Design and Optimization of a Mixed-Flow Drying Chamber for Tiger Nuts Based on CFD-DEM Heat and Mass Transfer Model

Abstract

1. Introduction

2. Materials and Methods

2.1. Mathematical Model

2.1.1. Governing Equations for Solid Phase

2.1.2. Governing Equations for Gas Phase

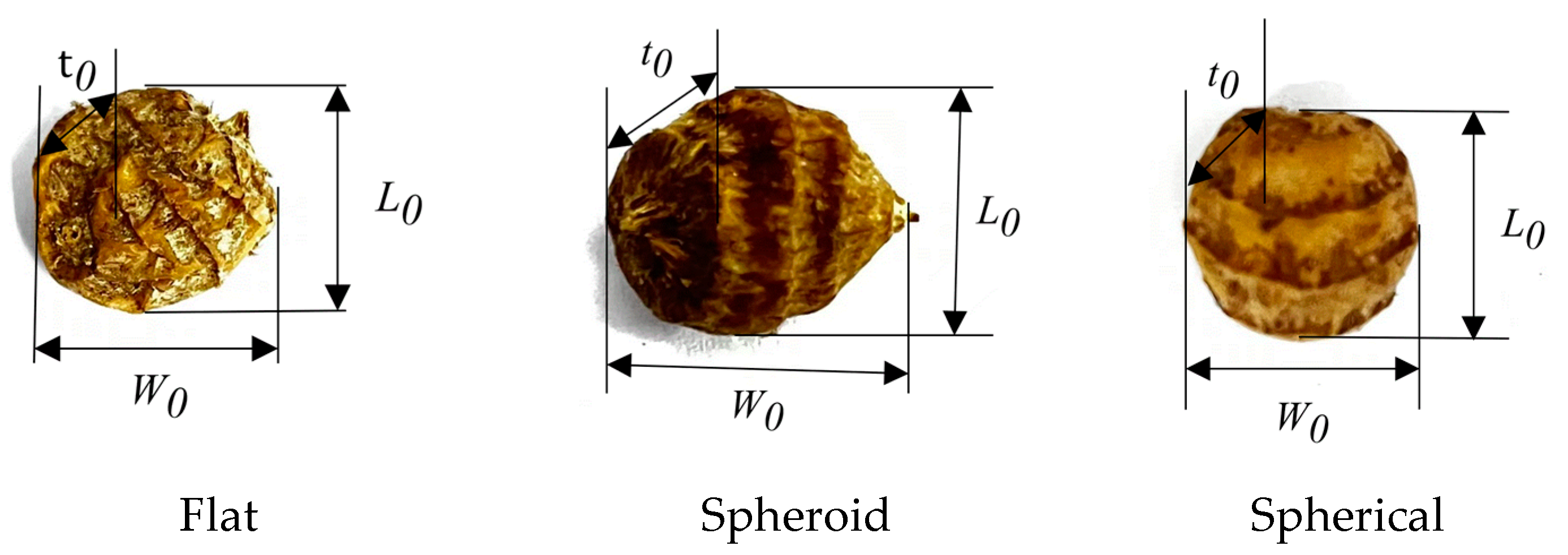

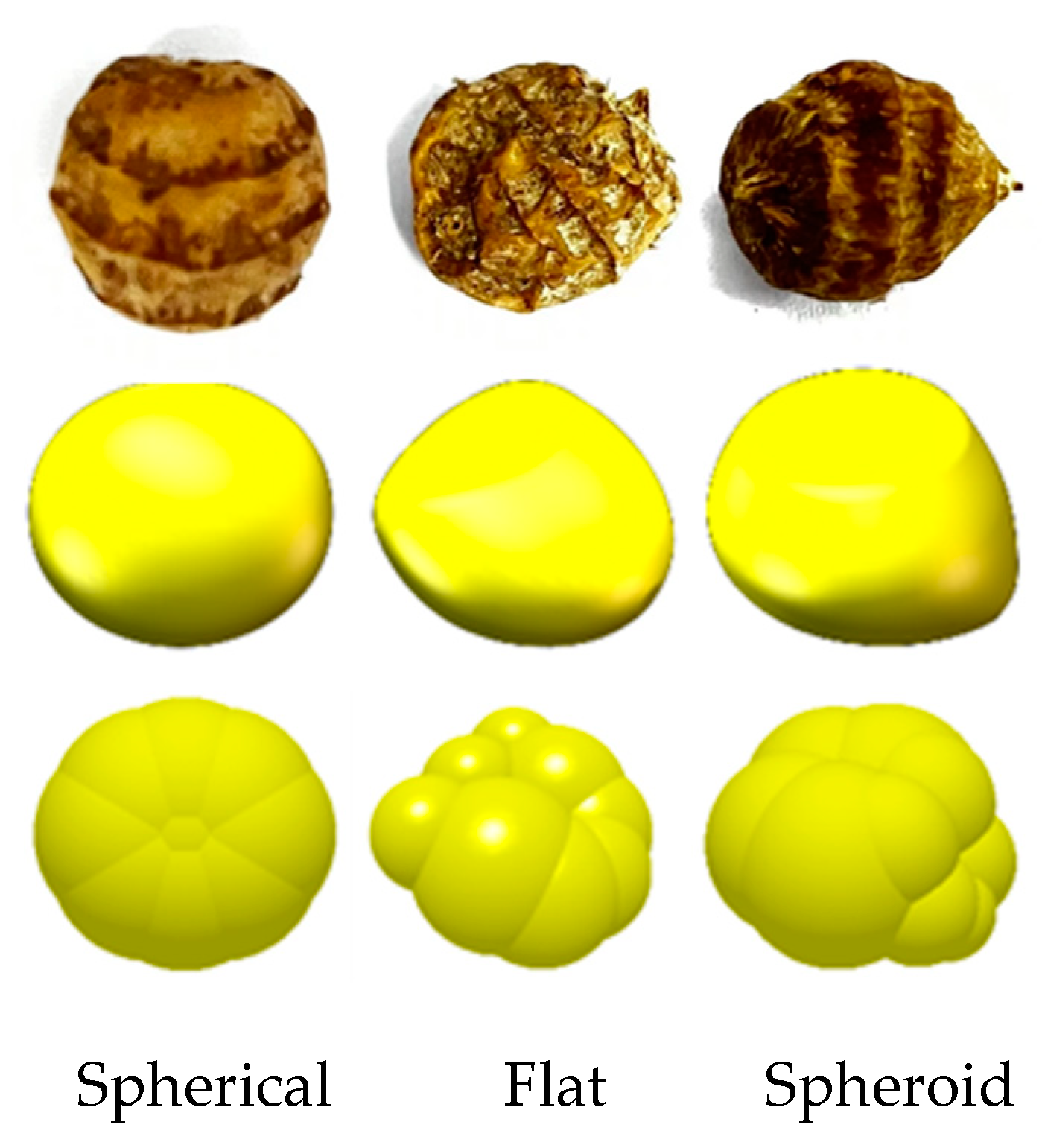

2.2. Particle Model

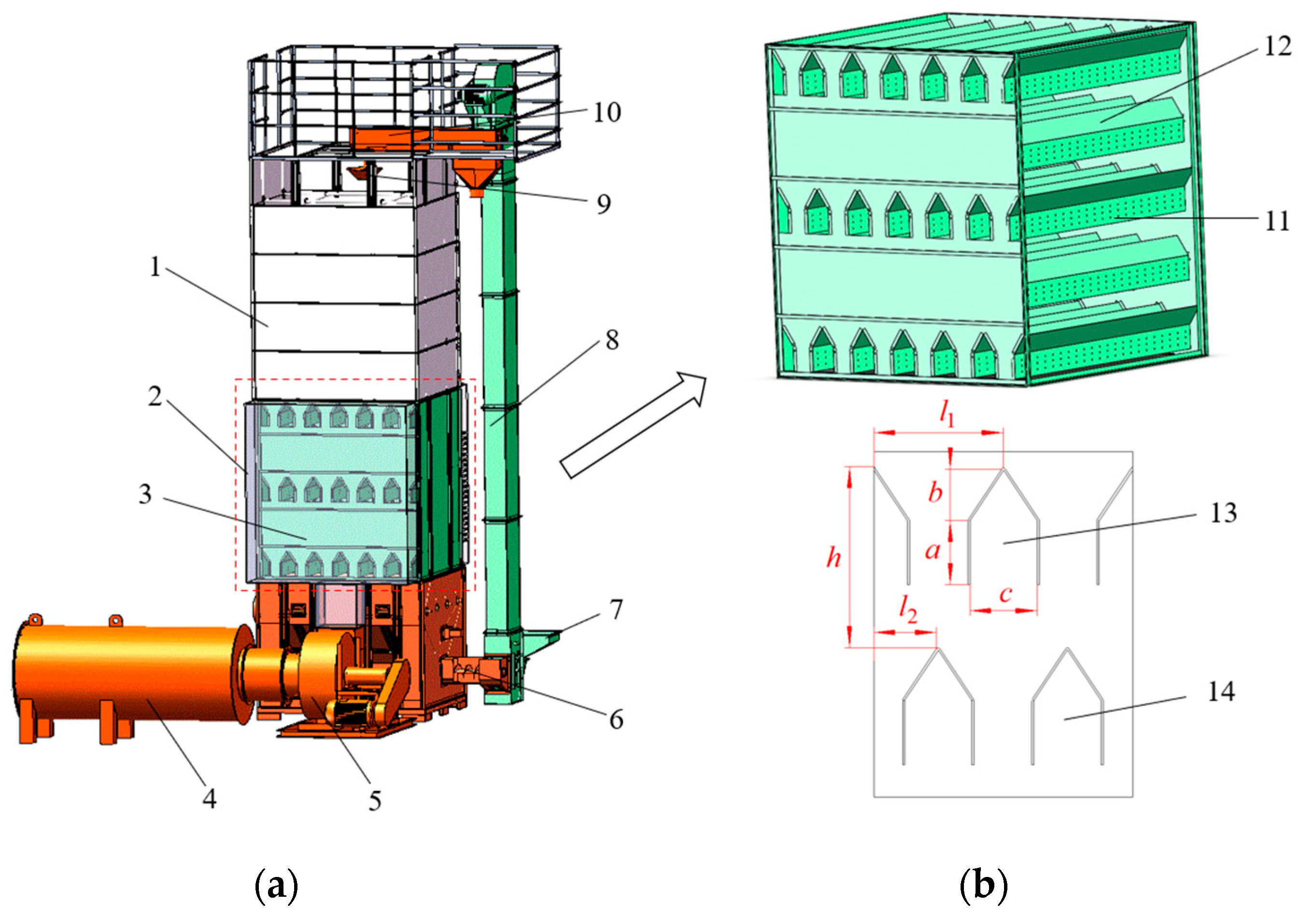

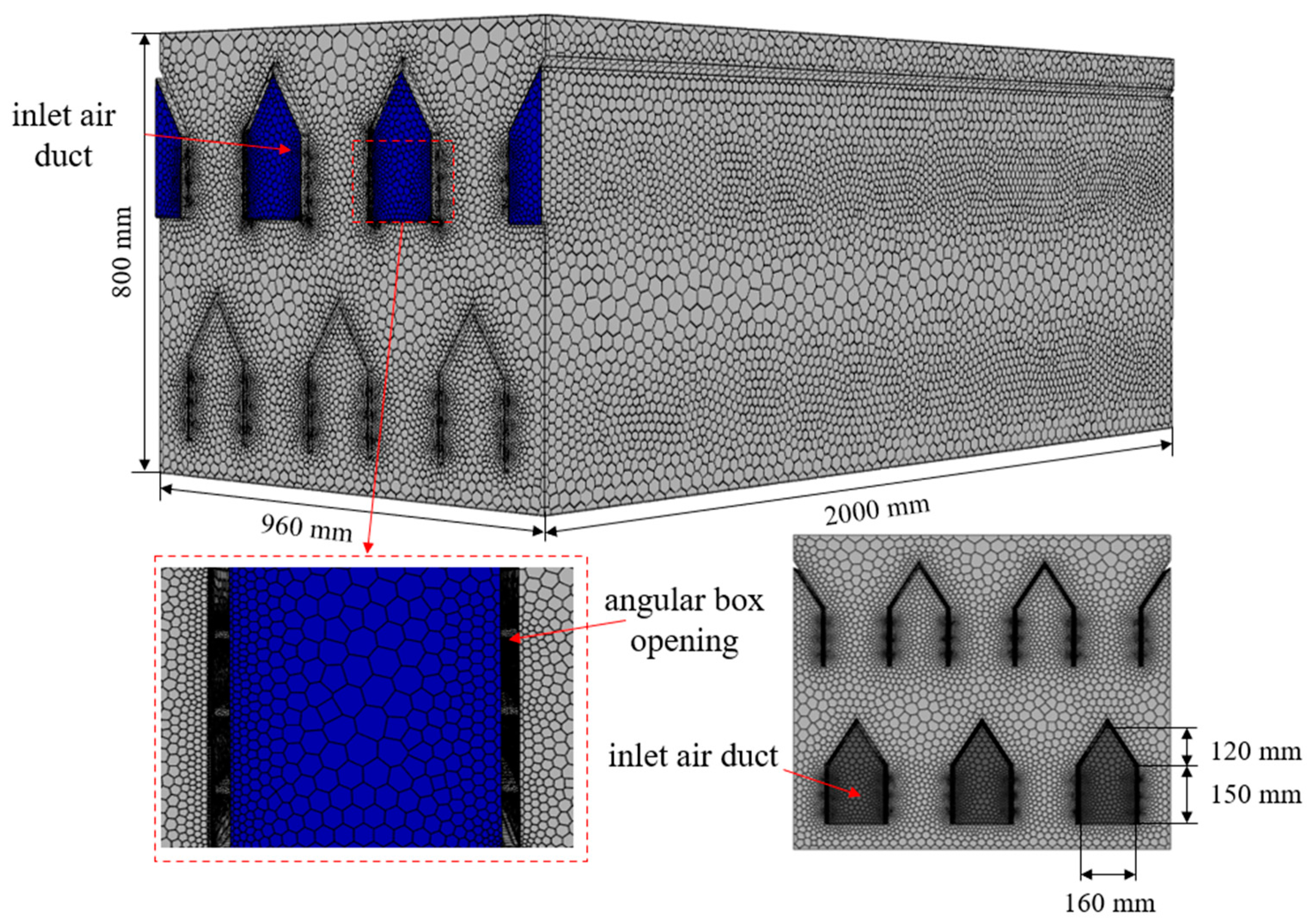

2.3. Geometric Model

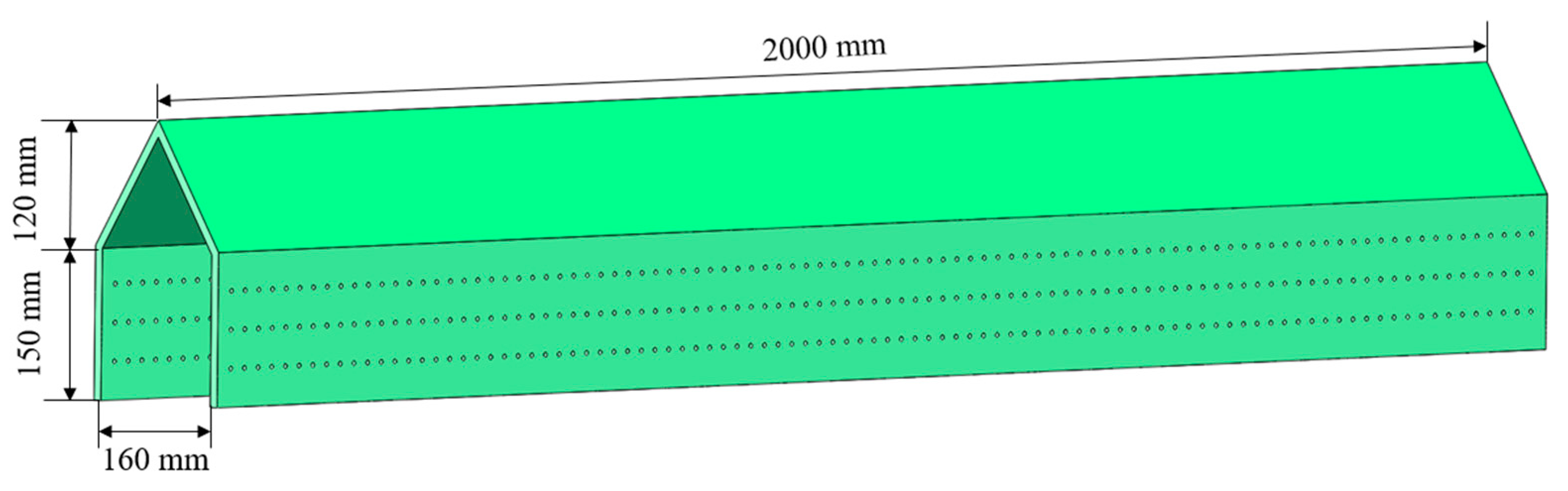

2.3.1. Corner Box

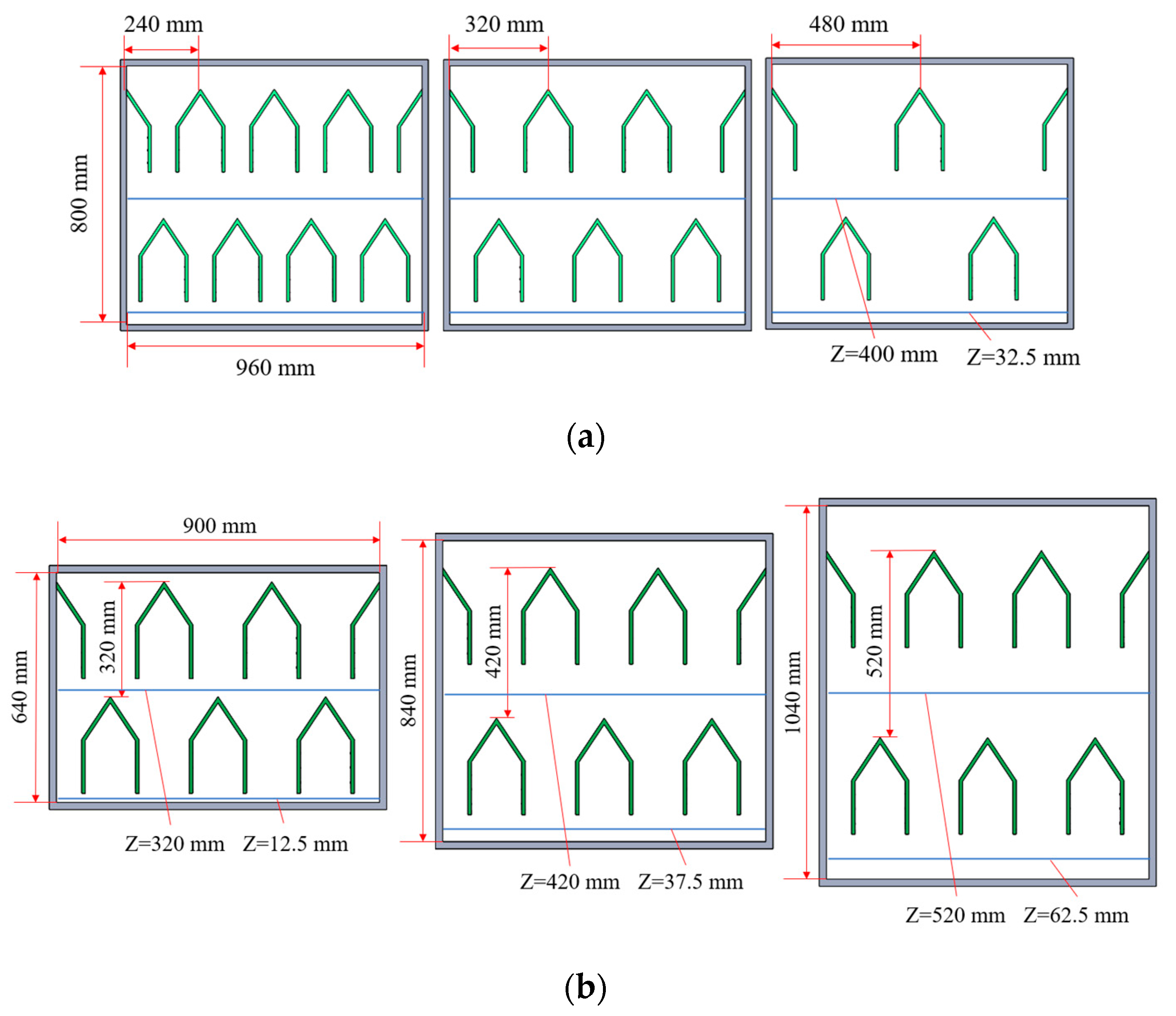

2.3.2. Corner Box Layout Analysis

2.4. Simulation Conditions

2.5. Experiment

2.5.1. Materials

2.5.2. Experiment Equipment

2.5.3. Experiment Method

3. Results and Discussion

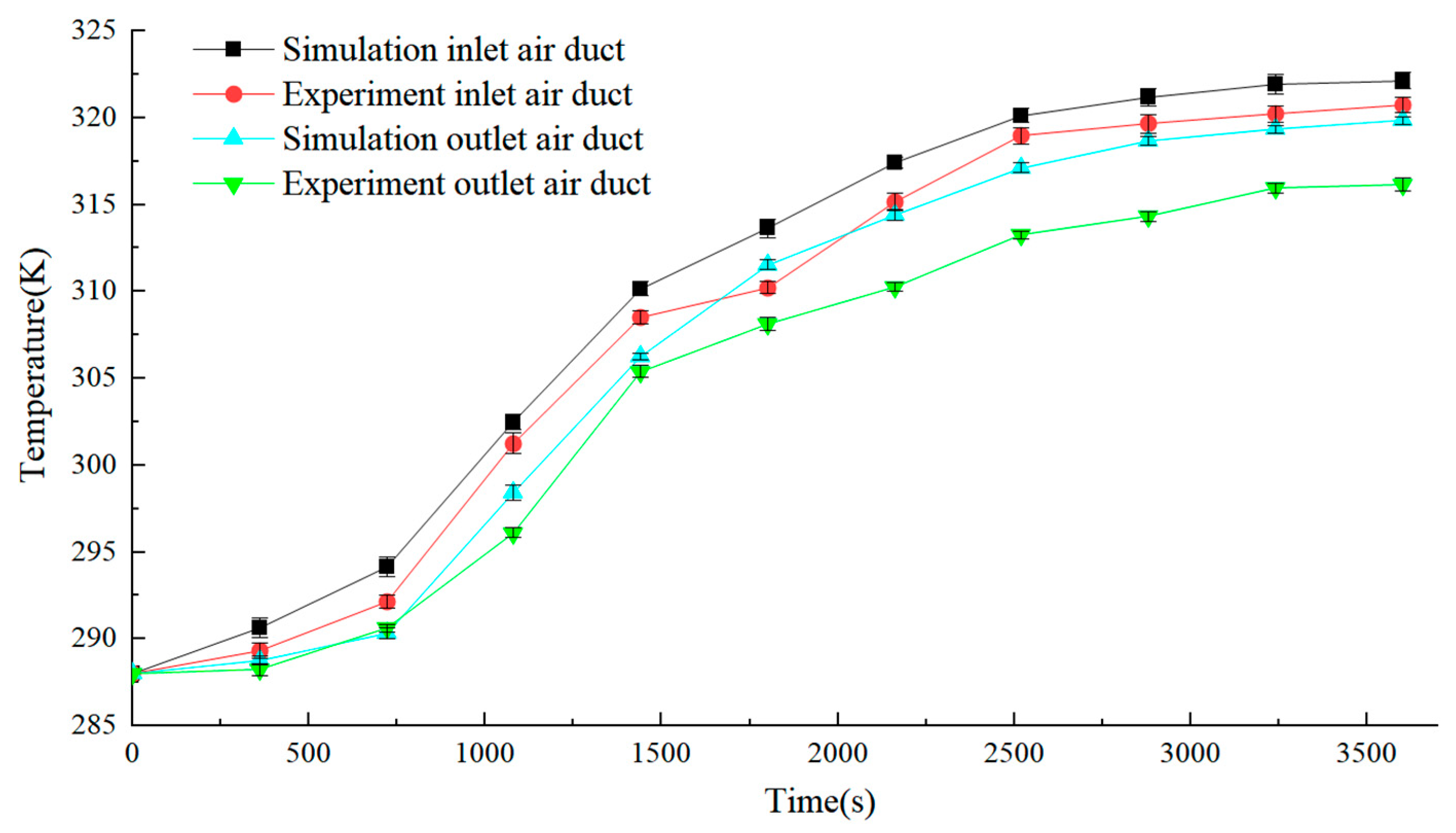

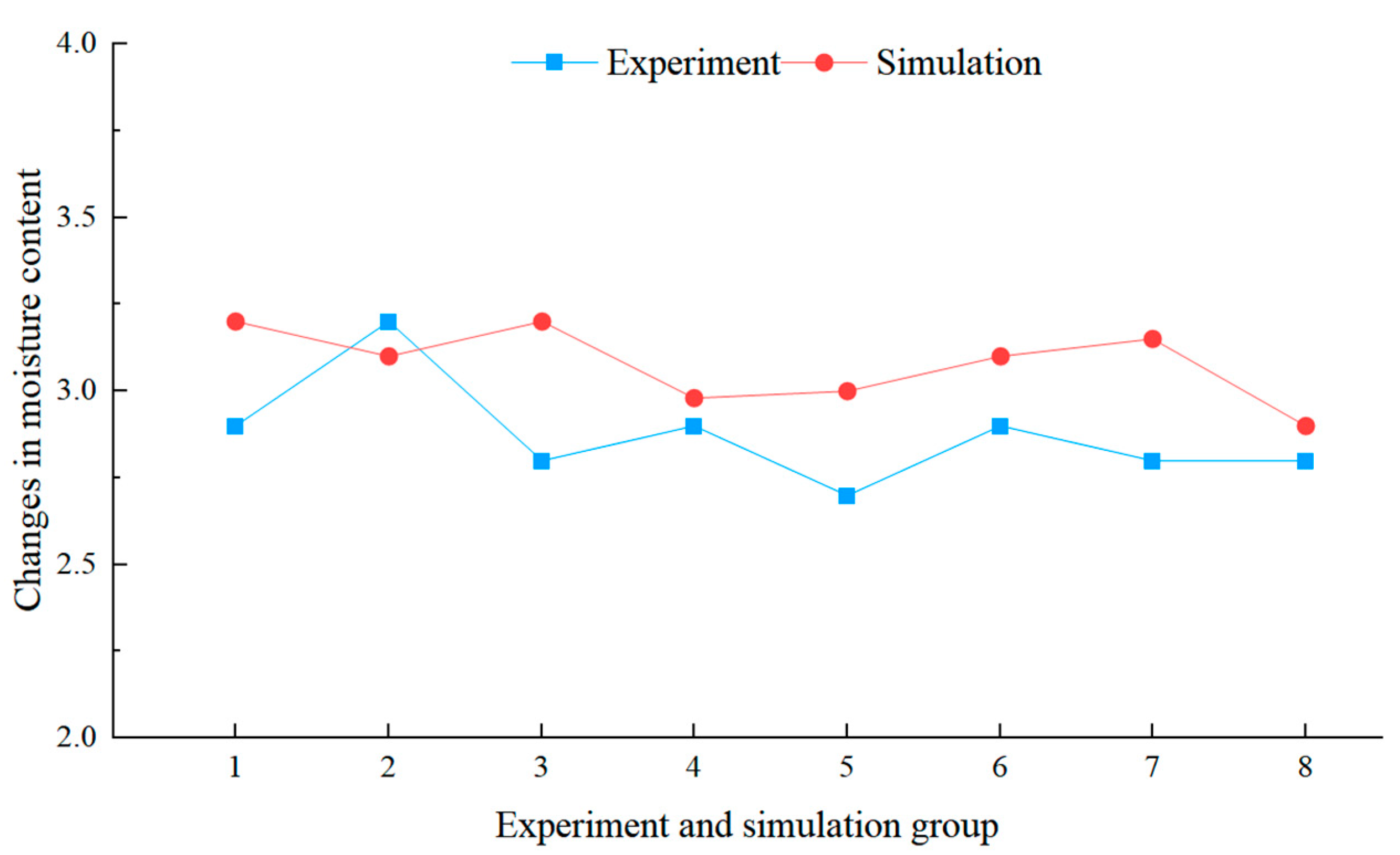

3.1. Simulation vs. Experimental Results

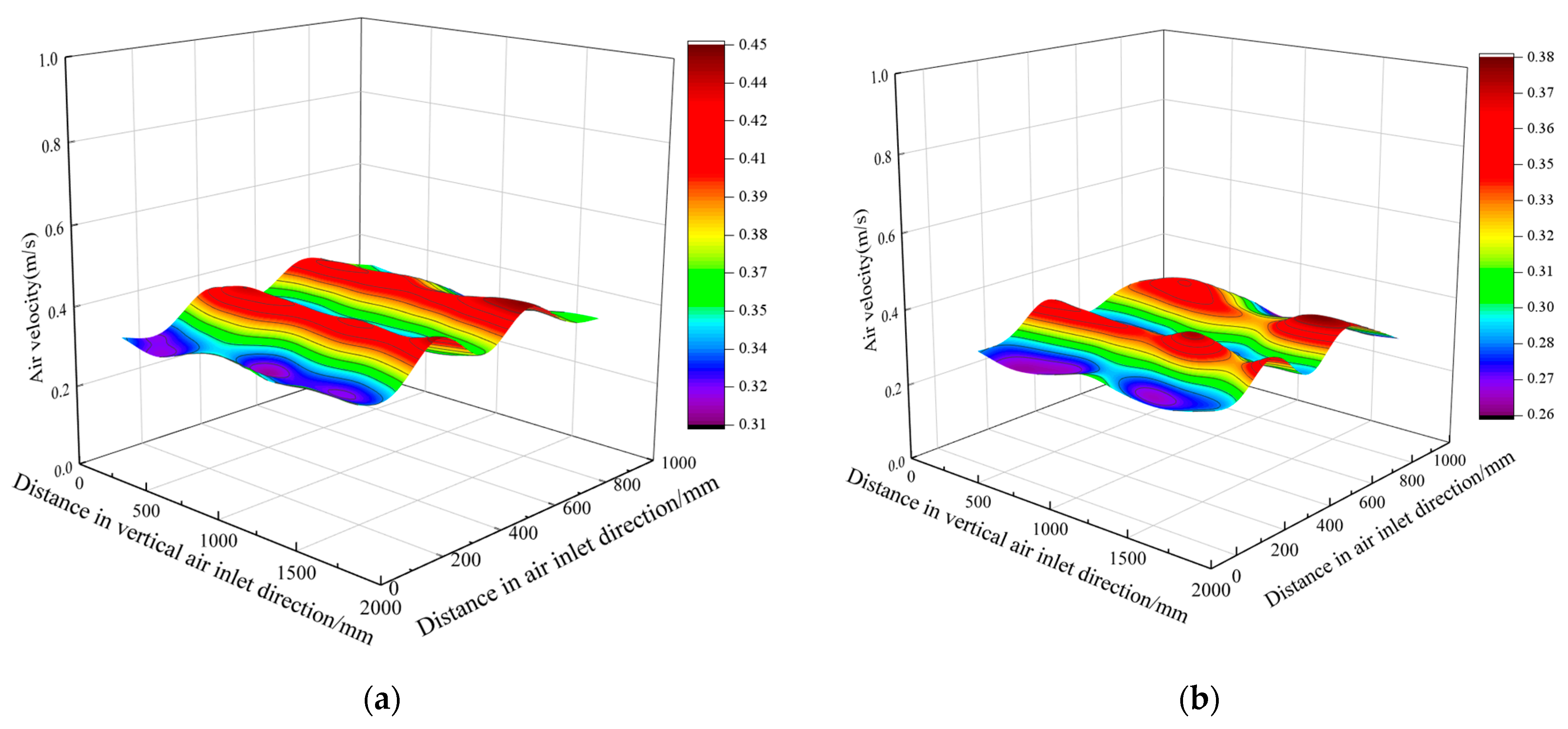

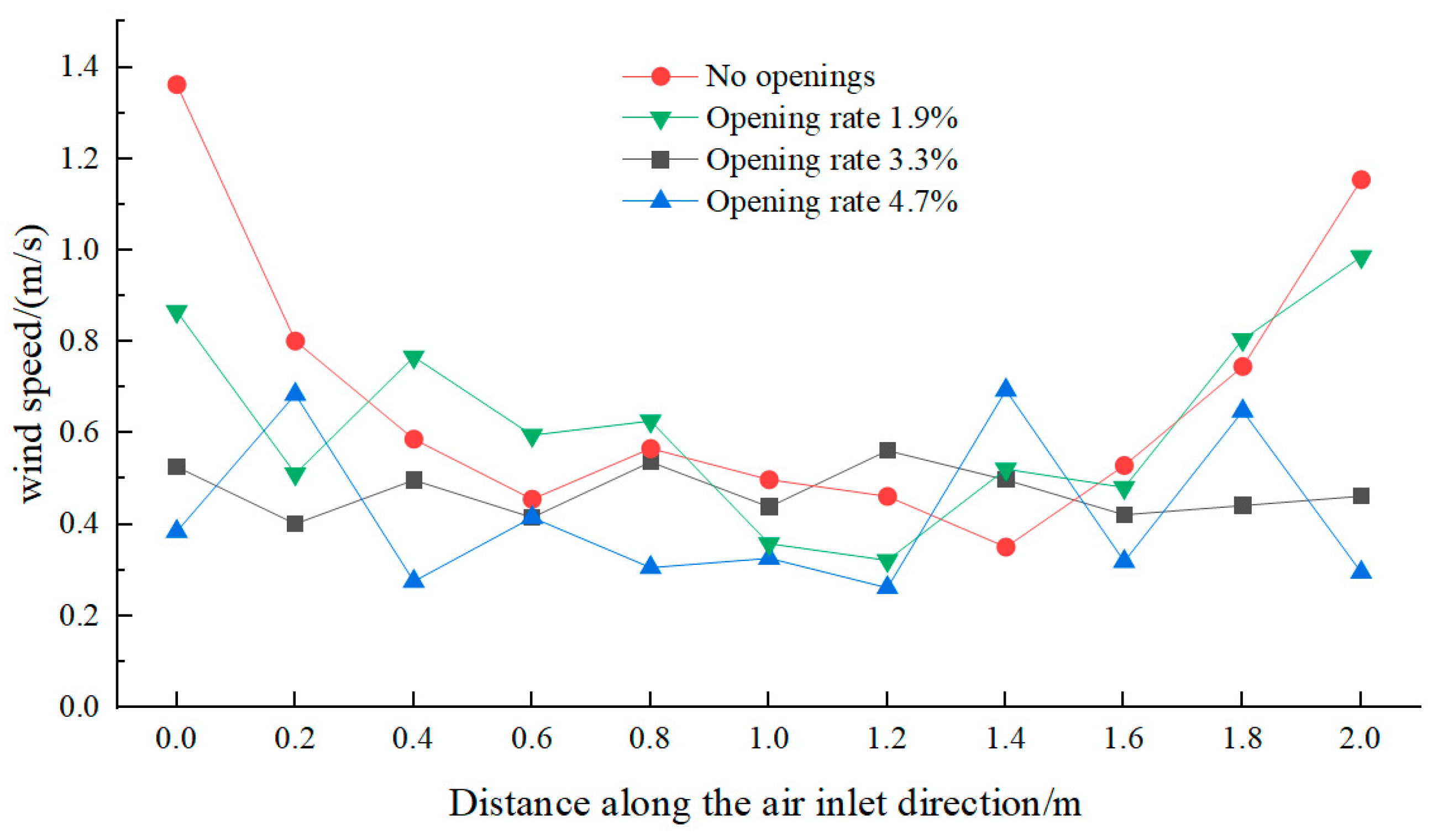

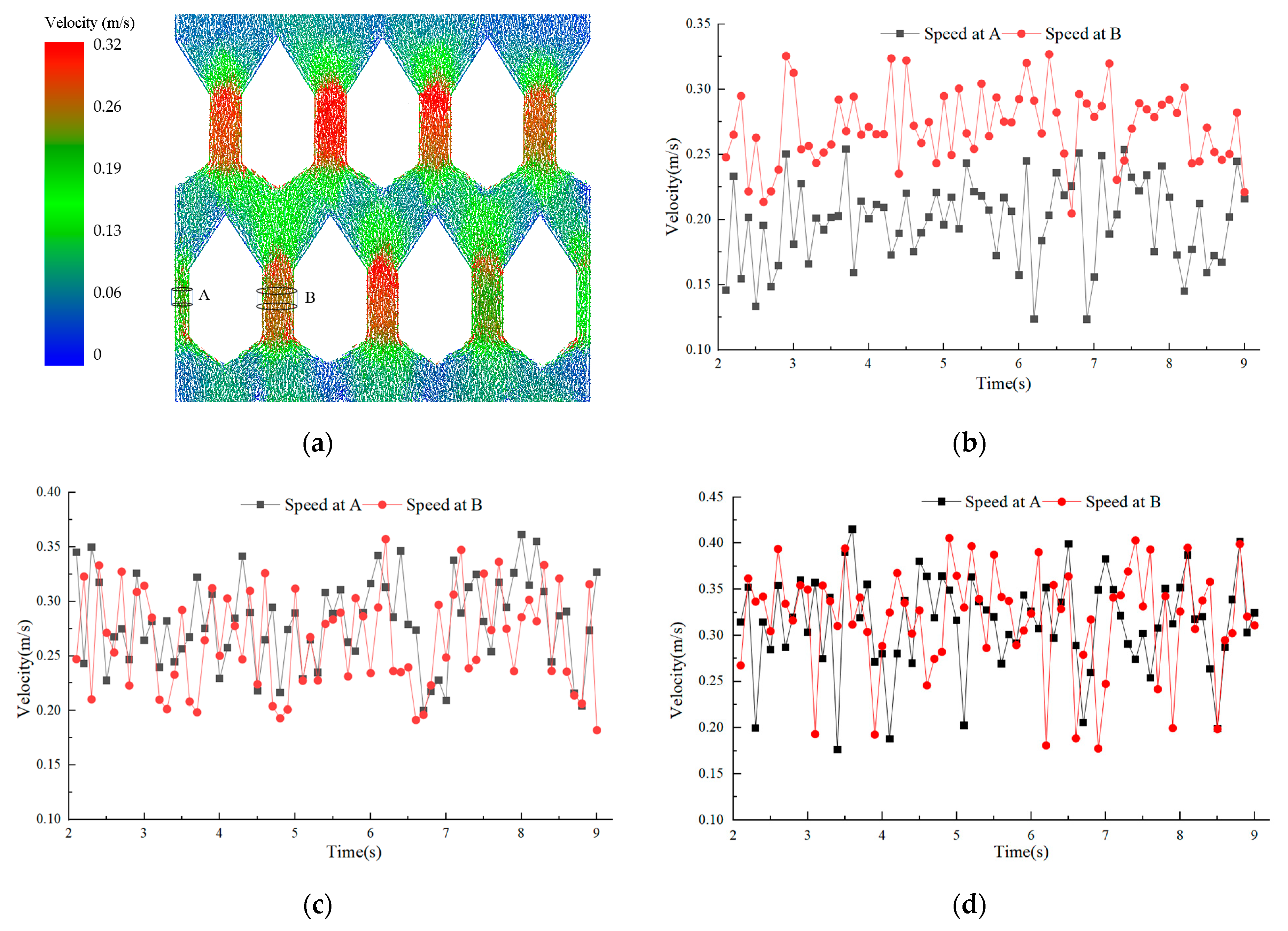

3.2. Effect of Opening Rate

3.3. Effects of Spatial Location

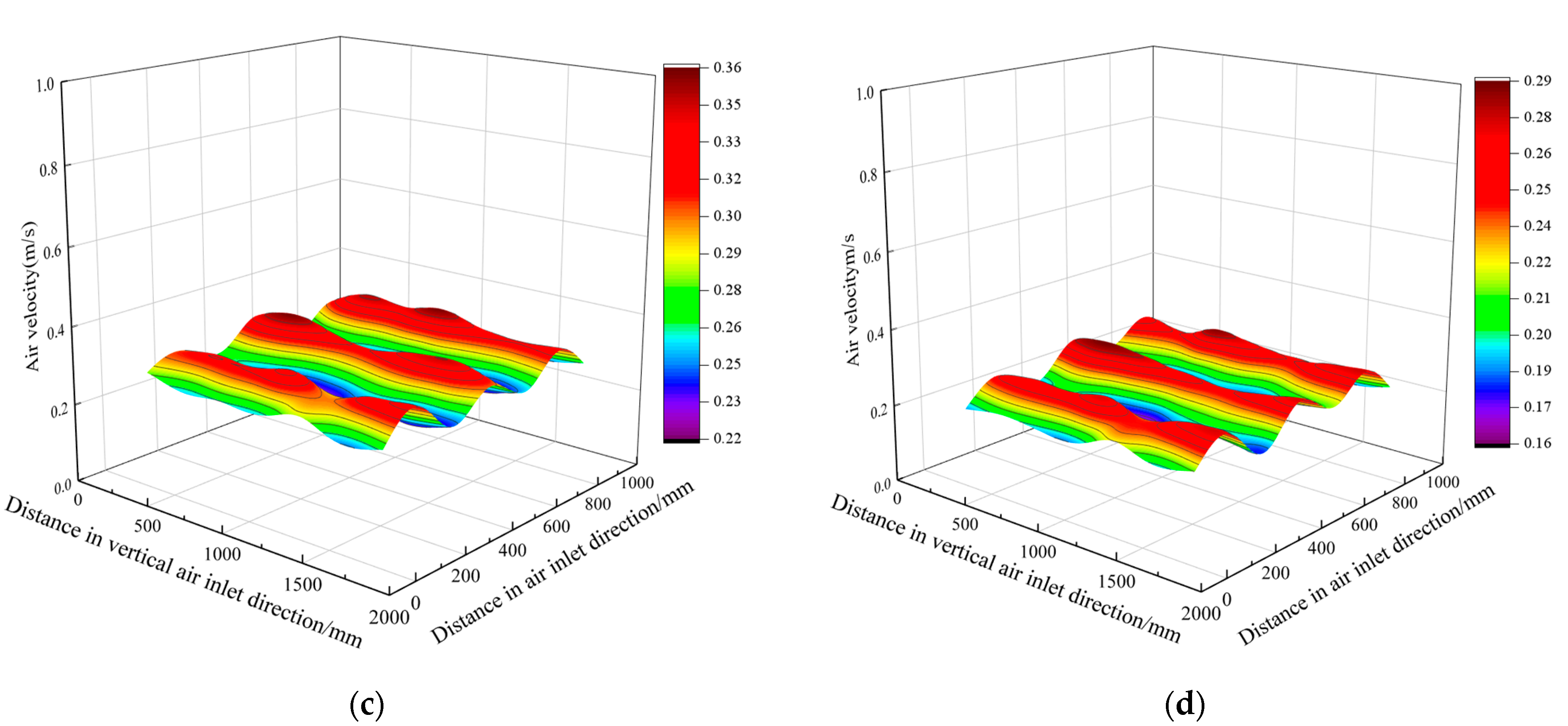

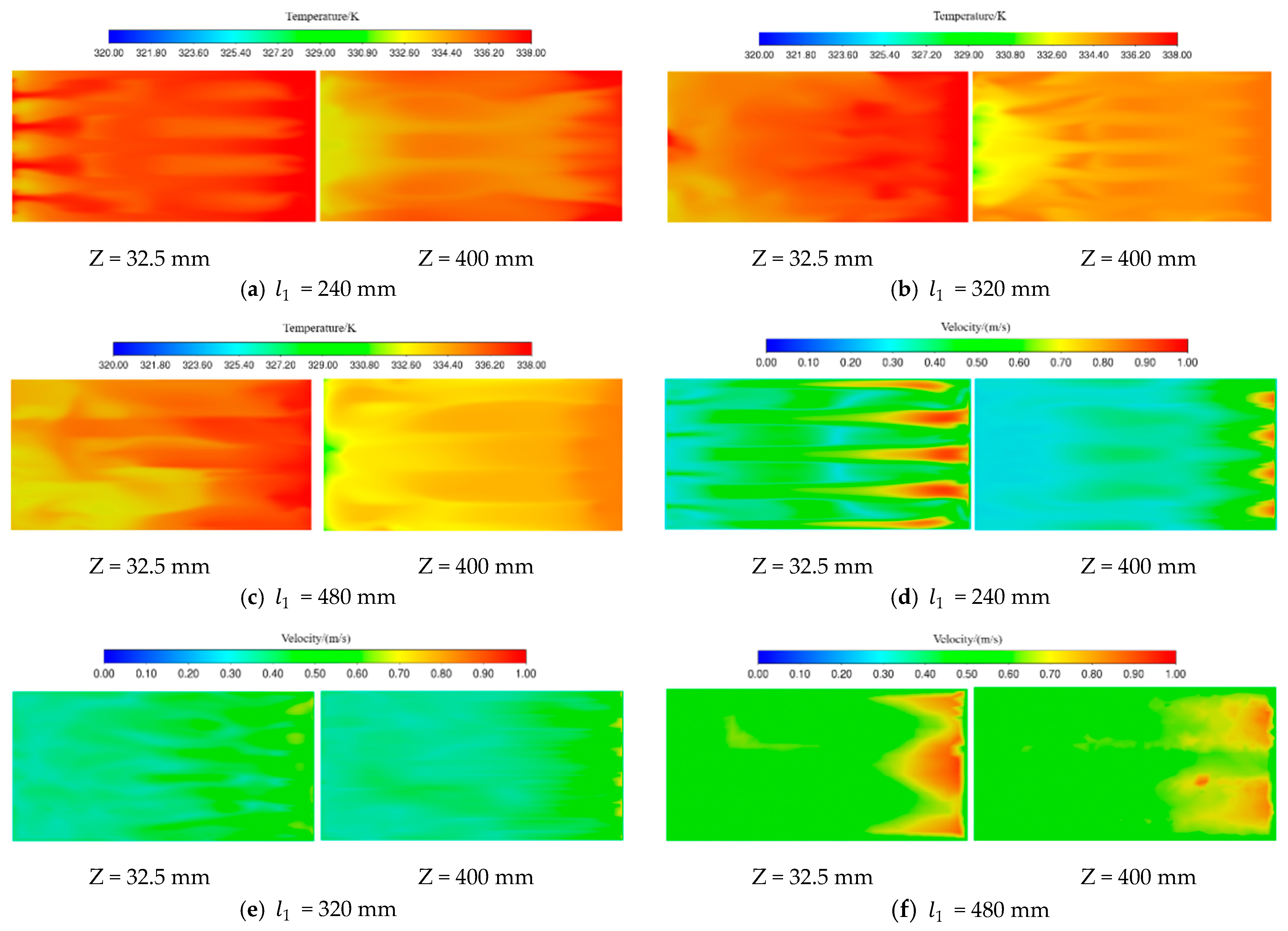

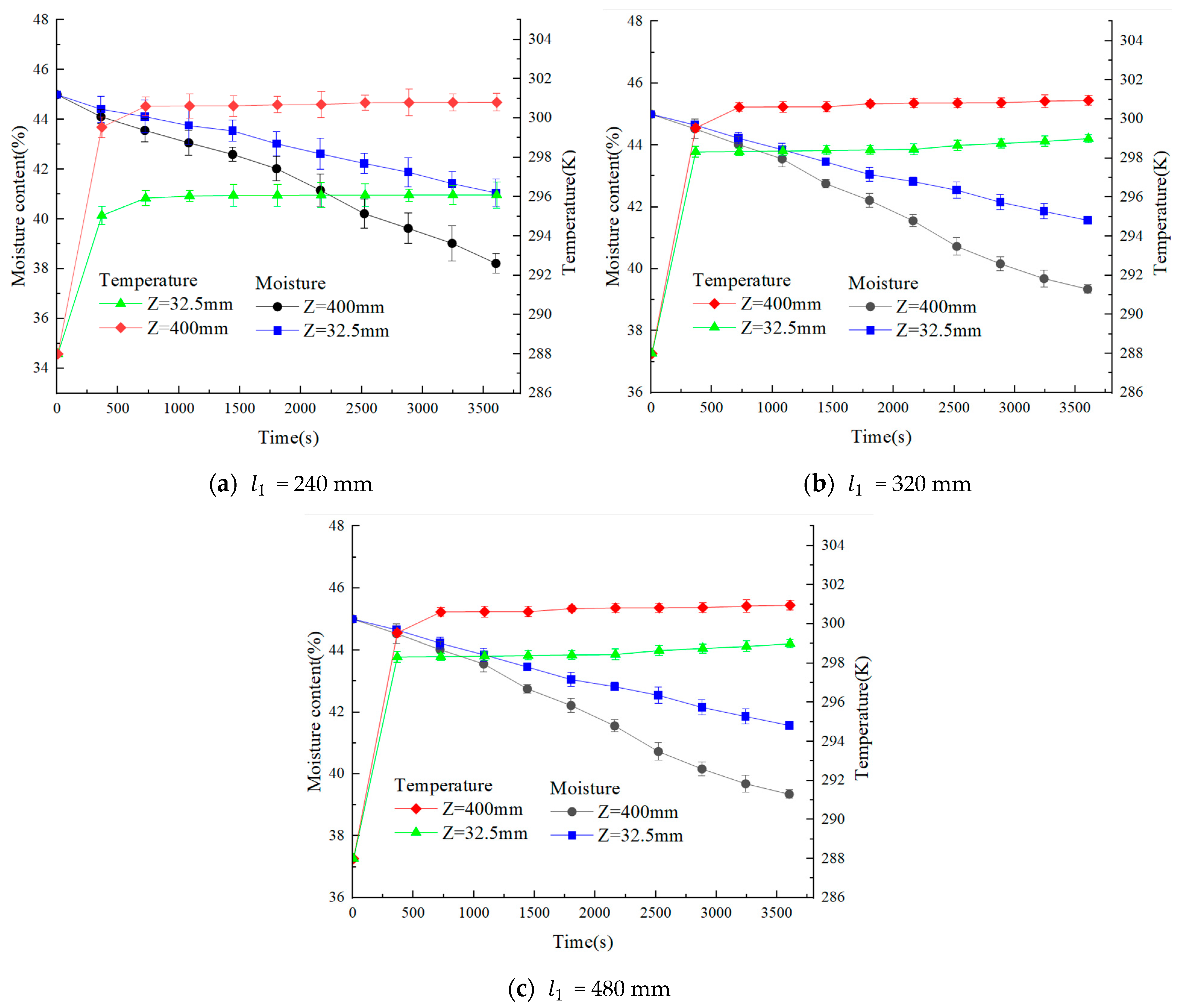

3.3.1. Effects of Lateral Distance

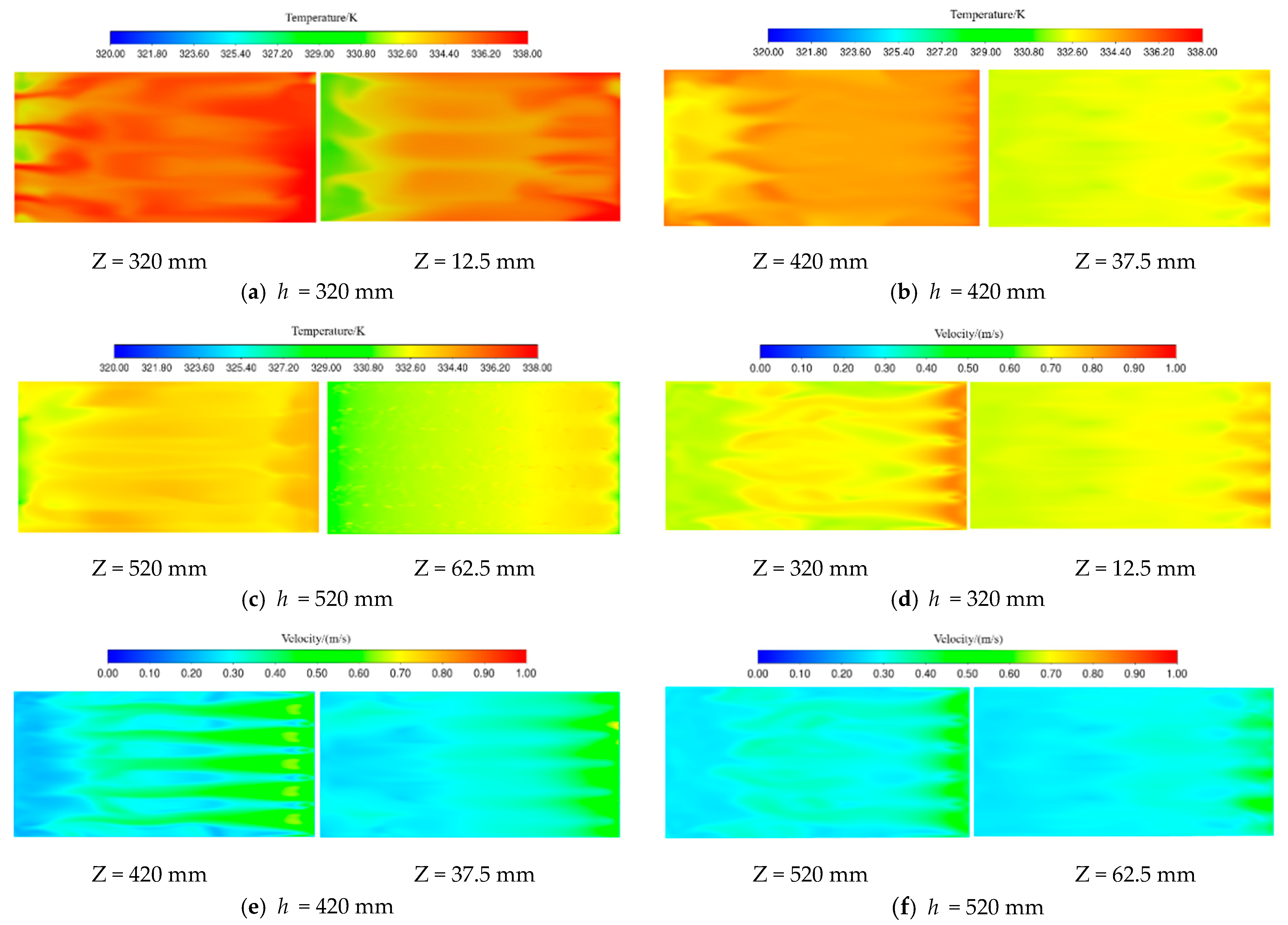

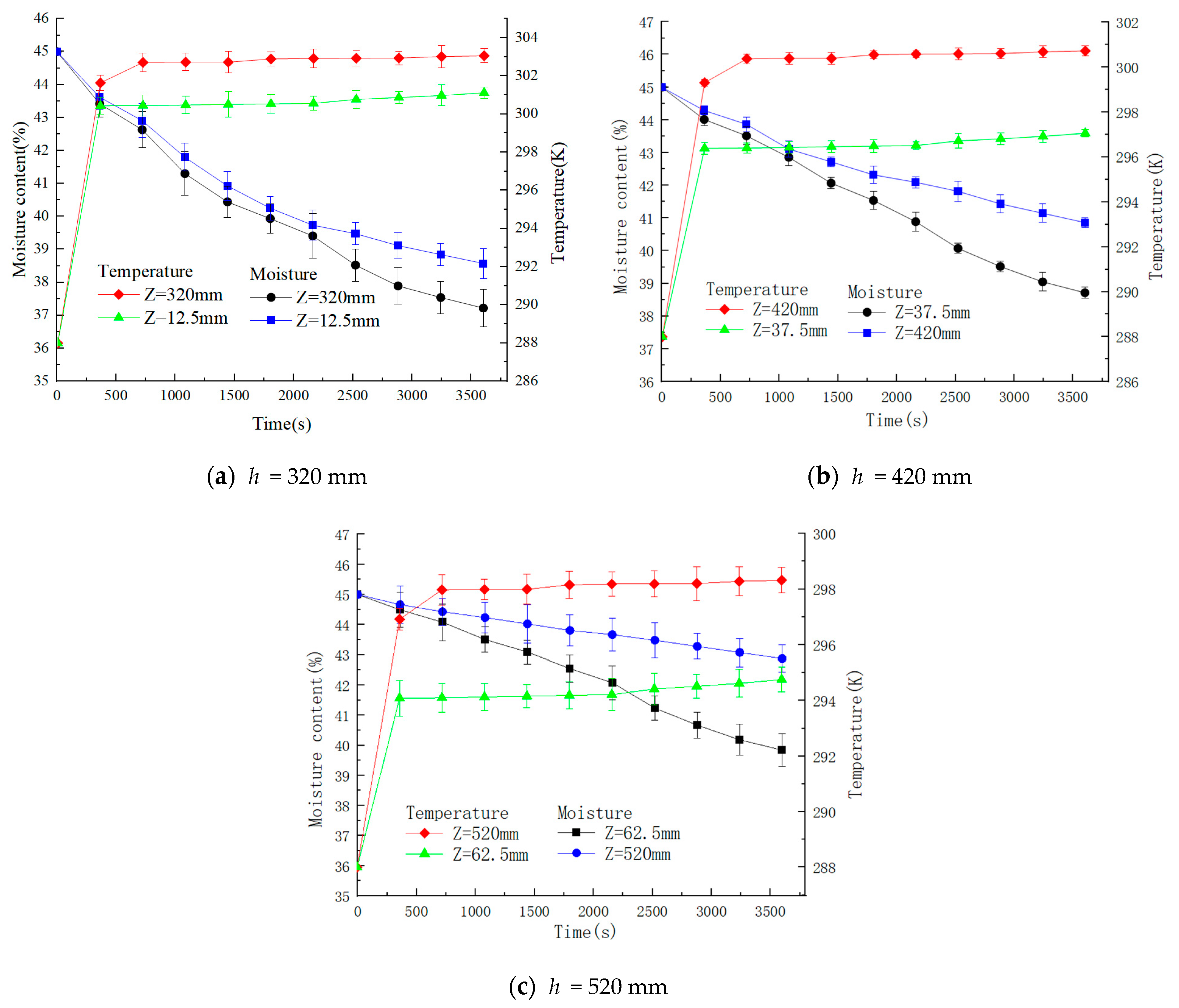

3.3.2. Effect of Longitudinal Distance

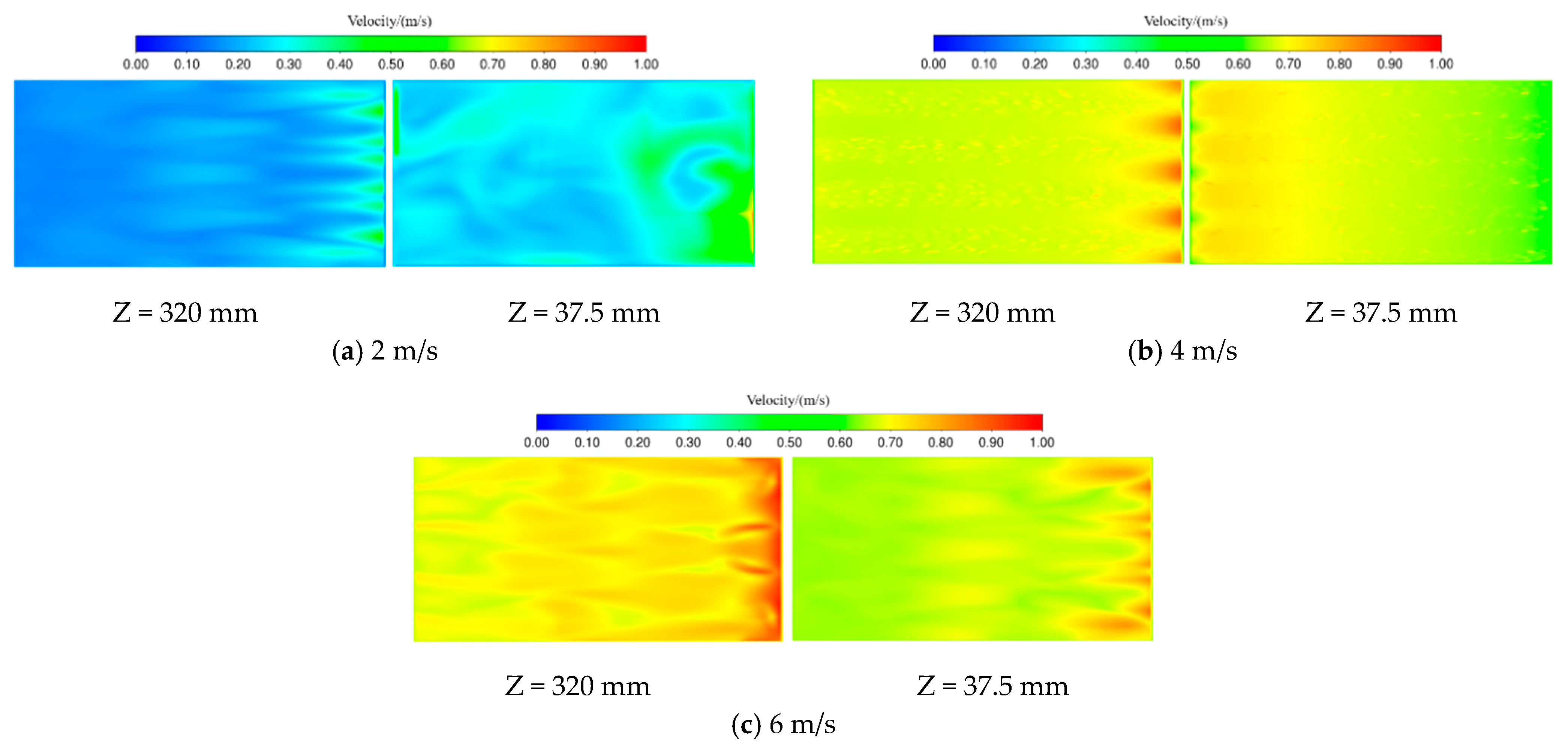

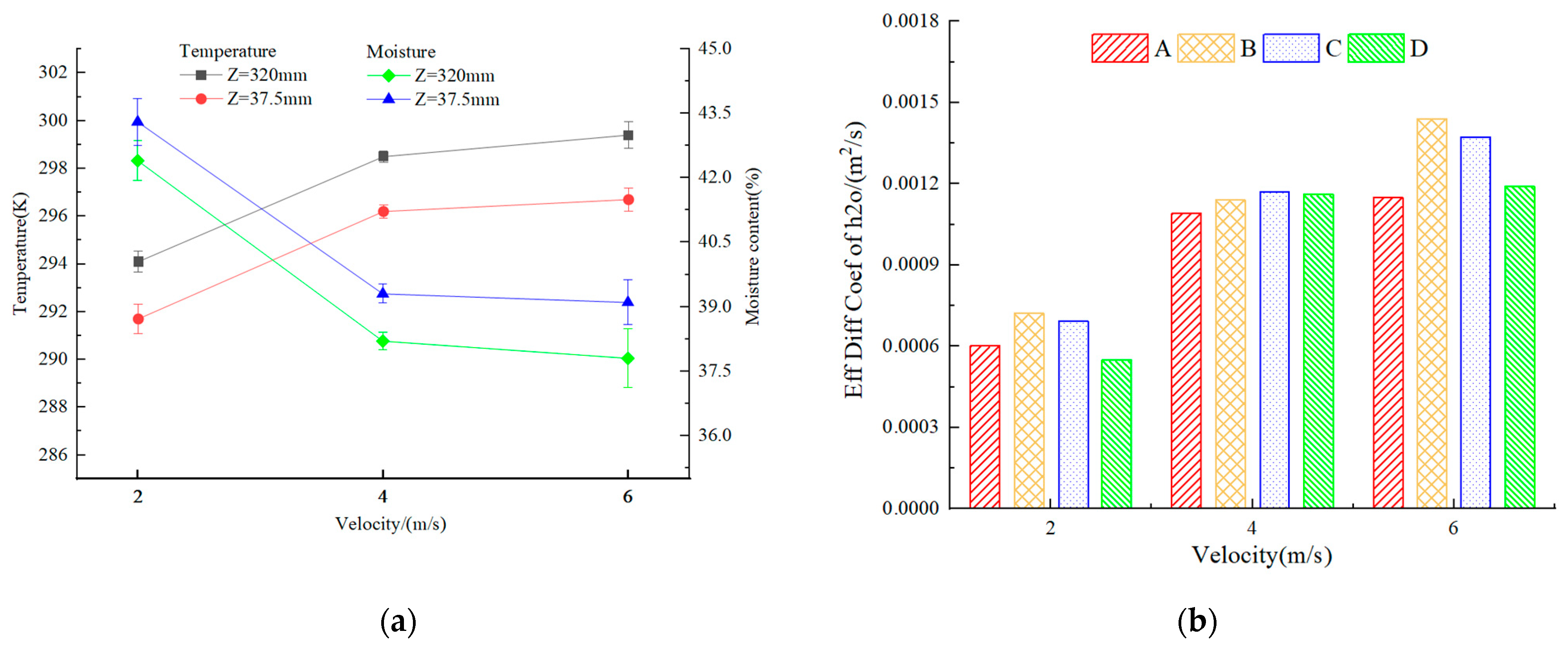

3.4. Effect of Wind Speed on Drying Effect

4. Conclusions

- (1)

- Using the principle of negative pressure micro-perforated air supply, the open-hole corner box is designed. The tiger nut model is established using EDEM, and the tiger nut drying process is simulated using CFD-DEM coupled simulation to verify the accuracy of the simulation model. Analysis of variance (ANOVA) is used to analyze the temperature and wind speed data of the simulation and test; it is concluded that there is no statistically significant difference between the test and simulation results. Therefore, the tiger nut drying process can be simulated better by using this model.

- (2)

- The wind fields of three corner boxes with different aperture ratios are compared and analyzed. The results show that the average wind speed below the air inlet increases gradually with the opening ratio increase. When the opening ratio is 0.33%, the wind field uniformity is better.

- (3)

- The influence of corner box distribution on changes in the water content of tiger nuts is analyzed. The consistency of water content distribution increases and then decreases with increasing lateral distance, and the flow rate of tiger nuts during grain discharge gradually increases. The rate of water content decrease gradually decreases with the longitudinal distance increase. When the lateral distance is 320 mm and the longitudinal distance is 420 mm, the water content of the grain is basically consistent.

- (4)

- The effects of different inlet wind speeds on the drying effect are analyzed. With the increase in wind speed, the temperature of the seeds warms up faster, the water content decreases faster, and the diffusion rate of water vapor increases faster. When the wind speed is 4 m/s, the temperature and water content of tiger nuts basically change in the same way, and the water content has good consistency. Therefore, this can provide a theoretical basis for the design of tiger nut drying equipment.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ezeh, O.; Gordon, M.; Niranjan, K. Enhancing the recovery of tiger nut (Cyperus esculentus) oil by mechanical pressing: Moisture content, particle size, high pressure and enzymatic pre-treatment effects. Food Chem. 2016, 194, 354–361. [Google Scholar] [CrossRef]

- Qu, Z.; Han, M.; Lv, Y.; Zhou, Z.; Lv, Z.; Wang, W.; He, X. Design and Test of a Crawler-Type Tiger-Nut Combine Harvester. Agriculture 2023, 13, 277. [Google Scholar] [CrossRef]

- Yu, Y.; Lu, X.; Zhang, T.; Zhao, C.; Guan, S.; Pu, Y.; Gao, F. Tiger Nut (Cyperus esculentus L.): Nutrition, Processing, Function and Applications. Foods 2022, 11, 601. [Google Scholar] [CrossRef] [PubMed]

- Jokiniemi, H.T.; Ahokas, J.M. Drying process optimisation in a mixed-flow batch grain dryer. Biosyst. Eng. 2014, 121, 209–220. [Google Scholar] [CrossRef]

- Mellmann, J.; Iroba, K.; Metzger, T.; Tsotsas, E.; Mészáros, C.; Farkas, I. Moisture content and residence time distributions in mixed-flow grain dryers. Biosyst. Eng. 2011, 109, 297–307. [Google Scholar] [CrossRef]

- Scaar, H.; Franke, G.; Weigler, F.; Delele, M.; Tsotsas, E.; Mellmann, J. Experimental and numerical study of the airflow distribution in mixed-flow grain dryers. Dry. Technol. 2016, 34, 595–607. [Google Scholar] [CrossRef]

- Cao, C.; Yang, D.; Liu, Q. Research on modeling and simulation of mixed flow grain dryer. Dry. Technol. 2007, 25, 681–687. [Google Scholar] [CrossRef]

- Weigler, F.; Scaar, H.; Mellmann, J. Investigation of particle and air flows in a mixed-flow dryer. Dry. Technol. 2012, 30, 1730–1741. [Google Scholar] [CrossRef]

- Keppler, I.; Kocsis, L.; Oldal, I.; Farkas, I.; Csatar, A. Grain velocity distribution in a mixed flow dryer. Adv. Powder Technol. 2012, 23, 824–832. [Google Scholar] [CrossRef]

- Jiang, Q.; Zhang, Y.; Yan, S.; Xu, L. Optimal design of an corner box for a mixed flow grain dryer. Appl. Eng. Agric. 2021, 37, 555–562. [Google Scholar] [CrossRef]

- Gang, C.; Ruili, G.; Lin, W. Optimized design and experimental study on rice negative pressure mixed flow drying chamber. Trans. CSAE 2021, 37, 87–96. [Google Scholar] [CrossRef]

- Visconcini, A.R.; Andrade, C.M.G.; de Souza Costa, A.M. Fluid flow simulation of industrial fixed bed mixed-flow grain dryer using k-ω SST turbulence model. Int. J. Agric. Biol. Eng. 2021, 14, 226–230. [Google Scholar] [CrossRef]

- Luo, H.; Li, C.; Zhang, Y. Design and experimental study of 5HP-25 type grain dryer. Trans. CSAE 2021, 37, 279–289. [Google Scholar] [CrossRef]

- Ma, H.; Zhou, L.; Liu, Z.; Chen, M.; Xia, X.; Zhao, Y. A review of recent development for the CFD-DEM investigations of non-spherical particles. Powder Technol. 2022, 412, 117972. [Google Scholar] [CrossRef]

- Handayani, S.U.; Wahyudi, H.; Agustina, S.; Yulianto, M.E.; Ariyanto, H.D. CFD-DEM Study of heat and mass transfer of ellipsoidal particles in fluidized bed dryers. Powder Technol. 2023, 425, 118535. [Google Scholar] [CrossRef]

- Wang, P.; Wang, H.; Zhang, R.; Hu, R.; Hao, B.; Huang, J. Numerical Simulation of an Online Cotton Lint Sampling Device Using Coupled CFD–DEM Analysis. Agriculture 2024, 14, 127. [Google Scholar] [CrossRef]

- Luo, X.; Yu, J.; Wang, B.; Wang, J. Heat transfer and hydrodynamics in stirred tanks with liquid-solid flow studied by CFD–DEM method. Processes 2021, 9, 849. [Google Scholar] [CrossRef]

- Yuan, Y.; Wang, J.; Zhang, X.; Zhao, S. Effect of Rotary Speed on Soil and Straw Throwing Process by Stubble-Crushing Blade for Strip Tillage Using DEM-CFD. Agriculture 2023, 13, 877. [Google Scholar] [CrossRef]

- Che, H.; Wang, H.; Xu, L.; Ge, R. Investigation of gas-solid heat and mass transfer in a Wurster coater using a scaled CFD-DEM model. Powder Technol. 2022, 406, 117598. [Google Scholar] [CrossRef]

- Xiao, Y.; Ma, Z.; Wu, M.; Luo, H. Numerical Study of Pneumatic Conveying of Rapeseed through a Pipe Bend by DEM-CFD. Agriculture 2022, 12, 1845. [Google Scholar] [CrossRef]

- Lan, B.; Zhao, P.; Xu, J.; Zhao, B.; Zhai, M.; Wang, J. CFD-DEM-IBM simulation of particle drying processes in gas-fluidized beds. Chem. Eng. Sci. 2022, 255, 117653. [Google Scholar] [CrossRef]

- Guo, R.; Bai, J.; Wu, F.; Wang, J.; Ma, X.; Hui, Z. CFD–DEM simulation of wet granular-fluid flows and heat transfer in an integral multi-jet spout-fluidized bed. Powder Technol. 2022, 403, 117384. [Google Scholar] [CrossRef]

- Sousani, M.; Hobbs, A.M.; Anderson, A.; Wood, R. Accelerated heat transfer simulations using coupled DEM and CFD. Powder Technol. 2019, 357, 367–376. [Google Scholar] [CrossRef]

- Khomwachirakul, P.; Devahastin, S.; Swasdisevi, T.; Soponronnarit, S. Simulation of flow and drying characteristics of high-moisture particles in an impinging stream dryer via CFD-DEM. Dry. Technol. 2016, 34, 403–419. [Google Scholar] [CrossRef]

- Aziz, H.; Ahsan, S.; De Simone, G.; Gao, Y.; Chaudhuri, B. Computational modeling of drying of pharmaceutical wet granules in a fluidized bed dryer using coupled CFD-DEM approach. Aaps Pharmscitech 2022, 23, 59. [Google Scholar] [CrossRef] [PubMed]

- Thornton, C. Granular Dynamics, Contact Mechanics and Particle System Simulations; A DEM Study; Particle Technology Series; Springer International Publishing: Cham, Switzerland, 2015; p. 24. [Google Scholar] [CrossRef]

- Shi, D. Advanced Simulation of Particle Processing: The Roles of Cohesion, Mass and Heat Transfer in Gas-Solid Flows. Ph.D. Thesis, University of Pittsburgh, Pittsburgh, PA, USA, 2008. [Google Scholar]

- Che, G.; Chen, W.; Wu, C.; Li, H.; Jin, Z.; Wan, L. Design and experiment of large-scale 5HFS-10 type automatic control negative pressure grain dryer. Trans. CSAE 2017, 33, 267–275. [Google Scholar] [CrossRef]

- Pan, Y. Modern Drying Technology; Chemical Industry Press: Beijing, China, 2007. [Google Scholar]

- Usman, D.; Adanu, E.; Jahun, B.; Ibrahim, K. Effect of moisture content variation on thermo-physical properties of brown variety Tigernut (Cyperus esculentus). Arid. Zone J. Eng. Technol. Environ. 2019, 15, 714–724. [Google Scholar]

- Chen, Z.; Che, G.; Wan, L.; Wang, H.; Qu, T.; Zhang, Q. Numerical simulation and experiment of four-way ventilation mixed flow drying section for rice. Trans. CSAE 2022, 38, 237–247. [Google Scholar] [CrossRef]

- Li, H.; Niu, X.; Chai, J.; Guo, C.; Sun, Y.; Li, J.; Li, C. Optimization of hot air drying process for tiger nut and analysis of fatty acid composition of tiger nut oil. Int. J. Agric. Biol. Eng. 2021, 14, 228–236. [Google Scholar] [CrossRef]

- Chen, Y.; Gao, X.; Jin, X.; Ma, X.; Hu, B.; Zhang, X. Calibration and Analysis of Seeding Parameters of Cyperus esculentus Seeds Based on Discrete Element Simulation. Trans. Chin. Soc. Agric. Mach. 2023, 54, 58–69. [Google Scholar]

- He, X.; Lv, Y.; Qu, Z.; Wang, W.; Zhou, Z.; He, H. Parameters Optimization and Test of Caterpillar Self-Propelled Tiger Nut Harvester Hoisting Device. Agriculture 2022, 12, 1060. [Google Scholar] [CrossRef]

- Chen, P.; Han, Y.; Jia, F.; Zhao, D.; Meng, X.; Li, A.; Chu, Y.; Zhao, H. Investigation of the mechanism of aerodynamic separation of rice husks from brown rice following paddy hulling by coupled CFD-DEM. Biosyst. Eng. 2022, 218, 200–215. [Google Scholar] [CrossRef]

- Lin, J.; Bao, M.; Li, H.; Yang, J. Characteristic simulation and working parameter optimization of the aggregate dryer. Dry. Technol. 2023, 41, 590–604. [Google Scholar] [CrossRef]

- Iroba, K.; Weigler, F.; Mellmann, J.; Metzger, T.; Tsotsas, E. Residence time distribution in mixed-flow grain dryers. Dry. Technol. 2011, 29, 1252–1266. [Google Scholar] [CrossRef]

- Mellmann, J.; Weigler, F.; Scaar, H. Research on procedural optimization and development of agricultural drying processes. Dry. Technol. 2019, 37, 569–578. [Google Scholar] [CrossRef]

| Shape and Size | ||||

|---|---|---|---|---|

| Flat | Average value (mm) | 14.18 | 9.12 | 6.76 |

| Standard deviation (mm) | 0.91 | 0.82 | 0.61 | |

| Spheroid | Average value (mm) | 12.24 | 10.18 | 9.56 |

| Standard deviation (mm) | 1.1 | 0.88 | 0.92 | |

| Spherical | Average value (mm) | 9.31 | 8.14 | 7.94 |

| Standard deviation (mm) | 0.78 | 0.85 | 0.79 |

| CFD Input Parameters | ||

|---|---|---|

| Air | Type of fluid | Air |

| Density (kg/m3) | 1.225 | |

| Specific heat capacity (j/Kg·K) | 4506.43 | |

| Viscosity (Pa·s) Wind speed (m/s) Wind temperature(K) | 1.789 × 10−5 2, 4, 6 338 | |

| Thermal conductivity (W/m·K) | 0.0242 | |

| DPM injection | Initial temperature (K) | 288 |

| Drag law Water content of particles (%) | Gidaspow 45 | |

| Walls | Adiabatic and no slip | |

| Turbulence model | Standard k-ε | |

| CFD cell type | Hybrid tetrahedral hexahedral | |

| CFD time step (sec) | 0.05 | |

| EDEM Input Parameters | |

|---|---|

| Particle density (kg/m3) | 1.186 × 103 |

| Particle diameter (mm) | 16 |

| Particle shear modulus (Pa) | 2.77 × 107 |

| Particle Poisson’s ratio | 0.18 |

| Geometry density (kg/m3) | 7850 |

| Geometry shear modulus (Pa) | 1 × 1010 |

| Geometry Poisson’s ratio | 0.3 |

| Particle–particle coefficient of restitution | 0.48 |

| Particle–particle static friction coefficient | 0.34 |

| Particle–particle rolling friction coefficient | 0.1 |

| Particle–geometry coefficient of restitution | 0.619 |

| Particle–geometry static friction coefficient | 0.254 |

| Particle–geometry rolling coefficient | 0.072 |

| EDEM time step (s) | 1 × 10−4 |

| Particle gravity (m/s2) Thermal conductivity (W/(m·k)) Specific heat capacity (J/(kg·k)) | 9.81 0.106 15,920 |

| Origin of Variance | Sum of Squares | df | Mean Squares | F Value | p Value |

|---|---|---|---|---|---|

| Different groups | 15.59608 | 1 | 15.59608 | 0.11269 | 0.740983 |

| Interior groups | 2491.165 | 18 | 138.3981 | ||

| Total | 2506.762 | 19 |

| Origin of Variance | Sum of Squares | df | Mean Squares | F Value | p Value |

|---|---|---|---|---|---|

| Different groups | 34.11533 | 1 | 34.11533 | 0.267978 | 0.610995 |

| Interior groups | 2291.513 | 18 | 127.3063 | ||

| Total | 2325.628 | 19 |

| Origin of Variance | Sum of Squares | df | Mean Squares | F Value | p-Value |

|---|---|---|---|---|---|

| Sample | 0.002778 | 6 | 0.000463 | 0.222059 | 0.967812 |

| Columns | 0.117978 | 6 | 0.019663 | 9.432044 | 7.03 × 10−7 |

| Interaction | 0.009594 | 36 | 0.000266 | 0.127835 | 1 |

| Interior-groups | 0.10215 | 49 | 0.002085 | ||

| Total | 0.232499 | 97 |

| Origin of Variance | Sum of Squares | df | Mean Squares | F Value | p-Value |

|---|---|---|---|---|---|

| Sample | 0.159396 | 6 | 0.026566 | 14.18718 | 2.75 × 10−9 |

| Columns | 0.001663 | 6 | 0.000277 | 0.148012 | 0.988613 |

| Interaction | 0.010264 | 36 | 0.000285 | 0.152264 | 1 |

| Interior-groups | 0.091754 | 49 | 0.001873 | ||

| Total | 0.263077 | 97 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, L.; Dou, Y.; Li, J.; Yao, T.; Ma, A.; Yuan, Y.; Wang, L.; Li, H. Design and Optimization of a Mixed-Flow Drying Chamber for Tiger Nuts Based on CFD-DEM Heat and Mass Transfer Model. Agriculture 2024, 14, 541. https://doi.org/10.3390/agriculture14040541

Ding L, Dou Y, Li J, Yao T, Ma A, Yuan Y, Wang L, Li H. Design and Optimization of a Mixed-Flow Drying Chamber for Tiger Nuts Based on CFD-DEM Heat and Mass Transfer Model. Agriculture. 2024; 14(4):541. https://doi.org/10.3390/agriculture14040541

Chicago/Turabian StyleDing, Li, Yufei Dou, Junying Li, Tan Yao, Aobo Ma, Yechao Yuan, Lele Wang, and He Li. 2024. "Design and Optimization of a Mixed-Flow Drying Chamber for Tiger Nuts Based on CFD-DEM Heat and Mass Transfer Model" Agriculture 14, no. 4: 541. https://doi.org/10.3390/agriculture14040541

APA StyleDing, L., Dou, Y., Li, J., Yao, T., Ma, A., Yuan, Y., Wang, L., & Li, H. (2024). Design and Optimization of a Mixed-Flow Drying Chamber for Tiger Nuts Based on CFD-DEM Heat and Mass Transfer Model. Agriculture, 14(4), 541. https://doi.org/10.3390/agriculture14040541