3.1. Plant Height and Biomass of Cereal Rye Cover Crop

Overall, the cover crop seeding rate had a significant effect on the rye height (

p-value = 0.0280;

Table 2) with an average height of 161.4 cm and 164.6 cm for the 50 and 101 kg ha

−1 seeding rates, respectively. Also, there were interactions between the cover crop seeding rates and the year (

p-value = 0.0962). In contrast, no difference in cereal rye height occurred among the years (

p-value = 0.5598).

Similarly, for cereal rye biomass, the growing season (year) and cover crop seeding rate did not affect the biomass amount of the cereal rye cover crop, generating a 3-year average of 5496 kg ha

−1 and 5526 kg ha

−1 for 50 and 101 kg ha

−1 seeding rates, respectively (

Table 3). No interactions between the cover crop seeding rate and the year were present. These cereal rye biomass results agree with different field studies. According to [

25], the cereal rye seeding rate did not generate proportional biomass, indicating that a higher cereal rye seeding rate does not generate higher biomass production. In another study, Boyd et al. [

10] stated that at a low rye seeding rate, there was an increased generation of multiple stems (tillering), which compensated for overall plant growth and biomass production. Research conducted by [

26] reported that no significant effect in biomass production was observed from increased seeding rates for cereal rye rates. They indicated that in higher plant population, because of competition, it can reduce the individual plant size, which can be translated into similar amounts of cereal rye biomass. Overall, biomass from the cereal rye cover crop was at a comparable production level obtained from a field experiment in Alabama [

27], which reported that cereal rye cover crop production was ranging from 5832 kg ha

−1 and 6891 kg ha

−1 with a respective plant height between 157 cm and 159 cm.

3.2. Emergence Rate Index (ERI)

The year (growing season) for cotton emergence rate index (ERI) was significantly different among growing seasons (

p-value < 0.0001;

Table 4). Similarly, cotton ERI values were significantly influenced by both the cotton seeding rate and rye seeding rate with respective

p-values of 0.0521 and 0.0277. Average ERI values were 8.7, 11.2, and 7.9 in 2018, 2019, and 2020, respectively. A higher ERI value of 9.7% day

−1 was reported for cotton in the 101 kg ha

−1 cereal rye planting rate treatments, whereas for the 50 kg ha

−1 rye rate, the cotton ERI value of 8.9 was lower. In addition, a higher ERI average value of 9.5% day

−1 was obtained for the low cotton seeding rate compared with a lower ERI of 9.1% day

−1 for the high cotton seeding rate.

Moreover, significant interactions occurred between the cover crop planting rate by year, cotton rate by year, planter type by year, and planter speed by year with

p-values ranging from <0.0001 to 0.0425 (

Table 4). Due to year and interactions of year and variables such as CovRT, PltType, and PltSpeed being significant, ERI data were again reanalyzed separately by each year. ANOVA results from each growing season are shown in

Table 5. For significant interactions that occurred among dependent variables, only two-way interactions between years and other dependent variables (cover and cotton seeding rates, planter type and speed) were evaluated.

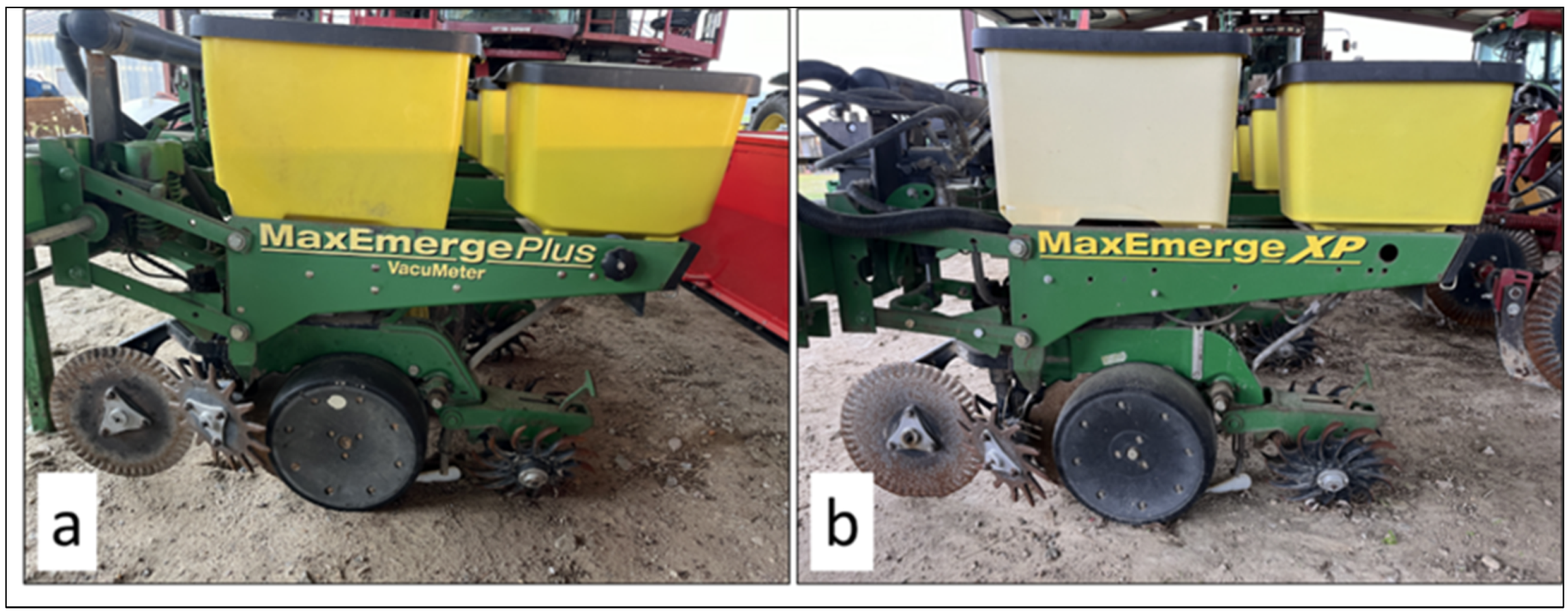

In 2018, cover crop seeding rates and planter type did affect cotton ERI. In contrast, cotton seeding rate and planter speed did not influence ERI. A lower ERI of 8.03 was associated with the 50 kg ha−1 cereal rye seeding rate compared with a higher ERI of 9.43 at 101 kg ha−1. Conversely, a higher ERI of 9.37 was obtained for the mechanical planter type compared to a lower ERI of 8.09% day−1 for the electronic planter type. The average ERI value across the cotton seeding rate and planter speed was the same (8.73% day−1).

In the 2019 growing season, the cover crop seeding rate, planter type, and planter speed affected the ERI, whereas the cotton planting rate did not influence the ERI, with an average ERI of 11.24% day

−1. At the 50 kg ha

−1 seeding rate for cereal rye, the ERI was lower compared to a higher ERI at the 101 kg ha

−1 cereal rye seeding rate. A higher ERI was obtained with the mechanical planter type compared to a lower ERI for the electronic planter type. Also, at the 5.6 km h

−1 planter’s speed, the ERI was higher when compared with a lower ERI at 11.2 km h

−1. Overall, ERI values in 2019 were similar to these reported by Kornecki [

28] with ERI values between 10.1 and 11.0 for cotton planted into a cereal rye cover crop. These results indicate no restriction in cotton emergence from the rolled down and crimped cereal rye cover crop residue.

In 2020, the cotton seeding rate and planter type influenced the ERI; in contrast, the cover crop seeding rate and planter speed did not. A higher ERI was associated with the low cotton seeding rate compared to a lower ERI at the high cotton seeding rate. The ERI value for the mechanical type planter was lower compared to a higher ERI for the electronic planter type.

Significant interaction for ERI was detected between planter type and planter speed (PltType*PltSpeed; p-value = 0.0044). The mechanical planter type at 5.6 km h−1 had a significantly higher ERI of 9.70% day−1 compared to a lower ERI of 9.06 and 9.05% day−1 for the mechanical type at 5.6 km h−1 and the electronic type planter at 5.6 km h−1, respectively. The ERI for the electronic planter type at a speed of 11.2 km h−1 had 9.32%, but was no different than for the mechanical type planter at both speeds and the electronic planter type at 5.6 km h−1.

3.3. Cotton Population

Across the three growing seasons, the cotton population varied between cotton seeding rates (CotRT;

p-value < 0.0001), planter types (PltType;

p-value = 0.0017), planter speeds (PltSpeed;

p-value = 0.0115), cover crop seeding rate (CovRT;

p-value = 0.0825), and among the growing seasons (

p-value = 0.0208). There were significant interactions between year and cotton seeding rates (

p-value < 0.0001) and between year and planter type (

p-value = 0.0008) influencing the plant cotton population. ANOVA results with respect to cotton population is presented in

Table 6. Because of these differences and interactions, data were reanalyzed separately by year with results presented in

Table 7.

Overall, a higher cotton population of 114,178 plants ha−1 averaged over other treatments and growing seasons were associated with the high cotton seeding rate compared with 66,650 plants ha−1 at the low cotton seeding rate. For planter type, a higher cotton population of 93,364 plants ha−1 was obtained with the mechanical planter type compared to a lower cotton population of 87,464 plants ha−1 for the new planter type. Likewise, for the cereal rye planting rate at 101 kg ha−1, the cotton plant population was higher with 93,538 plants ha−1 compared to the lower cotton population of 87,289 plants ha−1 at the 50 kg ha−1 seeding rate. Conversely, the higher cotton population of 92,767 plants ha−1 was obtained for the speed of 5.6 km h−1 compared to the lower cotton plant population of 88,061 plants ha−1 at the higher planter’s working speed of 11.2 km h−1.

In the 2018 growing season, cover crop seeding rates did not influence the cotton plant population. In contrast, the cotton seeding rate had a significant effect on the cotton population, generating a lower cotton population of 65,728 plants ha

−1 at a low cotton planting rate compared to a higher cotton population of 115,249 plants ha

−1 at the high cotton seeding rate. Similarly, the mechanical planter type generated a higher cotton population of 97,099 plants ha

−1 compared to a lower cotton population with the electronic type planter (83,878 plants ha

−1). Also, the planter speed affected the cotton population generating a higher cotton population at 5.6 km h

−1 compared to a lower cotton population at 11.2 km h

−1. Significant interaction between PltType*PltSpeed occurred having a higher cotton population with the mechanical planter type operating at 5.6 km h

−1 compared to a lower cotton population at 11.2 km h

−1 and the electronic planter type operating at both speeds (

Table 8). It appears that at the lower planter’s speed, there is better control for seeds discharge compared to the higher speed. This might be related to more skips due to not enough time for proper seed placing in the planting unit at a higher speed.

The same trend in cotton population continued in the 2019 growing season. The cover crop seeding rate did not influence the cotton population. Intuitively, the cotton seeding rate had a significant effect on the cotton population having a higher cotton population at a higher planting rate compared to a lower cotton population at the low cotton seeding rate. Significant interactions between the cotton seeding rate and planter type (PltType*CotRT) indicated that both planter types at the high seeding rate generated a higher cotton population than at the low cotton seeding rate for both planter types. Although, a 19% lower cotton population was indicated for the electronic planter at the low cotton seeding rate compared to the mechanical planter.

In 2020, only the cotton seeding rate influenced cotton population, whereas the cover crop seeding rate, planter type, and planter speed did not. A lower cotton population of 70,957 plants ha−1 was associated with the low cotton seeding rate compared to a higher cotton population of 103,448 plants ha−1 at the high cotton seeding rate.

Across growing seasons, significant interactions existed between the cotton seeding rate and planter type (

Table 8; CotRT*PltType

p-value = 0.0099). Specifically, at the high cotton seeding rate with both planter types, the cotton population was significantly higher (114,726 plants ha

−1 for the mechanical type and 113,630 plants ha

−1 for the electronic planter type) without difference between planters. In comparison, lower cotton populations at the low cotton seeding rate generated 72,002 plants ha

−1 for the mechanical type and a significantly lower population of 61,297 for the electronic planter type.

Similarly, a significant interaction was detected between the planter type and the planter speed (PltType*PltSpeed p-value = 0.0371). The mechanical planter type at 5.6 km h−1 generated a significantly higher cotton population of 97,647 plants ha−1 compared to a lower cotton population of 89,082 plants ha−1 at 11.2 km h−1. In addition, the electronic planter generated 87,887 plants ha−1 and 87,040 plants ha−1 at 5.6 and 11.2 km h−1, respectively, without statistical differences among planter’s speeds.

3.4. Seed Cotton Yield

Seed cotton yield was significantly different among growing seasons (YEAR;

p-value < 0.0001). In addition, across all growing seasons, significant difference in seed cotton yield were found between cotton planting rates (CotRT;

p-value = 0.0001). Likewise, there were significant interactions between the growing season and the seed cotton planting rate (CotRT*YEAR) with

p-value = 0.0045 (

Table 9). Furthermore, significant interaction occurred between the cover crop planting rate and the planter type (CovRT*PltType;

p-value = 0.0700).

Because seed cotton yield was significantly different among growing seasons, yield data were reanalyzed separately by each year and results are shown in

Table 10. Overall, a higher seed cotton yield was generated in 2020 (4152 kg ha

−1), followed by a lower yield in 2018 (3981 kg ha

−1), and the lowest significantly reduced yield of 1844 kg ha

−1 was observed in 2019. In addition, across all growing seasons, significant differences in seed cotton yield were found between cotton planting rates generating 3449 kg ha

−1 at the higher cotton planting rate compared to 3202 kg ha

−1 for the low cotton planting rate.

In 2018, the cotton seeding rate and planter speed affected the seed cotton yield. A higher cotton yield was obtained with the high seeding rate (4101 kg ha−1) compared to a lower yield (3860 kg ha−1) at the low seeding rate. Conversely, a higher yield (4066 kg ha−1) was generated at a lower speed of 5.6 km h−1 compared to a lower yield (3896 kg ha−1) at a planter’s speed of 11.2 km h−1. The cover crop rate and planter type did not influence the cotton yield.

In 2019, none of the cover crop, cotton planting rates, nor planter type and planting speed had an impact on the seed cotton yield. The yield was significantly decreased and generated only 1844 kg ha

−1, which was 46% of the seed cotton yield obtained in 2018 and 44% in 2020. The main reason for this decline was a hot summer and a drought period in 2019 compared to two other seasons. Specifically, the rainfall amount from cotton planting to cotton harvest was only 204 mm, which was 43% of the total rainfall amount (477 mm) that occurred in 2018 and 33% of rainfall fallen in 2020 (628 mm) during the same growing period. Also, the maximum average ambient temp of 33.8 °C was higher than in 2018 and 2020 (

Table 11). Physiological effects on cotton during drought stress include lower photosynthesis rates, decreased plant growth, fruit shed, early boll maturation, reduced lint quality, and lower yields [

29,

30].

In 2020, only the cotton seeding rate affected the cotton yield of 4407 kg ha

−1 at the high cotton seeding rate compared to a significantly lower yield of 3896 kg ha

−1 at the low cotton seeding rate. In contrast, the cover crop planting rate, planter type, and planter’s speed did not have any effect on cotton yield. Generally, a higher cotton yield in 2020 was associated with optimum rainfall amounts during cotton plant development (

Table 11).

3.5. Cotton Seed Planting Uniformity

A lower standard deviation (SD) indicates a better seed spacing uniformity. Since the spacing between cotton plants is substantially different at low and high cotton seeding rates, standard deviation of spacing was analyzed separately by low and high cotton seeding rates with results presented in

Table 12. Th planter type showed significant influence at both rates with Year*PltSpeed (

p-value = 0.0784) indicating a slight influence for the low rate. For the high speed, planter speed was significant at

p-value = 0.0269.

Plant spacing standard deviation was not impacted by the cover crop seeding rate for either low or high cotton rates. For the low rate in 2018 (

Table 13), the mechanical planter experienced increased standard deviations for plant spacing compared to the electronic planter (

p-value = 0.0231). However, no other significance was detected between the two planter types for the 2019 or 2020 season. Across all three seasons, the mechanical planter performed with 11.6% higher standard deviation compared to the electronic planter at the low cotton seeding rate.

For the low cotton seeding rate including both planter types for 2018, the higher speed showed significantly higher variation with 27.4% more standard deviation compared to the slower speed. However, no other differences were noticed between speeds for 2019, 2020, or across all years.

For the planter type in the high cotton rate, no differences existed between planters for any of the seasons. However, pooled over all seasons, a higher SD for the mechanical planter was observed compared to the electronic planter by 10.8% (

p-value = 0.0803). The high speed for the high cotton rate (

Table 14) noticed a 19.1% increase in standard deviation compared to the slower speed. Also, across all years, the higher speed showed a 10.5% increase in SD compared to the lower speed. These results are consisted with a study conducted by Virk [

14] confirming that their coefficient of variation had a significant increasing trend with increased meter speeds while planting corn. These results suggest that the planter seed spacing variation was more at the higher cotton rate and higher speed compared to the lower rate and lower cotton rate. This is expected as the planter seeding plate must rotate faster and place more seeds under these conditions compared to the lower cotton seeding rate.