The Use of Machine Learning to Assess the Impact of the Ozonation Process on Selected Mechanical Properties of Japanese Quince Fruits

Abstract

1. Introduction

2. Materials and Methods

2.1. Plant Materials

2.2. Ozonation Process

2.3. Determination of Water Content

2.4. Determination of Mechanical Properties of Japanese Quince Fruits

2.5. Statistical Analysis

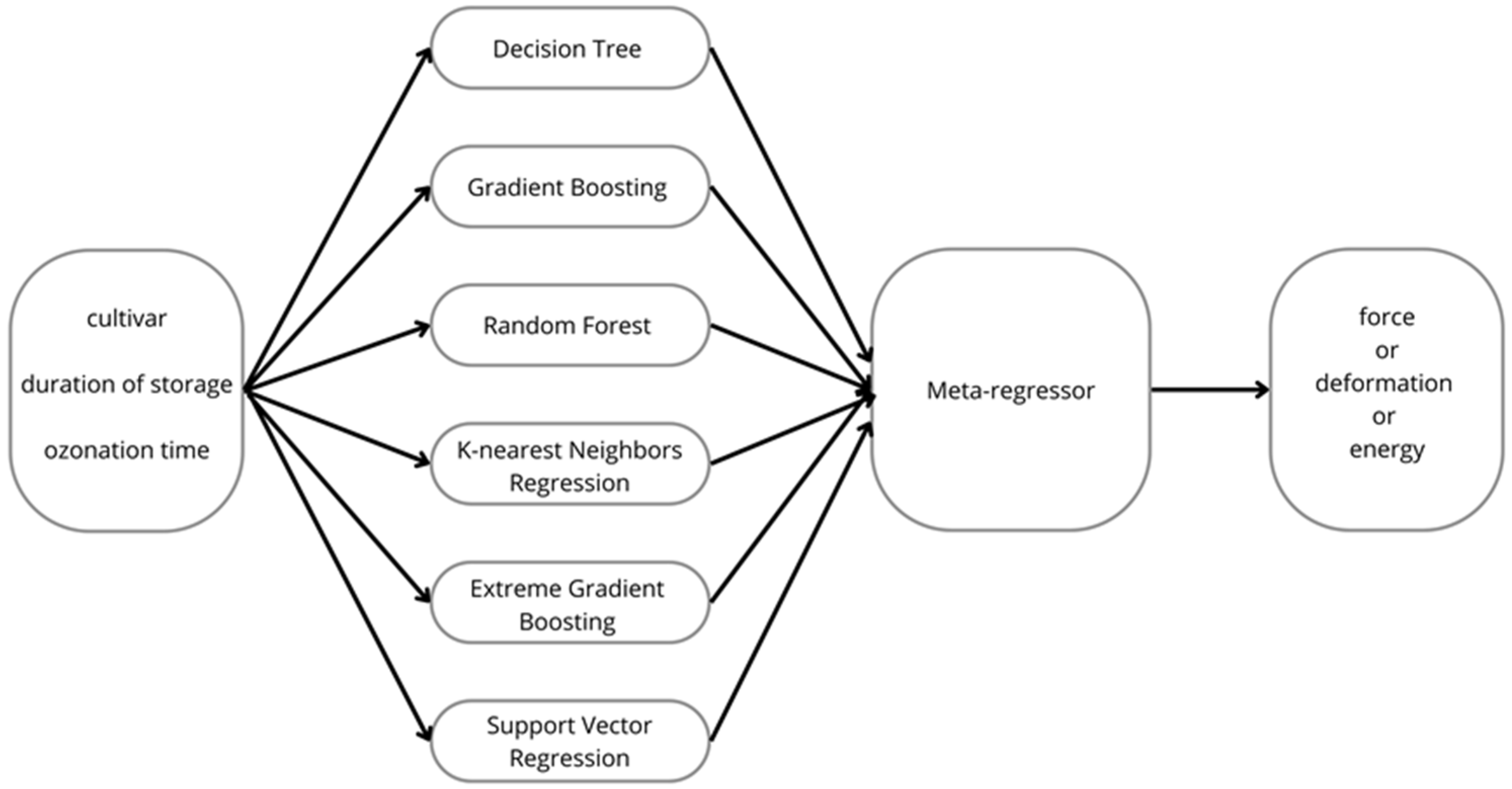

2.6. Machine Learning Models

3. Results and Discussion

3.1. Water Content and Mechanical Properties of Japanese Quince Fruits

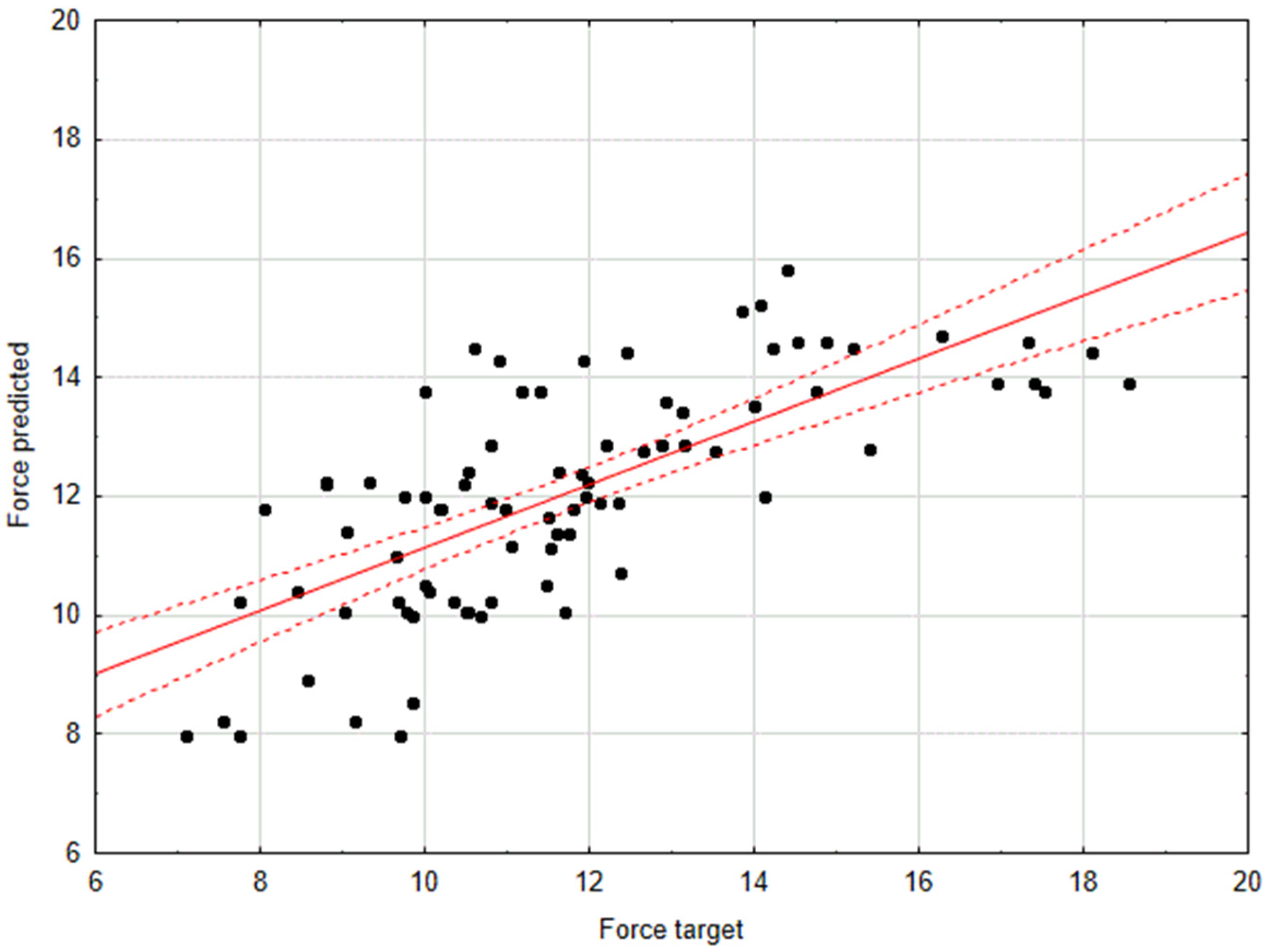

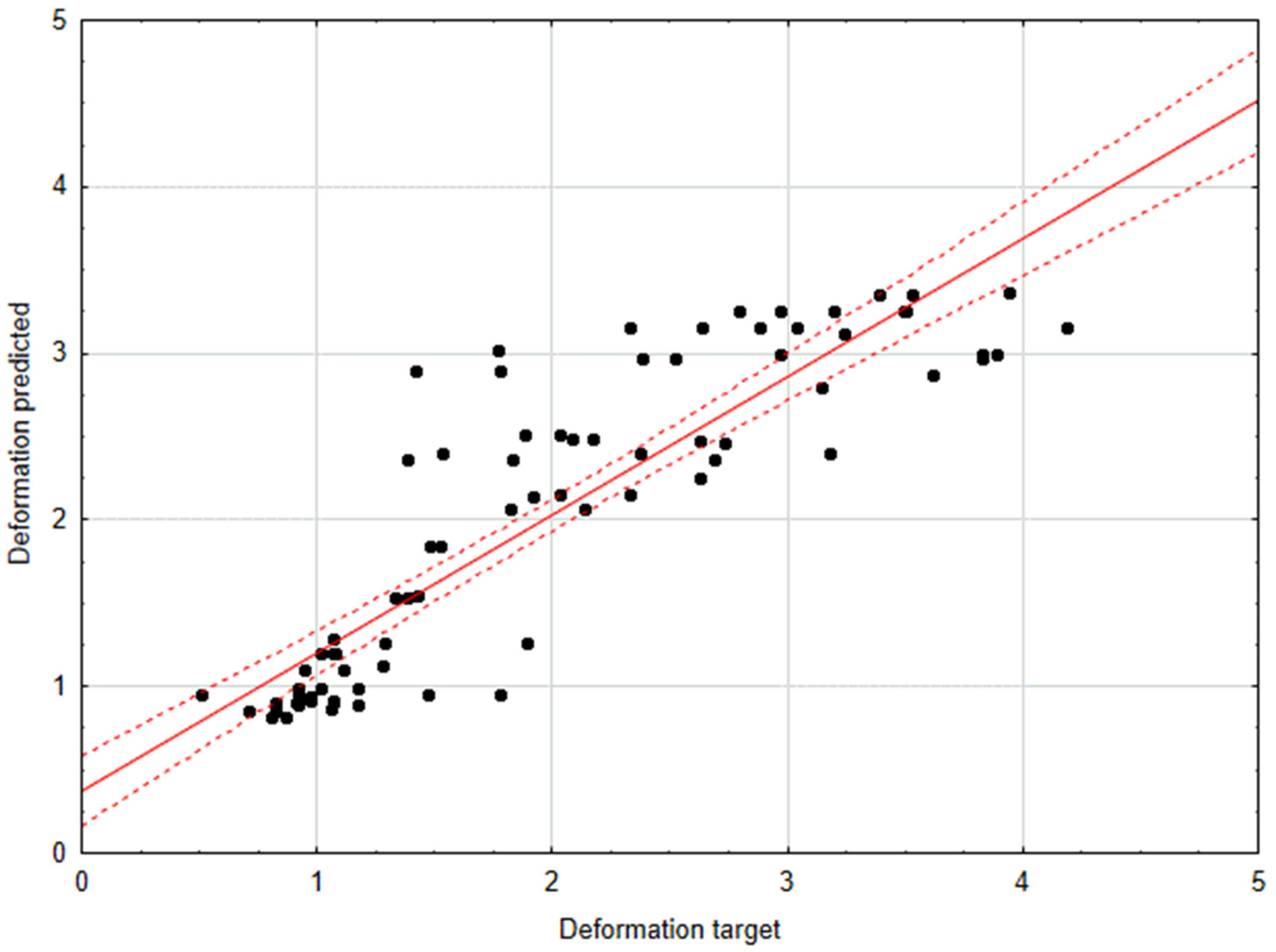

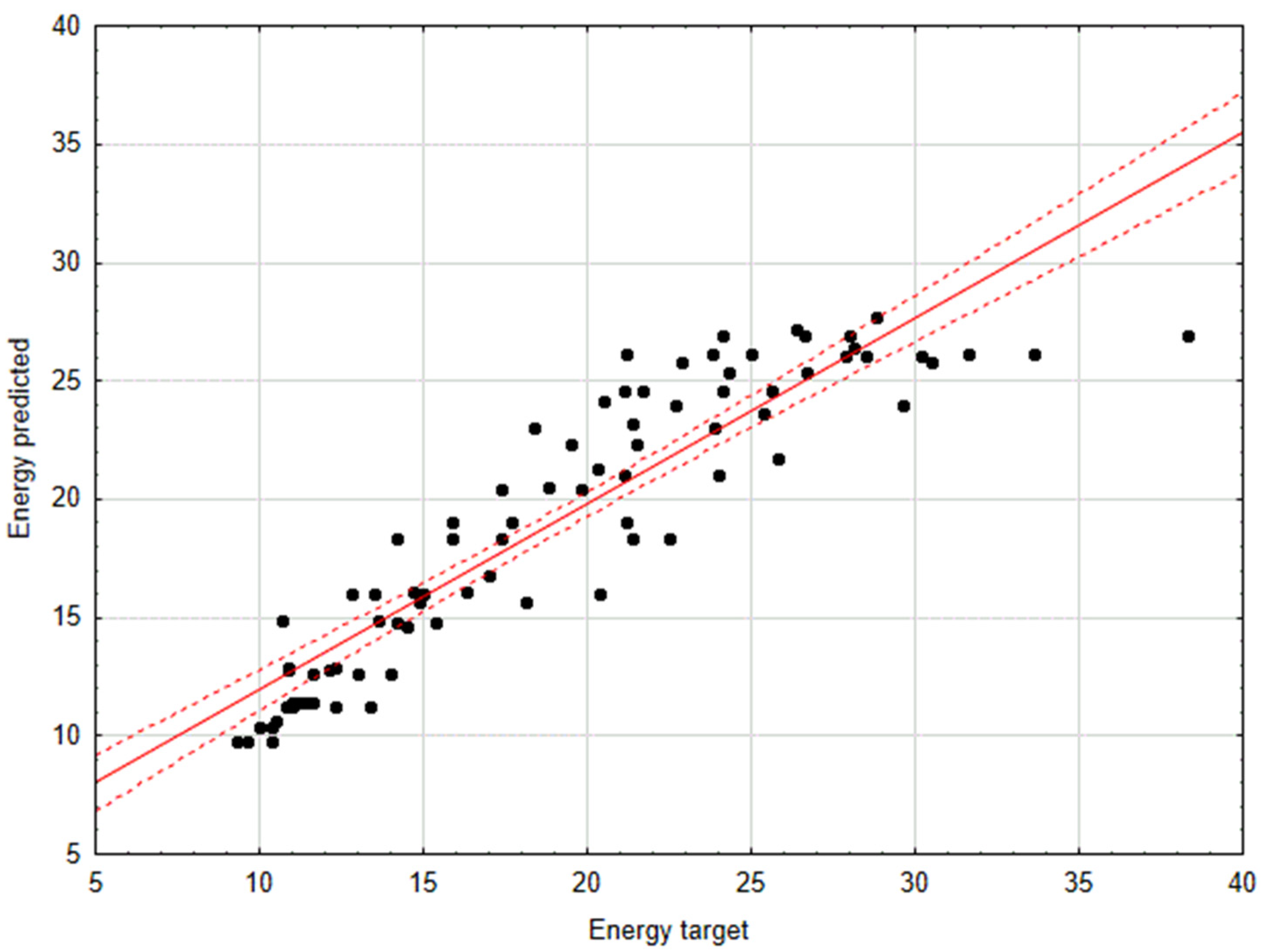

3.2. Machine Learning Models

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Byczkiewicz, S.; Kobus-Cisowska, J.; Szulc, P.; Telichowska, A.; Szczepaniak, O.; Dziedzinski, M. Pigwowiec japoński (Chaenomeles japonica L.) jako surowiec o właściwościach prozdrowotnych—Aktualny stan wiedzy. Tech. Rol. Ogrod. Leśna 2019, 5, 22–25. [Google Scholar]

- Zhang, R.; Li, S.; Zhu, Z.; He, J. Recent advances in valorization of Chaenomeles fruit: A review ofbotanical profile, phytochemistry, advanced extraction technologies and bioactivities. Trends Food Sci. Technol. 2019, 91, 467–482. [Google Scholar] [CrossRef]

- Rumpunen, K. Chaenomeles: Potential new fruit crop for northern Europe. In Trends in New Crops and New Uses; ASHA Press: Alexandria, VA, USA, 2002; pp. 385–392. [Google Scholar]

- Zhang, L.; Li, S. Effects of micronization on properties of Chaenomeles sinensis (Thouin) Koehne fruit powder. Innov. Food Sci. Emerg. Technol. 2009, 10, 633–637. [Google Scholar] [CrossRef]

- Tarko, T.; Duda-Chodak, A.; Pogon, P. Charakterystyka owoców pigwowca japońskiego i derenia jadalnego. Żywność. Nauka. Technol. Jakość. 2010, 6, 100–108. [Google Scholar]

- Zhang, M.; Zhao, R.; Zhou, S.; Liu, W.; Liang, Y.; Zhao, Z. Chemical characterization and evaluation of the antioxidants in Chaenomeles fruits by an improved HPLC-TOF/MS coupled to an online DPPH-HPLC method. J. Environ. Sci. Health Part C 2018, 36, 43–62. [Google Scholar] [CrossRef]

- Du, H.; Wu, J.; Li, H. Polyphenols and triterpenes from Chaenomeles fruits. Chemical analysis and antioxidant activities assessment. Food Chem. 2013, 141, 4260–4268. [Google Scholar] [CrossRef]

- Nahorska, A.; Dzwoniarska, M.; Thiem, B. Owoce pigwowca japońskiego (Chaenomelesjaponica (Thunb.) Lindi. ex Spach) źródłem substancji biologicznie aktywnych. Postępy Fitoter. 2014, 4, 239–246. [Google Scholar]

- Aliasgarian, S.; Ghassemzadeh, H.; Moghaddam, M.; Ghaffari, H. Mechanical Damage of Strawberry During Harvest and Postharvest Operations. Acta Technol. Agric. 2015, 18, 1–5. [Google Scholar] [CrossRef]

- El-Ramady, H.R.; Domokos-Szabolcsy, E.; Abdalla, N.A.; Taha, H.S.; Fári, M. Postharvest Management of Fruits and Vegetables Storage. Sustain. Agric. Rev. 2015, 15, 65–152. [Google Scholar]

- Sarig, Y. Mechanical harvesting of fruit—Past achievements, current status and future prospects. Acta Hortic. 2012, 965, 163–169. [Google Scholar] [CrossRef]

- Rabcewicz, J. Perspectives of mechanical harvesting of stone and berry fruit. Informator Sadowniczy, 5 May 2013. (In Polish) [Google Scholar]

- Paniagua, A.C.; East, A.R.; Hindmarsh, J.P.; Heyes, J.A. Moisture loss is the major cause of firmness change during postharvest storage of blueberry. Postharvest Biol. Technol. 2013, 79, 13–19. [Google Scholar] [CrossRef]

- Ruse, K.; Rakcejeva, T.; Dukalska, L. Changes in Physically-Chemical Parameters of Latvian Cranberries During Storage. Proc. Latv. Univ. Agric. 2013, 30, 11–19. [Google Scholar] [CrossRef]

- Bohdziewicz, J.; Czachor, G. The impact of load on deformation progress for ball-shaped vegetables. Agric. Eng. 2010, 1, 85–91. [Google Scholar]

- Bohdziewicz, J.; Czachor, G. The Rheological Properties of Redcurrant and Highbush Blueberry Berries. Agric. Eng. 2016, 2, 15–22. [Google Scholar] [CrossRef]

- Diaz-Garcia, L.; Rodriguez-Bonilla, L.; Phillips, M.; Lopez-Hernandez, A.; Grygleski, E.; Atucha, A.; Zalapa, J. Comprehensive analysis of the internal structure and firmness in American cranberry (Vaccinium macrocarpon Ait.) fruit. PLoS ONE 2019, 14, e0222451. [Google Scholar] [CrossRef]

- Kowalska, H.; Marzec, A.; Domian, E.; Masiarz, E.; Ciurzyńska, A.; Galus, S.; Małkiewicz, A.; Lenart, A.; Kowalska, J. Physical and Sensory Properties of Japanese Quince Chips Obtained by Osmotic Dehydration in Fruit Juice Concentrates and Hybrid Drying. Molecules 2020, 25, 5504. [Google Scholar] [CrossRef]

- Cirak, C.; Radusiene, J. Factors affecting the variation of bioactive compounds in Hypericum species. Biol. Futur. 2019, 70, 198–209. [Google Scholar] [CrossRef]

- Cao, S.; Meng, L.; Ma, C.; Ba, L.; Lei, J.; Ji, N.; Wang, R. Effect of ozone treatment on physicochemical parameters and ethylene biosynthesis inhibition in Guichang Kiwifruit. Food Sci. Technol. 2022, 42, e64820. [Google Scholar] [CrossRef]

- Xu, D.Y.; Shi, M.; Jia, B.; Yan, Z.C.; Gao, L.P.; Guan, W.Q.; Wang, Q.; Zuo, J.H. Effect of ozone on the activity of antioxidant and chlorophyll-degrading enzymes during postharvest storage of coriander (Coriandrum sativum L.). J. Food Process. Preserv. 2019, 43, e14020. [Google Scholar] [CrossRef]

- Pinto, L.; Palma, A.; Cefola, M.; Pace, B.; D’Aquino, S.; Carboni, C.; Baruzzi, F. Effect of modified atmosphere packaging (MAP) and gaseous ozone pre-packaging treatment on the physico-chemical, microbiological and sensory quality of small berry fruit. Food Packag. Shelf Life 2020, 26, 100573. [Google Scholar] [CrossRef]

- Zhang, L.K.; Lu, Z.X.; Yu, Z.F.; Gao, X. Preservation of fresh-cut celery by treatment of ozonated water. Food Control 2005, 16, 279–283. [Google Scholar] [CrossRef]

- Zardzewiały, M.; Matlok, N.; Piechowiak, T.; Gorzelany, J.; Balawejder, M. Ozone Treatment as a Process of Quality Improvement Method of Rhubarb (Rheum rhaponticum L.) Petioles during Storage. Appl. Sci. 2020, 10, 8282. [Google Scholar] [CrossRef]

- Wang, T.; Yun, J.; Zhang, Y.; Bi, Y.; Zhao, F.; Niu, Y. Effects of ozone fumigation combined with nano-film packaging on the postharvest storage quality and antioxidant capacity of button mushrooms (Agaricus bisporus). Postharvest Biol. Technol. 2021, 176, 111501. [Google Scholar] [CrossRef]

- Lin, F.; Kaiyu, L.; Shufeng, M.A.; Wang, F.; Li, J.; Wang, L. Effects of ozone treatment on storage quality and antioxidant capacity of fresh-cut water fennel (Oenanthe javanica). Food Sci. Technol. 2023, 43, e108422. [Google Scholar] [CrossRef]

- Postawa, K.; Klimek, K.; Kapłan, M.; Wrzesińska-Jędrusiak, E.; Kułażyński, M. Application of ozonation as a clean method of herbs freshness prolongation: Experiment and model construction. J. Food Process Eng. 2021, 44, e13913. [Google Scholar] [CrossRef]

- Brodowska, A.J.; Nowak, A.; Śmigielski, K. Ozone in the food industry: Principles of ozone treatment, mechanisms of action, and applications: An overview. Crit. Rev. Food Sci. Nutr. 2017, 58, 2176–2201. [Google Scholar] [CrossRef]

- Kuźniar, P.; Belcar, J.; Zardzewiały, M.; Basara, O.; Gorzelany, J. Effect of Ozonation on the Mechanical, Chemical, and Microbiological Properties of Organically Grown Red Currant (Ribes rubrum L.) Fruit. Molecules 2022, 27, 8231. [Google Scholar] [CrossRef]

- Pérez-López, A.; Chávez-Franco, S.H.; Villaseñor-Perea, C.A.; Espinosa-Solares, T.; Hernandez-Gomez, L.H.; Lobato-Calleros, C. Respiration rate and mechanical properties of peach fruit during storage at three maturity stages. J. Food Eng. 2014, 142, 111–117. [Google Scholar] [CrossRef]

- Pan, H.; Yang, J.; Shi, Y.; Li, T. BP neural network application model of predicting the apple hardness. J. Comput. Theor. Nanosci. 2015, 12, 2802–2807. [Google Scholar] [CrossRef]

- Saeidirad, M.H.; Rohani, A.; Zarifneshat, S. Predictions of viscoelastic behavior of pomegranate using artificial neural network and Maxwell model. Comput. Electron. Agric. 2013, 98, 1–7. [Google Scholar] [CrossRef]

- Zhang, P.; Shen, B.; Ji, H.; Wang, H.; Liu, Y.; Zhang, X.; Ren, C. Nondestructive Prediction of Mechanical Parameters to Apple Using Hyperspectral Imaging by Support Vector Machine. Food Anal. Methods 2022, 1, 1397–1406. [Google Scholar] [CrossRef]

- Mohsen, A.; Shabankareh, S.H.; Kiapey, A.; Rezaeiasl, A.; Mahmoodi, M.J.; Torshizi, M.V. Assessing kiwifruit quality in storage through machine learning. J. Food Process Eng. 2024, 47, e14681. [Google Scholar]

- Qiao, J.; Wang, N.; Ngadi, M.; Kazemi, S. Predicting mechanical properties of fried chicken nuggets using image processing and neural network techniques. J. Food Eng. 2007, 79, 1065–1070. [Google Scholar] [CrossRef]

- PN-90/A-75101/03:1990; Determination of Dry Matter Content by the Weight Method. Polish Standard. Polish Committee for Standardization: Warsaw, Poland, 1990. (In Polish)

- Zapałowska, A.; Matłok, N.; Zardzewiały, M.; Piechowiak, T.; Balawejder, M. Effect of Ozone Treatment on the Quality of Sea Buckthorn (Hippophae rhamnoides L.). Plants 2021, 10, 847. [Google Scholar] [CrossRef] [PubMed]

- Antos, P.; Piechowicz, B.; Gorzelany, J.; Matłok, N.; Migut, D.; Józefczyk, R.; Balawejder, M. Effect of Ozone on Fruit Quality and Fungicide Residue Degradation in Apples during Cold Storage. Ozone Sci. Eng. 2018, 40, 482–486. [Google Scholar] [CrossRef]

- Matłok, N.; Piechowiak, T.; Zardzewiały, M.; Saletnik, B.; Balawejder, M. Continuous Ozonation Coupled with UV-C Irradiation for a Sustainable Post-Harvest Processing of Vaccinium macrocarpon Ait. Fruits to Reduce Storage Losses. Sustainability 2024, 16, 5420. [Google Scholar] [CrossRef]

- Zardzewiały, M.; Matłok, N.; Piechowiak, T.; Saletnik, B.; Balawejder, M.; Gorzelany, J. Preliminary Tests of Tomato Plant Protection Method with Ozone Gas Fumigation Supported with Hydrogen Peroxide Solution and Its Effect on Some Fruit Parameters. Sustainability 2024, 16, 3481. [Google Scholar] [CrossRef]

- Yu, X.; Lu, H.; Wu, D. Development of deep learning method for predicting firmness and soluble solid content of postharvest Korla fragrant pear using Vis/NIR hyperspectral reflectance imaging. Postharvest Biol. Technol. 2018, 141, 39–49. [Google Scholar] [CrossRef]

- Saiedirad, M.H.; Mirsalehi, M. Prediction of mechanical properties of cumin seed using artificial neural networks. J. Texture Stud. 2010, 41, 34–48. [Google Scholar] [CrossRef]

- Cevher, E.Y.; Yildirim, D. Using Artificial Neural Network Application in Modeling the Mechanical Properties of Loading Position and Storage Duration of Pear Fruit. Processes 2022, 10, 2245. [Google Scholar] [CrossRef]

- Vasighi-Shojae, H.; Gholami-Parashkouhi, M.; Mohammadzamani, D.; Soheili, A. Predicting Mechanical Properties of Golden Delicious Apple Using Ultrasound Technique and Artificial Neural Network. Food Anal. Methods 2020, 13, 699–705. [Google Scholar]

- Qureshi, A.S.; Khan, A.; Zameer, A.; Usman, A. Wind power prediction using deep neural network based meta regression and transfer learning. Appl. Soft Comput. 2017, 58, 742–755. [Google Scholar] [CrossRef]

| Variety | Duration of Storage [days] | Ozonation Time [min] | Moisture Content [%] | Force [N] | Deformation [mm] | Energy [mJ] |

|---|---|---|---|---|---|---|

| Darius | 1 | 0 | 98.01 a ± 0.28 | 13.42 a ± 1.22 | 1.20 a ± 0.33 | 14.43 a ± 4.46 |

| 15 | 98.23 a ± 0.49 | 12.07 a ± 1.75 | 1.36 a ± 0.23 | 12.86 a ± 1.71 | ||

| 30 | 97.97 a ± 0.31 | 13.42 a ± 2.02 | 1.14 a ± 0.13 | 13.04 a ± 1.54 | ||

| 30 | 0 | 97.04 a ± 0.30 | 10.33 a ± 1.68 | 2.19 a ± 0.61 | 21.13 a ± 1.44 | |

| 15 | 97.26 a ± 0.51 | 12.07 a ± 0.99 | 2.71 b ± 0.36 | 21.94 a ± 1.68 | ||

| 30 | 97.00 a ± 0.33 | 14.21 b ± 1.95 | 3.07 b ± 1.23 | 26.65 b ± 3.54 | ||

| 60 | 0 | 94.81 a ± 0.55 | 13.11 a ± 2.22 | 2.91 a ± 0.59 | 24.15 a ± 3.34 | |

| 15 | 94.95 a ± 0.43 | 14.50 ab ± 1.79 | 3.15 a ± 0.37 | 23.61 a ± 1.62 | ||

| 30 | 95.31 a ± 1.21 | 15.12 b ± 1.72 | 2.93 a ± 0.50 | 22.91 a ± 2.46 | ||

| Gold Calif | 1 | 0 | 97.76 a ± 0.39 | 12.63 a ± 2.02 | 0.95 a ± 0.12 | 15.01 a ± 1.35 |

| 15 | 98.06 a ± 0.40 | 13.41 a ± 1.19 | 0.95 a ± 0.12 | 14.70 a ± 0.73 | ||

| 30 | 97.56 a ± 0.36 | 13.59 a ± 1.94 | 1.07 a ± 0.32 | 14.28 a ± 1.95 | ||

| 30 | 0 | 96.65 a ± 0.39 | 12.20 a ± 2.62 | 1.96 a ± 0.83 | 23.8 a ± 7.64 | |

| 15 | 96.95 a ± 0.31 | 14.83 b ± 1.95 | 1.88 a ± 0.27 | 28.6 b ± 3.04 | ||

| 30 | 96.45 a ± 0.35 | 15.32 b ± 1.49 | 2.43 a ± 0.17 | 27.6 b ± 1.59 | ||

| 60 | 0 | 93.68 a ± 0.47 | 14.85 a ± 1.98 | 2.47 a ± 0.52 | 26.20 a ± 2.94 | |

| 15 | 94.90 a ± 0.51 | 15.76 a ± 1.32 | 2.39 a ± 0.27 | 27.23 a ± 2.58 | ||

| 30 | 92.80 a ± 2.31 | 14.23 a ± 2.30 | 2.38 a ± 0.67 | 24.58 a ± 2.35 | ||

| Maksym | 0 | 0 | 98.33 a ± 0.44 | 9.71 a ± 1.44 | 0.86 a ± 0.15 | 11.15 a ± 0.58 |

| 15 | 96.99 a ± 0.93 | 11.01 a ± 1.48 | 0.91 a ± 0.17 | 12.91 a ± 1.77 | ||

| 30 | 97.85 a ± 0.90 | 10.20 a ± 1.38 | 0.94 a ± 0.11 | 11.96 a ± 0.98 | ||

| 30 | 0 | 97.26 a ± 0.39 | 9.13 a ± 2.39 | 1.45 a ± 0.16 | 18.30 a ± 5.00 | |

| 15 | 95.94 a ± 0.89 | 14.63 c ± 3.32 | 2.99 b ± 0.77 | 25.22 b ± 3.59 | ||

| 30 | 96.79 a ± 0.56 | 12.68 b ± 2.63 | 1.65 a ± 0.19 | 22.69 b ± 2.81 | ||

| 60 | 0 | 94.83 a ± 0.29 | 11.62 a ± 1.69 | 2.21 a ± 0.61 | 18.35 a ± 2.30 | |

| 15 | 94.11 a ± 0.41 | 15.39 b ± 2.44 | 3.06 b ± 0.88 | 28.49 c ± 4.91 | ||

| 30 | 94.04 a ± 0.83 | 11.76 a ± 2.33 | 2.46 a ± 0.44 | 23.70 b ± 2.01 | ||

| North Lemon | 1 | 0 | 97.90 a ± 0.49 | 12.10 a ± 1.92 | 1.04 a ± 0.18 | 16.08 a ± 3.05 |

| 15 | 98.28 a ± 0.53 | 12.08 a ± 1.72 | 0.88 a ± 0.08 | 16.09 a ± 2.22 | ||

| 30 | 97.91 a ± 0.65 | 12.93 a ± 2.24 | 0.97 a ± 0.31 | 16.54 a ± 2.65 | ||

| 30 | 0 | 96.79 a ± 1.37 | 11.64 a ± 1.20 | 2.18 a ± 0.53 | 24.65 b ± 2.05 | |

| 15 | 97.16 a ± 0.44 | 12.16 a ± 1.86 | 2.02 a ± 0.38 | 26.6 b ± 2.94 | ||

| 30 | 96.80 a ± 1.84 | 10.20 a ± 1.50 | 2.87 b ± 0.69 | 20.91 a ± 5.24 | ||

| 60 | 0 | 93.71 a ± 1.59 | 13.95 a ± 2.38 | 3.27 a ± 0.37 | 25.45 a ± 2.88 | |

| 15 | 94.35 a ± 1.93 | 12.70 a ± 2.05 | 3.49 a ± 0.65 | 28.05 a ± 2.18 | ||

| 30 | 95.33 a ± 0.58 | 13.54 a ± 2.89 | 3.11 a ± 0.68 | 27.41 a ± 5.57 | ||

| Rasa | 1 | 0 | 98.47 a ± 0.45 | 8.07 a ± 1.03 | 1.20 a ± 0.25 | 9.71 a ± 1.23 |

| 15 | 98.24 a ± 0.53 | 8.45 a ± 0.91 | 1.30 a ± 0.25 | 10.44 a ± 0.73 | ||

| 30 | 97.43 a ± 0.94 | 8.58 a ± 0.70 | 1.11 a ± 0.20 | 10.69 a ± 0.76 | ||

| 30 | 0 | 97.21 a ± 0.48 | 8.66 a ± 0.91 | 2.36 a ± 0.31 | 16.41 a ± 0.92 | |

| 15 | 96.98 a ± 0.63 | 8.74 a ± 2.40 | 2.68 a ± 0.45 | 15.43 a ± 4.35 | ||

| 30 | 96.18 a ± 1.14 | 10.19 a ± 1.18 | 3.24 b ± 0.25 | 18.55 a ± 2.87 | ||

| 60 | 0 | 94.49 a ± 2.31 | 9.96 a ± 1.05 | 2.78 a ± 0.36 | 17.73 a ± 1.00 | |

| 15 | 94.65 a ± 1.73 | 10.05 a ± 2.76 | 3.16 a ± 0.53 | 16.66 a ± 4.70 | ||

| 30 | 93.97 a ± 1.68 | 11.71 a ± 1.36 | 3.81 b ± 0.29 | 20.03 a ± 3.10 | ||

| Tamara | 1 | 0 | 97.82 a ± 0.73 | 11.04 a ± 1.14 | 0.86 a ± 0.13 | 11.56 a ± 1.42 |

| 15 | 97.69 a ± 1.11 | 10.04 a ± 1.20 | 0.86 a ± 0.09 | 11.24 a ± 0.82 | ||

| 30 | 98.35 a ± 0.74 | 11.52 a ± 0.93 | 0.83 a ± 0.08 | 12.83 a ± 1.31 | ||

| 30 | 0 | 96.57 a ± 0.99 | 11.71 a ± 2.77 | 2.01 b ± 1.01 | 21.46 a ± 6.27 | |

| 15 | 96.44 a ± 0.97 | 11.19 a ± 0.58 | 1.51 a ± 0.11 | 21.30 a ± 1.31 | ||

| 30 | 97.09 a ± 0.79 | 11.88 a ± 3.18 | 2.86 c ± 1.03 | 22.91 a ± 5.45 | ||

| 60 | 0 | 93.90 a ± 1.80 | 13.39 ± 0.67 | 2.75 b ± 0.89 | 24.55 b ± 3.50 | |

| 15 | 93.96 a ± 1.76 | 11.95 a ± 1.10 | 2.48 ab ± 0.54 | 21.24 a ± 1.72 | ||

| 30 | 95.18 a ± 0.92 | 11.58 a ± 1.04 | 2.06 a ± 0.22 | 19.79 a ± 2.04 |

| Variables | Moisture Content (%) | Force (N) | Deformation (mm) | Energy (mJ) | |

|---|---|---|---|---|---|

| Variety | Darius | 96.73 a ± 1.36 | 13.18 d ± 2.12 | 2.28 b ± 0.97 | 19.99 c ± 5.61 |

| Gold Calif | 96.24 a ± 1.60 | 14.09 e ± 2.15 | 1.83 a ± 0.75 | 22.44 d ± 6.50 | |

| Maksym | 96.09 a ± 1.87 | 11.79 bc ± 2.91 | 1.84 a ± 0.95 | 19.20 bc ± 6.60 | |

| North Lemon | 96.47 a ± 1.64 | 12.37 c ± 2.18 | 2.20 b ± 1.09 | 22.42 d ± 5.79 | |

| Rasa | 96.33 a ± 1.65 | 9.38 a ± 1.82 | 2.40 c ± 0.99 | 15.07 a ± 4.42 | |

| Tamara | 96.40 a ± 1.67 | 11.59 b ± 1.77 | 1.80 a ± 0.96 | 18.54 b ± 5.79 | |

| Time gaseous ozonation [min] | 0 | 96.40 a ± 1.69 | 11.55 a ± 2.51 | 1.92 a ± 0.90 | 18.85 a ± 6.09 |

| 15 | 96.40 a ± 1.53 | 12.28 b ± 2.74 | 2.10 ab ± 0.98 | 20.14 b ± 6.74 | |

| 30 | 96.34 a ± 1.58 | 12.37 b ± 2.57 | 2.16 b ± 1.06 | 19.84 ab ± 6.07 | |

| Duration of storage [days] | 1 | 97.94 c ± 0.37 | 11.36 a ± 2.28 | 1.02 a ± 0.24 | 13.09 a ± 2.72 |

| 30 | 96.81 b ± 0.38 | 11.77 a ± 2.79 | 2.34 b ± 0.79 | 22.46 b ± 5.18 | |

| 60 | 94.39 a ± 0.67 | 13.06 b ± 2.50 | 2.83 c ± 0.69 | 23.34 b ± 4.58 | |

| Mean | 96.38 ± 1.57 | 12.07 ± 2.63 | 2.06 ± 0.98 | 19.61 ± 6.32 | |

| Variety | Ozonation Time | Duration of Storage | |

|---|---|---|---|

| Variety | 1.000 | −0.001 | −0.065 |

| Ozonation time | −0.001 | 1.000 | 0.001 |

| Duration of storage | −0.065 | 0.001 | 1.000 |

| Meta-Regressor | Train | Test | ||||||

|---|---|---|---|---|---|---|---|---|

| R | RMSE | MAPE | NSC | R | RMSE | MAPE | NSC | |

| Force | ||||||||

| Decision tree | 0.74 | 1.72 | 0.11 | 0.54 | 0.68 | 1.91 | 0.13 | 0.45 |

| Gradient boosting | 0.75 | 1.70 | 0.11 | 0.56 | 0.68 | 1.92 | 0.13 | 0.44 |

| Random forest | 0.74 | 1.73 | 0.11 | 0.54 | 0.69 | 1.87 | 0.13 | 0.47 |

| K nearest neighbors regression | 0.75 | 1.68 | 0.11 | 0.57 | 0.66 | 1.97 | 0.13 | 0.41 |

| Extreme gradient boosting | 0.74 | 1.73 | 0.12 | 0.54 | 0.72 | 1.82 | 0.12 | 0.50 |

| Support vector regression | 0.74 | 1.74 | 0.11 | 0.54 | 0.71 | 1.82 | 0.12 | 0.50 |

| Deformation | ||||||||

| Decision tree | 0.88 | 0.46 | 0.15 | 0.77 | 0.85 | 0.52 | 0.19 | 0.72 |

| Gradient boosting | 0.87 | 0.46 | 0.16 | 0.76 | 0.87 | 0.50 | 0.19 | 0.75 |

| Random forest | 0.87 | 0.46 | 0.15 | 0.76 | 0.87 | 0.49 | 0.18 | 0.75 |

| K nearest neighbors regression | 0.87 | 0.46 | 0.16 | 0.77 | 0.84 | 0.54 | 0.20 | 0.70 |

| Extreme gradient boosting | 0.87 | 0.47 | 0.16 | 0.76 | 0.88 | 0.46 | 0.18 | 0.78 |

| Support vector regression | 0.87 | 0.47 | 0.15 | 0.75 | 0.88 | 0.46 | 0.17 | 0.78 |

| Energy | ||||||||

| Decision tree | 0.90 | 2.73 | 0.10 | 0.81 | 0.91 | 2.86 | 0.11 | 0.82 |

| Gradient boosting | 0.90 | 2.67 | 0.10 | 0.82 | 0.90 | 2.94 | 0.11 | 0.81 |

| Random forest | 0.90 | 2.75 | 0.10 | 0.81 | 0.91 | 2.81 | 0.11 | 0.83 |

| K nearest neighbors regression | 0.90 | 2.68 | 0.10 | 0.82 | 0.90 | 2.94 | 0.11 | 0.81 |

| Extreme gradient boosting | 0.90 | 2.77 | 0.11 | 0.80 | 0.92 | 2.74 | 0.10 | 0.84 |

| Support vector regression | 0.90 | 2.78 | 0.11 | 0.80 | 0.92 | 2.75 | 0.10 | 0.83 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gorzelany, J.; Kuźniar, P.; Zardzewiały, M.; Pentoś, K.; Murawski, T.; Wojciechowski, W.; Kurek, J. The Use of Machine Learning to Assess the Impact of the Ozonation Process on Selected Mechanical Properties of Japanese Quince Fruits. Agriculture 2024, 14, 1995. https://doi.org/10.3390/agriculture14111995

Gorzelany J, Kuźniar P, Zardzewiały M, Pentoś K, Murawski T, Wojciechowski W, Kurek J. The Use of Machine Learning to Assess the Impact of the Ozonation Process on Selected Mechanical Properties of Japanese Quince Fruits. Agriculture. 2024; 14(11):1995. https://doi.org/10.3390/agriculture14111995

Chicago/Turabian StyleGorzelany, Józef, Piotr Kuźniar, Miłosz Zardzewiały, Katarzyna Pentoś, Tadeusz Murawski, Wiesław Wojciechowski, and Jarosław Kurek. 2024. "The Use of Machine Learning to Assess the Impact of the Ozonation Process on Selected Mechanical Properties of Japanese Quince Fruits" Agriculture 14, no. 11: 1995. https://doi.org/10.3390/agriculture14111995

APA StyleGorzelany, J., Kuźniar, P., Zardzewiały, M., Pentoś, K., Murawski, T., Wojciechowski, W., & Kurek, J. (2024). The Use of Machine Learning to Assess the Impact of the Ozonation Process on Selected Mechanical Properties of Japanese Quince Fruits. Agriculture, 14(11), 1995. https://doi.org/10.3390/agriculture14111995