Discrete Element Model of Oil Peony Seeds and the Calibration of Its Parameters

Abstract

1. Introduction

2. Materials and Methods

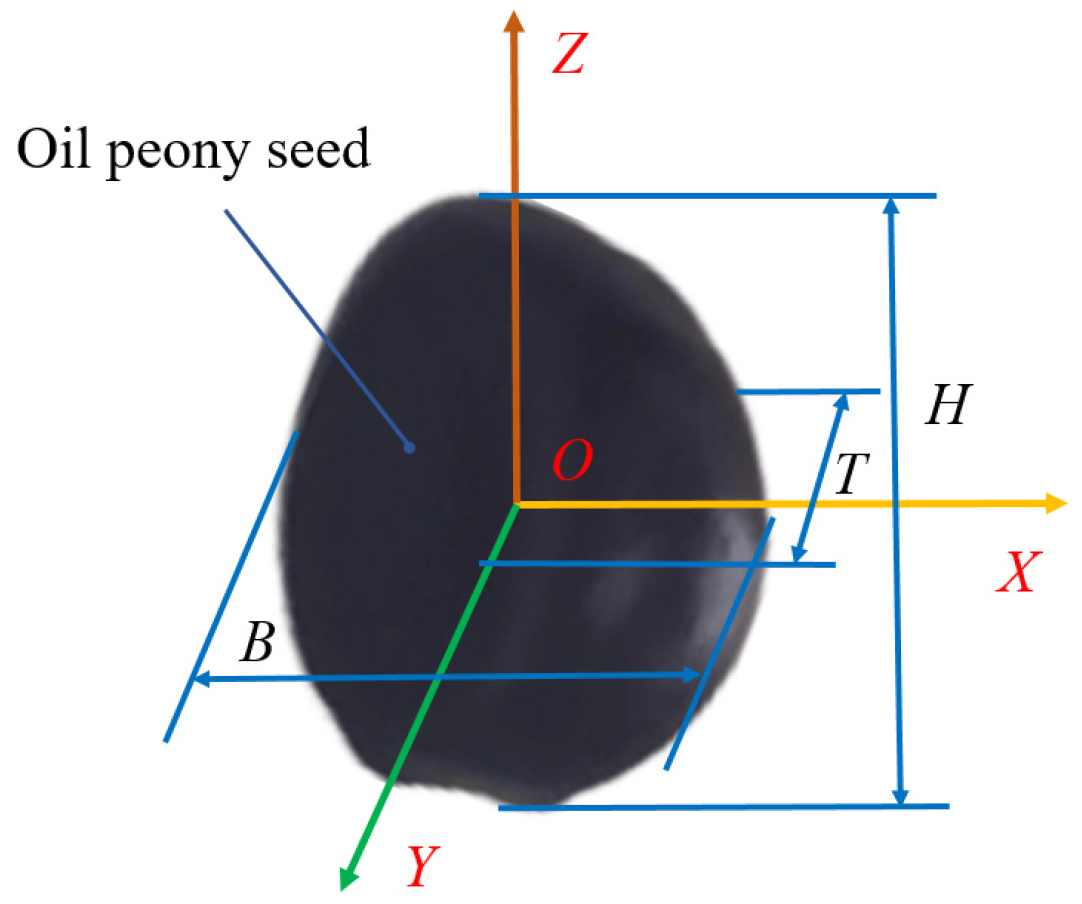

2.1. Geometric Parameters of Oil Peony Seeds

2.2. Thousand Particle Weight and Density Measurements

2.3. Elastic Modulus

2.4. Poisson’s Ratio

2.5. Friction Coefficient

2.6. Collision Recovery Coefficient

2.7. Repose Angle

2.8. Model Construction and Simulation

3. Results and Discussion

3.1. Laboratory Test Results

3.2. Plackett–Burman (PB) Test

3.3. Steepest Ascent (SA) Test

3.4. Box–Behnken (BBD) Test

3.5. Interactive Effects Analysis of Regression Model

3.6. Parameter Optimization and Verification Test

4. Conclusions

- (1)

- The ranges of values of each parameter of oil peony seeds in measurements obtained in the test were as follows: The Poisson’s ratio was 0.21–0.42 (average, 0.3), elastic modulus was 6.1–13 MPa (average, 9.21 MPa), coefficient of recovery from seed–steel collision was 0.67–0.83 (average, 0.78), coefficient of static friction was 0.32–0.46 (average, 0.38), and coefficient of rolling friction was 0.04–0.07 (average, 0.053). The seed–seed recovery coefficient was 0.10–0.90 (average, 0.70), the coefficient of static friction was 0.29–0.46 (average, 0.36), and the coefficient of rolling friction was 0.04–0.08 (average 0.05);

- (2)

- The seed–steel CRC (M4), seed–seed SFC (M5), seed–steel SFC (M6), and seed–seed RFC (M7) significantly affect the repose angle of the oil peony seeds. The optimal parameter combination M4, M5, M6, and M7 was 0.704, 0.324, 0.335, and 0.045, respectively;

- (3)

- The results of tests to verify the optimum parameter combination yielded an error of only 0.67% between the simulated and the measured pose angles. This showed that values of the parameters of the proposed DEM of oil peony seeds were reliable, and that it can be used to simulate and optimize the design of the seed discharge device.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Deng, R.; Gao, J.; Yi, J.; Liu, P. Peony seeds oil by-products: Chemistry and bioactivity. Ind. Crops Prod. 2022, 187, 115333. [Google Scholar] [CrossRef]

- Gao, L.-L.; Li, Y.-Q.; Wang, Z.-S.; Sun, G.-J.; Qi, X.-M.; Mo, H.-Z. Physicochemical characteristics and functionality of tree peony (Paeonia suffruticosa Andr.) seed protein. Food Chem. 2018, 240, 980–988. [Google Scholar] [CrossRef]

- Liu, P.; Zhang, Y.; Xu, Y.-F.; Zhu, X.-Y.; Xu, X.-F.; Chang, S.; Deng, R.-X. Three new monoterpene glycosides from oil peony seed cake. Ind. Crops Prod. 2018, 111, 371–378. [Google Scholar] [CrossRef]

- Su, J.; Ma, C.; Liu, C.; Gao, C.; Nie, R.; Wang, H. Hypolipidemic Activity of Peony Seed Oil Rich in α-Linolenic, is Mediated Through Inhibition of Lipogenesis and Upregulation of Fatty Acid β-Oxidation. J. Food Sci. 2016, 81, H1001–H1009. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Xin, Y.; Ma, H.; Fang, P.; Li, C.; Wan, X.; He, Z.; Jia, J.; Ling, Z. Rapid detection of Chinese-specific peony seed oil by using confocal Raman spectroscopy and chemometrics. Food Chem. 2021, 362, 130041. [Google Scholar] [CrossRef]

- Wu, G.; Shen, Y.; Nie, R.; Li, P.; Jin, Q.; Zhang, H.; Wang, X. The bioactive compounds and cellular antioxidant activity of Herbaceous peony (Paeonia lactiflora Pall) seed oil from China. J. Food Sci. 2020, 85, 3815–3822. [Google Scholar] [CrossRef]

- Xiu, Y.; Wu, G.; Tang, W.; Peng, Z.; Bu, X.; Chao, L.; Yin, X.; Xiong, J.; Zhang, H.; Zhao, X.; et al. Oil biosynthesis and transcriptome profiles in developing endosperm and oil characteristic analyses in Paeonia ostii var. lishizhenii. J. Plant Physiol. 2018, 228, 121–133. [Google Scholar] [CrossRef]

- Liu, P.; Xu, Y.-F.; Gao, X.-D.; Zhu, X.-Y.; Du, M.-Z.; Wang, Y.-X.; Deng, R.-X.; Gao, J.-Y. Optimization of ultrasonic-assisted extraction of oil from the seed kernels and isolation of monoterpene glycosides from the oil residue of Paeonia lactiflora Pall. Ind. Crops Prod. 2017, 107, 260–270. [Google Scholar] [CrossRef]

- Aikins, K.A.; Ucgul, M.; Barr, J.B.; Awuah, E.; Antille, D.L.; Jensen, T.A.; Desbiolles, J.M.A. Review of Discrete Element Method Simulations of Soil Tillage and Furrow Opening. Agriculture 2023, 13, 541. [Google Scholar] [CrossRef]

- Chen, Z.; Yu, J.; Xue, D.; Wang, Y.; Zhang, Q.; Ren, L. An approach to and validation of maize-seed-assembly modelling based on the discrete element method. Powder Technol. 2018, 328, 167–183. [Google Scholar] [CrossRef]

- Cunha, R.N.; Santos, K.G.; Lima, R.N.; Duarte, C.R.; Barrozo, M.A.S. Repose angle of monoparticles and binary mixture: An experimental and simulation study. Powder Technol. 2016, 303, 203–211. [Google Scholar] [CrossRef]

- Li, G.; Li, H.; Li, X.; Gong, Z.; Yang, Q.; Huang, Y.; Fu, Z. Establishment and Calibration of Discrete Element Model for Buckwheat Seed Based on Static and Dynamic Verification Test. Agriculture 2023, 13, 1024. [Google Scholar] [CrossRef]

- Radvilaite, U.; Ramirez-Gomez, A.; Kacianauskas, R. Determining the shape of agricultural materials using spherical harmonics. Comput. Electron. Agric. 2016, 128, 160–171. [Google Scholar] [CrossRef]

- Zhou, L.; Yu, J.; Wang, Y.; Yan, D.; Yu, Y. A study on the modelling method of maize-seed particles based on the discrete element method. Powder Technol. 2020, 374, 353–376. [Google Scholar] [CrossRef]

- Bai, S.; Yuan, Y.; Niu, K.; Zhou, L.; Zhao, B.; Wei, L.; Liu, L.; Xiong, S.; Shi, Z.; Ma, Y.; et al. Simulation Parameter Calibration and Experimental Study of a Discrete Element Model of Cotton Precision Seed Metering. Agriculture 2022, 12, 870. [Google Scholar] [CrossRef]

- Zhong, J.-Q.; Tao, L.-M.; Li, S.-P.; Zhang, B.; Wang, J.-Y.; He, Y.-L. Determination and interpretation of parameters of double-bud sugarcane model based on discrete element. Comput. Electron. Agric. 2022, 203, 107428. [Google Scholar] [CrossRef]

- Wang, S.; Yu, Z.; Zhang, W.; Aorigele. Study on the modeling method of sunflower seed particles based on the discrete element method. Comput. Electron. Agric. 2022, 198, 107012. [Google Scholar] [CrossRef]

- Lu, C.; Gao, Z.; Li, H.; He, J.; Wang, Q.; Wei, X.; Wang, X.; Jiang, S.; Xu, J.; He, D.; et al. An ellipsoid modelling method for discrete element simulation of wheat seeds. Biosyst. Eng. 2023, 226, 1–15. [Google Scholar] [CrossRef]

- Hu, M.; Xia, J.; Zhou, Y.; Luo, C.; Zhou, M.; Liu, Z. Measurement and Calibration of the Discrete Element Parameters of Coated Delinted Cotton Seeds. Agriculture 2022, 12, 286. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, F. Parameter calibration of American ginseng seeds for discrete element simulation. Int. J. Agric. Biol. Eng. 2022, 15, 16–22. [Google Scholar] [CrossRef]

- Yan, D.; Yu, J.; Wang, Y.; Zhou, L.; Sun, K.; Tian, Y. A Review of the Application of Discrete Element Method in Agricultural Engineering: A Case Study of Soybean. Processes 2022, 10, 1305. [Google Scholar] [CrossRef]

- Yan, D.; Yu, J.; Wang, Y.; Sun, K.; Zhou, L.; Tian, Y.; Zhang, N. Measurement and Calibration of DEM Parameters of Soybean Seed Particles. Agriculture 2022, 12, 1825. [Google Scholar] [CrossRef]

- Zheng, J.; Wang, L.; Wang, X.; Shi, Y.; Yang, Z. Parameter Calibration of Cabbages (Brassica oleracea L.) Based on the Discrete Element Method. Agriculture 2023, 13, 555. [Google Scholar] [CrossRef]

- Fu, H.; Yang, J.; Du, W.; Wang, W.; Liu, G.; Yang, Z. Determination of coefficient of restitution of fresh market apples caused by fruit-to-fruit collisions with a sliding method. Biosyst. Eng. 2022, 224, 183–196. [Google Scholar] [CrossRef]

- Zhou, B.; Zuo, Y.; Hou, L. Parameter Calibration of Xinjiang Paperbark Walnut Kernels by Discrete Element Simulation. Agriculture 2023, 13, 353. [Google Scholar] [CrossRef]

- Zhang, S.; Fu, J.; Zhang, R.; Zhang, Y.; Yuan, H. Experimental Study on the Mechanical Properties of Friction, Collision and Compression of Tiger Nut Tubers. Agriculture 2022, 12, 65. [Google Scholar] [CrossRef]

- Li, X.; Zhang, W.; Xu, S.; Ma, F.; Du, Z.; Ma, Y.; Liu, J. Calibration of Collision Recovery Coefficient of Corn Seeds Based on High-Speed Photography and Sound Waveform Analysis. Agriculture 2023, 13, 1677. [Google Scholar] [CrossRef]

- Liu, Y.; Mi, G.; Zhang, S.; Li, P.; Huang, Y. Determination of Discrete Element Modelling Parameters of Adzuki Bean Seeds. Agriculture 2022, 12, 626. [Google Scholar] [CrossRef]

- Li, H.; Zeng, R.; Niu, Z.; Zhang, J. A Calibration Method for Contact Parameters of Maize Kernels Based on the Discrete Element Method. Agriculture 2022, 12, 664. [Google Scholar] [CrossRef]

- Jiang, D.; Chen, X.; Yan, L.; Gou, H.; Yang, J.; Li, Y. Parameter Calibration of Discrete Element Model for Cotton Rootstalk-Soil Mixture at Harvest Stage in Xinjiang Cotton Field. Agriculture 2023, 13, 1344. [Google Scholar] [CrossRef]

| Parameters | Unit | Value |

|---|---|---|

| 3D sizes of seed (H × B × T) | mm | 8.92 × 7.15 × 6.22 |

| Weight of seed | g | 0.198 |

| Volume of seed | cm3 | 0.201 |

| Poisson’s ratio of seed | 0.3 | |

| Elastic modulus of seed | MPa | 9.21 × 106 |

| Seed–seed CRC | 0.7 | |

| Seed–steel CRC | 0.78 | |

| Seed–seed SFC | 0.36 | |

| Seed–steel SFC | 0.38 | |

| Seed–seed RFC | 0.05 | |

| Seed–steel RFC | 0.053 | |

| Repose Angle | ° | 30.3 |

| Symbol | Parameters | Unit | Low Level (−1) | High Level (+1) |

|---|---|---|---|---|

| M1 | Poisson’s ratio of seed | 0.21 | 0.42 | |

| M2 | Elastic modulus of seed | MPa | 6.10 | 13.00 |

| M3 | Seed–seed CRC | 0.10 | 0.90 | |

| M4 | Seed–steel CRC | 0.67 | 0.83 | |

| M5 | Seed–seed SFC | 0.29 | 0.46 | |

| M6 | Seed–steel SFC | 0.32 | 0.46 | |

| M7 | Seed–seed RFC | 0.04 | 0.08 | |

| M8 | Seed–steel RFC | 0.04 | 0.07 |

| No. | M1 | M2 | M3 | M4 | M5 | M6 | M7 | M8 | Repose Angle θ/° |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.21 | 13.00 | 0.90 | 0.67 | 0.46 | 0.46 | 0.08 | 0.04 | 37.6° |

| 2 | 0.42 | 6.10 | 0.10 | 0.67 | 0.46 | 0.32 | 0.08 | 0.07 | 37.1° |

| 3 | 0.42 | 13.00 | 0.10 | 0.83 | 0.46 | 0.46 | 0.04 | 0.04 | 32.9° |

| 4 | 0.42 | 6.10 | 0.90 | 0.83 | 0.46 | 0.32 | 0.04 | 0.04 | 29.8° |

| 5 | 0.21 | 6.10 | 0.10 | 0.83 | 0.29 | 0.46 | 0.08 | 0.04 | 33.2° |

| 6 | 0.42 | 13.00 | 0.90 | 0.67 | 0.29 | 0.32 | 0.08 | 0.04 | 34.2° |

| 7 | 0.21 | 13.00 | 0.90 | 0.83 | 0.29 | 0.32 | 0.04 | 0.07 | 27.9° |

| 8 | 0.21 | 13.00 | 0.10 | 0.83 | 0.46 | 0.32 | 0.08 | 0.07 | 34.5° |

| 9 | 0.42 | 13.00 | 0.10 | 0.67 | 0.29 | 0.46 | 0.04 | 0.07 | 34.1° |

| 10 | 0.21 | 6.10 | 0.90 | 0.67 | 0.46 | 0.46 | 0.04 | 0.07 | 33.6° |

| 11 | 0.42 | 6.10 | 0.90 | 0.83 | 0.29 | 0.46 | 0.08 | 0.07 | 32.3° |

| 12 | 0.21 | 6.10 | 0.10 | 0.67 | 0.29 | 0.32 | 0.04 | 0.04 | 27.7° |

| Parameter | Effect | Sum of Squares | Contribution/% | p-Value | Significance |

|---|---|---|---|---|---|

| M1 | 0.98 | 2.90 | 2.69 | 0.2205 | |

| M2 | 1.25 | 4.69 | 4.34 | 0.1447 | |

| M3 | −0.68 | 1.40 | 1.30 | 0.3622 | |

| M4 | −2.28 | 15.64 | 14.48 | 0.0372 | * |

| M5 | 2.68 | 21.60 | 20.00 | 0.0245 | * |

| M6 | 2.08 | 13.02 | 12.06 | 0.0468 | * |

| M7 | 3.82 | 43.70 | 40.46 | 0.0093 | ** |

| M8 | 0.68 | 1.40 | 1.30 | 0.3622 |

| No. | M4 | M5 | M6 | M7 | Repose Angle θ/° |

|---|---|---|---|---|---|

| 1 | 0.67 | 0.29 | 0.32 | 0.04 | 28.7° |

| 2 | 0.71 | 0.3325 | 0.355 | 0.05 | 31.2° |

| 3 | 0.75 | 0.375 | 0.39 | 0.06 | 34.5° |

| 4 | 0.79 | 0.4175 | 0.425 | 0.07 | 36.3° |

| 5 | 0.83 | 0.46 | 0.46 | 0.08 | 38.1° |

| Codes | Factors | |||

|---|---|---|---|---|

| M4 | M5 | M6 | M7 | |

| −1 | 0.67 | 0.29 | 0.32 | 0.04 |

| 0 | 0.71 | 0.3325 | 0.355 | 0.05 |

| 1 | 0.75 | 0.375 | 0.39 | 0.06 |

| No. | M4 | M5 | M6 | M7 | Repose Angle (°)/θ |

|---|---|---|---|---|---|

| 1 | 0.67 | 0.29 | 0.355 | 0.05 | 31° |

| 2 | 0.75 | 0.29 | 0.355 | 0.05 | 29.9° |

| 3 | 0.67 | 0.375 | 0.355 | 0.05 | 31.4° |

| 4 | 0.75 | 0.375 | 0.355 | 0.05 | 30.7° |

| 5 | 0.71 | 0.3325 | 0.32 | 0.04 | 28.8° |

| 6 | 0.71 | 0.3325 | 0.39 | 0.04 | 30.8° |

| 7 | 0.71 | 0.3325 | 0.32 | 0.06 | 30.5° |

| 8 | 0.71 | 0.3325 | 0.39 | 0.06 | 31.4° |

| 9 | 0.67 | 0.3325 | 0.355 | 0.04 | 28.8° |

| 10 | 0.75 | 0.3325 | 0.355 | 0.04 | 29.7° |

| 11 | 0.67 | 0.3325 | 0.355 | 0.06 | 31.7° |

| 12 | 0.75 | 0.3325 | 0.355 | 0.06 | 29.9° |

| 13 | 0.71 | 0.29 | 0.32 | 0.05 | 29.5° |

| 14 | 0.71 | 0.375 | 0.32 | 0.05 | 30.9° |

| 15 | 0.71 | 0.29 | 0.39 | 0.05 | 30.4° |

| 16 | 0.71 | 0.375 | 0.39 | 0.05 | 32.6° |

| 17 | 0.67 | 0.3325 | 0.32 | 0.05 | 30.1° |

| 18 | 0.75 | 0.3325 | 0.32 | 0.05 | 30.3° |

| 19 | 0.67 | 0.3325 | 0.39 | 0.05 | 32° |

| 20 | 0.75 | 0.3325 | 0.39 | 0.05 | 30.6° |

| 21 | 0.71 | 0.29 | 0.355 | 0.04 | 29.1° |

| 22 | 0.71 | 0.375 | 0.355 | 0.04 | 29.5° |

| 23 | 0.71 | 0.29 | 0.355 | 0.06 | 30.5° |

| 24 | 0.71 | 0.375 | 0.355 | 0.06 | 32.1° |

| 25 | 0.71 | 0.3325 | 0.355 | 0.05 | 31.8° |

| 26 | 0.71 | 0.3325 | 0.355 | 0.05 | 31.6° |

| 27 | 0.71 | 0.3325 | 0.355 | 0.05 | 31.4° |

| 28 | 0.71 | 0.3325 | 0.355 | 0.05 | 31.4° |

| 29 | 0.71 | 0.3325 | 0.355 | 0.05 | 31.8° |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value | Significance |

|---|---|---|---|---|---|---|

| Model | 27.73 | 14 | 1.98 | 18.48 | <0.0001 | ** |

| M4 | 1.27 | 1 | 1.27 | 11.82 | 0.0040 | ** |

| M5 | 3.85 | 1 | 3.85 | 35.94 | <0.0001 | ** |

| M6 | 4.94 | 1 | 4.94 | 46.09 | <0.0001 | ** |

| M7 | 7.36 | 1 | 7.36 | 68.69 | <0.0001 | ** |

| M4M5 | 0.400 | 1 | 0.400 | 0.3731 | 0.5511 | |

| M4M6 | 0.6400 | 1 | 0.6400 | 5.97 | 0.0284 | * |

| M4M7 | 1.82 | 1 | 1.82 | 17.00 | 0.0010 | * |

| M5M6 | 0.1600 | 1 | 0.1600 | 1.49 | 0.2420 | |

| M5M7 | 0.3600 | 1 | 0.3600 | 3.36 | 0.0882 | |

| M6M7 | 0.3025 | 1 | 0.3025 | 2.82 | 0.1152 | |

| M42 | 1.93 | 1 | 1.93 | 18.03 | 0.0008 | ** |

| M52 | 0.8329 | 1 | 0.8329 | 7.77 | 0.0145 | * |

| M62 | 0.6677 | 1 | 0.6677 | 6.23 | 0.0257 | * |

| M72 | 5.96 | 1 | 5.96 | 55.57 | <0.0001 | ** |

| Residual | 1.50 | 14 | 0.1072 | |||

| Lack of fit | 1.34 | 10 | 0.1341 | 3.35 | 0.1275 | |

| Pure error | 0.1600 | 4 | 0.0400 | |||

| Sum | 29.23 | 28 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, H.; Li, K.; Qin, Z.; Wang, S.; Wang, X.; Sun, F. Discrete Element Model of Oil Peony Seeds and the Calibration of Its Parameters. Agriculture 2024, 14, 1092. https://doi.org/10.3390/agriculture14071092

Zhou H, Li K, Qin Z, Wang S, Wang X, Sun F. Discrete Element Model of Oil Peony Seeds and the Calibration of Its Parameters. Agriculture. 2024; 14(7):1092. https://doi.org/10.3390/agriculture14071092

Chicago/Turabian StyleZhou, Hao, Kangtai Li, Zhiyu Qin, Shengsheng Wang, Xuezhen Wang, and Fengyun Sun. 2024. "Discrete Element Model of Oil Peony Seeds and the Calibration of Its Parameters" Agriculture 14, no. 7: 1092. https://doi.org/10.3390/agriculture14071092

APA StyleZhou, H., Li, K., Qin, Z., Wang, S., Wang, X., & Sun, F. (2024). Discrete Element Model of Oil Peony Seeds and the Calibration of Its Parameters. Agriculture, 14(7), 1092. https://doi.org/10.3390/agriculture14071092