Calibration and Testing of Discrete Elemental Simulation Parameters for Pod Pepper Seeds

Abstract

1. Introduction

2. Materials and Methods

2.1. Basic Parameters of Pod Pepper Seeds

2.2. Measurement of Moisture Content and Density of Pod Pepper Seeds

2.3. Measurement of Intrinsic Parameters of Pod Pepper Seeds

2.4. Measurement of Contact Parameters of Pod Pepper Seeds

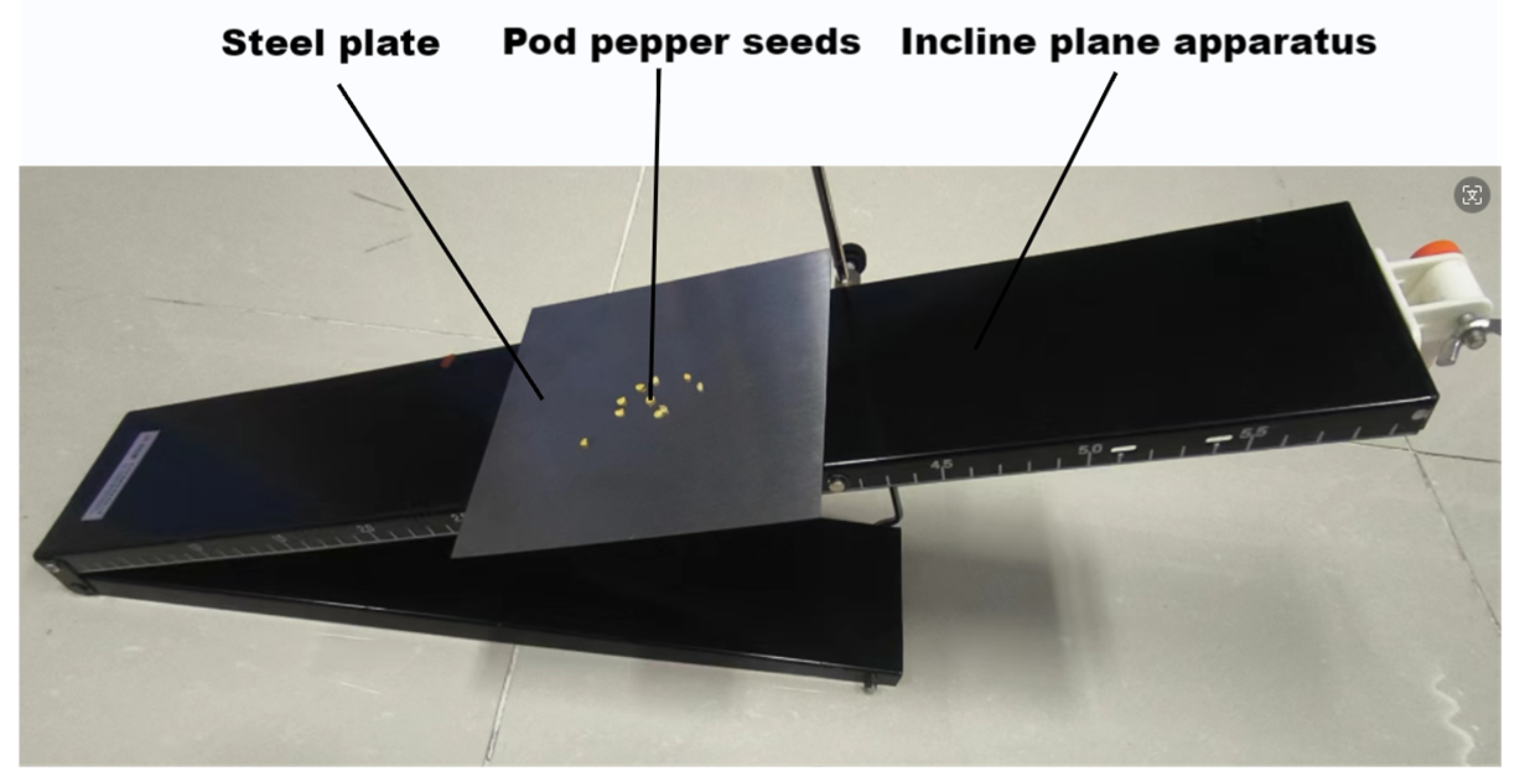

2.4.1. Static Friction Coefficient Determination Test

2.4.2. Measurement of Rolling Friction Coefficient

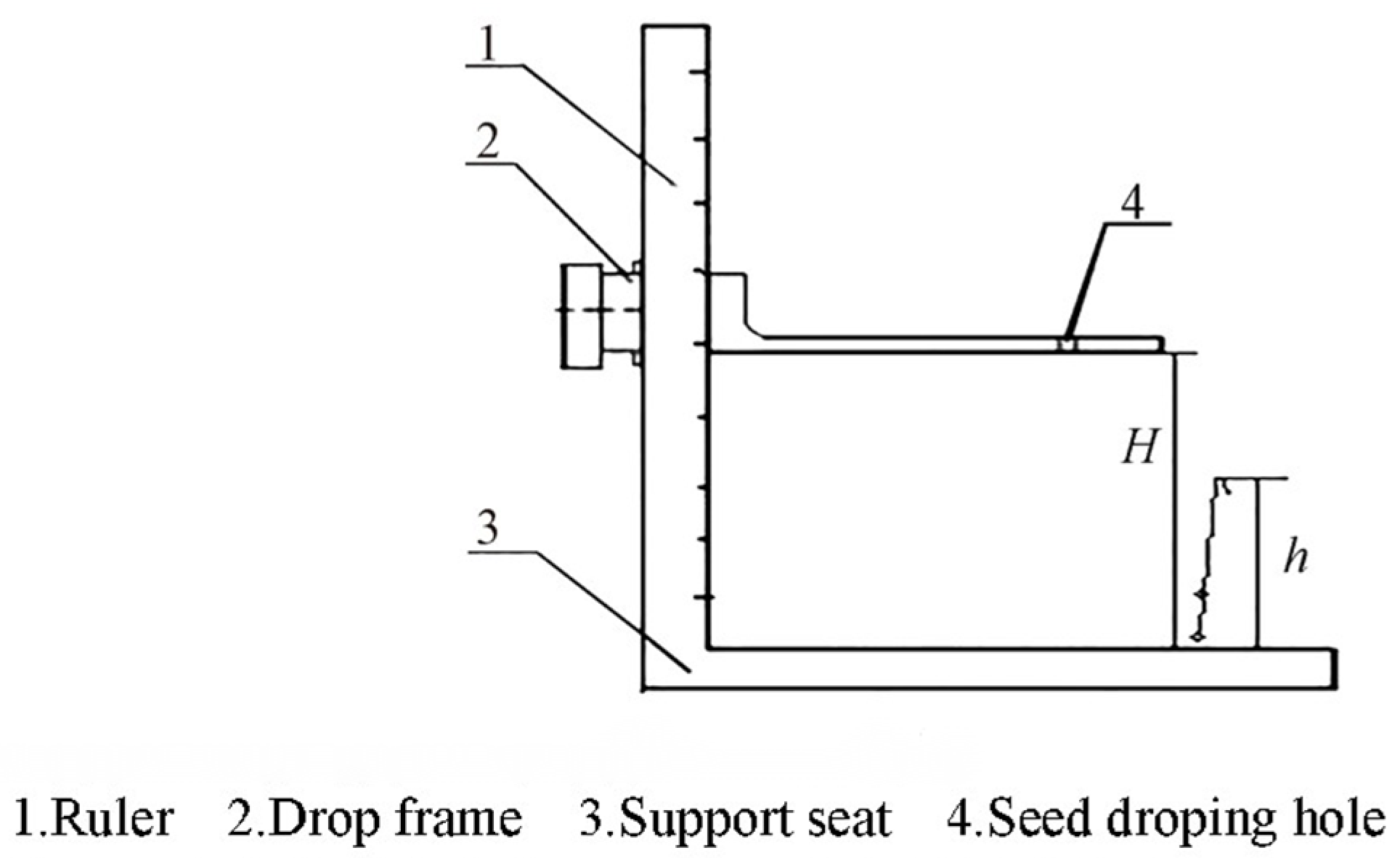

2.4.3. Measurement Test of Coefficient of Restitution

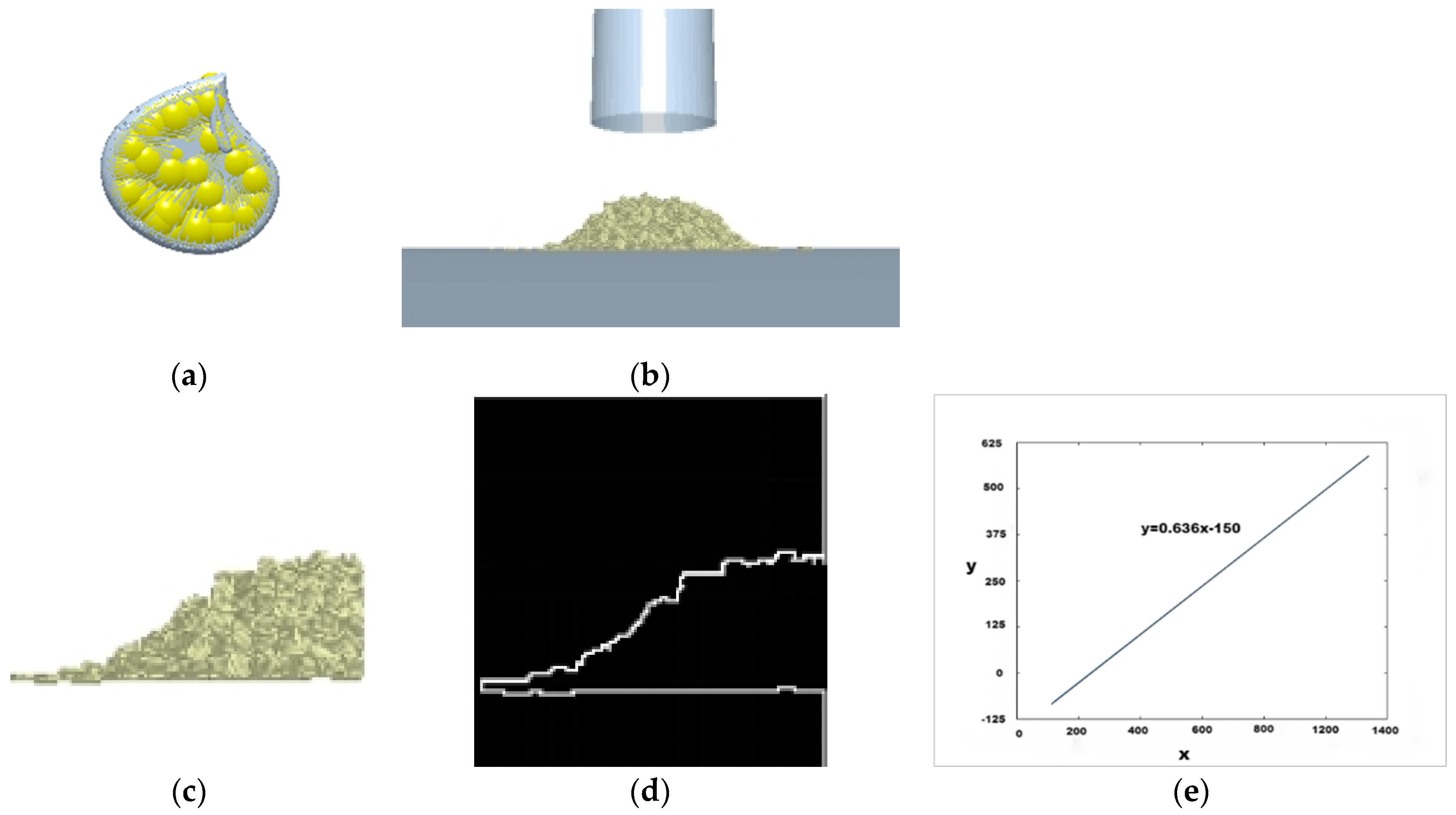

2.5. Determination of the Actual Repose Angle of Pod Pepper Seeds

2.6. DEM Model of Pod Pepper Seed for Simulation

3. Result and Discussion

3.1. Plackett–Burman Experiment

3.2. Steepest Ascent Test Design

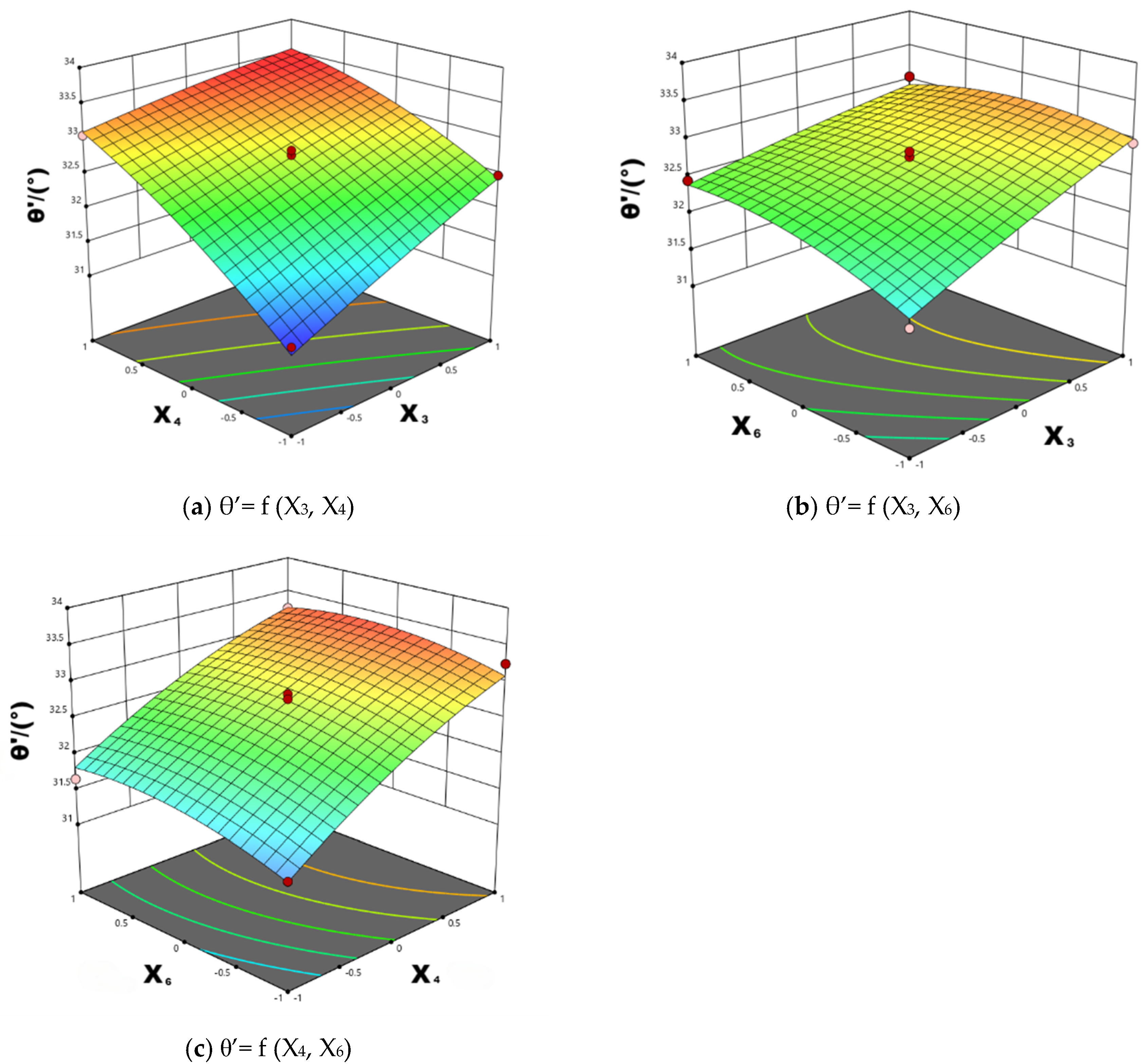

3.3. Box–Behnken Design of Experiments

3.4. Parameter Optimization and Simulation Test Check

4. Conclusions

- (1)

- The intrinsic and contact parameters (including three-dimensional dimensions, thousand-seed mass, moisture content, density, modulus of elasticity, Poisson’s ratio, shear modulus, and coefficient of friction) of pod pepper seeds were established through physical experiments. Additionally, the mean values of the coefficients of static friction and coefficient of restitution between pod pepper seeds were determined using an inclinometer and a high-speed video camera, resulting in values of 0.60 ± 0.031 and 0.28 ± 0.041, respectively. The mean values of the static friction coefficient and coefficient of restitution between pod pepper seeds and steel plates were 0.70 ± 0.035 and 0.39 ± 0.065, respectively. The ranges of rolling friction coefficients between pod pepper seeds and between pod pepper seeds and steel plates were determined through simulation approximation and prediction methods, ranging from 0.01 to 0.03 and from 0.005 to 0.020, respectively. From compression tests conducted by the texture analyzer, the mean values of Poisson’s ratio and shear modulus of pod pepper seeds were obtained as 0.35 ± 0.024 and 8.75 × 106 Pa, respectively.

- (2)

- Identification of the physical parameters of pod pepper seeds through physical experiments is the basis for selecting the parameters of the simulation tests. Results from the Plackett–Burman test revealed that the coefficients of static friction between seeds, static friction between seeds and steel plates, and rolling friction between pod pepper seeds were significant parameters affecting the repose angle. These three parameters were identified for the steepest ascent experiment to ascertain the optimal range intervals for simulation test parameters through the Plackett–Burman stacking test.

- (3)

- Based on the results of the Box–Behnken experiment, a secondary regression model was established correlating the significant parameters with the simulated angle of repose. The optimal simulation parameters for pod pepper seeds were identified through the optimization module of Design-Expert 13 software: the coefficient of static friction between pod pepper seeds (X3) was 0.608; the coefficient of rolling friction between seeds (X4) was 0.018; and the coefficient of static friction between seeds and steel plates (X6) was 0.787.

- (4)

- The two-sample T test yielded a p-value of 0.462, indicating that there was no significant difference between the simulated and actual angles of repose of pod pepper seeds. The relative error between the mean values of the simulated and actual inclinations was 0.68%, further confirming the reliability of the calibrated parameters for pod pepper seeds. The results of the study indicated that the calibration of material parameters of podded chili seeds by the discrete element method is a feasible and reasonable approach. It can provide a valuable reference for the calibration of parameters of other small irregular crops.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, R.; Zhou, Y.; Zhang, D.; Gao, X. Numerical investigation of the hydraulic transport of coarse particles in a vertical pipe based on a fully-coupled numerical model. Int. J. Multiph. Flow 2022, 155, 104094. [Google Scholar] [CrossRef]

- Zhou, L.; Wang, B.; Cao, Y.; Zhao, Z.; Agarwal, R. Fluidisation of spherocylindrical particles: Computational fluid dynamics-Discrete element method simulation and experimental investigation. Eng. Appl. Comput. Fluid Mech. 2024, 18, 2297537. [Google Scholar] [CrossRef]

- Shi, R.; Dai, F.; Zhao, W.; Zhang, F.; Shi, L.; Guo, J. Establishment of Discrete Element Flexible Model and Verification of Contact Parameters of Flax Stem. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2022, 53, 146–155. [Google Scholar] [CrossRef]

- Tian, X.; Cong, X.; Qi, J.; Guo, H.; Li, M.; Fan, X. Parameter Calibration of Discrete Element Model for Corn Straw-Soil Mixture in Black Soil Areas. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2021, 52, 100–108, 242. [Google Scholar] [CrossRef]

- Wang, Y.; Liang, Z.; Zhang, D.; Cui, T.; Shi, S.; Li, K.; Yang, L. Calibration method of contact characteristic parameters for corn seeds based on EDEM. Nongye Gongcheng Xuebao/Trans. Chin. Soc. Agric. Eng. 2016, 32, 36–42. [Google Scholar] [CrossRef]

- Coetzee, C.J.; Els, D.N.J. Calibration of discrete element parameters and the modelling of silo discharge and bucket filling. Comput. Electron. Agric. 2009, 65, 198–212. [Google Scholar] [CrossRef]

- Guo, J.; Karkee, M.; Yang, Z.; Fu, H.; Li, J.; Jiang, Y.; Duan, J. Discrete element modeling and physical experiment research on the biomechanical properties of banana bunch stalk for postharvest machine development. Comput. Electron. Agric. 2021, 188, 106308. [Google Scholar] [CrossRef]

- Ghodki, B.M.; Patel, M.; Namdeo, R.; Carpenter, G. Calibration of discrete element model parameters: Soybeans. Comput. Part. Mech. 2019, 6, 3–10. [Google Scholar] [CrossRef]

- Zhang, R.; Jiao, W.; Zhou, J.; Qi, B.; Liu, H.; Xia, Q. Parameter Calibration and Experiment of Rice Seeds Discrete Element Model with Different Filling Particle Radius. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2020, 51, 227–235. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, R.; Chen, T.; Fu, J.; Yuan, H. Calibration of Simulation Parameters of Mung Bean Seeds Using Discrete Element Method and Verification of Seed-metering Test. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2022, 53, 71–79. [Google Scholar] [CrossRef]

- Liu, W.; He, J.; Li, H.; Li, X.; Zheng, K.; Wei, Z. Calibration of Simulation Parameters for Potato Minituber Based on EDEM. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2018, 49, 125–135. [Google Scholar] [CrossRef]

- Santos, K.G.; Campos, A.V.P.; Oliveira, O.S.; Ferreira, L.V.; Francisquetti, M.C.; Barrozo, M.A.S. DEM simulations of dynamic angle of repose of acerola residue: A parametric study using a response surface technique. Blucher Chem. Eng. Proc. 2015, 1, 11326–11333. [Google Scholar]

- Khodabakhshian, R. Poisson’s ratio of pumpkin seeds and their kernels as a function of variety, size, moisture content and loading rate. Agric. Eng. Int. CIGR J. 2012, 14, 203–209. [Google Scholar]

- Yu, Q.; Liu, Y.; Chen, X.; Sun, K.; Lai, Q. Calibration and Experiment of Simulation Parameters for Panax notoginseng Seeds Based on DEM. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2020, 51, 123–132. [Google Scholar] [CrossRef]

- Al-Hashemi, H.M.B.; Al-Amoudi, O.S.B. A review on the angle of repose of granular materials. Powder Technol. 2018, 330, 397–417. [Google Scholar] [CrossRef]

- Xia, R.; Li, B.; Wang, X.; Li, T.; Yang, Z. Measurement and calibration of the discrete element parameters of wet bulk coal. Measurement 2019, 142, 84–95. [Google Scholar] [CrossRef]

- Shu, C.; Yang, J.; Wan, X.; Yuan, J.; Liao, Y.; Liao, Q. Calibration and experiment of the discrete element simulation parameters of rape threshing mixture in combine harvester. Nongye Gongcheng Xuebao/Trans. Chin. Soc. Agric. Eng. 2022, 38, 34–43. [Google Scholar] [CrossRef]

- Hou, Z.; Dai, N.; Chen, Z.; Qiu, Y.; Zhang, X. Measurement and calibration of physical property parameters for Agropyron seeds in a discrete element simulation. Nongye Gongcheng Xuebao/Trans. Chin. Soc. Agric. Eng. 2020, 36, 46–54. [Google Scholar] [CrossRef]

- Peng, C.; Zhou, T.; Song, S.; Fang, Q.; Zhu, H.; Sun, S. Measurement and Analysis of Restitution Coefficient of Black Soldier Fly Larvae in Collision Models Based on Hertz Contact Theory. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2021, 52, 125–134. [Google Scholar] [CrossRef]

- Wang, L.; Liu, T.; Feng, X.; Gao, Y.; Wang, B.; Zhang, S. Research progress of the restitution coefficients of collision of particles in agricultural and food fields. Nongye Gongcheng Xuebao/Trans. Chin. Soc. Agric. Eng. 2021, 37, 313–322. [Google Scholar] [CrossRef]

- Zhu, X.; Fu, S.; Li, X.; Wei, Y.; Zhao, W. General Method for Discrete Element Parameters Calibration of Goat Manure with Different Moisture Contents. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2022, 53, 34–41. [Google Scholar] [CrossRef]

- Yang, Q.; Shi, L.; Shi, A.; He, M.; Zhao, X.; Zhang, L.; Addy, M. Determination of key soil characteristic parameters using angle of repose and direct shear stress test. Int. J. Agric. Biol. Eng. 2023, 16, 143–150. [Google Scholar] [CrossRef]

- Hao, J.; Wei, W.; Huang, P.; Qin, J.; Zhao, J. Calibration and experimental verification of discrete element parameters of oil sunflower seeds. Nongye Gongcheng Xuebao/Trans. Chin. Soc. Agric. Eng. 2021, 37, 36–44. [Google Scholar] [CrossRef]

- Shi, L.; Sun, W.; Zhao, W.; Yang, X.; Feng, B. Parameter determination and validation of discrete element model of seed potato mechanical seeding. Nongye Gongcheng Xuebao/Trans. Chin. Soc. Agric. Eng. 2018, 34, 35–42. [Google Scholar] [CrossRef]

- Xu, L.; Wei, C.; Liang, Z.; Chai, X.; Li, Y.; Liu, Q. Development of rapeseed cleaning loss monitoring system and experiments in a combine harvester. Biosyst. Eng. 2019, 178, 118–130. [Google Scholar] [CrossRef]

- Jin, W.; Zhang, C.; Jin, S.; Tian, Y.; Wellmann, D.; Liu, W. Wire Arc Additive Manufacturing of Stainless Steels: A Review. Appl. Sci. 2020, 10, 1563. [Google Scholar] [CrossRef]

- Du, C.X.; Han, D.L.; Song, Z.Q.; Chen, Y.C.; Chen, X.G.; Wang, X.Z. Calibration of contact parameters for complex shaped fruits based on discrete element method: The case of pod pepper (Capsicum annuum). Biosyst. Eng. 2023, 226, 43–54. [Google Scholar] [CrossRef]

- Zhang, R.; Han, D.; Ji, Q.; He, Y.; Li, J. Calibration Methods of Sandy Soil Parameters in Simulation of Discrete Element Method. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2017, 48, 49–56. [Google Scholar] [CrossRef]

- Fang, W.Q.; Wang, X.Z.; Han, D.L.; Chen, X.G. Review of Material Parameter Calibration Method. Agriculture 2022, 12, 706. [Google Scholar] [CrossRef]

- Liu, F.; Zhang, J.; Li, B.; Chen, J. Calibration of parameters of wheat required in discrete element method simulation based on repose angle of particle heap. Nongye Gongcheng Xuebao/Trans. Chin. Soc. Agric. Eng. 2016, 32, 247–253. [Google Scholar] [CrossRef]

- Yue, R.; Hu, J.; Liu, Y.; Yao, M.; Zhang, T.; Shi, J. Design and Working Parameter Optimization of Pneumatic Reciprocating Seedling-Picking Device of Automatic Transplanter. Agriculture 2022, 12, 1989. [Google Scholar] [CrossRef]

- Yuan, H.; Liang, S.; Wang, J.; Lu, Y. Numerical Simulation and Analysis of Vibrating Rice Filling Based on EDEM Software. Agriculture 2022, 12, 2013. [Google Scholar] [CrossRef]

| Three-Dimensional Size | General Size/mm | Percent/% | Maximum/mm | Minimum/mm | Average/mm | Standard Deviation |

|---|---|---|---|---|---|---|

| Length | 4.02~4.57 | 88.74 | 5.17 | 3.93 | 4.30 | 0.342 |

| Width | 2.94~3.65 | 91.42 | 3.92 | 2.49 | 3.31 | 0.319 |

| Thickness | 0.97~1.28 | 96.15 | 1.42 | 0.82 | 1.09 | 0.296 |

| Parameters | Value |

|---|---|

| Poisson’s ratio of pod pepper seed () | 0.35 |

| Shear modulus of pod pepper seed/MPa () | 8.75 |

| Density of pod pepper seed/(kg·m−3) | 1071.3 |

| Poisson’s ratio of steel plate /Pa | 0.3 |

| Shear modulus of steel plate /Pa | 1.1 × 1010 |

| Density of steel plate/(kg·m−3) | 7 850 |

| Static friction coefficient between pod pepper seed and seed () | 0.60 |

| Rolling friction coefficient between pod pepper seed and seed () | 0.01~0.03 |

| Restitution coefficient between pod pepper seed and seed () | 0.28 |

| Static friction coefficient between pod pepper seed and steel plate () | 0.70 |

| Rolling friction coefficient between pod pepper seed and steel plate () | 0.005~0.020 |

| Restitution coefficient between pod pepper seed and steel plate () | 0.39 |

| Test Parameters | Low Level (−1) | Hight Level (+1) |

|---|---|---|

| 0.25 | 0.45 | |

| /MPa | 7.75 | 9.75 |

| 0.50 | 0.70 | |

| 0.01 | 0.03 | |

| 0.18 | 0.38 | |

| 0.65 | 0.85 | |

| 0.005 | 0.02 | |

| 0.29 | 0.49 |

| No. | Test Parameters | Simulated Angle of Repose θ′/(°) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| /MPa | |||||||||

| 1 | −1 | 1 | −1 | 1 | 1 | −1 | 1 | 1 | 31.48 |

| 2 | 1 | 1 | 1 | −1 | −1 | −1 | 1 | −1 | 29.54 |

| 3 | 1 | −1 | 1 | 1 | 1 | −1 | −1 | −1 | 33.07 |

| 4 | −1 | 1 | 1 | −1 | 1 | 1 | 1 | −1 | 32.43 |

| 5 | 1 | 1 | −1 | −1 | −1 | 1 | −1 | 1 | 29.65 |

| 6 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | 29.25 |

| 7 | 1 | 1 | −1 | 1 | 1 | 1 | −1 | −1 | 32.73 |

| 8 | −1 | −1 | −1 | 1 | −1 | 1 | 1 | −1 | 32.82 |

| 9 | −1 | −1 | 1 | −1 | 1 | 1 | −1 | 1 | 31.95 |

| 10 | −1 | 1 | 1 | 1 | −1 | −1 | −1 | 1 | 33.12 |

| 11 | 1 | −1 | −1 | −1 | 1 | −1 | 1 | 1 | 29.76 |

| 12 | 1 | −1 | 1 | 1 | −1 | 1 | 1 | 1 | 34.21 |

| Parameters | Effects | Sum of Squares | Contribution Rate/% | Significance Ranking |

|---|---|---|---|---|

| −0.35 | 0.36 | 0.89 | 6 | |

| −0.35 | 0.37 | 0.91 | 5 | |

| 1.44 | 6.21 | 15.23 | 2 | |

| 2.48 | 18.38 | 45.1 | 1 | |

| 0.48 | 0.67 | 1.64 | 4 | |

| 1.26 | 4.78 | 11.72 | 3 | |

| 0.078 | 0.018 | 0.045 | 7 | |

| 0.055 | 0.009 | 0.022 | 8 |

| No. | Simulated Angle of Repose θ′/(°) | Relative Errors Y/% | |||

|---|---|---|---|---|---|

| 1 | 0.50 | 0.01 | 0.65 | 29.55 | 8.94 |

| 2 | 0.55 | 0.015 | 0.7 | 30.95 | 4.62 |

| 3 | 0.60 | 0.02 | 0.75 | 32.75 | 0.92 |

| 4 | 0.65 | 0.025 | 0.8 | 33.64 | 3.67 |

| 5 | 0.70 | 0.03 | 0.85 | 34.05 | 4.93 |

| No. | Simulated Angle of Repose θ′/(°) | Relative Errors Y/% | |||

|---|---|---|---|---|---|

| 1 | 0 | 1 | 1 | 33.25 | 2.47 |

| 2 | −1 | 0 | 1 | 32.45 | 0 |

| 3 | 0 | 0 | 0 | 32.77 | 0.99 |

| 4 | 0 | −1 | 1 | 31.65 | 2.47 |

| 5 | 0 | 0 | 0 | 32.73 | 0.86 |

| 6 | −1 | −1 | 0 | 31.22 | 3.79 |

| 7 | 1 | 0 | −1 | 32.95 | 1.54 |

| 8 | 0 | 1 | −1 | 33.25 | 2.47 |

| 9 | 0 | 0 | 0 | 32.72 | 0.83 |

| 10 | −1 | 0 | −1 | 31.65 | 2.47 |

| 11 | 1 | 0 | 1 | 33.05 | 1.85 |

| 12 | 0 | −1 | −1 | 31.45 | 3.08 |

| 13 | 1 | 1 | 0 | 33.44 | 3.05 |

| 14 | 1 | −1 | 0 | 32.48 | 0.09 |

| 15 | 0 | 0 | 0 | 32.65 | 0.62 |

| 16 | 0 | 0 | 0 | 32.84 | 1.20 |

| 17 | −1 | 1 | 0 | 33.05 | 1.69 |

| Source of Variance | Sum of Square | Degree of Freedom | Mean Square | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 7.11 | 9 | 0.7901 | 40.95 | <0.0001 *** |

| 1.58 | 1 | 1.58 | 81.65 | <0.0001 *** | |

| 4.79 | 1 | 4.79 | 248.24 | <0.0001 *** | |

| 0.1512 | 1 | 0.1512 | 7.84 | 0.0265 ** | |

| 0.1892 | 1 | 0.1892 | 9.81 | 0.0166 ** | |

| 0.1225 | 1 | 0.1225 | 6.35 | 0.0398 ** | |

| 0.01 | 1 | 0.01 | 0.5183 | 0.4949 | |

| 0.0051 | 1 | 0.0051 | 0.2635 | 0.6235 | |

| 0.1075 | 1 | 0.1075 | 5.57 | 0.0503 | |

| 0.1399 | 1 | 0.1399 | 7.25 | 0.031 ** | |

| Residual | 0.1351 | 7 | 0.0193 | ||

| Lack of fit | 0.1156 | 3 | 0.0385 | 7.91 | 0.0371 |

| Pure error | 0.0195 | 4 | 0.0049 | ||

| Sum | 7.25 | 16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Bai, J.; Wang, X.; Fang, W.; Hong, T.; Zang, N.; Fang, L.; Wang, G. Calibration and Testing of Discrete Elemental Simulation Parameters for Pod Pepper Seeds. Agriculture 2024, 14, 831. https://doi.org/10.3390/agriculture14060831

Chen X, Bai J, Wang X, Fang W, Hong T, Zang N, Fang L, Wang G. Calibration and Testing of Discrete Elemental Simulation Parameters for Pod Pepper Seeds. Agriculture. 2024; 14(6):831. https://doi.org/10.3390/agriculture14060831

Chicago/Turabian StyleChen, Xingye, Jing Bai, Xinzhong Wang, Weiquan Fang, Tianyu Hong, Nan Zang, Liangliang Fang, and Gaoliang Wang. 2024. "Calibration and Testing of Discrete Elemental Simulation Parameters for Pod Pepper Seeds" Agriculture 14, no. 6: 831. https://doi.org/10.3390/agriculture14060831

APA StyleChen, X., Bai, J., Wang, X., Fang, W., Hong, T., Zang, N., Fang, L., & Wang, G. (2024). Calibration and Testing of Discrete Elemental Simulation Parameters for Pod Pepper Seeds. Agriculture, 14(6), 831. https://doi.org/10.3390/agriculture14060831