Abstract

Concerns over dried product quality and energy consumption have prompted researchers to explore integrated techniques for improving quality and reducing energy use. This study investigates the effect of gamma irradiation pretreatment (0, 1.2, 2.4, and 3.6 kGy) on button mushroom slices, followed by thin-layer drying at 50, 60, and 70 °C. The results indicated that increasing irradiation dose and drying temperature significantly reduced drying time. The Midilli model provided the best fıt to the drying data (R2 = 0.9969–0.9998). Artificial neural networks (ANN) accurately predicted moisture variations, achieving R2 = 0.9975 and RMSE = 0.0220. The Support Vector Machine (SVM) algorithm, employing the Pearson universal kernel in normalized mode, also performed well, with R2 = 0.9939 and RMSE = 0.0344. Similarly, in the k-nearest neighbors (kNN) algorithm with three neighbors (k = 3), the R2 and RMSE values were 0.9888 and 0.0458, respectively. Gamma irradiation enhanced the effective diffusion coefficient (Deff) to 10.796 × 10−8 m2/s, and reduced activation energy (Ea) to 11.09 kJ/mol. The highest heat utilization efficiency (41.1%) was observed at 3.6 kGy and 50 °C. These findings highlight the potential of integrating gamma irradiation pretreatment and advanced drying techniques to optimize energy use and improve the quality of dried mushroom slices.

1. Introduction

Mushrooms, due to their high respiration rate, high moisture, lack of a cuticle, and intense enzyme activity, are less durable and deteriorate more quickly upon harvest compared to other vegetables [1]. As mushroom production continues to rise, the need to extend their shelf life and minimize waste has become increasingly urgent. While numerous preservation methods have been developed to tackle this challenge, many of these techniques can also lead to undesirable chemical, biochemical, and biological changes in the product [2,3]. For example, drying has long been regarded as an effective preservation method [4,5,6]; however, it can also diminish the quality and nutritional value of mushrooms while causing irreversible structural damage [7]. According to the existing reports, only 45% of the produced mushrooms are consumed fresh, whereas 55% are processed (50% as canned and 5% in dried forms), and the reason for such a high proportion of canned products is the short shelf life of fresh mushrooms (1–3 days at ambient temperature) and the limitations of the drying process [8]. The long drying time, low efficiency, reduced quality of the dehydrated products and high thermal energy consumption have become major obstacles in the way of development and application of dryers [9]. Therefore, combined technologies play a crucial role in reducing both the drying time of the products and the energy consumption, while preserving their qualities. Generally, these technologies integrate traditional and innovative preservation methods to inhibit growth of microorganisms in food [10,11]. For this reason, food technologists today are attempting to improve the food stability in terms of microbial spoilage and quality degradation using combined techniques such as a combination of gamma irradiation along with other traditional methods such as drying.

Irradiation is a physical method that involves exposing the product to gamma-rays, X-rays, and electron beam to extend their shelf life. This technique is considered a safe and effective approach for prolonging the longevity of food products [12]. Gamma irradiation is a component of the electromagnetic spectrum that possesses higher energy compared to other radiation types. These beams are naturally generated from the spontaneous decay of radioisotopes. Cobalt-60 (60Co) is the most frequently used radioisotope for gamma-ray production which is produced by the neutron bombardment of 59Co in nuclear reactors and has a great penetration power [13]. According to the World Health Organization, food irradiation is permitted up to 10 kilogray (kGy) [14], with no specific microbial or nutritional issues reported in irradiated products. For fresh mushrooms, the recommended irradiation dose to extend shelf life is 1–3 kGy, while a dose of 5 to 10 kGy is suggested for decontaminating dehydrated mushrooms [15].

Designing and manufacturing a dryer optimized for a specific product is both challenging and costly [16]. The application of gamma irradiation to agricultural products often causes some changes in the texture and ultimately could affect its drying characteristics [17]. Research has already been conducted on enhancing the dehydration efficiency of various products, including vegetables and fruits [18,19], rice [20], and wheat [21], within the context of combined irradiation and drying techniques for agricultural products.

Microstructural studies on apple slices before drying revealed that irradiation induced extensive structural changes, leading to the development of very small vacuoles within the cytoplasm. These vacuoles adhered to the internal membrane and became damaged, whereas the cell walls of the non-irradiated samples remained intact. Therefore, the drying process resulted in the breakage of both the tonoplast and plasmalemma, with the most significant changes observed at an irradiation dose of 5 kGy. Higher doses reduced the drying time due to increased drying rates [17]. Additionally, Wang and Chao (2003b) reported that among the three major variables—irradiation dose, drying temperature, and slice thickness—irradiation dose had the most substantial impact on enhancing the drying rate of potato slices [22]. In a study by Kortei et al. (2016), oyster mushroom slices were irradiated at doses of 0, 0.5, 1, 1.5, and 2 kGy and subsequently dried at 53.5 ± 6.4 °C. The experimental data were fitted to five models defined for thin layer drying, with the page and diffusion models providing better estimations of drying characteristics at low and high irradiation doses, respectively. It was observed that irradiation effectively increased the drying rate of oyster mushroom slices [23]. Numerous studies in the field of modeling the drying process using artificial neural networks [24,25] and the SVM algorithm [26,27] have highlighted the high accuracy of these methods in predicting changes in various drying parameters.

Based on our surveys, the majority of reports on button mushroom drying have been mostly focused on determining the proper air velocity and temperature settings [28,29]. Therefore, this study investigates the effect of gamma irradiation as a pretreatment on the drying characteristics of mushroom slices and their heat utilization efficiency. Furthermore, this research aims to identify the most suitable mathematical model, along with the application of machine learning algorithms, to describe the drying behavior of button mushrooms under different temperatures and irradiation doses.

2. Materials and Methods

2.1. Sample Preparation and Drying Process

The experiments presented in our study were carried out in 2022. Fresh button mushrooms were sourced from a mushroom production facility in Tehran, Iran, and packaged in 40 mm thick polyethylene bags, each bag containing 1 kg of mushrooms. The samples were irradiated at Tehran Atomic Energy Organization, using a gamma cell, model GC-200 (Nordion Inc., Ottawa, Canada), at ambient temperature with doses of 0, 1.2, 2.4, and 3.6 kGy, at a dose rate of 1.98 Gy/s. To calculate the initial moisture content, 40 g of sliced mushrooms were placed in an oven, model D06836 (Memmert GmbH, Schwabach, Germany), at 105 °C until a constant weight was achieved [30]. The initial moisture content was approximately 92.5% (wet basis). For each drying test, 50 g of gamma-treated mushroom slices (3 mm thickness) were dried at 50, 60, and 70 °C, with an air velocity of 1 m/s and relative moisture ranging between 25% and 35% [7]. The drying process continued until the samples reached equilibrium weight.

2.2. Dryer Specifications

A thin-layer hot air dryer was used, ensuring complete exposure of the mushroom slices to the airflow. The drying rate is influenced by various factors, including air temperature, air velocity, relative moisture, drying time, air pressure, and the product’s physical properties. The dryer was equipped with an 18 cm diameter centrifugal fan driven by a 12 kW three-phase electric motor [31]. An inverter of 0.4 kW (ENC, Shenzhen, China) controlled the fan speed, with input from a computer via a digital-to-analog converter. MATLAB R2023a was employed to program the inverter. A 2 kW electric heater provided the necessary heat, and a solid-state relay (SSR) adjusted the power supplied to the dryer. Temperature and moisture levels within the drying chamber were monitored using sensors, model TPM8 (, ICP DAS, Tika, Iran). Sample trays were weighed using a digital scale (AND GF-6000, Japan) with an accuracy of 0.01 g, connected to a computer via RS–232C, and data were recorded every minute using RsCom Ver. 2.43 software.

2.3. Drying Rate

The drying rate of the mushroom slices was calculated using Equation (1) [32]:

where DR is the drying rate (g water/g dry matter.min), Mt is the moisture content at time t (g water/g dry matter), Mt+dt is the moisture content at time t + dt (g water/g dry matter), and dt is the time interval between weight measurements (min).

2.4. Mathematical Modeling of Drying Curves

To model the drying of mushroom slices, the moisture ratio was calculated based on the initial moisture content, equilibrium moisture content, and the moisture content of the samples, as given in Equation (2) [33]:

where M, Me, and M0 denote the instant, equilibrium, and initial moisture content (g water/g dry matter), respectively.

The moisture contents were fitted to eight time-dependent thin-layer drying models, as presented in Table 1.

Table 1.

Mathematical models utilized for evaluating their fit with experimental data from the thin-layer drying of mushroom slices.

The best-fitting model was selected based on several statistical parameters, including the correlation coefficient (R2), root mean square error (RMSE), and sum of squared error (SSE):

2.5. Artificial Neural Network (ANN)

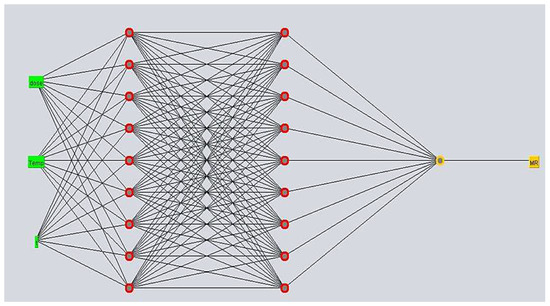

The multilayer feed-forward network architecture employed in this study is depicted in Figure 1.

Figure 1.

Topology of the artificial neural networks with two hidden layers and a total of 18 neurons (the green nodes represent inputs (irradiation dose, temperature, and drying time), the red nodes are hidden layer neurons, and the yellow node is the output (moisture ratio, MR)).

The network aimed to predict the moisture ratio, with three neurons in the input layer representing irradiation dose, temperature, and drying time. In our study, 70% of the data were used for training, while the remaining 30% were reserved for testing. Various network architectures, featuring one to three hidden layers, were trained to determine the model with the highest accuracy. The back propagation algorithm was used for training, enabling the network to self-adjust via an activation function after calculating each output. The sigmoid function, as defined by Equation (6), was utilized to optimize the network structure.

Before training, the raw data were normalized to an appropriate range, as the learning algorithm does not perform effectively with unprocessed data [42]. Linear normalization, as described by Equation (7), was used to transform the data.

where Xi′ is the normalized data, Xmin is the minimum value in the dataset, and Xmax is the maximum value in the dataset.

The training process consisted of four stages: initialization, activation, weight adjustment, and iteration. The parameters such as learning rate, momentum, and the number of epochs were set to 0.3, 0.2, and 500, respectively. Training time typically depends on the number of iterations, which was set to 200 due to the minimum error rate. Combined parameters, including the number of hidden layers, the number of neurons, and the number of training cycles, were determined through the network training process and trial and error. The hidden layer configurations selected for this research included (3), (6), (9), (3, 3), (6, 6), (9, 9), (3, 3, 3), (6, 6, 6), and (9, 9, 9). For example, the (9, 9) configuration represents two hidden layers with a total of 18 neurons (Figure 1). These configurations were selected empirically, and it was observed that using more than three hidden layers did not result in significant improvements in the final outcomes. Therefore, to optimize time and computational costs, these configurations were chosen for evaluation. The Weka software (version 3.9.2, Hamilton, New Zealand) was used to analyze the ANN model.

2.6. Support Vector Machine (SVM)

The SVM model for predicting moisture ratio values was developed using the SMOreg sequence in WEKA software, which implements SVM for regression tasks. Parameters were optimized using RegOptimizer with ReqSMOImproved as the learning algorithm. The model utilized three input variables (irradiation dose, temperature, and drying time) with the moisture ratio as the output. To evaluate the need for data transformation, normalization and standardization techniques were applied. Furthermore, three kernel functions (polynomial, Pearson universal, and Radial Basis Function (RBF)) were employed, and parameter optimization was conducted using the Grid Search technique. As with the ANN, the number of iterations was set to 200 to maintain a minimum error rate. The kernels functions were mathematically detailed in Equations (8)–(10):

2.7. k-Nearest Neighbors (kNN)

In this study, the k-nearest neighbors (kNN) algorithm was tested with k values of 3, 5, 7, 9, and 11, to identify the optimal k-value based on the highest statistical performance indicators. Debugging parameters, including mean squared error, cross-validation, distance weighting, nearest neighbor search algorithm, window size, and capability checks, remained unchanged in Weka software. The batch size was set to 150 to achieve the highest accuracy, and the number of iterations was fixed at 200 to minimize the error rate. Model outputs were formatted to display numbers with two decimal places (numDecimalPlaces = 2).

2.8. Effective Diffusion Coefficient

The drying process consists of two stages: constant and falling drying rates. The movement of moisture during the falling rate phase is described by the effective diffusion coefficient. This coefficient is essential for characterizing the mass transfer process, which is derived from Fick’s second law [43]:

where a is the thickness of mushroom slices (m), t is the drying time (min), and Deff represents the effective diffusion coefficient (m2/s).

For long drying times, Equation (11) is summarized as follows [44]:

Taking the logarithm of both sides of Equation (12), the following equation is obtained:

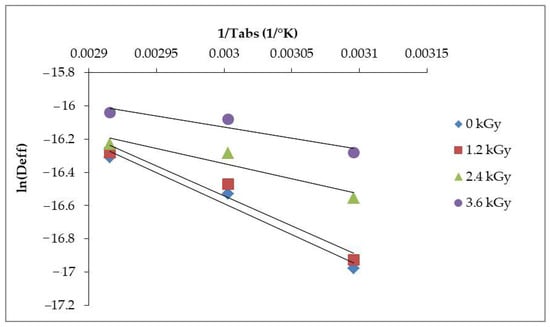

Therefore, the effective diffusion coefficient was calculated by plotting the ln(MR) curve against drying time.

2.9. Activation Energy

Activation energy, defined as the minimum energy required for initiating a chemical reaction, was calculated through the Arrhenius Equation [44]:

where D0 is the constant for effective diffusion coefficient (m2/s), Ea is the activation energy (kJ/mol), R is the gas constant (8.314 J/mol.k), and Tabs is the absolute air temperature (K). By taking the logarithm of both sides of Equation (14), the following equation is obtained:

According to Equation (15), the activation energy was calculated by plotting the ln(Deff) curve against (1/Tabs).

2.10. Heat Utilization Efficiency

This efficiency is defined as the ratio of the latent heat of vaporization to the energy required to evaporate moisture from free water. Equation (16) was used to determine the heat utilization efficiency [45]:

where η is the heat utilization efficiency (%), L is the loading density (kg/m2), Ad represents the total drying area (m2), λ is the latent heat of vaporization (kJ/kg), F denotes the utilized capacity of heat source (kW), t is the duration of heat source operation (h). Additionally, Mi and Mf are the initial and final moisture contents (wet basis), respectively.

3. Results

3.1. Drying Kinetics and Drying Rate of Button Mushroom

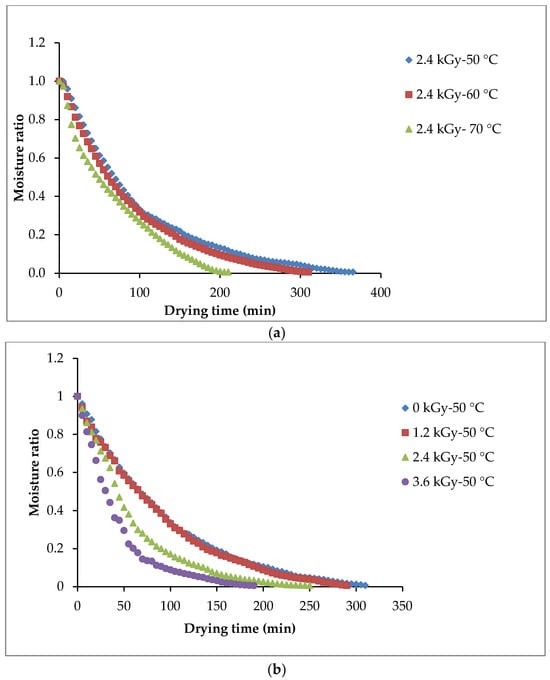

The moisture ratio curves as a function of drying time at various temperatures and irradiation doses are presented in Figure 2. The results show that increasing the drying temperature significantly reduces the drying time of mushroom slices. This reduction in drying time at higher temperatures can be attributed to several factors: higher temperatures provide increased energy to water molecules, enhancing their movement and evaporation. Additionally, the adhesion between water molecules and the material’s structure decreases, allowing water to escape more easily. The vapor pressure of water also rises with temperature, promoting faster migration of water from the material to the surrounding air. Moreover, higher temperatures accelerate the breakdown of cellular structures, facilitating moisture removal, while the increased moisture gradient between the interior and surface of the material enhances water transport to the surface for evaporation [46].

Figure 2.

Moisture ratio as a function of drying time at different: (a) temperatures (irradiation dose 2.4 kGy) illustrating the impact of varying temperatures (50, 60, and 70 °C) on moisture loss; (b) irradiation doses (temperature 50 °C), showing the effect of different irradiation doses (0, 1.2, 2.4, and 3.6 kGy) on moisture loss during drying.

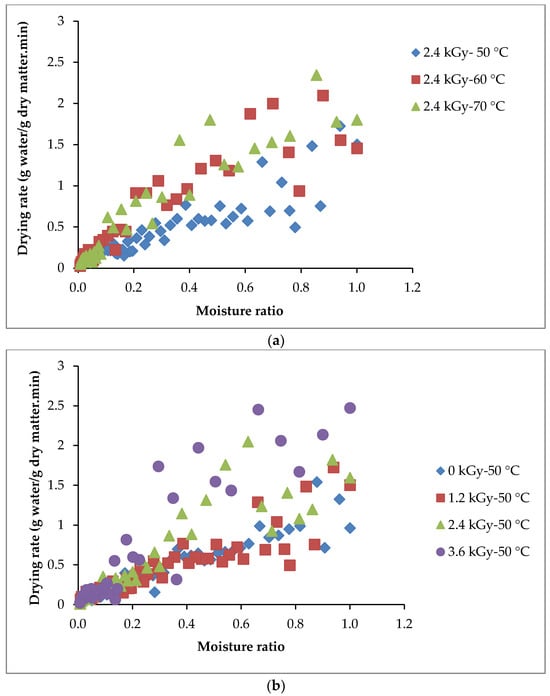

At 70 °C, the maximum energy is provided to facilitate the separation of water molecules, resulting in a more intense and rapid evaporation process (Figure 2a and Figure 3).

Figure 3.

Drying rate as a function of moisture ratio at different: (a) temperatures (irradiation dose 2.4 kGy) illustrating the impact of varying temperatures (50, 60, and 70 °C) on drying rate; (b) irradiation doses (temperature 50 °C), showing the effect of different irradiation doses (0, 1.2, 2.4, and 3.6 kGy) on drying rate during the process.

However, according to Figure 3a, there are specific points during the drying process, particularly at moisture ratios between 0.47 and 0.69, where the drying rate at 60 °C exceeds the other temperatures. Additionally, the drying rate of mushroom is comparably higher than most other fruits and vegetables, probably owing to its high moisture content. For instance, the drying rate for potatoes has been reported to range from 0.03 to 0.06 g/g min, and for red peppers, it ranges from 0.01 to 0.03 g/g min [47,48]. This elevated moisture content allows for a faster drying process. The drying rate is higher at the beginning of the process and decreases over time, with some fluctuations [48,49]. These fluctuations, despite constant drying temperatures, may be attributed to the non-uniform irradiation of different parts of the mushrooms, as evidenced by the smaller fluctuations in non-irradiated slices (0 kGy) shown in Figure 3b. Generally, internal mass transfer during drying is controlled by liquid diffusion, vapor diffusion, and capillary action. As moisture content decreases, capillary forces become the primary mechanism for moisture removal [50]. Over time, the pores and free spaces within the mushroom lose water, increasing the solid content and diminishing the rates of drying and heat transfer.

The effect of high irradiation dose on reducing drying time was approximately similar to drying at high temperatures. As shown in Figure 2b, at a constant temperature, the non-irradiated sample required 310 min for drying, while the sample irradiated at 3.6 kGy dried in just 190 min. Drying times for other samples are also detailed in this study. For non-irradiated samples (0 kGy), drying times were 310 and 180 min at 50 °C and 70 °C, respectively. This suggests that irradiation can be effectively used to reduce drying time, particularly for thinner samples, without needing to increase temperature and incur additional energy costs [9]. Furthermore, Figure 2b indicates that as irradiation dose increases, drying time decreases. The difference in drying time between samples irradiated at 0 and 1.2 kGy was 20 min, while the differences between 1.2 and 2.4 kGy, and between 2.4 and 3.6 kGy were 40 and 60 min, respectively. It is hypothesized that higher irradiation doses increase surface porosity by dilating cell wall pores, which accelerates moisture release (Figure 3b) [51]. Similar effects have been observed in the wheat cell walls exposed to doses higher than 1.5 kGy, where cytoplasm is expelled from the cell’s interior, thus shortening the drying process [21]. Chitin, a major component of the mushroom cell wall, is softened by irradiation [52]. Studies have shown that mushroom texture remains unaffected in terms of appearance by irradiation up to 4.5 kGy [53]. Therefore, it is advisable to use doses higher than 4.5 kGy only for moisture removal processes in mushroom slices, while lower doses should be employed for purposes such as extending shelf life. Existing reports indicate that as the irradiation dose increases, the surface temperature is raised more easily [21].

During the initial stages of drying, moisture evaporates primarily from the mushroom’s surface, requiring less energy at lower dose levels to increase the surface temperature. However, as the drying process progresses, the hardened surface can act as a barrier, hindering moisture diffusion from the interior to the surface, thereby prolonging the dehydration process. Irradiation pretreatment reduces this hardening effect by dilating surface pores, allowing for easier moisture loss, thus reducing drying time compared to control samples [51]. Since irradiation primarily affects surface layers, it does not damage internal capillary tubes, unlike increased drying temperatures, which may cause irreversible changes in capillary structure and negatively impact product quality and the rehydration ratio [54].

A notable observation in the study is the relationship between the specific heat of agricultural products and their moisture content. Specific heat, which refers to the amount of energy required to raise the temperature of a material, decreases as moisture content decreases [55]. This implies that products with lower moisture content require less energy to increase their internal temperature. In our study, at a given drying time, mushrooms subjected to higher irradiation doses exhibited lower moisture content compared to those treated with lower doses (Figure 2b). This indicates that higher doses of irradiation accelerated the drying process by reducing the moisture content more rapidly. This phenomenon aligns with previously reported findings for oyster mushrooms, where irradiation similarly enhanced drying rates by reducing specific heat [23].

3.2. Identification of Optimal Mathematical Models for Predicting Temporal Moisture Variations

The drying curves of mushrooms under various conditions were fitted to eight different models (Table 1), and the statistical results were analyzed using MATLAB R2015a software (Table 2).

Table 2.

Statistical parameters for fitting mathematical models to the thin-layer drying data of mushroom slices.

Based on the statistical parameters, such as high R2 values and low RMSE and SSE values, the models closely approximated the actual data. Among these models, the Midilli model provided the best fit, with an R2 value of 0.9980, outperforming other models. The coefficients and statistical results of the Midilli model under different conditions are presented in Table 3.

Table 3.

Values of the drying constant and coefficients for the Midilli model.

R2 values ranged from 0.9969 to 0.9998, RMSE values ranged from 0.004366 to 0.01600, and SSE values ranged from 0.001125 to 0.01203. Additionally, the drying rate constant (k) was notably higher for samples pretreated with a 3.6 kGy dose of gamma irradiation. Specifically, the k values for samples dried at 50, 60, and 70 °C were 0.01557, 0.009661, and 0.01028, respectively, under the same conditions.

Apart from the Midilli model, the logarithmic model performed better at 50 and 60 °C, while the two-term exponential model was more accurate at 70 °C. The Wang and Sing model showed the weakest performance, with the lowest R2 value (0.9654) and the highest RMSE and SSE values of 0.04846 and 0.14941, respectively (Table 2).

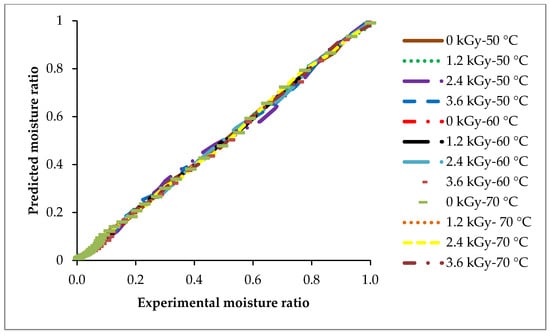

Figure 4 compares the experimental moisture ratio with those predicted by the Midilli model under various drying conditions. The plot reveals a line at an approximate 45-degree angle, demonstrating the high accuracy of the Midilli model in predicting moisture ratio changes. These findings are consistent with previous research, which also identified the Midilli model as the most effective for describing mushroom drying processes [56,57].

Figure 4.

Correlation between experimental moisture ratio data and values predicted by the Midilli model under various conditions.

3.3. Moisture Variation Prediction Using Artificial Neural Networks (ANN)

The architecture of an artificial neural network is a critical factor influencing its learning capabilities. Multilayer feed-forward networks, widely used in modeling agricultural and food systems, have demonstrated strong predictive capabilities [58]. In our study, ANN was employed to model and predict changes in the moisture content of products. The input parameters included irradiation dose (0, 1.2, 2.4, and 3.6 kGy), drying temperature (50, 60, and 70 °C), and drying time (starting at 0 min and recorded every 5 min). The statistical results from the training and testing phases of the multilayer feed-forward network are shown in Table 4.

Table 4.

Statistical results for predicting moisture variations in mushroom slices using the ANN model.

The findings indicated that network architectures with multiple hidden layers yielded the most accurate results. Specifically, configurations with two or three hidden layers, such as (6, 6), (9, 9), (6, 6, 6), and (9, 9, 9), achieved the highest R2 values and the lowest error rates (Table 4). It was observed that networks with fewer neurons resulted in poorer model fits, whereas networks with larger neuron counts significantly enhanced model performance. These findings differ from a previous study on the drying of Linden leaves using the infrared method, where increasing the number of hidden neurons did not significantly impact model accuracy. In that case, configurations of (6, 6) and (9, 9) achieved the highest R2 values for both training and testing data [59]. This discrepancy is likely attributed to differences in the drying method and, to a lesser extent, the pretreatment applied. Overall, the method demonstrated high accuracy in predicting moisture content changes.

3.4. Moisture Variation Prediction Using Machine Learning Algorithms

3.4.1. Support Vector Machine (SVM)

The performance of the SVM algorithm using different filters and kernels is summarized in Table 5. Notably, under both training and testing conditions, the Pearson universal kernel outperformed the others in both normalized and standardized datasets. In the training phase, the standardized filter delivered the highest R2 (0.9993) and the lowest RMSE (0.0112), making it the best-performing model.

Table 5.

Statistical results for predicting moisture variations in mushroom slices using the SVM model.

Similarly, in the testing phase, the normalized filter achieved an R2 of 0.9939 and an RMSE of 0.0344, indicating its superiority as the best model for prediction accuracy. Conversely, the polynomial kernel exhibited the lowest R2 values during both training and testing, particularly under the normalized and standardized conditions. These findings align with previous studies on the drying of persimmon fruit under hot air conditions [58], except that the RBF kernel also demonstrated strong performance in the training phase in the current study. In the food and agriculture industries, SVM has been successfully applied in various tasks, including diagnosing crop diseases and ensuring product quality control. Its robustness and accuracy make SVM a valuable tool in enhancing decision-making processes and improving productivity in these sectors [60].

3.4.2. k-Nearest Neighbors (kNN)

The kNN algorithm results demonstrated that the R2 values generally ranged from 0.9581 to 0.9998 across both training and testing modes. When the k-value was set to 3, the R2 reached 0.9998 for training and 0.9880 for testing. As the k-value increased from 3 to 11, the R2 value decreased, and RMSE increased (Table 6). This indicates that increasing the number of neighbors reduced the model’s accuracy in predicting moisture variations. At k = 3, the model’s training accuracy was superior to both SVM and ANN methods, although kNN still provided satisfactory accuracy for moisture content prediction in other cases.

Table 6.

Statistical results for predicting moisture variations in mushroom slices using the kNN model.

Similar findings were reported by Khaled et al. (2020) during the hot air drying of persimmons, where model accuracy improved as k increased from 3 to 7 but decreased when k exceeded 7. In vacuum drying, results were closely aligned with the current study’s findings [58]. The kNN algorithm has gained widespread adoption in the food and agriculture industries due to its simplicity and effectiveness in handing complex datasets, contributing to improved productivity and product quality [61].

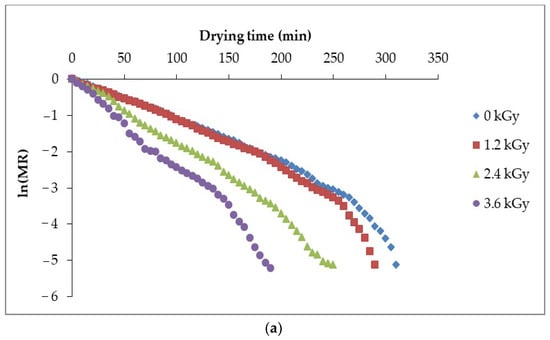

3.5. Effective Moisture Diffusivity

The curves of ln(MR) as a function of drying time for various irradiation doses and temperatures are shown in Figure 5. The data points generally align with a linear fit, although slight deviations from the straight-line behavior occur, particularly towards the end of the drying process. These deviations likely result from uneven moisture distribution within the mushroom slices, changes in product temperature during drying, and shrinkage formation [62]. The R2 value for these linear fits range from 0.95 to 0.99, which indicates a high degree of correlation between ln(MR) and drying time.

Figure 5.

Linear relationship (R2 = 0.95–0.99) between ln(MR) and drying time at different temperatures: (a) 50 °C; (b) 60 °C; (c) 70 °C.

The effective moisture diffusivity (Deff) was calculated from the slope of these drying curves using Equation (17):

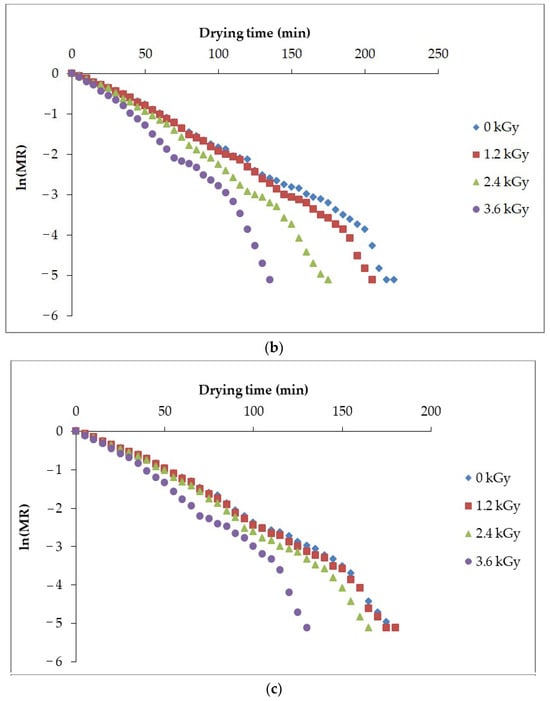

The results demonstrated that higher temperatures and irradiation doses increased the drying curve slope, enhancing mass transfer [63]. The effective moisture diffusivity values for various pretreatments are shown in Figure 6 as a function of temperature. As temperature increased, the evaporation rate and Deff also increased significantly, attributed to the reduction in the theoretical moisture gradient within the mushroom slices [64,65]. Higher temperatures enhance the activity of water molecules, increasing effective moisture diffusivity.

Figure 6.

Effective diffusion coefficient (Deff) as a function of drying temperature at various irradiation doses.

The maximum Deff value, 10.7968 × 10−8 m2/s, was observed in the sample pretreated with a 3.6 kGy at 70 °C, while the lowest value, 4.2311 × 10−8 m2/s, was found in the control sample (0 kGy) at 50 °C (Table 7). This suggests that pretreatment before drying affects effective moisture diffusivity.

Table 7.

Values of effective moisture diffusivity (Deff × 10−8 m2/s) under different drying conditions.

Irradiation pretreatment alters mushroom cell walls, significantly influencing moisture diffusion rates [9]. These structural alterations increase the rate of water discharge from the capillary tubes. Mass transfer continues until the exposed end of the capillary tube enters the air, after which the internal resistance to both mass and heat transfer rises [66]. In contrast, in non-irradiated samples, cellular and intercellular spaces tightly stick together and this has reduced the amount of moisture diffusion [21]. These findings are consistent with studies on agricultural products, such as raspberry [67], red beetroot [68], and edible mushrooms [69,70], under different temperatures and air velocities.

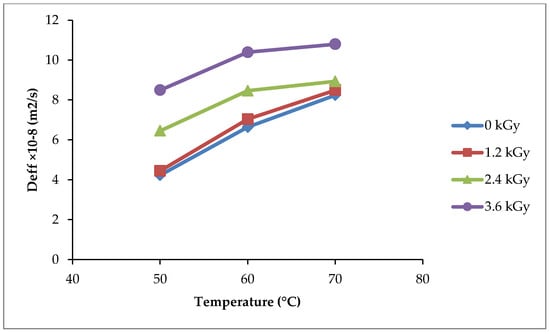

3.6. Activation Energy

Figure 7 shows the linear relationship between ln(Deff) and the reciprocal of absolute temperature. Activation energy (Ea) values were calculated by multiplying the slope of this curve by the gas constant (8.314 J/mol k).

Figure 7.

Linear relationship between effective moisture diffusivity and the reciprocal of absolute temperature at various irradiation doses.

As shown in Figure 7, the correlation coefficient (R2) decreases with increasing irradiation dose, indicating higher points dispersion at higher doses. The Ea values, along with the correlation coefficient and diffusion coefficients (D0) under different drying conditions, are presented in Table 8.

Table 8.

Values of activation energy and correlation coefficient under different drying conditions.

At higher doses, less energy is required to initiate evaporation. Samples irradiated at 0 and 1.2 kGy did not show significant difference in Ea, suggesting that irradiation up to 1.2 kGy does not significantly affect mushroom dehydration. The maximum Ea was 30.81 kJ/mol, while the minimum was 11.09 kJ/mol. Compared to most agricultural products, mushrooms require less energy to remove moisture due to their high moisture and soft structure. The Ea for olive pomace has been reported to range between 19.62 and 30.69 kJ/mol [38], between 16.74 and 20.48 kJ/mol for peach [71], between 19.02 and 29.83 kJ/mol for apple [72], and around 22.22 kJ/mol for oyster mushrooms [73]. The Ea value for oyster mushroom closely aligns with the results of the present study for button mushrooms.

3.7. Heat Utilization Efficiency

Equation (16) was employed to analyze heat utilization efficiency during drying. The initial moisture content of the samples (Mi) was 92.5% (wet basis), while the final moisture content (Mf) was 6.8% (wet basis). The product of loading density and drying area (LAd) was equal to the initial sample weight. Since water constitutes more than 92% of mushrooms, the heat of vaporization of water (approximately 2260 kJ/kg) was used [74]. The capacity of the heating source was 2 kW. The durations of heat source operation and heat utilization efficiency under various drying conditions are given in Table 9.

Table 9.

Values of drying time, heating duration, and heat utilization efficiency under thin-layer drying conditions.

All parameters in Equation (16), except for the duration of heat source operation (t), remained constant for all experiments. Therefore, the heat utilization efficiency depends solely on t. In the dryer’s control program, both the fan and heater operated only when the air temperature dropped below the desired temperature. The maximum heat utilization efficiency was recorded at a 3.6 kGy dose and 50 °C, where the shorter operation time of the heat source at lower temperatures enhanced efficiency. Lower efficiency was observed at 0 and 1.2 kGy at 70 °C. The variation in heat utilization efficiency was more significant at 3.6 kGy (ranging from 29.97% to 41.07%) compared to 0 kGy (21.64% to 25.13%). This indicates that irradiation has a more pronounced effect on improving heat utilization than temperature control. However, drying at moderate temperatures (50–60 °C) is preferred to preserve the product’s quality, as higher temperatures can degrade pigments and induce non-enzymatic reactions [75,76].

4. Conclusions

The irradiation pretreatment significantly enhanced the drying rate and reduced the drying time of button mushroom slices compared to untreated samples. The highest drying rate was observed at a dose of 3.6 kGy and a temperature of 70 °C. Among the various models tested, the Midilli model provided the best fit for predicting moisture content changes over time, with an R2 value of 0.9998, RMSE of 0.004366, and SSE of 0.001125. In artificial neural networks modeling, R2 values ranged from 0.9926 to 0.9975, with RMSE values between 0.0220 and 0.0452. For the SVM and kNN algorithms, the best R2 and RMSE values were 0.9939 and 0.0344 for SVM, and 0.9880 and 0.0458 for kNN, respectively. The effective moisture diffusivity ranged between 4.2311 × 10−8 and 10.7968 × 10−8 m2/s, while activation energy values varied from 11.09 to 30.81 kJ/mol. The maximum heat utilization efficiency (41.01%) was recorded for samples irradiated at 3.6 kGy and dried at 50 °C, while the minimum efficiency (21.64%) was noted for control samples (0 kGy) dried at 70 °C. The combination of 2.4 kGy and 50 °C yielded an average heat utilization efficiency of 31.17%. Therefore, irradiation pretreatment is recommended for mushroom products to accelerate the drying process and reduce energy consumption in drying systems. Future research is expected to provide more comprehensive information on the nutritional quality of irradiated mushrooms that have been dried.

Author Contributions

Conceptualization, E.F.N., M.H.K., K.Ç.S., N.U. and S.A.; methodology, E.F.N. and M.H.K.; software, M.H.K., K.Ç.S. and S.A.; validation, M.H.K., K.Ç.S. and S.A.; formal analysis, M.H.K., K.Ç.S., N.U. and S.A.; investigation, E.F.N., M.H.K. and K.Ç.S.; resources, E.F.N., K.Ç.S. and S.A.; data curation, E.F.N., K.Ç.S. and N.U.; writing—original draft preparation, E.F.N., K.Ç.S. and N.U.; writing—review and editing, E.F.N. and N.U.; visualization, K.Ç.S.; supervision, E.F.N. and K.Ç.S.; project administration, E.F.N., M.H.K. and N.U.; funding acquisition, N.U. All authors have read and agreed to the published version of the manuscript.

Funding

The APC was funded by the National University of Science and Technology Politehnica Bucharest, Romania, within the PubArt Program.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding authors.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Criado, P.; Fraschini, C.; Shankar, S.; Salmieri, S.; Lacroix, M. Influence of cellulose nanocrystals gellan gum-based coating on color and respiration rate of Agaricus bisporus mushrooms. J. Food Sci. 2021, 86, 420–425. [Google Scholar] [CrossRef]

- Gong, M.; Zhang, T.; Wu, Y.; Shang, J.; Su, E.; Cao, Y.; Zhang, J. Synergizing postharvest physiology and nanopackaging for edible mushroom preservation. Food Chem. 2024, 463, 141099. [Google Scholar] [CrossRef] [PubMed]

- Guo, W.; Tang, X.; Cui, S.; Zhang, Q.; Zhao, J.; Mao, B.; Zhang, H. Recent advance in quality preservation of non-thermal preservation technology of fresh mushroom: A review. Crit. Rev. Food Sci. Nutr. 2024, 64, 7878–7894. [Google Scholar] [CrossRef]

- Arsenoaia, V.N.; Vlăduț, V.; Țenu, I.; Voicea, I.; Cârlescu, P.M. Mathematical modeling and numerical simulation of the drying process of seeds in a pilot plant. INMATEH—Agric. Eng. 2019, 57, 55–62. [Google Scholar] [CrossRef]

- Arsenoaia, V.; Vlăduţ, V.; Ţenu, I.; Voicea, I.; Cârlescu, P.M. Drying process modeling with effects of physical parameters on dehydrated seeds. In Proceedings of the 47th International Symposium “Actual Tasks on Agricultural Engineering”, Opatija, Croaţia, 5–7 March 2019. [Google Scholar]

- Sorică, C.; Pătruț, A.; Șovăială, G.H.; Sorică, E.; Vlăduțoiu, L.; Matache, G.; Pavel, I.; Cristea, M. Preliminary researches on some technical-functional parameters of an experimental model of convective dryer with total energy independence. INMATEH—Agric. Eng. 2024, 72, 547–556. [Google Scholar] [CrossRef]

- Huo, J.; Zhang, M.; Wang, D.S.; Mujumdar, A.; Bhandari, B.; Zhang, L. New preservation and detection technologies for edible mushrooms: A review. J. Sci. Food Agric. 2023, 103, 3230–3248. [Google Scholar] [CrossRef]

- Singh, P.; Langowski, H.C.; Wani, A.A.; Saengerlaub, S. Recent advances in extending the shelf life of fresh Agaricus mushrooms: A review. J. Sci. Food Agric. 2010, 90, 1393–1402. [Google Scholar] [CrossRef]

- Wang, J.; Chao, Y. Effect of 60Co irradiation on drying characteristics of apple. J. Food Eng. 2003, 56, 347–351. [Google Scholar] [CrossRef]

- Mahmood, N.; Liu, Y.; Zheng, X.; Munir, Z.; Pandiselvam, R.; Zhang, Y.; Saleemi, M.A.; Yves, H.; Sufyan, M.; Lei, D. Influences of emerging drying technologies on rice quality. Food Res. Int. 2024, 184, 114264. [Google Scholar] [CrossRef] [PubMed]

- Xie, S.; Yang, Z.; Yang, L.; Li, S.; Wang, J.; Yang, M. Performance analysis and technology optimization of infrared drying of sweet potato slice. INMATEH—Agric. Eng. 2024, 64, 119–130. [Google Scholar] [CrossRef]

- Ravindran, R.; Jaiswal, A.K. Wholesomeness and safety aspects of irradiated foods. Food Chem. 2019, 285, 363–368. [Google Scholar] [CrossRef]

- Lester, G.E.; Hallman, G.J.; Pérez, J.A. γ-irradiation dose: Effects on baby-leaf spinach ascorbic acid, carotenoids, folate, α-tocopherol, and phylloquinone concentrations. J. Agric. Food Chem. 2010, 58, 4901–4906. [Google Scholar] [CrossRef]

- World Health Organization (WHO). High-Dose Irradiation: Wholesomeness of Food Irradiatied with Doses Above 10 kGy: Report of a Joint FAO/IAEA/WHO Study Group. No. 890. 1999. Available online: https://www.who.int/publications/i/item/9241208902 (accessed on 10 November 2024).

- International Consultative Group on Food Irradiation (ICGFI). Facts About Food Irradiation; International Consultative Group on Food Irradiation: Buckinghamshire, UK, 1999. [Google Scholar]

- Joseph, T.; Baah, K.; Jahanfar, A.; Dubey, B. A comparative life cycle assessment of conventional hand dryer and roll paper towel as hand drying methods. Sci. Total Environ. 2015, 515, 109–117. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Chao, Y. Drying characteristics of irradiated apple slices. J. Food Eng. 2002, 52, 83–88. [Google Scholar] [CrossRef]

- Cătunescu, G.M.; Muntean, M.; Marian, O.; David, A.P.; Rotar, A.M. Comparative effect of gamma irradiation, drying and freezing on sensory, and hygienic quality of parsley leaves. LWT 2019, 115, 108448. [Google Scholar] [CrossRef]

- Zhang, M.; Chen, H.; Mujumdar, A.S.; Tang, J.; Miao, S.; Wang, Y. Recent developments in high-quality drying of vegetables, fruits, and aquatic products. Crit. Rev. Food Sci. Nutr. 2017, 57, 1239–1255. [Google Scholar] [CrossRef]

- Irchad, A.; Razouk, R.; Ouaabou, R.; Mouhib, M.; Hssaini, L. Effect of 60Co γ-rays on dried figs adsorption isotherms and thermodynamic properties. Front. Nutr. 2022, 9, 940111. [Google Scholar] [CrossRef]

- Yu, Y.; Wang, J. Effect of gamma-ray irradiation on drying characteristics of wheat. Biosyst. Eng. 2006, 95, 219–225. [Google Scholar] [CrossRef]

- Wang, J.; Chao, Y. Effect of gamma irradiation on quality of dried potato. Radiat. Phys. Chem. 2003, 66, 293–297. [Google Scholar] [CrossRef]

- Kortei, N.; Odamtten, G.; Ayim-Akonor, M.; Akonor, P. Modeling the solar drying kinetics of gamma irradiation-pretreated oyster mushrooms (Pleurotus ostreatus). Int. Food Res. J. 2016, 23, 34–39. [Google Scholar]

- Chasiotis, V.K.; Tzempelikos, D.A.; Filios, A.E.; Moustris, K.P. Artificial neural network modelling of moisture content evolution for convective drying of cylindrical quince slices. Comput. Electron. Agric. 2020, 172, 105074. [Google Scholar] [CrossRef]

- Chokphoemphun, S.; Hongkong, S.; Chokphoemphun, S. Evaluation of drying behavior and characteristics of potato slices in multi–stage convective cabinet dryer: Application of artificial neural network. Inf. Process. Agric. 2023, 11, 2214–3173. [Google Scholar] [CrossRef]

- Al-Mashhadany, S.A.; Hasan, H.A.; Al-Sammarraie, M.A. Using machine learning algorithms to predict the sweetness of bananas at different drying times. J. Ecol. Eng. 2024, 25, 231–238. [Google Scholar] [CrossRef]

- Hadjout-Krimat, L.; Belbahi, A.; Dahmoune, F.; Hentabli, M.; Boudria, A.; Achat, S.; Remini, H.; Oukhmanou-Bensidhoum, S.; Spigno, G.; Madani, K. Study of microwave and convective drying kinetics of pea pods (Pisum sativum L.): A new modeling approach using support vector regression methods optimized by dragonfly algorithm techniques. J. Food Process Eng. 2023, 46, e14232. [Google Scholar] [CrossRef]

- Jiang, Q.; Zhang, M.; Mujumdar, A.S. UV induced conversion during drying of ergosterol to vitamin D in various mushrooms: Effect of different drying conditions. Trends Food Sci. Technol. 2020, 105, 200–210. [Google Scholar] [CrossRef]

- Zhao, Y.; Bi, J.; Yi, J.; Jin, X.; Wu, X.; Zhou, M. Evaluation of sensory, textural, and nutritional attributes of shiitake mushrooms (Lentinula edodes) as prepared by five types of drying methods. J. Food Process Eng. 2019, 42, e13029. [Google Scholar] [CrossRef]

- AOAC. International Official Methods of Analysis, 13th ed.; Association of Official Analytical Chemists: Washington, DC, USA, 1990. [Google Scholar]

- Khazaei, N.B.; Tavakoli, T.; Ghassemian, H.; Khoshtaghaza, M.H.; Banakar, A. Applied machine vision and artificial neural network for modeling and controlling of the grape drying process. Comp. Electron. Agricul. 2013, 98, 205–213. [Google Scholar] [CrossRef]

- Zhu, J.F.; Liu, J.Z.; Wu, J.H.; Cheng, J.; Zhou, J.H.; Cen, K.F. Thin-layer drying characteristics and modeling of Ximeng lignite under microwave irradiation. Fuel Process. Technol. 2015, 130, 62–70. [Google Scholar] [CrossRef]

- Zhu, G.; Raghavan, G.S.V.; Li, Z. Predicting the moisture ratio of a hami melon drying process using image processing technology. Foods 2023, 12, 672. [Google Scholar] [CrossRef] [PubMed]

- Man, X.; Li, L.; Fan, X.; Zhang, H.; Lan, H.; Tang, Y.; Zhang, Y. Drying kinetics and mass transfer characteristics of walnut under hot air drying. Agriculture 2024, 14, 182. [Google Scholar] [CrossRef]

- An, J.; Yan, J.; Wei, H.; Liao, X.; Liu, T.; Xie, H. Investigation of the kinetic dynamics in the intermittent microwave–hot-air combined drying of peanut pods. Agriculture 2024, 14, 2259. [Google Scholar] [CrossRef]

- Gomes, F.P.; Resende, O.; de Sousa, E.P.; Célia, J.A.; de Oliveira, K.B. Application of mathematical models and thermodynamic properties in the drying of jambu leaves. Agriculture 2022, 12, 1252. [Google Scholar] [CrossRef]

- Toğrul, İ.T.; Pehlivan, D. Mathematical modelling of solar drying of apricots in thin layers. J. Food Eng. 2002, 55, 209–216. [Google Scholar] [CrossRef]

- Kaleta, A.; Górnicki, K. Some remarks on evaluation of drying models of red beet particles. Energy Convers. Manag. 2010, 51, 2967–2978. [Google Scholar] [CrossRef]

- Ertekin, C.; Yaldiz, O. Drying of eggplant and selection of a suitable thin layer drying model. J. Food Eng. 2004, 63, 349–359. [Google Scholar] [CrossRef]

- da Silva, R.C.; da Silva, W.P.; Gomes, J.P.; de Melo Queiroz, A.J.; de Figueirêdo, R.M.F.; de Lima, A.G.B.; Rocha, A.P.T.; da Silva, L.D.; de Lima Ferreira, J.P.; da Costa Santos, D.; et al. A new empirical model for predicting intermittent and continuous drying of “Neve” melon (Cucumis melo sp.) seeds. Agriculture 2022, 12, 328. [Google Scholar] [CrossRef]

- Carrillo Luis, V.; Beristain Rios, D.; Hernández-Flores, O.A.; Romero-Salazar, C.; Sandoval-Torres, S. Mathematical modeling of goat meat drying kinetics with thermal oscillations. Foods 2024, 13, 3836. [Google Scholar] [CrossRef] [PubMed]

- Taghavifar, H.; Mardani, A.; Taghavifar, L. A hybridized artificial neural network and imperialist competitive algorithm optimization approach for prediction of soil compaction in soil bin facility. Measurement 2013, 46, 2288–2299. [Google Scholar] [CrossRef]

- Zhang, J.; Zheng, X.; Xiao, H.; Li, Y.; Yang, T. Effect of combined infrared hot air drying on yam slices: Drying kinetics, energy consumption, microstructure, and nutrient composition. Foods 2023, 12, 3048. [Google Scholar] [CrossRef]

- Koukouch, A.; Idlimam, A.; Asbik, M.; Sarh, B.; Izrar, B.; Bostyn, S.; Bah, A.; Ansari, O.; Zegaoui, O.; Amine, A. Experimental determination of the effective moisture diffusivity and activation energy during convective solar drying of olive pomace waste. Renew. Energy 2017, 101, 565–574. [Google Scholar] [CrossRef]

- Yahya, M.; Fahmi, H.; Hasibuan, R. Experimental performance analysis of a pilot-scale biomass-assisted recirculating mixed-flow dryer for drying paddy. Int. J. Food Sci. 2022, 2022, 4373292. [Google Scholar] [CrossRef] [PubMed]

- He, C.; Wang, H.; Yang, Y.; Huang, Y.; Zhang, X.; Arowo, M.; Ye, J.; Zhang, N.; Xiao, M. Drying behavior and kinetics of drying process of plant-based enteric hard capsules. Pharmaceutics 2021, 13, 335. [Google Scholar] [CrossRef] [PubMed]

- Akpinar, E.; Midilli, A.; Bicer, Y. Single layer drying behaviour of potato slices in a convective cyclone dryer and mathematical modeling. Energy Conv. Manag. 2003, 44, 1689–1705. [Google Scholar] [CrossRef]

- Cao, Z.; Zhou, L.; Bi, J.; Yi, J.; Chen, Q.; Wu, X.; Zheng, J.; Li, S. Effect of different drying technologies on drying characteristics and quality of red pepper (Capsicum frutescens L.): A comparative study. J. Sci. Food Agric. 2016, 96, 3596–3603. [Google Scholar] [CrossRef] [PubMed]

- Pinheiro, M.C.; Madaleno, R.O.; Castro, L.M. Drying kinetics of two fruits Portuguese cultivars (Bravo de Esmolfe apple and Madeira banana): An experimental study. Heliyon 2022, 8, e09341. [Google Scholar] [CrossRef]

- Fikry, M.; Benjakul, S.; Al-Ghamdi, S.; Tagrida, M.; Prodpran, T. Evaluating Kinetics of Convection Drying and Microstructure Characteristics of Asian Seabass Fish Skin without and with Ultrasound Pretreatment. Foods 2023, 12, 3024. [Google Scholar] [CrossRef]

- Akram, K.; Ahn, J.J.; Kwon, J.H. Identification and characterization of gamma-irradiated dried Lentinus edodes using ESR, SEM, and FTIR analyses. J. Food Sci. 2012, 77, 690–696. [Google Scholar] [CrossRef]

- Koorapati, A.; Foley, D.; Pilling, R.; Prakash, A. Electron-beam irradiation preserves the quality of white button mushroom (Agaricus bisporus) slices. J. Food Sci. 2004, 69, 25–29. [Google Scholar] [CrossRef]

- Zhong, Y.; Dong, S.; Cui, Y.; Dong, X.; Xu, H.; Li, M. Recent Advances in Postharvest Irradiation Preservation Technology of Edible Fungi: A Review. Foods 2023, 12, 103. [Google Scholar] [CrossRef] [PubMed]

- Francis, F. Wiley Encyclopedia of Food Science and Technology; Francis, F.J., Ed.; John Wiley and Sons, Inc.: Hoboken, NJ, USA, 2000; Volume 1. [Google Scholar]

- Feng, H.; Yin, Y.; Tang, J. Microwave drying of food and agricultural materials: Basics and heat and mass transfer modeling. Food Eng. Rev. 2012, 4, 89–106. [Google Scholar] [CrossRef]

- Nadew, T.T.; Tedla, T.S.; Bizualem, Y.D.; Abate, S.N.; Teklehaymanot, L.T. Data on drying kinetics, moisture sorption isotherm, composition study of Ethiopian oyster mushroom (Pleurotus ostreatus mushroom) drying in tray dryer. Data Brief 2024, 56, 110861. [Google Scholar] [CrossRef]

- Tran, T.N.T.; Khoo, K.S.; Chew, K.W.; Phan, T.Q.; Nguyen, H.S.; Nguyen-Sy, T.; Nguyen, T.D.P.; Chen, W.-H.; Show, P.L. Modelling drying kinetic of oyster mushroom dehydration—The optimization of drying conditions for dehydratation of Pleurotus species. Mater. Sci. Energy Technol. 2020, 3, 840–845. [Google Scholar] [CrossRef]

- Khaled, A.Y.; Kabutey, A.; Selvi, K.Ç.; Mizera, Č.; Hrabe, P.; Herák, D. Application of computational intelligence in describing the drying kinetics of persimmon fruit (Diospyros kaki) during vacuum and hot air drying process. Processes 2020, 8, 544. [Google Scholar] [CrossRef]

- Selvi, K.Ç.; Alkhaled, A.Y.; Yıldız, T. Application of artificial neural network for predicting the drying kinetics and chemical attributes of linden (Tilia platyphyllos Scop.) during the infrared drying process. Processes 2022, 10, 2069. [Google Scholar] [CrossRef]

- Shin, J.; Mahmud, M.S.; Rehman, T.U.; Ravichandran, P.; Heung, B.; Chang, Y.K. Trends and prospect of machine vision technology for stresses and diseases detection in precision agriculture. AgriEngineering 2022, 5, 20–39. [Google Scholar] [CrossRef]

- Nath, P.C.; Mishra, A.K.; Sharma, R.; Bhunia, B.; Mishra, B.; Tiwari, A.; Nayak, P.K.; Sharma, M.; Bhuyan, T.; Kaushal, S.; et al. Recent advances in artificial intelligence towards the sustainable future of agri-food industry. Food Chem. 2024, 447, 138945. [Google Scholar] [CrossRef]

- Macedo, L.L.; Vimercati, W.C.; da Silva Araújo, C.; Saraiva, S.H.; Teixeira, L.J.Q. Effect of drying air temperature on drying kinetics and physicochemical characteristics of dried banana. J. Food Process Eng. 2020, 43, e13451. [Google Scholar] [CrossRef]

- Amiri Chayjan, R.; Kaveh, M. Physical parameters and kinetic modeling of fix and fluid bed drying of terebinth seeds. J. Food Process. Preserv. 2014, 38, e12092. [Google Scholar] [CrossRef]

- Lin, X.; Lyng, J.; O’Donnell, C.; Sun, D.W. Effects of dielectric properties and microstructures on microwave-vacuum drying of mushroom (Agaricus bisporus) caps and stipes evaluated by non-destructive techniques. Food Chem. 2022, 367, 130698. [Google Scholar] [CrossRef]

- Salehi, F.; Cheraghi, R.; Rasouli, M. Mass transfer analysis and kinetic modeling of ultrasound-assisted osmotic dehydration of kiwifruit slices. Sci. Rep. 2023, 13, 11859. [Google Scholar] [CrossRef] [PubMed]

- Sawhney, R.; Pangavhane, D.; Sarsavadia, P. Drying studies of single layer thompson seedless grapes. In Proceedings of the International Solar Food Processing Conference, Indore, India, 14–16 January 2009. [Google Scholar]

- Tejeda-Miramontes, J.P.; Espinoza-Paredes, B.C.; Zatarain-Palffy, A.; García-Cayuela, T.; Tejada-Ortigoza, V.; Garcia-Amezquita, L.E. Process modeling and convective drying optimization of raspberry pomace as a fiber-rich functional ingredient: Effect on techno-functional and bioactive properties. Foods 2024, 13, 3597. [Google Scholar] [CrossRef] [PubMed]

- Sousa, E.P.d.; Oliveira, E.N.A.d.; Lima, T.L.S.; Almeida, R.F.; Barros, J.H.T.; Lima, C.M.G.; Giuffrè, A.M.; Wawrzyniak, J.; Wybraniec, S.; Coutinho, H.D.M.; et al. Empirical modeling of the drying kinetics of red beetroot (Beta vulgaris L.; Chenopodiaceae) with peel, and flour stability in laminated and plastic flexible packaging. Foods 2024, 13, 2784. [Google Scholar] [CrossRef] [PubMed]

- Peter, M.; Liu, Z.; Fang, Y.; Dou, X.; Awuah, E.; Soomro, S.A.; Chen, K. Computational intelligence and mathematical modelling in chanterelle mushrooms’ drying process under heat pump dryer. Biosyst. Eng. 2021, 212, 143–159. [Google Scholar] [CrossRef]

- Reyes, A.; Mahn, A.; Vásquez, F. Mushrooms dehydration in a hybrid-solar dryer, using a phase change material. Energy Convers. Manag. 2014, 83, 241–248. [Google Scholar] [CrossRef]

- Barforoosh, M.Y.; Borghaee, A.M.; Rafiee, S.; Minaei, S.; Beheshti, B. Determining the effective diffusivity coefficient and activation energy in thin-layer drying of Haj Kazemi peach slices and modeling drying kinetics using ANFIS. Int. J. Low-Carbon Tech. 2024, 19, 192–206. [Google Scholar] [CrossRef]

- El-Mesery, H.S.; Ashiagbor, K.; Hu, Z.; Rostom, M. Mathematical modeling of thin-layer drying kinetics and moisture diffusivity study of apple slices using infrared conveyor-belt dryer. J. Food Sci. 2024, 89, 1658–1671. [Google Scholar] [CrossRef] [PubMed]

- Tulek, Y. Drying kinetics of oyster mushroom (Pleurotus ostreatus) in a convective hot air dryer. J. Agric. Sci. Technol. 2011, 13, 655–664. [Google Scholar]

- Datt, P. Latent heat of vaporization/condensation. In Encyclopedia of Snow, Ice and Glaciers; Springer: Dordrecht, The Netherlands, 2011. [Google Scholar]

- Li, W.; Li, R.; Chen, W.; Feng, J.; Wu, D.; Zhang, Z.; Zhang, J.; Yang, Y. The anabolism of sulphur aroma volatiles responds to enzymatic and non-enzymatic reactions during the drying process of shiitake mushrooms. Food Chem. 2022, 371, 131123. [Google Scholar] [CrossRef] [PubMed]

- Muliterno, M.M.; Rodrigues, D.; Lima, F.S.; Ida, E.I.; Kurozawa, L.E. Conversion/degradation of isoflavones and color alterations during the drying of okara. LWT 2017, 75, 512–519. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).