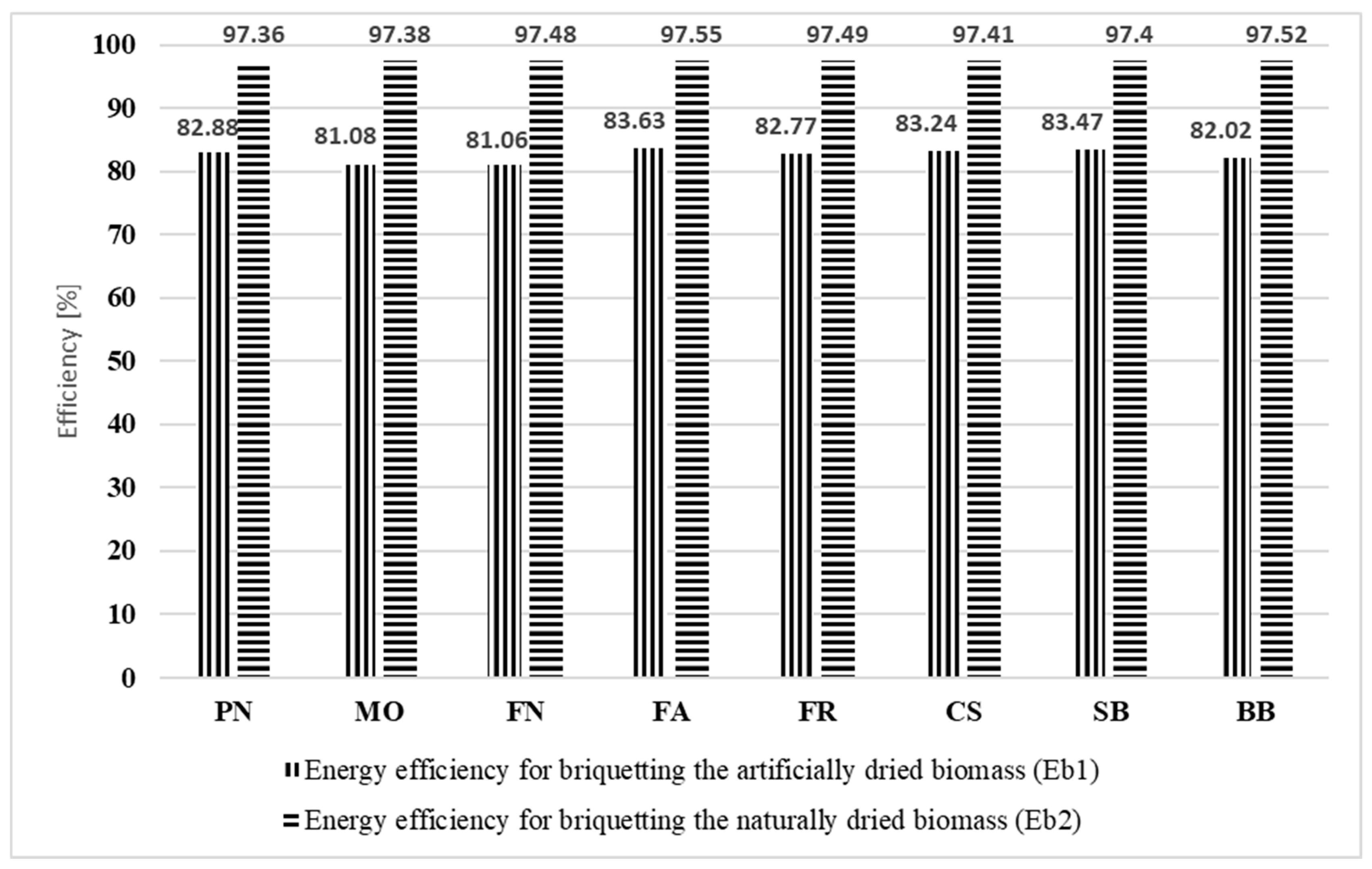

3.4. Energy Consumption and Energy Efficiency for Producing Briquettes from Vine Tendrils

3.5. Multivariate Analysis

4. Conclusions

- The average quantity of dried biomass (12% moisture ratio) exceeded 1000 kg/ha;

- The lower calorific value of the briquettes from vine tendrils is over 17 MJ/kg;

- The unit density of the produced Pini-kay-type briquettes is over 1330 kg/m3;

- The dimensions of the briquettes are within the limits imposed by the international standards;

- The chemical composition of the briquettes is within the limits imposed by the ISO 17225-3 standard [26] for Class A1, A2, and B1 briquettes for most parameters; however, the values for chrome, copper, and cadmium exceed the maximum limits imposed by the standard;

- The overall energy consumption in producing briquettes is mainly affected by the drying method: forced convection requires a significantly higher energy consumption for reducing the moisture ratio from 44% to 12% in comparison with natural convection;

- Artificial drying leads to an average energy efficiency of 82.52%, while a higher average efficiency (97.45%) was obtained for the natural drying of biomass.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Sarker, T.R.; Nanda, S.; Meda, V.; Dalai, A.K. Densification of waste biomass for manufacturing solid biofuel pellets: A review. Environ. Chem. Lett. 2023, 21, 231–264. [Google Scholar] [CrossRef]

- Kpalo, S.Y.; Zainuddin, M.F.; Manaf, L.A.; Roslan, A.M. A Review of Technical and Economic Aspects of Biomass Briquetting. Sustainability 2020, 12, 4609. [Google Scholar] [CrossRef]

- Tkemaladze, G.S.; Makhashvili, K.A. Climate changes and photosynthesis. Ann. Agrar. Sci. 2016, 14, 119–126. [Google Scholar] [CrossRef]

- Kaltschmitt, M. Renewable energy from biomass, Introduction. In Renewable Energy Systems; Kaltschmitt, M., Themelis, N.J., Bronicki, L.Y., Söder, L., Vega, L.A., Eds.; Springer: New York, NY, USA, 2013; pp. 45–71. [Google Scholar]

- Tursi, A. A review on biomass: Importance, chemistry, classification, and conversion. Biofuel Res. J. 2019, 6, 962–979. [Google Scholar] [CrossRef]

- Parmar, K. Biomass. An overview on composition characteristics and properties. IRA-Int. J. Appl. Sci. 2017, 7, 42–51. [Google Scholar] [CrossRef]

- Kalak, T. Potential Use of Industrial Biomass Waste as a Sustainable Energy Source in the Future. Energies 2023, 16, 1783. [Google Scholar] [CrossRef]

- Watts, N.; Amann, M.; Ayeb-Karlsson, S.; Berry, H.; Boykoff, M.; Montgomery, H.; Costello, A. The 2018 report of the Lancet Countdown on health and climate change: Shaping the health of nations for centuries to come. Lancet 2018, 392, 2479–2514. [Google Scholar] [CrossRef] [PubMed]

- Dilpreet, S.B.; Tyler, P.; Neeta, S.; Jamileh, S.; Sreekala, G.B. A review of densified solid biomass for energy production. Renew. Sustain. Energy Rev. 2018, 96, 296–305. [Google Scholar] [CrossRef]

- Liu, T.; McConkey, V.; Huffman, V.; Smith, S.; MacGregor, B.; Yemshanov, D.; Kulshreshtha, S. Potential and impacts of renewable energy production from agricultural biomass in Canada. Appl. Energy 2014, 130, 222–229. [Google Scholar] [CrossRef]

- Anenberg, S.C.; Balakrishnan, K.; Jetter, J.; Masera, O.; Mehta, S.; Moss, J.; Ramanathan, V. Cleaner Cooking Solutions to Achieve Health, Climate, and Economic Cobenefits. Environ. Sci. Technol. 2013, 47, 3944–3952. [Google Scholar] [CrossRef]

- Ibitoye, S.E.; Jen, T.C.; Mahamood, R.M.; Akinlabi, E.T. Densification of agro-residues for sustainable energy generation: An overview. Bioresour. Bioprocess. 2021, 8, 75. [Google Scholar] [CrossRef] [PubMed]

- Wei, M.; Ma, T.; Ge, Q.; Li, C.; Zhang, K.; Fang, Y.; Sun, X. Challenges and opportunities of winter vine pruning for global grape and wine industries. J. Clean. Prod. 2022, 380, 135086. [Google Scholar] [CrossRef]

- Scarlat, N.; Blujdea, V.; Dallemand, J. Assessment of the availability of agricultural and forest residues for bioenergy production in Romania. Biomass Bioenergy 2011, 35, 1995–2005. [Google Scholar] [CrossRef]

- Senila, L.; Ţenu, I.; Carlescu, P.; Corduneanu, O.R.; Dumitrachi, E.P.; Kovacs, E.; Scurtu, D.A.; Cadar, O.; Becze, A.; Senila, M.; et al. Sustainable Biomass Pellets Production Using Vineyard Wastes. Agriculture 2020, 10, 501. [Google Scholar] [CrossRef]

- Jeguirim, M.; Khiari, B. Chapter 11—Solid biofuels production and combustion at domestic scales. In Advances in Biofuels Production, Optimization and Applications; Jeguirim, M., Zorpas, A.A., Eds.; Elsevier: Amsterdam, The Netherlands, 2024; pp. 207–239. ISBN 9780323950763. [Google Scholar] [CrossRef]

- Eling, J.; Okot, D.K.; Menya, E.; Atim, M.R. Densification of raw and torrefied biomass: A review. Biomass Bioenergy 2024, 184, 107210. [Google Scholar] [CrossRef]

- Gong, C.; Meng, X.; Thygesen, L.G.; Sheng, K.; Pu, Y.; Wang, L.; Ragauskas, A.; Zhang, X.; Thomsen, S.T. The significance of biomass densification in biological-based biorefineries: A critical review. Renew. Sustain. Energy Rev. 2023, 183, 113520. [Google Scholar] [CrossRef]

- Stelte, W.; Sanadi, A.R.; Shang, L.; Holm, J.K.; Ahrenfeldt, J.; Henriksen, U.B. Recent developments in biomass pelletization—A review. Bioresources 2012, 7, 4451–4490. [Google Scholar] [CrossRef]

- Priyabrata, P.; Amit, A.; Sanjay, M.M. Pilot scale evaluation of fuel pellets production from garden waste biomass. Energy Sustain. Dev. 2018, 43, 1–14. [Google Scholar] [CrossRef]

- Dragusanu, V.; Lunguleasa, A.; Spirchez, C.; Scriba, C. Some Properties of Briquettes and Pellets Obtained from the Biomass of Energetic Willow (Salix viminalis L.) in Comparison with Those from Oak (Quercus robur). Forests 2023, 14, 1134. [Google Scholar] [CrossRef]

- Ţenu, I.; Roman, C.; Senila, L.; Roşca, R.; Cârlescu, P.; Băetu, M.; Arsenoaia, V.; Dumitrachi, E.P.; Corduneanu, O.-R. Valorization of Vine Tendrils Resulted from Pruning as Densified Solid Biomass Fuel (Briquettes). Processes 2021, 9, 1409. [Google Scholar] [CrossRef]

- Zardzewiały, M.; Bajcar, M.; Saletnik, B.; Puchalski, C.; Gorzelany, J. Biomass from Green Areas and Its Use for Energy Purposes. Appl. Sci. 2023, 13, 6517. [Google Scholar] [CrossRef]

- Polonini, L.F.; Petrocelli, D.; Lezzi, A.M. The Effect of Flue Gas Recirculation on CO, PM and NOx Emissions in Pellet Stove Combustion. Energies 2023, 16, 954. [Google Scholar] [CrossRef]

- Giorio, C.; Pizzini, S.; Marchiori, E.; Piazza, R.; Grigolato, S.; Zanetti, M.; Cavalli, R.; Simoncin, M.; Soldà, L.; Badocco, D.; et al. Sustainability of using vineyard pruning residues as an energy source: Combustion performances and environmental impact. Fuel 2019, 243, 371–380. [Google Scholar] [CrossRef]

- ISO 17225-3:2021; Solid Biofuels. Fuel Specifications and Classes—Part 3: Graded Wood Briquettes. ISO: Geneva, Switzerland, 2021.

- Waheed, M.A.; Akogun, O.A.; Enweremadu, C.C. An overview of torrefied bioresource briquettes: Quality-influencing parameters, enhancement through torrefaction and applications. Bioresour. Bioprocess. 2022, 9, 122. [Google Scholar] [CrossRef]

- Xie, F.; Liu, Y.; Guan, F.; Wang, N. How to coordinate the relationship between renewable energy consumption and green economic development: From the perspective of technological advancement. Environ. Sci. Eur. 2020, 32, 71. [Google Scholar] [CrossRef]

- Petković, D. Technology for Producing Briquettes from Wet Biomass. In Encyclopedia of Renewable and Sustainable Materials; Hashmi, S., Choudhury, I.A., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; Volume 1, pp. 901–907. ISBN 9780128131961. [Google Scholar] [CrossRef]

- Thornley, P.; Rogers, J.; Huang, Y. Quantification of employment from biomass power plants. Renew. Energy 2008, 33, 1922–1927. [Google Scholar] [CrossRef]

- Saidur, R.; Abdelaziz, E.A.; Demirbas, A.; Hossain, M.S.; Mekhilef, S. A review on biomass as a fuel for boilers. Renew. Sustain. Energy Rev. 2011, 15, 2262–2289. [Google Scholar] [CrossRef]

- Moura, P.; Henriques, J.; Alexandre, J.; Oliveira, A.C.; Abreu, M.; Gírio, F.; Catarino, J. Sustainable value methodology to compare the performance of conversion technologies for the production of electricity and heat, energy vectors and biofuels from waste biomass. Clean. Waste Syst. 2022, 3, 100029. [Google Scholar] [CrossRef]

- Sassine, Y.N.; Nabhan, S.; Rachkidy, E.; Sebaaly, Z. Valorization of agro-forest wastes (oak acorns, vineyard pruning, and olive pruning) through the cultivation of shiitake (Lentinula edodes) mushrooms. Helyion 2024, 10, e32562. [Google Scholar] [CrossRef]

- Tascione, V.; Raggi, A.; Petti, L.; Manca, G. Evaluating the environmental impacts of smart vineyards through the Life Cycle Assessment. Sci. Total Environ. 2024, 922, 171240. [Google Scholar] [CrossRef] [PubMed]

- Postawa, K.; Klimek, K.; Maj, G.; Kapłan, M.; Szczygieł, J. Advanced dual-artificial neural network system for biomass combustion analysis and emission minimization. J. Environ. Manag. 2024, 349, 119543. [Google Scholar] [CrossRef] [PubMed]

- Imberti, R.M.; Padilha, J.C.; Arrieche, L.d.S. Production of sawdust and chicken fat briquettes as an alternative solid fuel. Renew. Energy 2024, 228, 120638. [Google Scholar] [CrossRef]

- Rath, D.P.; Mahapatro, A.; Pattanayak, B. Briquette production and performance evaluation from coal and agricultural waste. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Senila, L.; Ţenu, I.; Cârlescu, P.; Scurtu, D.A.; Kovacs, E.; Senila, M.; Cadar, O.; Roman, M.; Dumitras, D.E.; Roman, C. Characterization of biobriquettes produced from vineyard wastes as a solid biofuel resource. Agriculture 2022, 12, 341. [Google Scholar] [CrossRef]

- ISO 16948:2015; Solid Biofuels. Determination of Total Content of Carbon, Hydrogen and Nitrogen. ISO: Geneva, Switzerland, 2015.

- ISO 16994:2016; Solid Biofuel. Determination of Total Content of Sulphur and Chlorine. ISO: Geneva, Switzerland, 2016.

- ISO 16968:2015; Solid Biofuels. Determination of Minor Elements. ISO: Geneva, Switzerland, 2015.

- ISO 17831-2:2015; Solid Biofuels. Determination of Mechanical Durability of Pellets and Briquettes. ISO: Geneva, Switzerland, 2015.

- ISO 17827-1:2024; Solid Biofuel. Determination of Particle Size Distribution for Uncompressed Fuels. Part 1: Oscillating Screen Method Using Sieves with Apertures of 3,15 mm and Above. ISO: Geneva, Switzerland, 2024.

- ISO 17827-2:2024; Solid Biofuel. Determination of Particle Size Distribution for Uncompressed Fuels. Part 2: Vibrating Screen Method Using Sieves with Apertures of 3,15 mm and Below. ISO: Geneva, Switzerland, 2024.

- ISO 18847:2024; Solid Biofuels — Determination of Particle Density of Pellets and Briquettes. ISO: Geneva, Switzerland, 2024.

- Țenu, I.; Roșca, R.; Cârlescu, P.; Cecilia, R.; Senila, L.; Arsenoaia, V.; Corduneanu, O. Researches regarding the evaluation of energy consumption for the manufacturing of pellets from vine pruning residues. In Proceedings of the Engineering for Rural Development Conference, Jelgava, Latvia, 20–22 May 2020; pp. 54–62. [Google Scholar] [CrossRef]

- Spinelli, R.; Magagnotti, N.; Nati, C. Harvesting vineyard pruning residues for energy use. Biosyst. Eng. 2010, 105, 16–322. [Google Scholar] [CrossRef]

- Marian, G.; Ianus, G.; Istrate, B.; Banari, A.; Nazar, B.; Munteanu, C.; Malutan, T.; Daraduda, N.; Paleu, V. Evaluation of Agricultural Residues as Organic Green Energy Source Based on Seabuckthorn, Blackberry, and Straw Blends. Agronomy 2022, 12, 2018. [Google Scholar] [CrossRef]

- Ramírez-Gómez, Á.; Gallego, E.; Fuentes, J.M.; González-Montellano, C.; Ayuga, F. Values for particle-scale properties of biomass briquettes made from agroforestry residues. Particuology 2014, 12, 100–106. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Yancey, N.A.; Kane, J.J. Pilot-scale grinding and briquetting studies on variable moisture content municipal solid waste bales—Impact on physical properties, chemical composition, and calorific value. Waste Manag. 2021, 125, 316–327. [Google Scholar] [CrossRef]

- Spinelli, R.; Nati, C.; Pari, L.; Mescalchin, E.; Magagnotti, N. Production and quality of biomass fuels from mechanized collection and processing of vineyard pruning residues. Appl. Energy 2012, 89, 374–379. [Google Scholar] [CrossRef]

- Nattassha, R.; Handayati, Y.; Simatupang, T.M.; Siallagan, M. Understanding Circular Economy Implementation in the Agri-Food Supply Chain: The Case of an Indonesian Organic Fertiliser Producer. Agric. Food Secur. 2020, 9, 10. [Google Scholar] [CrossRef]

| Specification | Variety | |||||||

|---|---|---|---|---|---|---|---|---|

| PN | MO | FN | FA | FR | CS | SB | BB | |

| Average quantity of tendrils/stump [kg/stump] | 0.420 ab | 0.433 a | 0.367 ab | 0.347 ab | 0.343 ab | 0.327 b | 0.370 ab | 0.332 ab |

| Quantity of biomass at the initial moisture ratio [kg/ha] | 1825.7 ab | 1882.2 a | 1595.3 ab | 1508.4 ab | 1491.0 ab | 1421.4 b | 1608.4 ab | 1443.2 ab |

| Initial moisture ratio of tendrils [%] | 43.86 a | 45.45 a | 47.47 a | 41.87 a | 44.25 a | 42.37 a | 42.71 a | 45.02 a |

| Quantity of biomass at a 12% moisture ratio [kg/ha] | 1244.0 a | 1250.8 a | 1029.4 ab | 907.0 b | 1010.1 ab | 961.3 ab | 1121.5 ab | 966.6 ab |

| Vine Variety | Status of Biomass | Operation | >8 mm (%) | 8–3.15 mm (%) | ˂3.15 mm (%) |

|---|---|---|---|---|---|

| PN | wet | Shredding | 62.30 | 36.89 | 0.81 |

| dry | Shredding | 51.6 | 46.80 | 1.60 | |

| dry | Grinding | - | 96.22 | 3.78 | |

| MO | wet | Shredding | 62.91 | 36.23 | 0.86 |

| dry | Shredding | 52.35 | 45.78 | 1.87 | |

| dry | Grinding | - | 96.38 | 3.62 | |

| FN | wet | Shredding | 62.23 | 36.9 | 0.87 |

| dry | Shredding | 51.05 | 47.22 | 1.73 | |

| dry | Grinding | - | 96.82 | 3.18 | |

| FA | wet | Shredding | 61.48 | 37.67 | 0.85 |

| dry | Shredding | 50.61 | 47.27 | 2.12 | |

| dry | Grinding | - | 96.34 | 3.66 | |

| FR | wet | Shredding | 62.83 | 36.34 | 0.83 |

| dry | Shredding | 52.41 | 46.07 | 1.52 | |

| dry | Grinding | - | 96.04 | 3.96 | |

| CS | wet | Shredding | 63.39 | 35.79 | 0.82 |

| dry | Shredding | 52.63 | 46.05 | 1.32 | |

| dry | Grinding | - | 97.03 | 2.97 | |

| SB | wet | Shredding | 62.48 | 36.68 | 0.84 |

| dry | Shredding | 51.42 | 46.5 | 2.08 | |

| dry | Grinding | - | 96.33 | 3.67 | |

| BB | wet | Shredding | 60.89 | 38.28 | 0.83 |

| dry | Shredding | 49.06 | 48.96 | 1.98 | |

| dry | Grinding | - | 96.54 | 3.46 |

| Parameter | Variety * | |||||||

|---|---|---|---|---|---|---|---|---|

| BB | CS | FA | FN | FR | MO | PN | SB | |

| Diameter (D) [mm] | 49 ± 0.34 *a | 49 ± 0.72 *a | 49 ± 0.53 *a | 49 ± 0.45 *a | 49 ± 0.62 *a | 49 ± 0.36 *a | 49 ± 0.28 *a | 49 ± 0.83 *a |

| Length (L) [mm] | 200 ± 2.5 *a | 200 ± 1.8 *a | 200 ± 1.6 *a | 200 ± 1.7 *a | 200 ± 1.8 *a | 200 ± 1.5 *a | 200 ± 2.0 *a | 200 ± 2.0 *a |

| Moisture ratio [%] | 8.20 ± 0.1 *a | 7.86 ± 0.2 *a | 8.01 ± 0.1 *a | 7.78 ± 0.1 *a | 8.07 ± 0.1 *a | 7.89 ± 0.1 *a | 8.02 ± 0.2 *a | 8.18 ± 0.1 *a |

| Ash content [%] | 2.68± 0.04 **a | 3.05± 0.04 ***a | 3.08± 0.02 ***a | 3.27± 0.03 ***a | 2.99± 0.05 **a | 2.09± 0.04 **a | 3.18 ± 0.02 ***a | 3.05± 0.03 ***ab |

| Density [kg/cm] | 1349.0 *a | 1362.5 *a | 1227.0 *a | 1334.0 *a | 1310.3 *a | 1389.0 *a | 1312.0 *a | 1370.3 *a |

| Additives | - | - | - | - | - | - | - | - |

| Lower calorific value, Q [MJ/kg] | 17.71 ± 1.1 *a | 17.61 ± 1.2 *a | 17.62 ± 0.9 *a | 17.62 ± 1.1 *a | 17.77 ± 1.3 *a | 16.92 ± 1.2 *a | 17.45 ± 1.1 *a | 17.94 ± 1.1 *a |

| Nitrogen, N [%] | 0.95± 0.06 ***a | 0.93± 0.08 ***a | 0.76± 0.03 ***a | 1.15± 0.04 ***a | 0.91± 0.02 ***a | 0.86± 0.02 ***a | 0.94± 0.05 ***a | 0.99± 0.07 ***a |

| Sulphur, S [%] | 0.041± 0.01 ***a | 0.037± 0.01 *a | 0.038± 0.01 *a | 0.042± 0.01 ***a | 0.037± 0.01 *a | 0.036± 0.01 *a | 0.033± 0.01 *a | 0.044± 0.01 ***a |

| Chlorine, Cl [%] | 0.07± 0.01 IVab | 0.06± 0.01 IVc | 0.05± 0.02 ***a | 0.07± 0.01 IVbc | 0.06± 0.01 IVab | 0.04± 0.01 ***ab | 0.06± 0.01 IVab | 0.07± 0.01 IVa |

| Arsenic, Ar [mg/kg] | 0.09± 0.01 *ab | 0.13± 0.01 *bc | 0.14± 0.1 *ab | 0.15± 0.01 *ab | 0.16± 0.01 *a | 0.12± 0.1 *ab | 0.15± 0.01 *ab | 0.16± 0.01 *c |

| Cadmium, Cd [mg/kg] | 2.78± 0.3 IVa | 2.89± 0.5 IVa | 2.78± 0.1 IVa | 2.89± 0.4 IVa | 2.84± 0.4 IVa | 2.78± 0.3 IVa | 2.85± 0.2 IVa | 2.80± 0.4 IVa |

| Chromium, Cr [mg/kg] | 11.6± 1.2 IVa | 11.5± 1.0 IVa | 12.3± 1.3 IVa | 11.5± 1.0 IVa | 11.5± 0.9 IVa | 11.3± 1.0 IVa | 11.4 ± 1.2 IVa | 11.9± 1.1 IVa |

| Copper, Cu [mg/kg] | 23.8± 1.4 IVa | 23.4± 1.6 IVa | 22.7± 1.1 IVa | 25.1± 1.3 IVa | 23.9± 1.0 IVa | 22.3± 1.5 IVa | 25.2± 1.2 IVa | 23.1± 1.5 IVa |

| Lead, Pb [mg/kg] | 11.8± 0.6 IVa | 10.0± 0.8 *a | 11.0± 0.3 IVa | 10.2± 0.9 IVa | 10.0± 0.2 *a | 9.83± 0.6 *a | 9.80± 0.9 *a | 9.98± 0.7 *a |

| Mercury, Hg [mg/kg] | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 |

| Nickel, Ni [mg/kg] | 9.74± 0.3 *a | 9.81 ± 0.7 *a | 9.99 ± 0.5 *a | 10.0 ± 0.6 *a | 9.86 ± 0.3 *a | 9.7 ± 0.5 *a | 10.0± 0.6 *a | 9.73 ± 0.44 *a |

| Zinc, Zn [mg/kg] | 16.25± 1.8 *bc | 11.0± 0.8 *e | 23.6± 1.8 *ab | 22.3± 1.2 *a | 12.8± 1.9 *de | 9.6± 0.5 *e | 18.0± 0.9 *e | 13.3± 1.5 *cd |

| Variety | Ebcg (MJ/kg Product) | Ebd (MJ/kg Product) | Ebcd (MJ/kg Product) | Ebs (MJ/kg Product) | kb1 | kb2 | Ebm (MJ/kg Product) | Eb (MJ/kg Product) |

|---|---|---|---|---|---|---|---|---|

| PN | 0.0842 a | 2.502 a | 0.0624 a | 0.0072 a | 0.623 a | 0.516 a | 0.0987 a | 0.340 a |

| MO | 0.0858 a | 2.731 a | 0.0656 a | 0.0079 a | 0.629 a | 0.523 a | 0.1032 a | 0.315 a |

| FN | 0.0865 a | 2.752 a | 0.0664 a | 0.0081 a | 0.622 a | 0.510 a | 0.0931 a | 0.322 a |

| FA | 0.0829 a | 2.421 a | 0.0619 a | 0.0073 a | 0.615 a | 0.506 a | 0.0983 a | 0.313 a |

| FR | 0.0848 a | 2.585 a | 0.0639 a | 0.0075 a | 0.628 a | 0.524 a | 0.0992 a | 0.323 a |

| CS | 0.0832 a | 2.465 a | 0.0631 a | 0.0074 a | 0.634 a | 0.526 a | 0.0977 a | 0.335 a |

| SB | 0.0838 a | 2.486 a | 0.0629 a | 0.0076 a | 0.643 a | 0.514 a | 0.0976 a | 0.327 a |

| BB | 0.0853 a | 2.689 a | 0.0642 a | 0.0079 a | 0.609 a | 0.490 a | 0.1004 a | 0.319 a |

| Feature | Mean Average | Standard Deviation | Sum | Minimum Value | Median | Maximum Value | Coefficient of Variation (%) |

|---|---|---|---|---|---|---|---|

| Average quantity of tendrils/stump (kg/stump) | 0.36738 | 0.03959 | 2.939 | 0.327 | 0.357 | 0.433 | 8.10 |

| Quantity of biomass at the initial moisture ratio (kg/ha) | 1596.95 | 172.10932 | 12,775.6 | 1421.4 | 1551.85 | 1882.2 | 8.10 |

| Initial moisture ratio of tendrils (%) | 44.125 | 1.85159 | 353 | 41.87 | 44.055 | 47.47 | 4.61 |

| Quantity of biomass at a 12% moisture ratio (kg/ha) | 1061.3375 | 130.56427 | 8490.7 | 907 | 1019.75 | 1250.8 | 11.65 |

| Moisture (%) | 7.96125 | 0.13789 | 63.69 | 7.78 | 7.95 | 8.2 | 1.68 |

| Ash (%) | 2.92375 | 0.37811 | 23.39 | 2.09 | 3.05 | 3.27 | 4.62 |

| Density (kg/cm3) | 1330.7875 | 49.69425 | 10,646.3 | 1227 | 1341.5 | 1389 | 2.79 |

| LCV (MJ/kg) | 17.53875 | 0.26643 | 140.31 | 16.92 | 17.615 | 17.77 | 0.42 |

| N (%) | 0.92875 | 0.10895 | 7.43 | 0.76 | 0.93 | 1.15 | 3.19 |

| S (%) | 0.03762 | 0.00283 | 0.301 | 0.033 | 0.037 | 0.042 | 4.01 |

| Cl (%) | 0.05875 | 0.00991 | 0.47 | 0.04 | 0.06 | 0.07 | 12.36 |

| As (mg/kg) | 0.13375 | 0.022 | 1.07 | 0.09 | 0.135 | 0.16 | 16.47 |

| Cd (mg/kg) | 2.8375 | 0.0512 | 22.7 | 2.78 | 2.845 | 2.89 | 2.35 |

| Cr (mg/kg) | 11.575 | 0.30589 | 92.6 | 11.3 | 11.5 | 12.3 | 0.65 |

| Cu (mg/kg) | 23.725 | 1.02783 | 189.8 | 22.3 | 23.6 | 25.2 | 3.77 |

| Pb (mg/kg) | 10.32875 | 0.70552 | 82.63 | 9.8 | 10 | 11.8 | 2.74 |

| Ni (mg·kg−1) | 9.86375 | 0.12011 | 78.91 | 9.7 | 9.835 | 10 | 1.73 |

| Zn (mg/kg) | 15.56875 | 5.36157 | 124.55 | 9.6 | 14.525 | 23.6 | 35.98 |

| Ebcg (MJ/kg product) | 0.08456 | 0.00127 | 0.6765 | 0.0829 | 0.0845 | 0.0865 | 1.84 |

| Ebd (MJ/kg) | 2.57887 | 0.12967 | 20.631 | 2.421 | 2.5435 | 2.752 | 5.86 |

| Ebcd (MJ/kg) | 0.0638 | 0.00156 | 0.5104 | 0.0619 | 0.0635 | 0.0664 | 2.10 |

| Ebs (MJ/kg) | 0.00761 | 3.22656 × 10−4 | 0.0609 | 0.0072 | 0.00755 | 0.0081 | 5.89 |

| kb1 | 0.62538 | 0.01068 | 5.003 | 0.609 | 0.6255 | 0.643 | 1.42 |

| kb2 | 0.51363 | 0.01186 | 4.109 | 0.49 | 0.515 | 0.526 | 2.45 |

| Ebm (MJ/kg) | 0.09852 | 0.00285 | 0.7882 | 0.0931 | 0.0985 | 0.1032 | 1.28 |

| Eb (MJ/kg) | 0.32425 | 0.00939 | 2.594 | 0.313 | 0.3225 | 0.34 | 2.76 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ţenu, I.; Roșca, R.; Corduneanu, O.-R.; Roman, C.; Senila, L.; Arsenoaia, V.; Butnaru, L.; Băetu, M.; Chirilă, C.; Cârlescu, P.M. Briquette Production from Vineyard Winter Pruning Using Two Different Approaches. Agriculture 2024, 14, 1109. https://doi.org/10.3390/agriculture14071109

Ţenu I, Roșca R, Corduneanu O-R, Roman C, Senila L, Arsenoaia V, Butnaru L, Băetu M, Chirilă C, Cârlescu PM. Briquette Production from Vineyard Winter Pruning Using Two Different Approaches. Agriculture. 2024; 14(7):1109. https://doi.org/10.3390/agriculture14071109

Chicago/Turabian StyleŢenu, Ioan, Radu Roșca, Oana-Raluca Corduneanu, Cecilia Roman, Lacrimioara Senila, Vlad Arsenoaia, Liviu Butnaru, Marius Băetu, Constantin Chirilă, and Petru Marian Cârlescu. 2024. "Briquette Production from Vineyard Winter Pruning Using Two Different Approaches" Agriculture 14, no. 7: 1109. https://doi.org/10.3390/agriculture14071109

APA StyleŢenu, I., Roșca, R., Corduneanu, O.-R., Roman, C., Senila, L., Arsenoaia, V., Butnaru, L., Băetu, M., Chirilă, C., & Cârlescu, P. M. (2024). Briquette Production from Vineyard Winter Pruning Using Two Different Approaches. Agriculture, 14(7), 1109. https://doi.org/10.3390/agriculture14071109